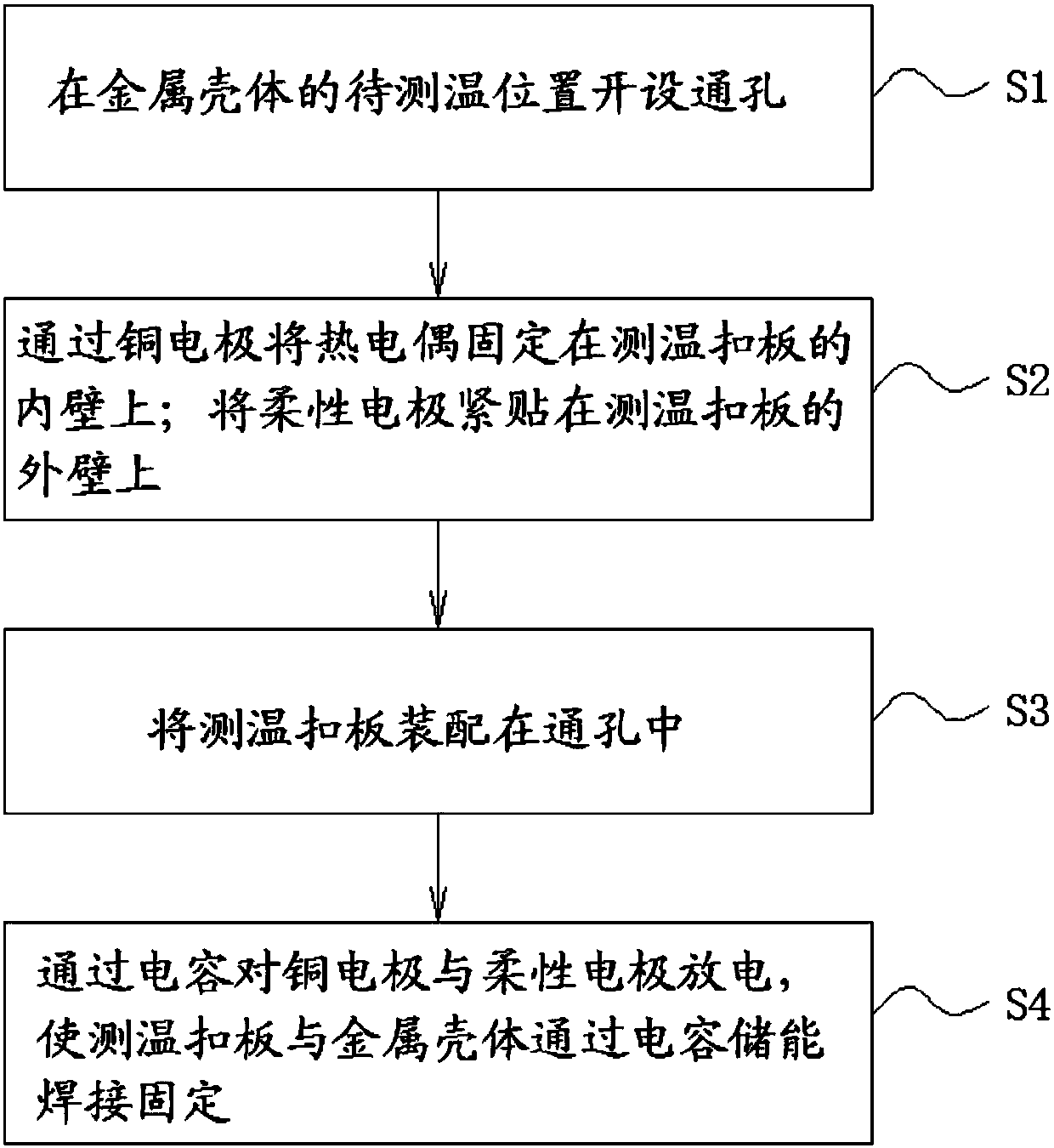

Capacitor energy storage welding forming method for cone metal shell and thermocouples

A metal shell and capacitor energy storage technology, which is applied in energy storage discharge welding, welding power supply, welding equipment, etc., can solve problems such as the inability to guarantee the stability of thermocouple welding quality, difficult welding, and small operating space for metal shells. , to achieve the effect of solving the difficult problem of welding, reducing the difficulty of operation and improving the stability of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

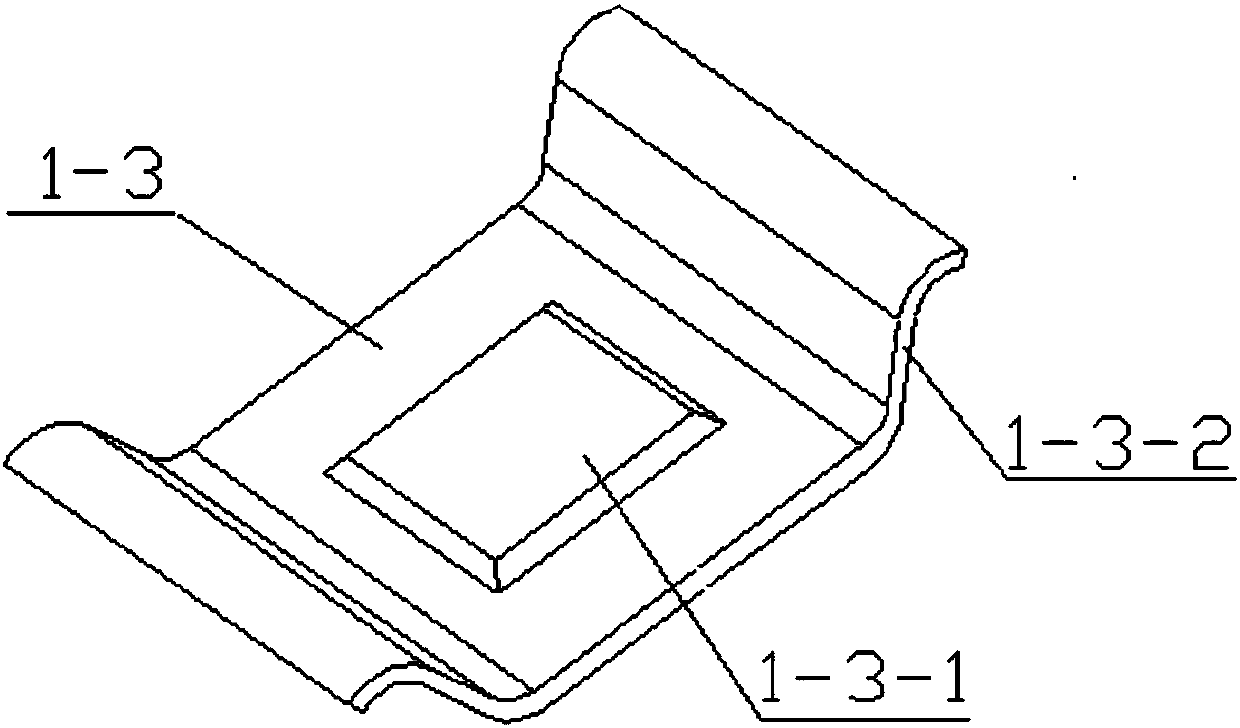

[0083] The structure of the flexible electrode 1 is as follows: it is composed of a copper wire bundle 1-1, a wrapping tape 1-2, an electrode shell 1-3 and a cable 1-4. Copper wire bundle 1-1 is made of thousands of fine copper wire bundles with a diameter of φ0.1~0.3mm; wrapping tape 1-2 is made of copper foil with a thickness of 0.2mm, wrapped on the copper wire bundle The two ends of 1-1 are used to tightly wrap the copper wire bundle 1-1; the electrode shell 1-3 is used to place the copper wire bundle 1-1, and the center of the bottom surface of the electrode shell 1-3 is processed with a boss 1-3- 1. It is used to press the copper wire bundle 1 on the central area of the electrode shell 1-3, and the two side wall plates 1-3-2 of the electrode shell 1-3 are relatively thin and have certain elasticity.

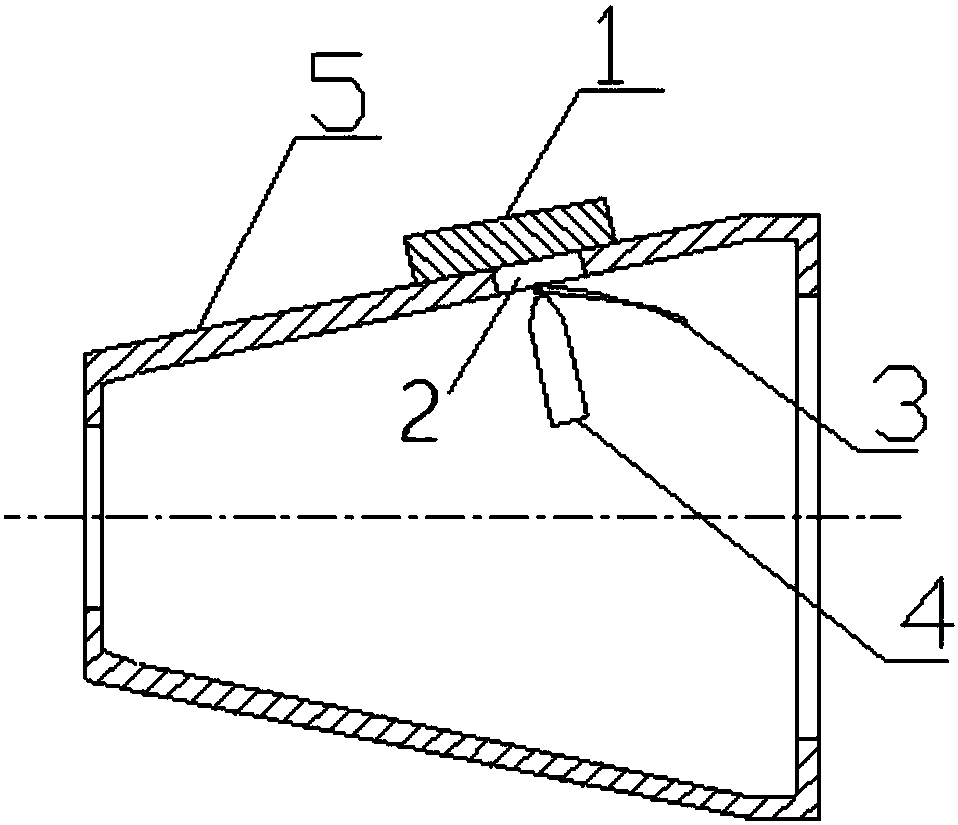

[0084] The thickness of the temperature measuring buckle 2 is the same as that of the metal shell 5, the shape of the inner wall is adapted to the inner surface of the me...

Embodiment 2

[0092] The structure of the flexible electrode 1 is as follows: it is composed of a copper wire bundle 1-1, a wrapping tape 1-2, an electrode shell 1-3 and a cable 1-4. Copper wire bundle 1-1 is made of thousands of fine copper wire bundles with a diameter of φ0.1~0.3mm; wrapping tape 1-2 is made of copper foil with a thickness of 0.2mm, wrapped on the copper wire bundle The two ends of 1-1 are used to tightly wrap the copper wire bundle 1-1; the electrode shell 1-3 is used to place the copper wire bundle 1-1, and the center of the bottom surface of the electrode shell 1-3 is processed with a boss 1-3- 1. It is used to press the copper wire bundle 1 on the central area of the electrode shell 1-3, and the two side wall plates 1-3-2 of the electrode shell 1-3 are relatively thin and have certain elasticity.

[0093] The thickness of the temperature measuring buckle 2 is the same as that of the metal shell 5, the shape of the inner wall is adapted to the inner surface of the me...

Embodiment 3

[0101] The structure of the flexible electrode 1 is as follows: it is composed of a copper wire bundle 1-1, a wrapping tape 1-2, an electrode shell 1-3 and a cable 1-4. Copper bundle 1-1 is made of thousands of thin copper wire bundles with a diameter of φ0.1~0.3mm; Tape 1-2 is made of copper foil with a thickness of 0.15mm, wrapped on the copper bundle The two ends of 1-1 are used to tightly wrap the copper wire bundle 1-1; the electrode shell 1-3 is used to place the copper wire bundle 1-1, and the center of the bottom surface of the electrode shell 1-3 is processed with a boss 1-3- 1. It is used to press the copper wire bundle 1 on the central area of the electrode shell 1-3, and the two side wall plates 1-3-2 of the electrode shell 1-3 are relatively thin and have certain elasticity.

[0102] The thickness of the temperature measuring buckle 2 is the same as that of the metal shell 5, the shape of the inner wall is adapted to the inner surface of the metal shell 5, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com