Valve arrangement

A technology of valve device and valve housing, which is applied in the direction of fuel injection device, special fuel injection device, charging system, etc., can solve the problem of pump waste and achieve the effect of compact design and precise orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

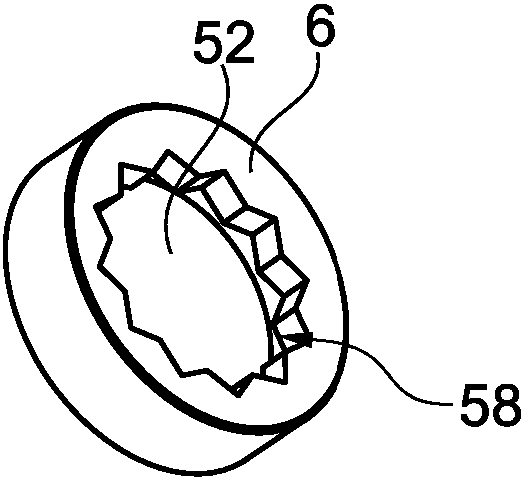

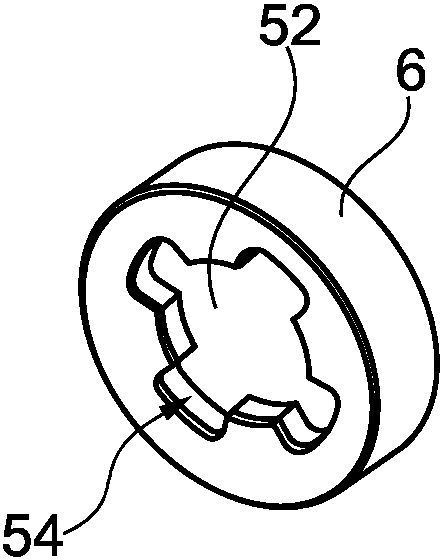

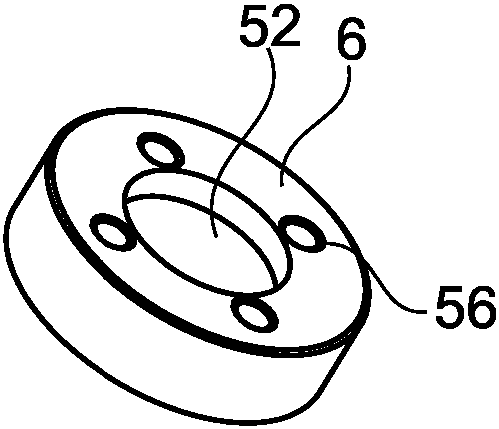

[0026] figure 1 A valve arrangement 2 is shown with a valve housing 4 , a clamping disk 6 and an actuator 8 in an actuator housing 10 . The core component of the valve arrangement 2 is the valve lifter 12 , which is pressed via a spring 14 against a stop 16 , wherein the actuator 8 is able to carry out an axial movement of the valve lifter 12 against the force of the spring. Depending on the electrical control flow, the opening area between the valve tappet 12 and the valve seat 60 is controlled by the actuator 8 . In this way the magnitude of the volume flow from fluid inlet 18 to outlet 20 is controlled.

[0027] In order to be able to inspect and / or replace individual components of the valve device 2 individually, the valve device 2 according to the invention has a functional mechanical separation which results in the structure shown. The valve housing 4 is configured in such a way that it can be inserted into the recess 22 of the pump housing 24 . This means that the va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com