Individually cooled turbocharger for no flow strategy in engine block coolant jacket

A technology of engine block and turbocharger, which is applied in the direction of engine cooling, coolant flow control, liquid cooling, etc., can solve the problems of expensive cast steel and heavy weight, and achieve light-weight manufacturing, rapid warm-up, The effect of reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

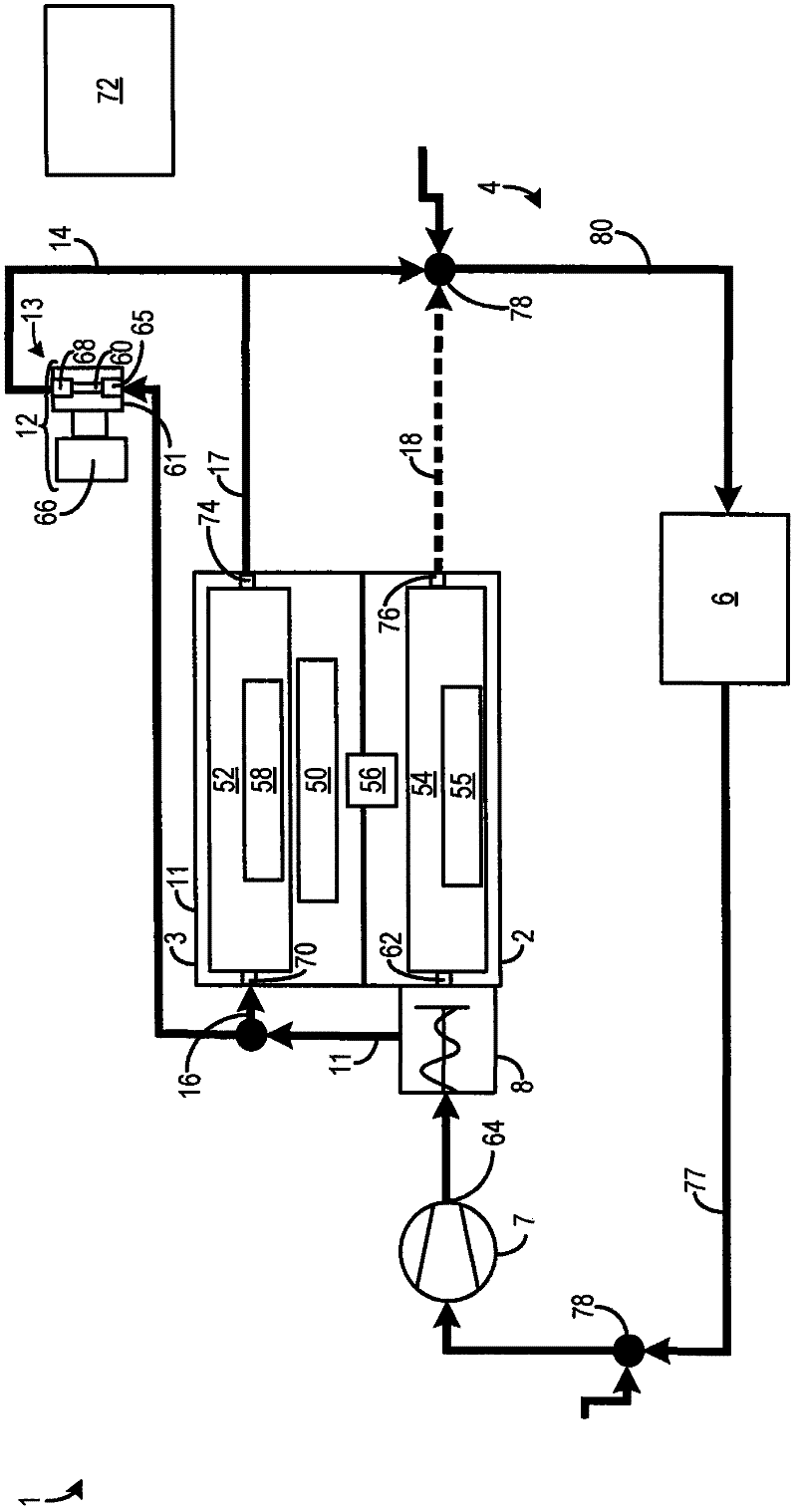

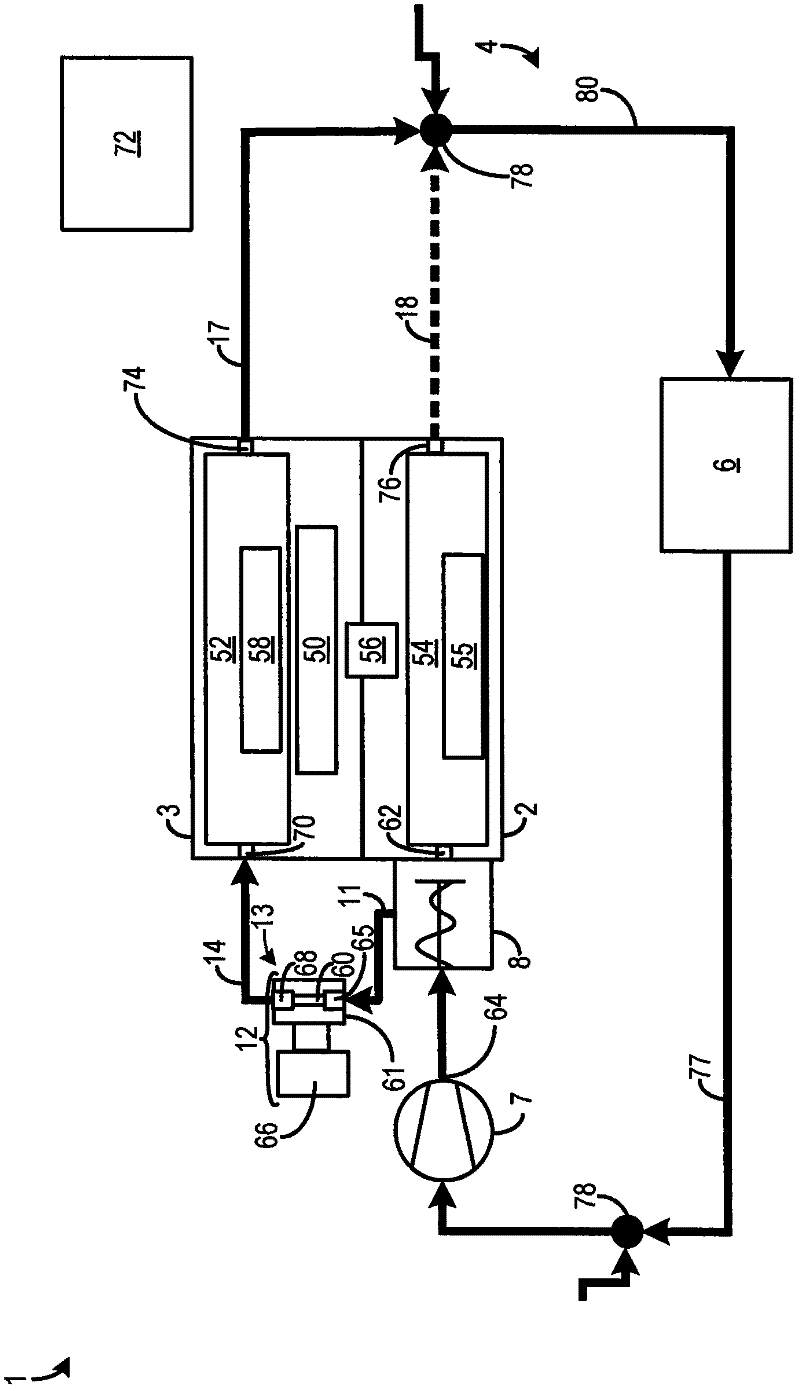

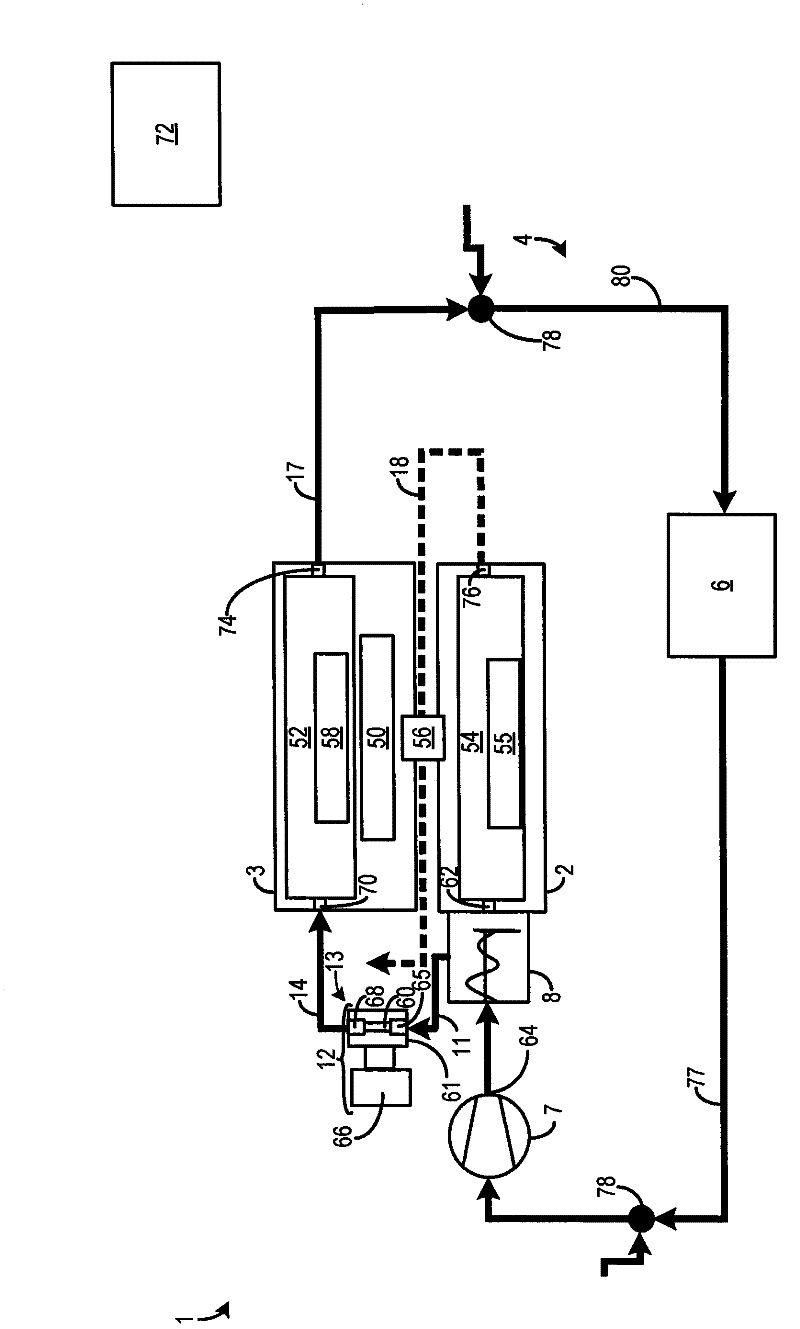

[0035] An internal combustion engine is described herein. The internal combustion engine includes a turbocharger with a turbine in the exhaust duct, the turbine having a turbine housing. The internal combustion engine further includes a cooling system comprising an engine block coolant jacket fluidly connected to the pump, a cylinder head coolant jacket fluidly connected to the pump, and a turbine coolant passage through the turbine housing and liquid Connects to the pump and bypasses the engine block coolant jacket. In some examples, a thermostat is positioned downstream of the pump and upstream of the engine block coolant jacket, cylinder head coolant jacket, and turbine coolant passages. The thermostat is configured to control the flow of coolant into the engine block coolant jacket, cylinder head coolant jacket and / or turbine coolant passages based on coolant and / or engine temperature.

[0036] A variety of cooling flow control strategies can be used in cooling systems. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com