Device and method for preparing amorphous carbon and nitrogen thin films on surface of silicon

An amorphous carbon nitrogen and silicon surface technology, applied in ion implantation plating, coating, metal material coating process, etc., can solve the problems of effective control of content and distribution, system research, etc., and achieve chemical bond content and structure. control, uniform structure distribution, and strong process operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

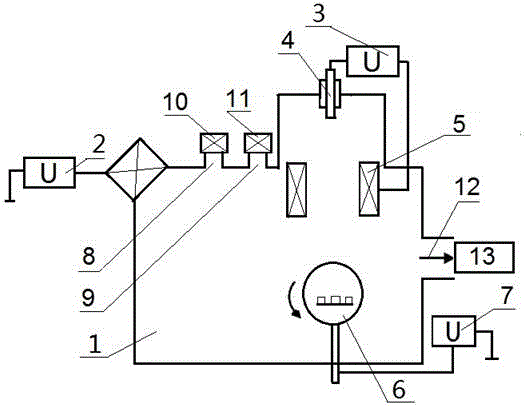

[0039] use figure 1 The shown device prepares atomized nitrogen-doped amorphous carbon-nitride film on the surface of silicon substrate.

[0040] A single crystal silicon substrate with a diameter of 20 mm and a thickness of 0.5 mm was tested, and the operation steps were as follows:

[0041] (1) Surface treatment of silicon substrate: Place the monocrystalline silicon wafer into acetone solution, ethanol solution and deionized water for 10 minutes to ultrasonically clean each to remove surface grease and other pollutants, then place the substrate in an oven to dry for use ;

[0042] (2) Fix the pretreated silicon substrate on such as figure 1 On the rotating sample stage in the vacuum chamber of the cathodic arc device shown, the high-purity graphite target is used as the cathode of the pulsed arc;

[0043] (3) Use a vacuum device to evacuate the vacuum chamber to make the vacuum degree reach 6×10 −4 Pa; argon gas is introduced into the vacuum chamber through the air i...

Embodiment 2

[0046] use figure 1 The shown device prepares an ionized nitrogen-doped amorphous carbon-nitride film on the surface of a silicon substrate.

[0047] A single crystal silicon substrate with a diameter of 20 mm and a thickness of 0.5 mm was tested, and the operation steps were as follows:

[0048] (1) Surface treatment of silicon substrate: Place the monocrystalline silicon wafer into acetone solution, ethanol solution and deionized water for 10 minutes to ultrasonically clean each to remove surface grease and other pollutants, then place the substrate in an oven to dry for use ;

[0049] (2) Fix the pretreated silicon substrate on such as figure 1 On the rotating sample stage in the vacuum chamber of the cathodic arc device shown, the high-purity graphite target is used as the cathode of the pulsed arc;

[0050] (3) Use a vacuum device to evacuate the vacuum chamber to make the vacuum degree reach 6×10 −4 Pa; argon gas is introduced into the vacuum chamber through the a...

Embodiment 3

[0055] use figure 1 The shown device prepares atomized nitrogen-doped amorphous carbon-nitride film on the surface of silicon substrate.

[0056] A single crystal silicon substrate with a diameter of 20 mm and a thickness of 0.5 mm was tested, and the operation steps were as follows:

[0057] (1) Surface treatment of silicon substrate: Place the monocrystalline silicon wafer into acetone solution, ethanol solution and deionized water for 10 minutes to ultrasonically clean each to remove surface grease and other pollutants, then place the substrate in an oven to dry for use ;

[0058] (2) Fix the pretreated silicon substrate on such as figure 1 On the rotating sample stage in the vacuum chamber of the cathodic arc device shown, the high-purity graphite target is installed on the pulsed cathodic arc power supply;

[0059] (3) Use a vacuum device to evacuate the vacuum chamber to make the vacuum degree reach 6×10 −4 Pa; argon gas is introduced into the vacuum chamber throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com