Double-disc loop-forming rod closing machine on aluminum rod continuous casting and rolling production line and method of using the rod closing machine

A continuous casting, continuous rolling, production line technology, applied in metal rolling, metal rolling, bending workpieces, etc., can solve the problems of troublesome storage, large space occupation, irregular extrusion, etc. The effect of transportation, small exhaust emission, and reduced operation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

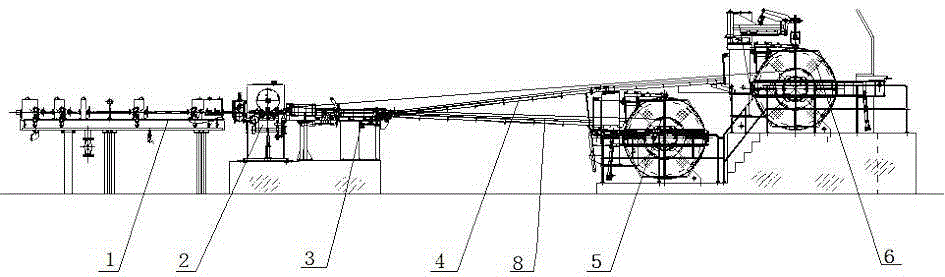

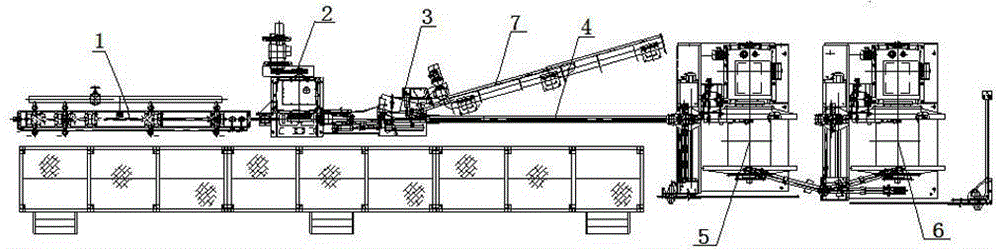

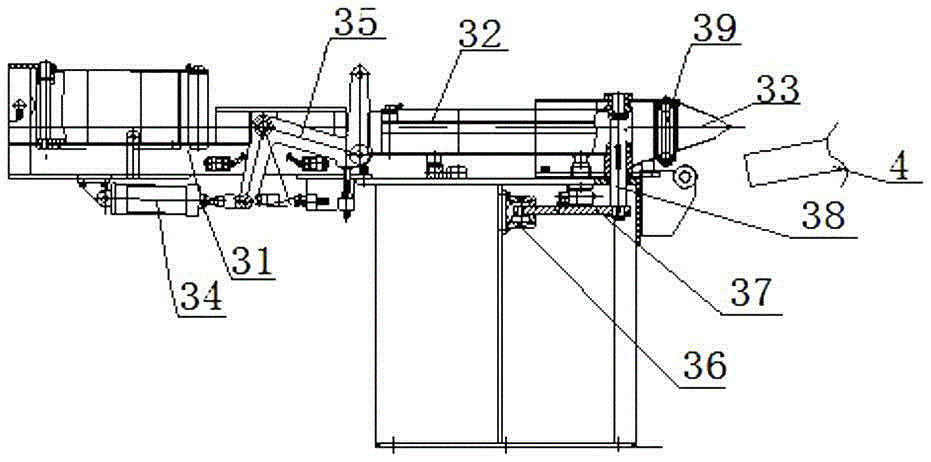

[0028] see figure 1 , figure 2 , image 3 and Figure 4 Summary of the invention: the present invention is a double-disk loop-forming rod closing machine on the aluminum rod continuous casting and rolling production line, and the double-disk loop forming rod closing machine is arranged at the discharge port (usually the end of the finishing mill) of the continuous casting and rolling mill through a guide device , used for coiling the aluminum rod made by the continuous casting and rolling machine.

[0029] The above-mentioned double-disc coil forming machine is mainly composed of a cooling mechanism 1, a flying shear mechanism 2, a branching mechanism 3, a second lead groove 4, a first rod retracting mechanism 5 and a second rod retracting mechanism 6 connected in sequence from front to back. , Waste bar groove 7, the first lead wire groove 8 constitute.

[0030] Wherein, the cooling mechanism 1 is used for cooling the aluminum rod discharged from the finishing mill of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com