Welding technology for manual argon arc welding of thick plate titanium material

A technology of manual argon arc welding and welding technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of weld mechanical properties, adverse effects of process performance, difficult welding, poor thermal conductivity, etc. The qualified rate of flaw detection, the effect of reducing the difficulty of welding operation and reducing the amount of metal filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

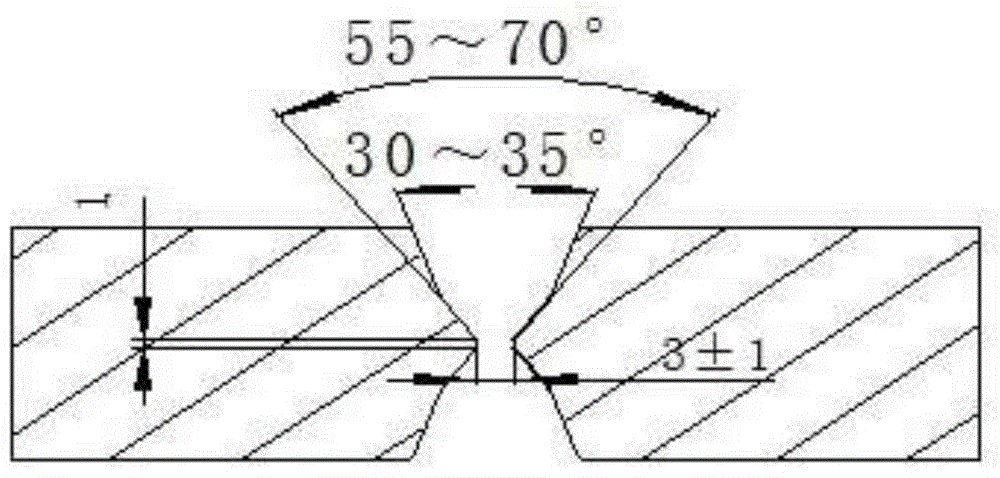

[0020] A 28mm titanium welding process. Design groove form such as Figure 4 As shown, the improved "double V" groove is adopted, the groove angle of the lower section is 60°, the thickness is 3-6mm; the angle of the upper section is 30°, the thickness is 7.5-10.5mm, and the pair gap is 3±1mm. Preparation before welding:

[0021] (1) Clean the welding wire, the surface of the groove, and the 20mm range on both sides of the groove. Alloy cutter head, stainless steel wire brush, and ethanol can be selected according to the degree of surface pollution. It is strictly forbidden to use stainless steel wire wheels to weld the weld. to clean up.

[0022] (2) Before welding, use ethanol and silk cloth to clean the groove and welding wire. Do not touch it directly with your hands in the future, and weld in time. If it has not been welded for a long time, it should be cleaned again. The cleaned welding wire should not be thrown on the ground at will to prevent it contamination, it sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com