Method for preparing iron nano-magnetic particles by taking T4 phage as template

A technology of magnetic particles and bacteriophages, applied in the directions of viruses/bacteriophages, biochemical equipment and methods, magnetic materials, etc., can solve the problems of limiting the application of Fe nanoparticles, irregular particle morphology, and lack of ferromagnetism, and achieve large-scale Large-scale production, uniform distribution, small particle size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1. Amplification and purification of T4 phage

[0021] First, insert T4 bacteriophage strains into 50ml of pre-incubated Escherichia coli suspension with a concentration of 10mg / ml, and culture at 37°C on a shaking table at a speed of 100r / min for 8h. Centrifuge the suspension containing Escherichia coli residual shell and T4 phage at 4°C at speeds of 4,000, 5,000, and 6,000 r / min, respectively, for 15 minutes each time, remove the precipitate, and take the supernatant. Finally, ultracentrifuge the pure T4 phage liquid at 4°C, 45000r / min for 2.5h, remove the supernatant, and disperse the T4 phage pellets into 2ml of deionized water.

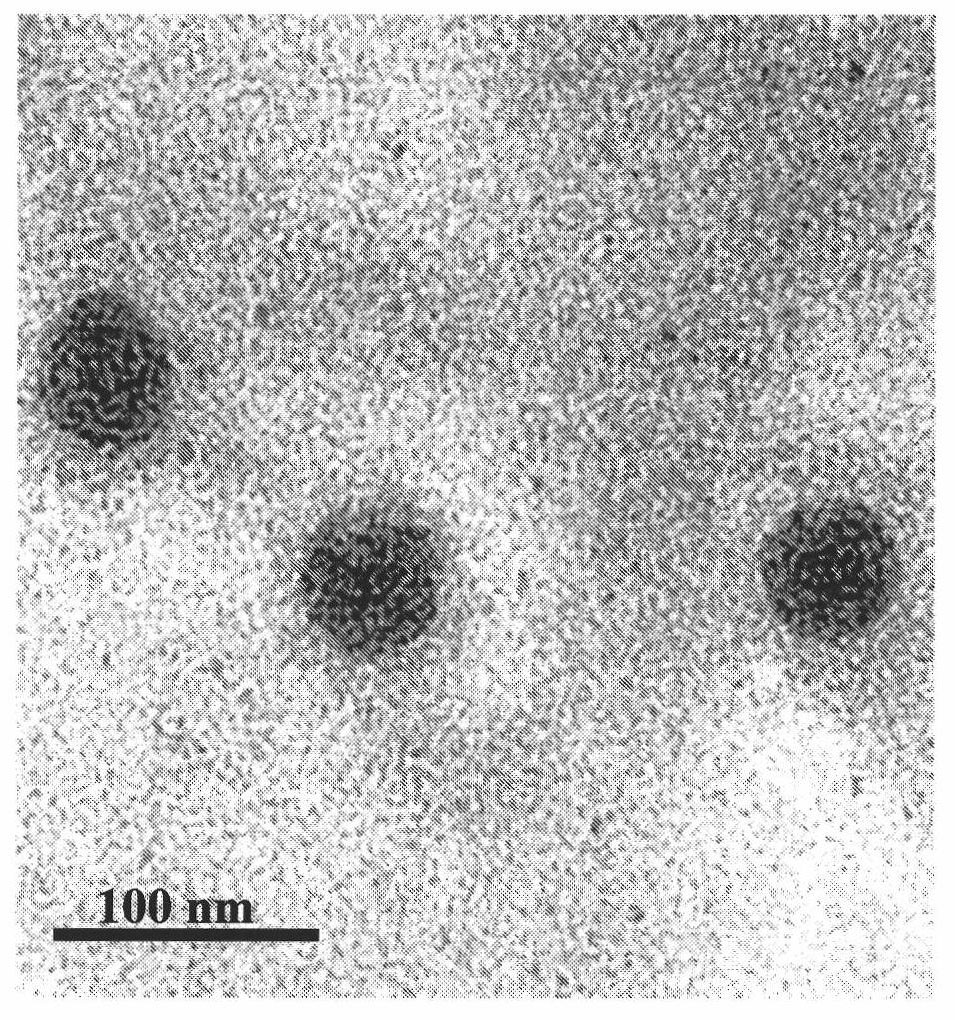

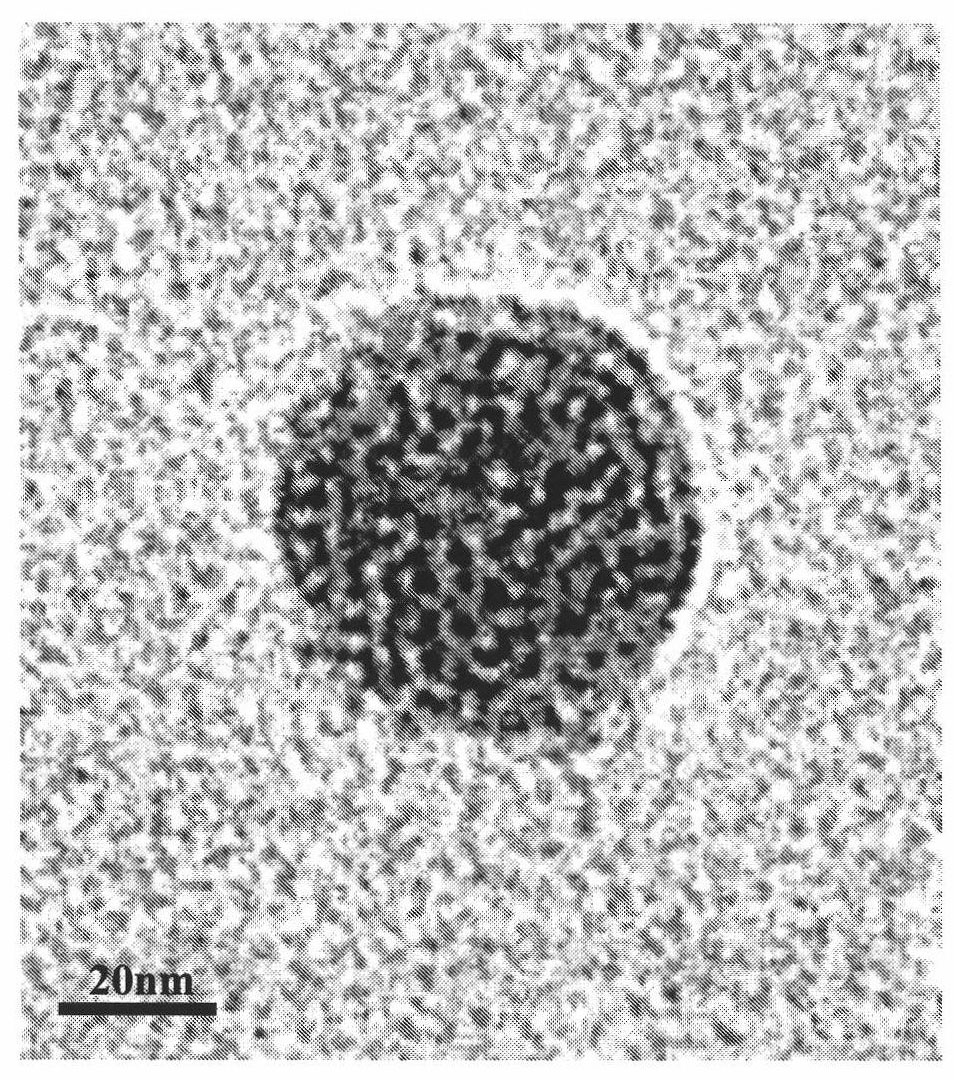

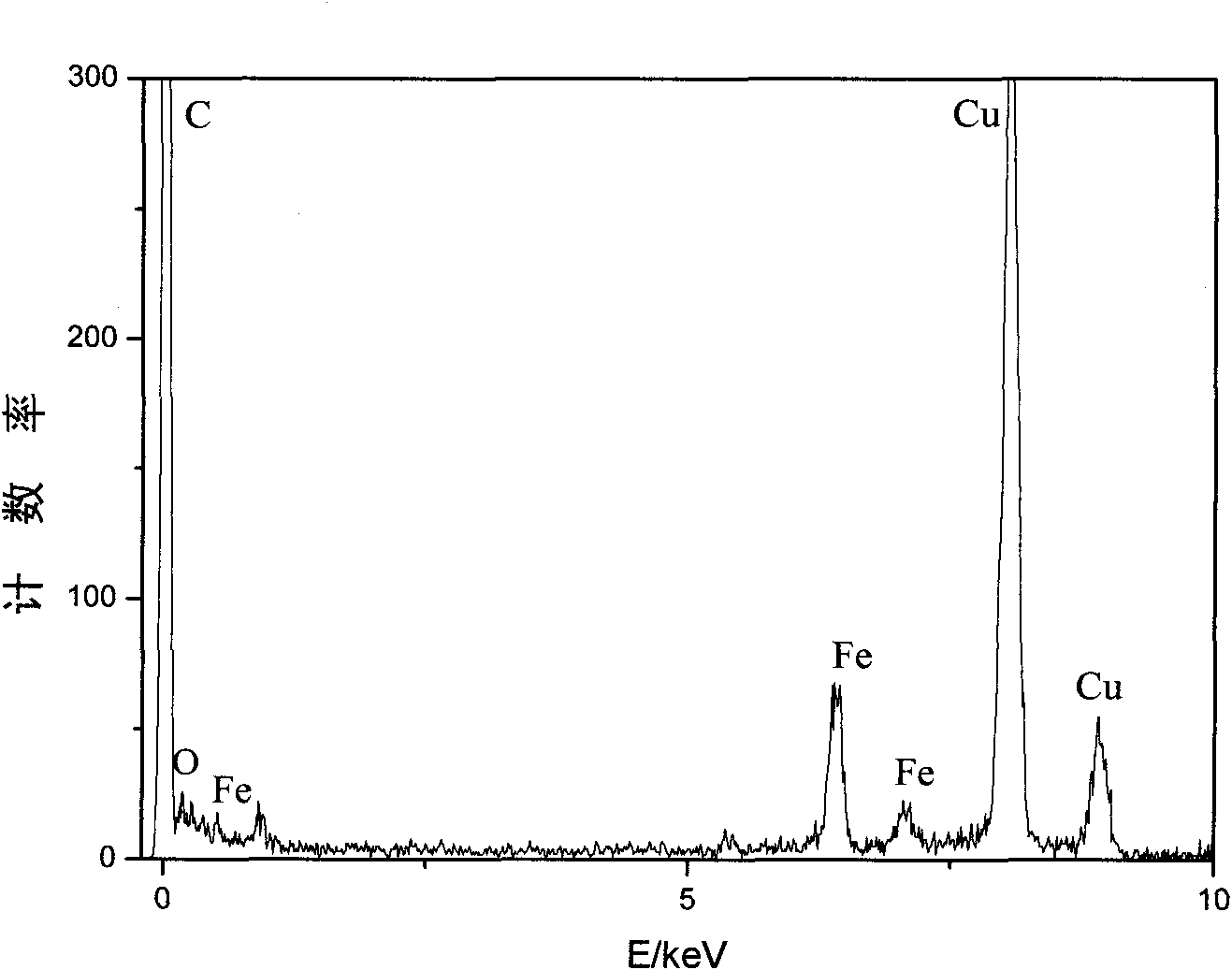

[0022] 2. Preparation of Fe nanomagnetic particles using T4 phage as template

[0023] Take 300 ul of the enriched T4 phage liquid, adjust the pH value to 8.5 with 1 mol / l NaOH, and incubate on a shaking table at 4°C and 60 r / min for 3 hours. Take 300ul of FeCl with a concentration of 5mM 3 The solution was added to the above-mentioned ...

Embodiment 2

[0025] 1. Amplification and purification of T4 phage

[0026] First, insert T4 phage strains into 50 ml of pre-incubated Escherichia coli suspension with a concentration of 12 mg / ml, and culture at 37° C. on a shaking table at a speed of 130 r / min for 12 hours. Centrifuge the suspension containing Escherichia coli residual shell and T4 phage at 10°C at speeds of 4,000, 5,000, and 6,000 r / min, respectively, for 17 minutes each time, remove the precipitate, and take the supernatant. Finally, ultracentrifuge the pure T4 phage liquid at 10°C, 42100r / min for 3h, remove the supernatant, and disperse the T4 phage pellets into 2ml of deionized water.

[0027] 2. Preparation of Fe nanomagnetic particles using T4 phage as template

[0028] Take 400 ul of the enriched T4 phage liquid, adjust the pH value to 8.5 with 1 mol / l NaOH, and incubate at 10°C and 90 r / min on a shaking table for 4 hours. Take 400ul of FeCl with a concentration of 10mM 3The solution was added to the above-mentio...

Embodiment 3

[0030] 1. Amplification and purification of T4 phage

[0031] First, insert T4 bacteriophage strains into 50 ml of pre-incubated Escherichia coli suspension at a concentration of 15 mg / ml, and culture at 37° C. on a shaking table at a speed of 150 r / min for 15 hours. Centrifuge the suspension containing Escherichia coli residual shell and T4 phage at 6°C at speeds of 4,000, 5,000, and 6,000 r / min, respectively, for 20 minutes each time, remove the precipitate, and take the supernatant. Finally, ultracentrifuge the pure T4 phage liquid at 6°C and 40,000 r / min for 3 hours, remove the supernatant, and disperse the T4 phage pellets into 2 ml of deionized water.

[0032] 2. Preparation of Fe nanomagnetic particles using T4 phage as template

[0033] Take 500 ul of the enriched T4 phage liquid, adjust the pH value to 9.0 with 1 mol / l NaOH, and incubate at 6° C. for 5 h on a shaker at 110 r / min. Take 500ul of FeCl with a concentration of 10mM 3 The solution was added to the above-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com