Preparation method of magnesium alloy reinforced by nano-quasi-crystal particles

A technology for strengthening magnesium alloys and quasicrystals, which is applied in the field of alloys, can solve problems such as particle size, distribution changes, coarseness, and unfavorable mechanical properties of alloys, and achieve high nucleation energy storage, microstructure refinement, and microstructure refinement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Taking the Mg-6Zn-1Er alloy as an example, firstly, solid solution treatment at 420°C, grinding, and processing were performed to obtain magnesium alloy chips, and multiple cycles of plastic deformation equipment (model: 100AF-AB[F-0563], purchased from Japan ) The alloy is subjected to multiple cyclic plastic deformation processing methods, the number of cycles is 100, and an extrusion blank is obtained, and then a vertical extruder is extruded at a temperature of 250° C. to obtain an extruded alloy. The size of the nano-quasicrystal particles in the alloy is 10-100nm. The tensile strength of the extruded alloy is 312MPa, the yield strength is 193MPa, and the elongation is 6.8%.

Embodiment 2

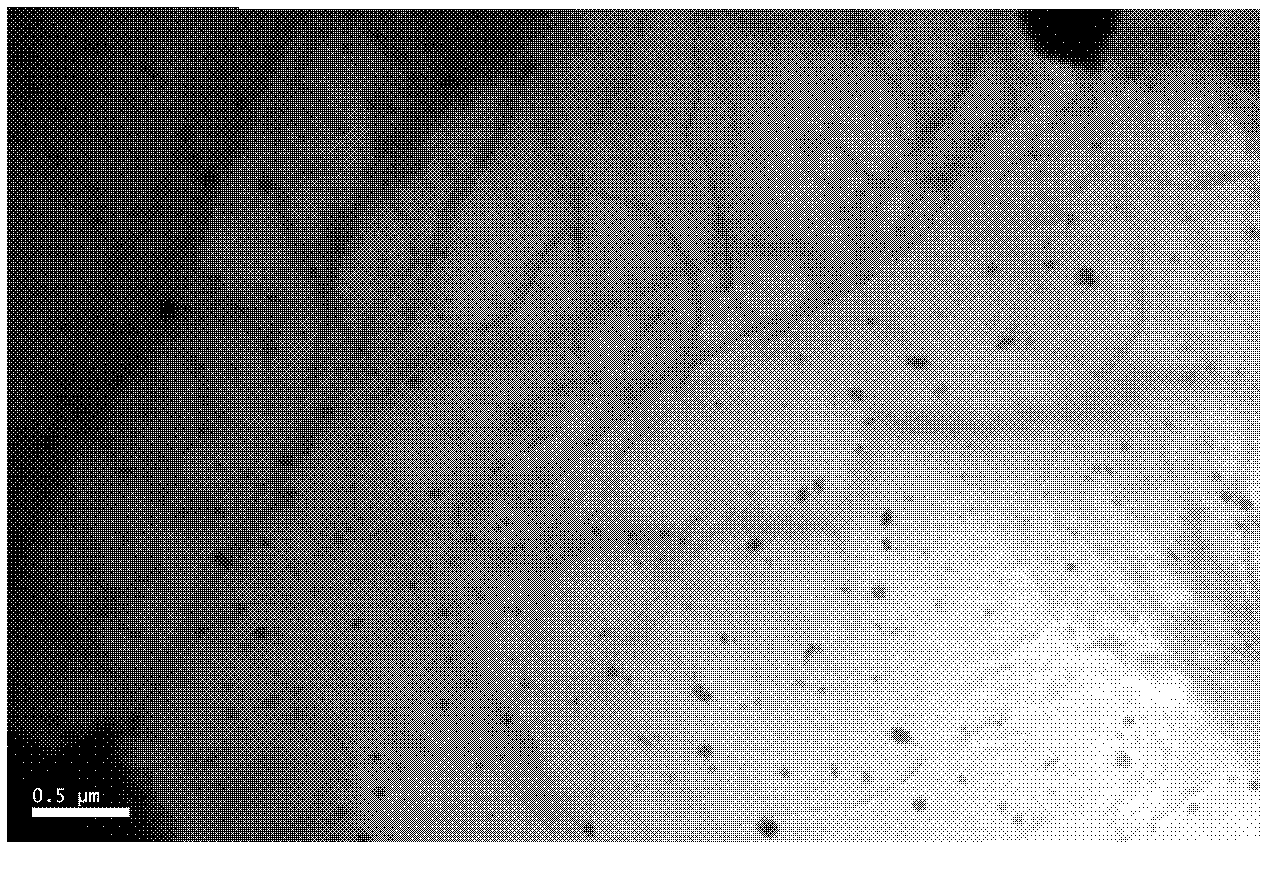

[0025] Taking the Mg-6Zn-1Er alloy as an example, firstly, solid solution treatment at 400°C, grinding, and processing are performed to obtain magnesium alloy chips, and the extrusion blank is obtained after multiple cycles of plastic deformation for 300 times. , and then use a vertical extruder to extrude it at a temperature of 250° C. to obtain an extruded alloy. The size of the nano-quasicrystal particles in the alloy is 10-100nm, such as figure 1 shown. Its tensile strength is 337MPa, yield strength is 237MPa, and elongation is 5.1%.

Embodiment 3

[0027] Taking Mg-6Zn-1.5Er alloy as an example, firstly, solution treatment at 450°C, cold rolling, each deformation amount is about 5%, rolling 15 times, and then the plate is made, and the plate is annealed at 350°C for 15 minutes. The size of the nano-quasicrystal particles in the alloy is 10-100nm. Measure its tensile properties, the tensile strength and yield strength in the parallel rolling direction are 341MPa and 233MPa respectively, and the elongation is 8.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com