3D printing head with follow-up pressurization and heating

A technology of follow-up pressurization and printing head, which is applied in the field of 3D printing head, can solve the problems of increasing manufacturing time and complicated processing technology, and achieve the effect of improving the bonding strength between layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

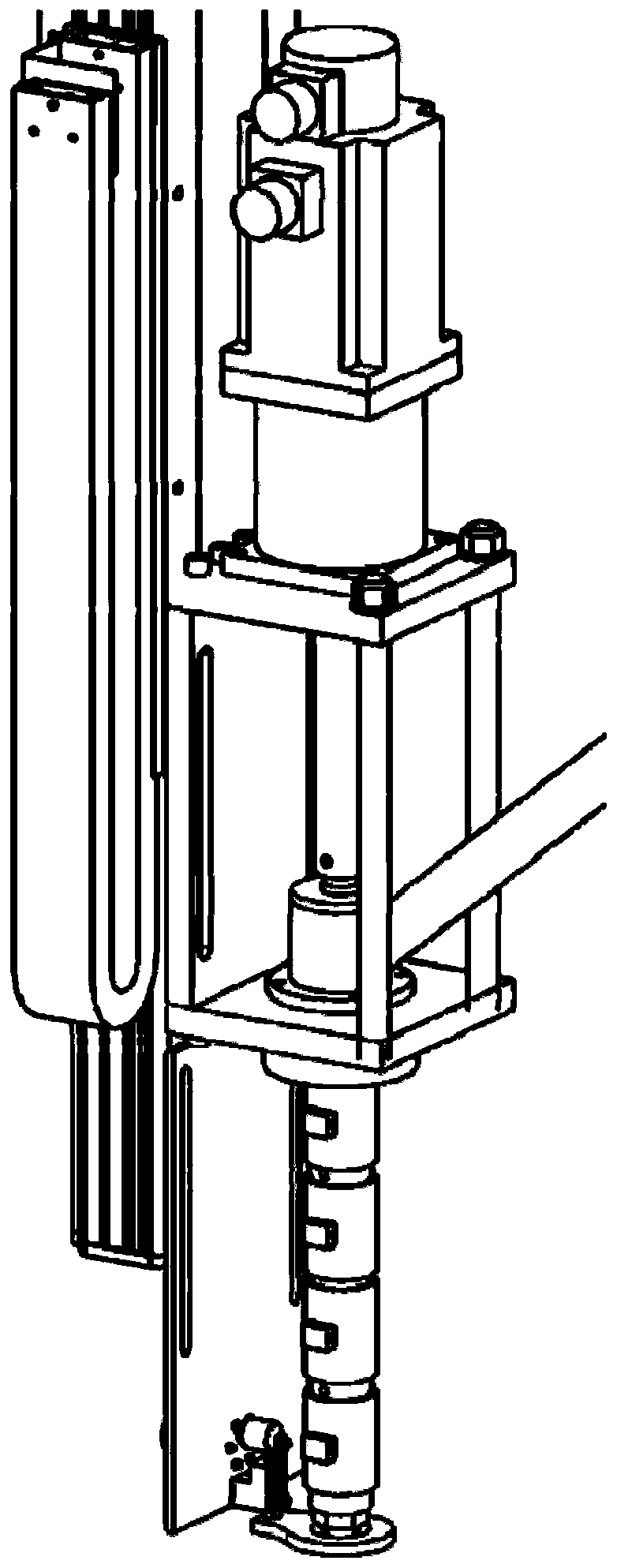

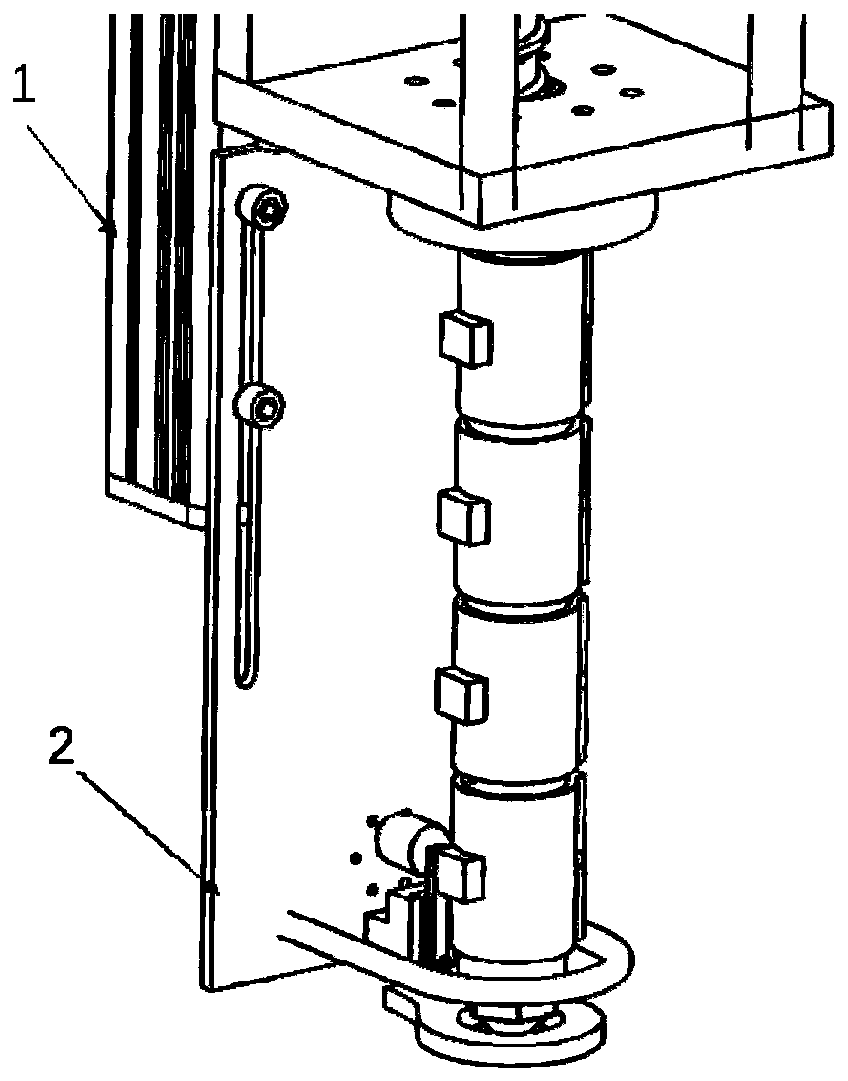

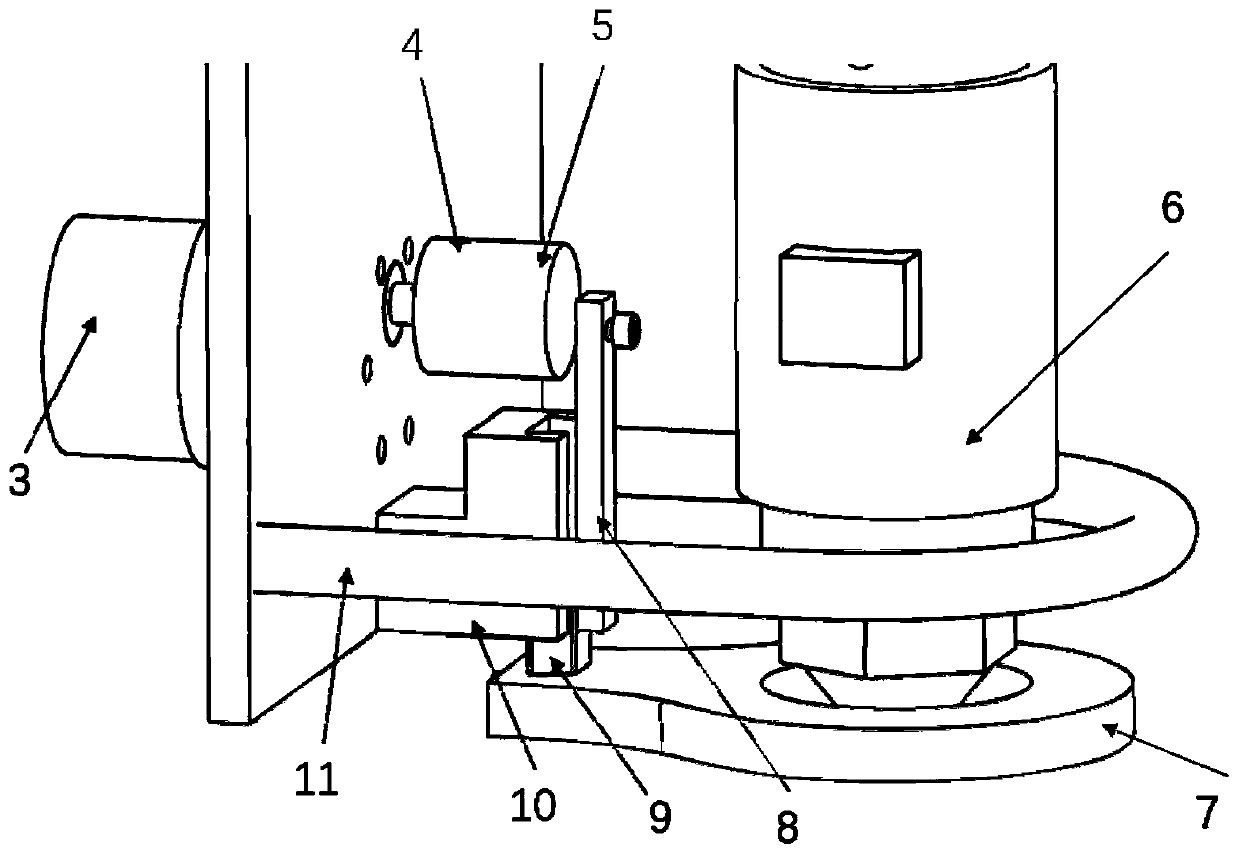

[0030] The high-performance 3D printing head with pressure and heating includes: a Z-axis linear module (that is, a mechanism whose working direction is perpendicular to the 3D printing layer), a mounting plate installed on the bottom of the front side of the Z-axis linear module, and a The speed-regulating motor on the back of the mounting plate; the print head of the 3D printer is fixed on the Z-axis linear module by screws, and the diameter of the bottom of the print head is 20-40mm.

[0031] An eccentric wheel that rotates synchronously with the speed-regulating motor is installed on the front of the mounting plate; the eccentric wheel is fixed on the output shaft of the speed-regulating motor through a top screw. The diameter of the eccentric wheel is 20-30mm, the eccentric distance is 2.5-5mm, the material of the eccentric wheel is 6061 aluminum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com