Layout structure of floating nuclear power plant

A technology for layout structure and nuclear power plant, applied in the directions of nuclear power plant auxiliary equipment, nuclear power generation, reactor, etc., can solve problems such as cabins that do not consider the autonomous refueling of ships, increase the construction requirements of onshore refueling bases, and ship space and weight restrictions, etc. Achieve the effect of reduced shielding requirements, low dose levels, and regular layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

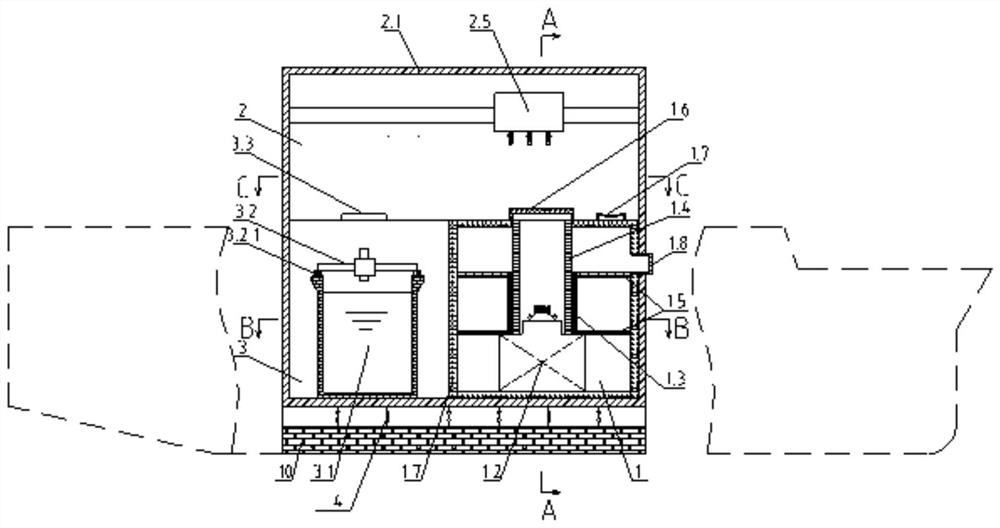

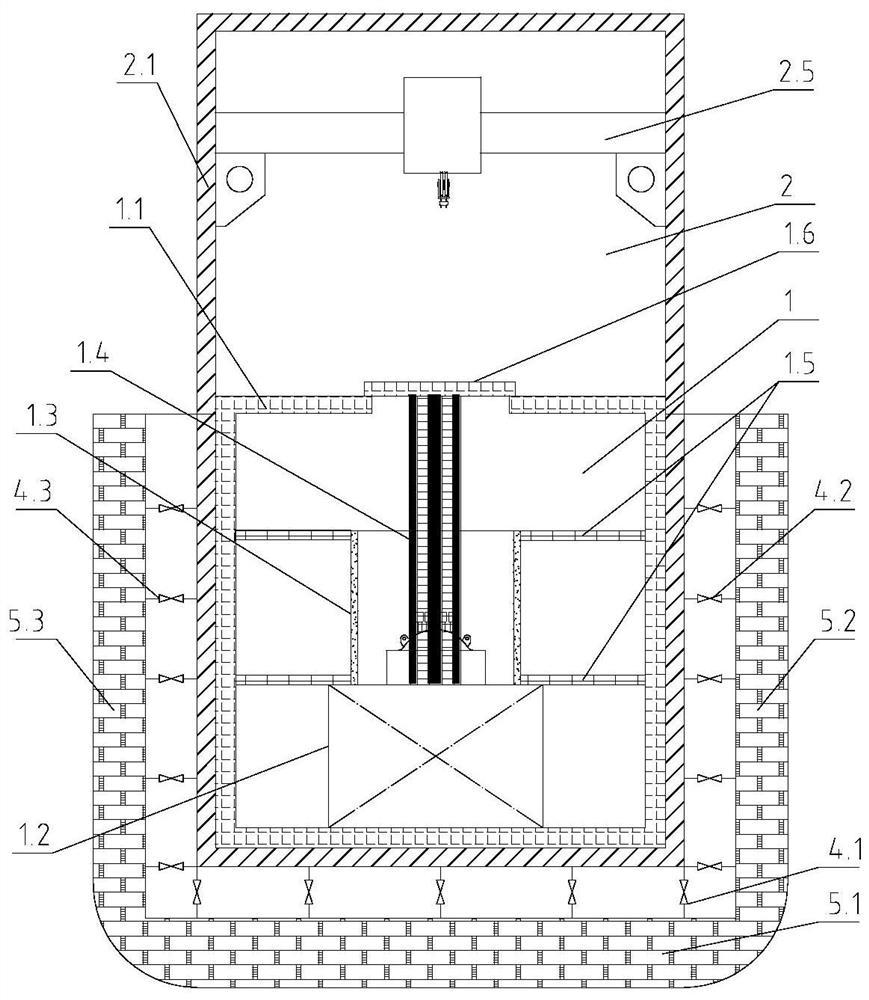

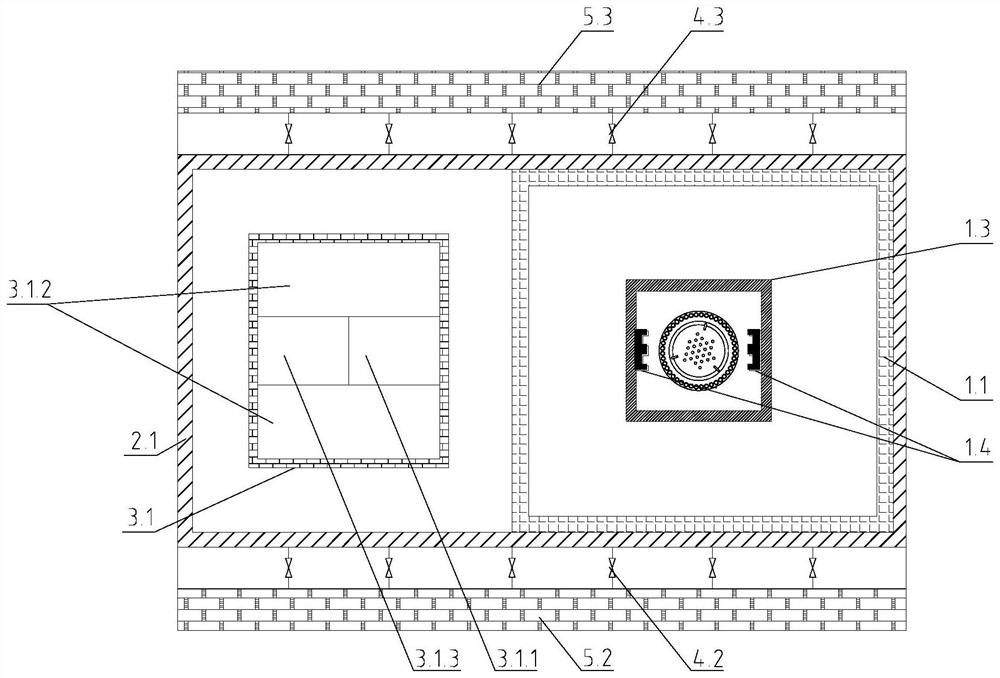

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific examples, but the embodiments of the present invention are not limited thereto.

[0027] like Figure 1 ~ Figure 4 As shown, a floating nuclear power plant stack layout structure proposed by the present invention includes a double-hull hull 5 arranged on an offshore nuclear power platform, and a primary containment vessel 1 and a spent fuel storage tank are arranged in the inner cavity of the double-hull hull 5 3. The primary containment vessel 1 is provided with a reactor and primary circuit system equipment, and the spent fuel storage compartment 3 is provided with spent fuel storage facilities. The bottom and sides of the primary containment vessel 1 and the spent fuel storage compartment 3 are connected to each other through an elastic connection structure 4 The double-hull hull 5 is elastically connected, the upper part of the primary containme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com