Cylinder head for arched combustion chamber and gasoline engine employing same

A combustion chamber and cylinder head technology, applied to combustion engines, internal combustion piston engines, cylinders, etc., can solve the problem that the advantages of spherical combustion chambers cannot be fully utilized, affect the arrangement of intake and exhaust valve components, and cannot be applied to combustion chambers of different structures and other problems to achieve the effects of reducing deformation, improving cooling effect, and smooth intake and exhaust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

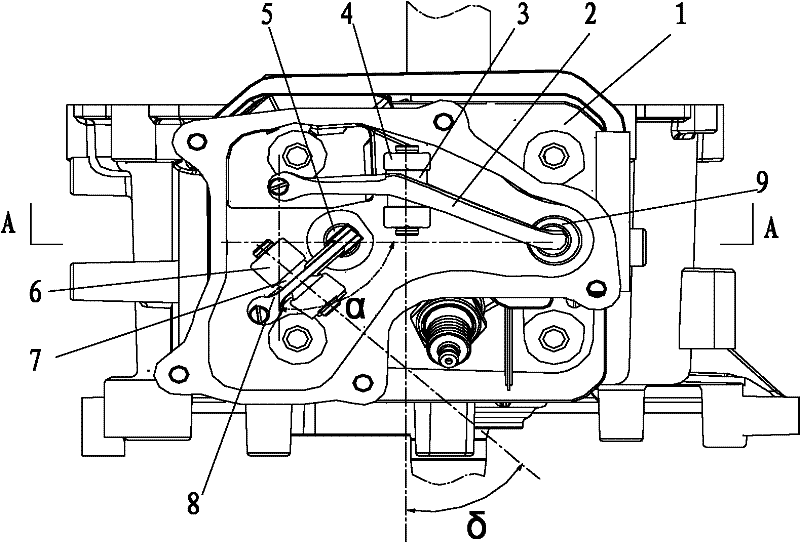

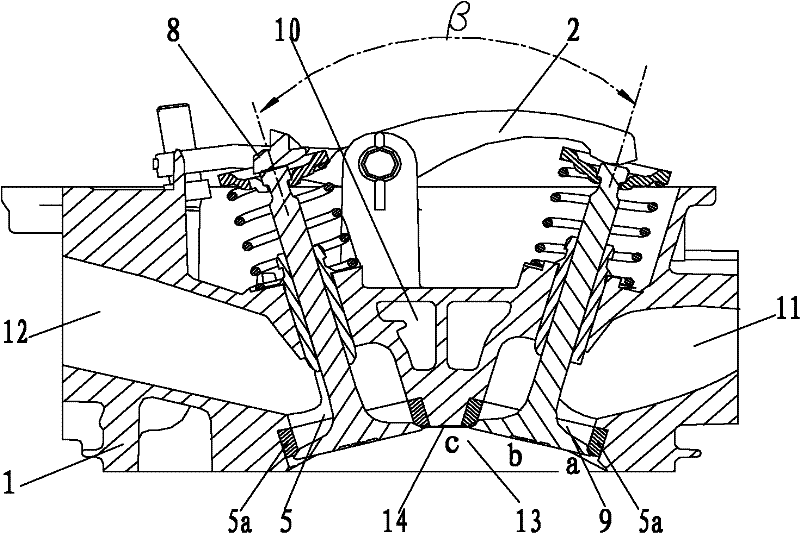

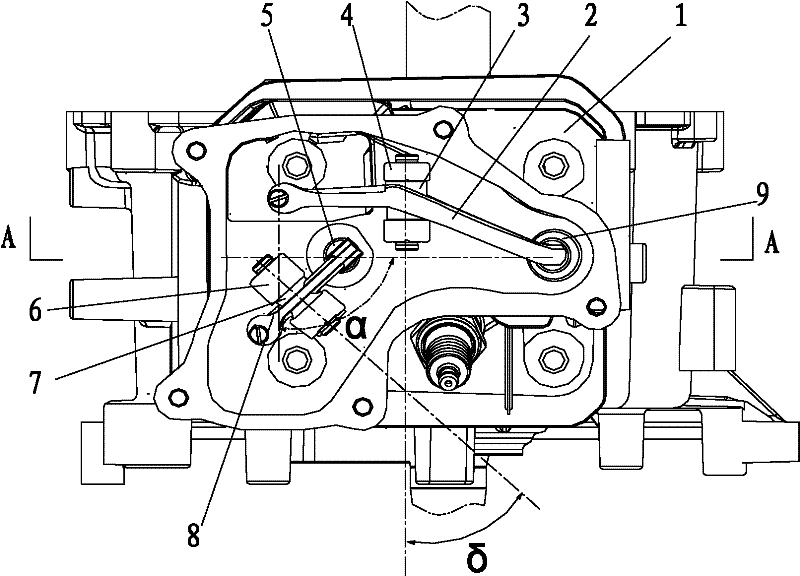

[0020] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 A sectional view along A-A, as shown in the figure: the cylinder head of the arched combustion chamber of this embodiment includes a cylinder head body 1, and the inner side of the cylinder head body 1 forms a combustion chamber surface 13, and the combustion chamber surface 13 is formed by a smooth curved surface Arched structure.

[0021] In the present embodiment, the combustion chamber surface 13 is composed of at least three smooth curved surfaces that smoothly transition from the bottom to the top successively, and the smooth curved surfaces are paraboloids or hyperboloids; the present embodiment adopts three smooth curved surfaces (respectively paraboloid a, Hyperboloid b and paraboloid c), smooth curved surfaces can be combined in other ways such as paraboloids, hyperboloids, etc., to form a combustion chamber with an arched structure; it can better eliminate the exi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com