Patents

Literature

38results about How to "Layout rules" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

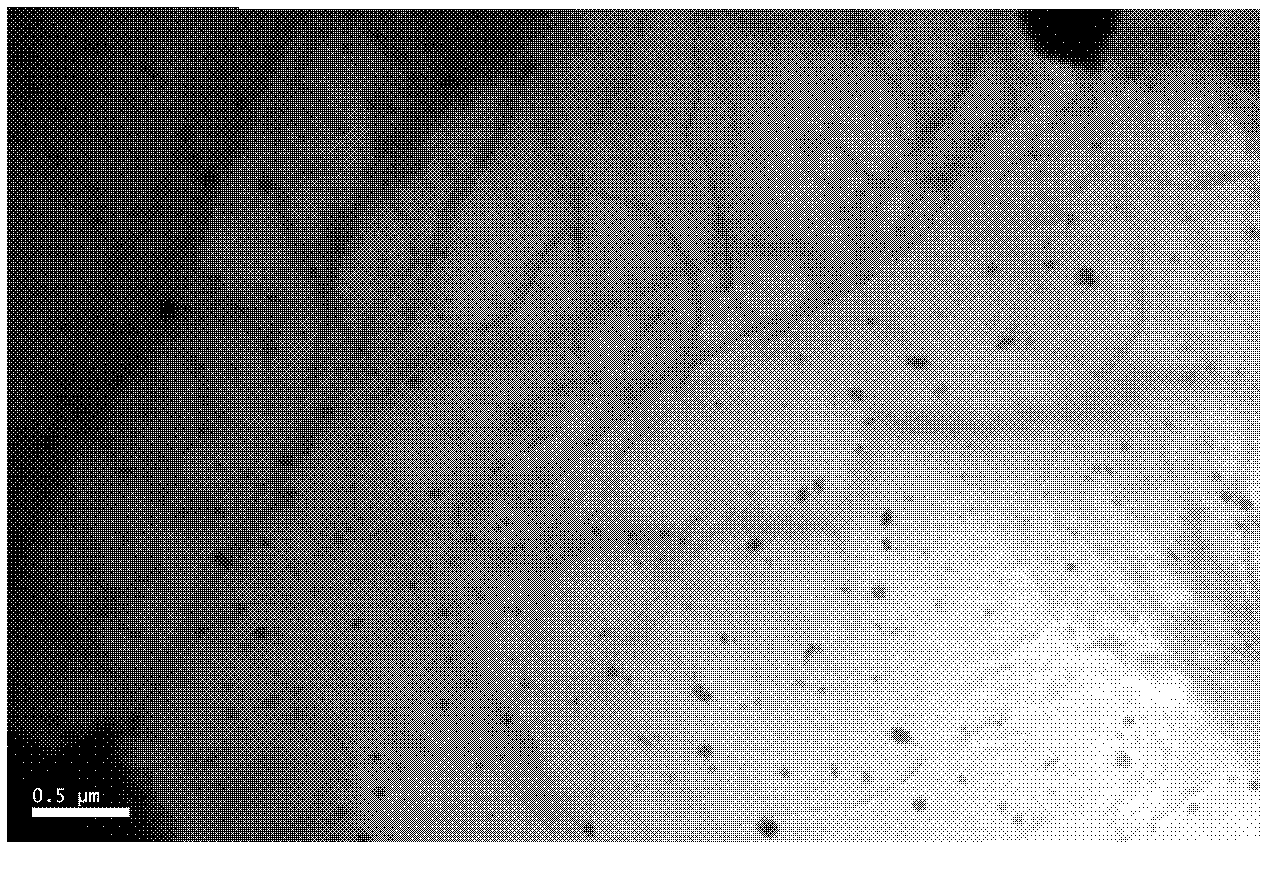

Magnesium alloy reinforced by nano-quasi-crystal particles and preparation method of the alloy

ActiveCN102605227AHigh nucleation energy storageImprove solid solubilitySolution treatmentDistribution characteristic

The invention discloses a magnesium alloy reinforced by nano-quasi-crystal particles and a preparation method of the alloy, and belongs to the technical field of alloy. The alloy comprises the following components in percentage by mass: Er not higher than 10%, Zn not higher than 10%, impurity element with total amount less than 0.05%, and balance of magnesium, wherein the mass ratio of Zn to Er is 4-8. The preparation method comprises the following steps: firstly performing solution treatment to the selected alloy, cleaning the alloy, removing impurities and crushing the alloy; utilizing a multi-cyclic plastic deformation device to process the alloy, at last obtaining an extrusion blank, and extruding the blank with an extruder at 220-350 DEG C to obtain a bar; or utilizing a rolling mill to roll the alloy at a temperature not higher than 300 DEG C, and annealing the rolled alloy. According to the invention, the size of phase I in the alloy is effectively reduced; the distribution characteristics of phase I are reasonably changed; and the size of phase I in the alloy is about 10-100nm.

Owner:北京二七铁丰龙科技有限公司

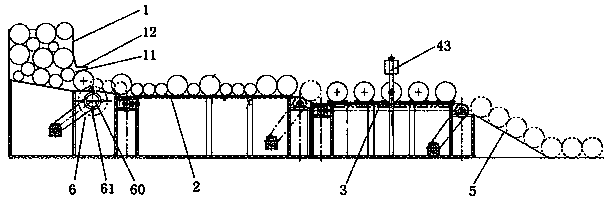

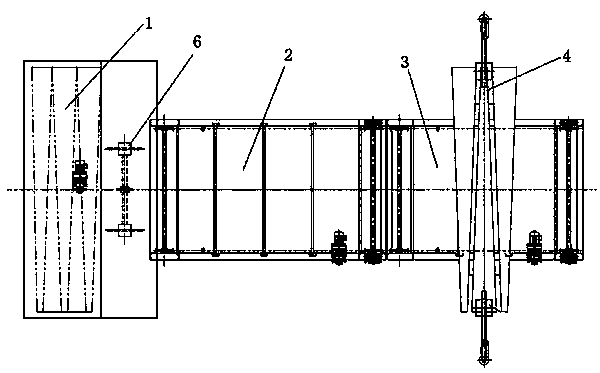

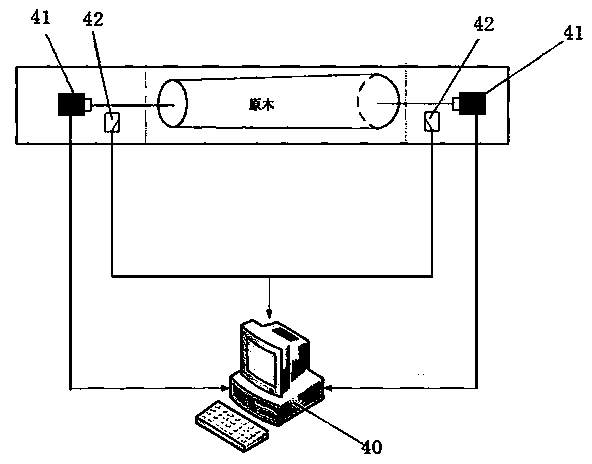

Detecting and metering device for wood

ActiveCN103449154ANo cloggingAccurate measurement dataConveyorsUsing optical meansChain conveyorChain type

The invention discloses a detecting and metering device for wood. The detecting and metering device comprises a wood storage tank, a wood conveying device and a detection device, wherein the wood storage tank is provided with a wood outlet along the length direction of the wood; the wood conveying device is used for conveying the wood such as log from the wood outlet to a detection area; the detection device is used for detecting the length and the section areas of two ends of the wood passing through the detection area; the wood conveying device comprises a plate type conveyor and a chain type conveyor which are adjacently arranged along the conveying direction of the wood; the plate type conveyor is arranged close to the wood storage tank; the conveying speed of the chain type conveyor is higher than that of the plate type conveyor; the height of a conveying surface of the chain type conveyor is smaller than that of a conveying surface of the plate type conveyor. According to the detecting and metering device disclosed by the invention, two adjacent woods falling on the chain type conveyor can be enabled to be arranged at a certain interval; in addition, each log falls on one section of chain not between two sections of chains, so that a sorting beat of the plate type conveyor still can meet the detection beat of the chain type conveyor, the phenomenon that the whole conveying line is blocked is avoided, more accurate measurement data are obtained and the detection efficiency is increased.

Owner:BEIJING HUALIXING SCI TECH DEV

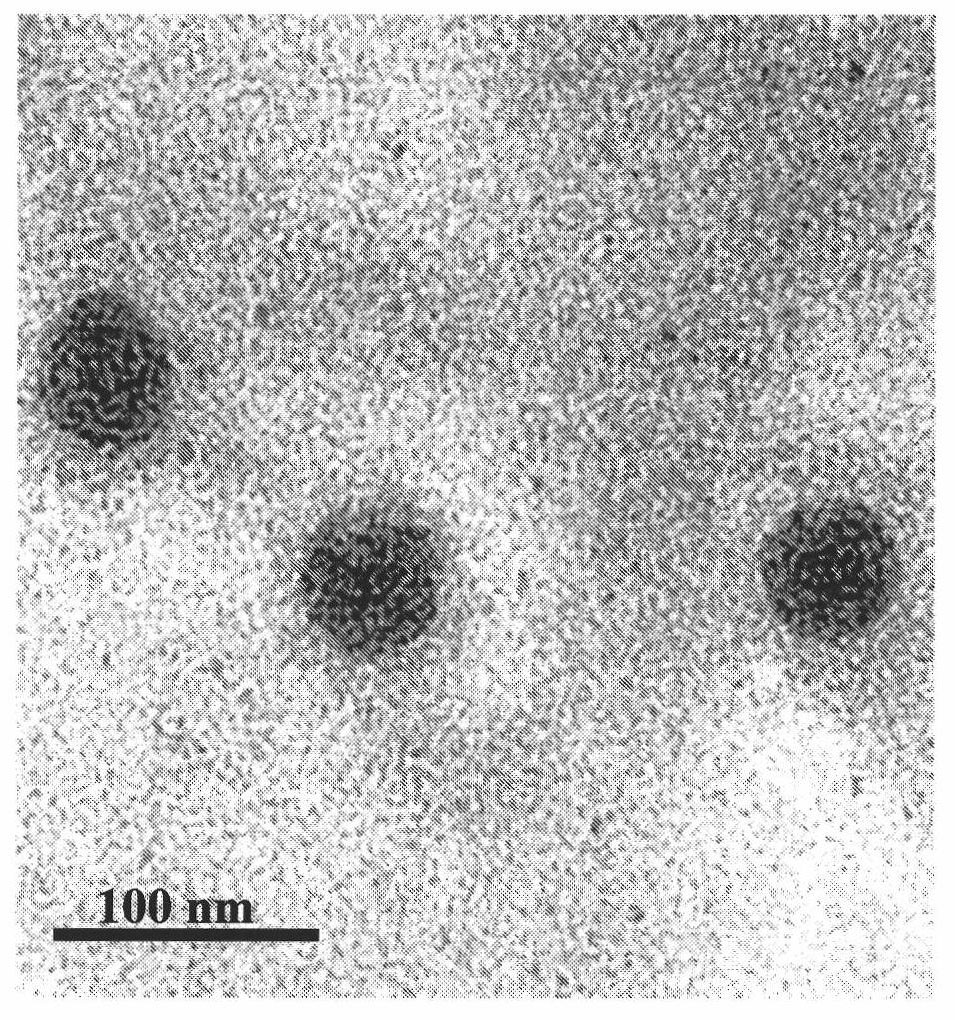

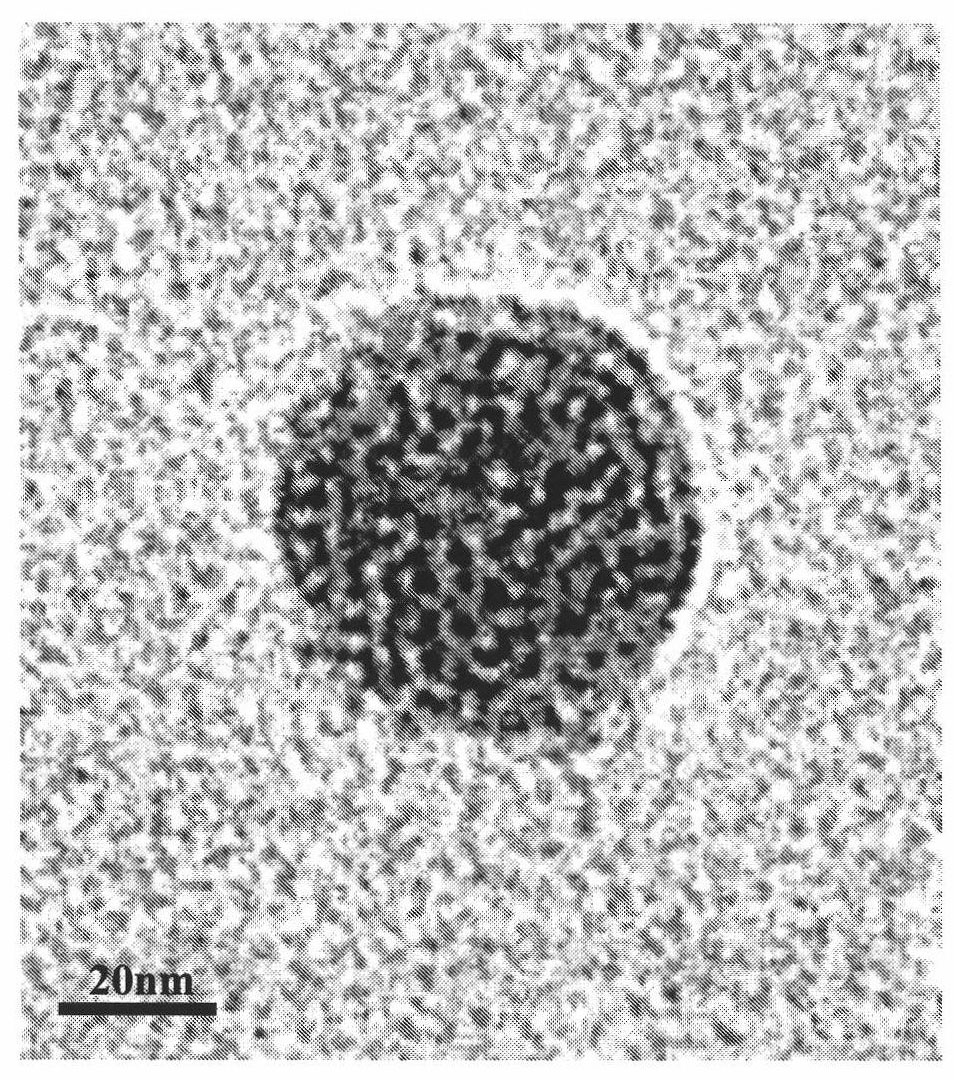

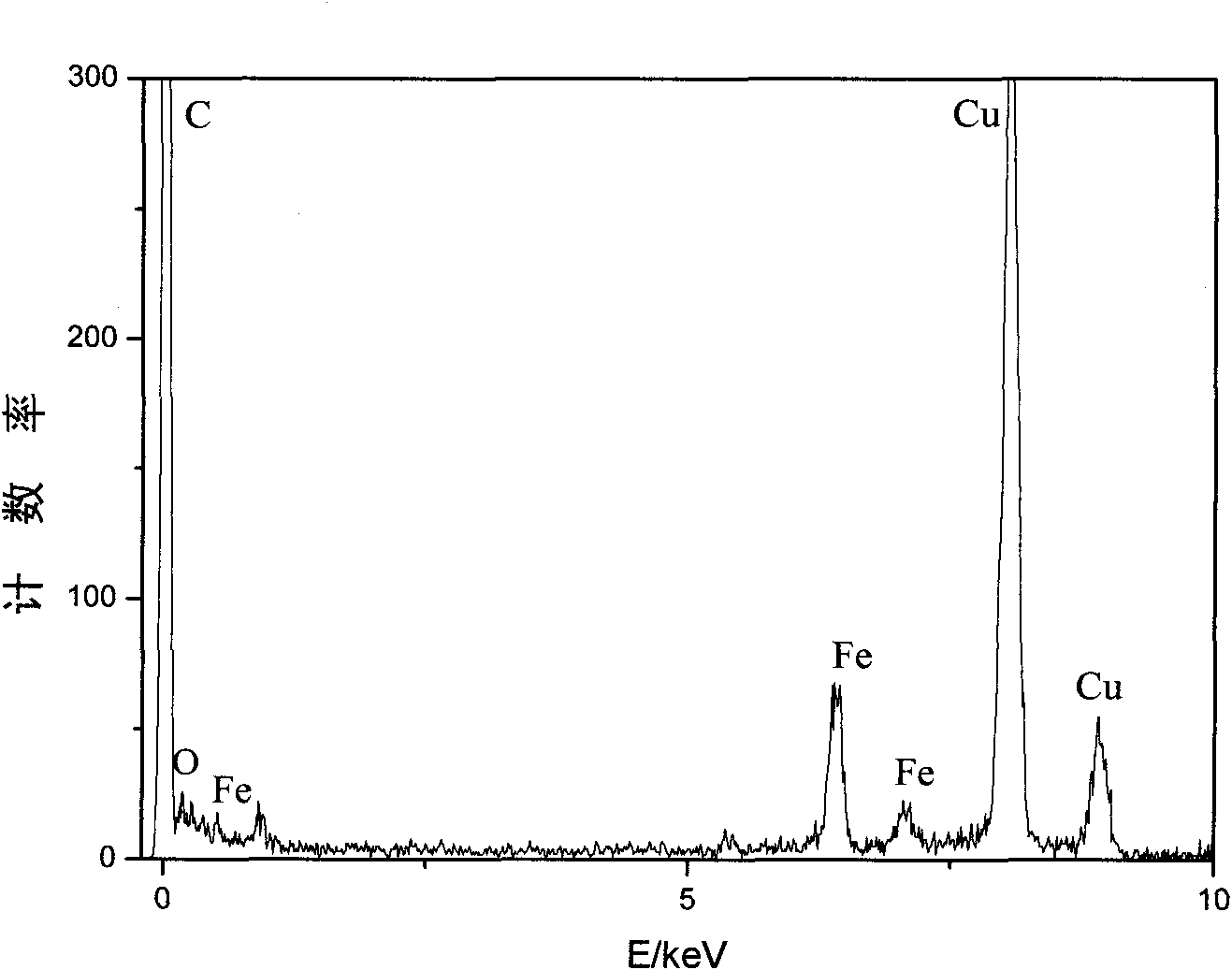

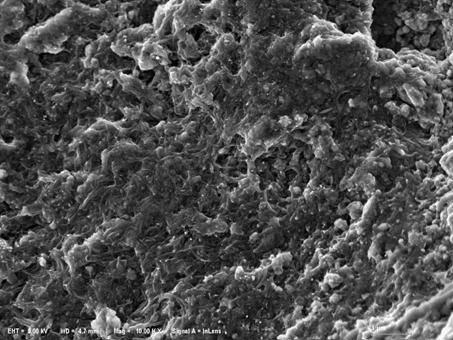

Method for preparing iron nano-magnetic particles by taking T4 phage as template

InactiveCN101817091AEvenly distributedLayout rulesViruses/bacteriophagesMagnetic materialsNano structuringMagnetization

The invention discloses a method for preparing iron nano-magnetic particles by taking a T4 phage as a template in the field of magnetic recording materials. In the method, the T4 phage obtained by enrichment and the solution of iron chloride are incubated, centrifuged and reduced by utilizing intrinsic structural characteristics of an organism and a molecular recognition function thereof to obtain iron nano-particles which have small particle sizes and high dispersion degrees and are regularly distributed on the capsid surface of the T4 phage, and the prepared iron nano-particles have the characteristics of nonreversible magnetization process, high coercive force and the like, so that the iron nano-particles prepared by the method have wide application prospect in the field of high-intensity magnetic recording materials. Moreover, in the method, a biological nano-structure which exists in nature is directly taken as the template, so that the method has simple preparation processes, moderate reaction conditions and environment friendliness. Since a biological template has the characteristics of self-producing capability, high appearance repeatability and the like, large scale production is easy to realize.

Owner:YANSHAN UNIV

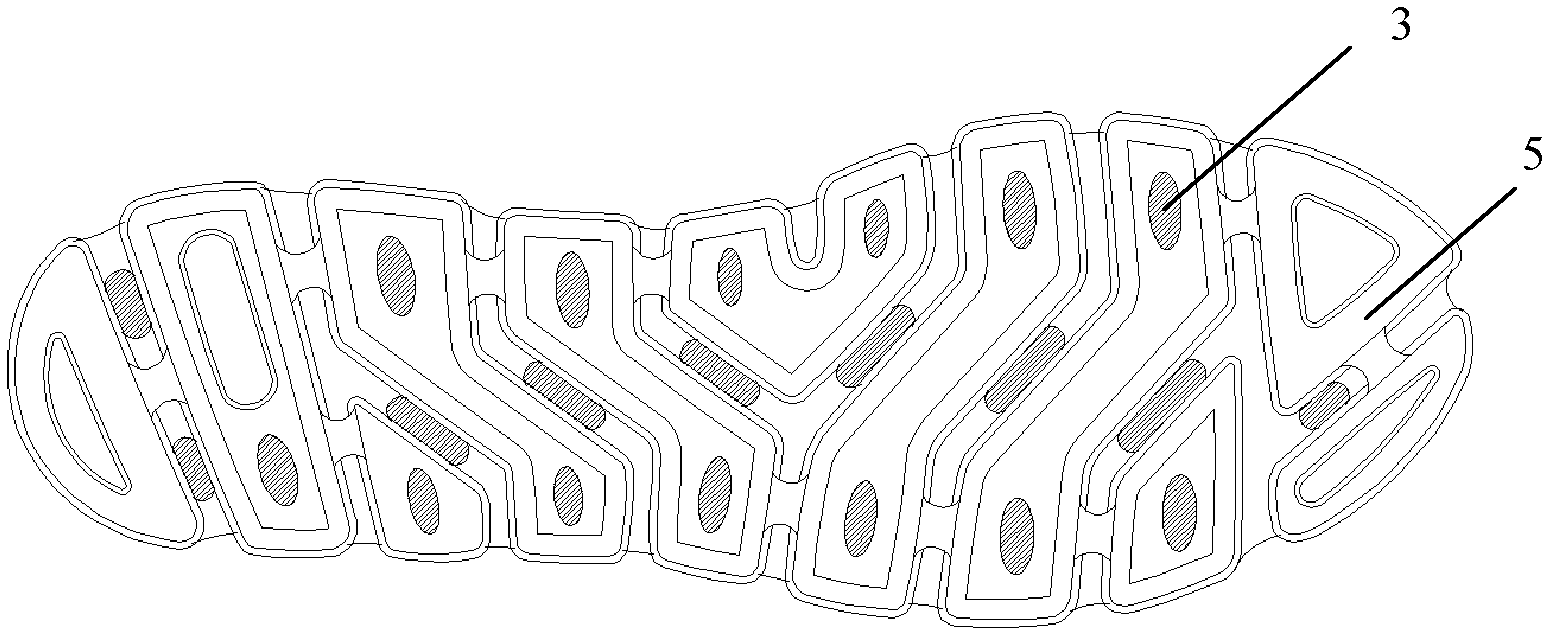

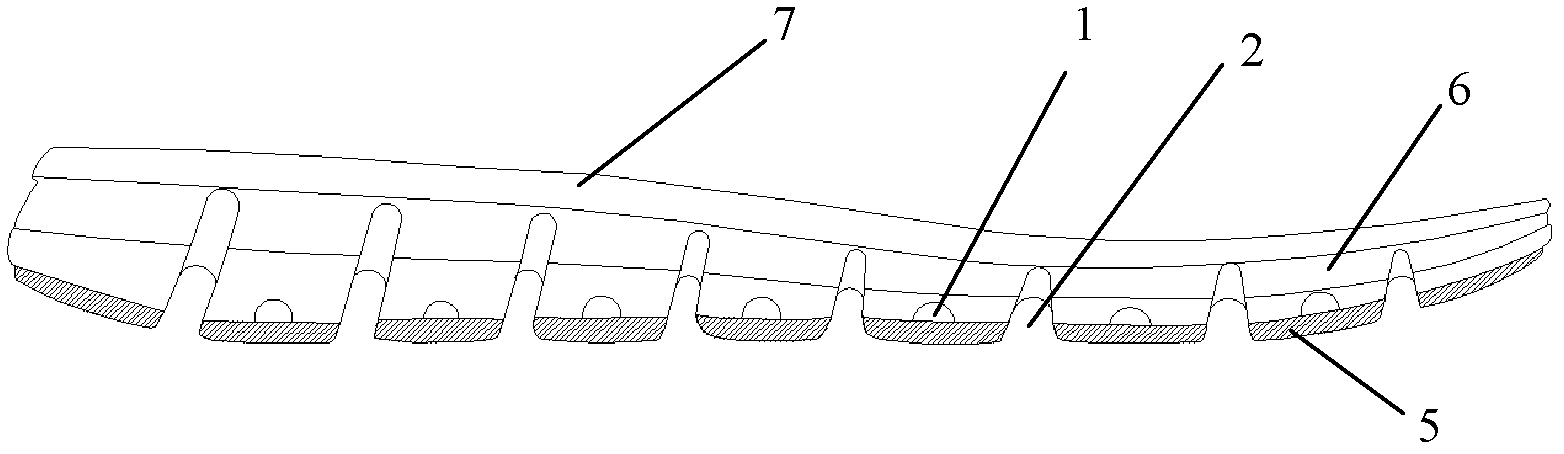

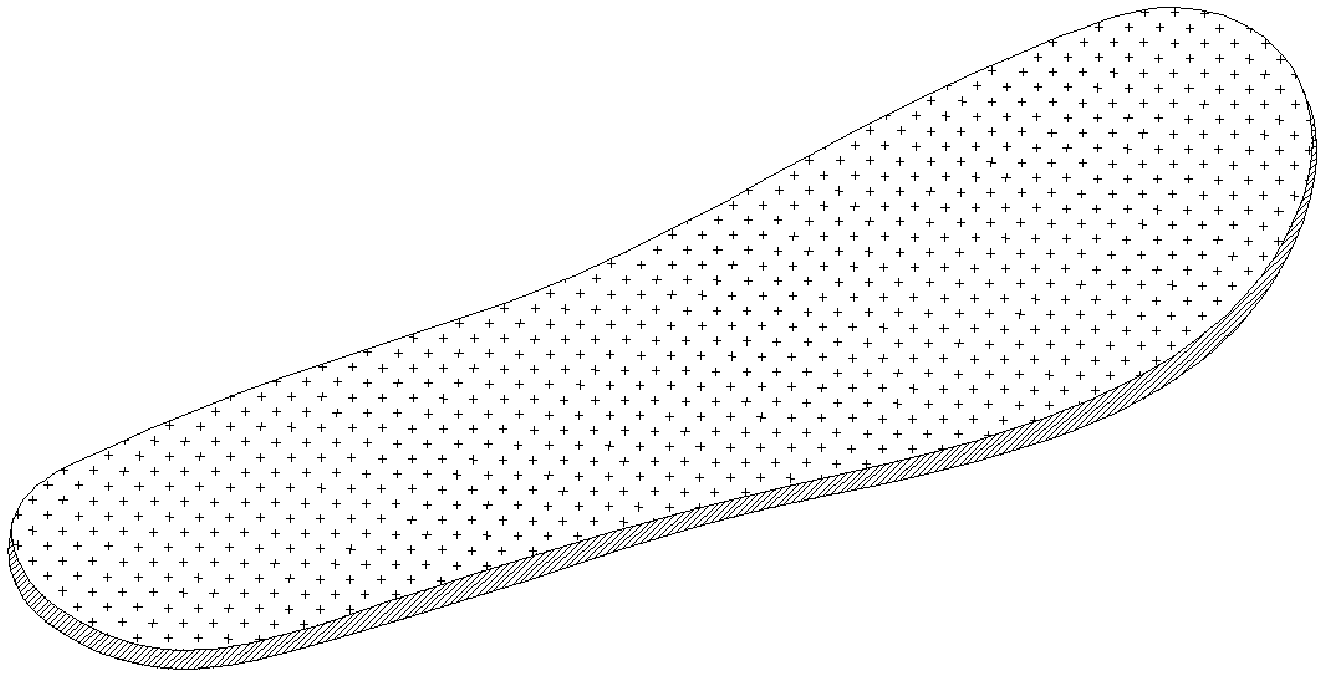

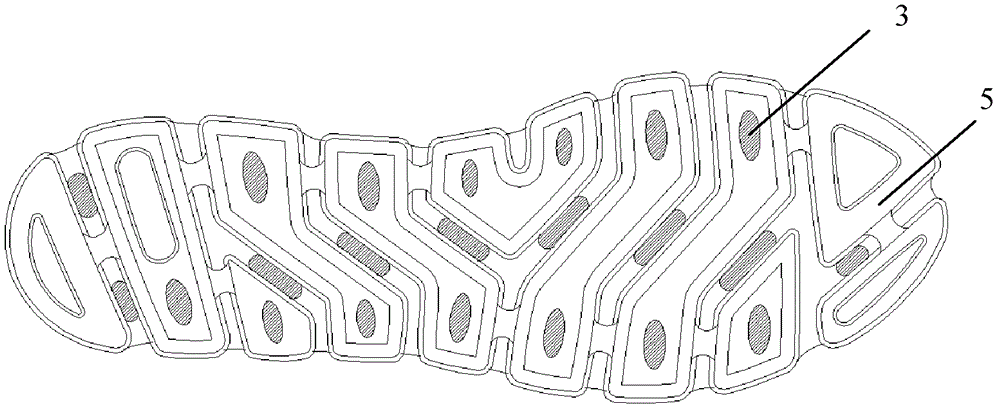

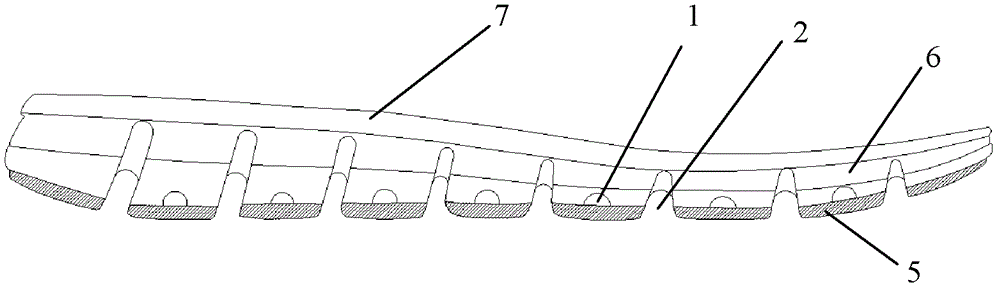

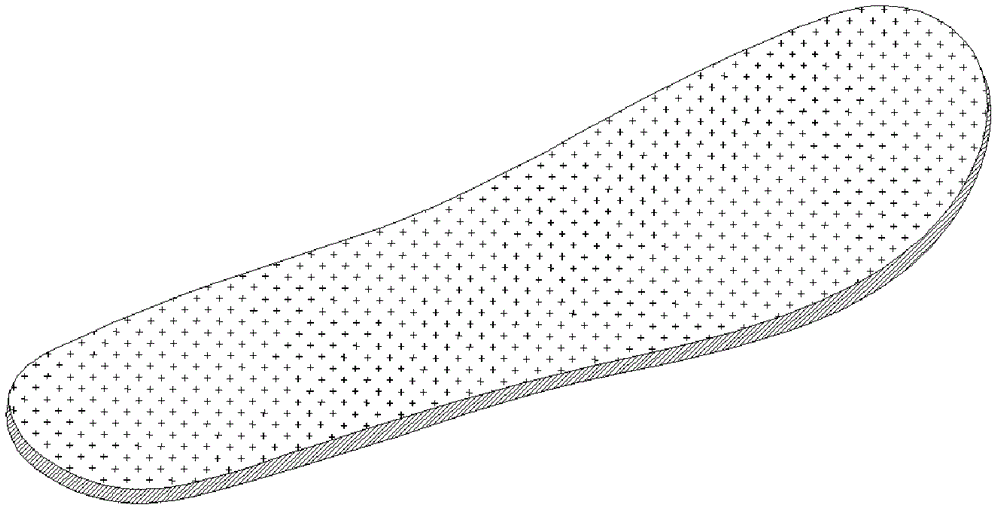

Waterproof breathable sole and shoes adopting waterproof breathable soles

Owner:MAOTAI FUJIAN SOLES CO LTD

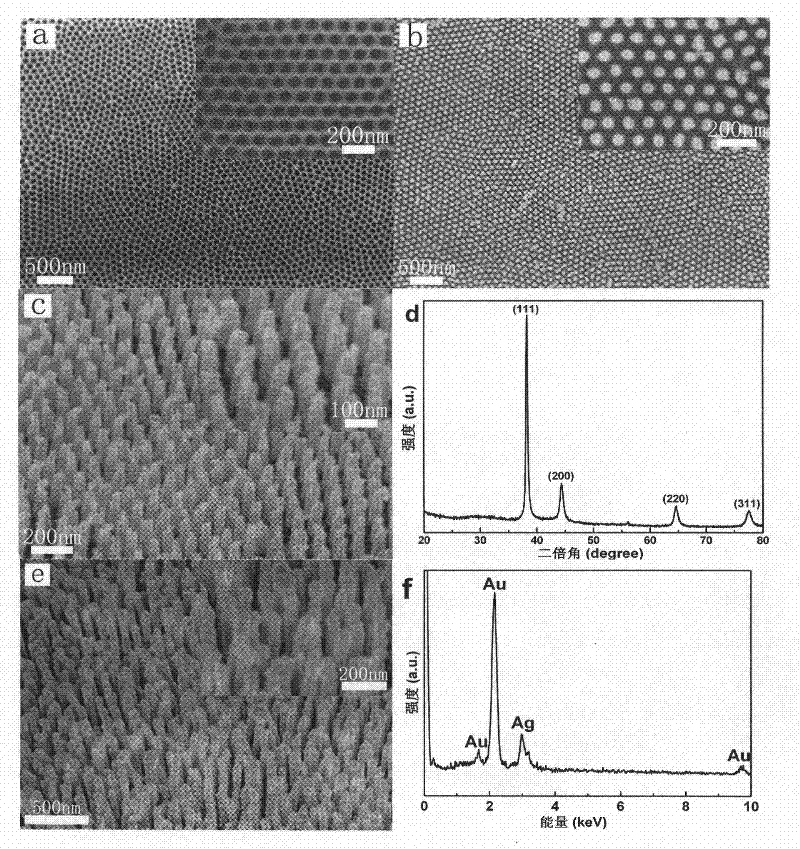

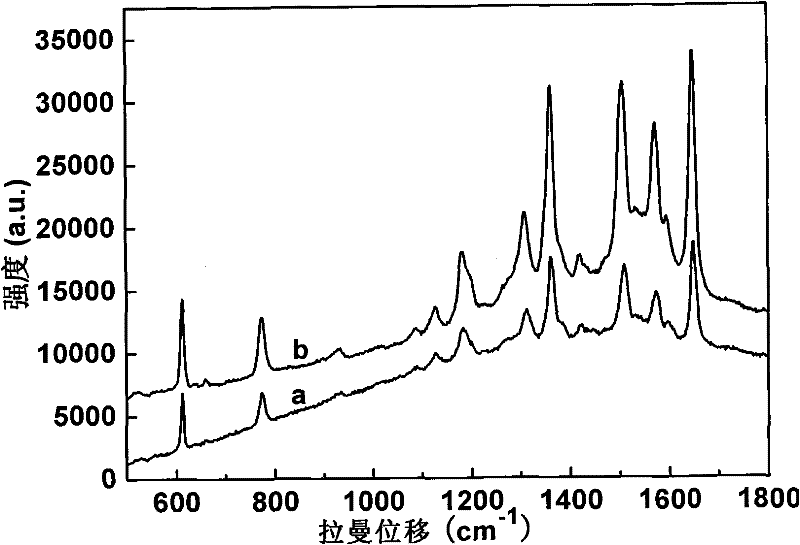

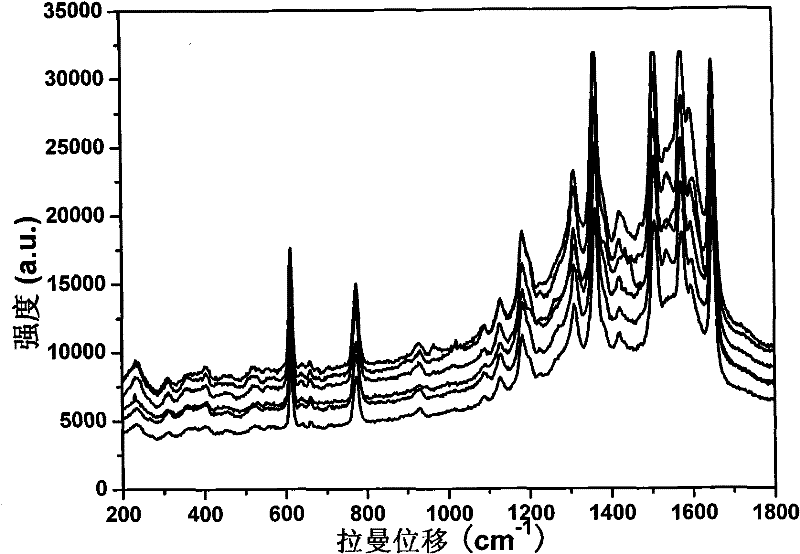

Metal nano-lattice/single-layer graphene SERS substrate and preparation method and application thereof

InactiveCN110715916AGood repeatabilityImprove stabilityGrapheneRaman scatteringSingle layer grapheneGraphite

The invention discloses a metal nano-lattice / single-layer graphene SERS substrate and a preparation method and an application thereof. The metal nano-lattice / single-layer graphene SERS substrate prepared by the preparation method comprises a silicon substrate, single-layer graphene and uniform metal nano-lattices, wherein the single-layer graphene is located on the silicon substrate; the uniform metal nano-lattices are uniformly distributed on the single-layer graphene; and the regularly arranged metal nano-lattice / single-layer graphene SERS substrate is obtained. Electromagnetic enhancement of a metal nanostructure is coupled with chemical enhancement of the graphene, thereby detecting hydrophobic aromatic compounds; the method is simple, easy to operate and capable of preparing the large-area SERS substrate; the prepared SERS substrate is uniform in surface hotspot distribution and large in area; and the repeatability and stability of an SERS signal can be improved.

Owner:SHANDONG UNIV

Top silver-cladding gold nanorod array and preparation method and application thereof

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

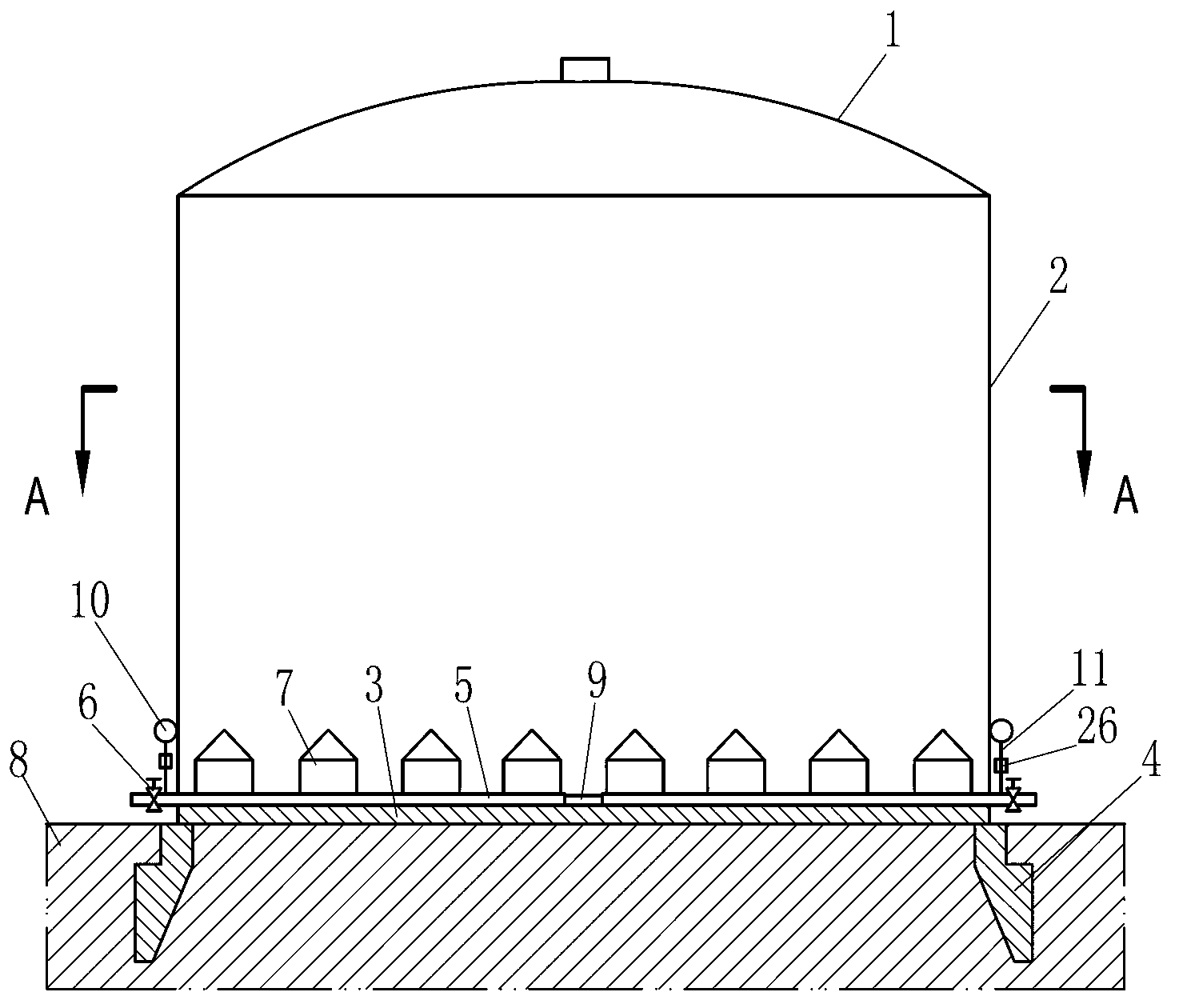

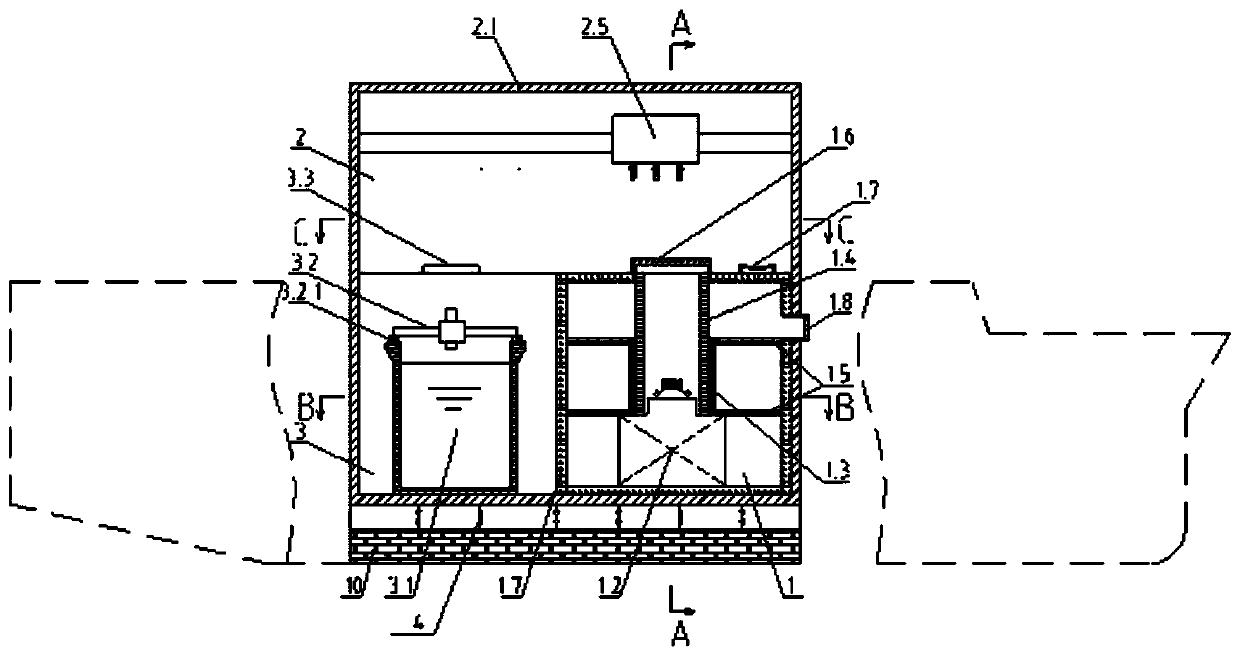

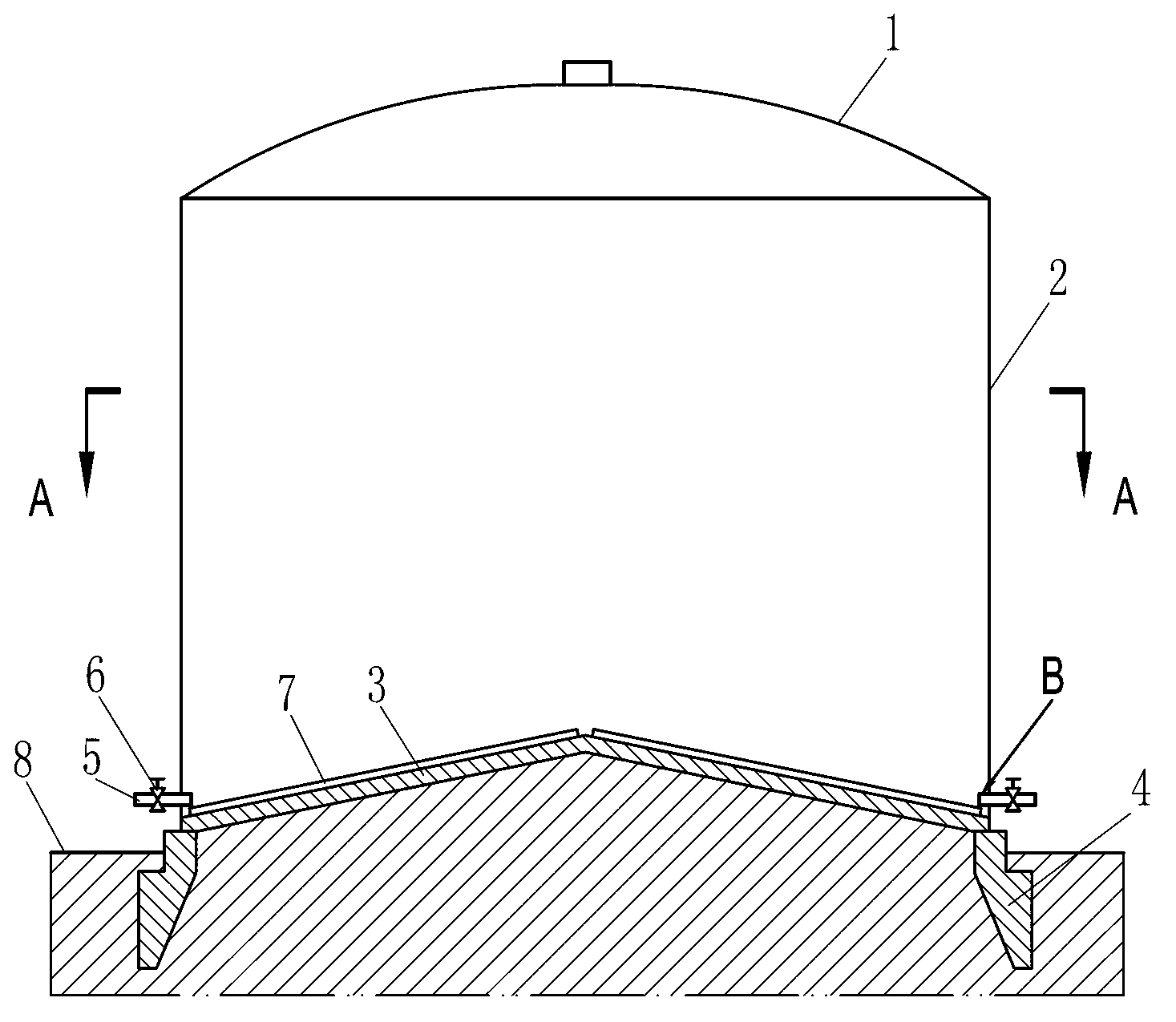

Floor type powdery material storehouse

ActiveCN103287858AImprove space utilizationLess investmentBulk conveyorsBulk storage containerEngineeringMechanical engineering

The invention relates to a floor type powdery material storehouse which comprises a storehouse top, storehouse walls, a storehouse bottom and a storehouse foundation, wherein material flowing assisting devices are arranged on the storehouse bottom and are composed of pneumatic fluidization rods which are connected with air supply pipelines, material falling openings are formed in material conveying pipes, a decompression cabin is arranged on each material falling opening of the material conveying pipes, the side wall of each decompression cabin is provided with a feeding notch, the pneumatic fluidization rods are arranged in the material conveying pipes, the material conveying pipes are horizontally arranged on the surface of the storehouse bottom and penetrate through the bottoms of the storehouse walls and extend out of the storehouse, a material flow control device is arranged at a discharge end, located outside each storehouse wall, of each material conveying pipe, the other end, located inside the storehouse, of each material conveying pipe is an air supply end, and the air supply end of each material conveying pipe is connected with an air supply pipeline. In addition, barriers can be arranged on the periphery of each material falling opening of the material conveying pipes. The floor type powdery material storehouse is simple in structure and good in economy and safety performance, and can be widely applied to storage of powdery materials such as coal ash and cement.

Owner:赵世青

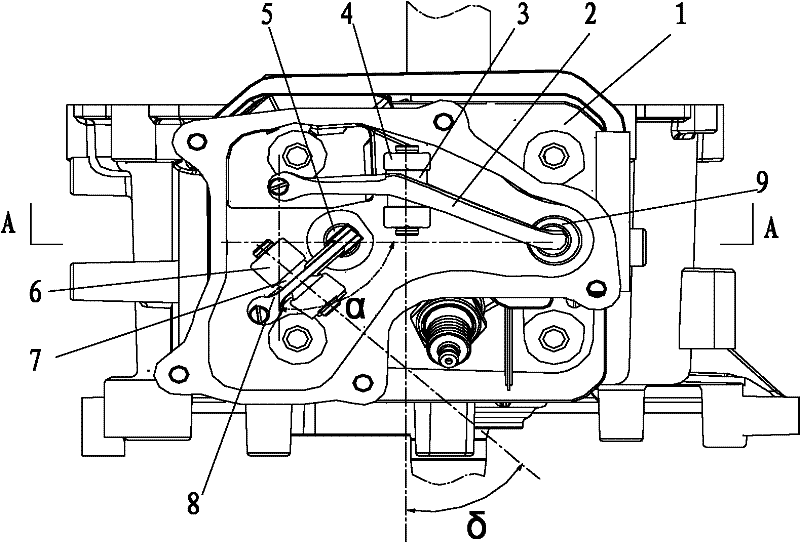

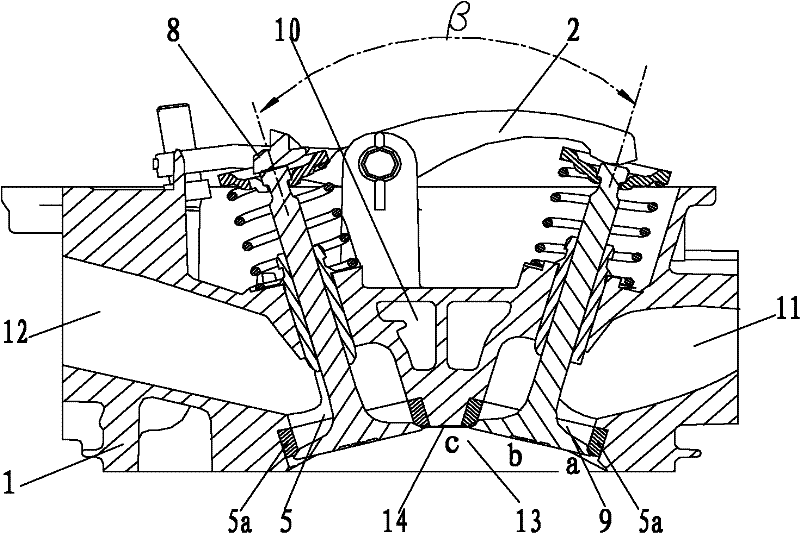

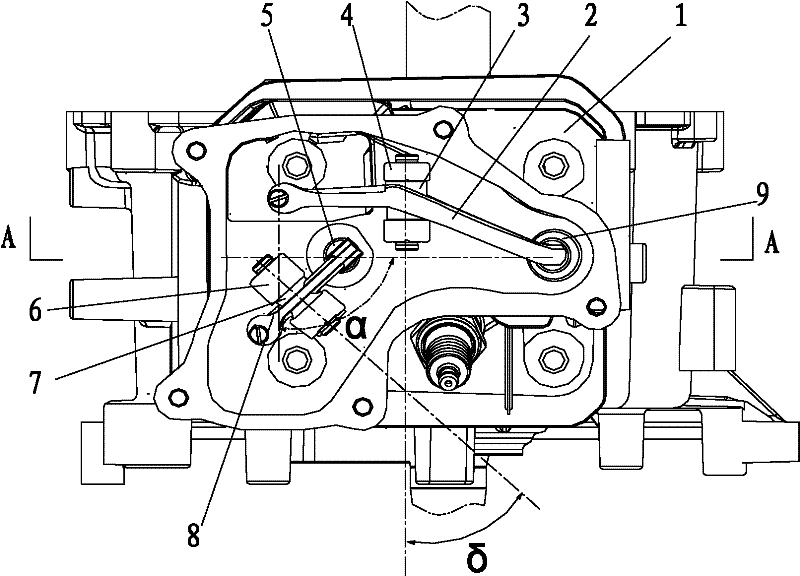

Cylinder head for arched combustion chamber and gasoline engine employing same

InactiveCN102305143AReduce consumption rateIncrease motivationInternal combustion piston enginesCylinder headsCombustion chamberCylinder head

The invention discloses a cylinder head for an arched combustion chamber and a gasoline engine employing the cylinder head. The cylinder head comprises a cylinder head body, wherein a combustion chamber face is formed on the inner side of the cylinder head body; the combustion chamber face has an arched face structure consisting of smooth curved surfaces; the surface to volume ratio of the combustion chamber can be reduced further, the working efficiency of the gasoline engine is improved, and gas flow which enters the combustion chamber is subjected to resistance in different directions, so that fuel oil mixed gas can be well formed into turbulent flow and combusted fully; therefore, the fuel oil consumption rate is reduced effectively, combustion is facilitated, and CH+NO(x) emission can be reduced, and gasoline power is increased; and the emission reaches or even exceeds the environmental protection agency (EPA) standard in America. The power of a gasoline engine with the maximum power of 3.0 kW (the rotating speed is 3,600 rpm) can be increased to 3.5 kW and the emission is reduced from 9.0 g / kW.h to 8.0 g / kW.h; the power of a gasoline engine with the maximum power of 3.5 kW can be increased to 4.0 kW and the emission is reduced from 9.0 g / kW.h to 8.0 g / kW.h; and the emission of the two gasoline engines meets the standard of 10 g / kW.h in the EPA3 stage; therefore, the power increment and the emission reduction of the gasoline engine are obvious, and environmental protection is facilitated.

Owner:LONCIN MOTOR

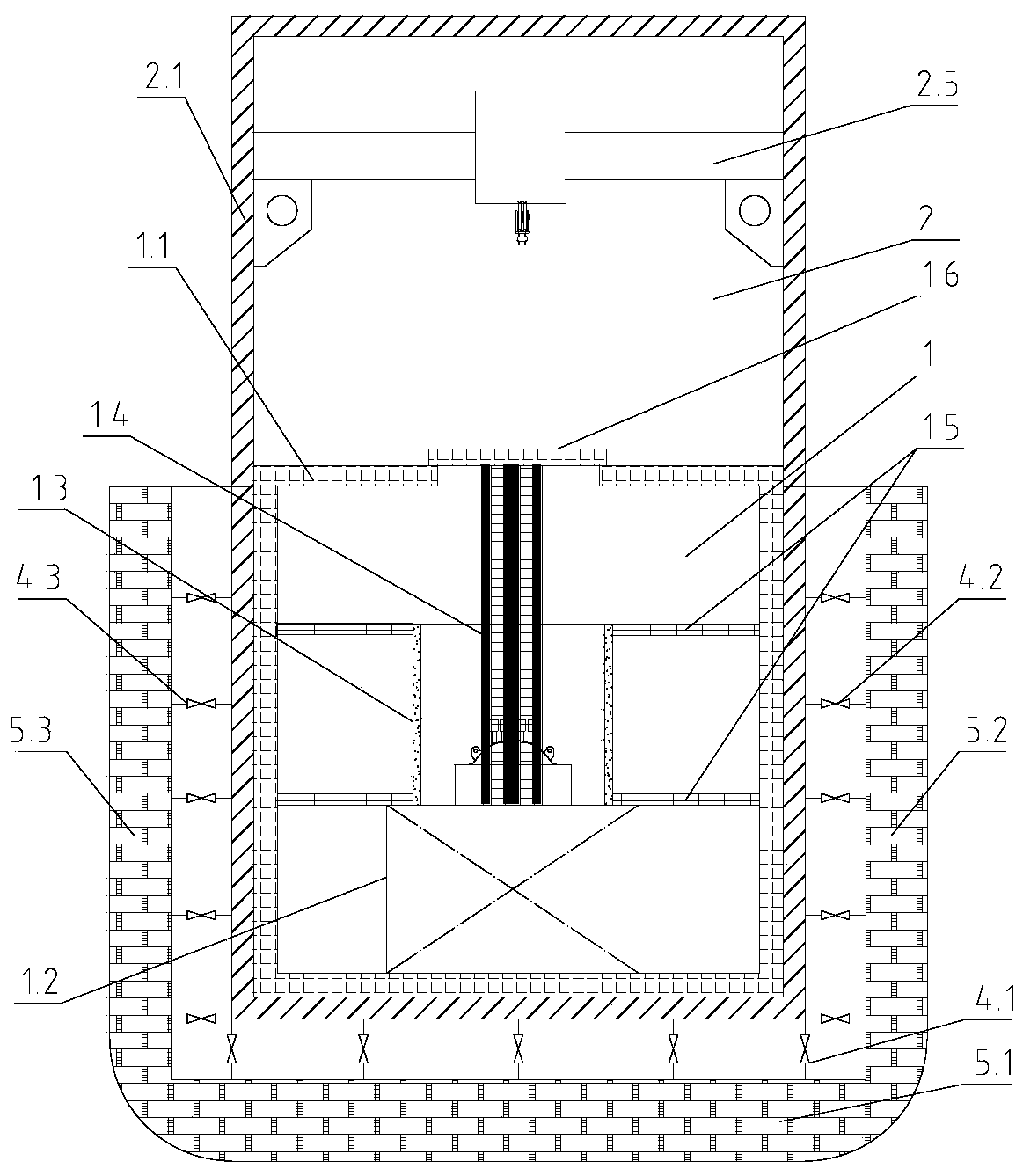

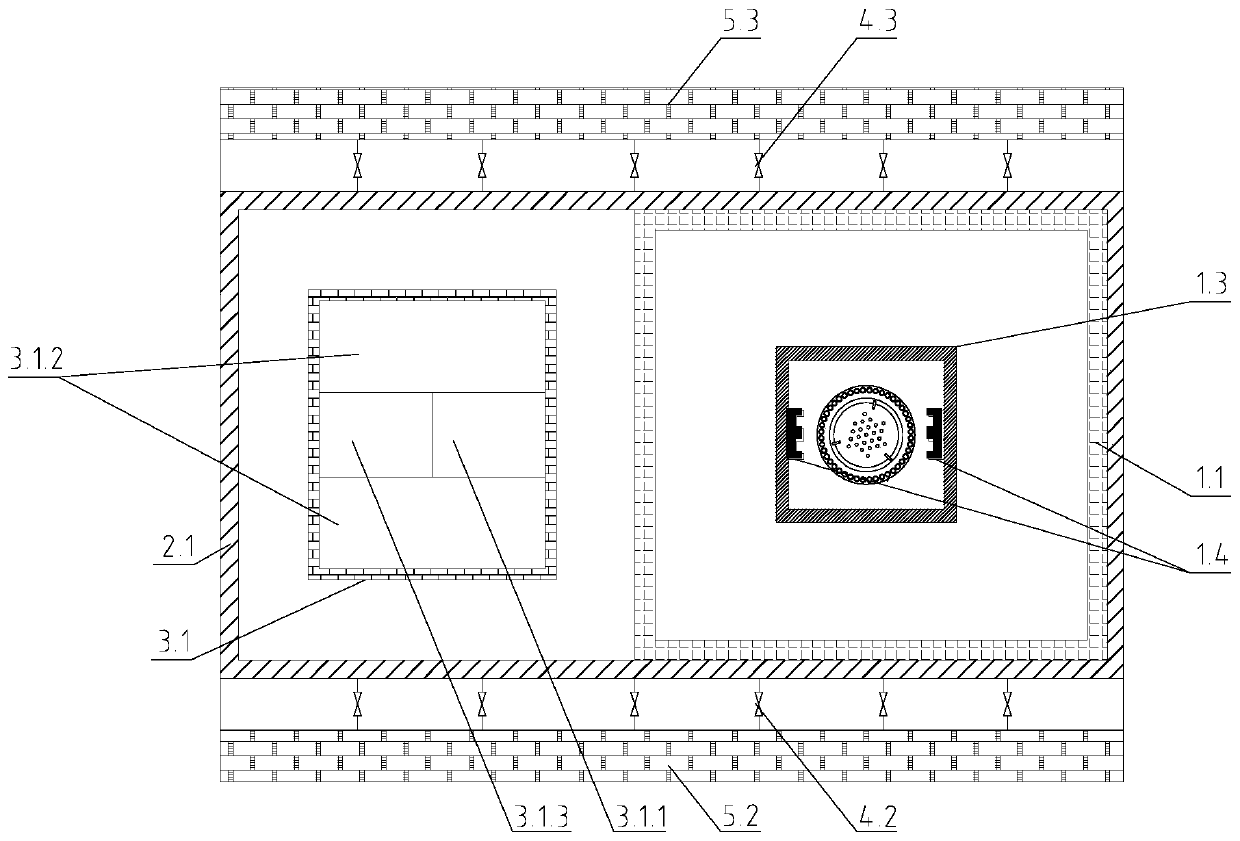

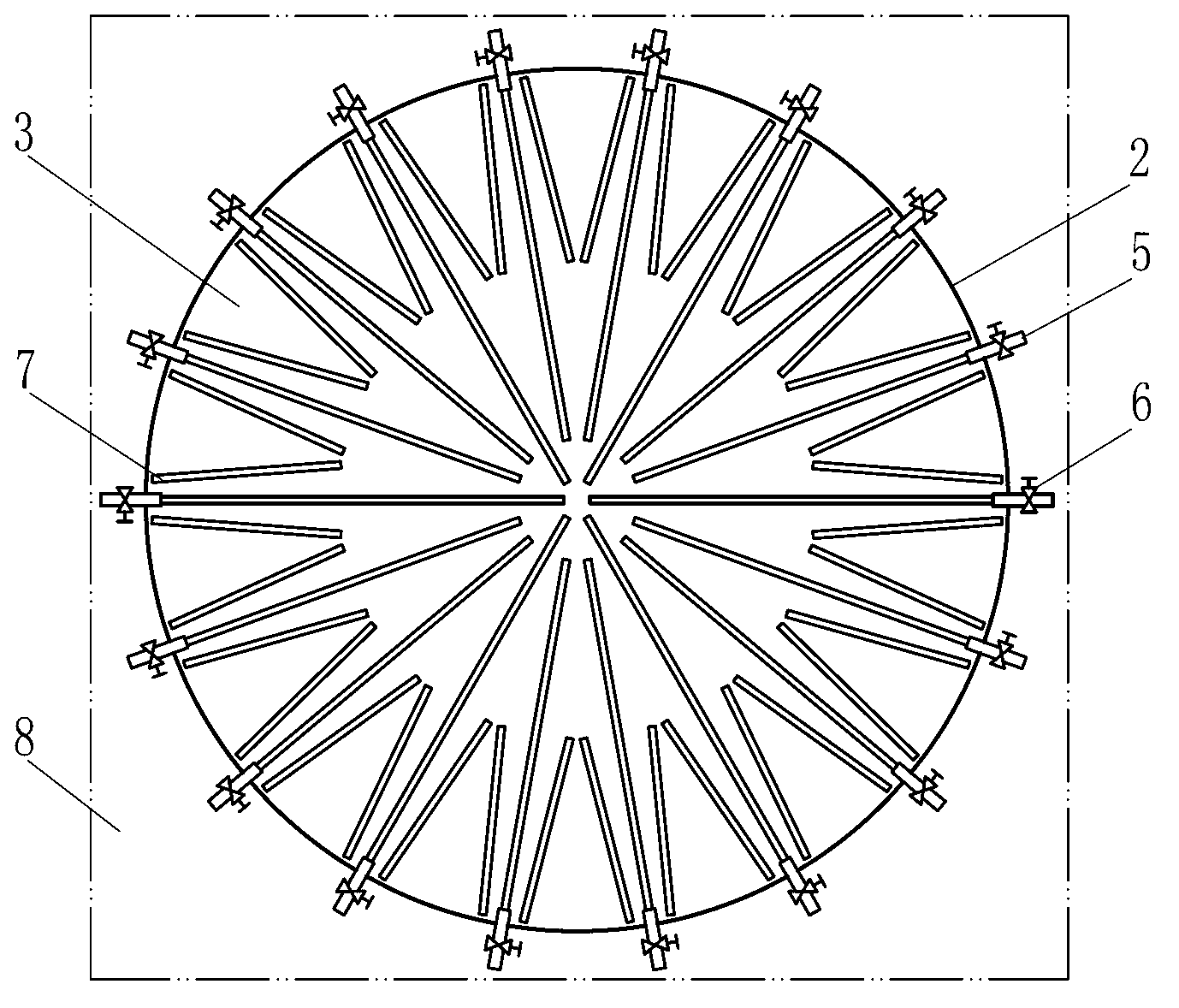

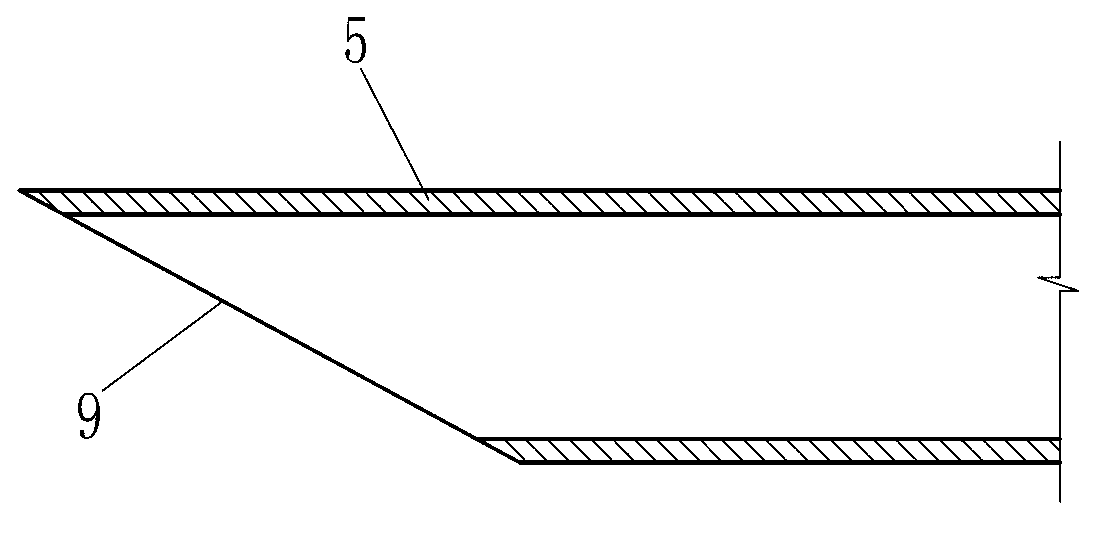

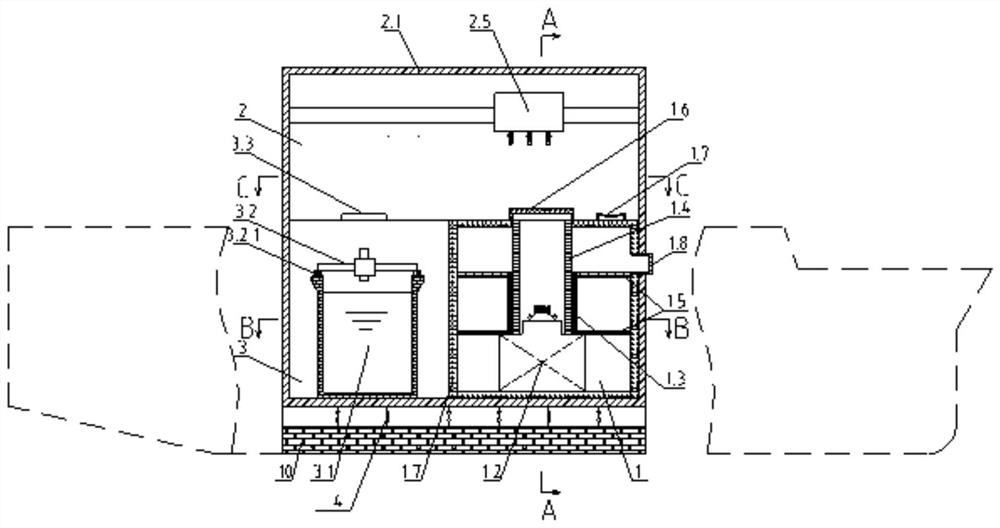

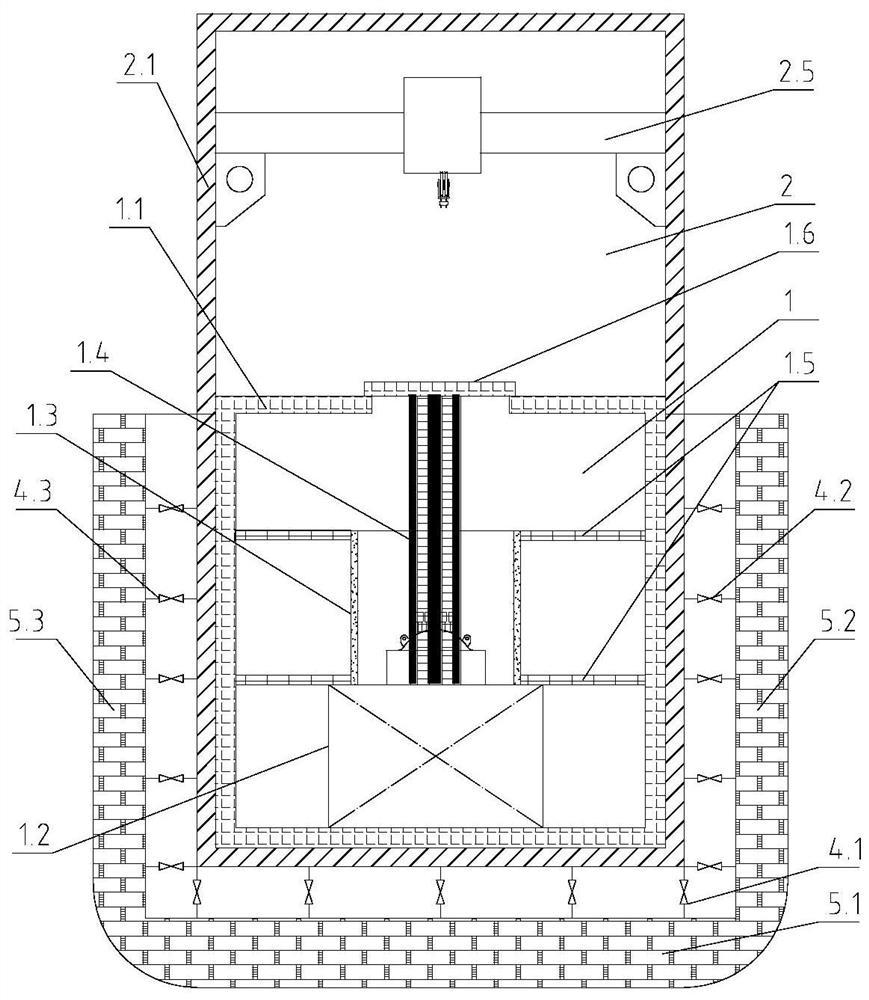

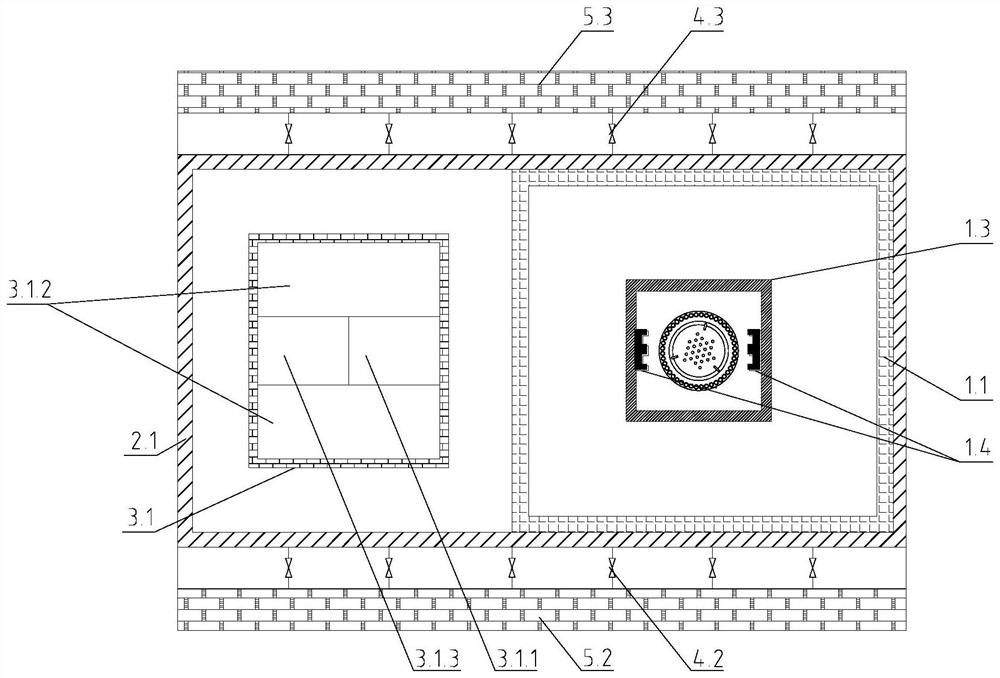

Floating nuclear power station reactor compartment arrangement structure

ActiveCN110619964ALayout rulesCompact layoutNuclear energy generationContainmentNuclear powerNuclear fuel

The invention discloses a floating nuclear power station reactor compartment arrangement structure which comprises a double-shell ship body arranged on an offshore nuclear power platform, wherein a primary containment vessel and a spent fuel storage cabin are arranged in an inner cavity of the double-shell ship body; a reactor and primary loop system equipment are arranged in the primary containment vessel; a spent fuel storage facility is arranged in the spent fuel storage cabin; the bottoms and the side faces of the primary containment and the spent fuel storage cabin are elastically connected with the double-shell ship body through elastic connecting structures; a nuclear fuel loading and unloading cabin is arranged on the upper portions of the primary containment and the spent fuel storage cabin; and communication ports are formed between the nuclear fuel loading and unloading cabin and the primary containment and between the nuclear fuel loading and unloading cabin and the spent fuel storage cabin respectively. The nuclear fuel tank has three functions of containment, nuclear fuel loading and unloading and spent fuel storage, and has the characteristics of regular appearance,compact layout, low design pressure and light shielding weight; and an elastic connecting structure is provided, so that the safety of the reactor cabin is further improved.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

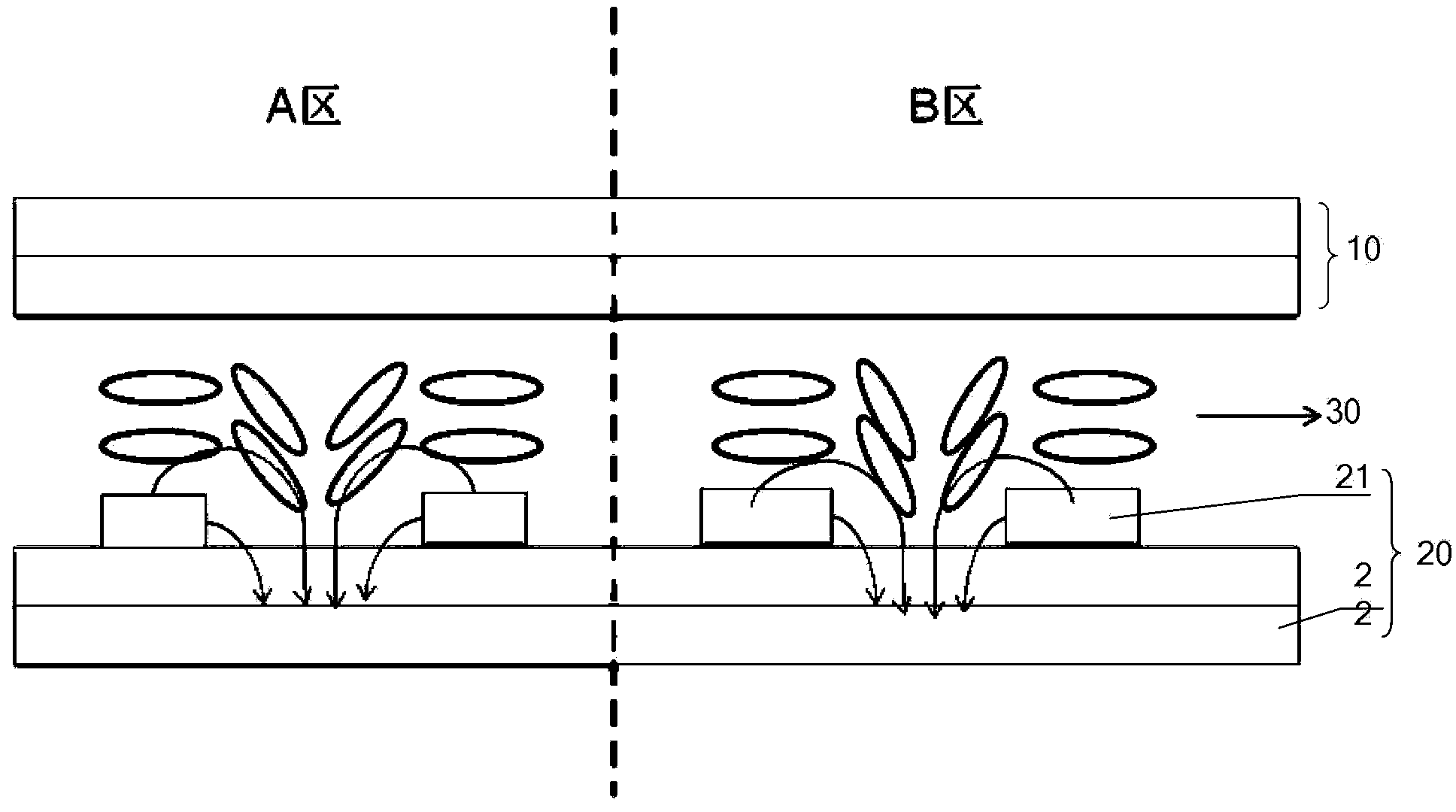

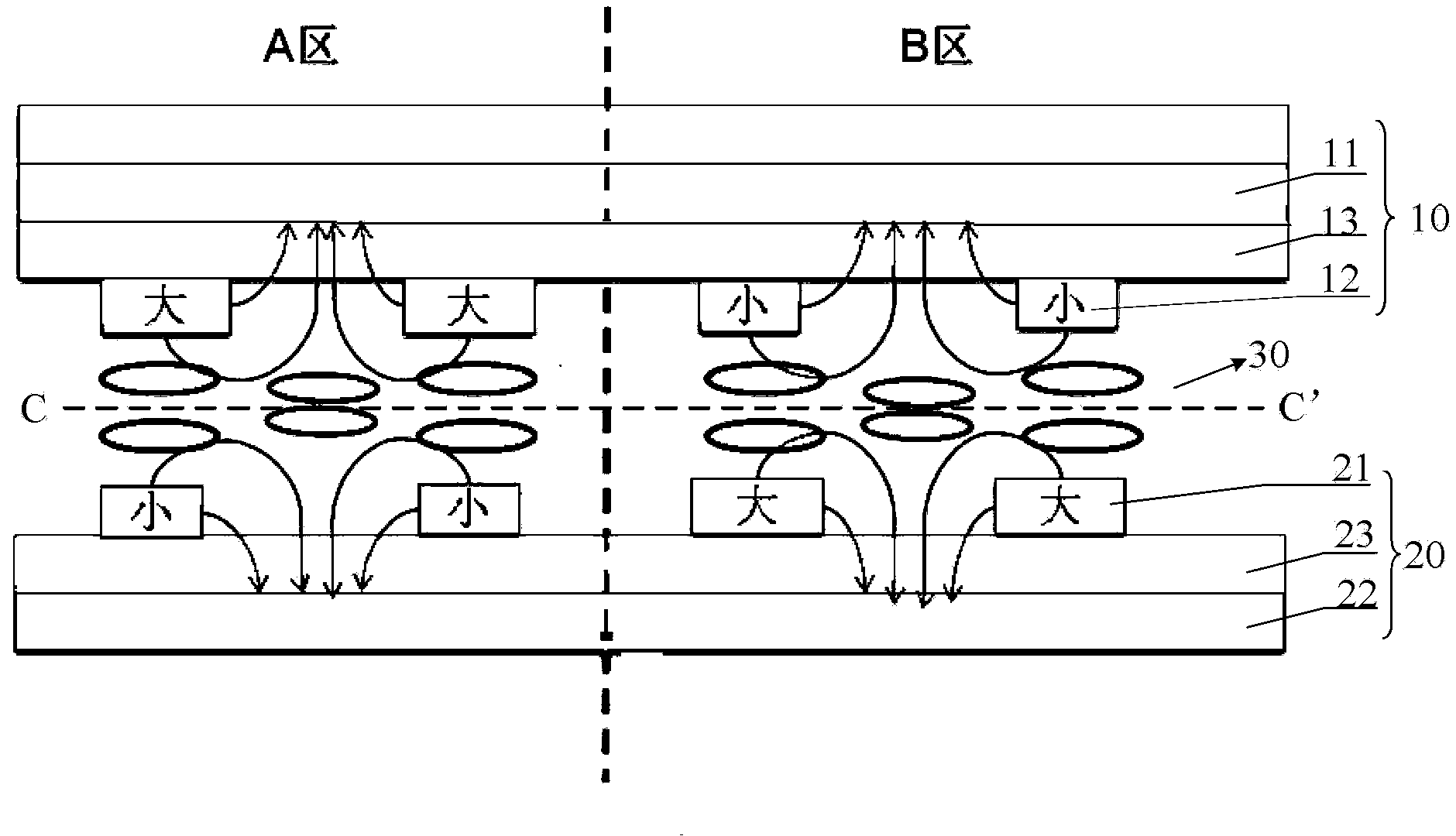

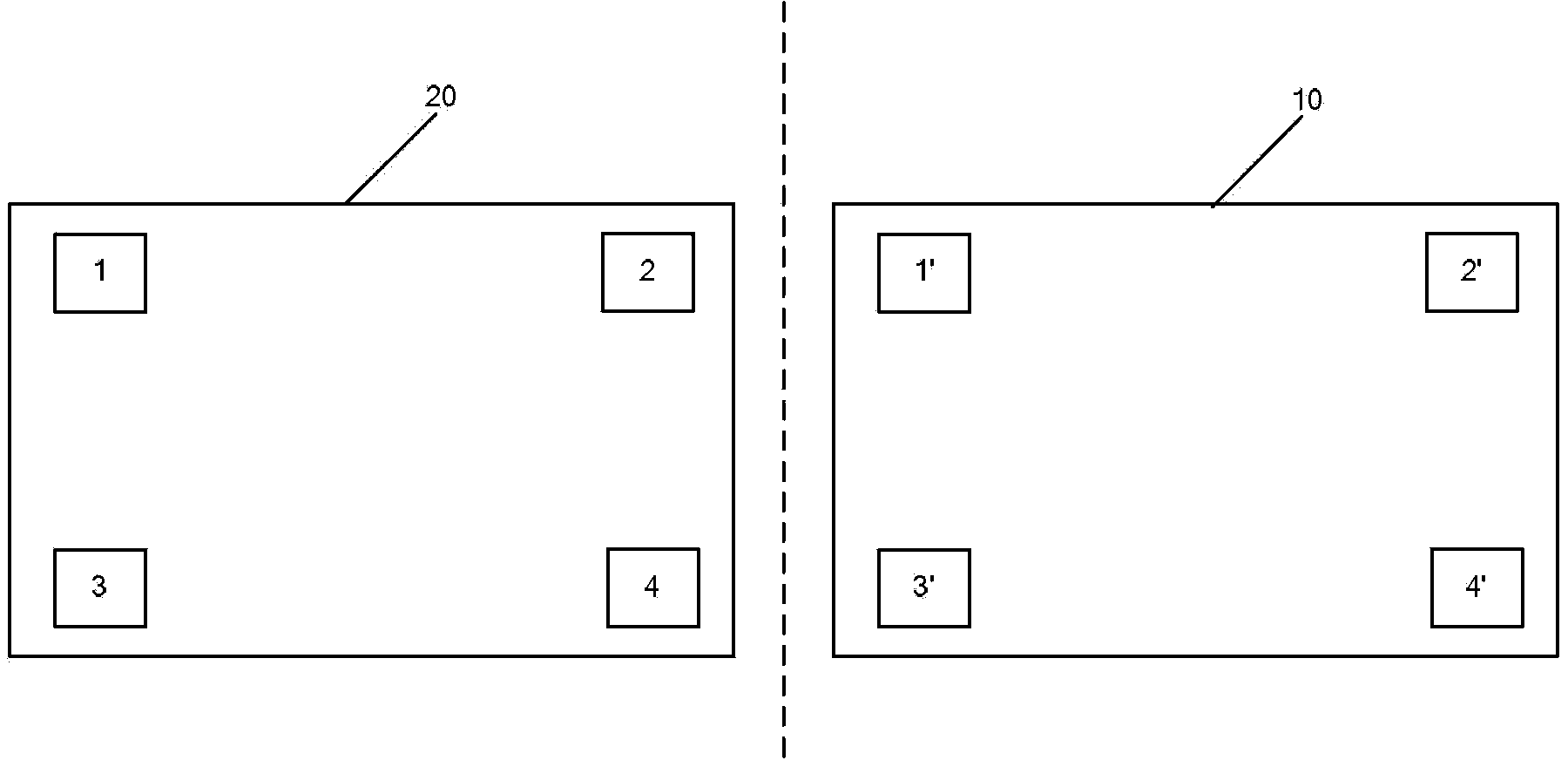

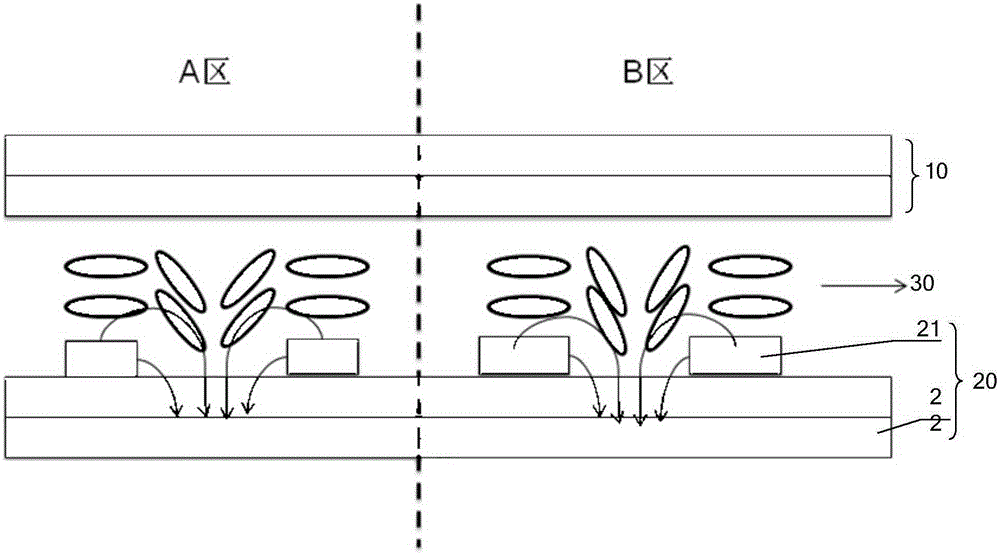

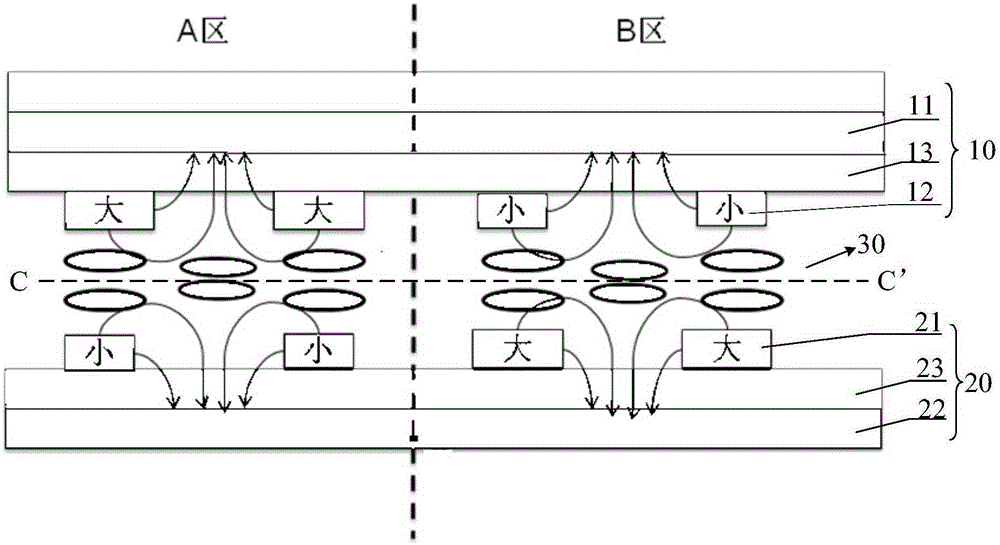

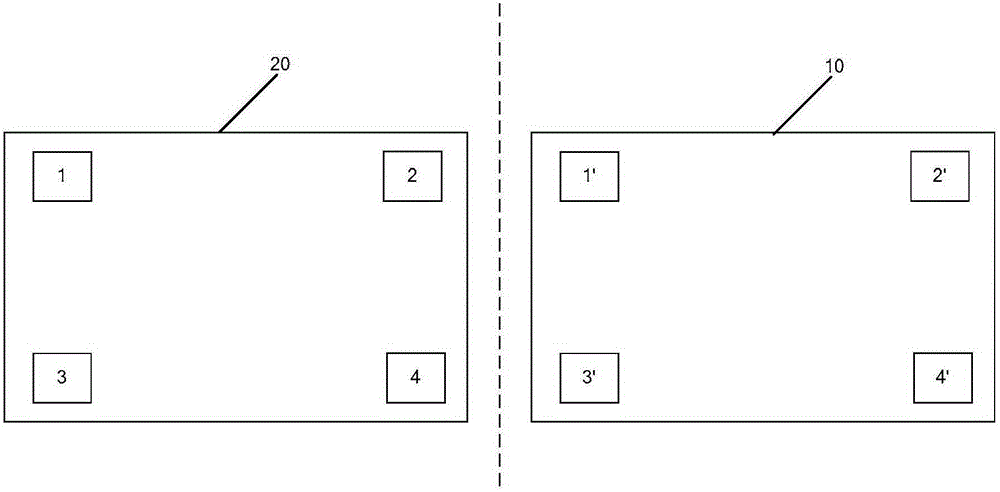

LCD panel, display device and manufacturing and driving methods of LCD panel and display device

InactiveCN103412448AImprove distribution variabilityLayout rulesStatic indicating devicesSolid-state devicesManufacturing technologyDisplay device

The invention discloses an LCD panel, a display device and manufacturing and driving methods of the LCD panel and the display device, relates to the field of display, and can improve electric field distributional difference caused by manufacturing technology and liquid crystal distribution difference caused by pixel edge vertical electric field, and improve optical display features of a product. The LCD panel comprises an array substrate, a color membrane substrate and a liquid crystal layer arranged between the two substrates, wherein a first electrode and a second electrode are arranged on the array substrate on different layers, a third electrode and a fourth electrode are arranged on the color membrane substrate on different layers, the first electrode and the third electrode are oppositely arranged, the first electrode and the third electrode are slit-shaped electrodes, the second electrode and the fourth electrode are plate-shaped electrodes, the first electrode is arranged on the side of the second electrode, which is close to the liquid crystal layer. and the third electrode is arranged on the side of the fourth electrode, which is close to the liquid crystal layer.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

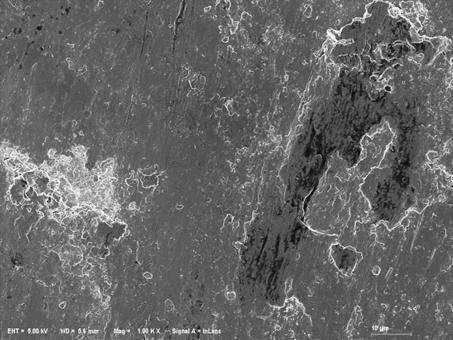

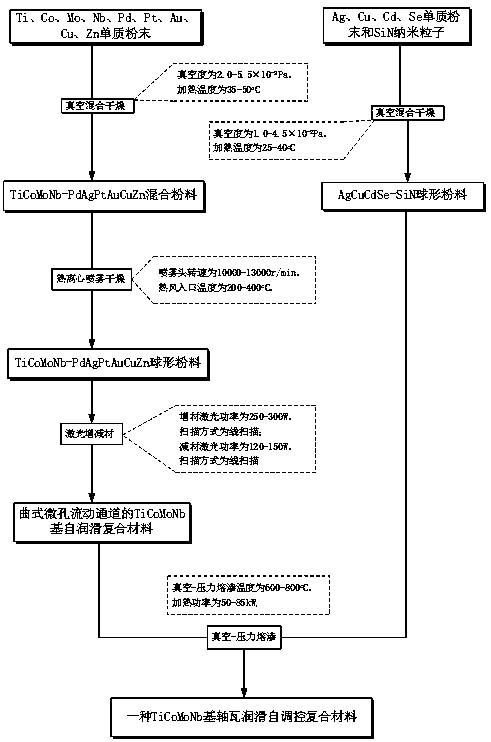

TiCoMoNb basic shaft tile lubricating self-regulating composite material and preparation method thereof

InactiveCN110315065AUniform structure distributionLayout rulesAdditive manufacturing apparatusTransportation and packagingVacuum pressureMaterials science

The invention relates to a TiCoMoNb basic shaft tile lubricating self-regulating composite material. The composite material comprises a basic material TiCoMoNb, a solid lubricating phase PdAgPtAuCuZnand a lubricating regulating agent AgCuCdSe-SiN; a preparation method is characterized in that a hot centrifugal spray drying device is adopted and used for preparing TiCoMoNb-PdAgPtAuCuZn spherical powder, and preparing AgCuCdSe-SiN spherical powder; laser additive manufacturing and subtractive manufacturing equipment is adopted and used for preparing a TiCoMoNb-PdAgPtAuCuZn self-lubricating composite material; and a vacuum-pressure infiltration method is adopted and used for filling a curved micro-pore structure with a regulating agent AgCuCdSe-SiN powder. The TiCoMoNb basic shaft tile lubricating self-regulating composite material has the advantages of being compact in structure, high in purity, short in preparation period, simple in operation, easy to control, regular in arrangement ofmicropore flow channels, uniform in size distribution, good in self-lubricating property and good in lubricating regulation effect.

Owner:ANYANG INST OF TECH

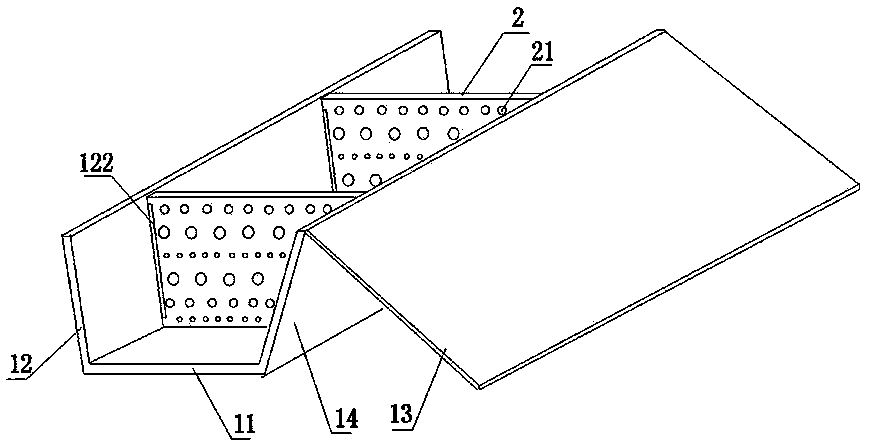

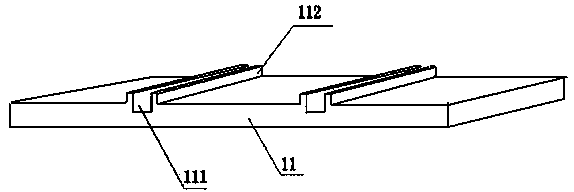

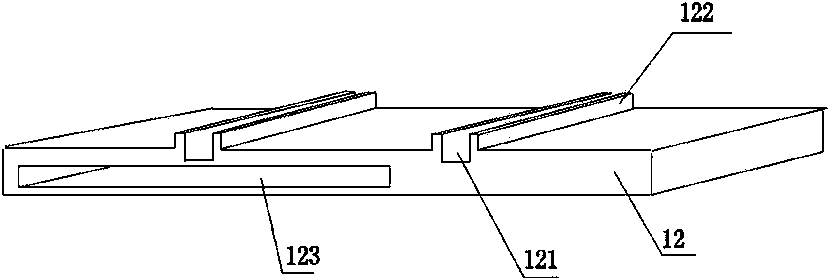

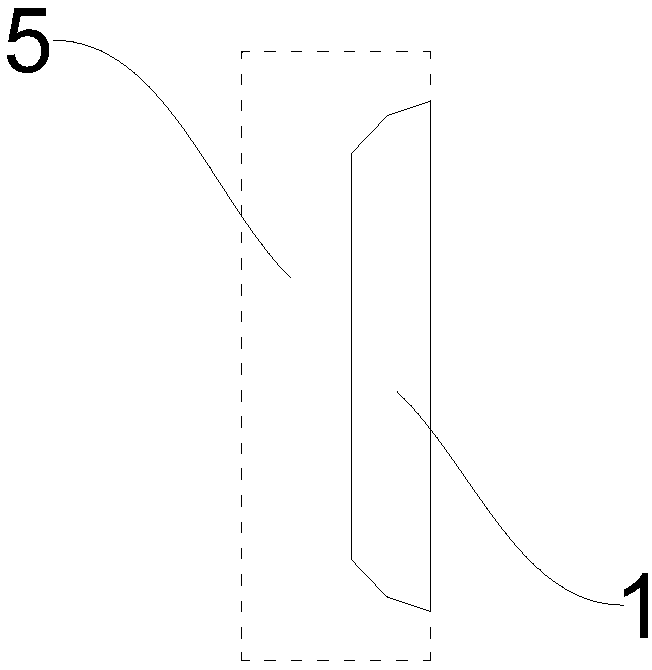

Cable arranging mechanism convenient to mount and demount

InactiveCN104235510ALayout rulesEasily identifiablePipe supportsElectrical apparatusPetroleum engineering

The invention discloses a cable arranging mechanism convenient to mount and demount. The cable arranging mechanism comprises a cable arranging groove which comprises a groove baseplate (11), a left side plate (12), a right side plate (14) and a cover plate (13), at least one cable arranging plate (2) is arranged in the cable arranging groove, multiple cable passing holes (21) are formed in the cable arranging plate (2), cross section of the cable arranging groove is trapezoidal, and shape and size of the cable arranging plate (2) are identical with those of the cross section of the cable arranging groove. By the cable arranging mechanism, the problem that cables contained in an existing cable arranging device are still quite disorderly and difficult to recognize is solved, the cables can be arranged orderly and regularly in the cable arranging device, each cable is easy to differentiate, and a certain distance can be maintained between each cable and other cables. The cable arranging mechanism has the advantages of simple and compact structure, low cost and the like.

Owner:STATE GRID CORP OF CHINA +1

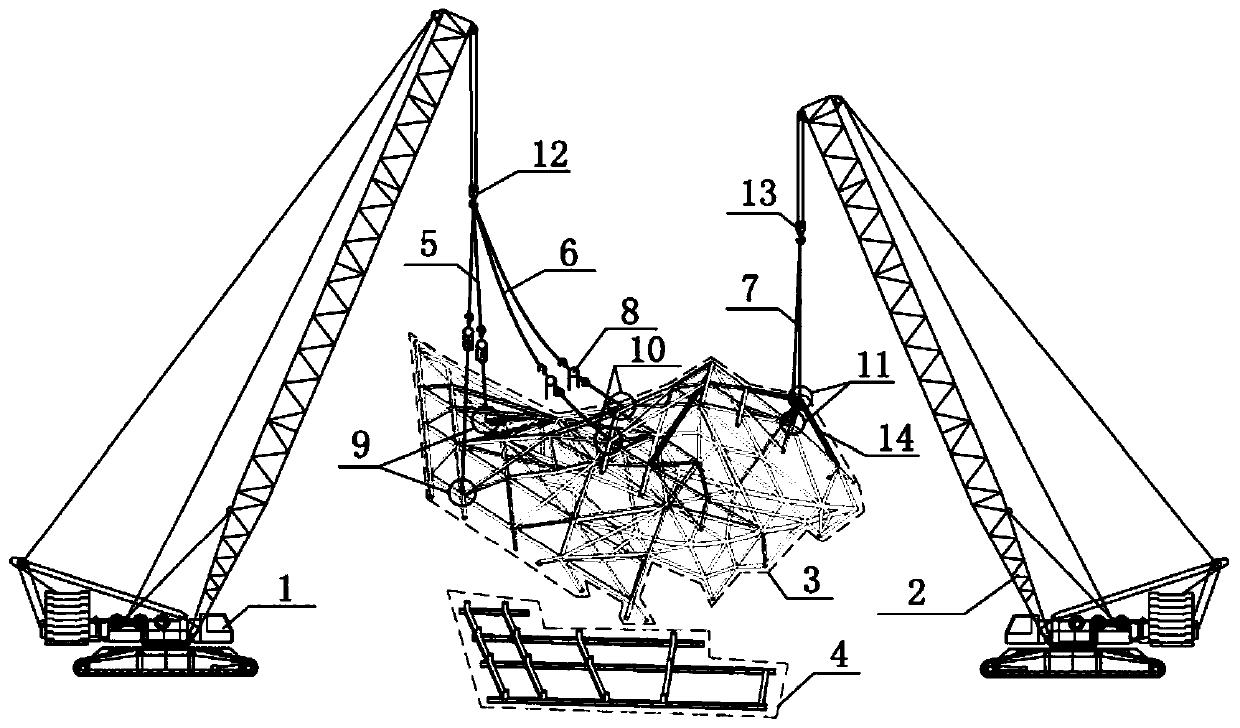

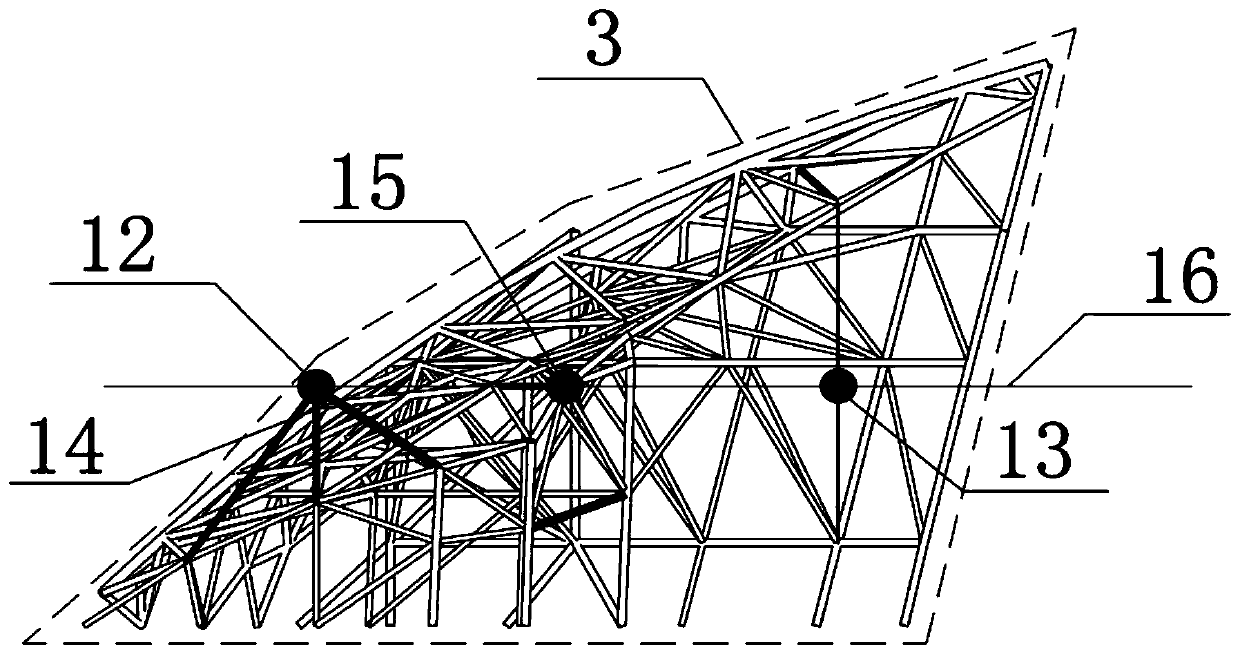

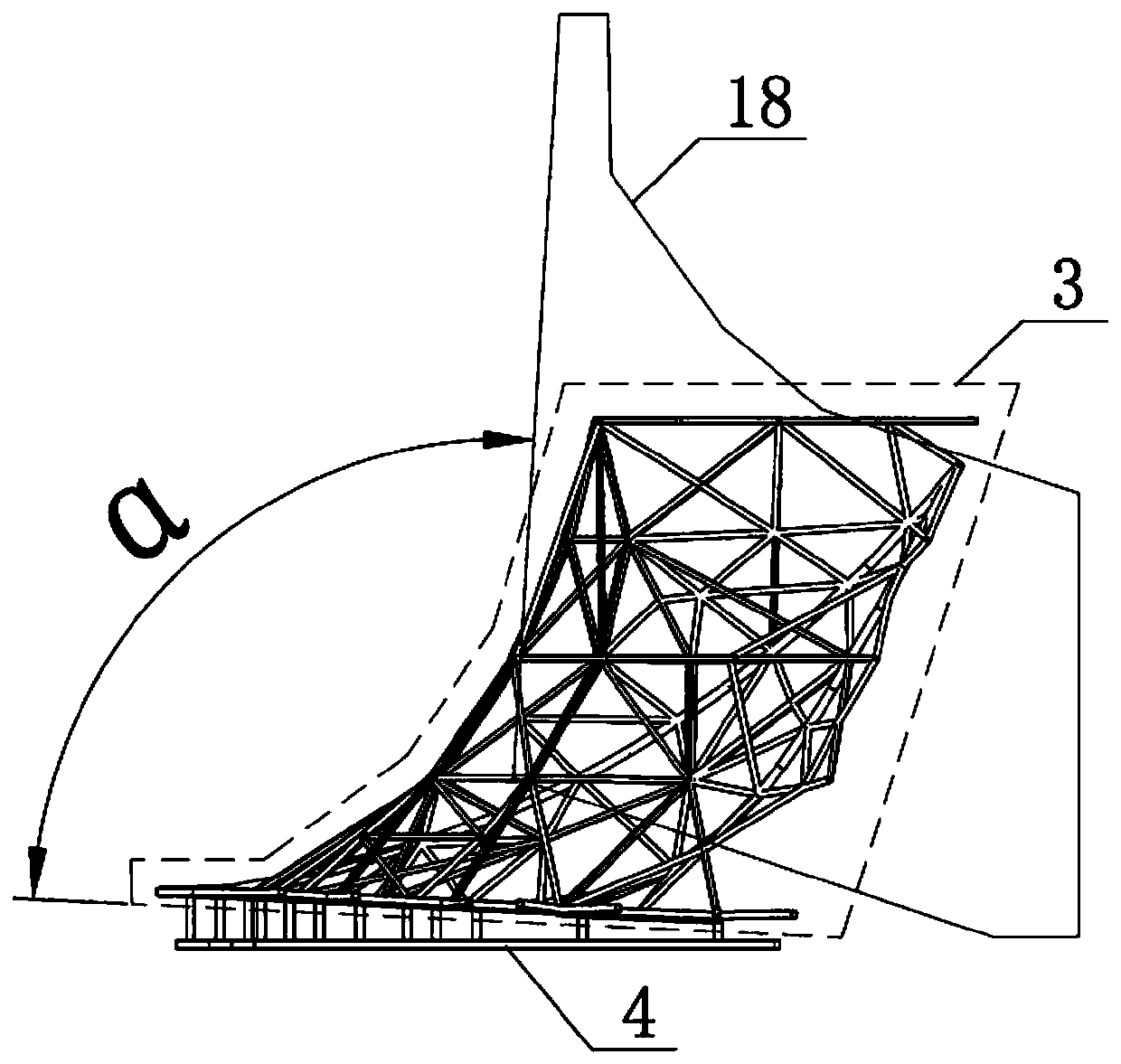

Space grid structure turn-over and base stripping construction method based on BIM technology

InactiveCN110295755ALayout rulesLower center of gravityBuilding material handlingSimulationGravity center

Owner:ZHEJIANG JINGGONG STEEL BUILDING GRP

Fair-faced concrete formwork construction technology

ActiveCN104164967AFlat surfaceLayout rulesForming/stuttering elementsBeam columnBuilding construction

The invention relates to a fair-faced concrete formwork construction technology. The structure surface of fair-faced concrete is not decorated. In the construction process, split bolt holes are handled, panel joints are handled, and finally visible joints are handled. The fair-faced concrete produced with the fair-faced concrete formwork construction technology can be formed at a time and is not decorated externally at all, the natural color of concrete is directly adopted as the decorating color, and it is required that beam columns and plates are flat and smooth in surface, regular and clear in line and consistent in appearance and color, the shape and the size in the axial direction are accurate, cross sections are large, variable-cross-section structures are adopted, lines are regular, corners and edges are clear, beam column joints are smooth, obvious connection marks do not exist, the concrete is solid inside and smooth outside, voids, pits and bubbles are eliminated, embedded parts and embedded bolt sleeves are smooth in surface and accurate in size, split bolts are arranged in order in position, formwork edge joints are regular, and the surface of the concrete should not be damaged or polluted.

Owner:CHINA HYDROPOWER ELEVENTH ENG BUREAU ZHENGZHOU CO LTD +1

Lithium battery diaphragm, preparation method and electrostatic spinning device

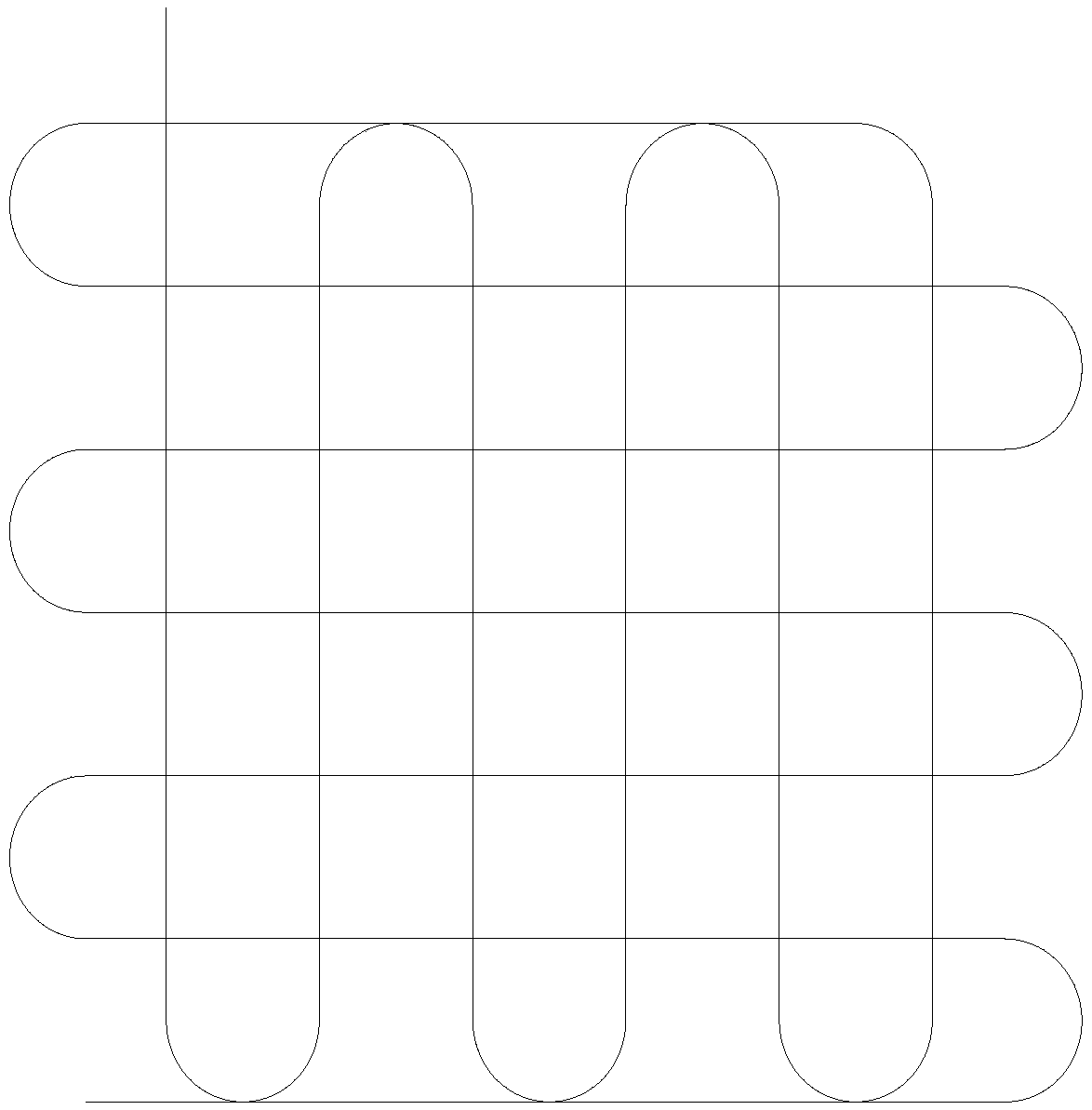

InactiveCN109449357AExtended service lifeLower resistanceSecondary cellsCell component detailsElectrospinningVacuum drying

The invention discloses a lithium battery diaphragm. The lithium battery diaphragm comprises the following components in parts by weight: 93-96 parts of N,N-dimethylamide, 10-13 parts of polyacrylonitrile and 1-2 parts of lithium lanthanite oxide. A preparation method comprises the following steps of 1) mixing the N,N-dimethylamide and polyacrylonitrile powder to prepare a solution; 2) adding lithium lanthanite oxide powder into the mixed solution of the N,N-dimethylamide and the polyacrylonitrile, and carrying out uniform stirring by a stirrer; 3) putting a mixed solution into an electrostatic spinning device, carrying out sequential unidirectional spinning, namely, carrying out transverse reciprocating spinning first, and then carrying out longitudinal reciprocating spinning after the end is reached, until an initial point is reached; and continuing the next spinning to ensure that a fiber has three layers, wherein technological parameters of the electrostatic spinning device are asfollows: an electrostatic voltage is 15-20KV, a jet speed is 0.2-0.71ml / h, and a receiving distance is 16cm; and 4) carrying out vacuum drying on the fiber subjected to spinning forming at 45 DEG C for 5 hours so as to complete the preparation. The lithium battery diaphragm is high in structural strength, high in liquid absorption capacity, high in ionic conductivity, and convenient and fast to prepare.

Owner:苏州华骞时代新能源科技有限公司

Large-scale fluidization storehouse

The invention relates to a large-scale fluidization storehouse. The large-scale fluidization storehouse comprises a storehouse top, a storehouse wall, a storehouse bottom and a storehouse foundation. The large-scale fluidization storehouse is characterized in that the storehouse bottom comprises a conical arch, the highest point of the conical arch is located at the center of the storehouse bottom or near the center of the storehouse bottom, the inclined plane of the conical arch extends to the bottom of the storehouse wall, a material flow-assisting device is arranged on the inclined plane of the conical arch, a discharging channel is disposed at the bottom of the storehouse wall, a feeding end of the discharging channel extends nearby the material flow-assisting device arranged on the inclined plane of the conical arch in the storehouse wall, and a discharging end of the discharging channel, which is positioned on the outer side of the storehouse wall, is provided with a channel flow control device. The large-scale fluidization storehouse has the advantages of being simple in structure, small in investment, large in storage capacity, short in construction cycle, low in construction difficulty, easy to maintain, small in occupies area, superior in economy and safety, capable of being widely applied to storage of powdery or granular materials such as fly ash, cement and grain and the like.

Owner:赵世青

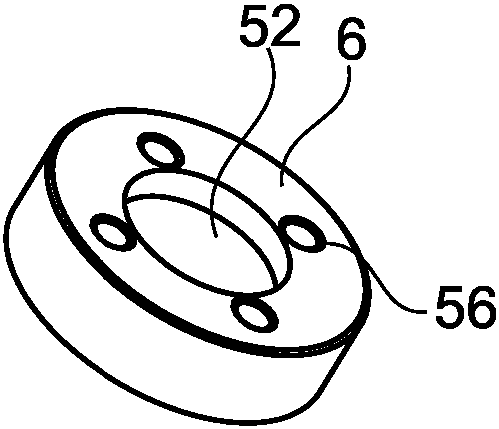

Valve arrangement

ActiveCN105074193APromote absorptionCompact designPositive displacement pump componentsFuel injecting pumpsEngineeringHigh pressure

A valve arrangement (2) for a high pressure pump is proposed, which valve arrangement (2) has a pump housing (24) with a depression (22), a valve housing (4) which is configured so as to correspond with the depression (22) in the pump housing (24), with the result that it can be inserted into the depression (22), and a clamping disc (6). The valve housing (4) has at least one radial projection (36) with a first axial boundary surface (5) and a second axial boundary surface (44) which is arranged so as to lie opposite said first axial boundary surface (5), wherein the clamping disc (6) extends radially over the radial projection (36) of the valve housing (4) and has a third axial boundary surface (46) which is configured so as to correspond with the second axial boundary surface (44) of the valve housing (4). On the circumferential side, the clamping disc (6) has a thread (40) which can be screwed into a thread (42) on the inner side of the depression (22) in such a way that the valve housing (4) is braced onto the first boundary surface (5).

Owner:VTESCO TECH GMBH

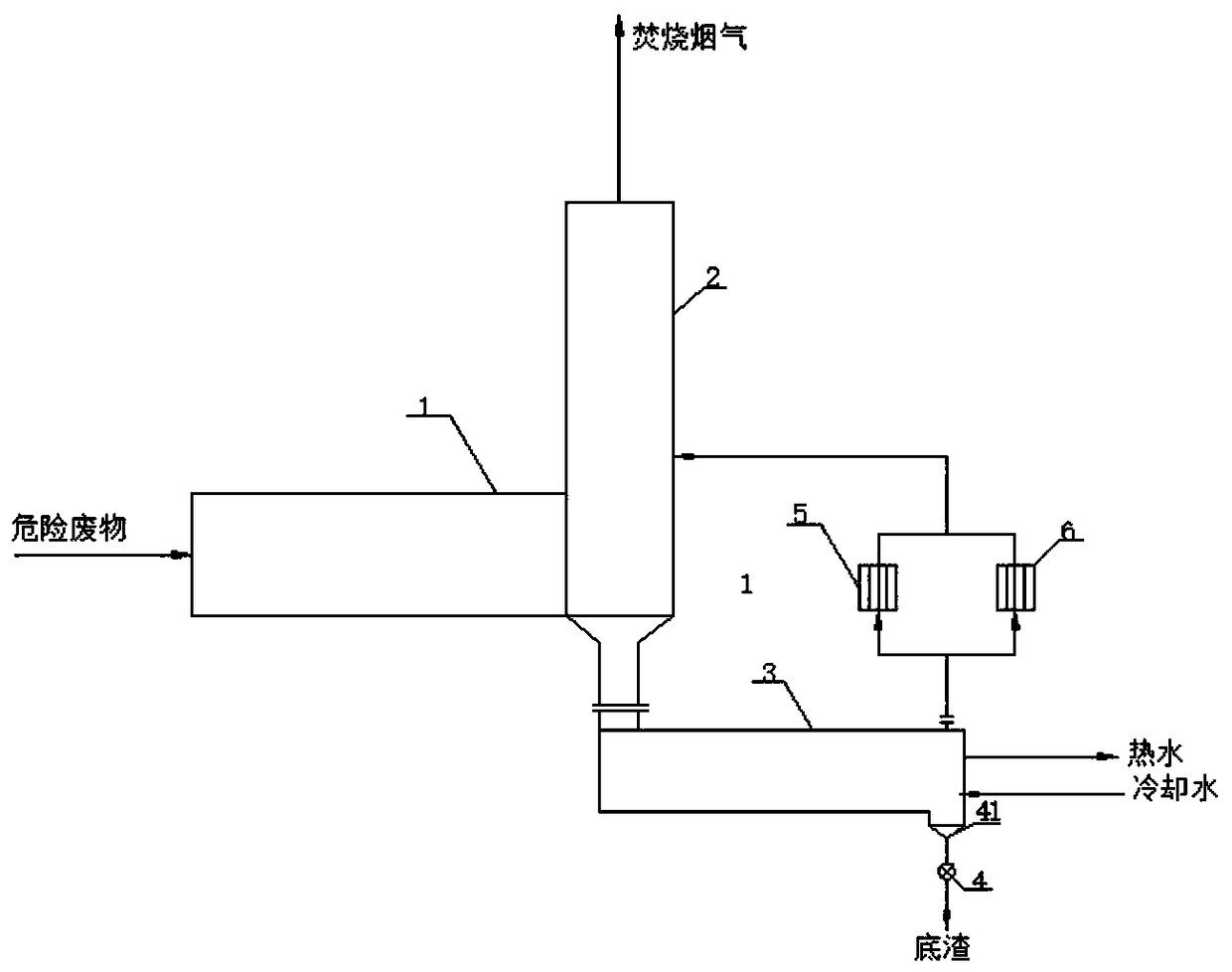

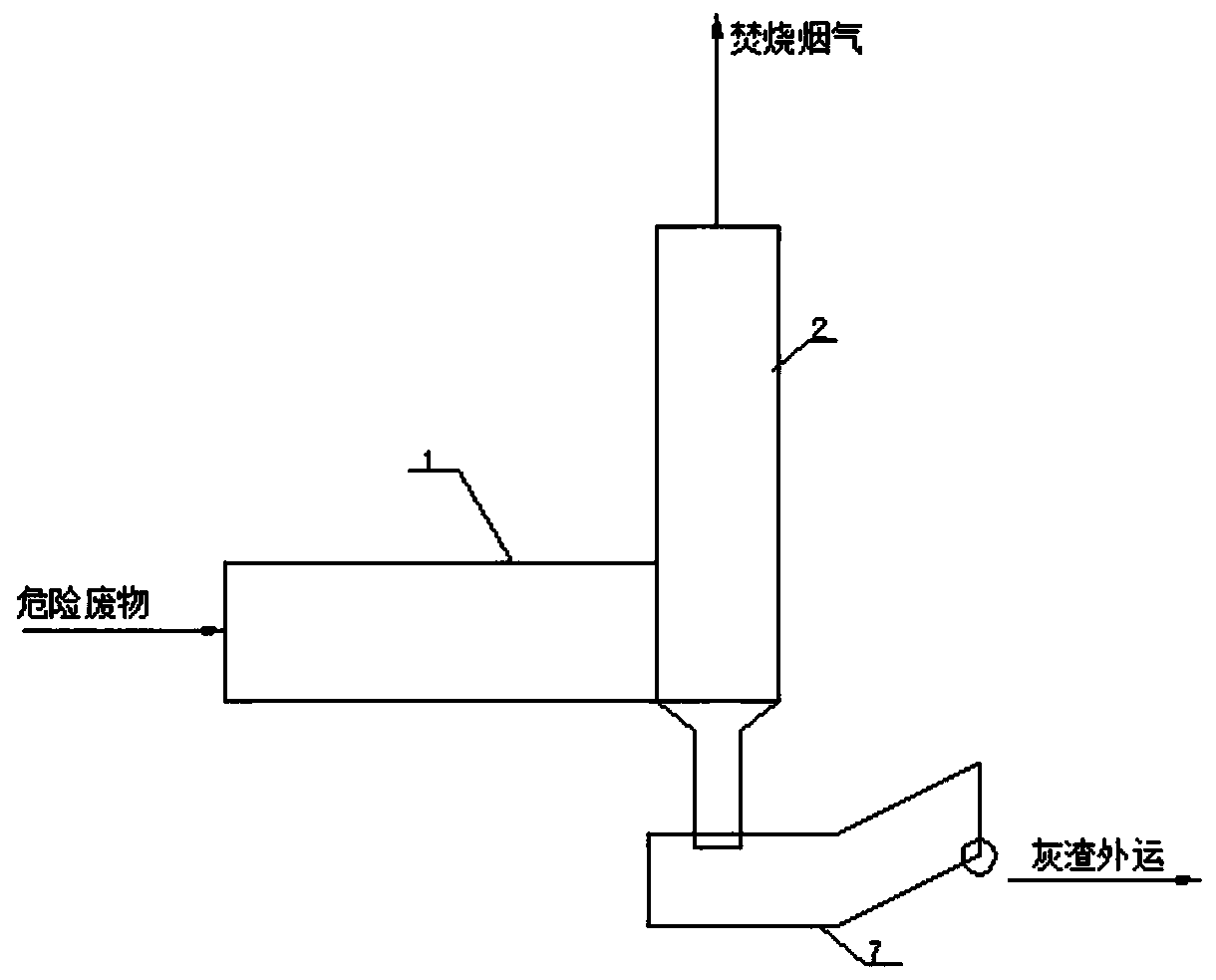

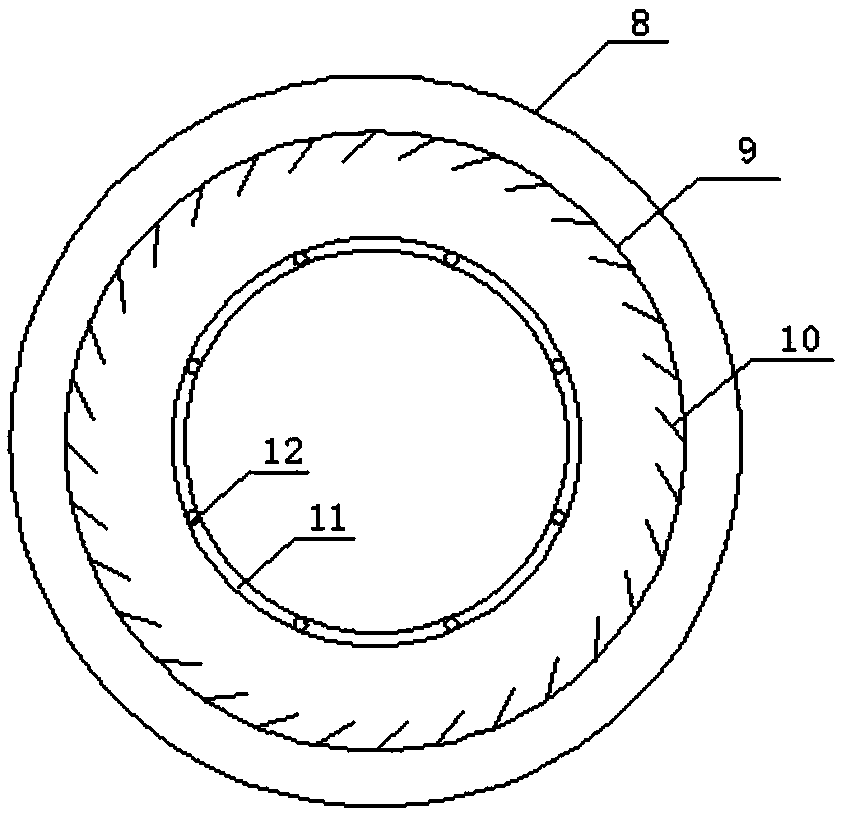

Hazardous waste incinerator with dry cooling slag discharging mechanism

ActiveCN108826319AReduce lossesReduce energy consumptionIncinerator apparatusMoving conduit heat exchangersCombustion chamberSlag

The invention relates to the technical field of hazardous waste disposal, in particular to a hazardous waste incinerator with a dry cooling slag discharging mechanism. The hazardous waste incineratorcomprises a rotary kiln, a secondary combustion chamber and a slag discharging mechanism which are arranged in series; the slag discharging mechanism comprises ash slag cooling equipment and a filtering device; the ash slag cooling equipment comprises a shell and a roller which are coaxially arranged, one axial end of the roller is connected with a driving motor through a connecting shaft, and rotation of the roller relative to the shell is achieved; a circular-ring-shaped water pipe is coaxially arranged in one end of the roller; and a cooling water pipe is coaxially arranged in the roller and symmetrically provided with water pipe fins arranged along a pipe body. According to the hazardous waste incinerator with the dry cooling slag discharging mechanism, reverse-flow indirect contact heat exchange is achieved, and the condition that in the prior art, water source pollution is caused by direct contact heat exchange is changed; and meanwhile, roller fins and the water pipe fins can significantly increase the heat transfer area and can better conduct ash slag heat, the roller fins and the water pipe fins are arranged regularly and achieve a guiding effect on ash slag discharging, and the energy efficiency of the disposal system is improved.

Owner:EAST CHINA ENG SCI & TECH

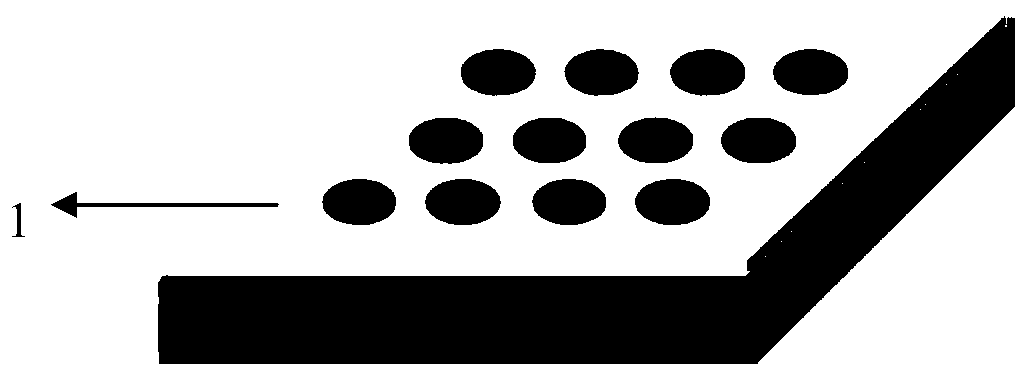

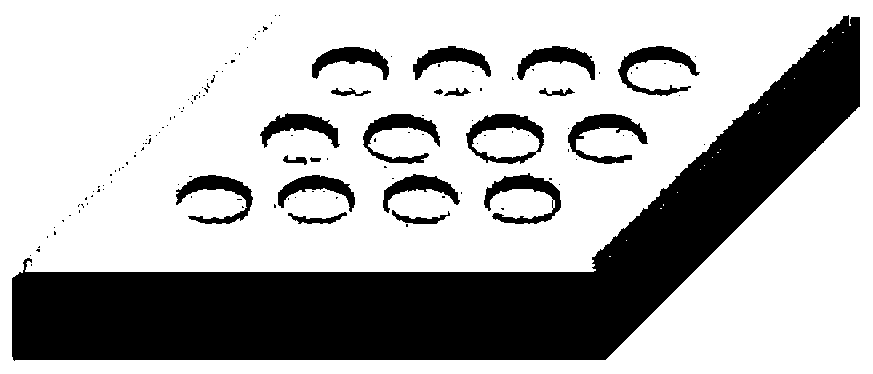

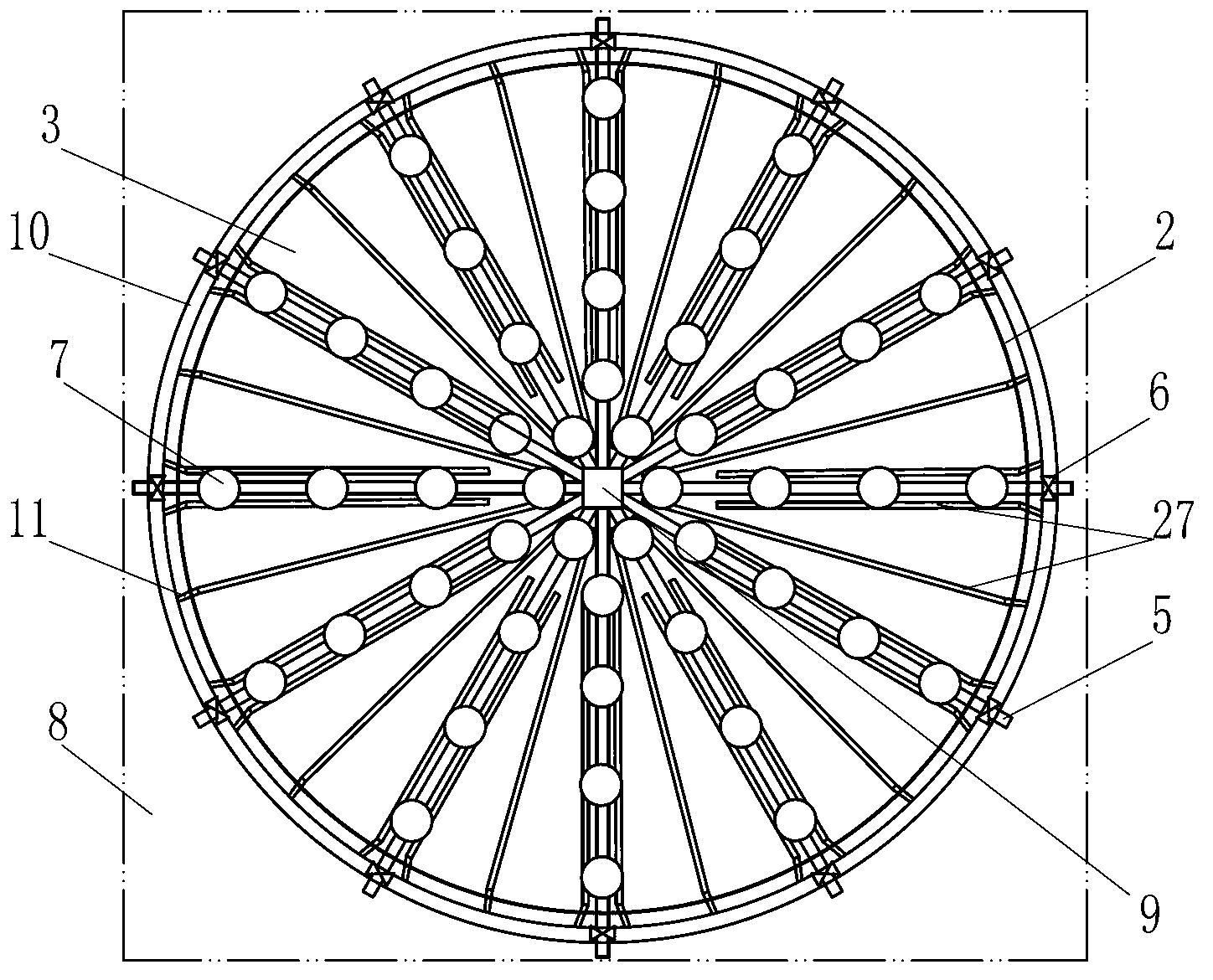

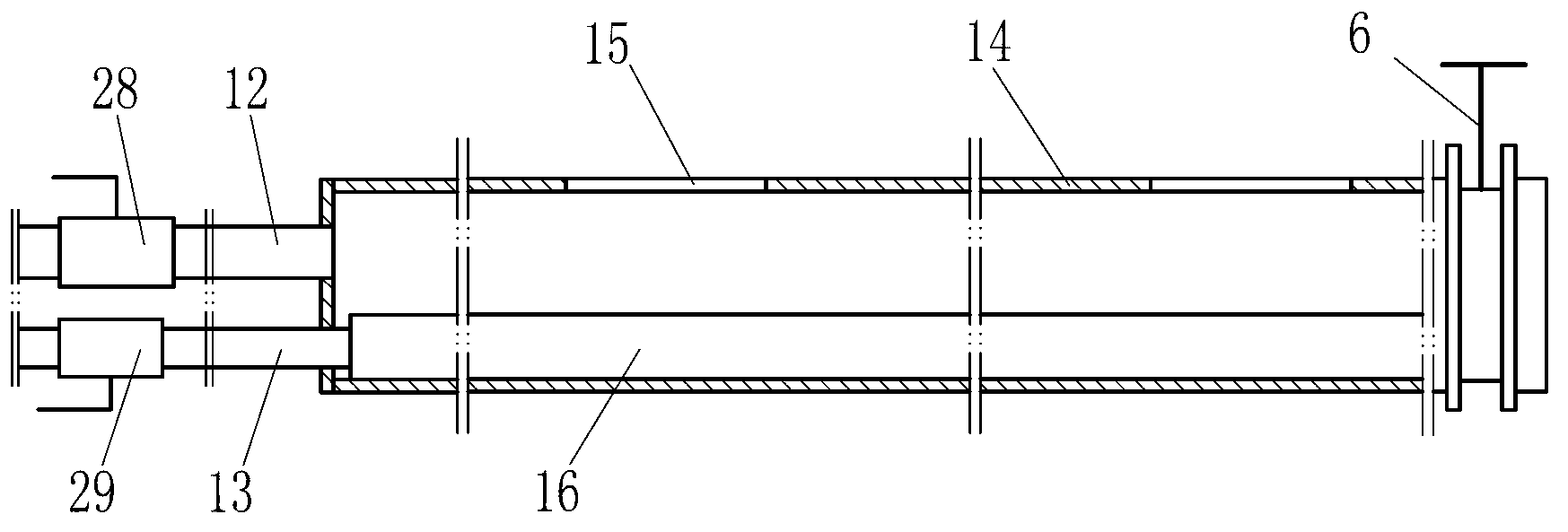

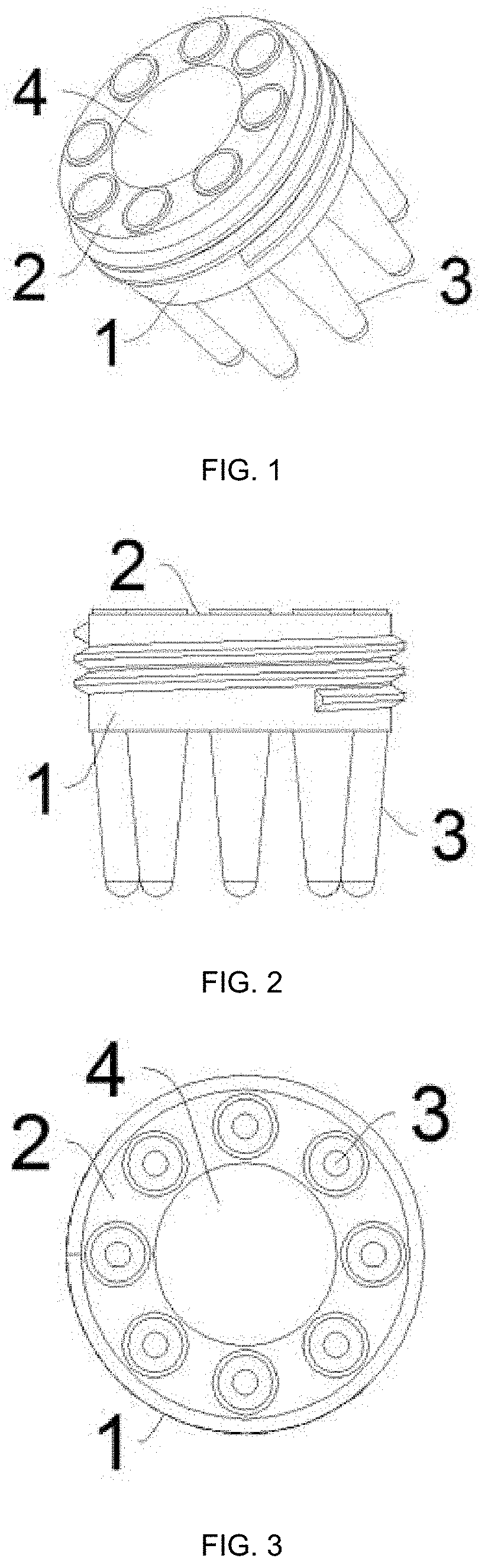

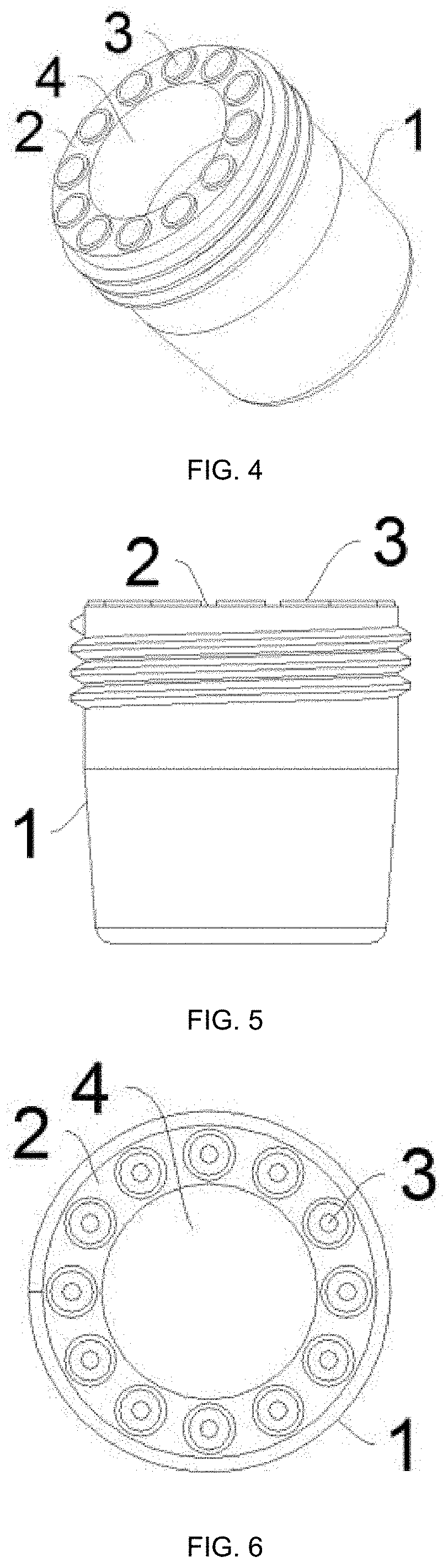

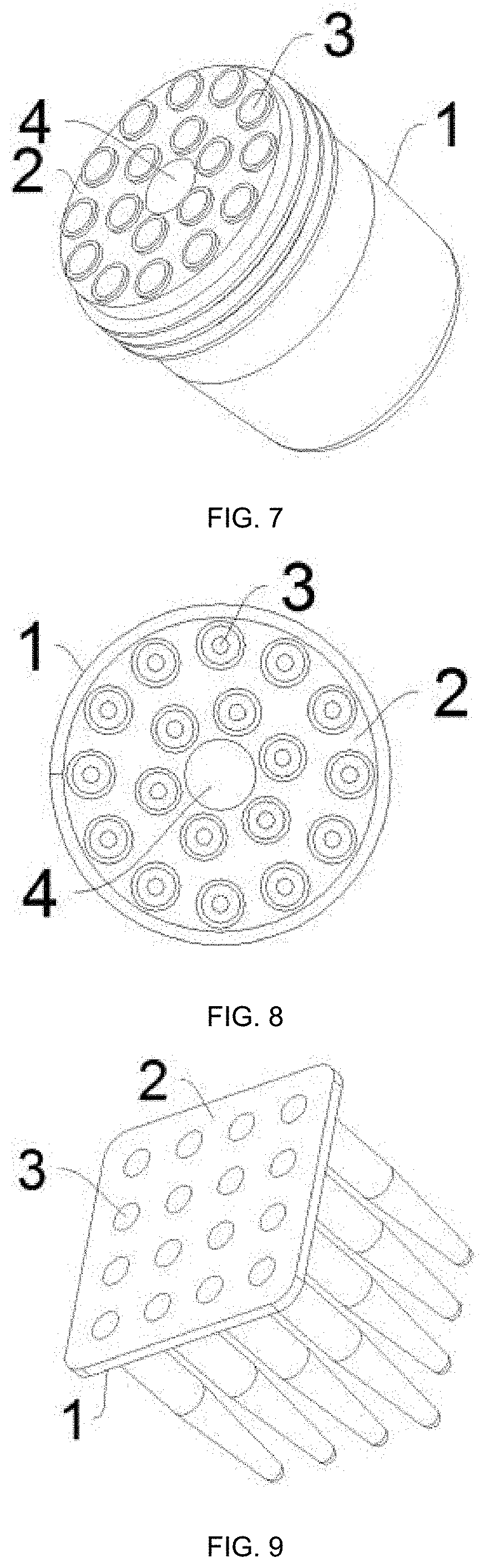

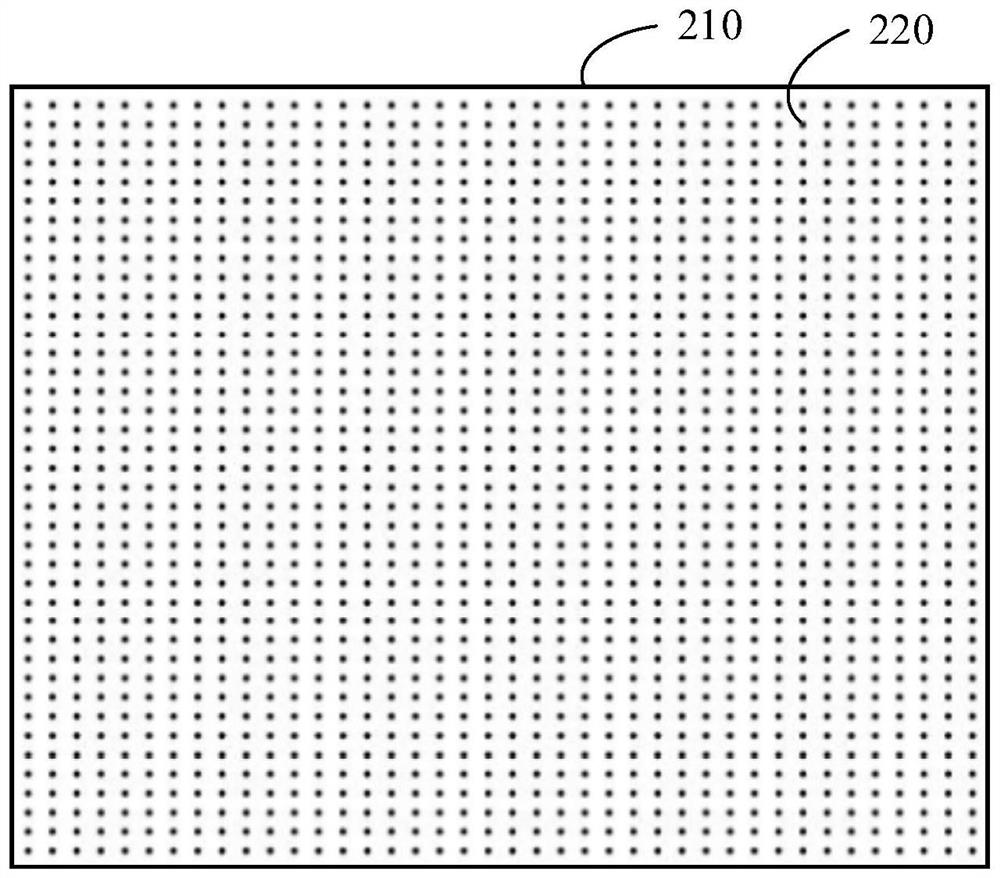

Reaction tube for multiple nucleic acid amplification

PendingUS20220111379A1Improving nucleic acid amplification efficiencyEnsure uniformitySequential/parallel process reactionsLaboratory glasswaresMolecular biologyBiophysics

A reaction tube for multiple nucleic acid amplification, related to the applied technical field of biological science research and medical tests. The reaction tube for multiple nucleic acid amplification comprises a base (1) and multiple reaction tube cavities (3). The base (1) is provided with a reference plane (2). Openings of the multiple reaction cavities (3) are provided on the reference plane (2). The cavities are perpendicular to the reference plane (2) and extended towards the interior of the base (1). The reaction tube for multiple nucleic acid amplification provides the multiple reaction tube cavities (3) on the reference plane (2) of the base (1).

Owner:ACADEMY OF MILITARY MEDICAL SCI

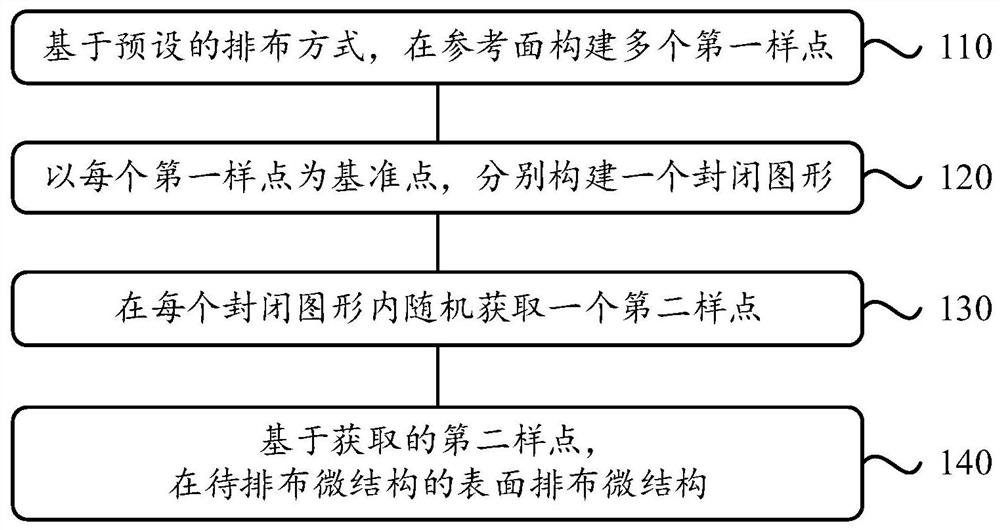

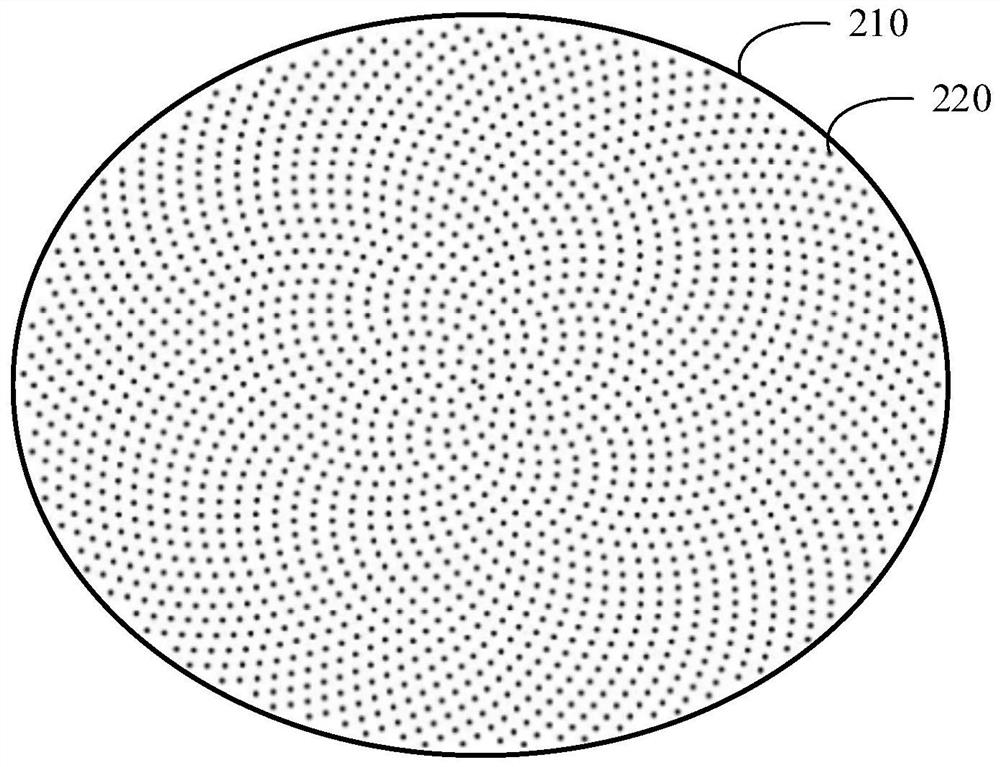

Microstructure arrangement method and diffusion plate

PendingCN114662291AConsistent structureSolve the problem of unstable optical effectDiffusing elementsDesign optimisation/simulationMechanical engineeringMicrostructure

The embodiment of the invention provides a microstructure arrangement method and a diffusion plate, relates to the technical field of optical element design, and aims to solve the problem that a frosted surface is arranged on an optical element, and the optical effect of the optical element is unstable due to the frosted surface. The microstructure arrangement method comprises the following steps: constructing a plurality of first sample points on a reference plane based on a preset arrangement mode; respectively constructing a closed graph by taking each first sample point as a reference point; randomly acquiring a second sampling point in each closed graph; and arranging the microstructure on the surface of the microstructure to be arranged based on the obtained second sample point.

Owner:SUZHOU OPPLE LIGHTING

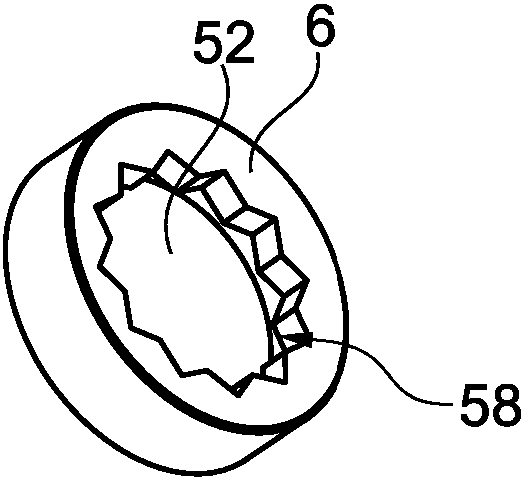

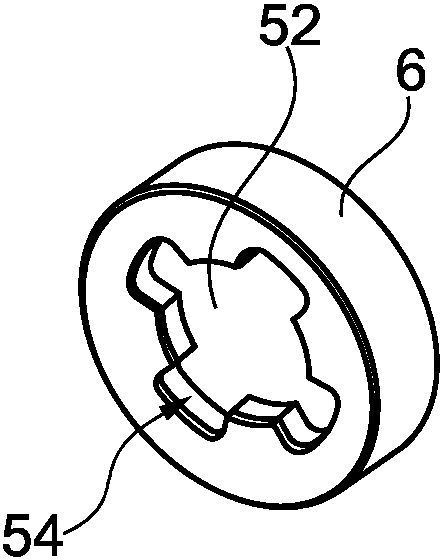

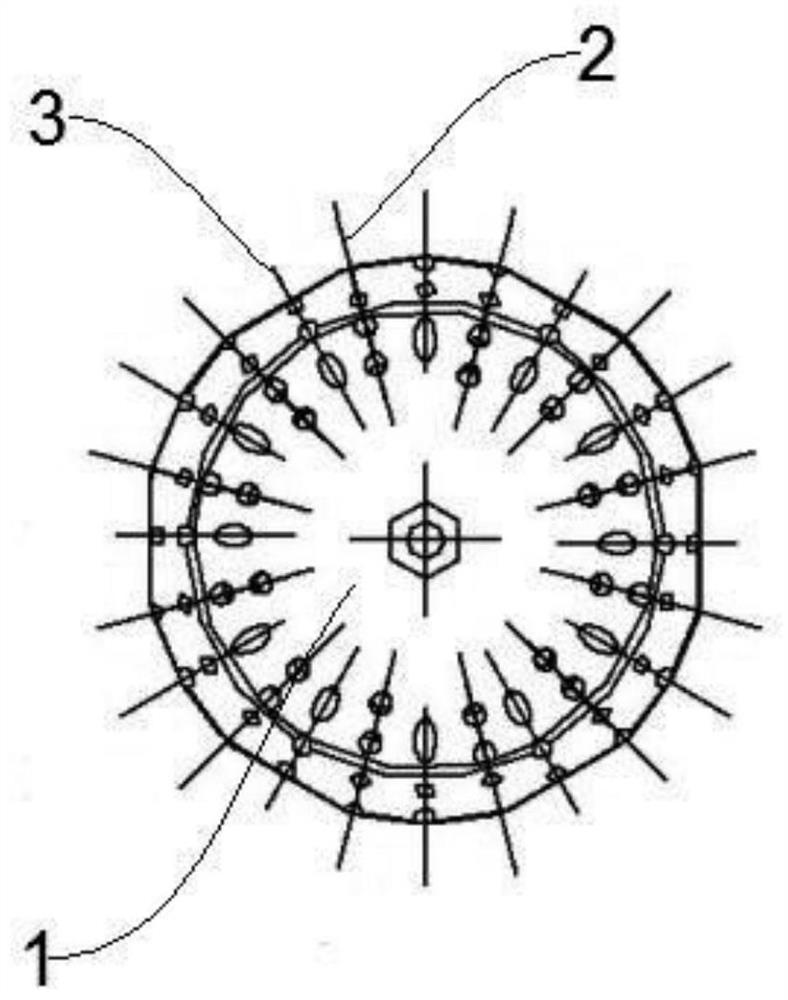

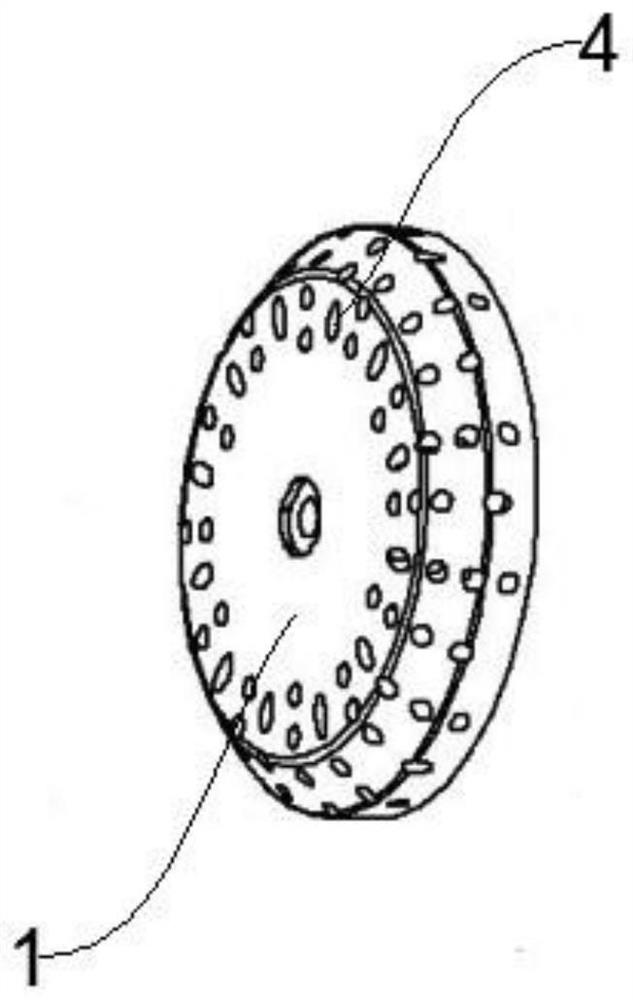

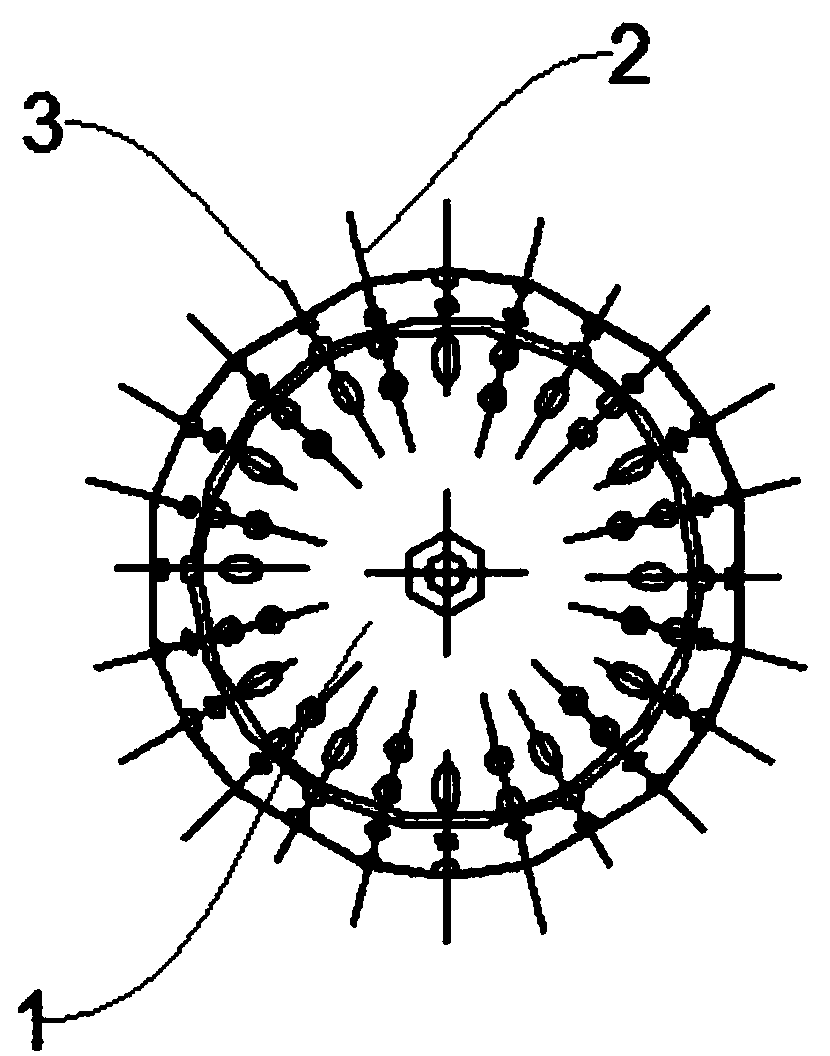

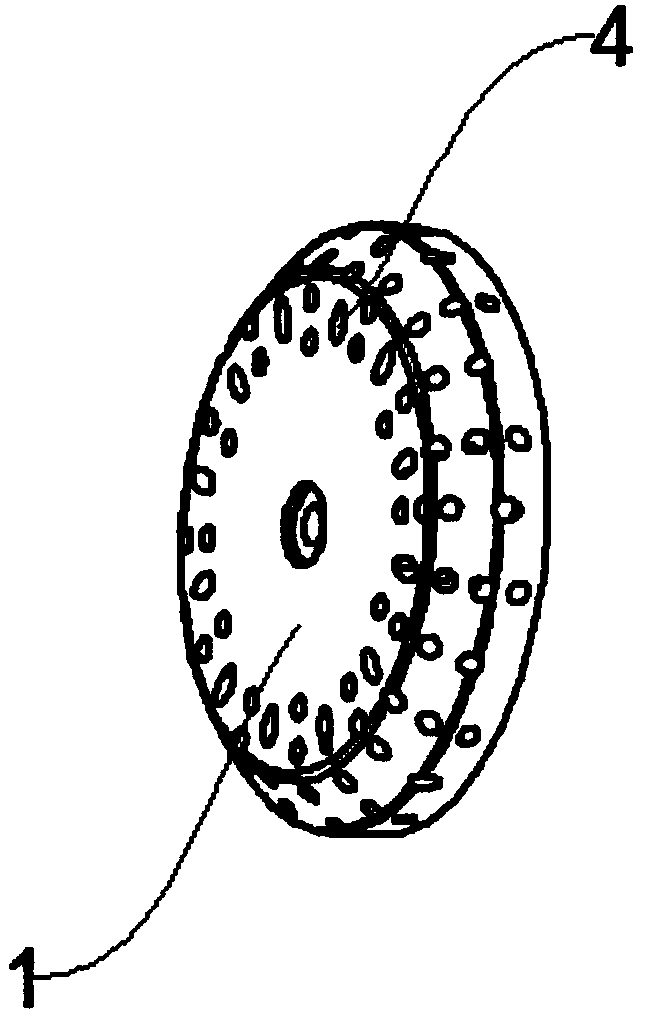

Brush wheel for shoe washing machine, brush wheel assembly and shoe washing machine

ActiveCN109549601BRealize no dead angle brushingEasy to cleanBristleFootwear cleanersBristleEngineering

The invention belongs to the technical field of shoe washing machines and aims to solve the problem that the brush wheels of the existing shoe washing machines have poor cleaning effect on shoes. For this reason, the present invention provides a kind of hair brush wheel for shoe washing machine, brush wheel assembly and shoe washing machine, and this hair brush wheel comprises brush plate and the multi-tuft bristle that is arranged on the brush disc, the multi-tuft bristle at least A part is configured to extend from the brush plate in different directions, and the brush plate is preferably provided with multiple rows of installation holes along its circumference, and the installation holes are used for installing bristles. In the present invention, the bristles with different angles are arranged so that the bristles extend in different directions on the brush plate, thereby increasing the area of interaction with the shoes when scrubbing the shoes, thereby realizing all-round scrubbing of the shoes without dead ends, and improving the wear resistance of the shoes. Cleaning effect of shoes.

Owner:HEFEI HAIER WASHING MACHINE +1

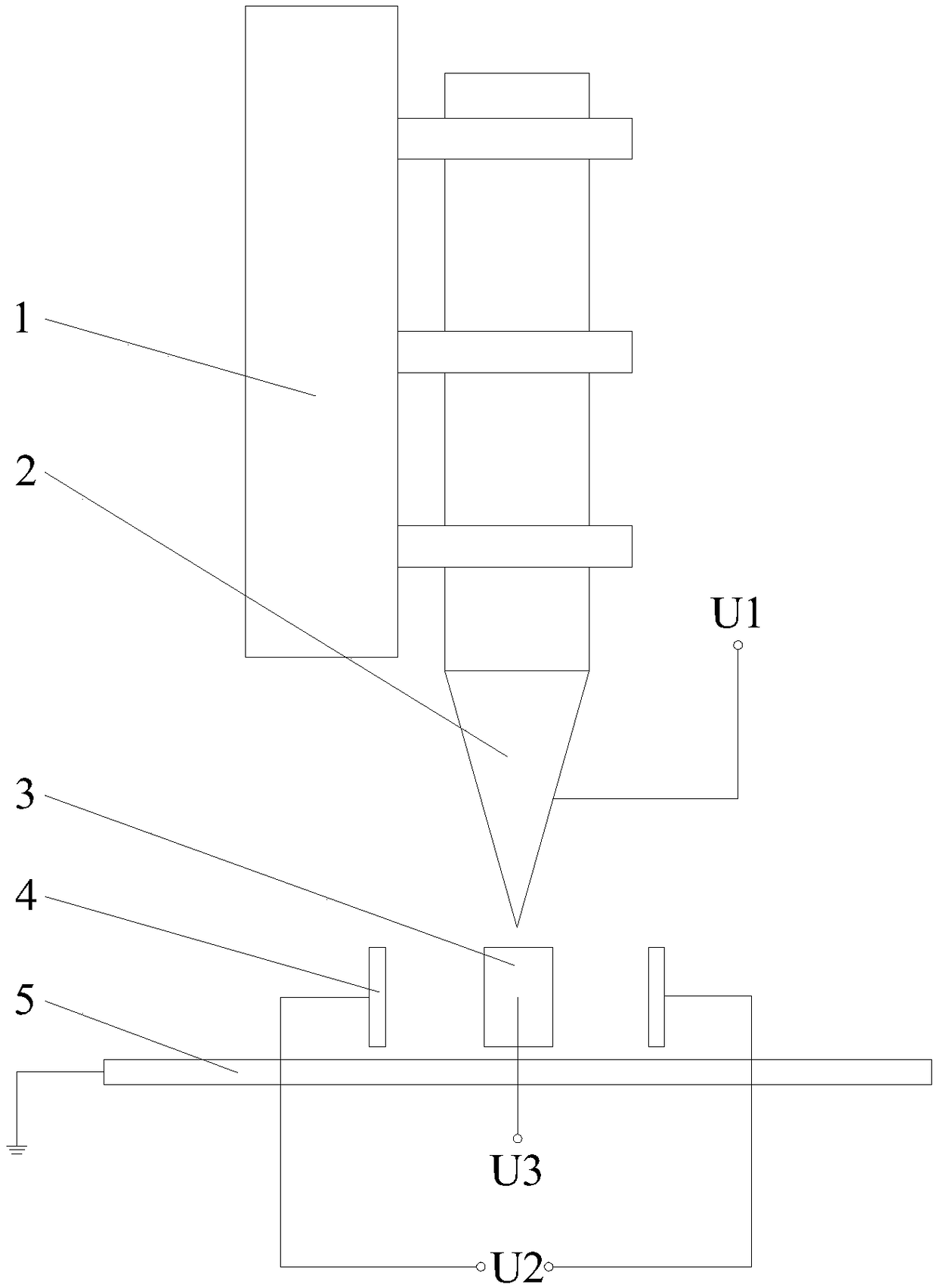

Preparation method of dependent electrospinning intravascular stent

InactiveCN113041406AConsistent porositySmall diameterSurgeryFilament/thread formingNanofiberIntravascular stent

The invention relates to a preparation method of a dependent electrospinning intravascular stent, and belongs to the field of intravascular stents. The preparation method of the dependent electrospinning intravascular stent is characterized by comprising the following steps: dissolving a pH dependent material and PLGA mixed powder into trichloromethane to prepare a solution, and stirring the solution by a reinforcement stirrer to uniformly mix all components into one group; then, taking PLGA powder with the same mass, dissolving the PLGA powder in trichloromethane to prepare a solution, and stirring the solution by the reinforcement stirrer to prepare a second group; respectively sucking the prepared two groups of solutions by injectors, installing the injectors on a controllable injection pump of an electrostatic spinning device, connecting an anode of a high-voltage power supply with metal needles of the injectors, and connecting a cathode of the high-voltage power supply with a rod-shaped rotating shaft of a receiving device; and obtaining the tubular stent formed by nanofibers. The porosity of the prepared intravascular stent is basically consistent, the diameter of the nanofibers is smaller, the arrangement is more regular, and pH sensitivity is reserved. The mechanical strength, the tensile strength, the elongation at break and the bursting strength are all remarkably improved, and the mechanical property is relatively good.

Owner:高佳琪

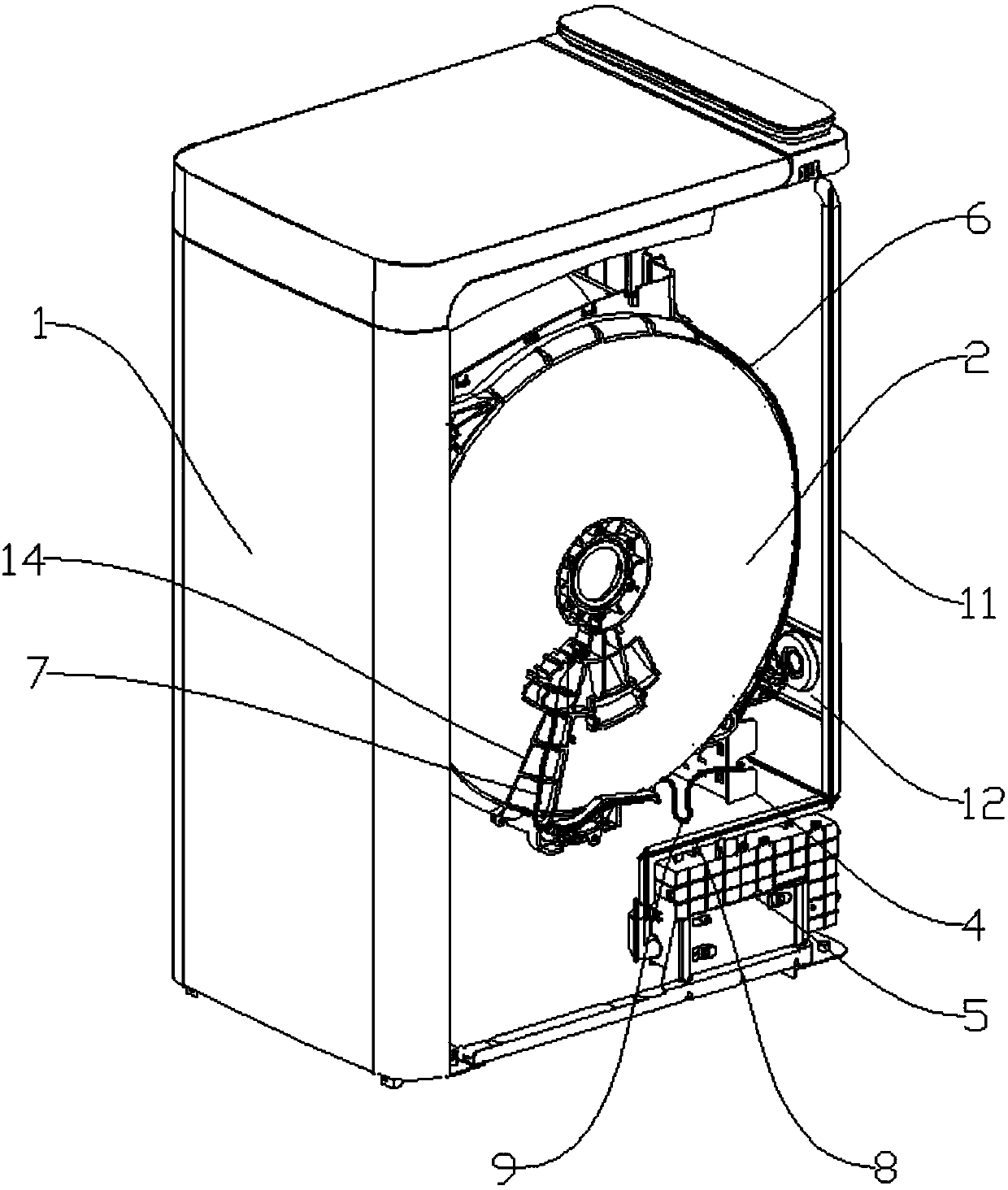

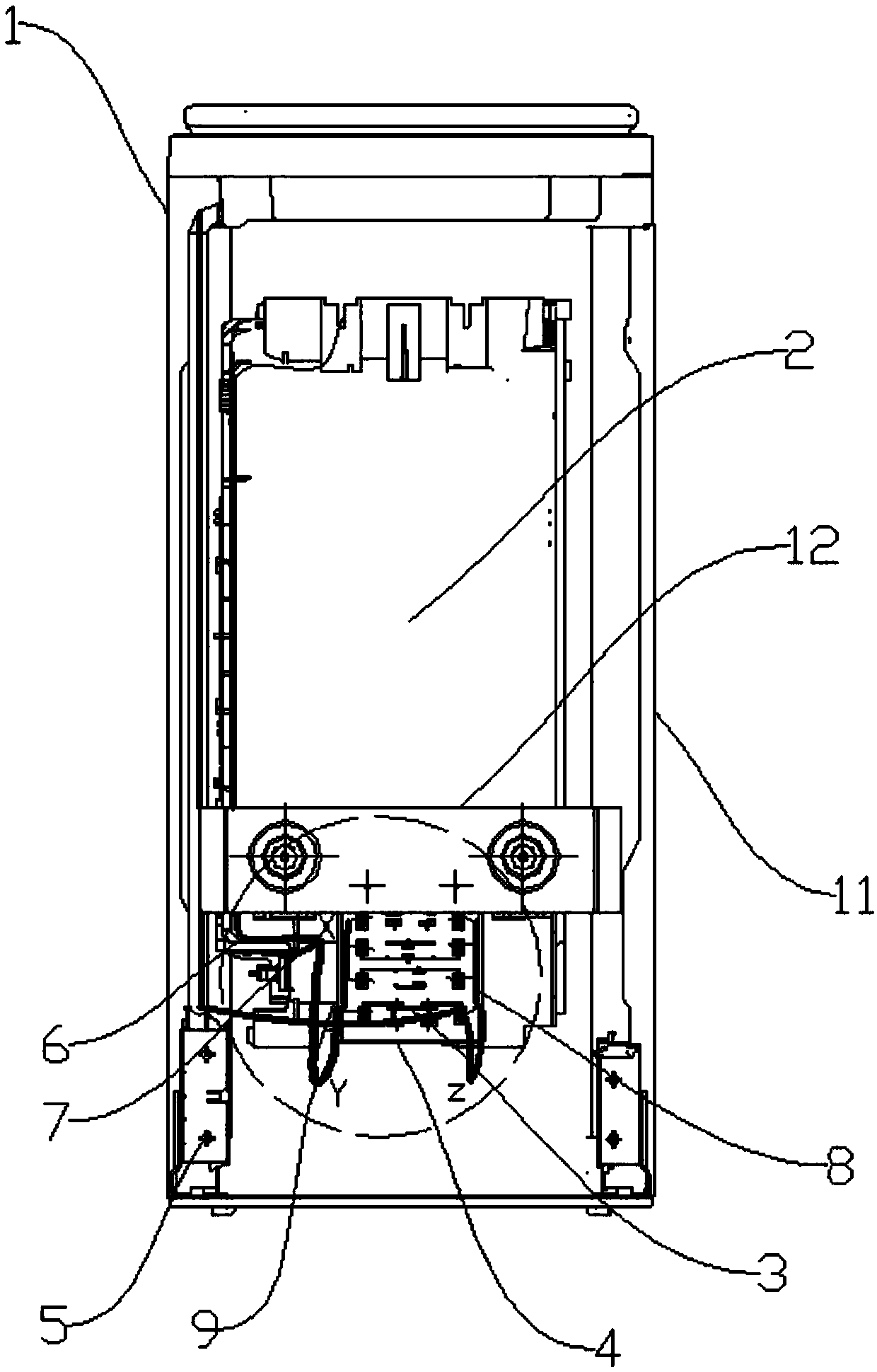

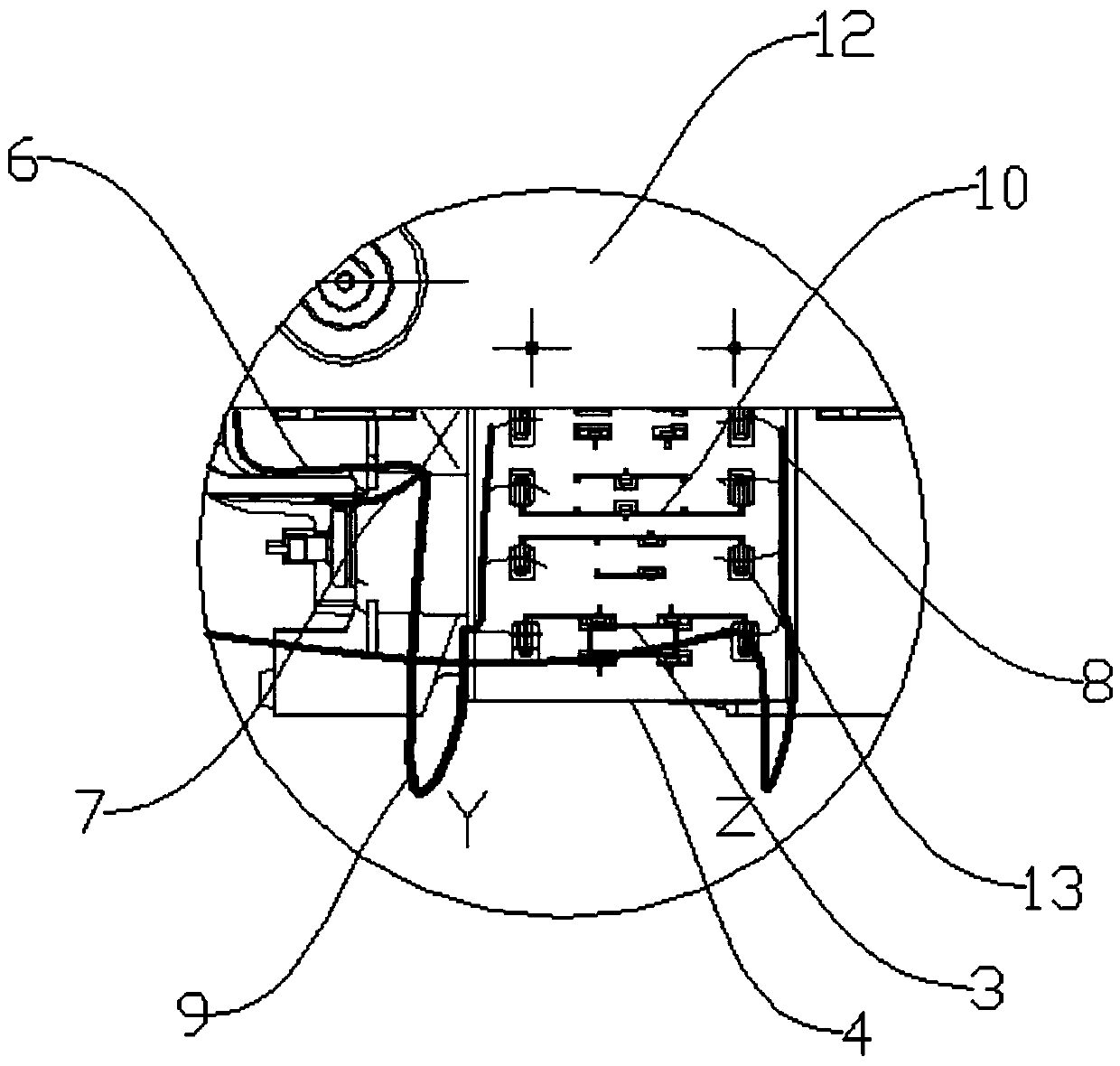

Wiring assembly for clothes treatment equipment and clothes treatment equipment

PendingCN109898275AAdequate isolationEasy to fixOther washing machinesTextiles and paperElectric power transmissionEngineering

The invention belongs to the technical field of clothes treatment, and aims to solve the problem of poor safety of clothes treatment equipment caused by power transmission of docking terminals and connecting wires in the existing clothes treatment equipment. To this end, the invention provides a wiring assembly for clothes treatment equipment and the clothes treatment equipment, the clothes treatment equipment comprises a circuit board assembly and an electrical device, and the wiring assembly comprises a docking terminal for connecting the circuit board assembly with the electrical device, wherein at least one of the circuit board assembly and the electrical device is connected with the docking terminal through connecting wires, and a part of the connecting wires close to the docking terminal is bent downward to form a waterproof section, so that the lowest point of the waterproof section is lower than the docking terminal. Water and the docking terminal can be fully isolated, and thus the risk that the docking terminal is soaked by water is reduced, so that the operation safety of the clothes treatment equipment is improved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

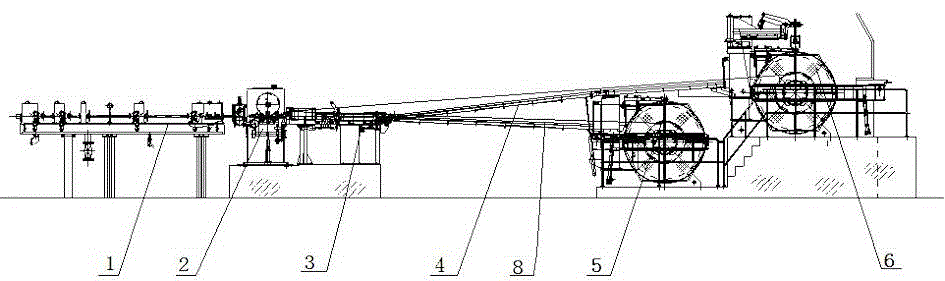

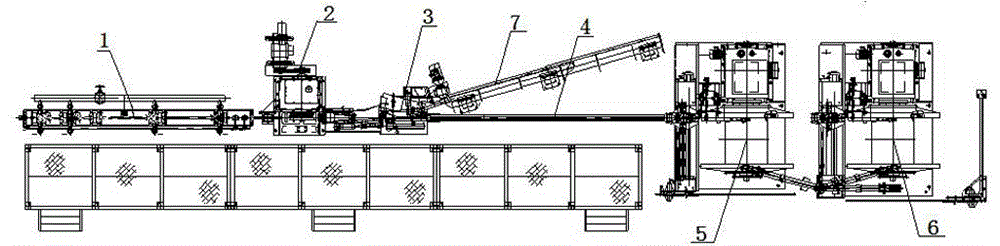

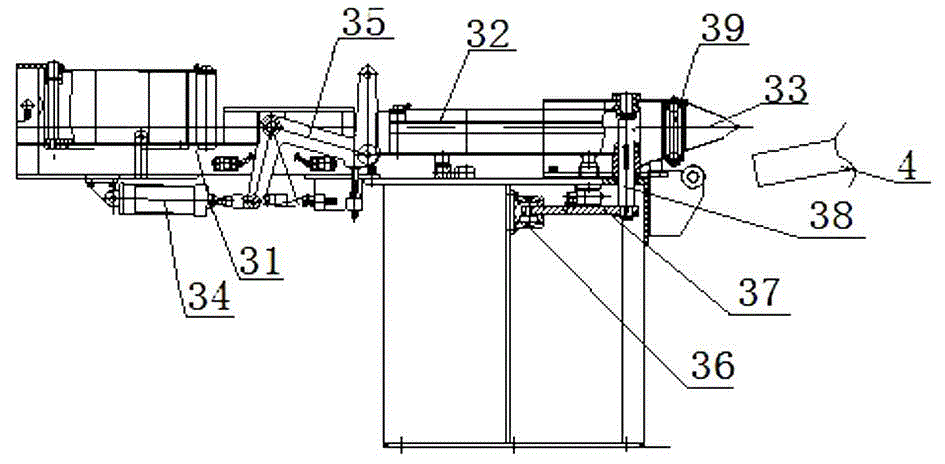

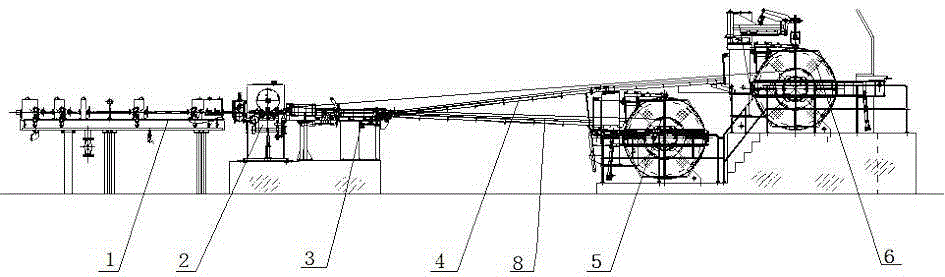

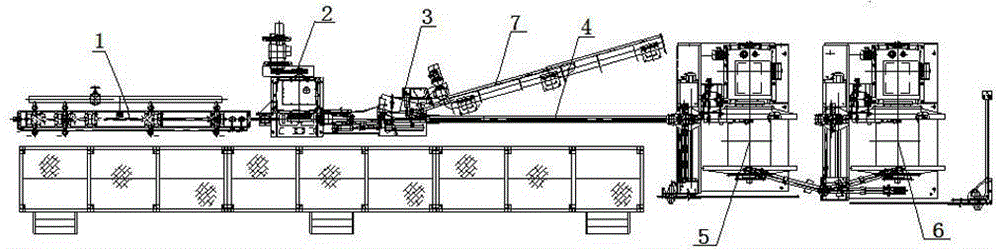

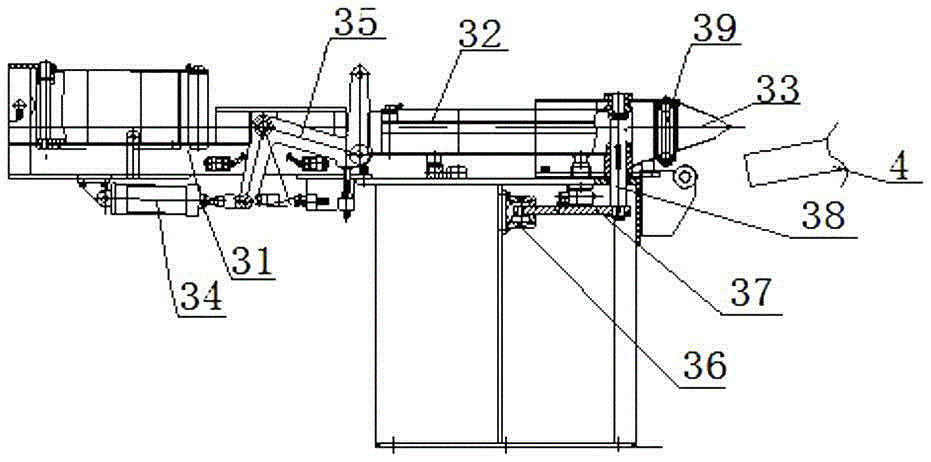

Double-disc coiled rod take-up machine on aluminum rod continuous casting-and-rolling line and rod taking-up method thereof

InactiveCN104128369AReduce energy consumptionPromote environmental protectionFlexible work arrangmentsMetal rolling arrangementsEngineeringManufacturing line

The invention discloses a double-disc coiled rod take-up machine on an aluminum rod continuous casting-and-rolling production line and a rod taking-up method thereof. The double-disc coiled rod take-up machine, which is arranged at a discharging outlet of a continuous casting-and-rolling machine and used for taking up and coiling aluminum rods made by the continuous cast-and-rolling machine, mainly comprises a cooling mechanism, a shearing mechanism, a distributing mechanism, a first rod taking up mechanism and a second rod taking up mechanism which are sequentially connected from front to back. A discharging outlet of the distributing mechanism is correspondingly connected with a first wire leading slot, a second wire leading slot and a waste rod slot. The first wire leading slot extends to the first rod taking up mechanism, the second wire leading slot extends to the second rod taking up mechanism, and the waste rod slot extends to the waste rod taking up mechanism. According to the arrangement, continuous running of the continuous cast-and-rolling machine is achieved with greatly lowered running energy consumption, environmental protection and high production efficiency. The shaped aluminum rods are uniformly and closely took up and coiled, so that the following storage or transferring and processing of the coiled aluminum rods are facilitated.

Owner:德阳东佳港智能装备制造股份有限公司

Liquid crystal panel, display device, manufacturing and driving method thereof

InactiveCN103412448BImprove distribution variabilityLayout rulesStatic indicating devicesSolid-state devicesLiquid-crystal displayDisplay device

A liquid crystal panel, a display device, and a manufacturing method and a driving method thereof are provided. The liquid crystal panel comprises an array substrate (20), a color filter substrate (10), and a liquid crystal layer (30) disposed between two substrates; the array substrate (20) is provided with a first electrode (21) and a second electrode (22) thereon in different layers, the color filter substrate (10) is provided with a third electrode (12) and a fourth electrode (11) thereon in different layers, the first electrode (21) and the third electrode (22) are disposed opposite to each other, the first electrode (21) and the third electrode (12) are slit-like electrodes, the second electrode (22) and the fourth electrode (11) are plate-like electrodes, the first electrode (21) and the third electrode (12) are respectively located on sides close to the liquid crystal layer of the second electrode (22) and the fourth electrode (11). The driving method of a display device comprises: with regard to each frame of image, calculating and acquiring an average value of pixel voltages applied to pixel electrodes when the frame of image is shown, and applying the average value to the third electrode (12) or the fourth electrode (11) of the color filter substrate (10); or, in any one pixel region, the third electrode (12) is applied with a same signal as the first electrode (11), and the fourth electrode (11) is applied with a same signal as the second electrode (22).

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

Preparation method of magnesium alloy reinforced by nano-quasi-crystal particles

ActiveCN102605227BSmall sizeReasonably change the distribution characteristicsSolution treatmentDistribution characteristic

Owner:北京二七铁丰龙科技有限公司

Double-disc loop-forming rod closing machine on aluminum rod continuous casting and rolling production line and method of using the rod closing machine

InactiveCN104128369BReduce energy consumptionPromote environmental protectionFlexible work arrangmentsMetal rolling arrangementsProduction lineEnergy consumption

Owner:德阳东佳港智能装备制造股份有限公司

A waterproof and breathable sole and shoes using the waterproof and breathable sole

Owner:MAOTAI FUJIAN SOLES CO LTD

Hairbrush wheel and hairbrush wheel assembly used for shoe washing machine, and shoe washing machine

ActiveCN109549601ARealize no dead angle brushingEasy to cleanBristleFootwear cleanersMechanical engineering

The invention belongs to the technical field of shoe washing machine, and provides a hairbrush wheel and a hairbrush wheel assembly which are used for a shoe washing machine, and the shoe washing machine. The hairbrush wheel is capable of solving a problem in the prior art that cleaning effect of conventional hairbrush wheels on shoes is poor. The shoe washing machine comprises a brush disc and aplurality of clusters of brush-hair arranged on the brush disc; at least a part of the brush-hair clusters are designed to stretch out from the brush disc along different directions; the brush disc isprovided with a plurality of rows of installation holes along the circumferential direction; and the installation holes are used for installation of the brush-hair. According to the hairbrush wheel,the brush-hair of different angles are adopted, and are designed to stretch toward different directions on the brush disc, so that in brushing of shoes, the effect area with shoes is enlarged, comprehensive dead-angle-free brushing on shoes is realized, and cleaning effect on shoes is improved.

Owner:HEFEI HAIER WASHING MACHINE +1

Layout structure of floating nuclear power plant

ActiveCN110619964BLayout rulesCompact layoutNuclear energy generationContainmentNuclear powerNuclear power plant

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com