Manufacturing method of sand core

A production method and sand core technology, which are applied in the directions of cores, manufacturing tools, casting and molding equipment, etc., can solve problems such as unsatisfactory effect and economy, and achieve the effects of strong heat storage capacity, avoidance of shrinkage porosity, and fast heat conduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The core of this specific embodiment is to provide a sand core manufacturing method, which can avoid shrinkage around the cylinder head bolt holes and solve the current problems in this field.

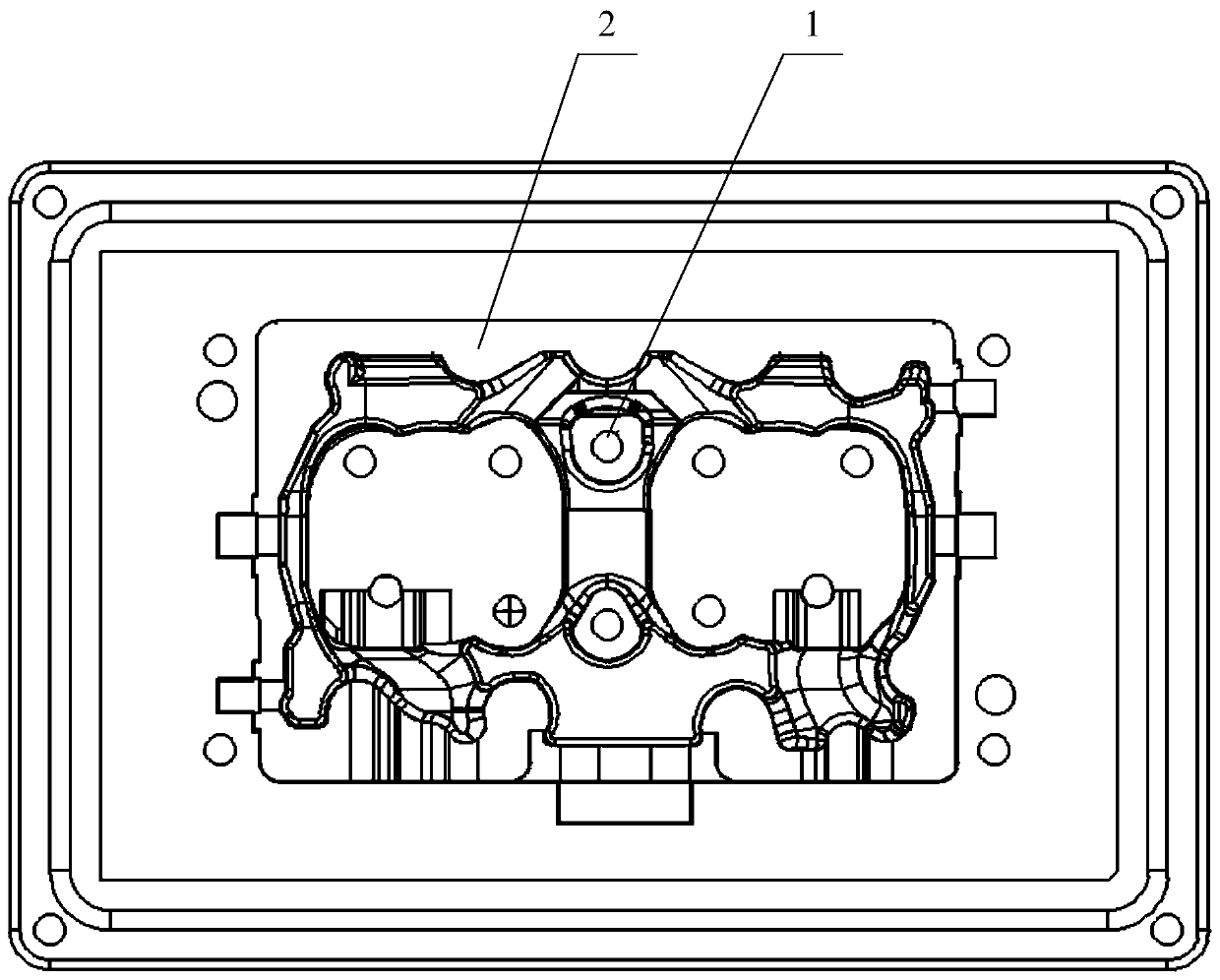

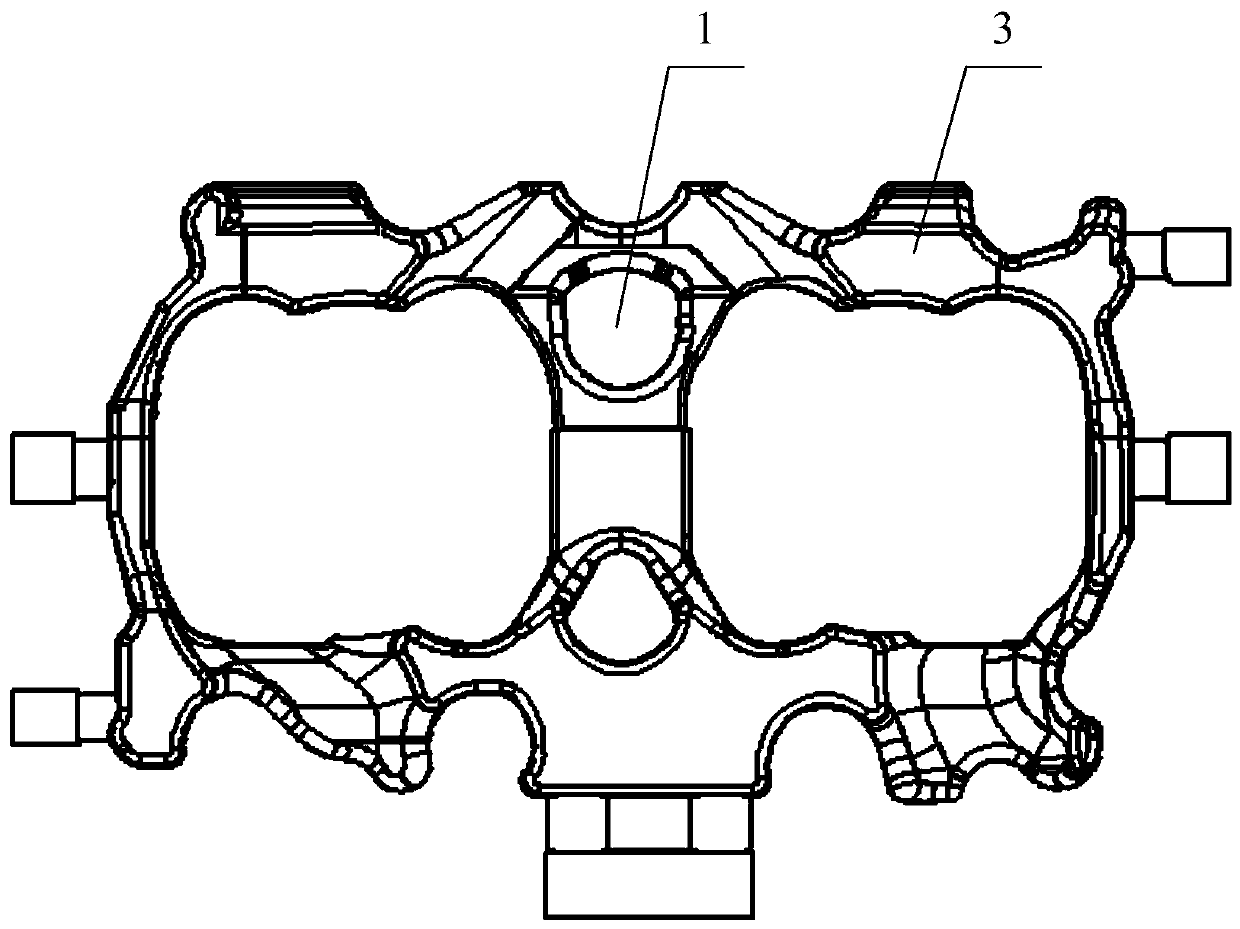

[0026] Hereinafter, an embodiment will be described with reference to the drawings. In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solution of the invention described in the claims.

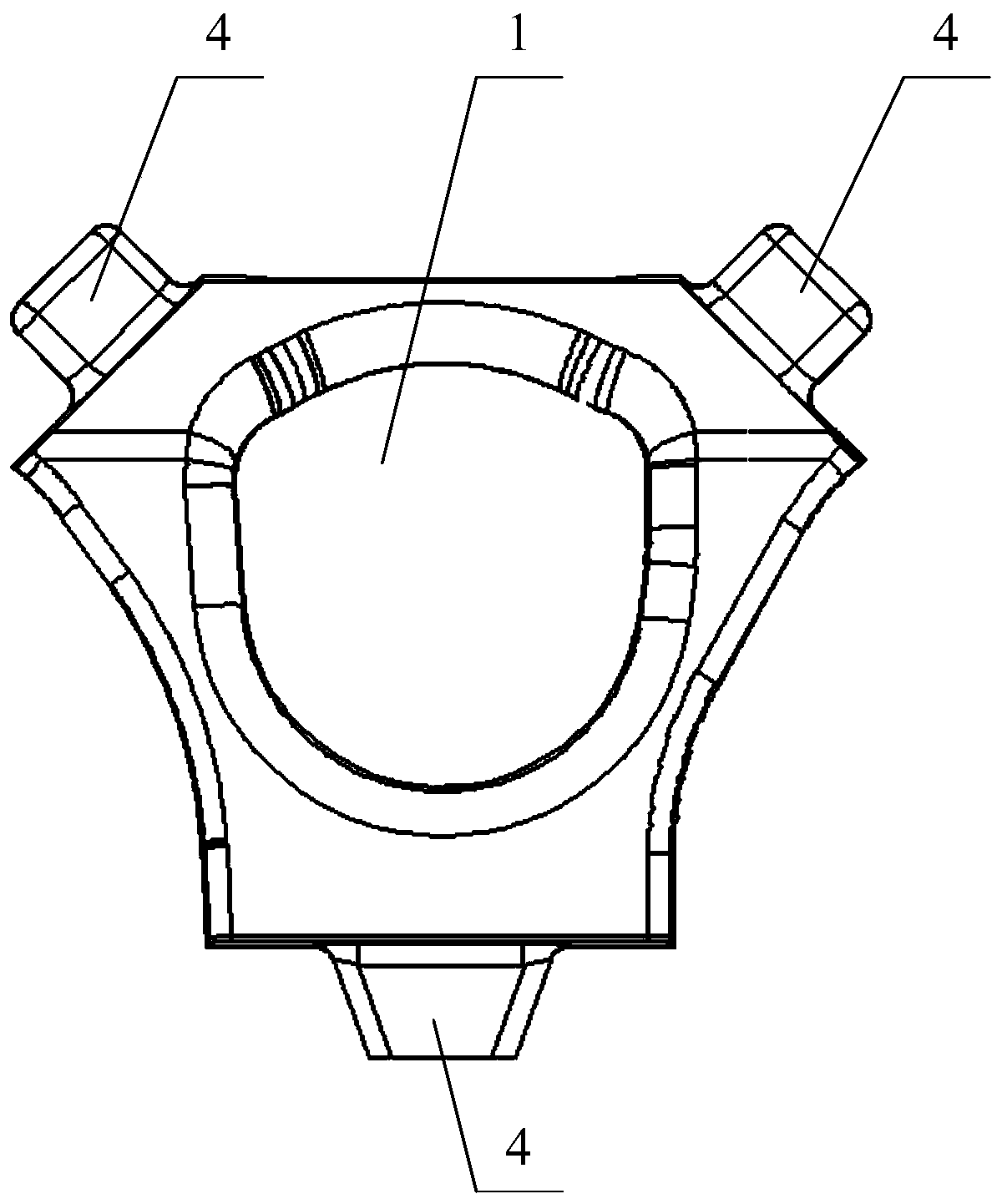

[0027] The sand core manufacturing method provided in this specific embodiment includes step a): using chromite-coated sand to make a local sand core 1 in a region prone to shrinkage and porosity. Chromite has the characteristics of fast heat conduction and strong heat storage capacity. This method uses chromite sand to make sand cores that are prone to shrinkage, and obtains local sand cores 1, so that th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com