Patents

Literature

49results about How to "Control energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

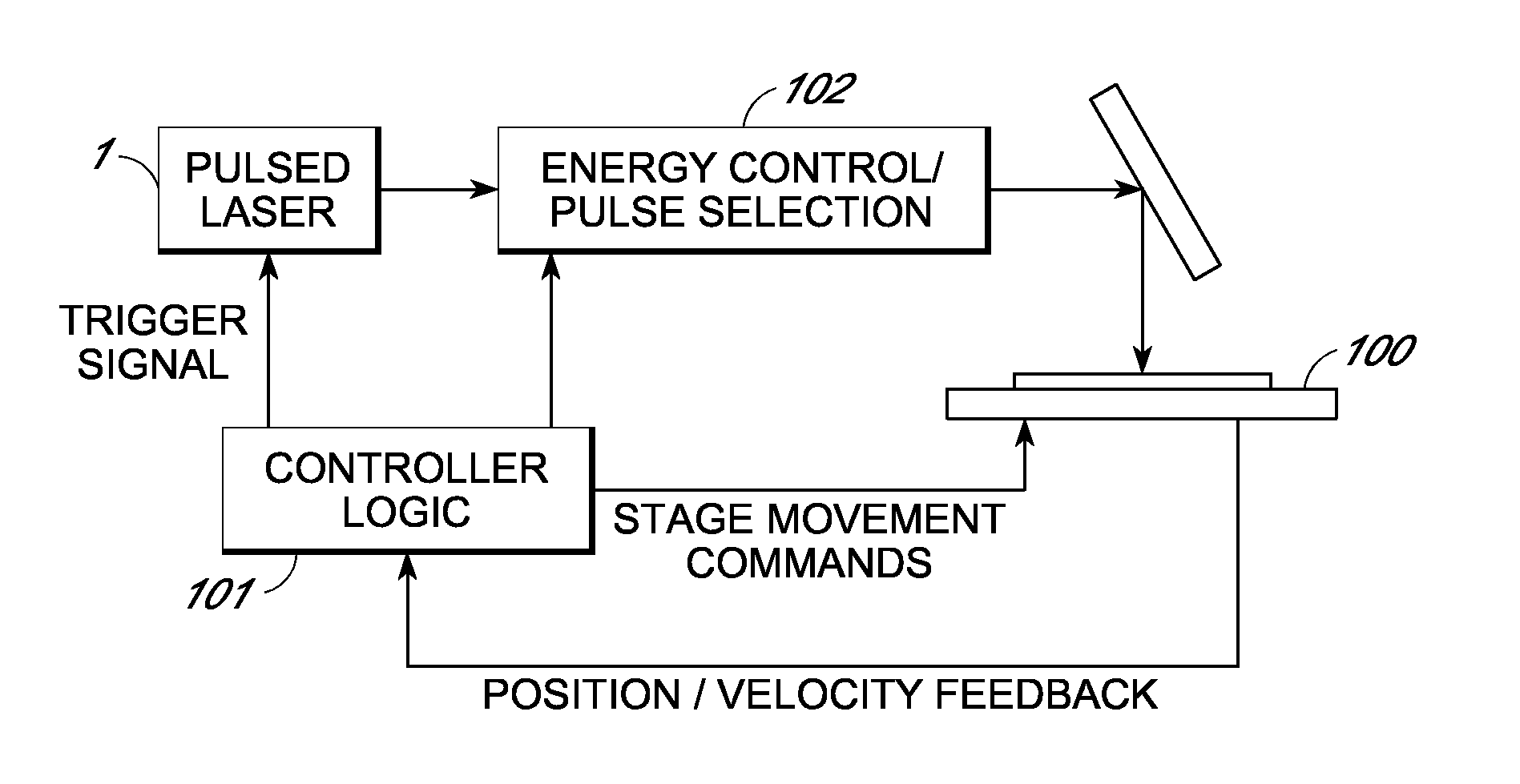

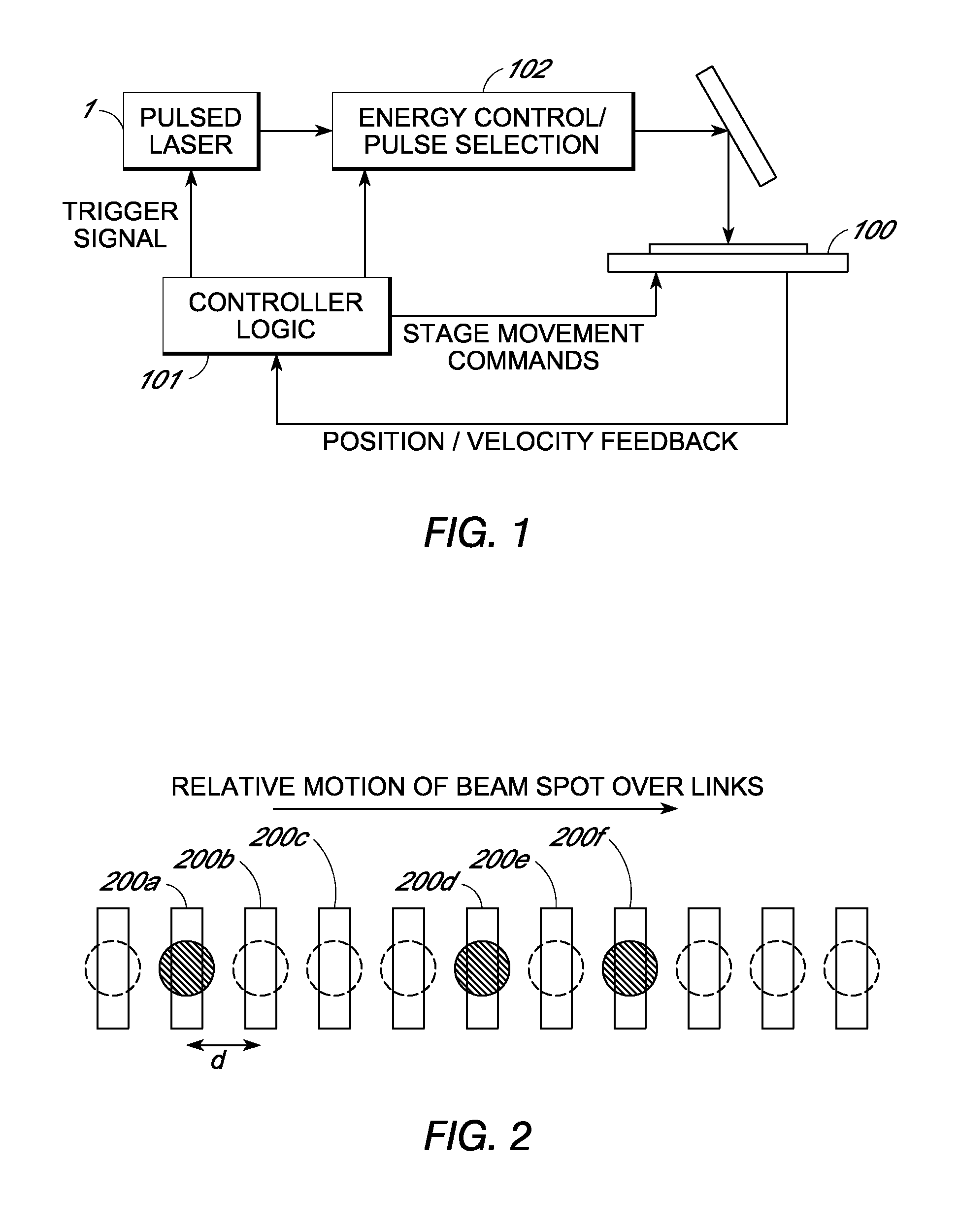

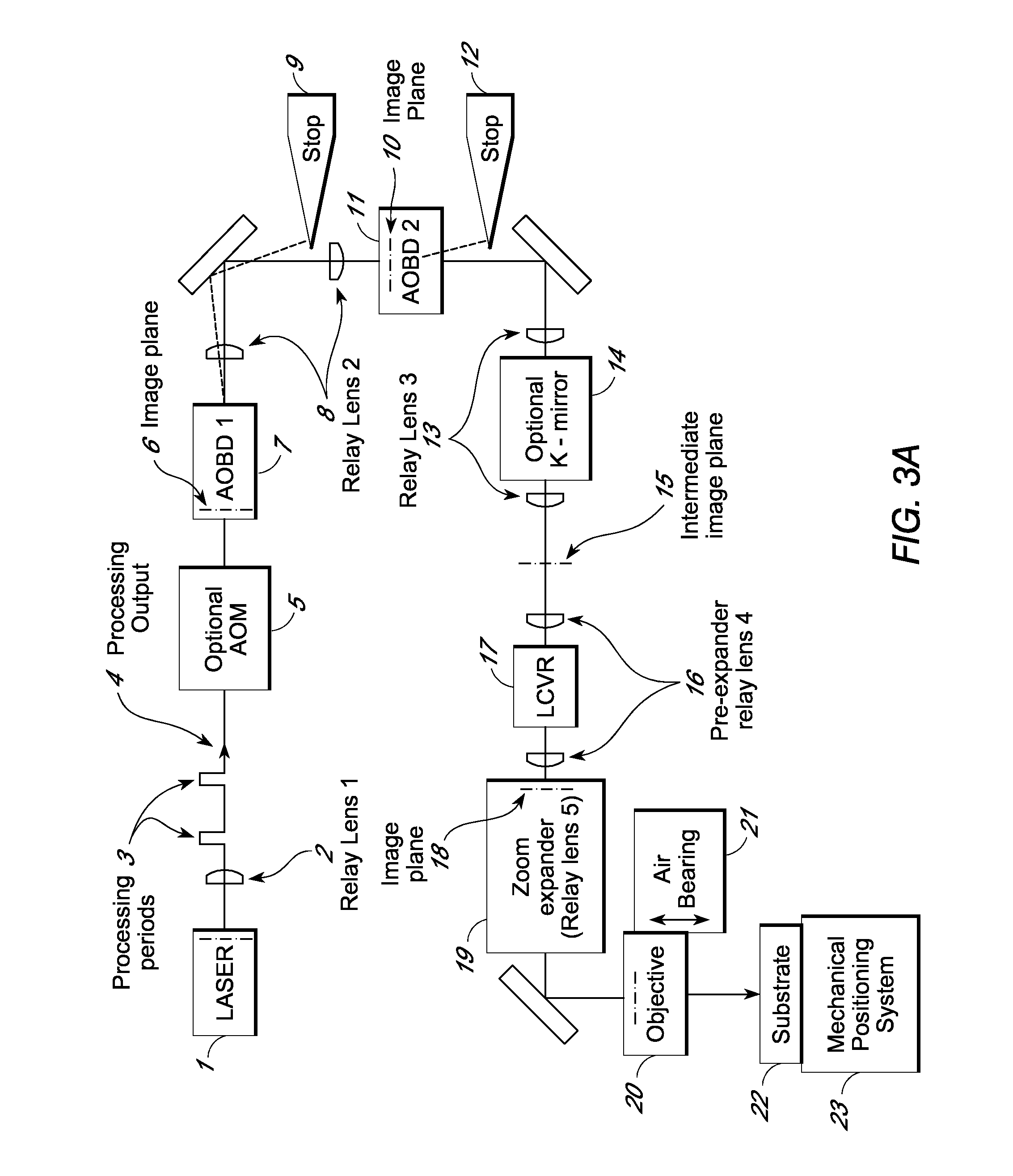

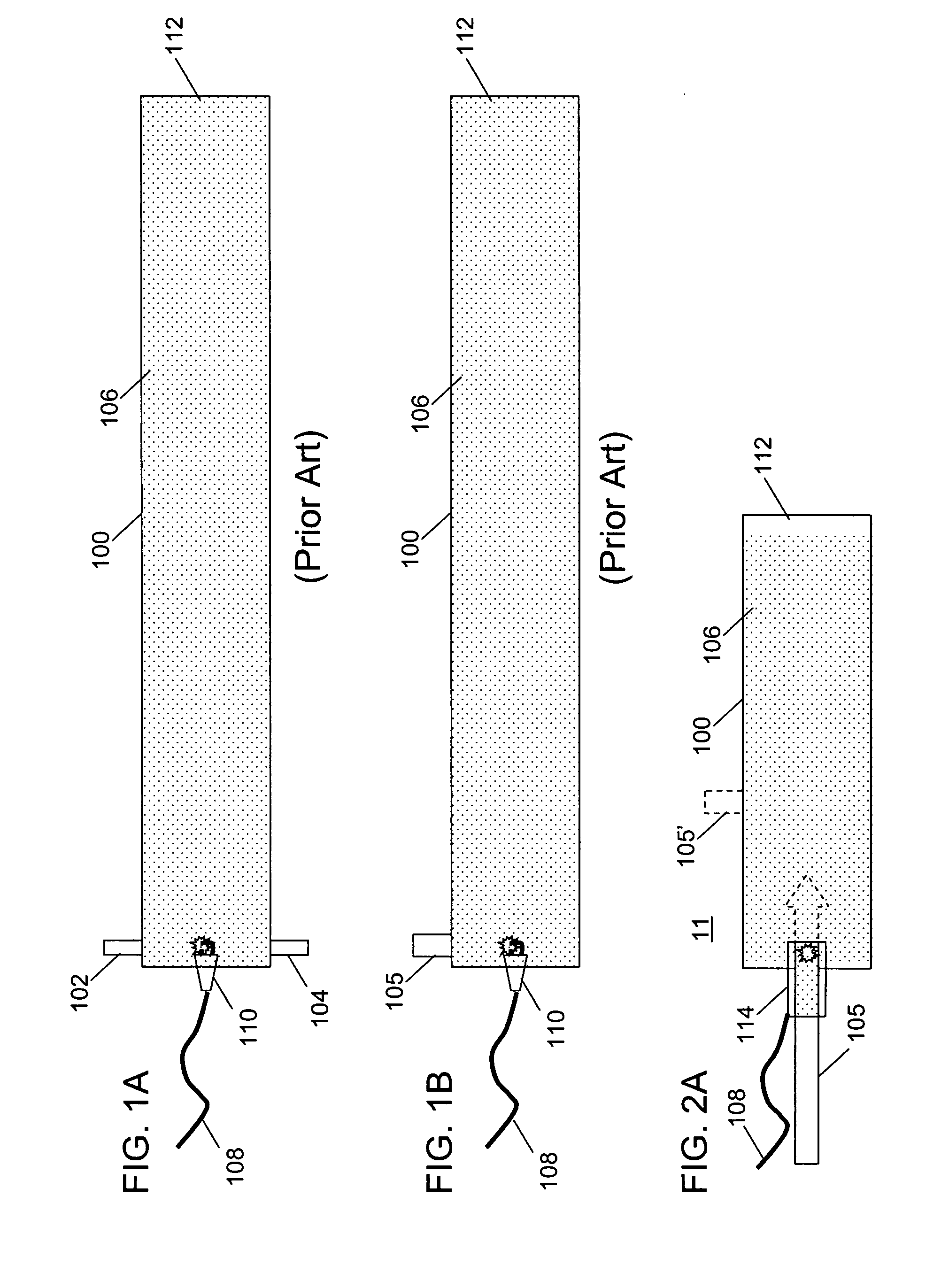

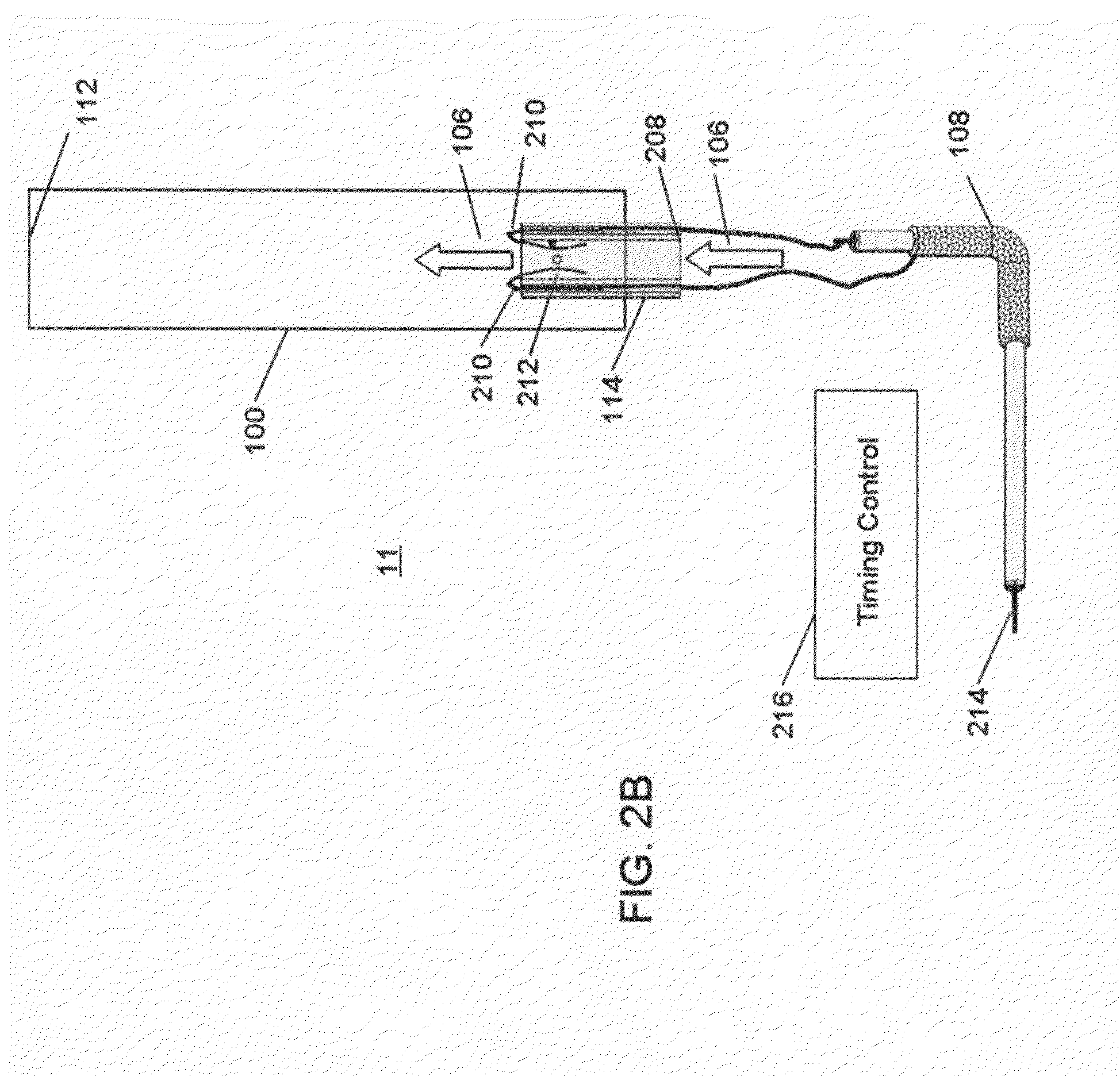

Link processing with high speed beam deflection

InactiveUS20110210105A1Control energyLaser detailsSemiconductor/solid-state device detailsConstant velocityOptical axis

Link processing systems and methods use controlled two dimensional deflection of a beam along an optical axis trajectory to process links positioned along and transverse to the trajectory during a pass of the optical axis along the trajectory. Predictive position calculations allow link blowing accuracy during constant velocity and accelerating trajectories.

Owner:ELECTRO SCI IND INC

Lasers and LiDAR

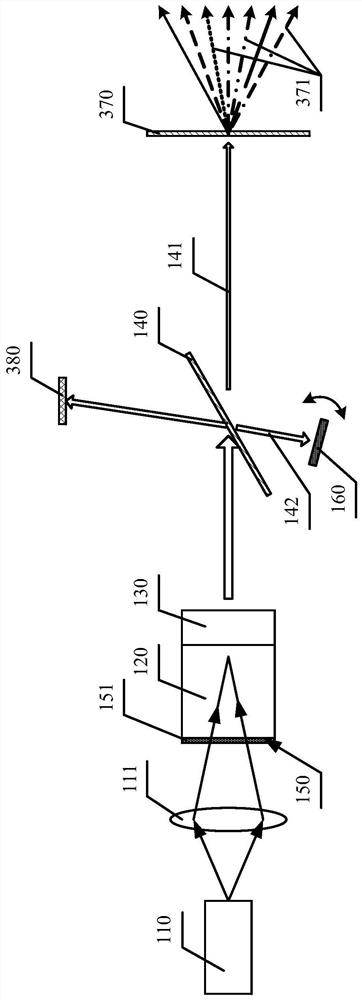

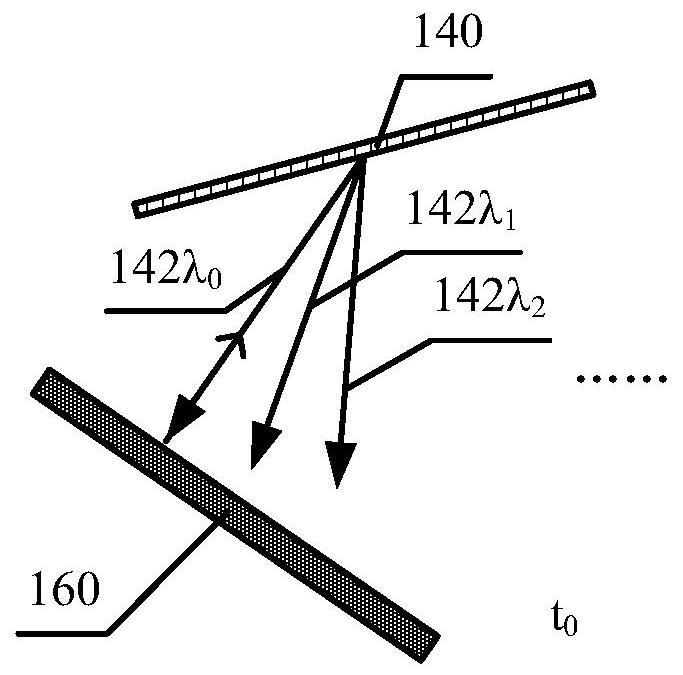

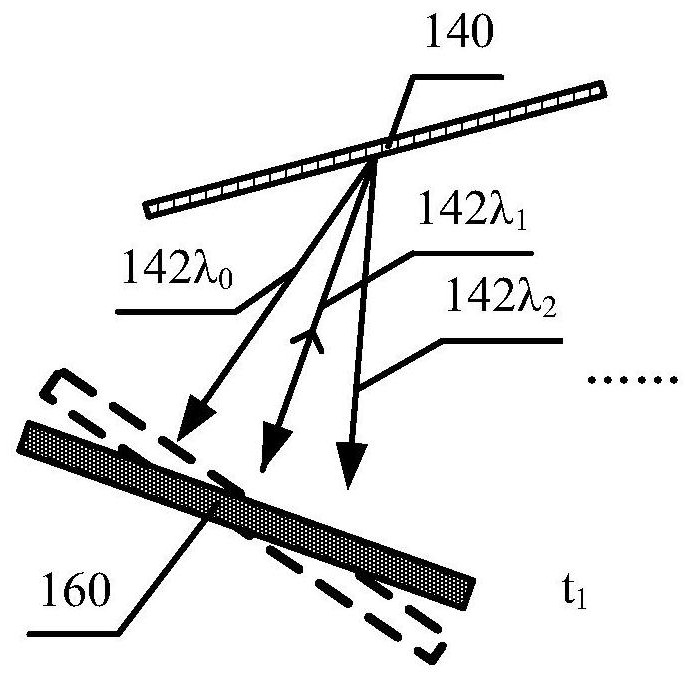

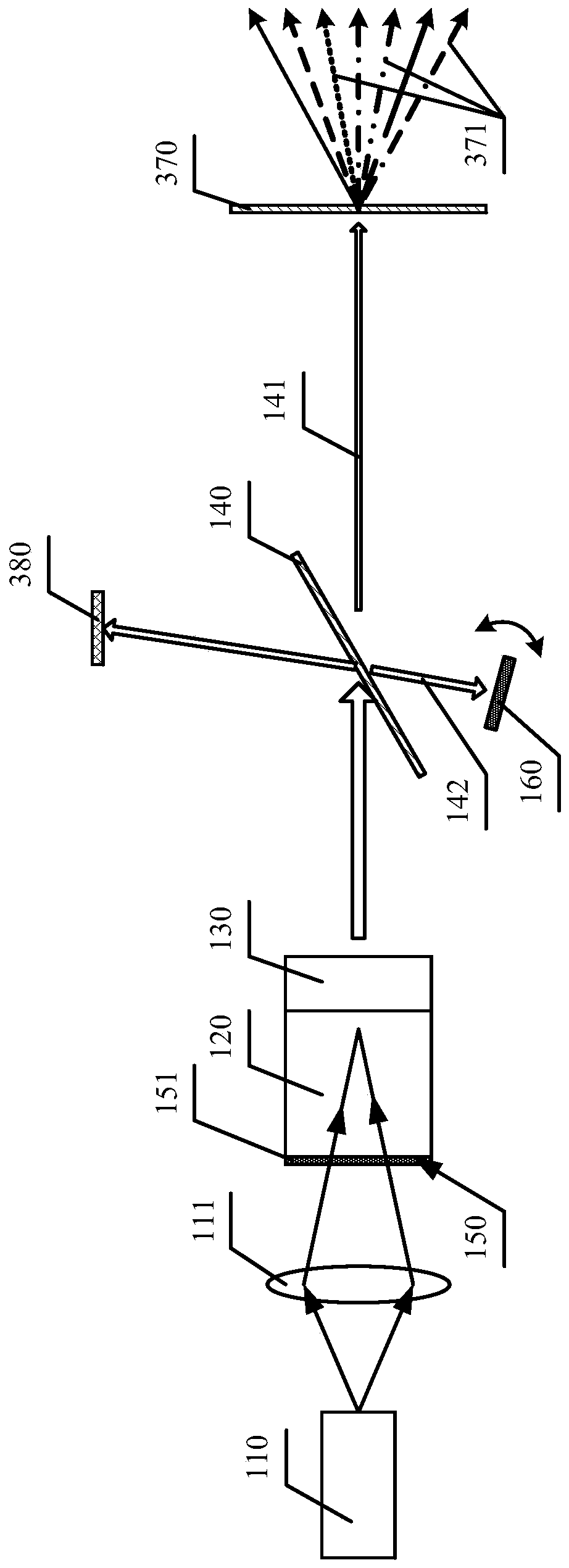

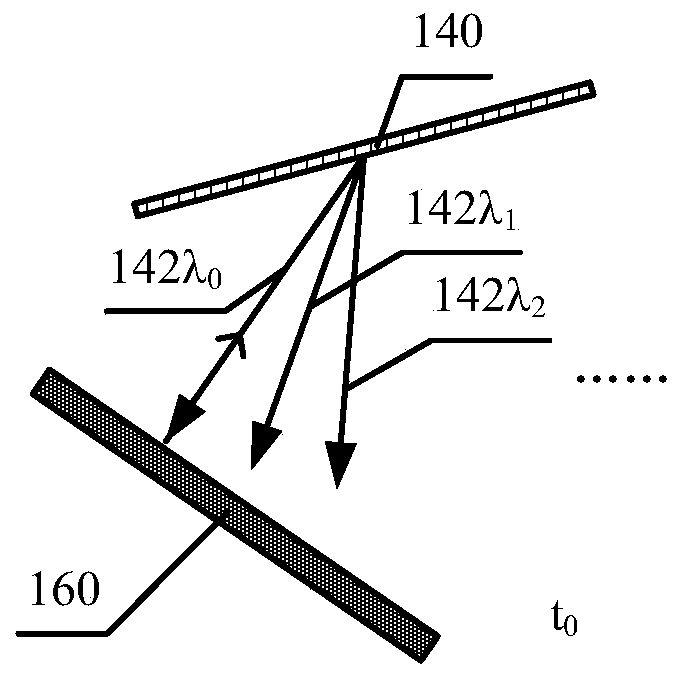

ActiveCN109950784BShorten cavity lengthReduce volumeLaser detailsElectromagnetic wave reradiationHigh peakOptical axis

A laser and a laser radar, the laser comprises: a pump unit, a gain unit, a Q-switching unit and a light splitting unit arranged in sequence along an optical axis; the pump unit generates pump light; the gain unit includes a gain medium; the The Q-switching unit includes a saturable absorber; the light splitting unit generates outgoing laser light and a plurality of tuned lights of different wavelengths; a resonant reflection surface and a scanning unit, the resonant reflection surface is located between the gain unit and the pump unit , the scanning unit is located on the optical path of the plurality of tuned lights, and the scanning unit selects one from the plurality of tuned lights and returns the selected tuned light according to the original optical path. The laser is a tunable laser that can realize Q-switching, can obtain higher peak power and greater pulse energy, and can effectively shorten the cavity length and volume of the resonator cavity, which is conducive to the realization of high integration and high peak power. Consideration of value power.

Owner:HESAI TECH CO LTD

Laser device and lidar

ActiveCN109950784AHigh peak powerHigh pulse energyLaser detailsElectromagnetic wave reradiationTunable laserOptical path

The invention provides a laser device and a laser radar. The laser device comprises a pump unit, a gain unit, a Q-switching unit, and a beam splitting unit disposed in sequence along an optical axis.The pump unit generates pump light. The gain unit includes a gain medium. The Q-switching unit includes a saturable absorber. The beam splitting unit generates exiting laser and a plurality of tuninglight of different wavelengths. The laser device also comprises a resonant reflecting surface and a scanning unit, the resonant reflecting surface is located between the gain unit and the pump unit, and the scanning unit selects one piece of tuning light from the plurality of tuning light and returns the selected tuning light according to an original optical path. The laser device is a tunable laser device capable of realizing Q-switching, higher peak power and larger pulse energy can be obtained, the cavity length of a resonant cavity and the volume of the resonant cavity can be effectively reduced, and the realization of the consideration of both high integration and high peak power is facilitated.

Owner:HESAI TECH CO LTD

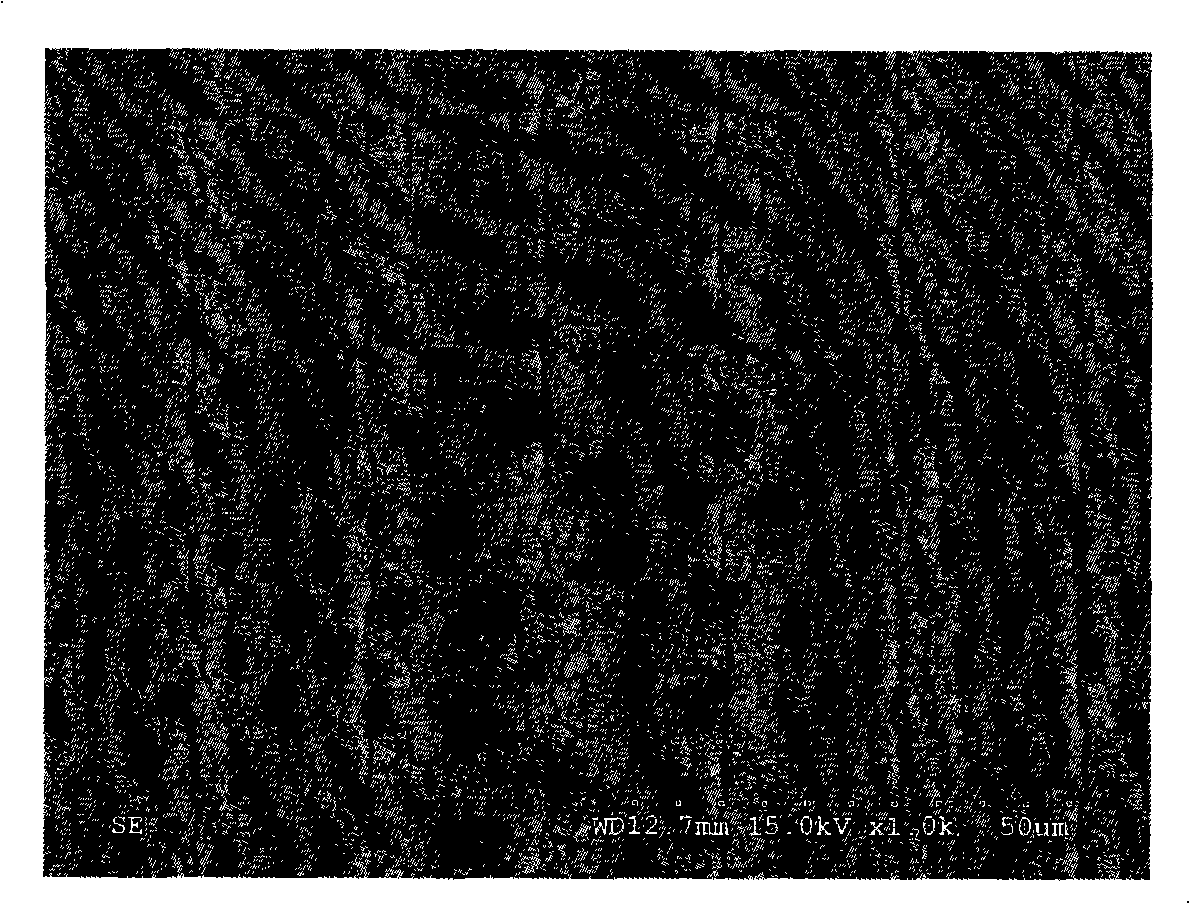

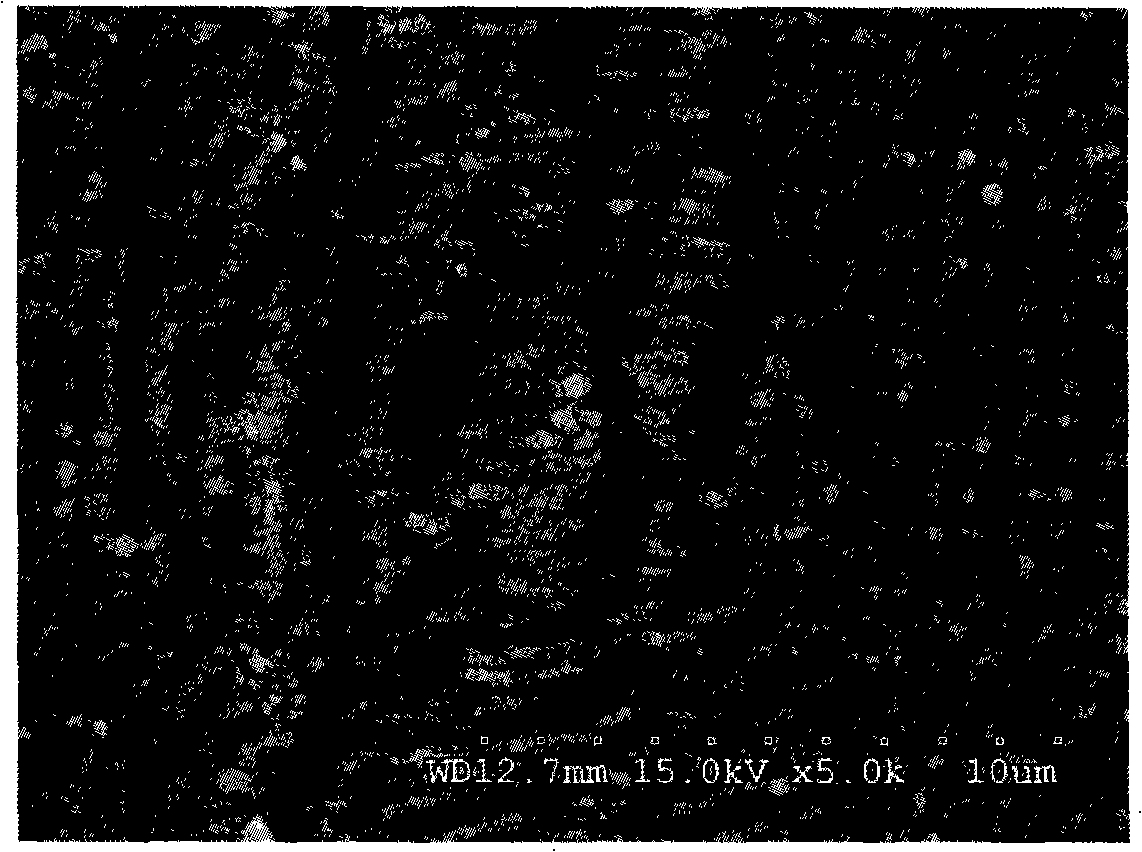

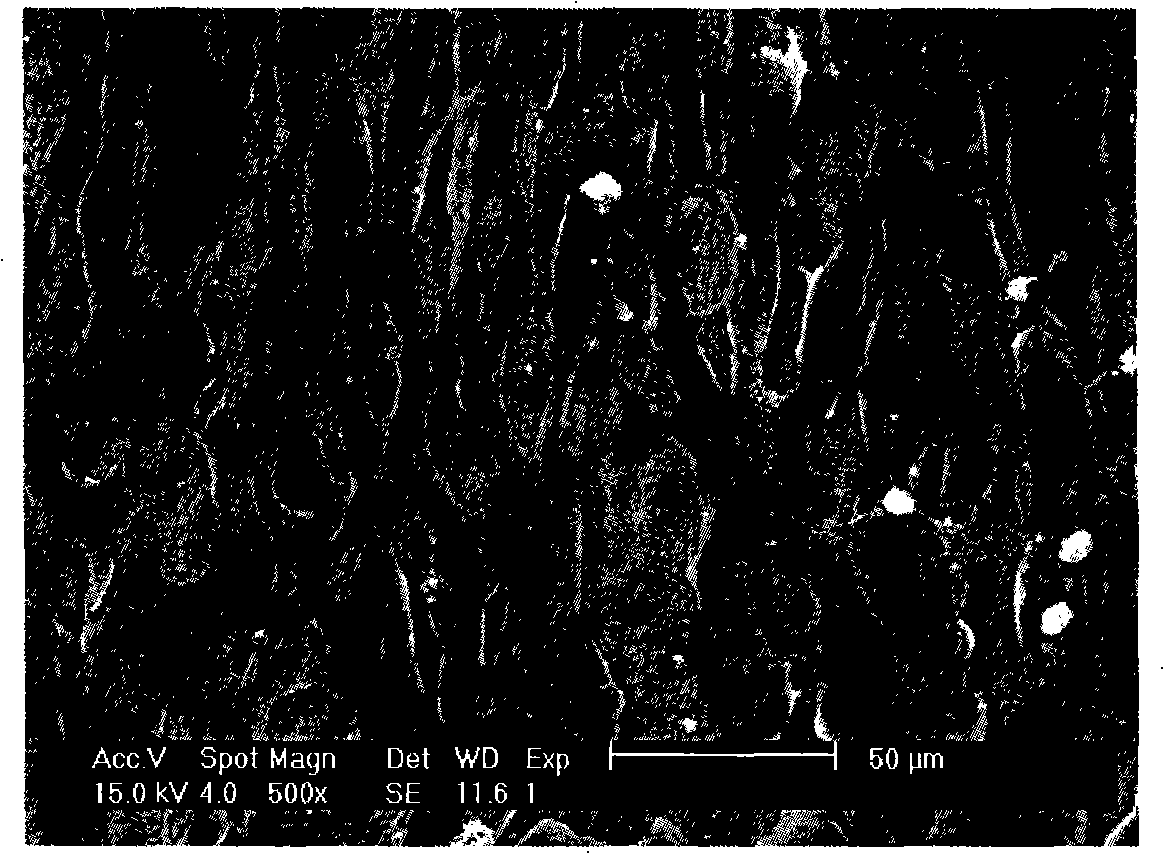

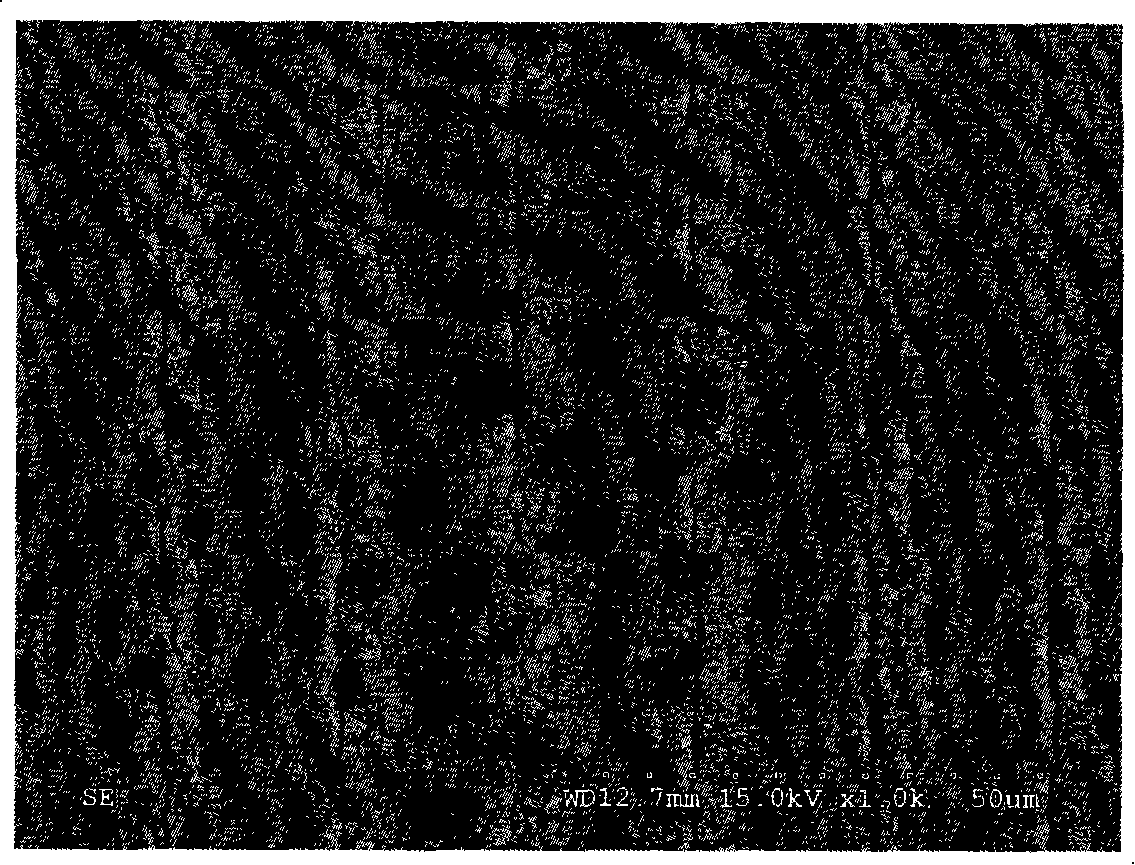

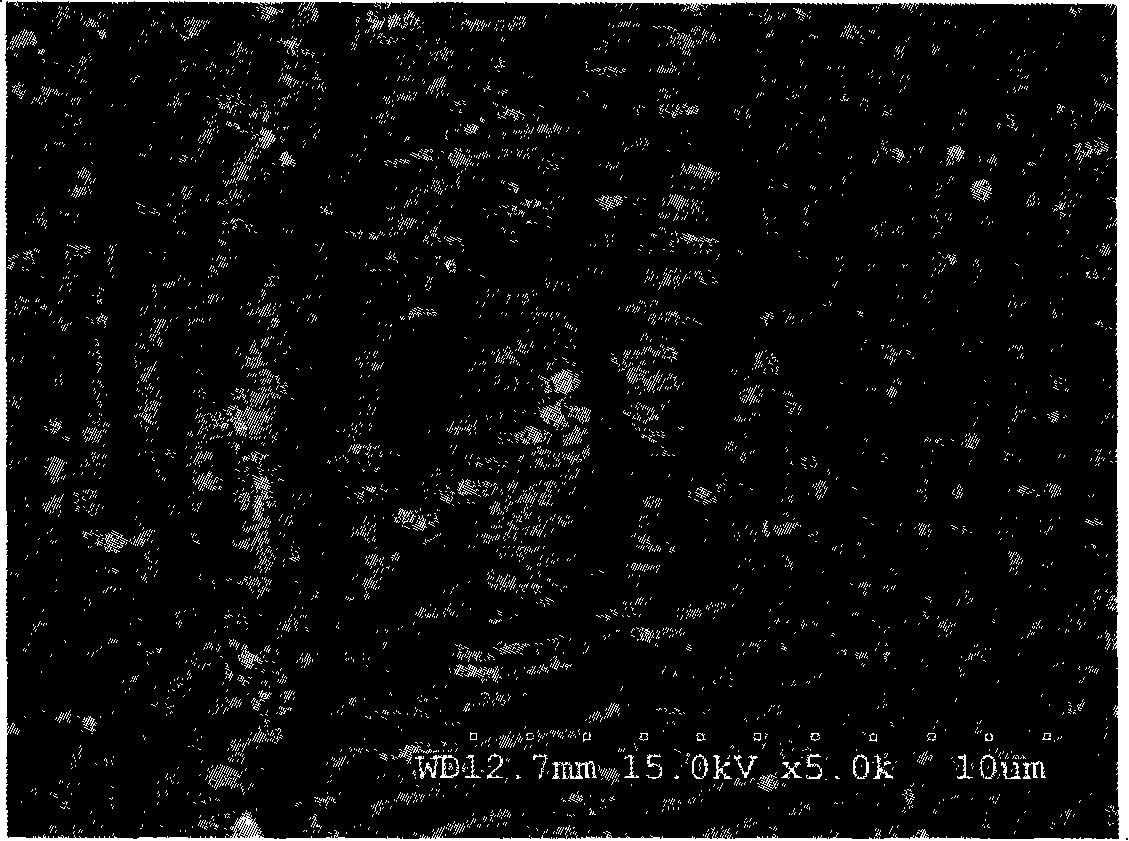

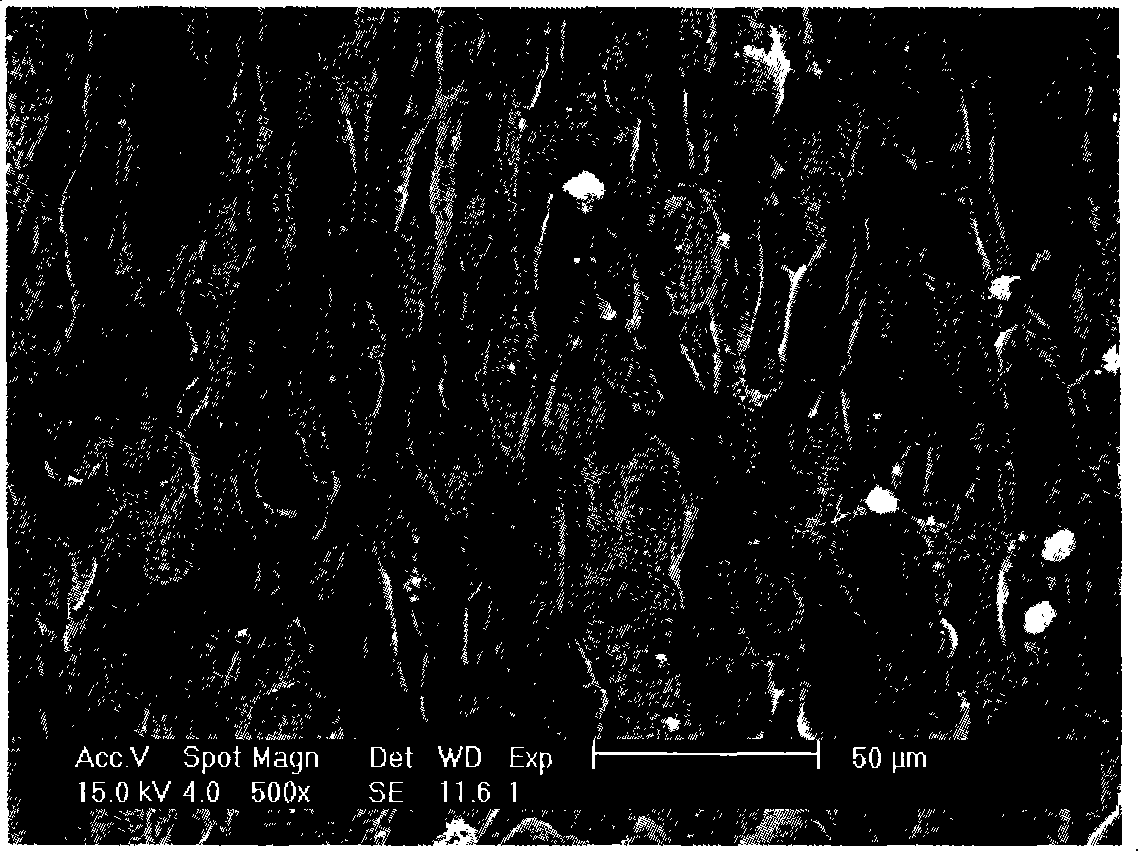

Application of femtosecond laser in pure titanium implantation material surface treatment

InactiveCN101264551AGood biocompatibilityReduce the impactTeeth fillingBone implantTitanium surfaceLaser processing

The invention relates to an application of femto-second laser in the surface treatment of the pure titanium implanting material, belonging to the technical field of application of laser in the material surface treatment. The application method comprises the following steps: in the air, the femto-laser impulse is in normal incidence and focused right on the top of the lump pure titanium implanting material which is ground and dried, a light spot with a radius of 5um is formed at the surface of the pure titanium implanting material, the femto-laser processing parameters are defined as follows: the impulse repeat frequency is 1 kHz, the single impulse power is from 5 to 200 micro joule, the impulse width is 50 femtosecond, the impulse center wavelength is 800 nanometer, the line interval of the laser processing is between 10 to 100 micron, the laser scanning speed is between 0.5 to 1.2 mm / sec, the laser polarization direction is regulated to be parallel to the laser scanning direction, the femto-laser scans the whole surface of the pure titanium implanting material, a titanium based biomedical material with an oxide layer generated on the titanium surface, even roughness, and a pattern of strips, holes, grooves or the combined pattern thereof formed on the pure titanium implanting material is made.

Owner:HEBEI UNIV OF TECH +2

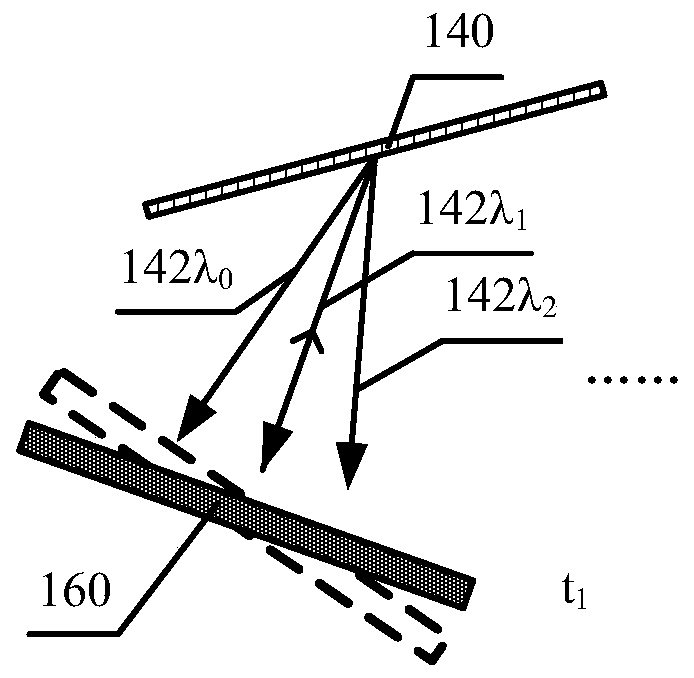

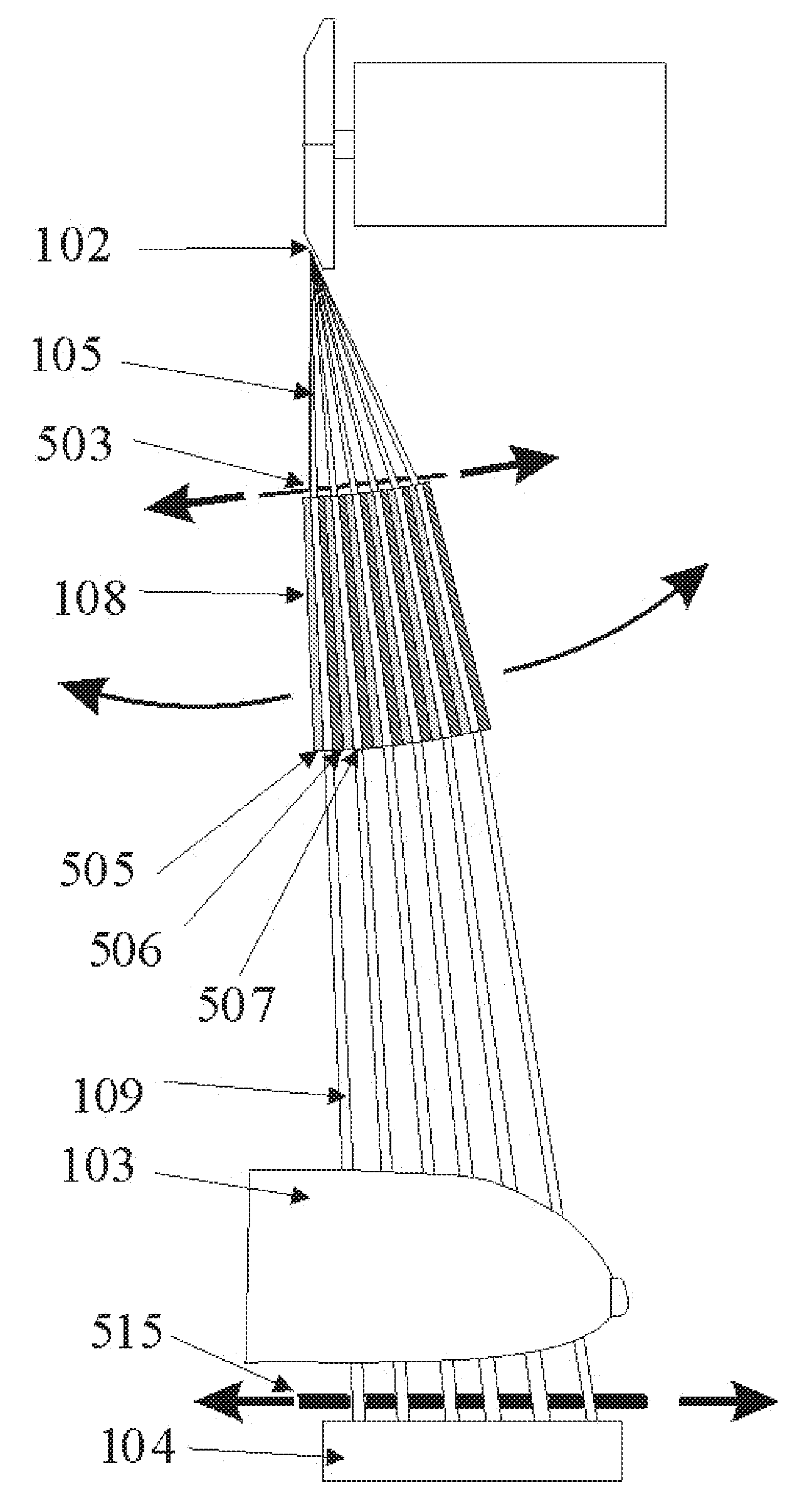

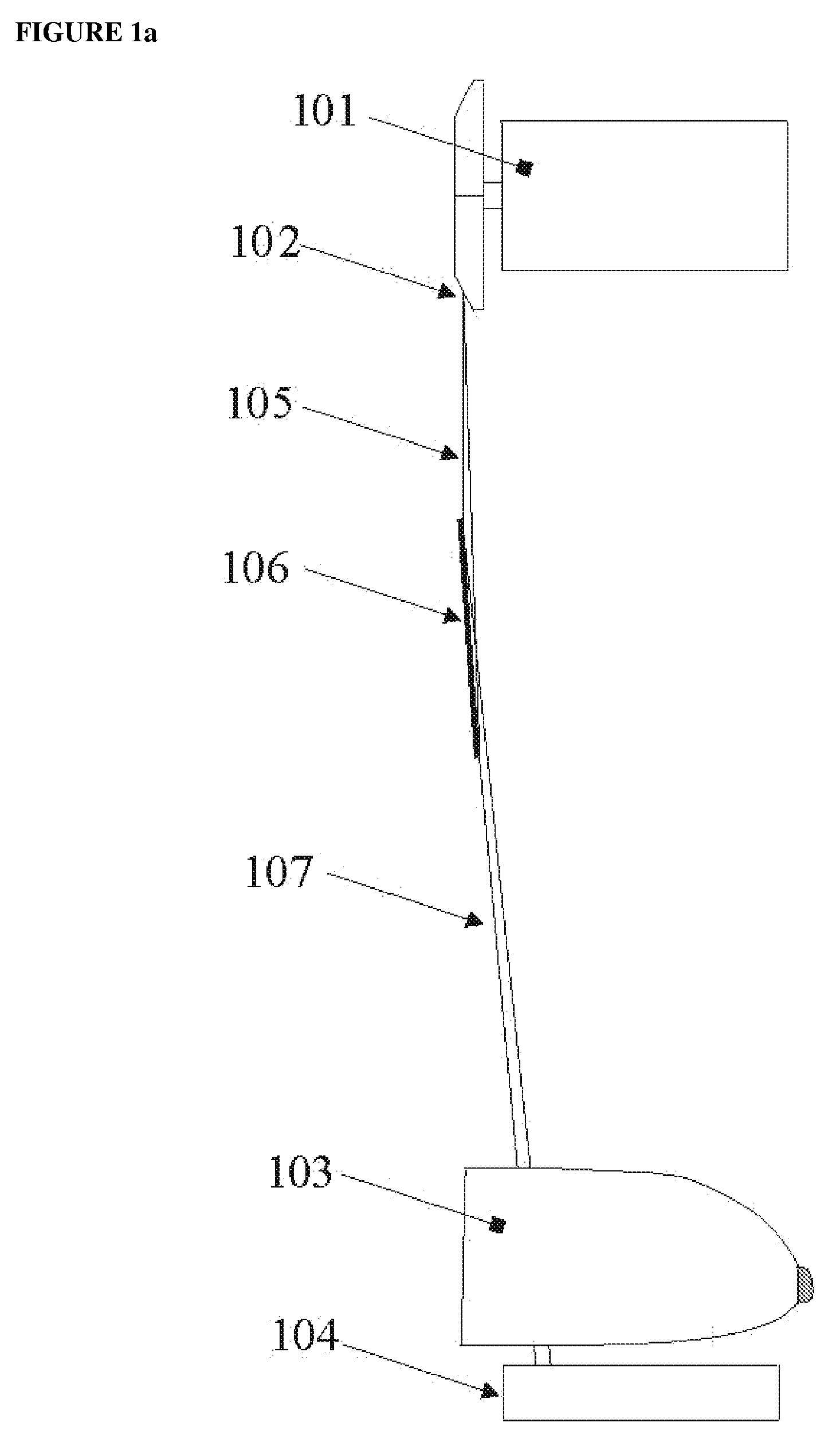

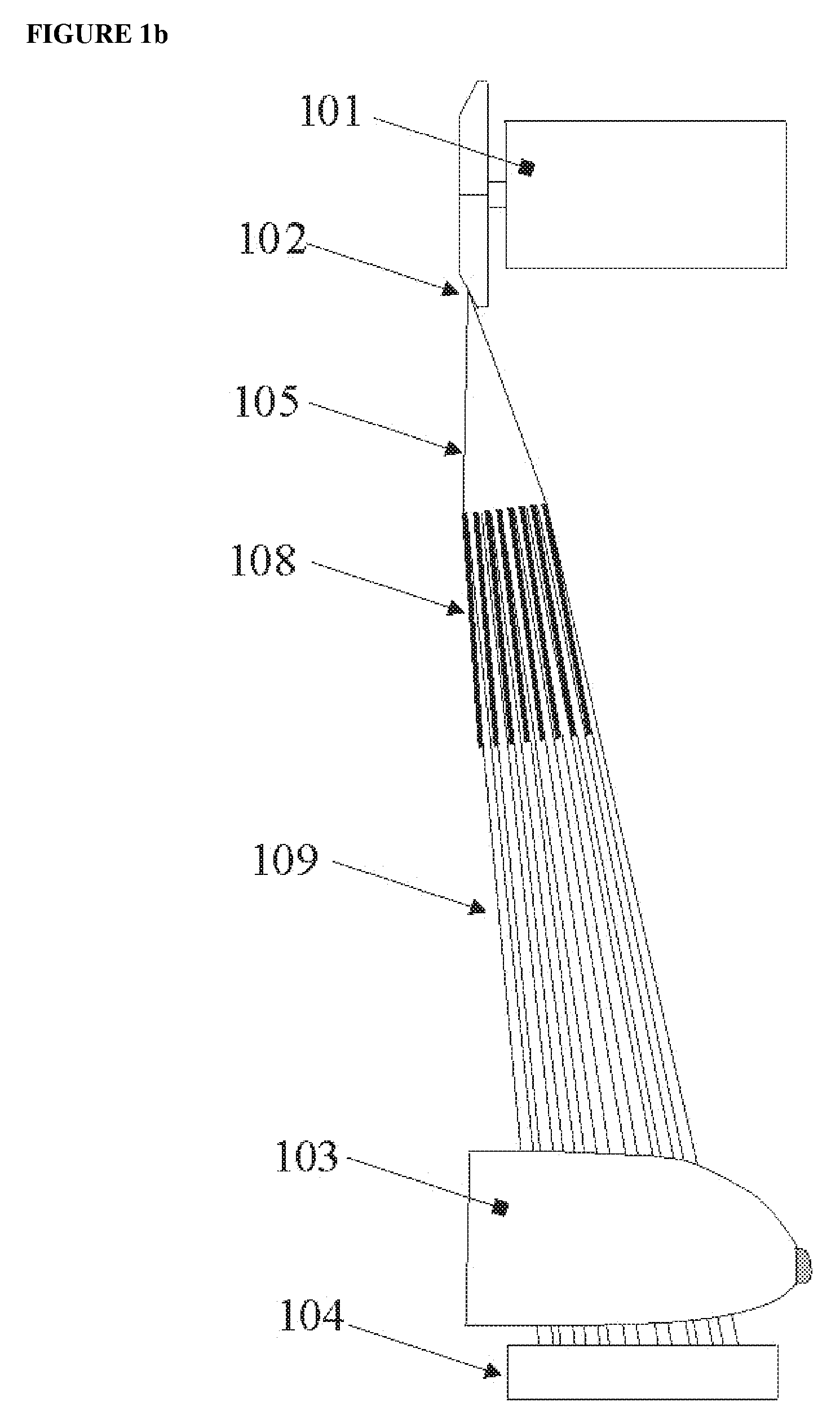

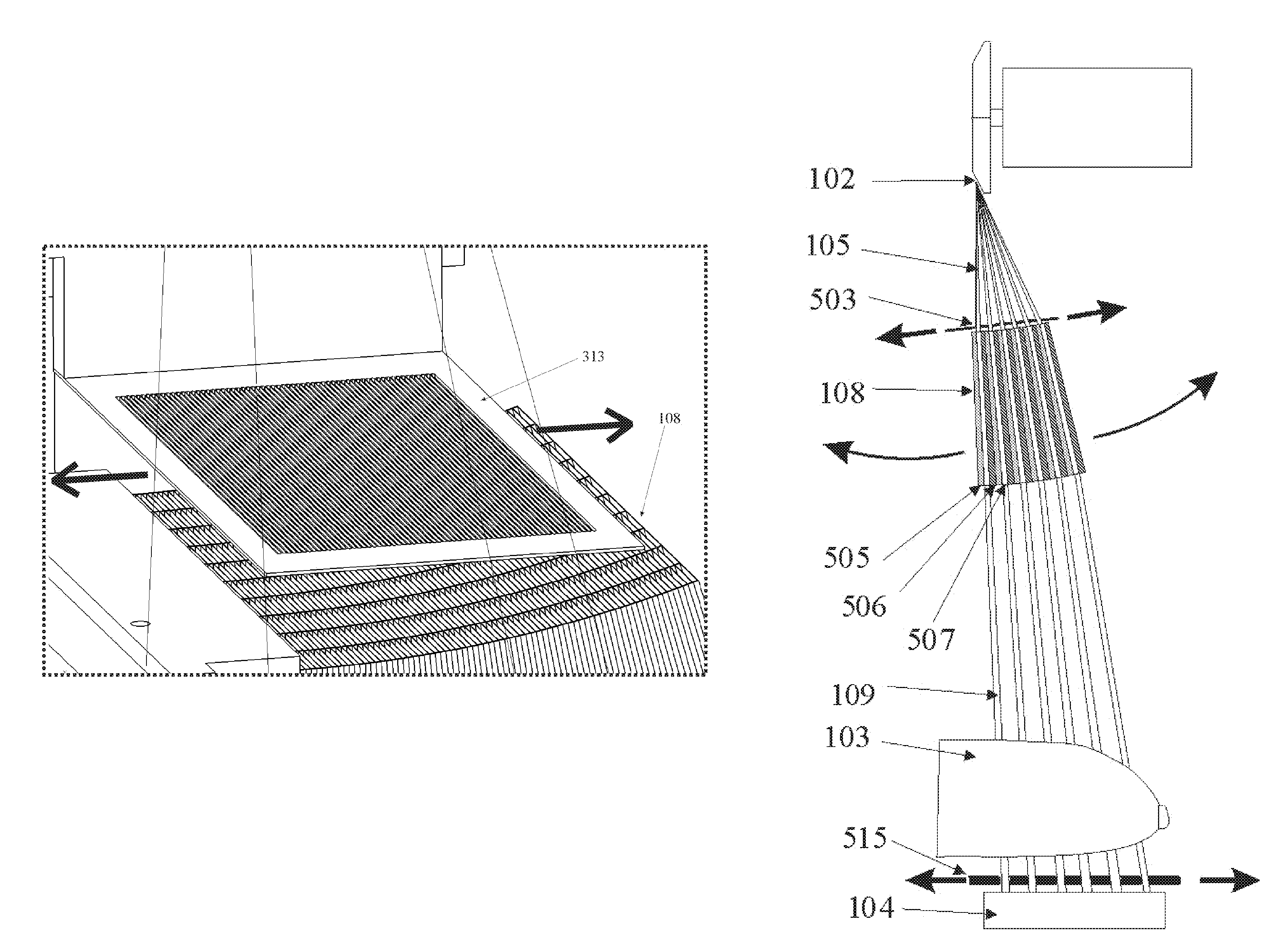

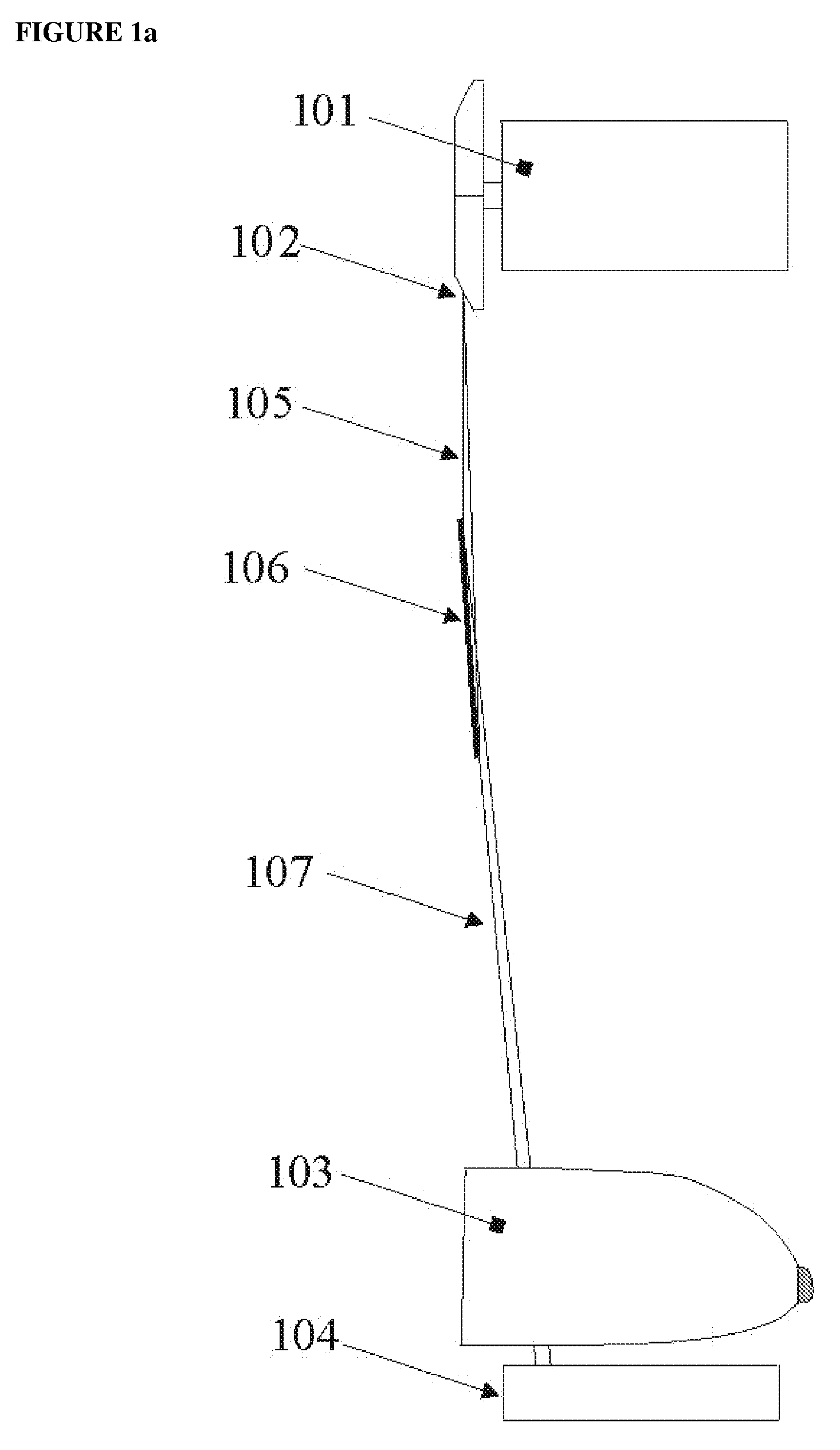

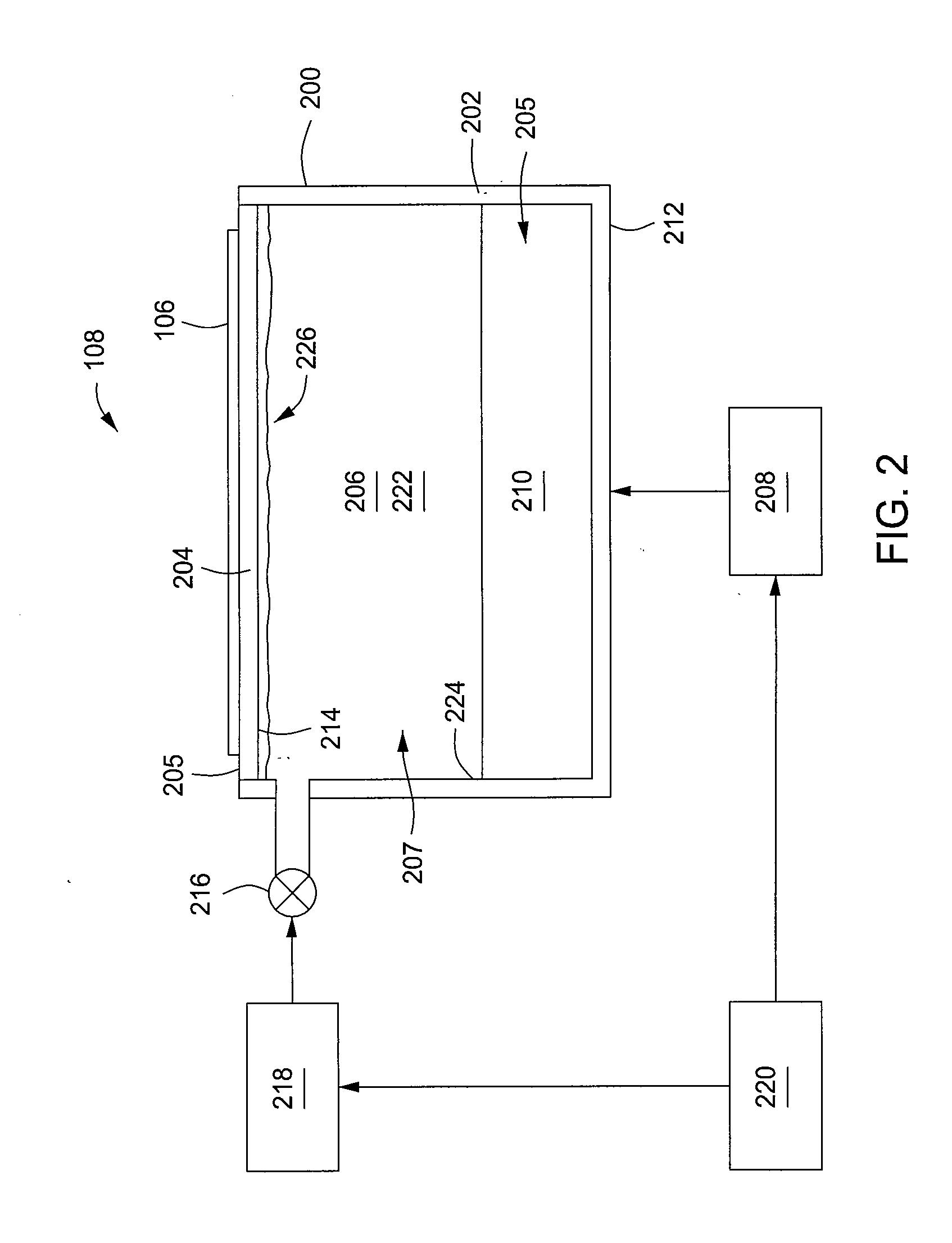

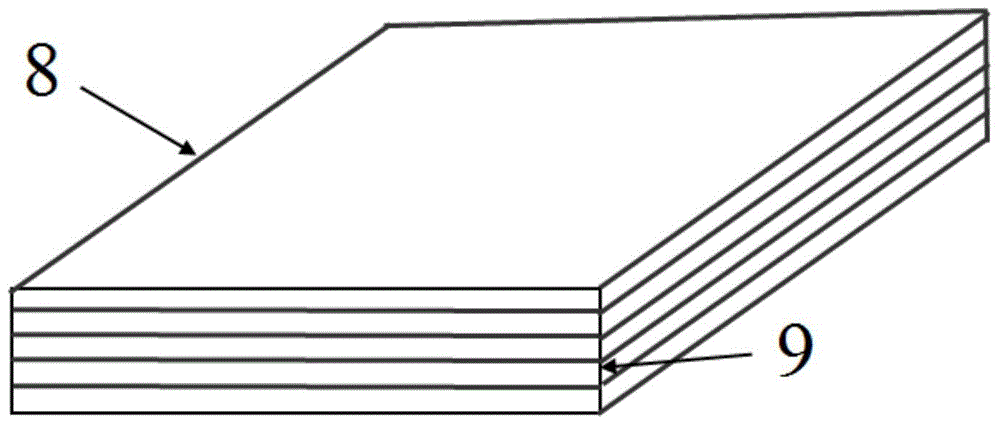

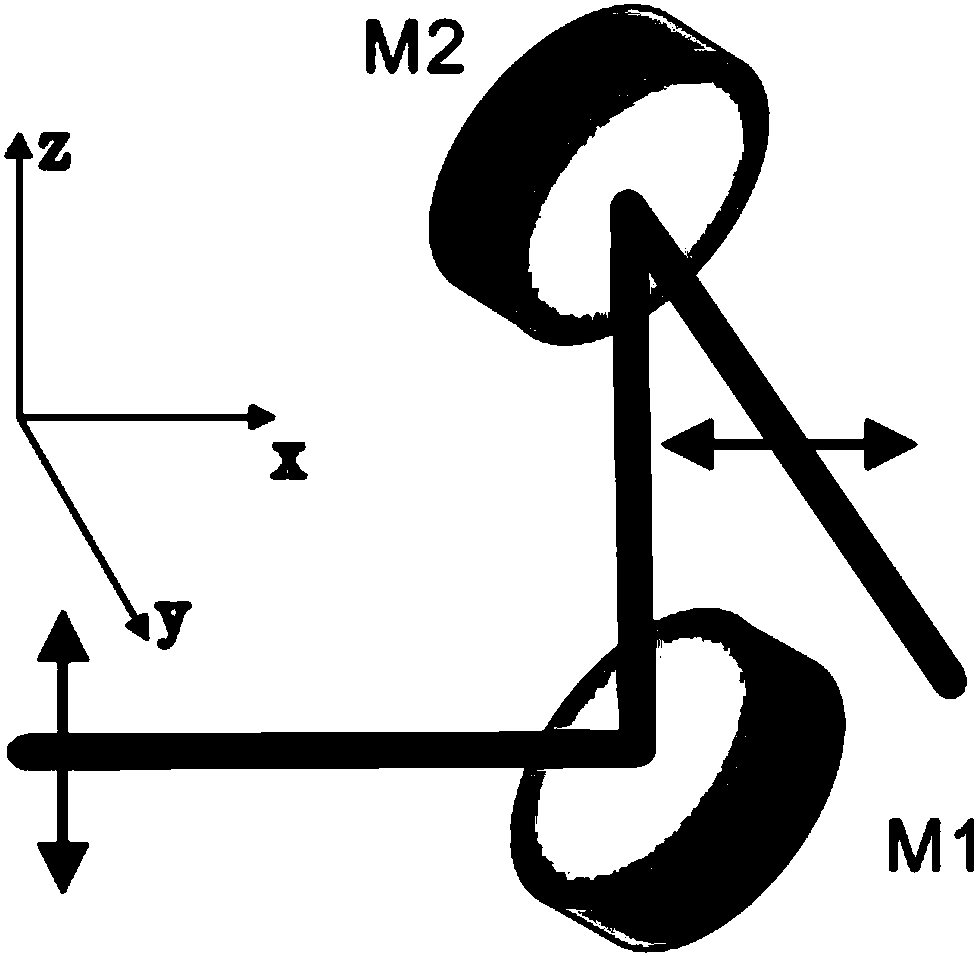

Mirror mounting, alignment, and scanning mechanism and scanning method for radiographic x-ray imaging, and x-ray imaging device having same

InactiveUS20090190720A1Minimise scatteringPrecise positioningMirrorsHandling using diffraction/refraction/reflectionUltrasound attenuationSoft x ray

An X-ray imaging device and alignment / scanning system include at least one multilayer X-ray mirror mounted on a multi-axis adjustable mirror mount pivotable about a scanning axis. A mirror scanner is coupled with the mirror mount and synchronized with the X-ray source so that the mirror scanner moves the mirror mount about the scanning axis. The invention may include a plurality of mirrors, optionally in a stack, and preferably including first and second mirrors respectively adapted to reflect X-rays of first and second energies. A movable attenuation plate having a window selectively allows X-rays to be transmitted by one of the mirrors and blocks X-rays from the other mirror(s). Sets of the mirrors may be configured in blocks or interspersed. The mirror scanner may be operable at variable speeds to enable selective control of the scanning speed of the mirror.

Owner:REFLECTIVE X RAY OPTICS

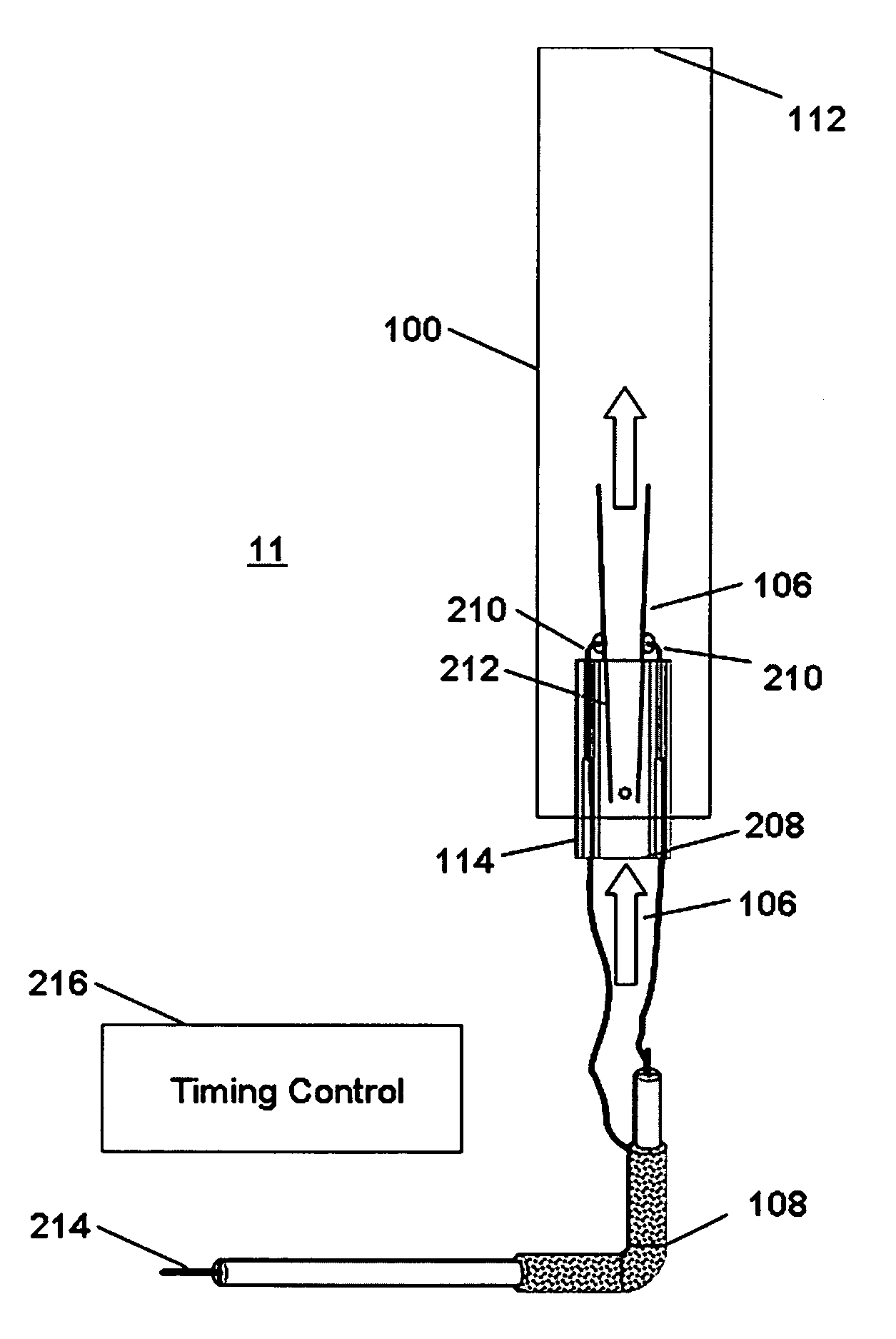

System and method for ignition of a gaseous or dispersed fuel-oxidant mixture

An improved system and method for ignition of a gaseous or dispersive fuel-oxidant mixture is provided where a gaseous or dispersive fuel-oxidant mixture is supplied to a detonator tube having a fill point and an open end and an igniter placed at an ignition point within the detonator tube is ignited while the gaseous or dispersive fuel-oxidant mixture is flowing through the detonator tube. A detonation impulse is produced at the ignition point that propagates to the open end of said detonator tube where it can be supplied to a detonation tube having an open end, to an internal combustion engine, a combustion chamber, and to a pulse detonation engine.

Owner:SOUNDBLAST TECH

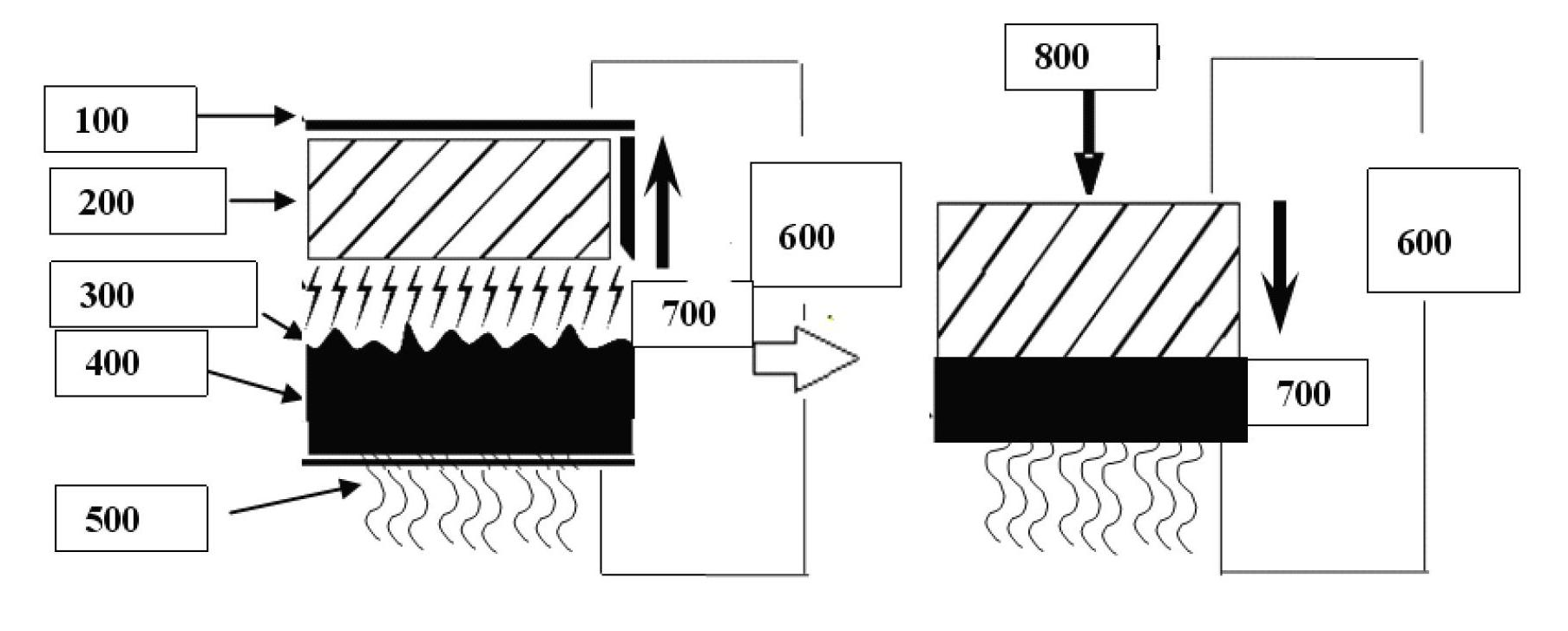

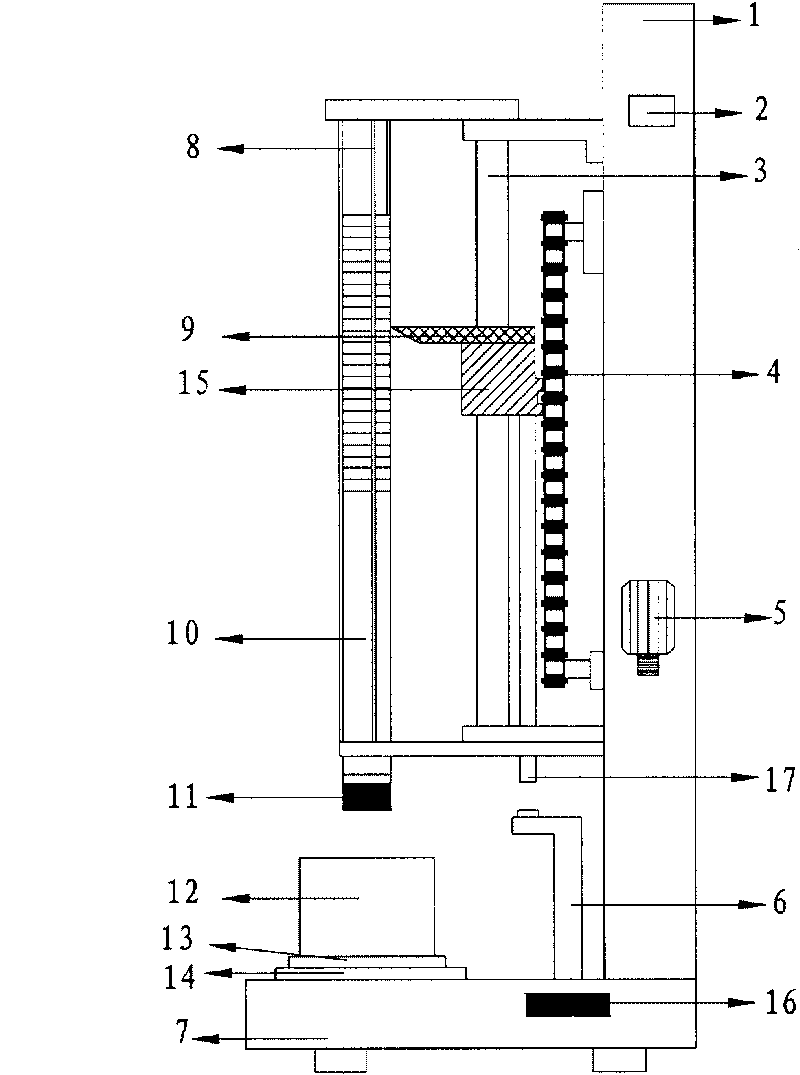

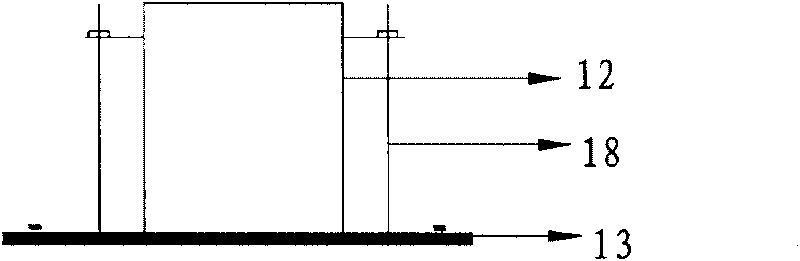

High-molecular material 3D printing device applying nanosecond lasers to accurately control temperatures

ActiveCN103978685AEvenly distributed temperature gradientReduce defectsNanosecond laserBeam expander

The invention discloses a high-molecular material 3D printing device applying nanosecond lasers to accurately control temperatures. The device includes two laser devices, a beam expander, a light beam scanning controller, a preheating chamber, a powder feeding device, a working platform, two temperature sensors and a control module. Through use of the device and in a laser sintering type printing technological process, energy emitted by the laser devices in unit time can be accurately controlled through controlling increase or decrease of the repetition frequency of pulses outputted by a pulse laser, so that a high-molecular material powder is allowed to maintain in a sufficient accuracy range in preheating and sintering processes, the temperature gradient of the interior of the material is uniformly distributed, defects of the interior of a molded workpiece are greatly reduced, moreover, the workpiece molding quality is better, and higher machining accuracy is maintained.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

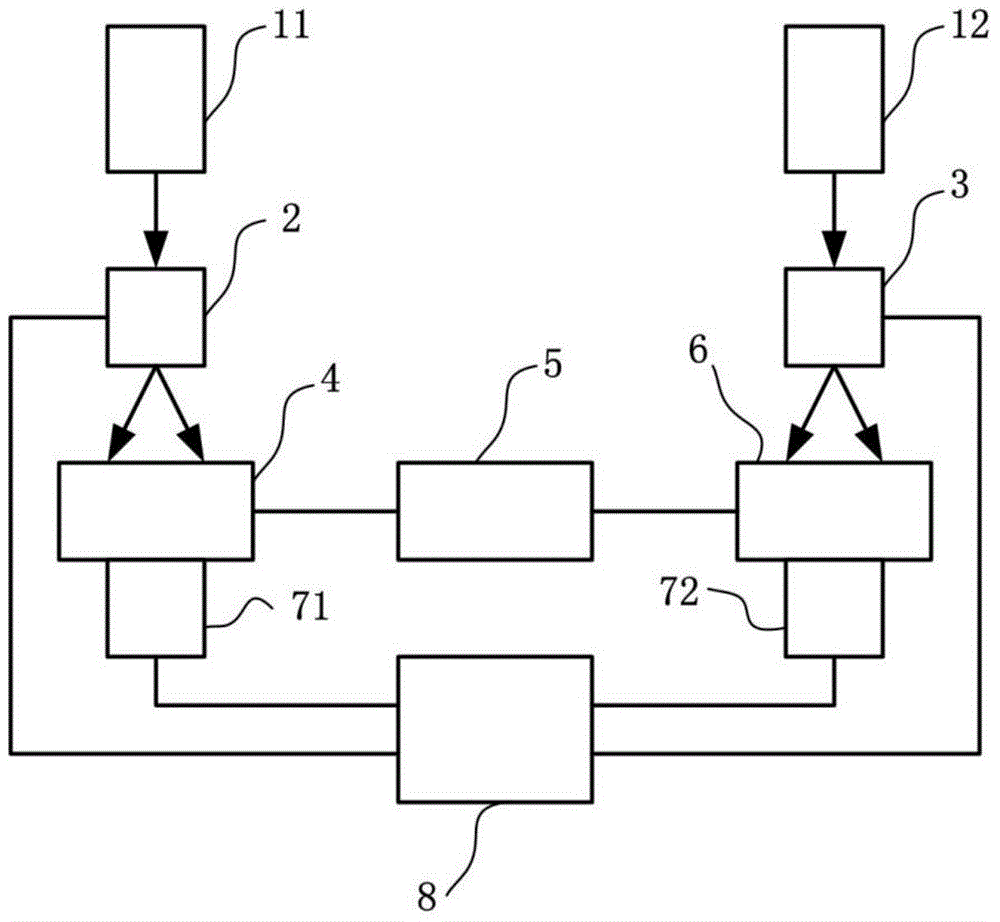

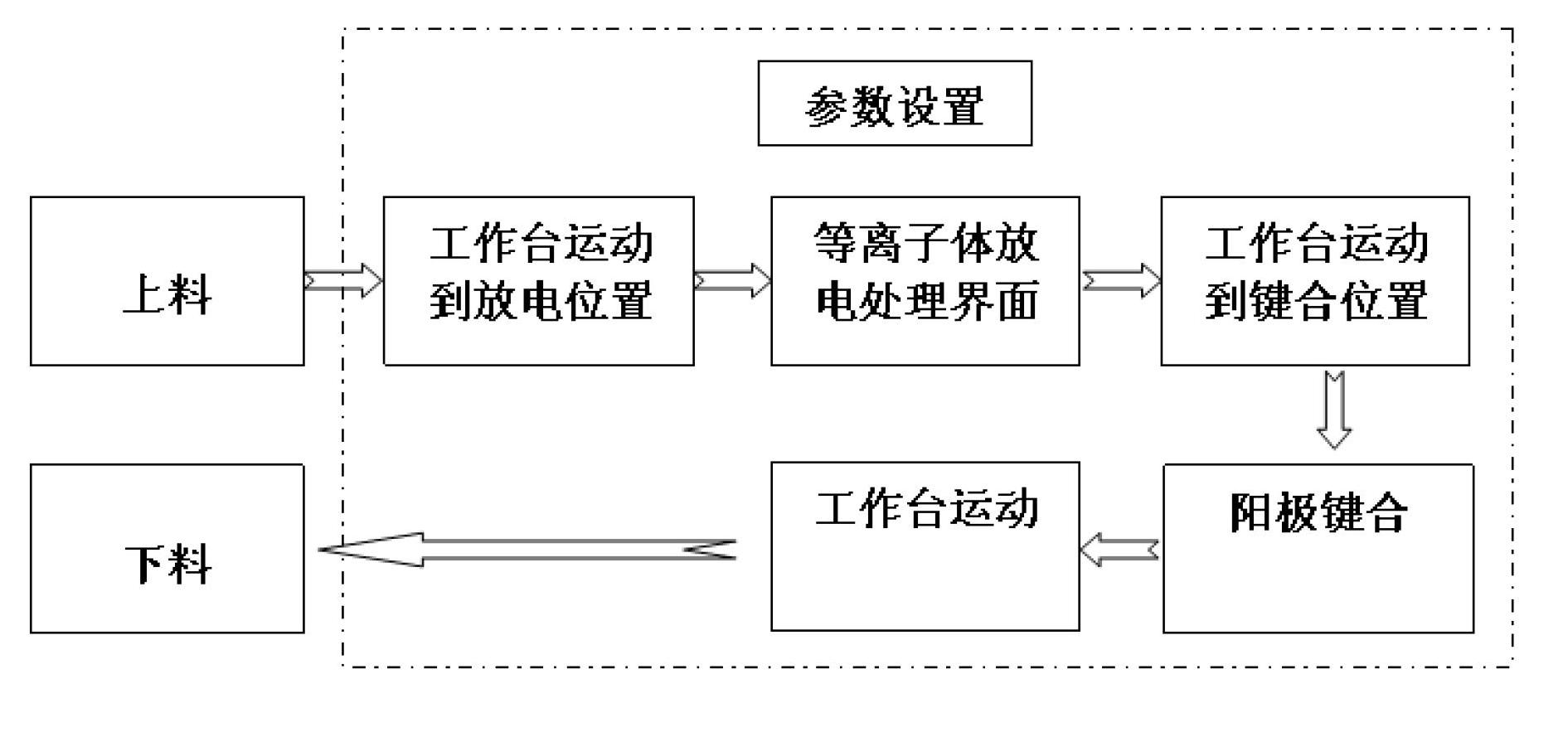

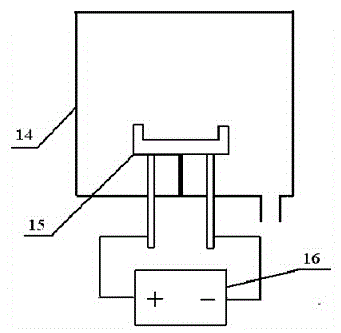

Composite anodic bonding method

InactiveCN102659071ABonding process is easy to implementGood controllability of bonding performancePrecision positioning equipmentSoldering apparatusDielectricBond interface

The invention relates to a composite anodic bonding method. According to the composite anodic bonding method, two working procedures of bonding interface pretreatment through dielectric-barrier plasma discharge and anodic bonding are finished on the same station. The composite anodic bonding method comprises the following steps of: clamping a silicon wafer or glass on a fixed workbench, and clamping a vitreous body or the silicon wafer on a movable workbench; simultaneously heating the two workbenches to 250-350 DEG C, wherein the movable workbench drives the vitreous body or the silicon wafer to move so as to urge a 1-500mum gap to be formed between bonded faces; generating plasma discharge in the gap under the action of DC 500-2000V or AC500-2000V / 10-1000Hz discharge voltage, and carrying out activating treatment for 0.1-20s on bonding interfaces through plasma discharge; then removing discharge voltage, simultaneously the movable workbench drives the vitreous body or the silicon wafer to move so that the bonding interfaces are mutually in touch and form 0.1-50g pressure, and finally finishing the anodic bonding under the action of DC500-2000V bonding voltage. According to the composite anodic bonding method, as the two working procedures of bonding interface activation pretreatment through dielectric-barrier plasma discharge and anodic bonding are integrated and finished on the same station, the bonding controllability is good, and the operation is convenient.

Owner:SUZHOU UNIV

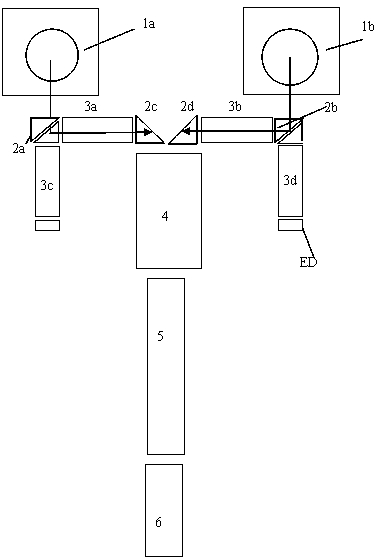

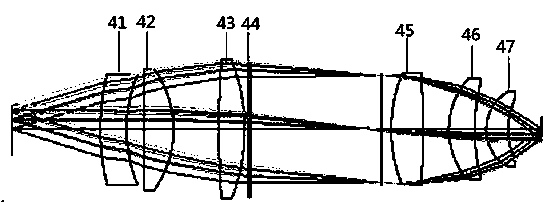

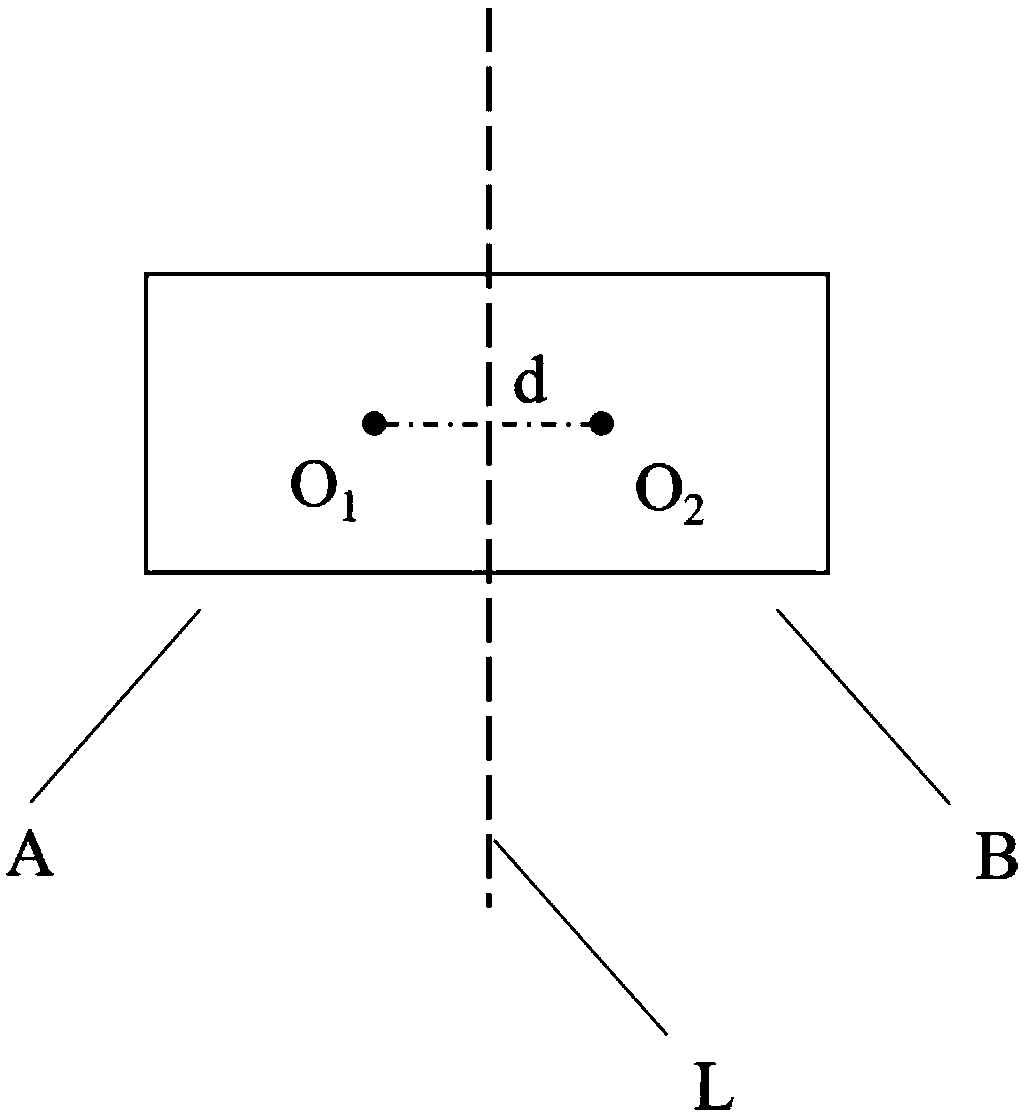

Double-mercury lamp spliced exposure system for lithography equipment

ActiveCN103543609AImplement working mode switchingIncrease illuminationPhotomechanical exposure apparatusMicrolithography exposure apparatusLithographic artistCoupling

The invention discloses a double-mercury lamp spliced exposure system for lithography equipment. The double-mercury lamp spliced exposure system comprises a first light source and a second light source used for simultaneously or respectively providing illuminating beams; a first dodging component and a second dodging component which respectively correspond to the first light source and the second light source, a coupling lens group used for improving the illumination uniformity of the exposure system, and an illuminating and dodging component used for dodging emergent light of the coupling lens group to illuminate an illumination surface.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

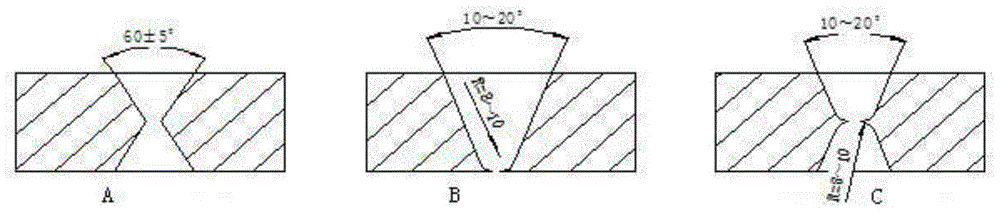

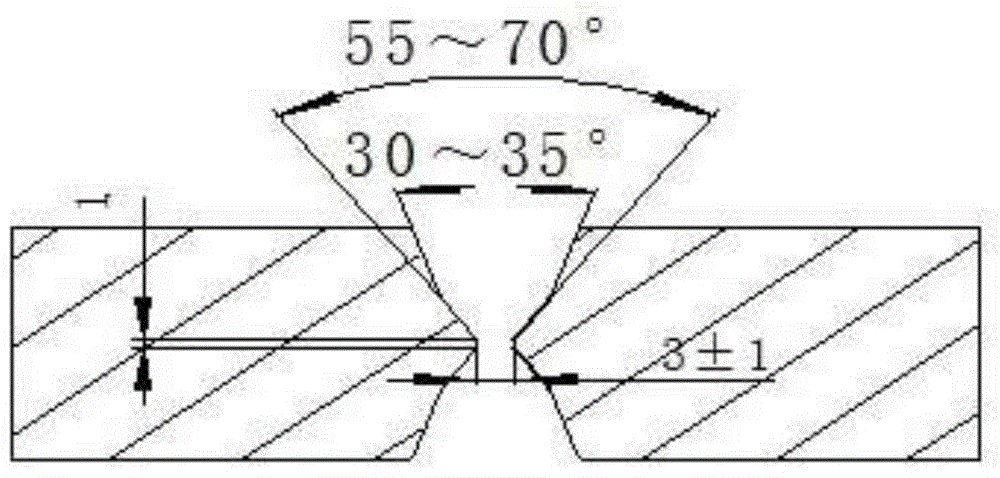

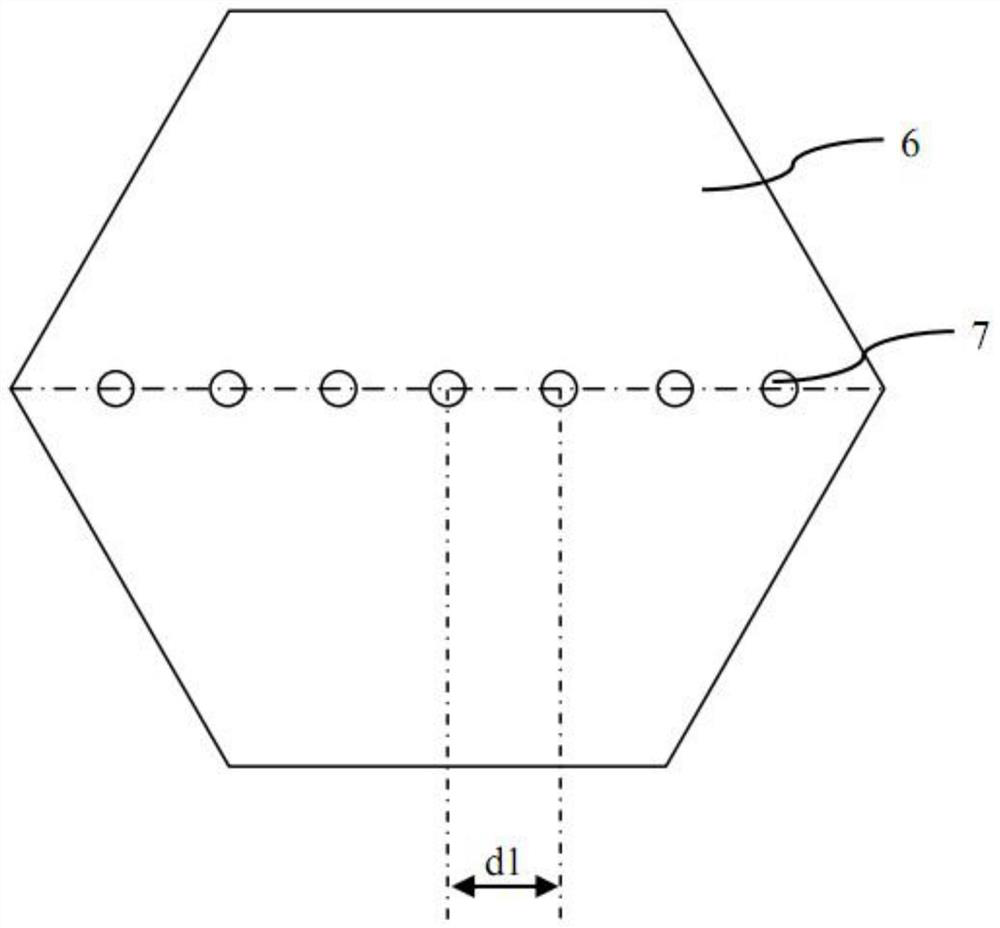

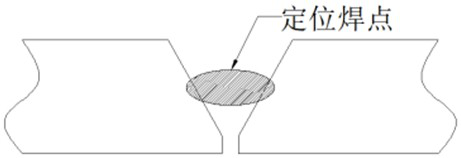

Welding technology for manual argon arc welding of thick plate titanium material

InactiveCN104057185AReduce the difficulty of welding operationGuarantee welding qualityArc welding apparatusWelding/soldering/cutting articlesTitaniumEngineering

The invention discloses a welding technology for manual argon arc welding of a thick plate titanium material. The welding technology comprises the following steps: 1) cleaning welding wires, the surface of a groove and two sides of the groove; 2) adopting a double V-shaped groove, setting the angle of the lower section of the groove to be 55-70 degrees, and setting the angle of the upper section of the groove to be 30-35 degrees; 3) determining welding parameters, and welding. The application range of welding technology for manual argon arc welding of the titanium material is enabled to be further enlarged, and is particularly suitable for welding the titanium material of more than or equal to 20mm. The angle of the lower section of the groove is 55-70 degrees, so that a sufficient welding operation space is ensured, the defects of incomplete fusion, incomplete penetration and the like are prevented from being generated, and the welding quality is guaranteed; the angle of the upper section of the groove is 30-35 degrees, so that the metal filling volume is effectively reduced, and the difficulty requirements of improved groove processing technology is greatly reduced compared with U-shaped and double U-shaped grooves.

Owner:LUXI IND EQUIP

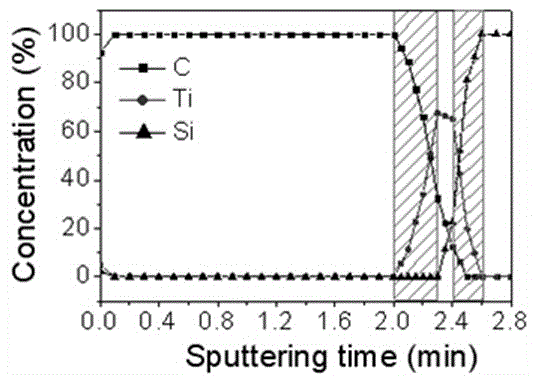

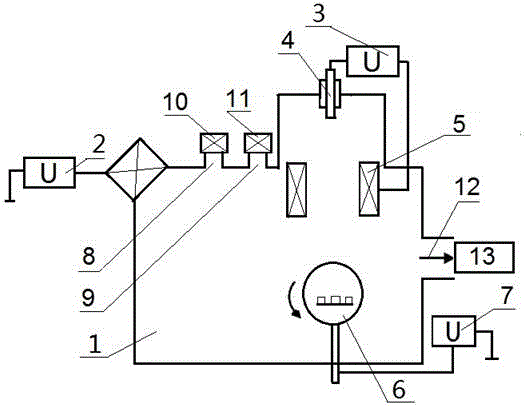

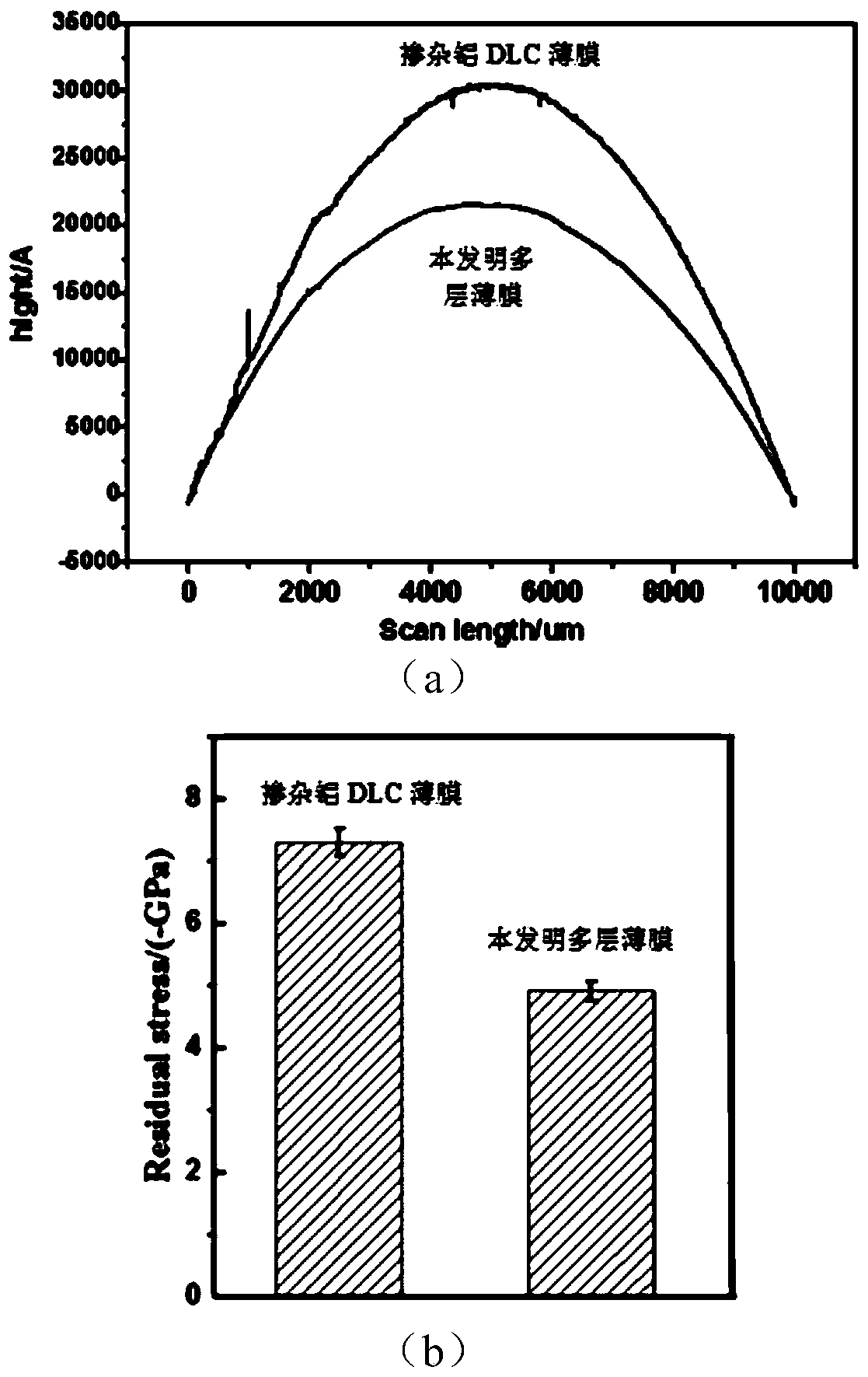

Method for preparing titanium/diamond-like nanometer multilayer film on silicon surface

InactiveCN105132878AHigh bonding strengthReduce interface stressVacuum evaporation coatingSputtering coatingComposite filmVacuum chamber

The invention discloses a method for preparing a titanium / diamond-like nanometer multilayer film on a silicon surface. The method concretely comprises the following steps of: drying a monocrystalline silicon substrate subjected to chemical cleaning in advance; putting the dried monocrystalline silicon substrate onto a rotating sample table of a cathode arcing device; performing vacuum pumping; introducing argon gas into a vacuum chamber; performing sputtering cleaning on the surface of the silicon substrate through an ion source; using high-purity metal titanium and graphite as targets, and using a direct current and pulse double-excitation-source cathode plasma discharge technology for respectively preparing a titanium nanometer function layer and a diamond-like film; and performing later-stage vacuum annealing treatment according to needs. The method has the advantages that the preparing process is simple; and the method can be used for preparing the diamond-like nanometer multilayer composite film with different surface structures. The titanium / diamond-like nanometer multilayer film prepared by the method provided by the invention has the advantages of high hardness, low stress and friction-reduction and abrasion-resistant performance.

Owner:TAIYUAN UNIV OF TECH

Mirror mounting, alignment, and scanning mechanism and scanning method for radiographic X-ray imaging, and X-ray imaging device having same

InactiveUS7978822B2Minimise scatteringPrecise positioningMirrorsHandling using diffraction/refraction/reflectionUltrasound attenuationX-ray

An X-ray imaging device and alignment / scanning system include at least one multilayer X-ray mirror mounted on a multi-axis adjustable mirror mount pivotable about a scanning axis. A mirror scanner is coupled with the mirror mount and synchronized with the X-ray source so that the mirror scanner moves the mirror mount about the scanning axis. The invention may include a plurality of mirrors, optionally in a stack, and preferably including first and second mirrors respectively adapted to reflect X-rays of first and second energies. A movable attenuation plate having a window selectively allows X-rays to be transmitted by one of the mirrors and blocks X-rays from the other mirror(s). Sets of the mirrors may be configured in blocks or interspersed. The mirror scanner may be operable at variable speeds to enable selective control of the scanning speed of the mirror.

Owner:REFLECTIVE X RAY OPTICS

Device and method for preparing amorphous carbon and nitrogen thin films on surface of silicon

ActiveCN106011745AEvenly distributedThe relative content is controllableVacuum evaporation coatingSputtering coatingNitrogen gasVacuum chamber

The invention discloses a device and method for preparing amorphous carbon and nitrogen thin films on the surface of silicon. The device is a pulse cathode electric arc device assisted by an ion source. The preparation device includes the following steps that a silicon substrate which is chemically cleaned in advance is dried and placed on a rotating sample table; vacuumization is performed, argon gas is led into a vacuum chamber, and the surface of the silicon substrate is physically cleaned through an ion sputtering source; and high-purity graphite serves as a cathode target material of a pulse electric arc, the pulse discharging frequency is adjusted, nitrogen gas is led at the same time, the ion source is opened, and the atomization and ionization nitrogen-doped amorphous carbon and nitrogen thin films are prepared. By means of the device and method, the content of carbon / nitrogen atoms and carbon-nitrogen bonds / carbon-carbon bonds in the amorphous carbon and nitrogen thin films is adjustable, and the carbon and nitrogen bonding types and the graphite-like nitrogen / pyridine-like nitrogen structures are controllable.

Owner:BEIJING WUKE GUOHUA TECH CO LTD

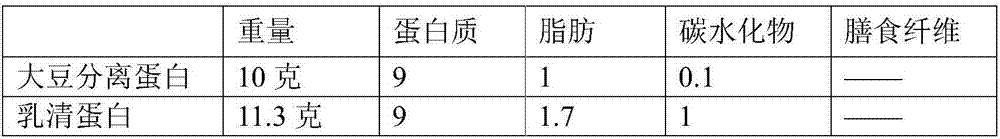

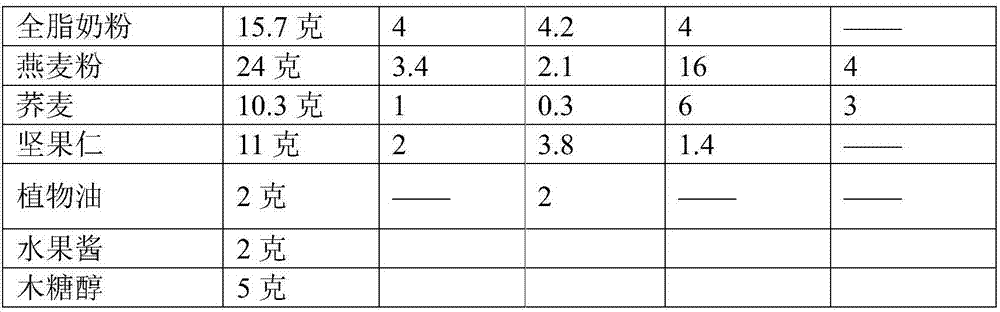

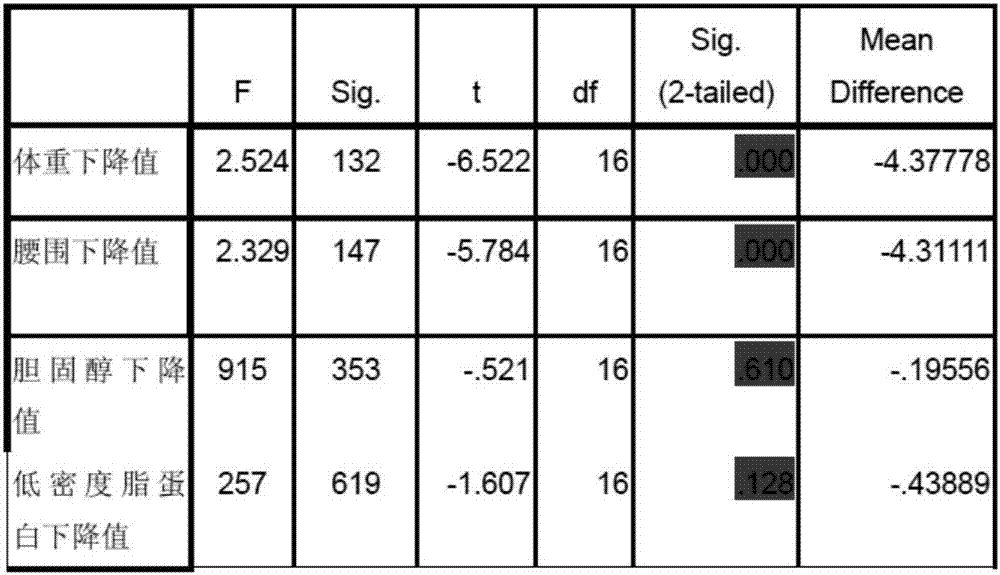

Meal replacement nutrition bar for weight reduction and preparation method thereof

InactiveCN107114798AHigh energyIncrease labor costFood ingredient as taste affecting agentLipidic food ingredientsPolygonum fagopyrumFood additive

The invention discloses a meal replacement nutrition bar for weight reduction, which is prepared from the following food ingredients in parts by mass: 10 parts of soybean isolate protein powder, 15.7 parts of whole milk powder, 11.3 parts of whey protein powder, 24 parts of oat, 10.3 parts of buckwheat, 11 parts of nut meat, 2 parts of vegetable oil, 5 parts of xylitol, and 2 parts of fruit jam. The meal replacement nutrition bar is applied for replacing meal in medical weight reduction, replaces meal before meal and when hungry, is beneficial for enhancing satiety, reducing meal acceptable daily intake, increasing dietary fiber and various vitamins and minerals, and supplementing nutrients insufficient to intake during weight reduction, is suitable, health and safe meal replacement bar for weight reduction selected by individuals, hospitals and social institutions during weight management work, meanwhile, solves the problems of high sugar, high energy, excess food additives and the like in existing meal replacement food, and is safe without toxic or side effects since all ingredients are food and the food additives are less.

Owner:徐大凤

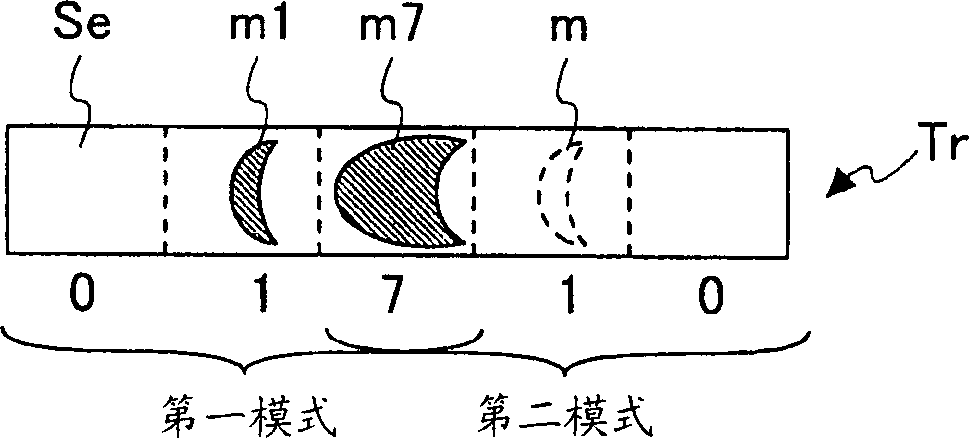

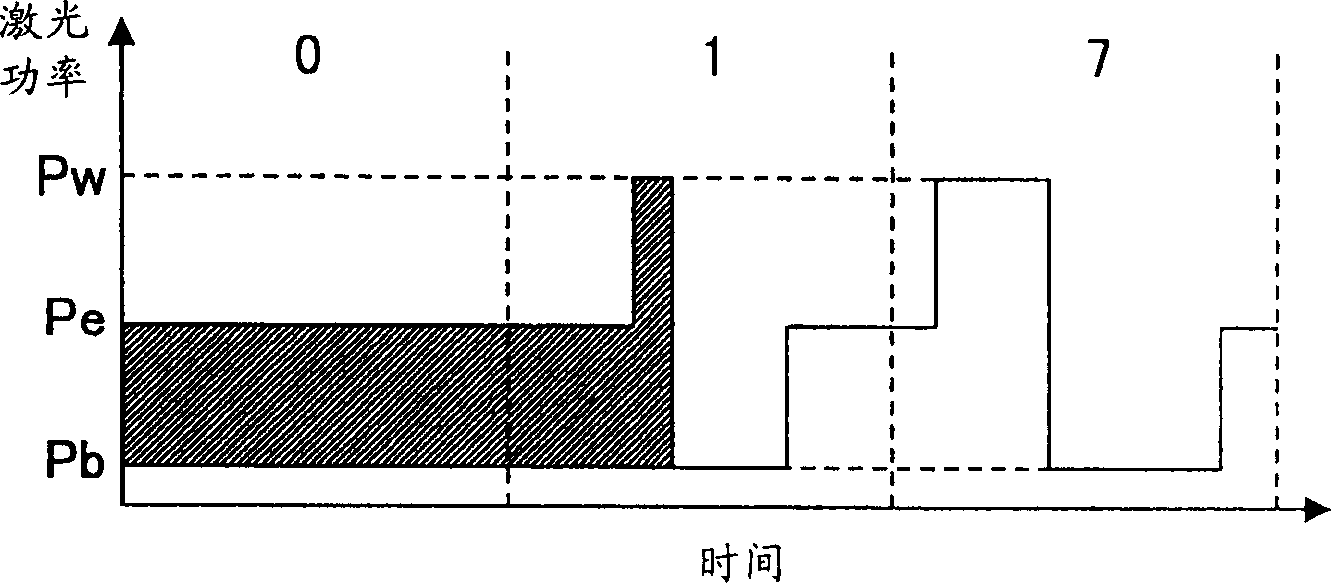

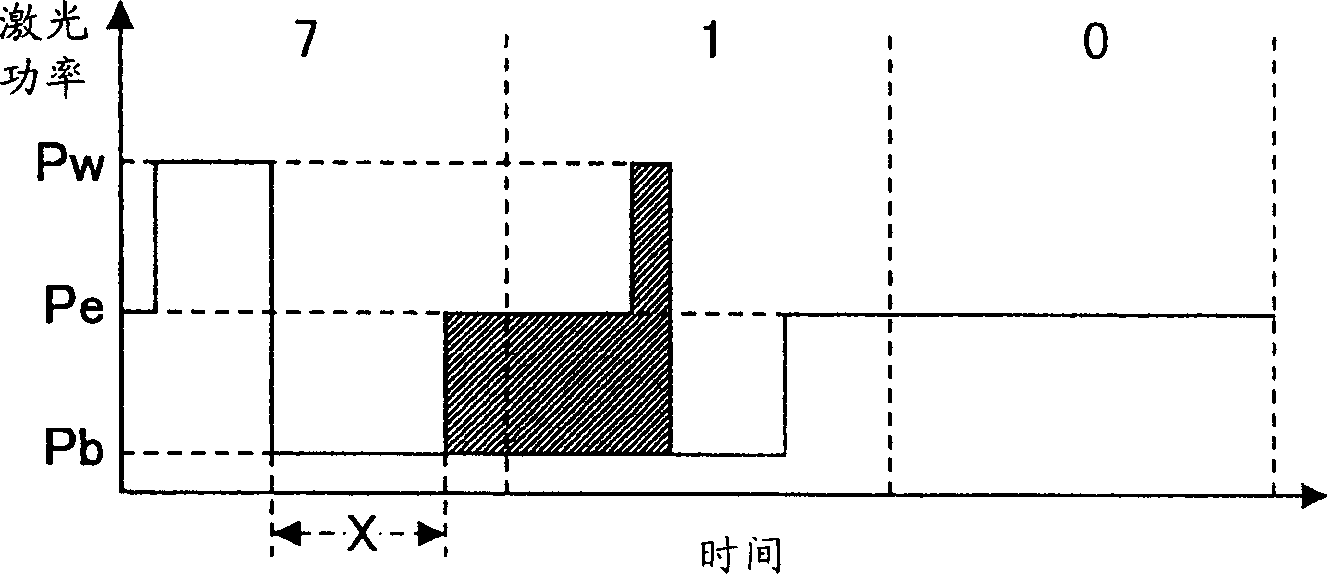

Multi-value information recorder, method, medium and information recording-reproducing device

InactiveCN1447314AImplement the record methodControl energyRecording strategiesRecord information storageRecording densityData sequences

A multi-level information recording-reproducing apparatus can accurately determine multi-level information even if recording density is increased. A multi-level information recording-reproducing apparatus radiates a laser beam to an information recording medium by switching a radiation energy level of the laser beam in a multi-level fashion and records a recorded mark in the information recording medium. The multi-level information recording-reproducing apparatus reproduces a multi-level data sequence recorded as a test pattern in the information recording medium, sets a reproduction signal level of a recorded mark based on an immediately-before cell located immediately before a cell to be reproduced, and corrects the radiation energy level of the laser beam so that the reproduction signal level can have a separate distribution from a distribution of another reproduction signal level.

Owner:RICOH KK

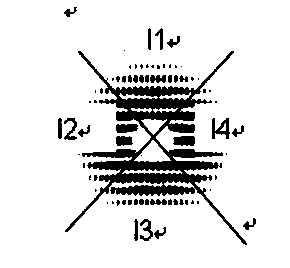

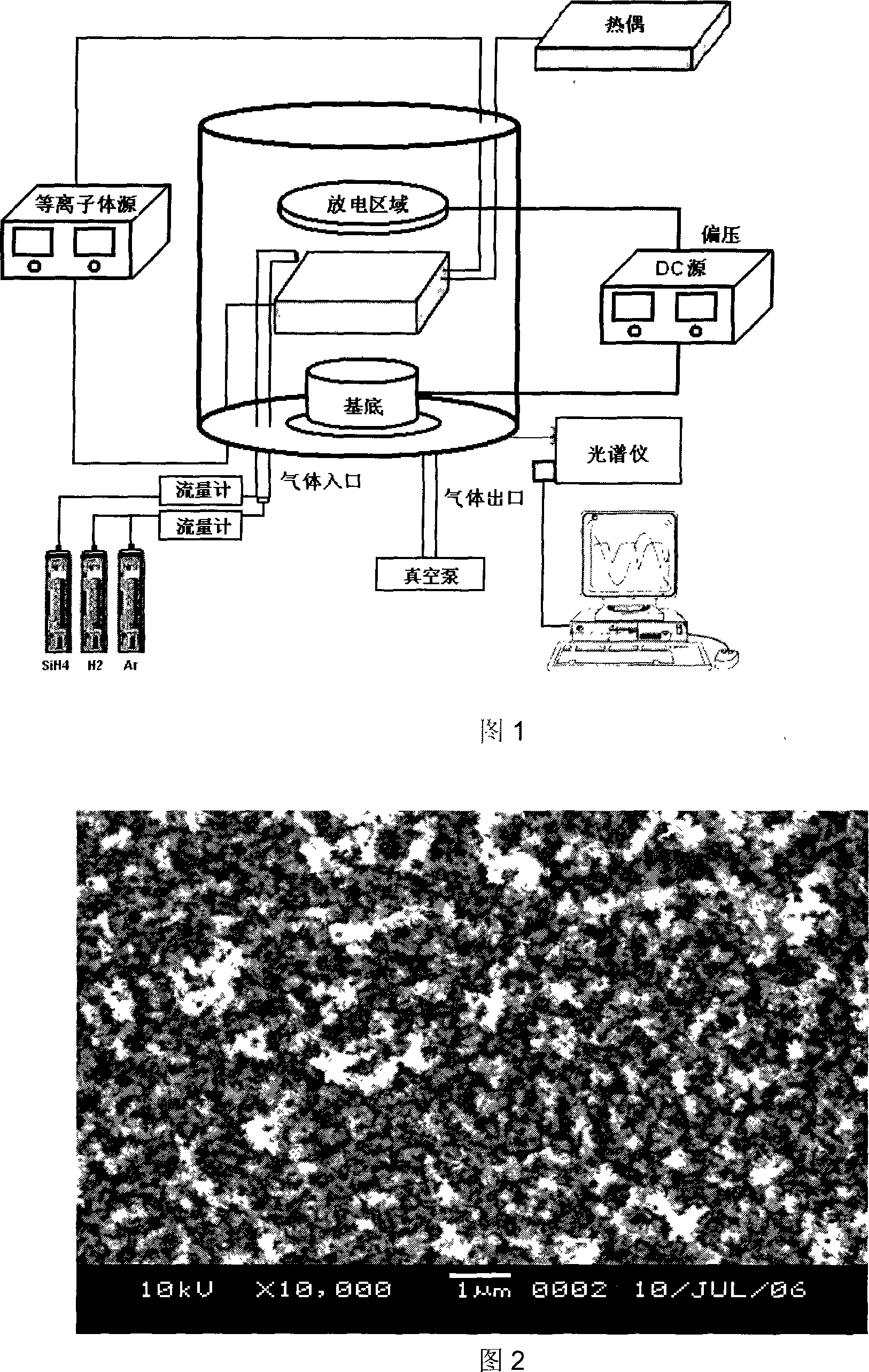

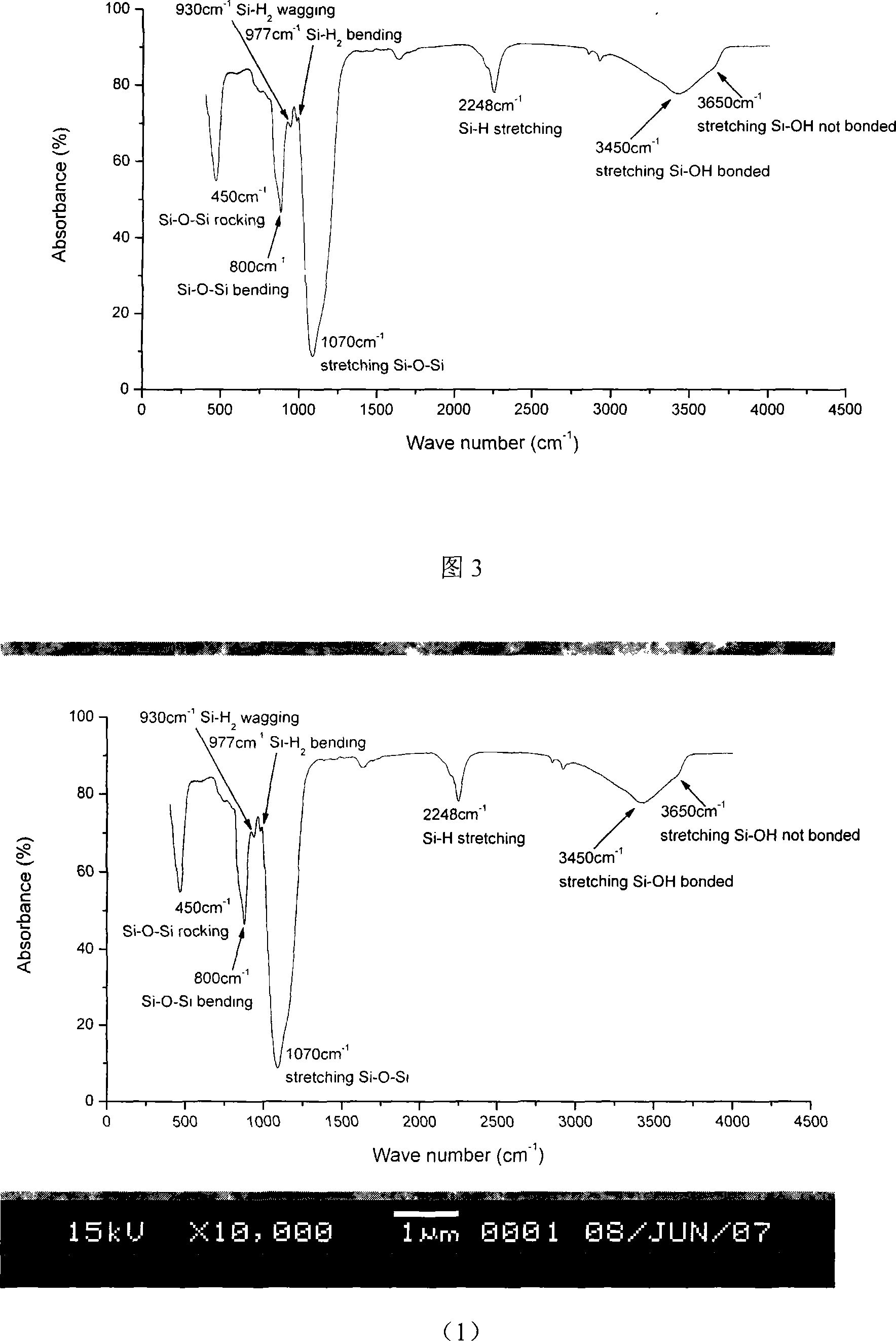

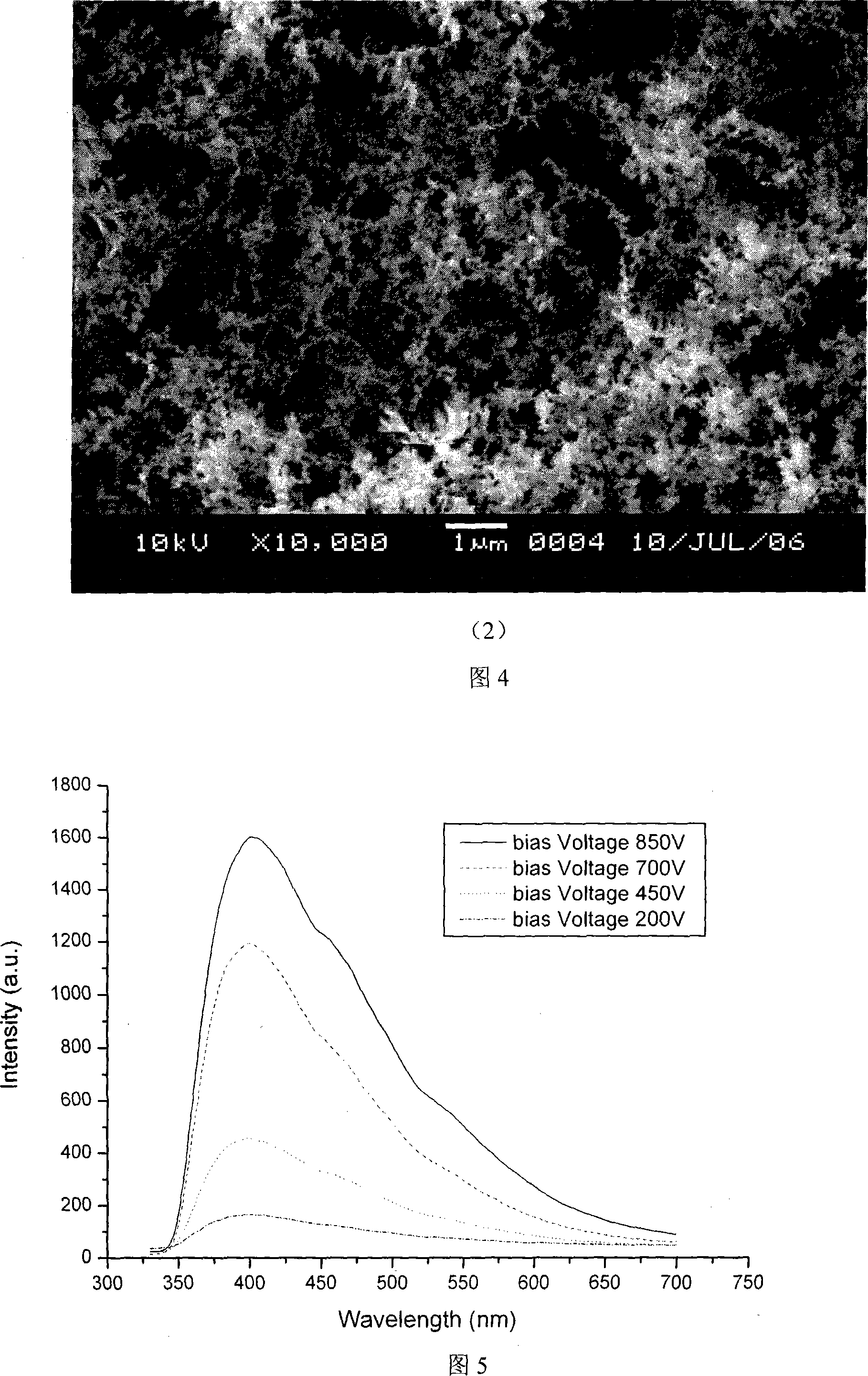

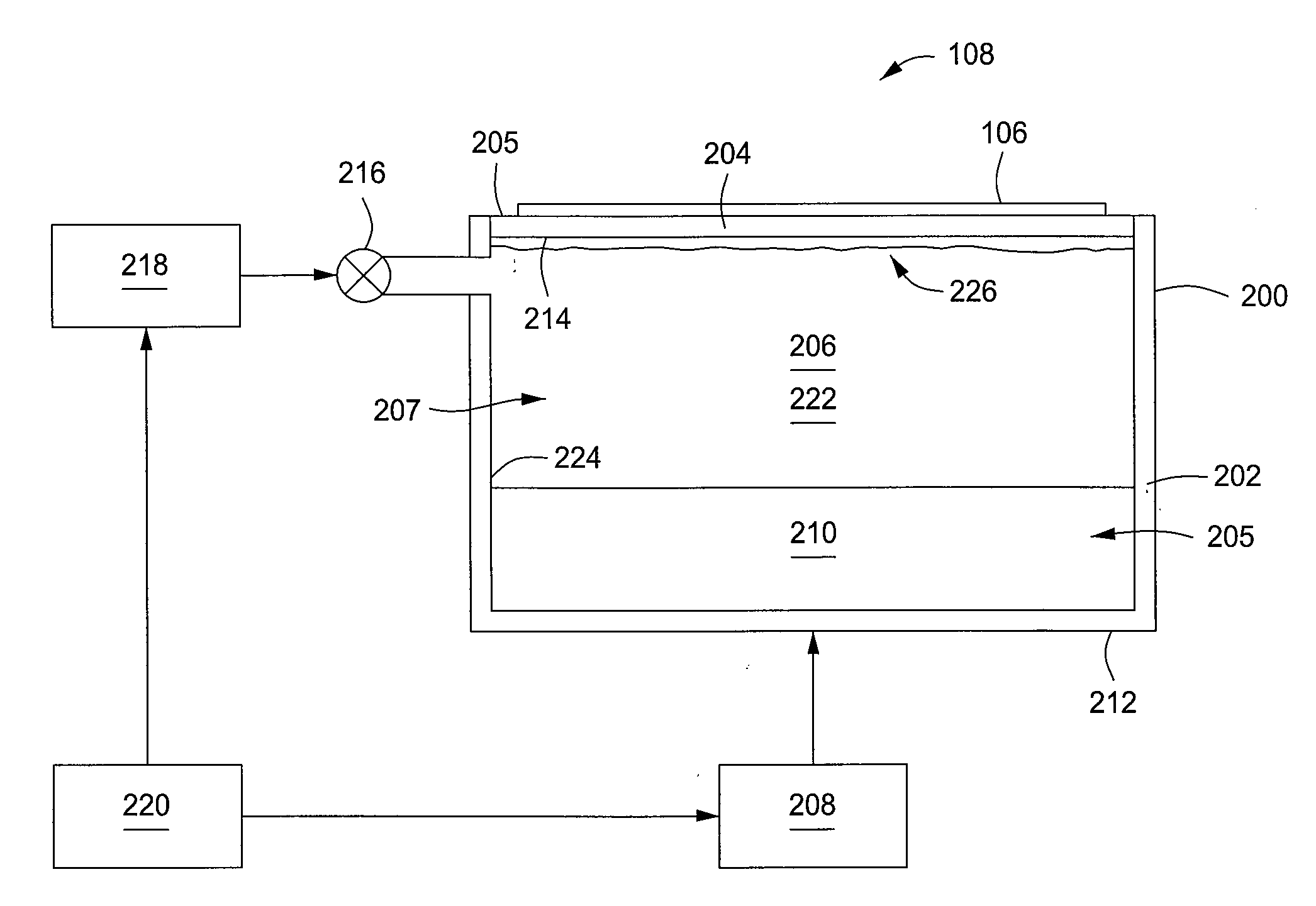

Method for preparing nano silicon-base porous luminescent material by normal pressure plasma gas phase deposition

InactiveCN101122015AChange sizeChange the time to pass through the discharge zoneChemical vapor deposition coatingLuminescent compositionsPlasma generatorWavelength

The invention relates to a method of preparing nano Si-based multi-hole luminescent material by atmospheric pressure plasma vapor deposition, which includes the following procedures: (1) a deposition substrate is arranged below a three-dimensional comb-shaped electrode, and a mechanical pump removes the air in a reaction chamber. (2) the mixed gas is fed through an umbrella washer of a gas inlet, to adjust the flow speed of the mixed gas and control the pressure in a deposition chamber to be near atmospheric pressure. (3)after the pressure in the reaction chamber becomes stable, the pulse bias is added to a basal, to adjust the frequency and power of a plasma generator. (4) after the discharge reaction, the substrate is taken out, and the nano Si-based multi-hole luminescent film is obtained. The method can be used in equipments which has dry environment, simple fitting, convenience in operation, and is near to atmospheric pressure, to change the plasma discharge parameters and pulse bias, and adjust the proportion and flow, etc of monomers and carrier gases, which can obtain high quality nano Si-based multi-hole luminescent films with different grain size, hole structures, components and film thicknesses, and provides adjustable luminescence radiation wave length and improved luminescence efficiency.

Owner:DONGHUA UNIV

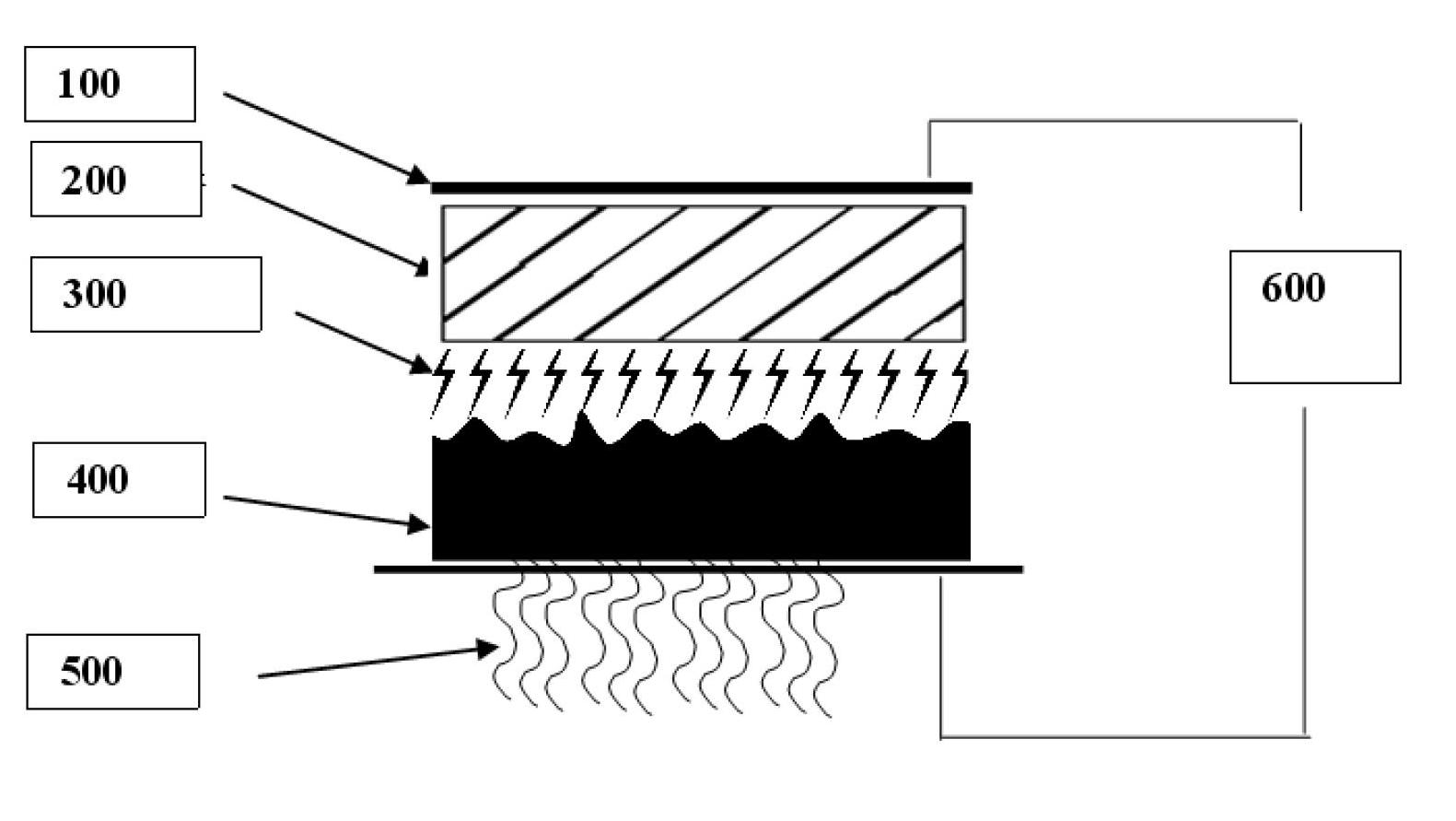

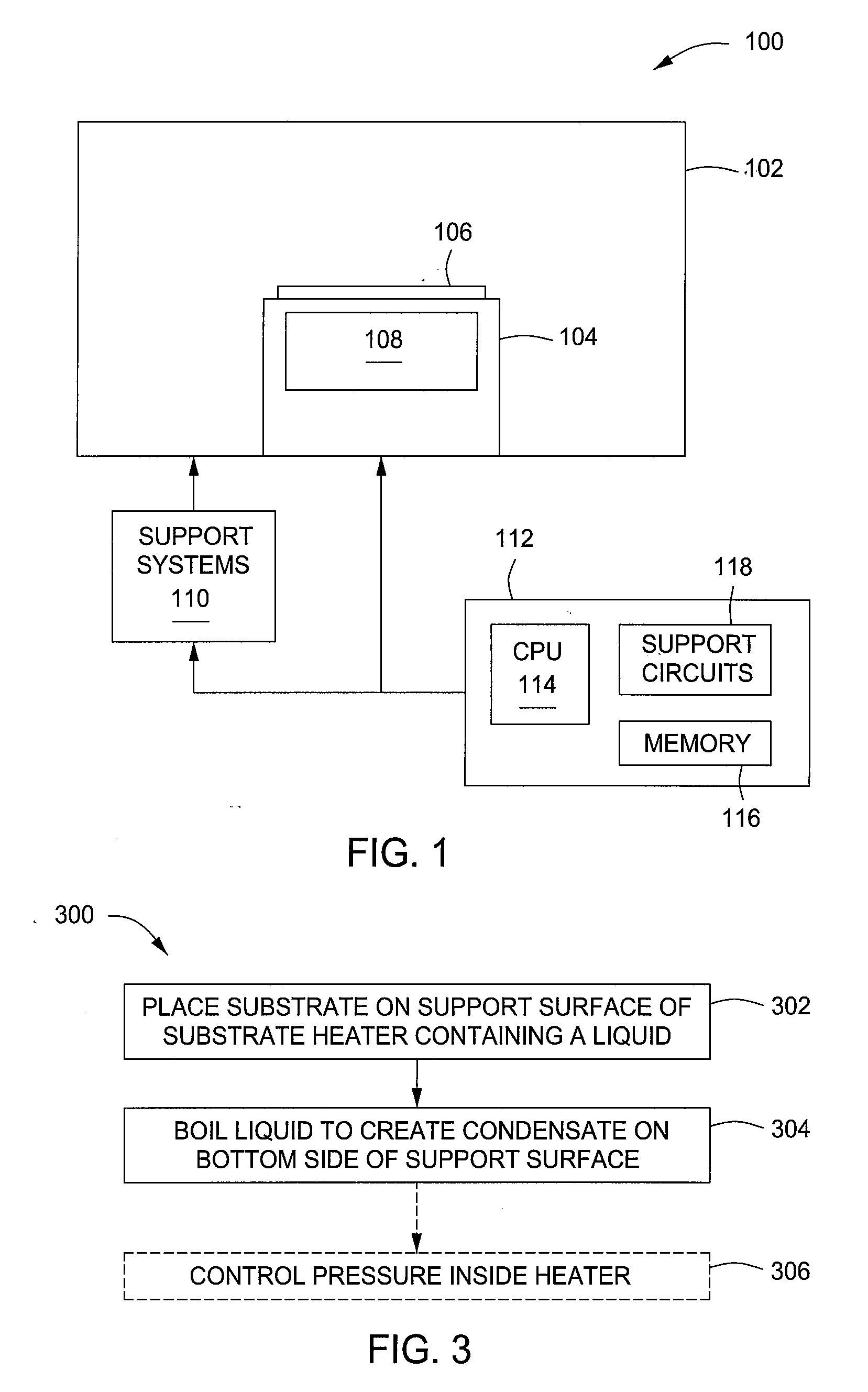

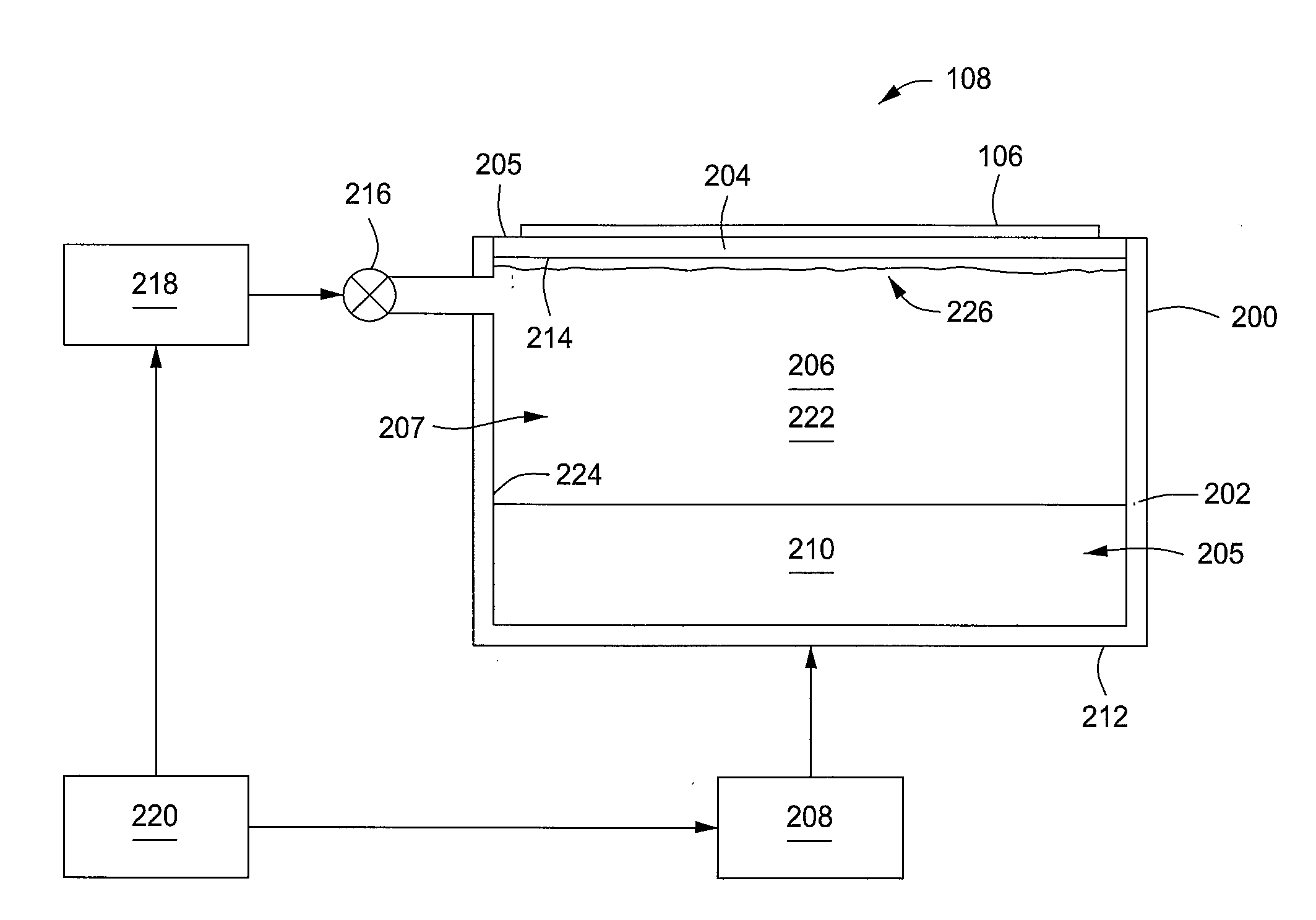

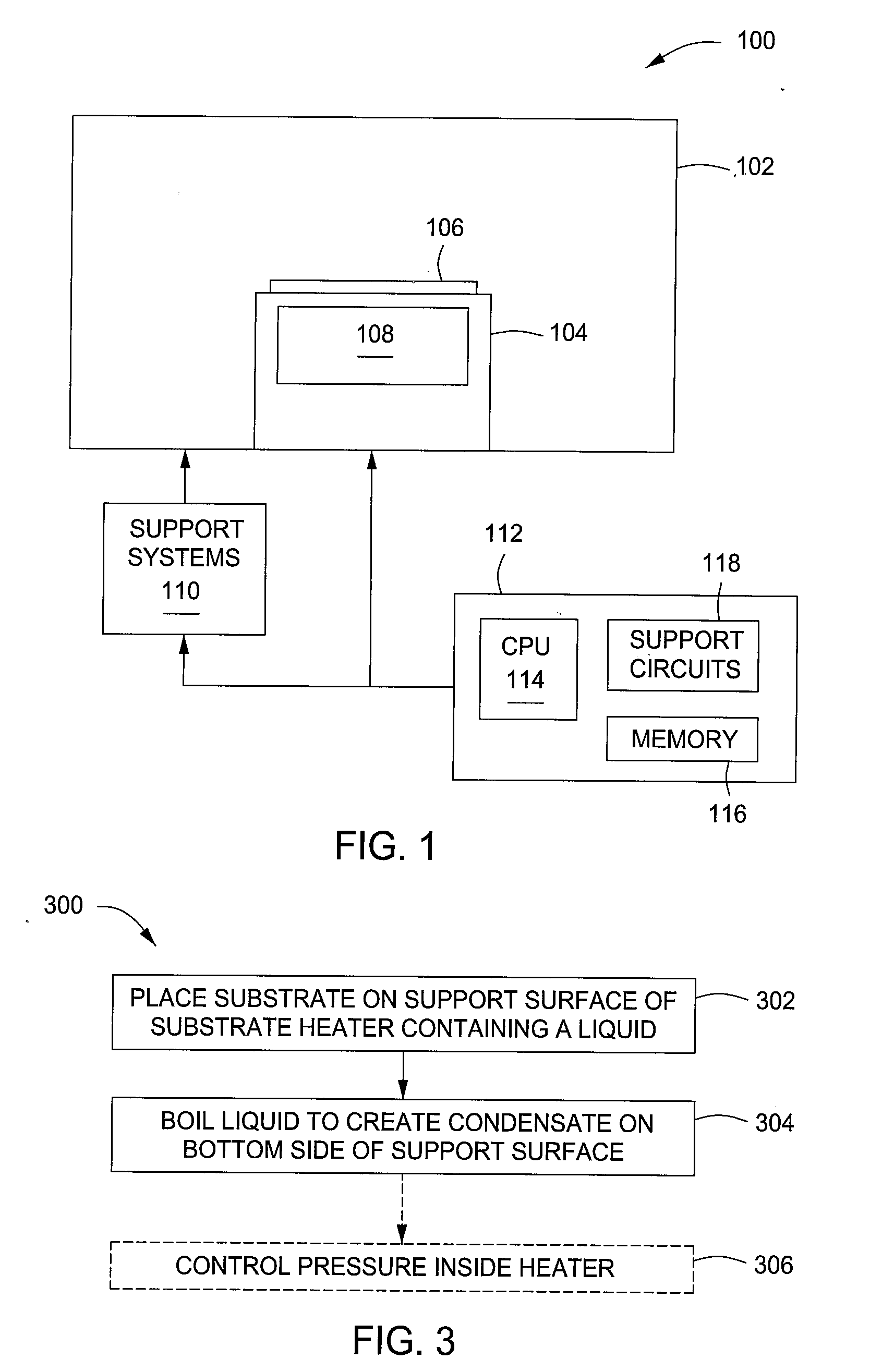

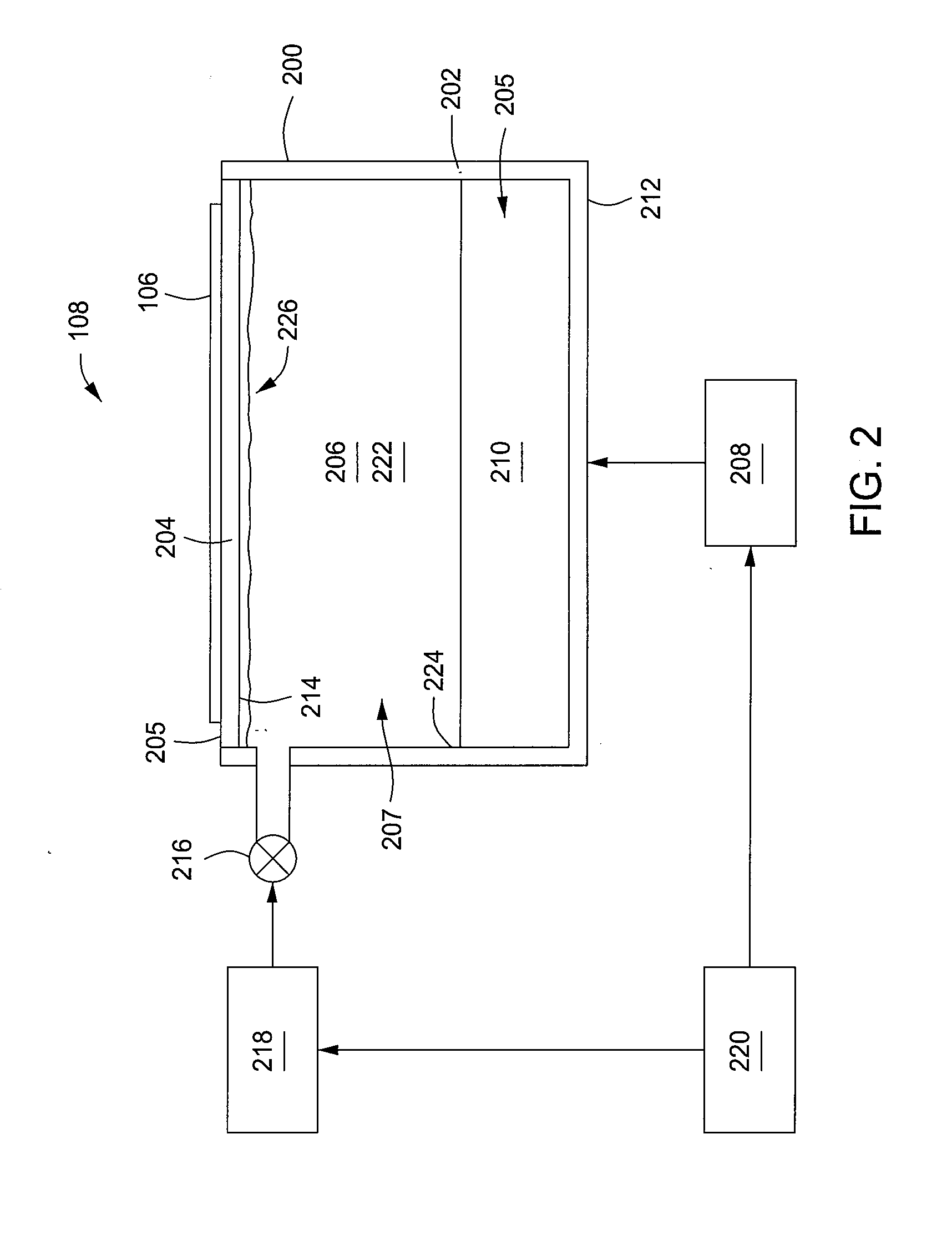

Method and apparatus for heating a substrate

InactiveUS20080142208A1Control pressureControl energyDrying solid materials with heatSemiconductor/solid-state device manufacturingEngineeringPartial filling

A method and apparatus for heating a substrate is provided herein. In one embodiment, a substrate heater includes a vessel having an upper member including a top surface for supporting a substrate thereon; a liquid disposed within and partially filling the vessel; and a heat source for providing sufficient heat to the liquid to boil the liquid. Optionally, a pressure controller for regulating the pressure within the vessel may be provided. The substrate is heated by first placing the substrate on the support surface of the vessel of the substrate heater. The liquid contained in the vessel is then boiled. As the liquid is boiling, a uniform film of heated condensation is deposited on a bottom side of the support surface. The heated condensation heats the support surface which in turn, heats the substrate.

Owner:APPLIED MATERIALS INC

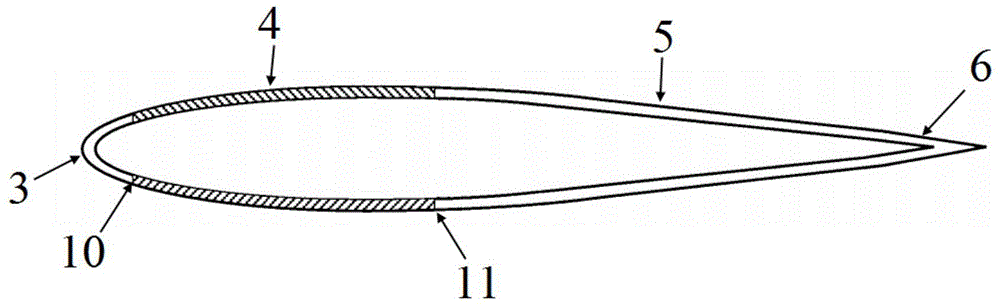

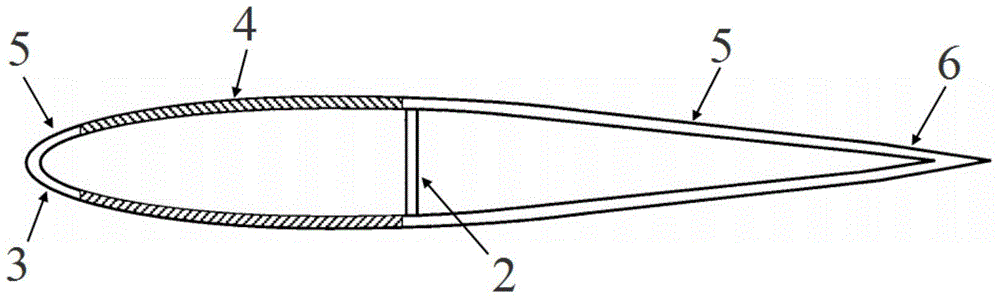

Piezoelectric composite material helicopter blade structure and control method thereof

InactiveCN104590558AImprove performanceExtended service lifeAircraft assemblyRotocraftElectricityEngineering

The invention discloses a piezoelectric composite material helicopter blade structure and a control method thereof. A piezoelectric composite material is embedded into a composite material lamination structure of a rotor blade. An analysis model is established and is capable of accurately describing the motion rule of the rotor blade based on a structure model, an aerodynamic force model, a piezoelectric composite material model and the like, and further accurately calculates the dynamics characteristics of the rotor blade. According to the control method, a controller is employed for controlling the rotor blade, a Kalman observer is employed for obtaining rotor blade data under the condition of white noise interference, and the rotor blade data is taken as input variable for controlling, and further by using the controller to control the input voltage of the piezoelectric composite material, the purpose of controlling blade dynamics response and deformation is finally realized. The provided model establishing method and the control method have relatively high versatility and accuracy, help to accurately obtain dynamics characteristics of the helicopter rotor blade, and are high in control efficiency.

Owner:HUNAN UNIV

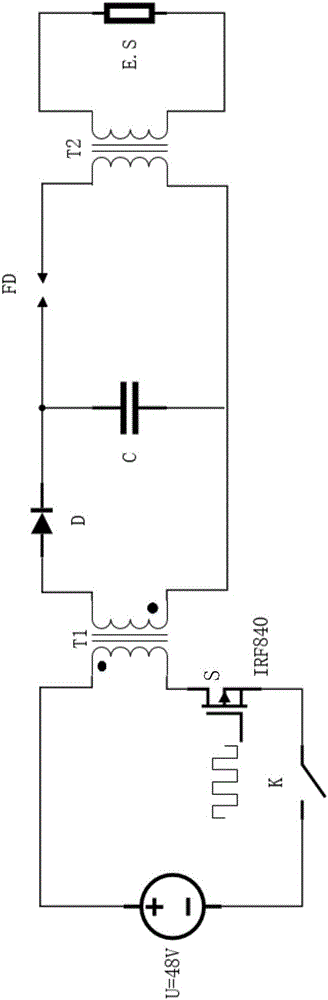

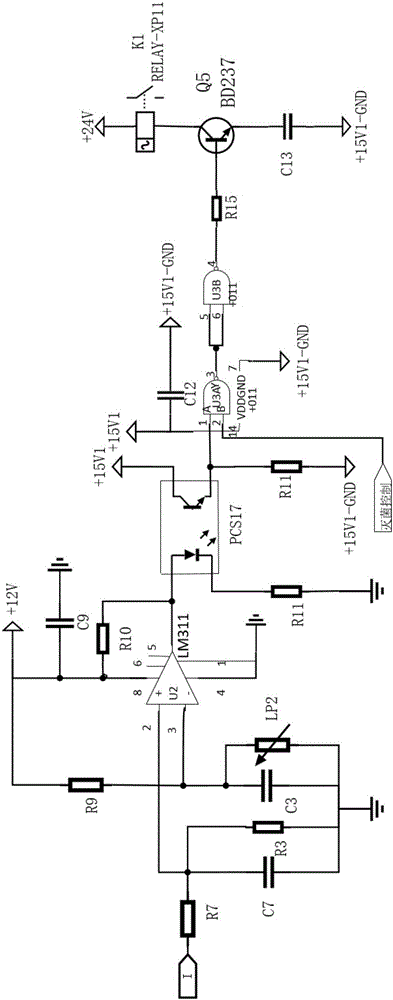

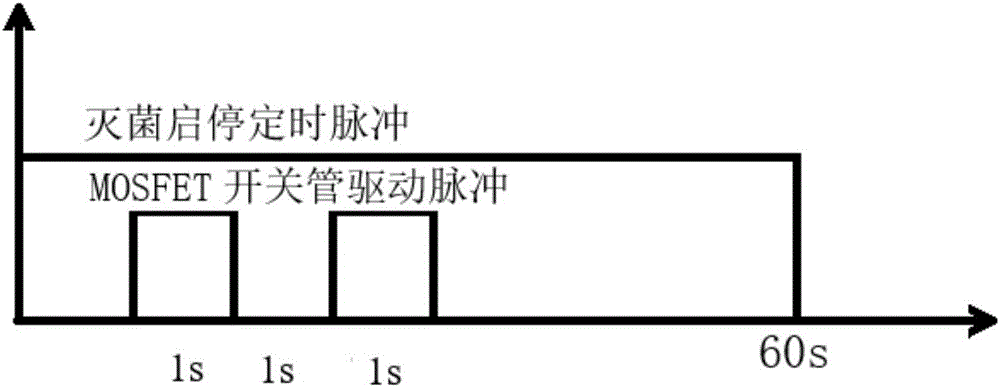

High-frequency and high-voltage pulse generator for sterilizing

InactiveCN105703659AControl energyWon't changeFood preservationPower conversion systemsCapacitanceMOSFET

A high-frequency and high-voltage pulse generator for sterilization relates to a pulse generator. A control circuit and a pulse generating circuit are provided; the control circuit is provided with a voltage comparator, a triode, a first NAND gate, a second NAND gate, a coupler, and a relay; the pulse generating circuit is provided with a relay normally open switch, MOSFET switching tube, first transformer, second transformer, diode, capacitor, spark arrestor. Based on the traditional high-frequency pulse device, a timer based on NE555 is designed, and DSP is used to digitally process the sterilization signal, so that the interference of the sterilization circuit is greatly reduced. Capacitor charging and discharging is used to obtain high-voltage pulses, so that the output pulse can reach 12-100kV / cm, and the width is controlled at the microsecond level, and the pulse front is controlled at the nanosecond level, which can effectively sterilize and will not change the food composition. ; It can be turned on and off in an instant and has a large flow capacity and reliable operation.

Owner:XIAMEN UNIV

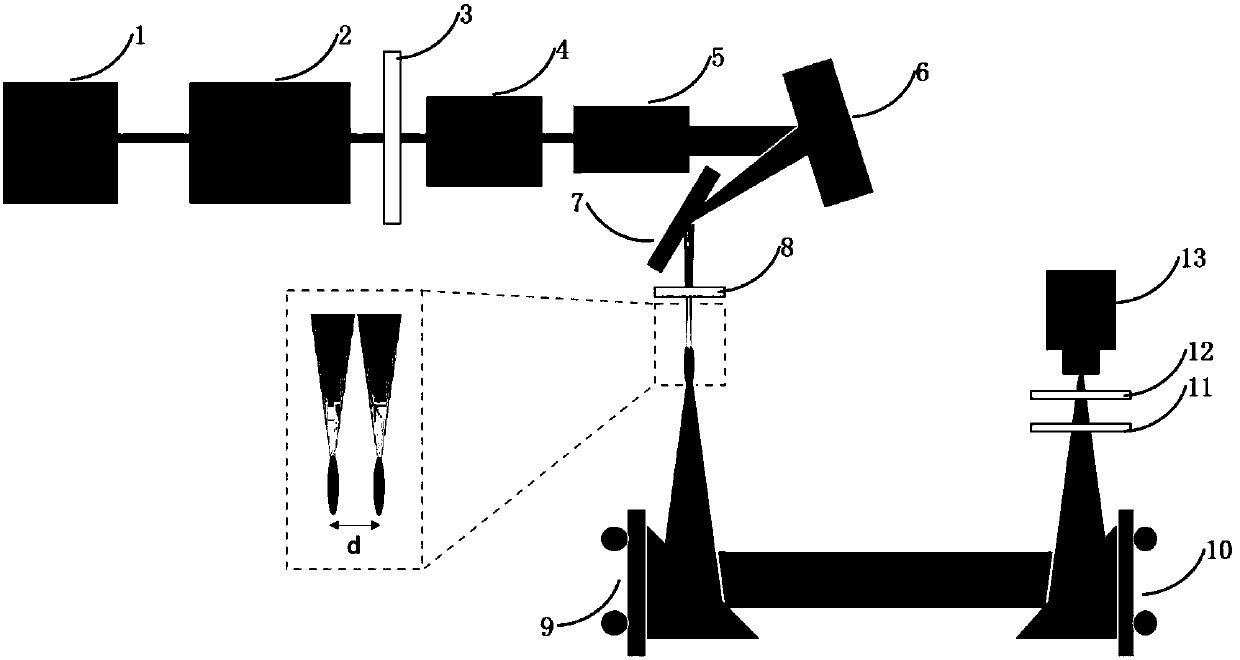

System and method for generating high-intensity terahertz wave by double plasmas with adjustable spacing

The invention discloses a system and method for generating a high-intensity terahertz wave by double plasmas with an adjustable spacing. The system comprises a laser, an optical parametric amplifier,a chopper, a climbing device, a laser beam expander, a spatial light modulator, a mirror, a BBO crystal, a first off-axis parabolic mirror, a second off-axis parabolic mirror, a filter, and a siliconwafer which are set along the light path in order. By adjusting the spacing between phase diagrams of two pairs of Fresnel lens loaded on the spatial light modulator and the rotation angle of the symmetric axis, the system and method can control the spacing and spatial distribution between double plasmas, which not only improves the intensity of the terahertz wave, but also precisely controls theenergy and polarization state of the terahertz wave, fills in the vacancy in the technical field of high-intensity terahertz wave generation, and has strong scientific research and practical application value. The system has the advantages of simple structure, low construction cost, easy maintenance, high stability. The generated terahertz wave has stronger energy and wider spectrum, and can facilitate spectrum measurement.

Owner:CAPITAL NORMAL UNIVERSITY

Traditional Chinese medicine for treating diabetes and preventing and treating diabetic complications

InactiveCN110478443AImprove viscera functionEnhance viscera functionAntipyreticMetabolism disorderSalvia miltiorrhizaDiabetic complication

The invention relates to a traditional Chinese medicine, specifically to a traditional Chinese medicine for treating diabetes and preventing and treating diabetic complications. The traditional Chinese medicine is characterized by being prepared from the following medicinal materials (by mass): 30-50 parts of Radix Rehmanniae Preparata, 20-30 parts of Chinese yam, 20-30 parts of cornus officinalis, 15-20 parts of astragalus membranaceus, 10-15 parts of honeysuckle, 10-15 parts of cape jasmine, 15-20 parts of red sage root, 10-15 parts of radix scrophulariae, 15-20 parts of schisandra chinensis, 15-20 parts of ligustrum lucidum, 20-30 parts of radix ophiopogonis, 10-15 parts of reed rhizome and 10-15 parts of radix trichosanthis. The traditional Chinese medicine has effects of tonifying kidney and spleen, clearing heat and moistening lung, nourishing yin and increasing fluids, promoting blood circulation to remove blood stasis, conditioning five internal organs, recovering dysregulatedviscera function and improving reduced viscera function to fundamentally treat diabetes, and is suitable for treatment of diabetes and complications thereof. The traditional Chinese medicine is convenient and simple to take and has good effects. After a patient takes the medicine, blood sugar and urine sugar are effectively controlled, and energy, physical strength and other functions are recovered satisfactorily. The diabetes is effectively prevented and controlled through the comprehensive effects of various traditional Chinese medicines, and the medicine also can calm the liver, clear heat,harmonize blood, tonify qi, clear heat, moisten the lung, nourish yin, increase fluids and reinforce the kidney.

Owner:王茹

Multi-layer nano-film suitable for titanium alloy surface and preparation method thereof

ActiveCN110218971AHigh hardnessExcellent friction and wear resistanceVacuum evaporation coatingSputtering coatingTitanium nitrideTitanium carbide

The invention provides a multi-layer nano-film suitable for a titanium alloy surface and a preparation method thereof. The multi-layer film comprises a titanium nitride film layer, a titanium carbidefilm layer, a titanium nitride film layer, a titanium carbide film layer and an aluminum-doped diamond-like film layer from the titanium alloy surface to outside in sequence. The preparation method ofthe multi-layer nano-film comprises the steps of conducting cleaning and vacuumizing on a titanium alloy base body, conducting sputtering deposition to form the titanium nitride film layer, conducting sputtering deposition to form the titanium carbide film layer, conducting repeated deposition to form one titanium nitride film layer and the titanium carbide film layer respectively, preparing onealuminum-doped diamond-like film layer, and finally conducting sputtering after-treatment. Compared with the prior art, the preparation method has the advantages that the rate of finished multi-layerfilm products is high, and the preparation process is convenient, quick and efficient; the bonding force between the prepared film and the prepared base body and between the films is large, and the internal stress is small; and the multi-layer nano-film has good frictional wear resistance and is applicable to the high-intensity operation fields such as aerospace and geological drilling.

Owner:CHONGQING UNIV OF ARTS & SCI

Coarse aggregate void test equipment

ActiveCN101750271AReduce breakageImprove flatnessMaterial testing goodsPermeability/surface area analysisFree fallingReducer

The invention provides coarse aggregate void test equipment comprising a stand part, a base part and a controller. In the stand part, a stand is provided with a magnet, a motor and a speed reducer, and is further provided with a hammer lifting chain, a guide rail and a drop hammer guide rod; a slide block is sleeved on the guide rail, one side of the slide block is connected with the hammer lifting chain and the other side fixes a force transmission rod; a hammer lifting tongue board is fixed above the slide block and controls a drop hammer to move upwards to the set height along the drop hammer guide rod; the drop hammer can make free fall, and the lower end of the drop hammer is provided with a detachable hammer head; in the base part, the stand is fixed on the base, a graduator is fixed in the base, a servomotor on the graduator extends out of the top of the base and corresponds to the position of the force transmission rod, the base is provided with a rolling disc controlled by the graduator, and the rolling disc is provided with a fixed base and a test bucket; the drop hammer guide rod and the drop hammer can swing around a vertical shaft of the guide rail till corresponding to the center of the test bucket under the control of the magnet; and the controller is used for controlling the starting and the stopping of a counter, the switching on and off of a motor and the swinging of the drop hammer.

Owner:交通部公路科学研究院

Application of femtosecond laser in pure titanium implantation material surface treatment

InactiveCN101264551BGood biocompatibilityTightly boundTeeth fillingBone implantTitanium surfaceLaser processing

The invention relates to an application of femto-second laser in the surface treatment of the pure titanium implanting material, belonging to the technical field of application of laser in the material surface treatment. The application method comprises the following steps: in the air, the femto-laser impulse is in normal incidence and focused right on the top of the lump pure titanium implantingmaterial which is ground and dried, a light spot with a radius of 5um is formed at the surface of the pure titanium implanting material, the femto-laser processing parameters are defined as follows: the impulse repeat frequency is 1 kHz, the single impulse power is from 5 to 200 micro joule, the impulse width is 50 femtosecond, the impulse center wavelength is 800 nanometer, the line interval of the laser processing is between 10 to 100 micron, the laser scanning speed is between 0.5 to 1.2 mm / sec, the laser polarization direction is regulated to be parallel to the laser scanning direction, the femto-laser scans the whole surface of the pure titanium implanting material, a titanium based biomedical material with an oxide layer generated on the titanium surface, even roughness, and a pattern of strips, holes, grooves or the combined pattern thereof formed on the pure titanium implanting material is made.

Owner:HEBEI UNIV OF TECH +2

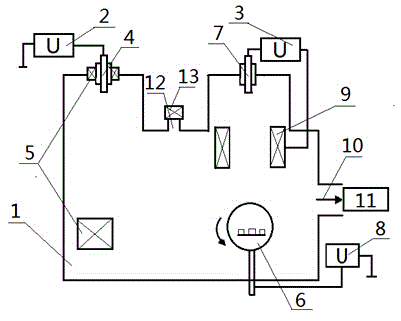

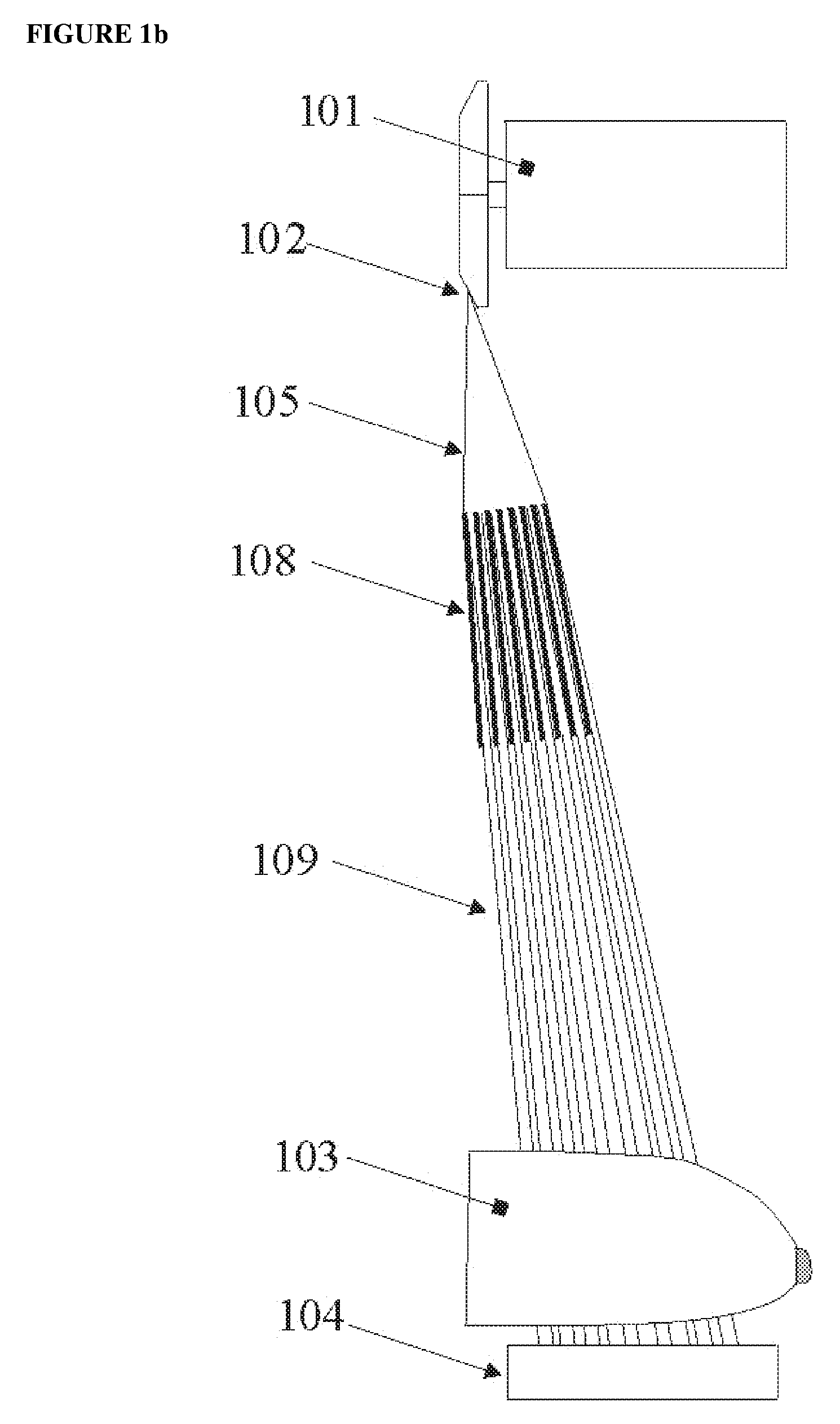

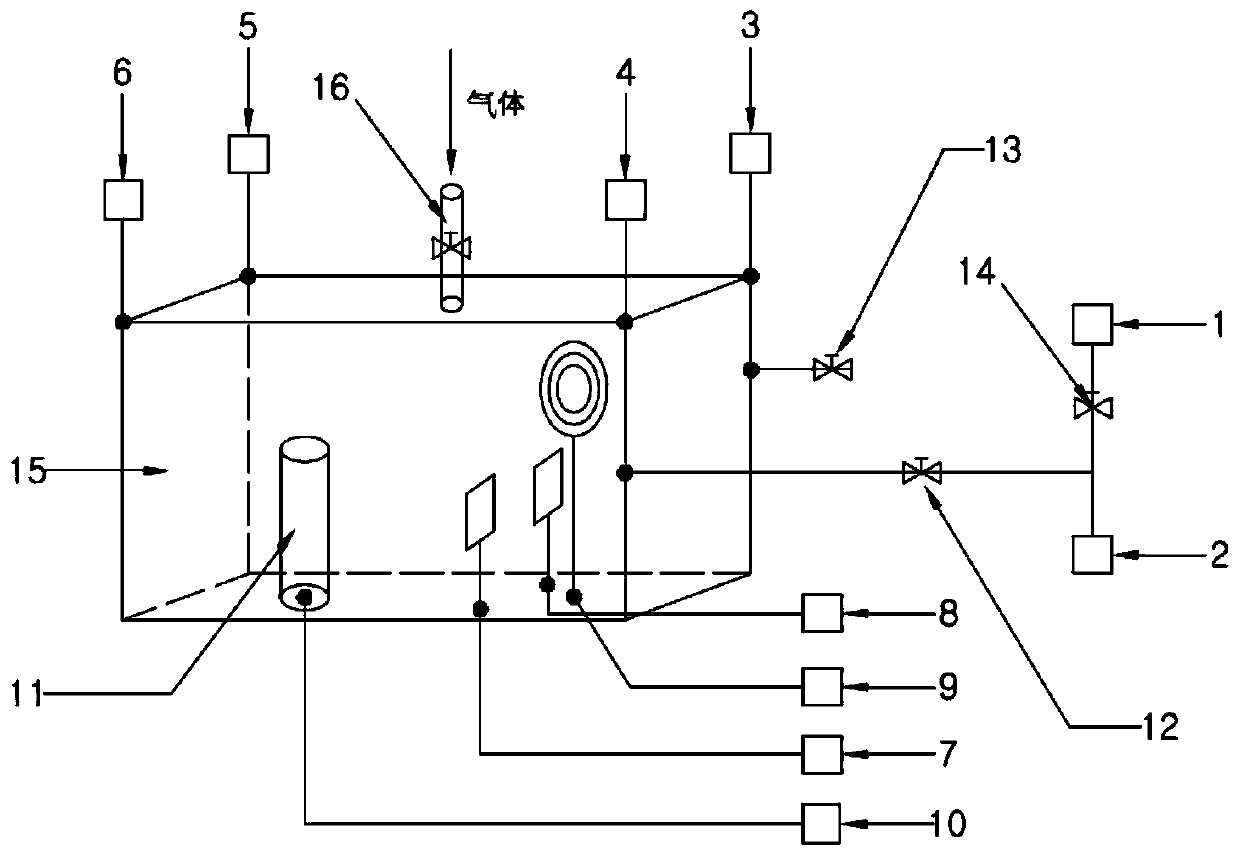

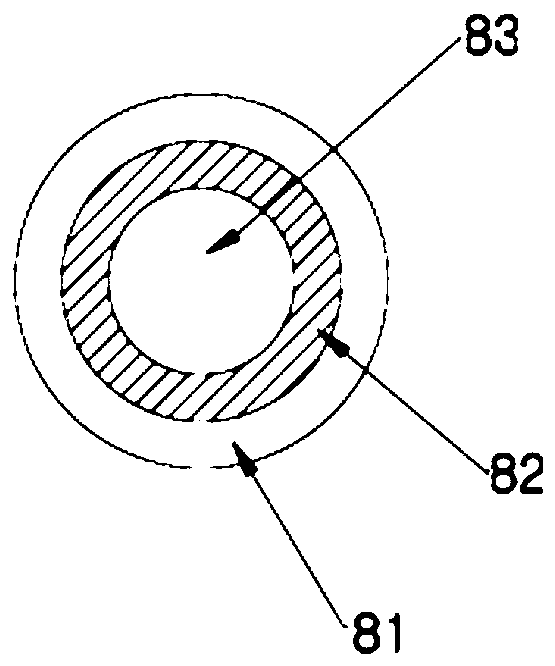

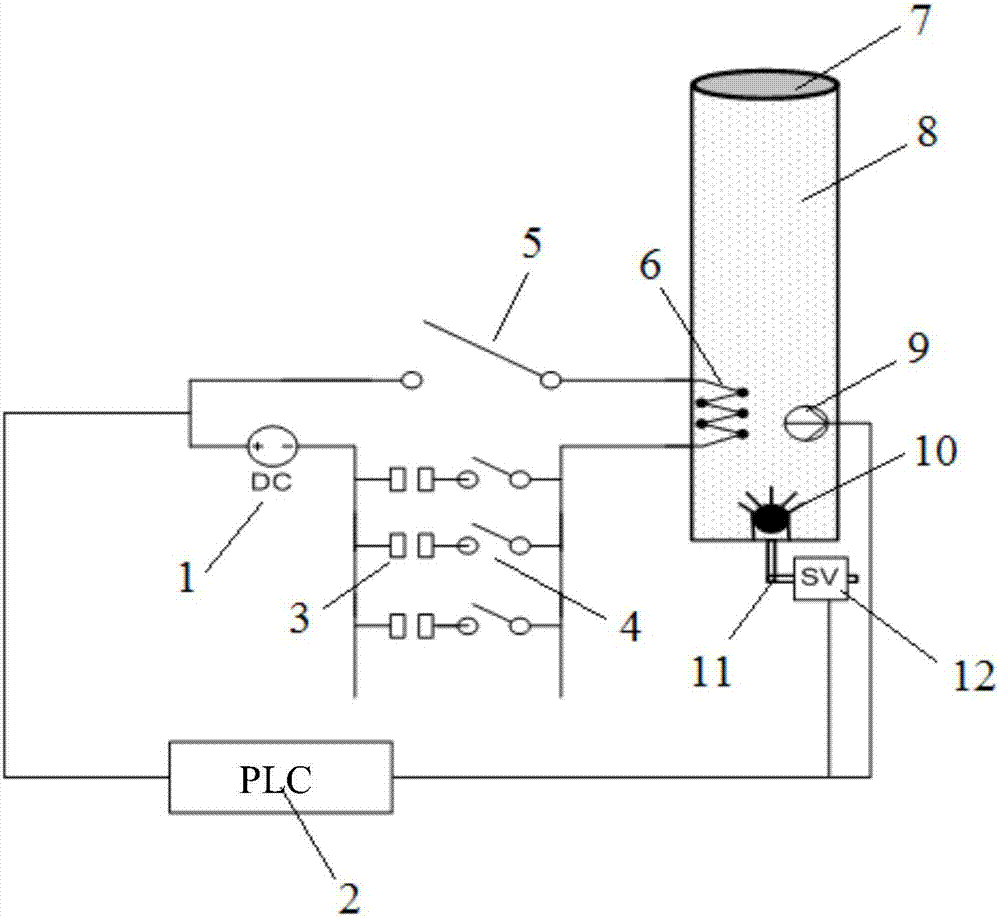

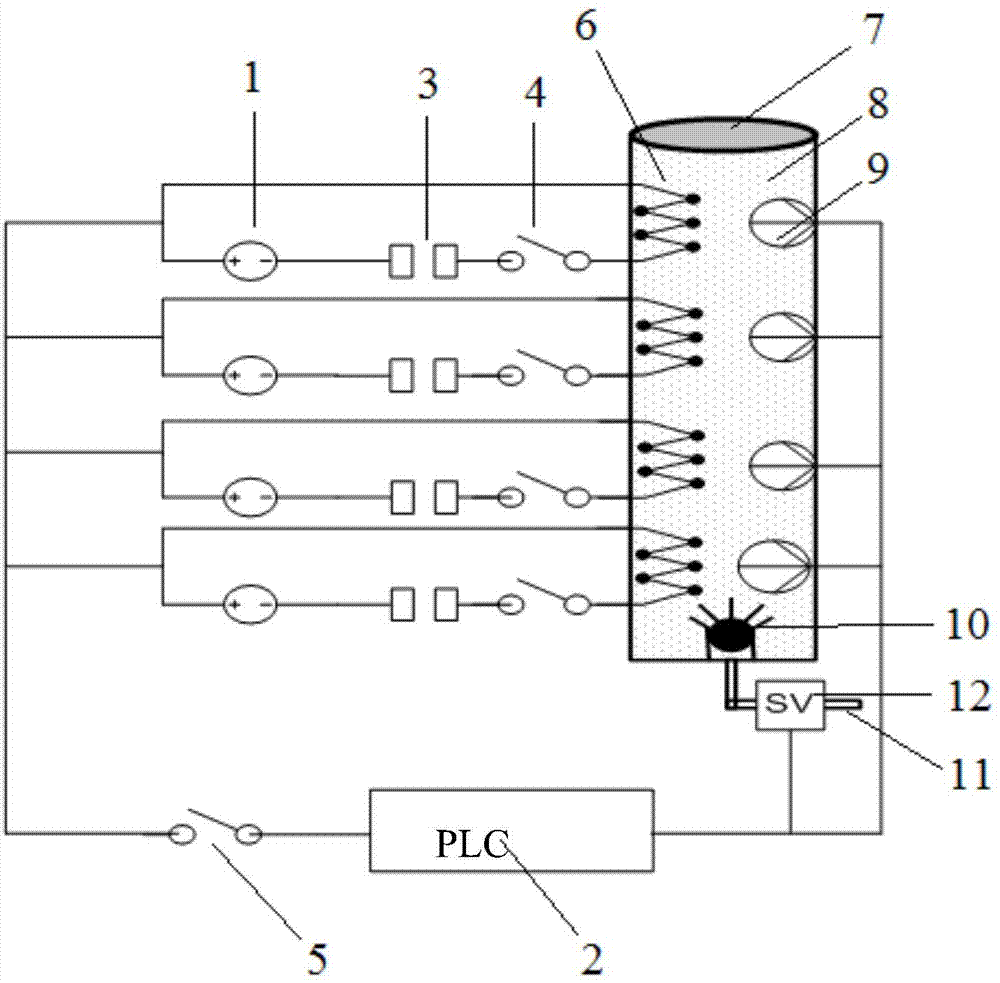

Device for testing gas/dust combustion and explosion performances with super-capacitor

The invention relates to a device for testing gas / dust combustion and explosion performances with a super-capacitor. The device comprises a control end and a testing end, wherein the control end comprises a switch power supply (1), the super-capacitor (3), a unit control switch (4), a main power control switch (5) and a master controller used PLC control system (2) that are connected with one another in series; the testing end comprises an explosive combustion reaction observation tube (8), an electric heating wire (6), a powder / gas jet dispersion device (10), an infrared thermometer (9) and arelease top cover (7); the electric heating wire (6), the powder / gas jet dispersion device (10) and the infrared thermometer (9) are arranged in the observation tube; the release top cover (7) coversthe top of the explosive combustion reaction observation tube (8); the electric heating wire (6) is connected with the control end. Compared with the prior art, the device has the advantages of beingreliable in safety, variable in combination of equipment and easy to disassemble and having the performances of gas observation and dust combustion and explosion; therefore, the device is suitable for various simulations, tests and demonstrations of gas and dust combustion and explosion performances.

Owner:SHANGHAI RES INST OF CHEM IND +1

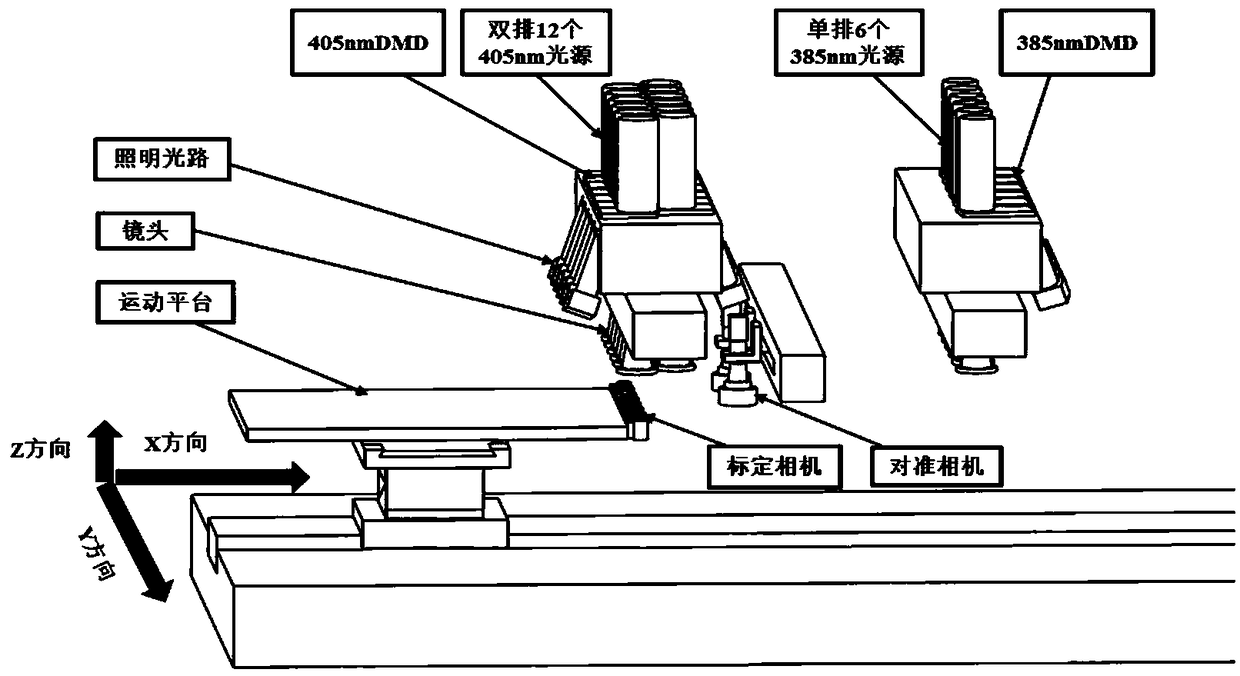

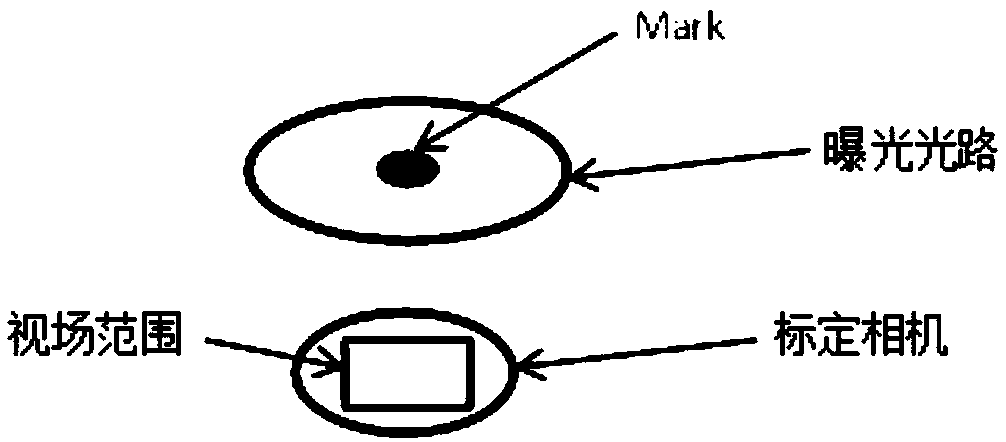

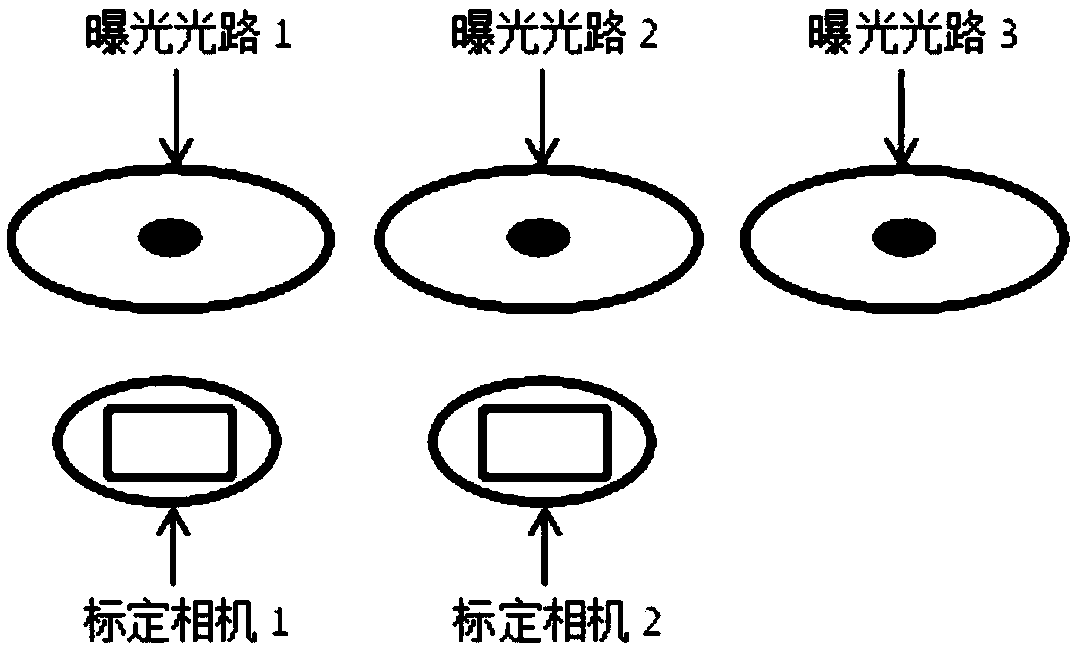

Multi-band optical exposure system, device and method

ActiveCN109407473AImprove work efficiencyExtended service lifePhotomechanical exposure apparatusMicrolithography exposure apparatusMulti bandChemical reaction

The invention discloses a multi-band optical exposure system, device and method, and belongs to the technical field of printed circuit boards. The multi-band optical exposure system, device and methodseparate light sources of different wavelengths, the light sources of the different wavelengths are matched with corresponding optical devices, and the service life of the optical devices is prolonged. Exposure subsystems matched with the light sources of the different wavelengths are arranged at different positions of the multi-band optical exposure system in the scanning direction, so that thedifferent exposure subsystems can achieve the effect that photochemical reactions at different depths of a material or photochemical reactions with different photoinitiators have certain time intervals, the photochemical reactions are more sufficient, and a composite photosensitive material has better graphic gloss and higher definition. At the same time, the overall capacity and the working efficiency of the exposure device are improved.

Owner:JIANGSU YSPHOTECH INTERGRATED CIRCUIT EQUIP CO LTD

Method and apparatus for heating a substrate

InactiveUS20080145038A1Control pressureControl energyDrying solid materials with heatSemiconductor/solid-state device manufacturingEngineeringPartial filling

A method and apparatus for heating a substrate is provided herein. In one embodiment, a substrate heater includes a vessel having an upper member including a top surface for supporting a substrate thereon; a liquid disposed within and partially filling the vessel; and a heat source for providing sufficient heat to the liquid to boil the liquid. Optionally, a pressure controller for regulating the pressure within the vessel may be provided. The substrate is heated by first placing the substrate on the support surface of the vessel of the substrate heater. The liquid contained in the vessel is then boiled. As the liquid is boiling, a uniform film of heated condensation is deposited on a bottom side of the support surface. The heated condensation heats the support surface which in turn, heats the substrate.

Owner:APPLIED MATERIALS INC

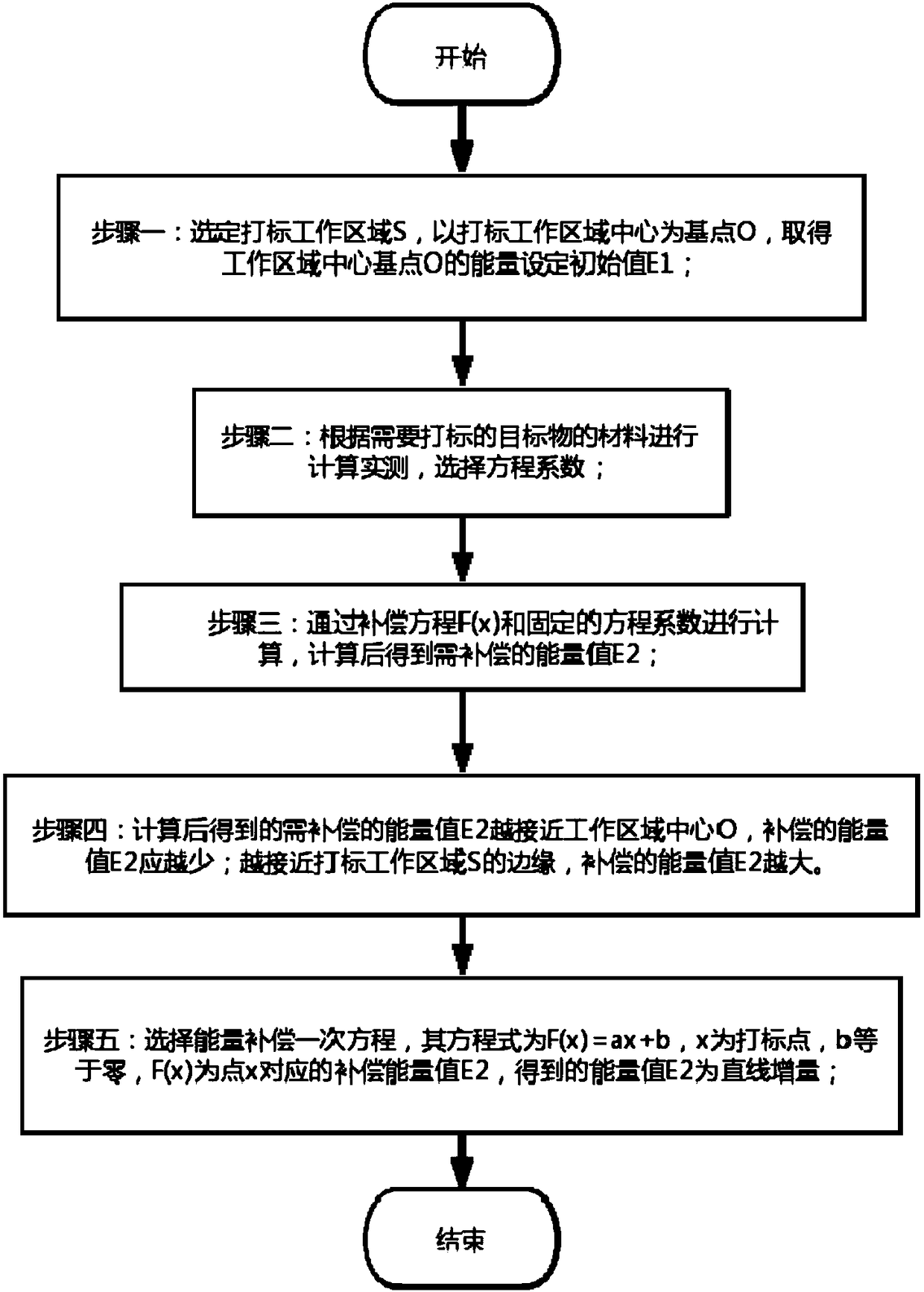

Energy enhancement optimization method for marking edge of laser equipment

The invention provides an energy enhancement optimization method for a marking edge of laser equipment. The method includes the steps that firstly, a marking work area S is selected, and with the center of the marking work area as a base point O, an energy setting initial value E1 of the center base point O of the work area is acquired; secondly, calculating and actual measuring are performed according to a material of a target object needing marking, and an equation coefficient is selected; thirdly, calculating is performed through a compensating equation F(x) and the selected equation coefficient, and an energy value E2 needing compensation is obtained after calculating; and fourthly, the closer the energy value E2, needing compensation, obtained after calculating is to the center O of the work area, the less the energy value E2 for compensation should be, and the closer to the edge of the marking work area S, the larger the energy value E2 for compensation should be. According to the energy enhancement optimization method for the marking edge of the laser equipment, directing at the marking feature of a marking machine, that is, the energy for the edge of the marking work area is less than the energy for the center point of the marking area, compensation is performed on the edge energy of the marking work region by using energy compensation, and the marking effect is better.

Owner:GUANGZHOU NEW CKLASER CO LTD

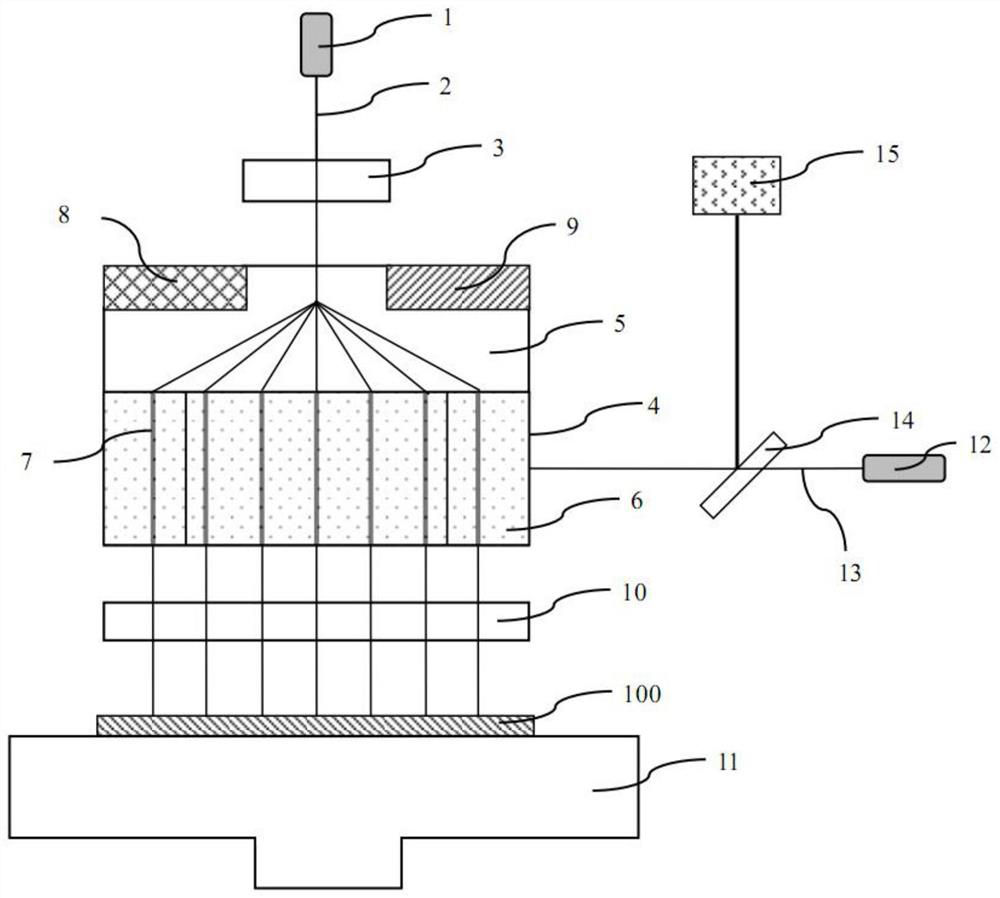

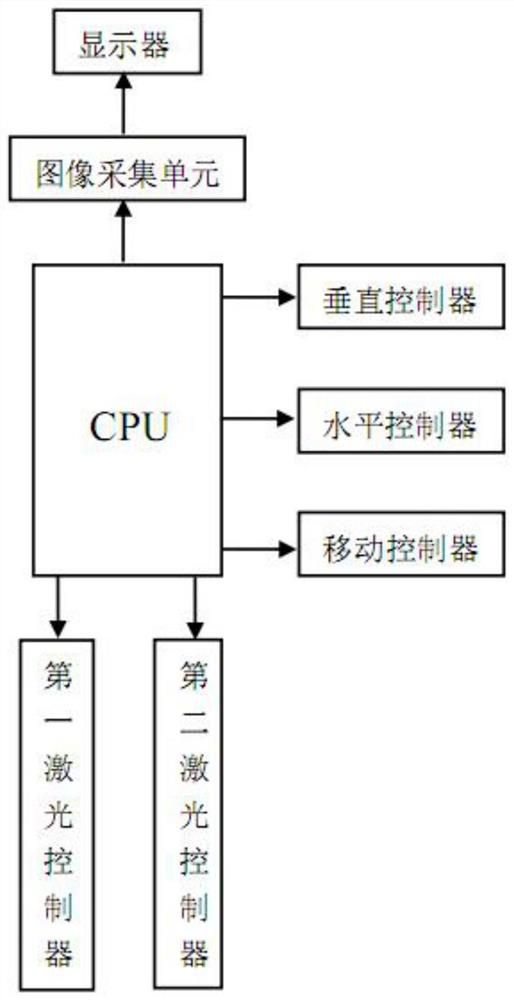

A computer-controlled laser processing device and processing method thereof

ActiveCN109483067BGuaranteed verticalityFlexible Control of SpacingLaser beam welding apparatusLaser processingEnergy control

The invention provides a computer control laser machining device and a machining method thereof. The computer control laser machining device can implement simultaneous cutting of multiple cutting channels and can also ensure the perpendicularity of the cutting channels and flexibly control the distance between the cutting channels. The computer control laser machining device can reduce cracks andfragments to the maximum extent, control energy of a first laser device and control the cutting speed. The computer control laser machining device achieves accurate control to prevent improper cuttingoperation through full computer control.

Owner:ZIBO VOCATIONAL INST

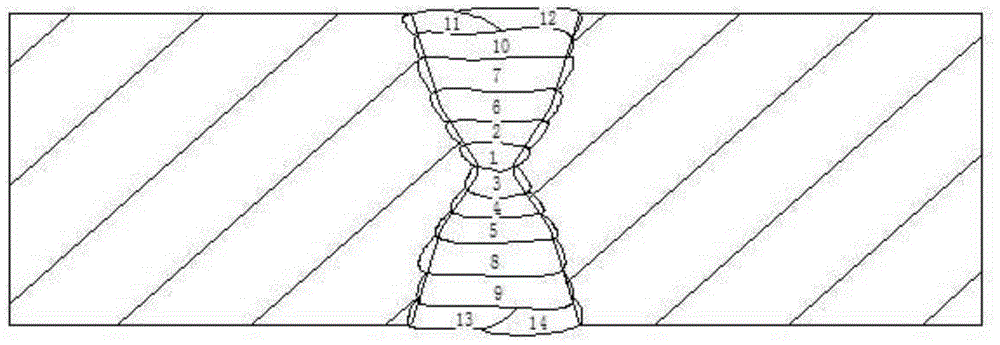

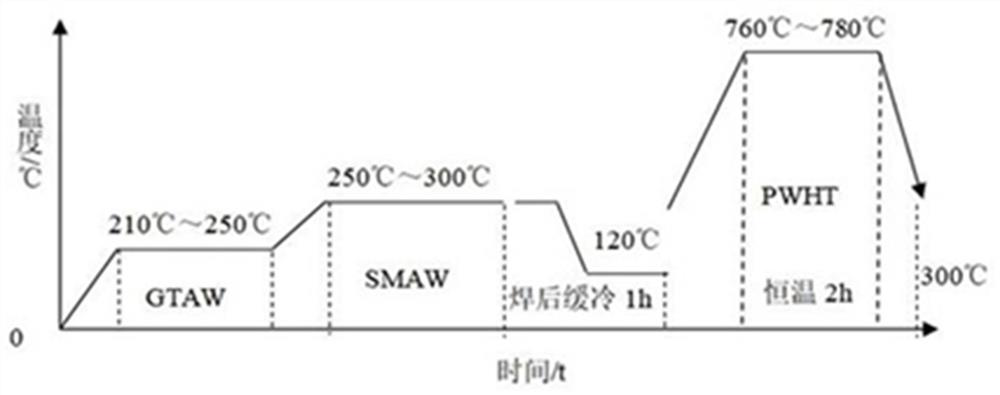

Welding method for thick-wall alloy pipeline of needle coke device

The invention discloses a welding method for a thick-wall alloy pipeline of a needle coke device. The alloy pipeline is made of a 1Cr5Mo material. The welding method comprises the following steps of material selection, groove preparation and joint pairing, preheating before welding, multi-layer and multi-pass welding and heat treatment. According to the welding method, through proper material selection, preparation of a welding groove and multi-layer and multi-pass welding, welding heat input can be reduced, and welding line energy is controlled; in addition, through heat treatment of a rear-layer welding pass on a front layer, grains can be refined, and the comprehensive performance of a welding joint is improved; and during heat treatment after welding, preheating treatment is conducted firstly, austenite is completely converted into martensite, then tempering heat treatment is conducted, the hardness of all areas of the joint can be reduced, the toughness, the deformation capacity and the high-temperature endurance strength of the joint are improved, the internal stress of the joint is eliminated, and welding cracks are greatly reduced.

Owner:CHINA NAT CHEM ENG NO 14 CONSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com