Patents

Literature

48results about How to "Improve welding speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

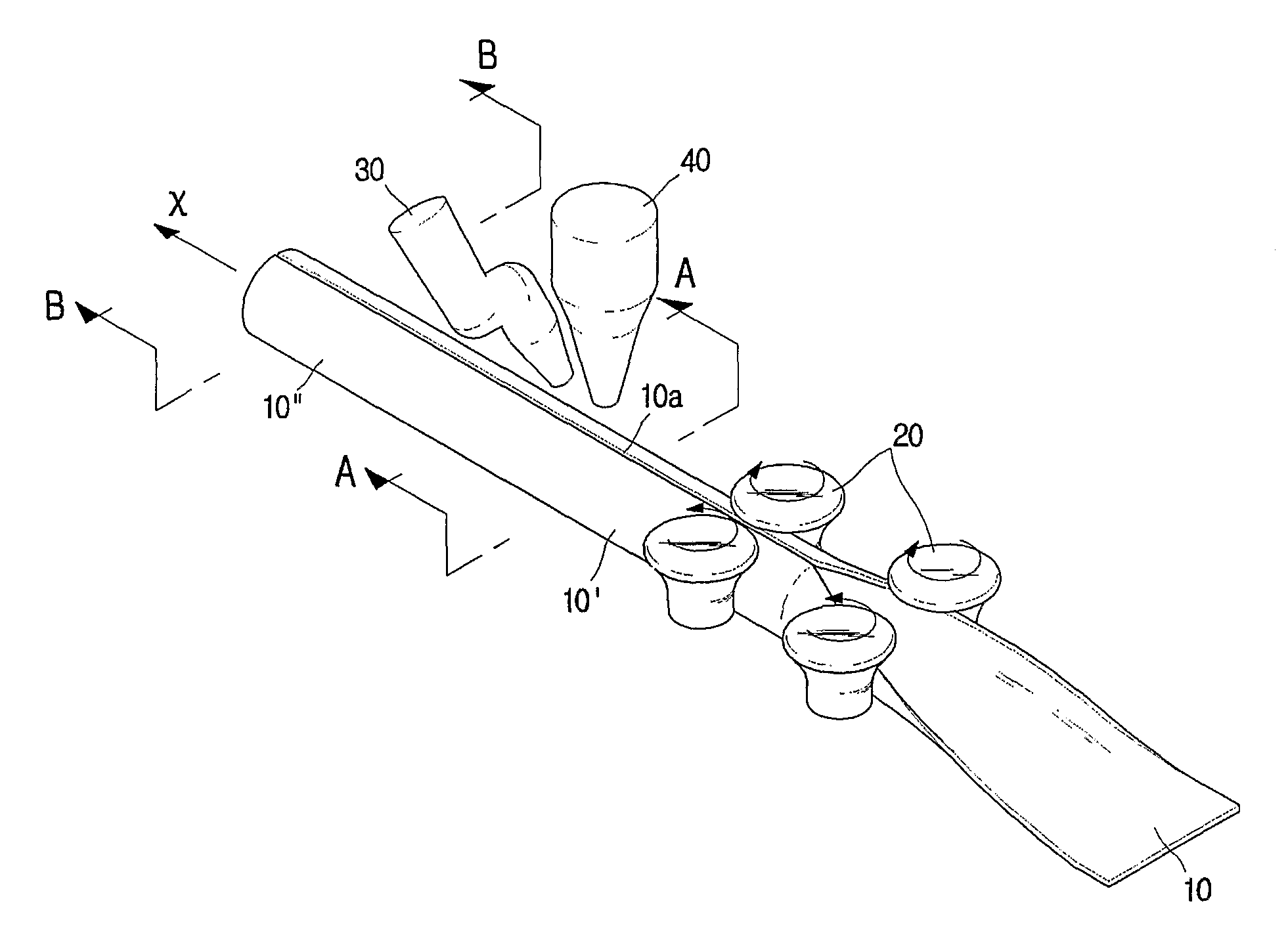

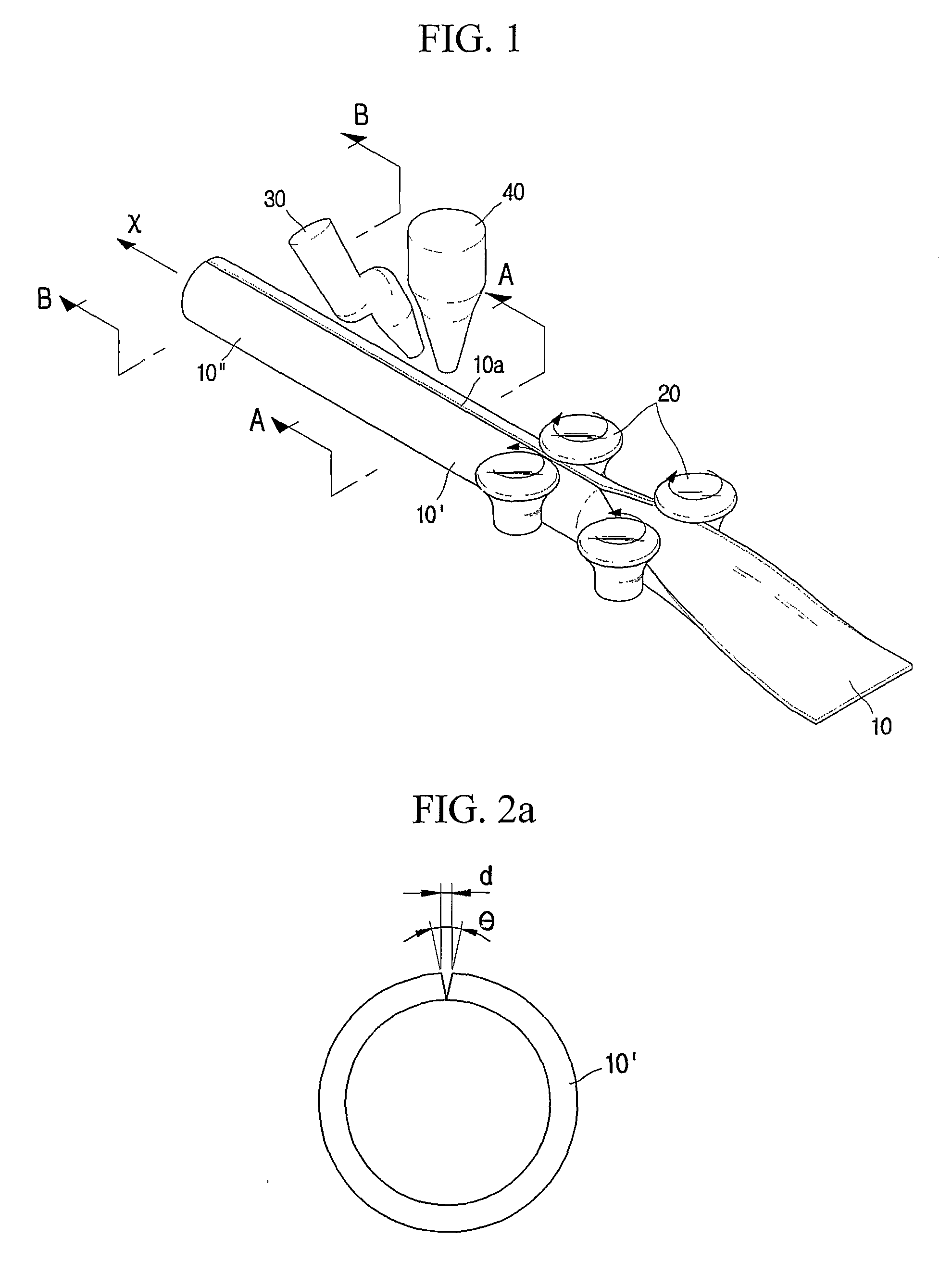

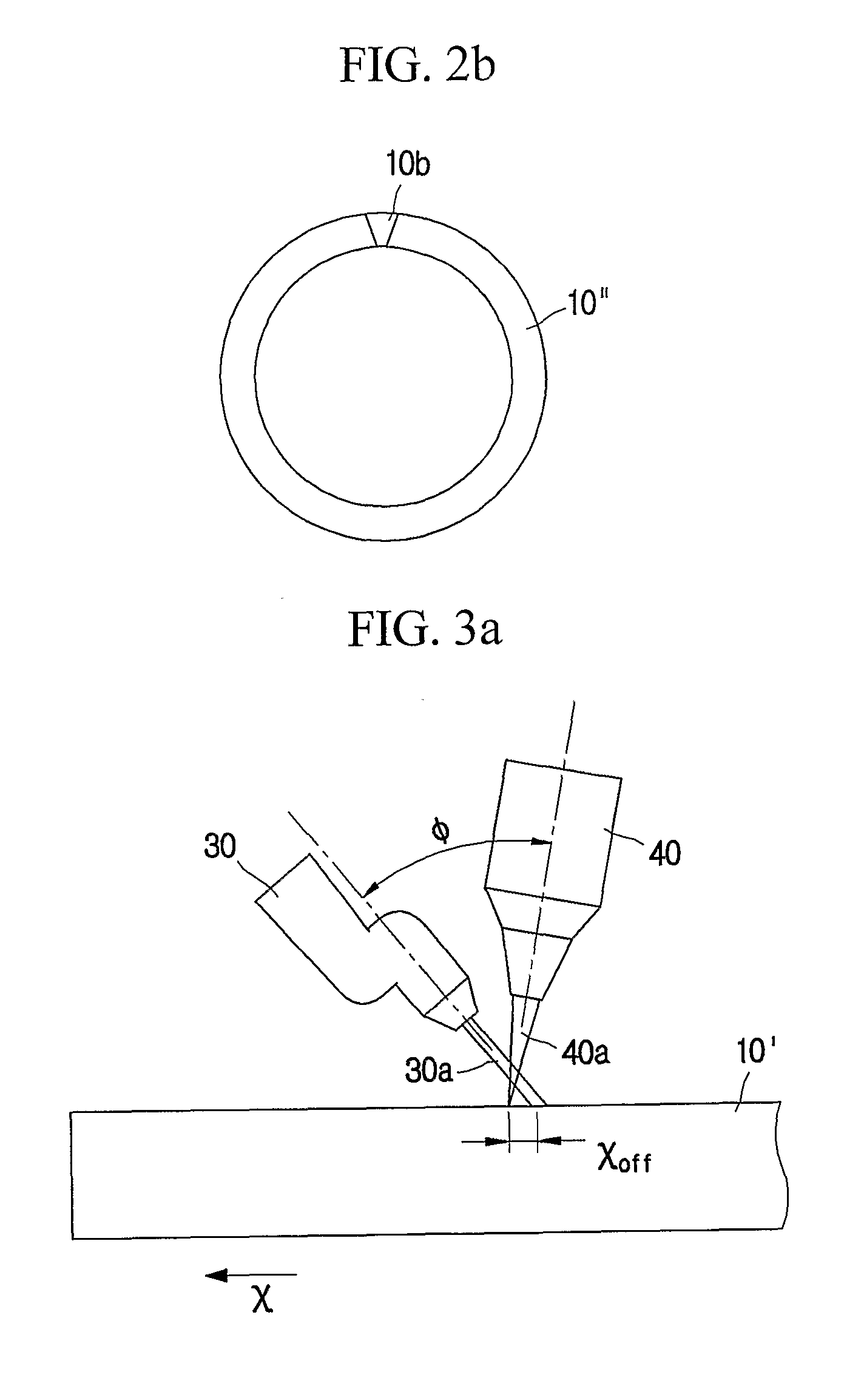

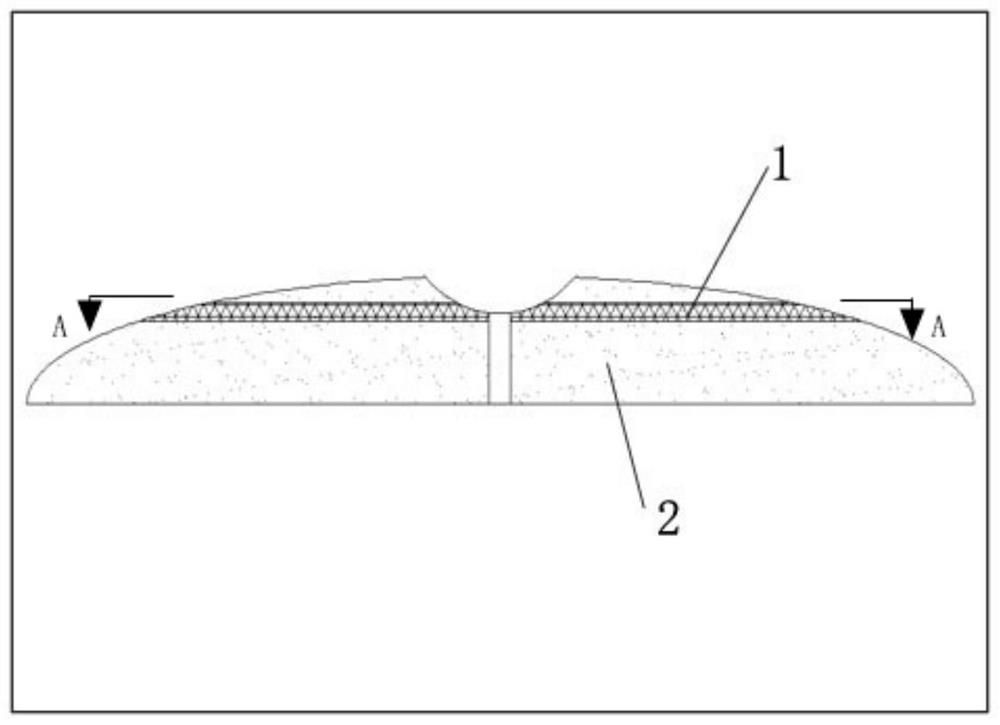

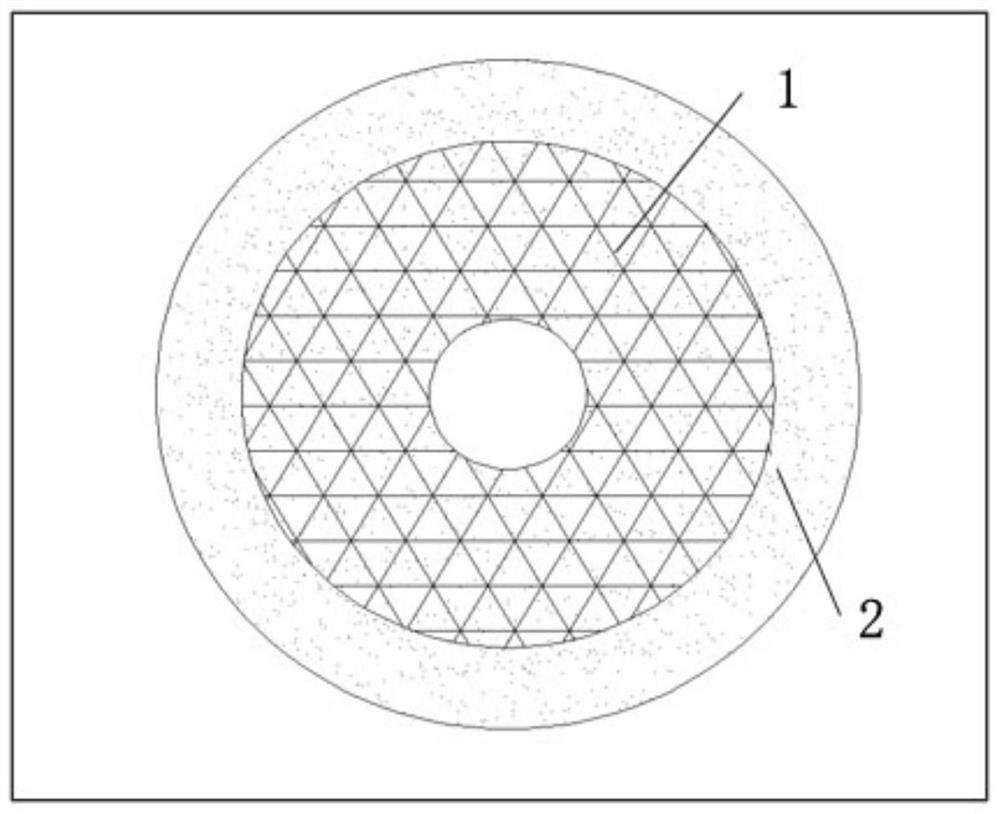

Continous Butt Welding Method Using Plasma and Laser, and Method for Fabricating Metal Tube Using the Same

InactiveUS20070246446A1Fast welding speedSpace minimizationPlasma welding apparatusWelding/soldering/cutting articlesProduction rateButt welding

A continuous butt welding method using plasma and laser, and a method for fabricating a metal tube using the butt welding method are disclosed. The butt welding method conducts a laser welding and a plasma welding together against an object to be welded, which has a very narrow butt space. In particular, the plasma is prior to the laser so that the object is preheated by the plasma, and then a preform is melted by a laser beam in order to accomplish the major welding. In addition, a metal sheet is bent to have a circular section so that its both ends are faced with each other, and then the faced both ends are welded using the aforementioned butt welding method, thereby fabricating a metal tube. The butt welding method and the metal tube fabricating method mentioned above remarkably improve a welding speed and productivity of metal tube.

Owner:LG CABLE LTD (KR) +1

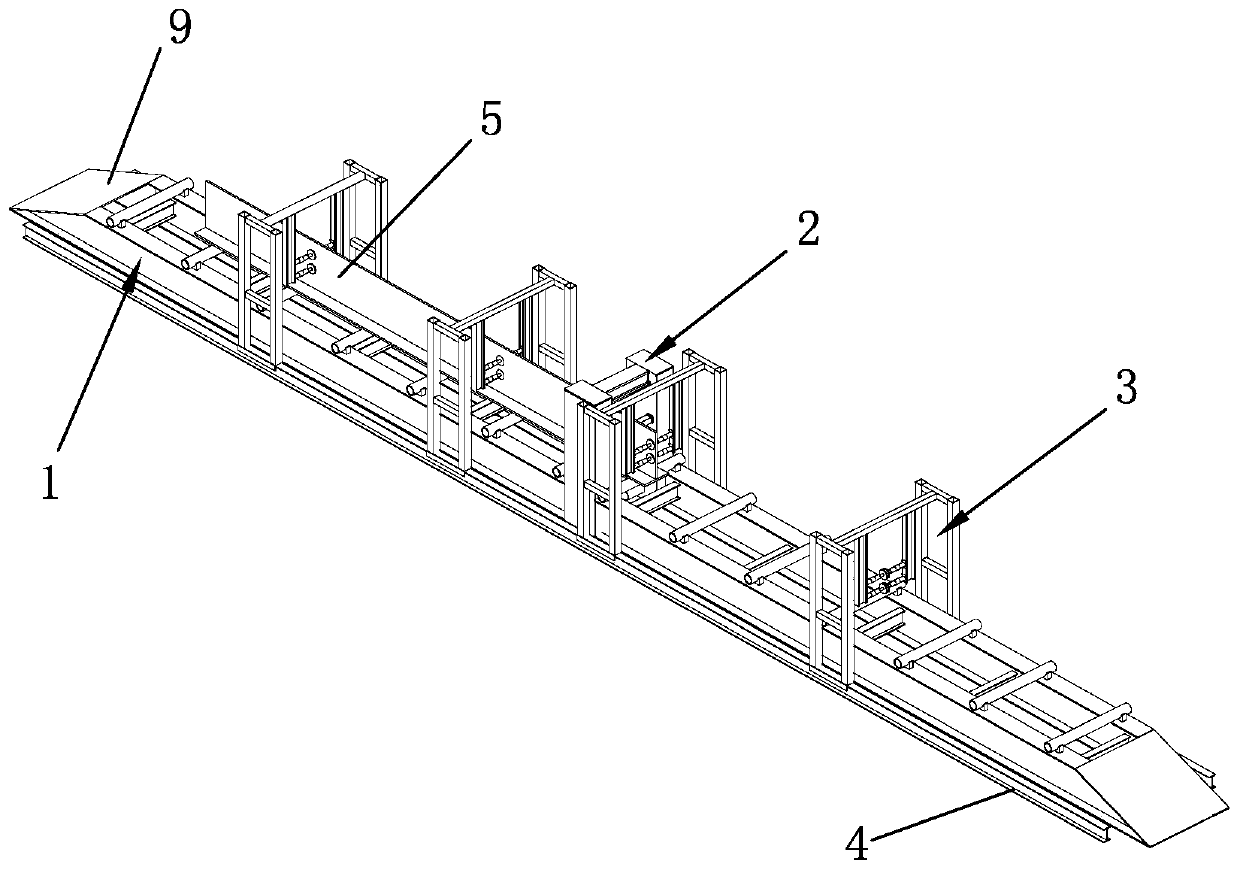

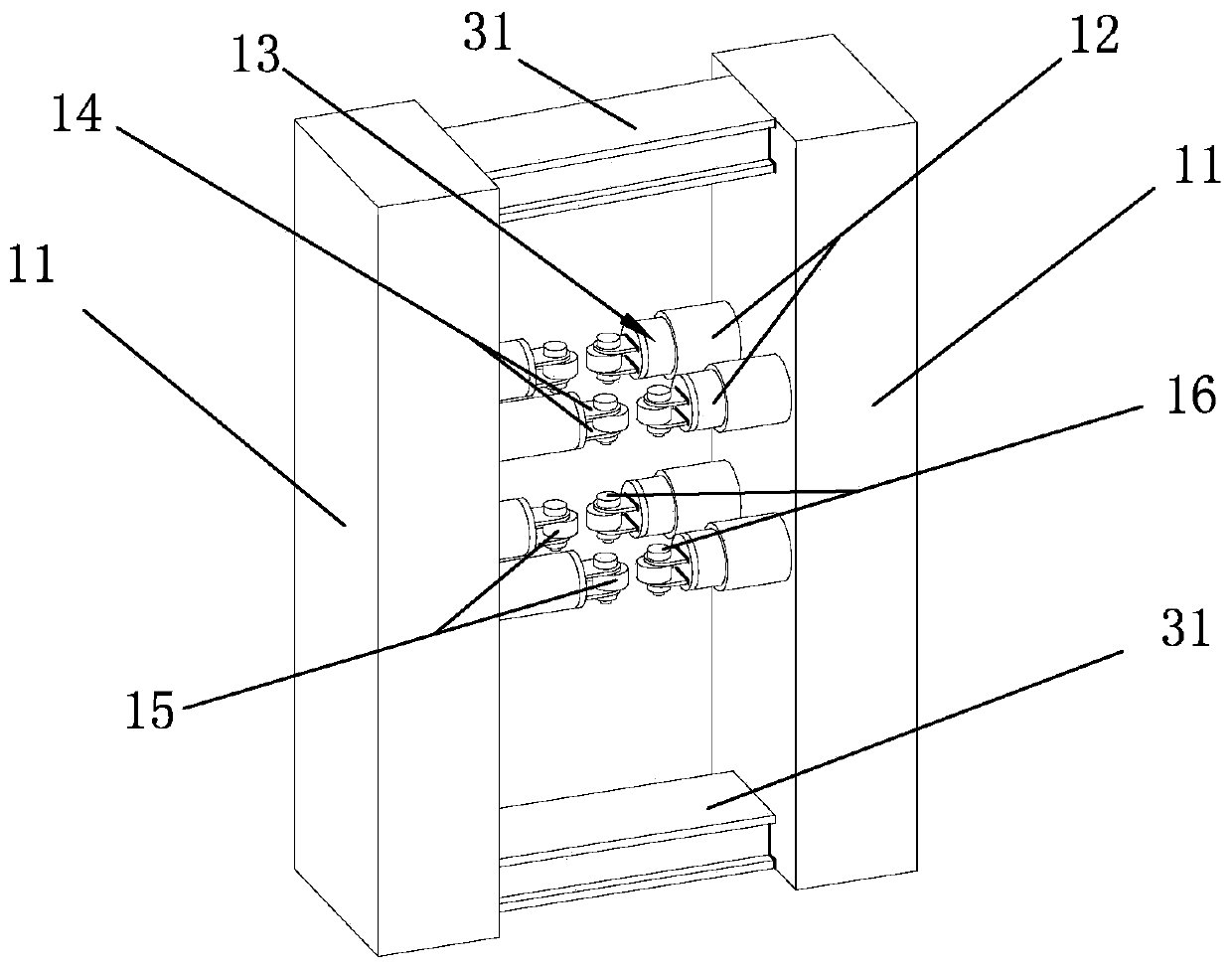

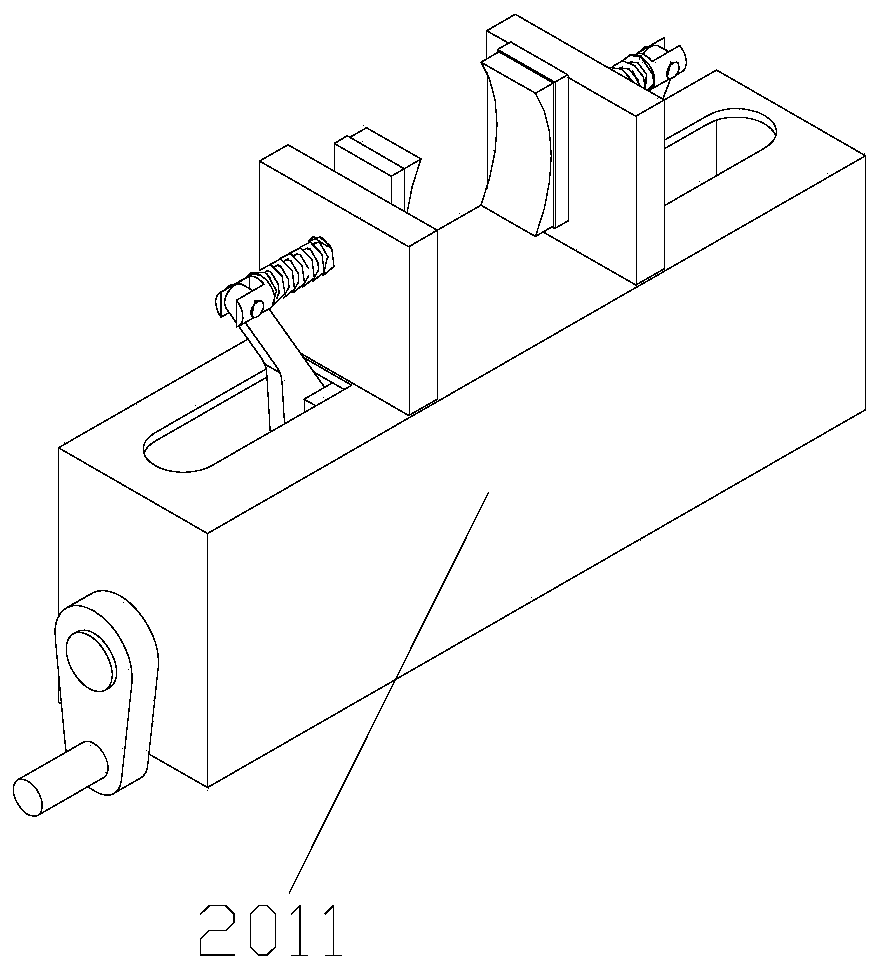

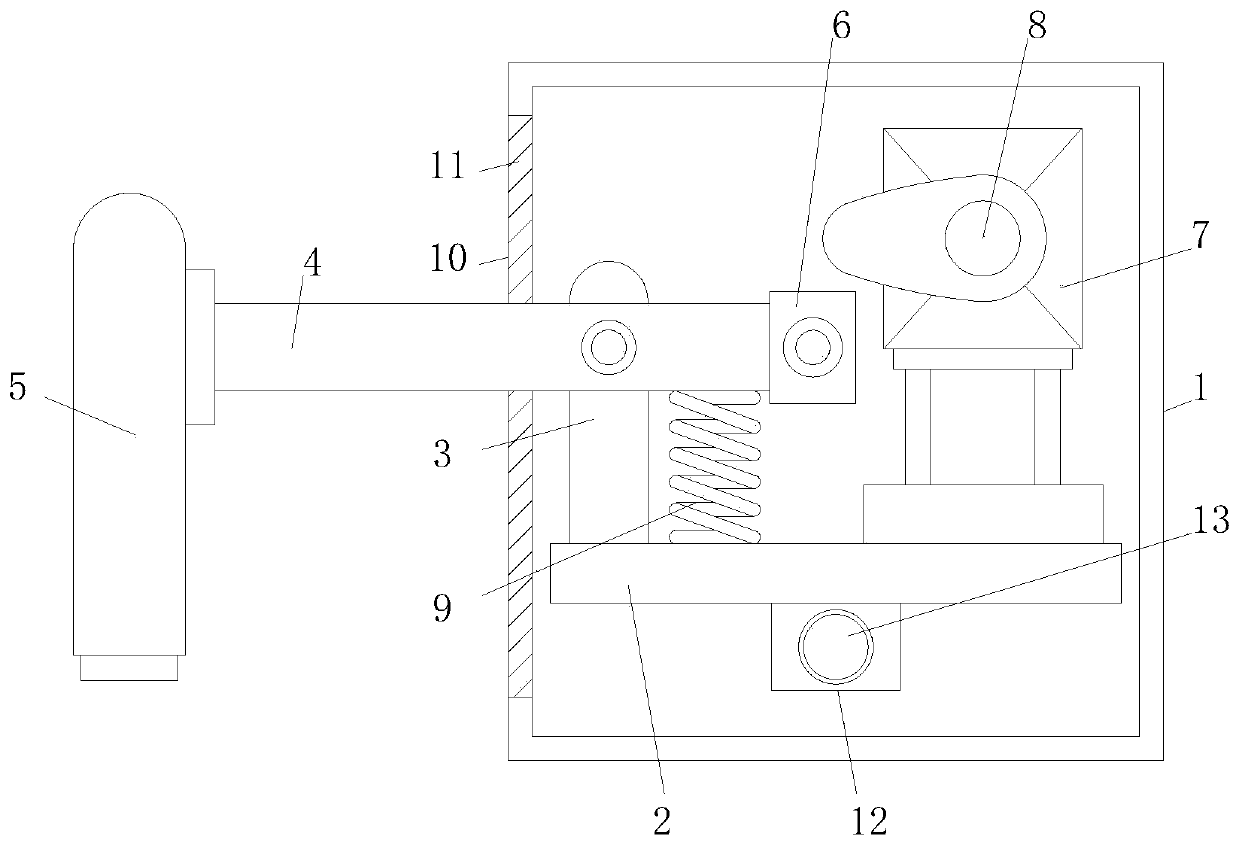

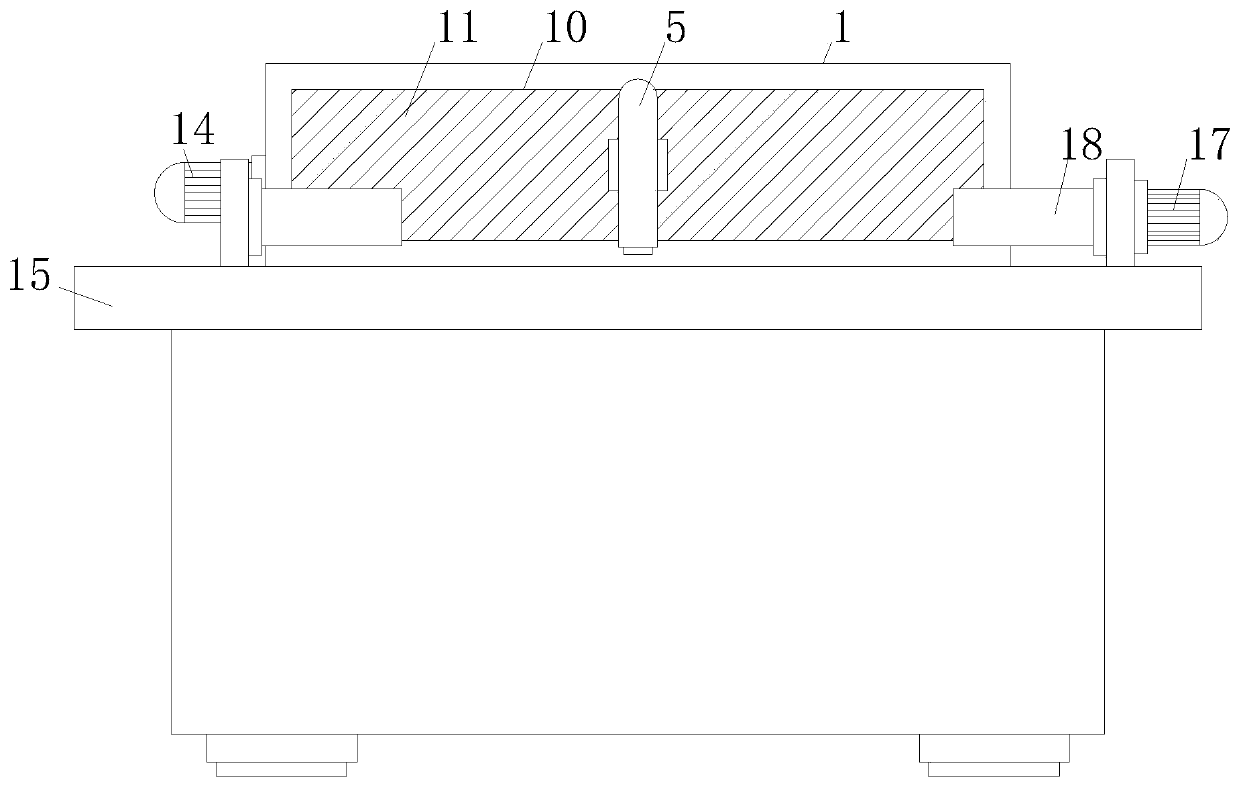

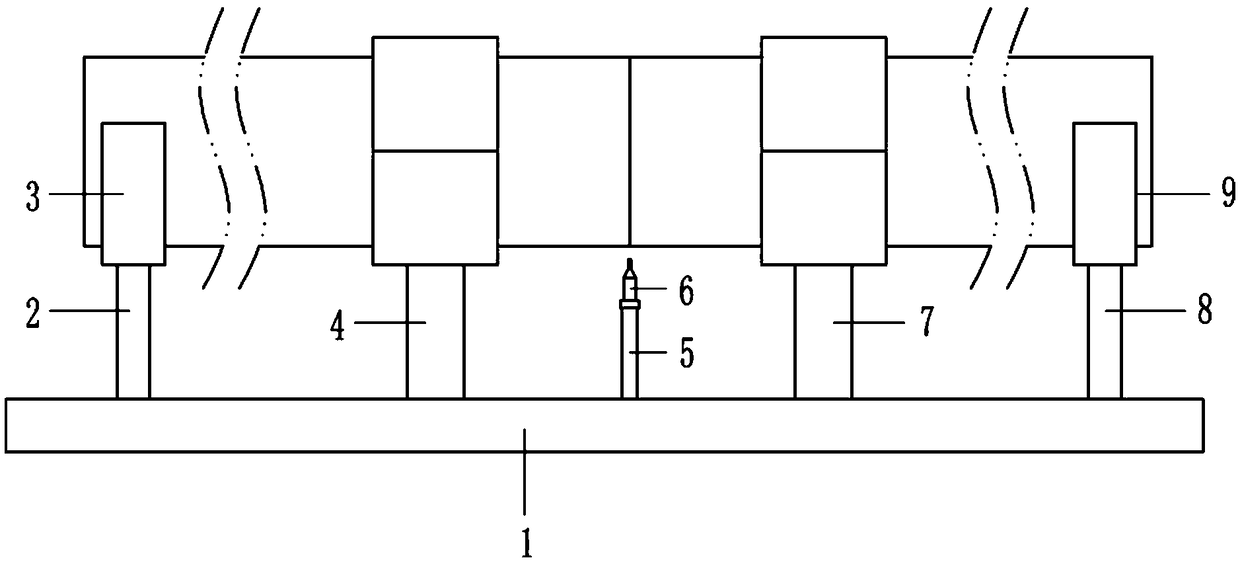

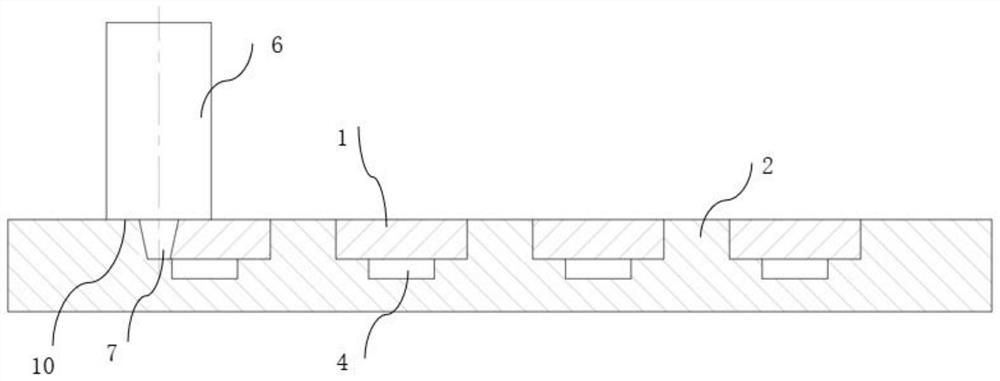

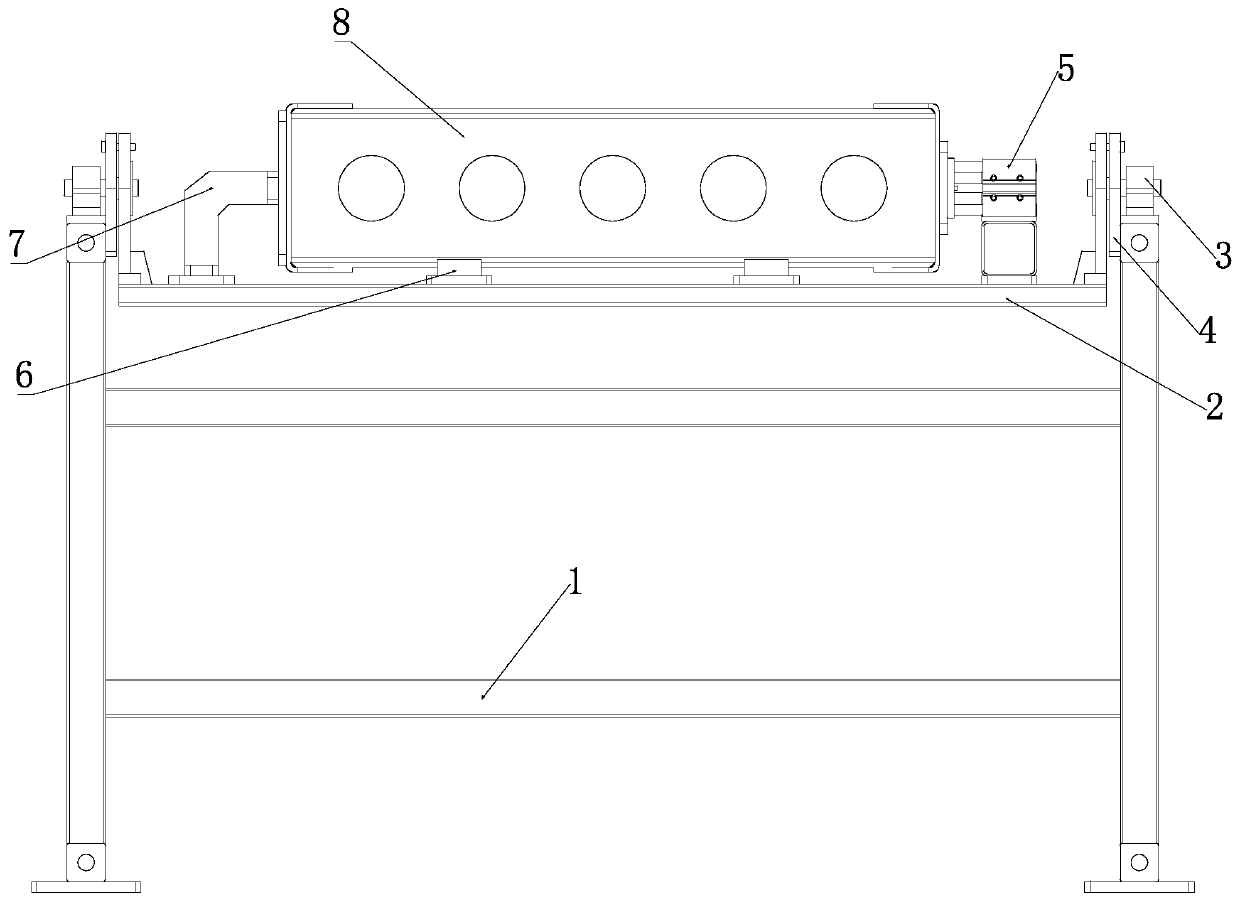

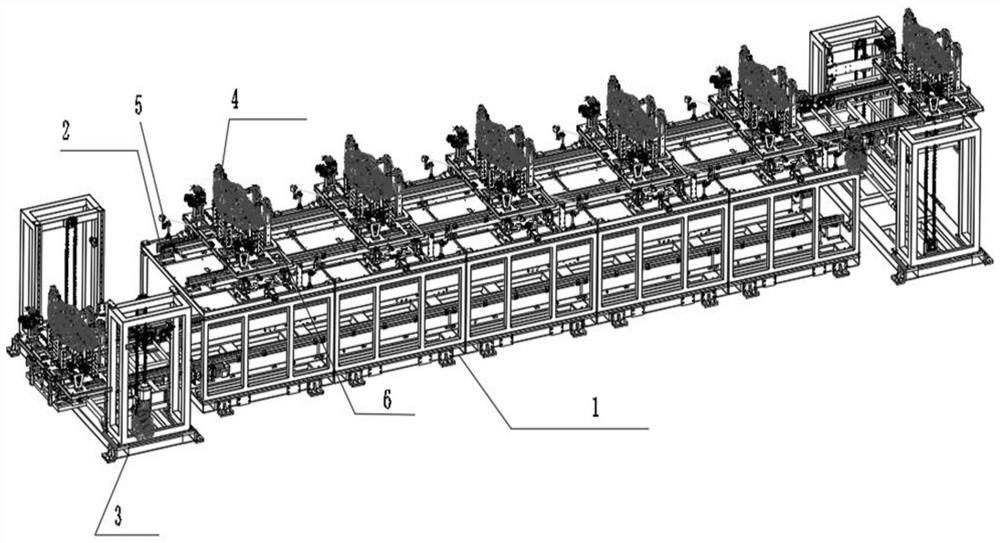

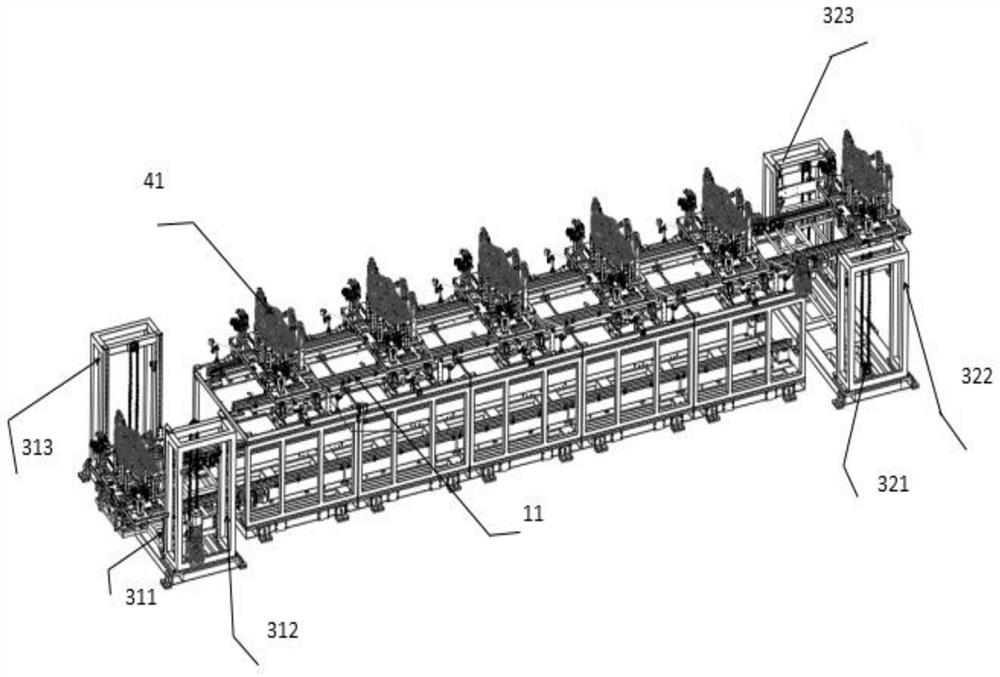

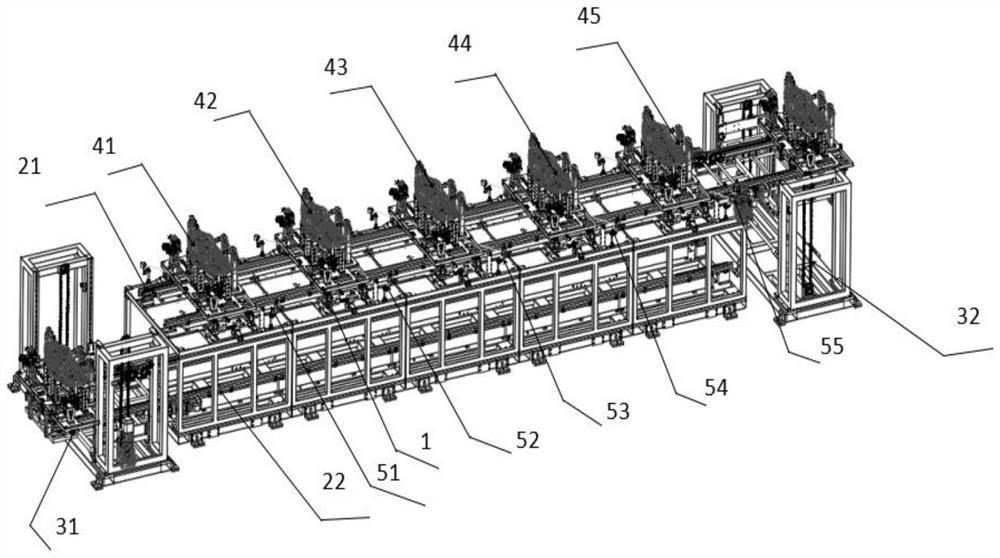

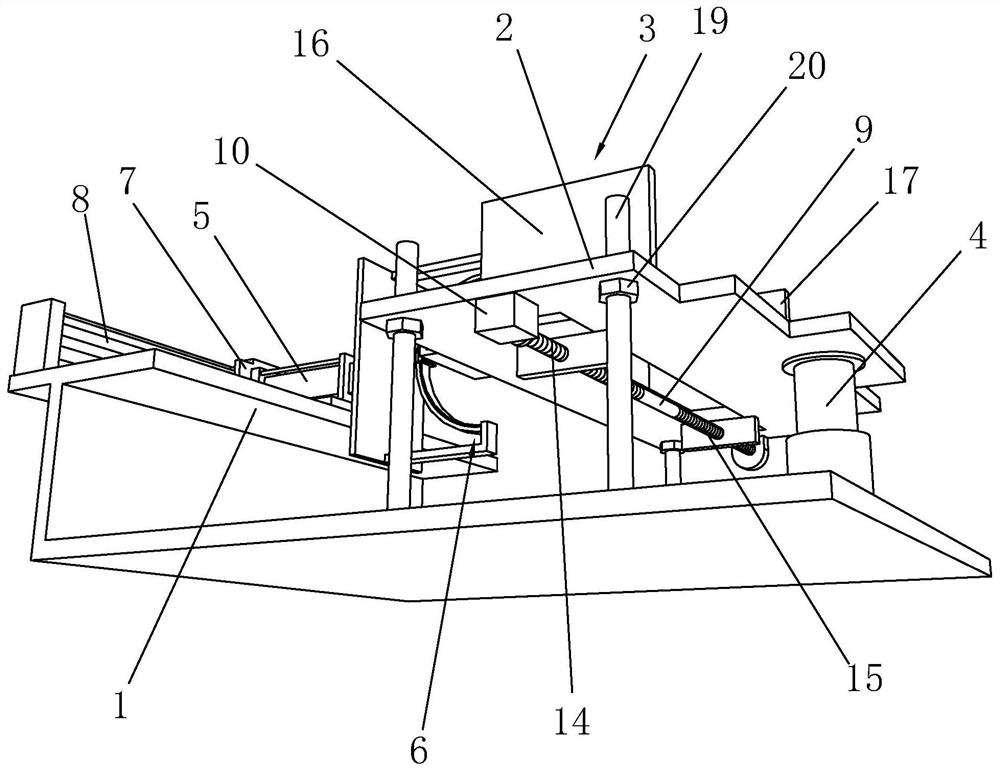

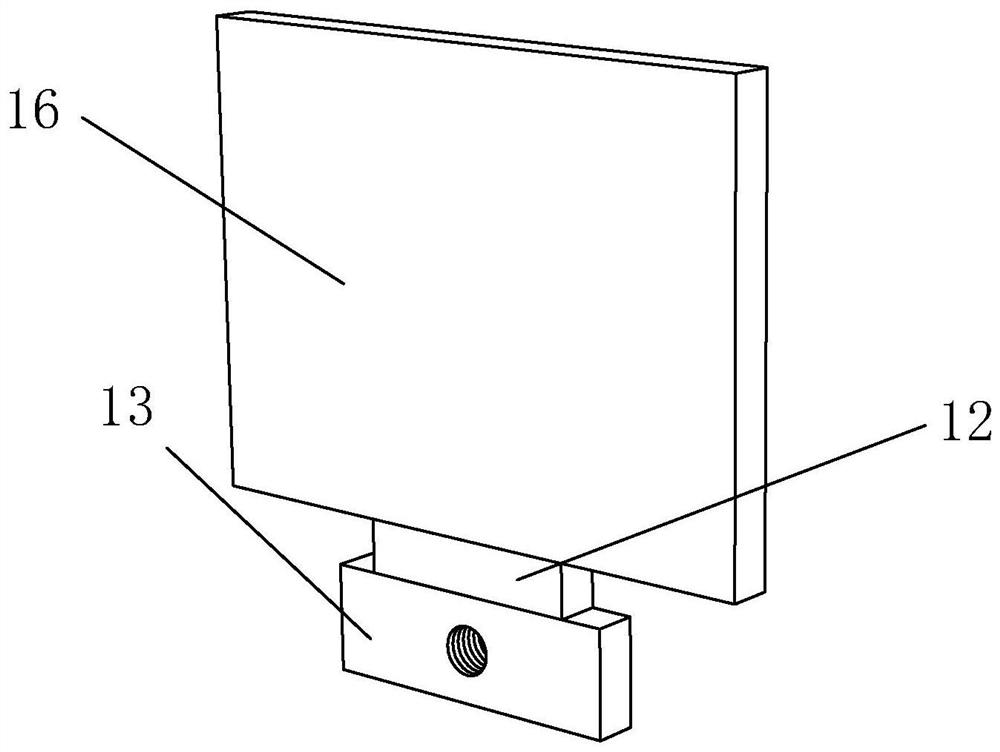

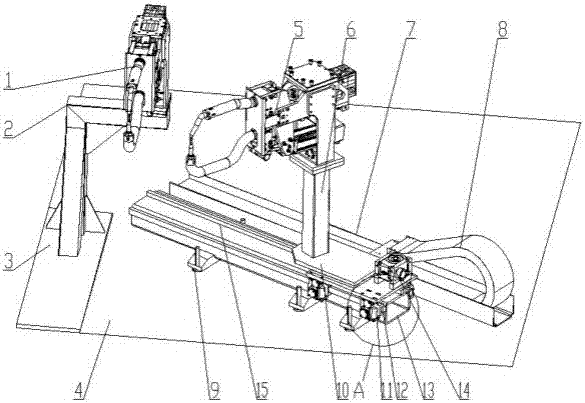

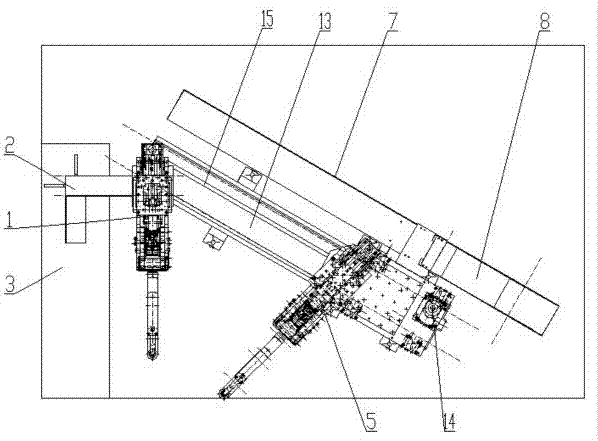

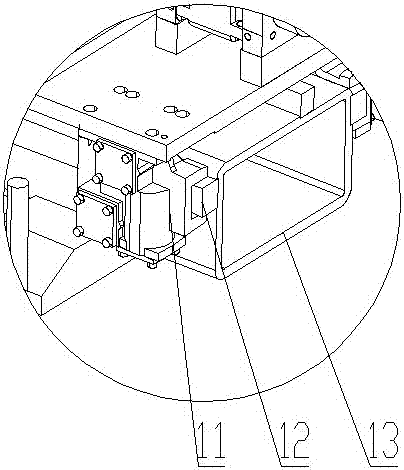

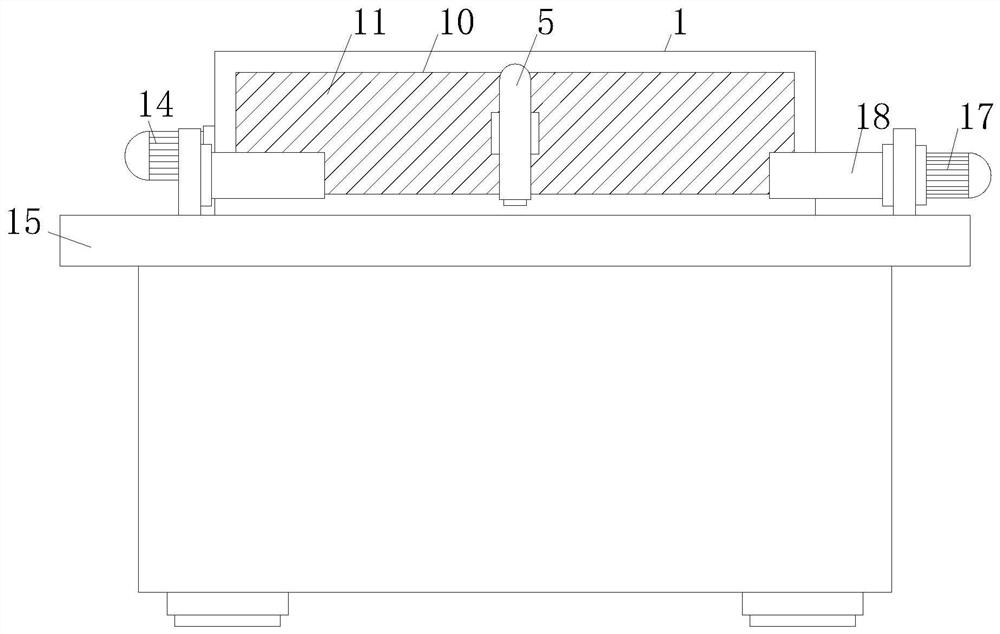

Anti-sidewise-bending deformation control device of H-shaped steel component and welding method

ActiveCN110102862AGuaranteed structural strengthEnsure structural stabilityWelding/cutting auxillary devicesAuxillary welding devicesCompression deviceEngineering

The invention discloses an anti-sidewise-bending deformation control device of an H-shaped steel component. The anti-sidewise-bending deformation control device comprises an assembly jig, an anti-sidewise-bending device, compression devices, a sliding rail and the to-be-welded component; the anti-sidewise-bending device is located in the middle of the assembly jig; the compression devices with thesame number are arranged on the left side and the right side of the anti-sidewise-bending device; and the compression devices are distributed in the direction of the assembly jig. A welding method comprises the steps: (1) the compression devices are adjusted; (2) a lower flange plate and a web are welded; and (3) an upper flange plate and the web are welded. During welding, the web at a welding point is compressed through the anti-sidewise-bending device, thus deformation and bending of the web in the welding process are avoided, two welding heads are symmetrically arranged on the welding positions of the flange plates and the web, the compression devices work to drive the to-be-welded component to move, the two sides of contact points of the web and the flange plates are synchronously welded through the two welding heads, in the process, the to-be-welded component can be semi-automatically welded, the machining efficiency of the H-shaped component can be improved, and the welding quality of the H-shaped component is guaranteed.

Owner:浙江中南绿建科技集团有限公司

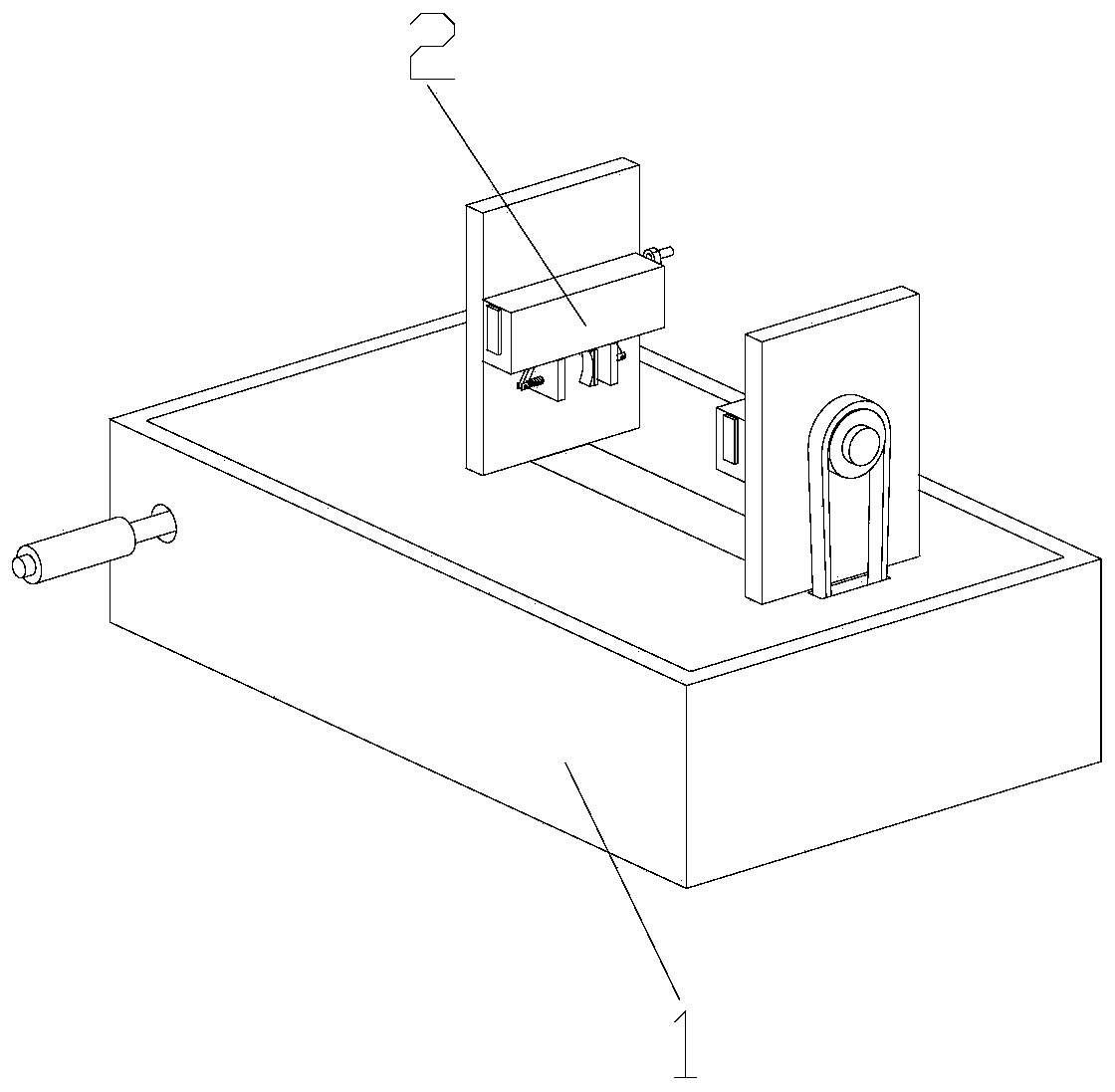

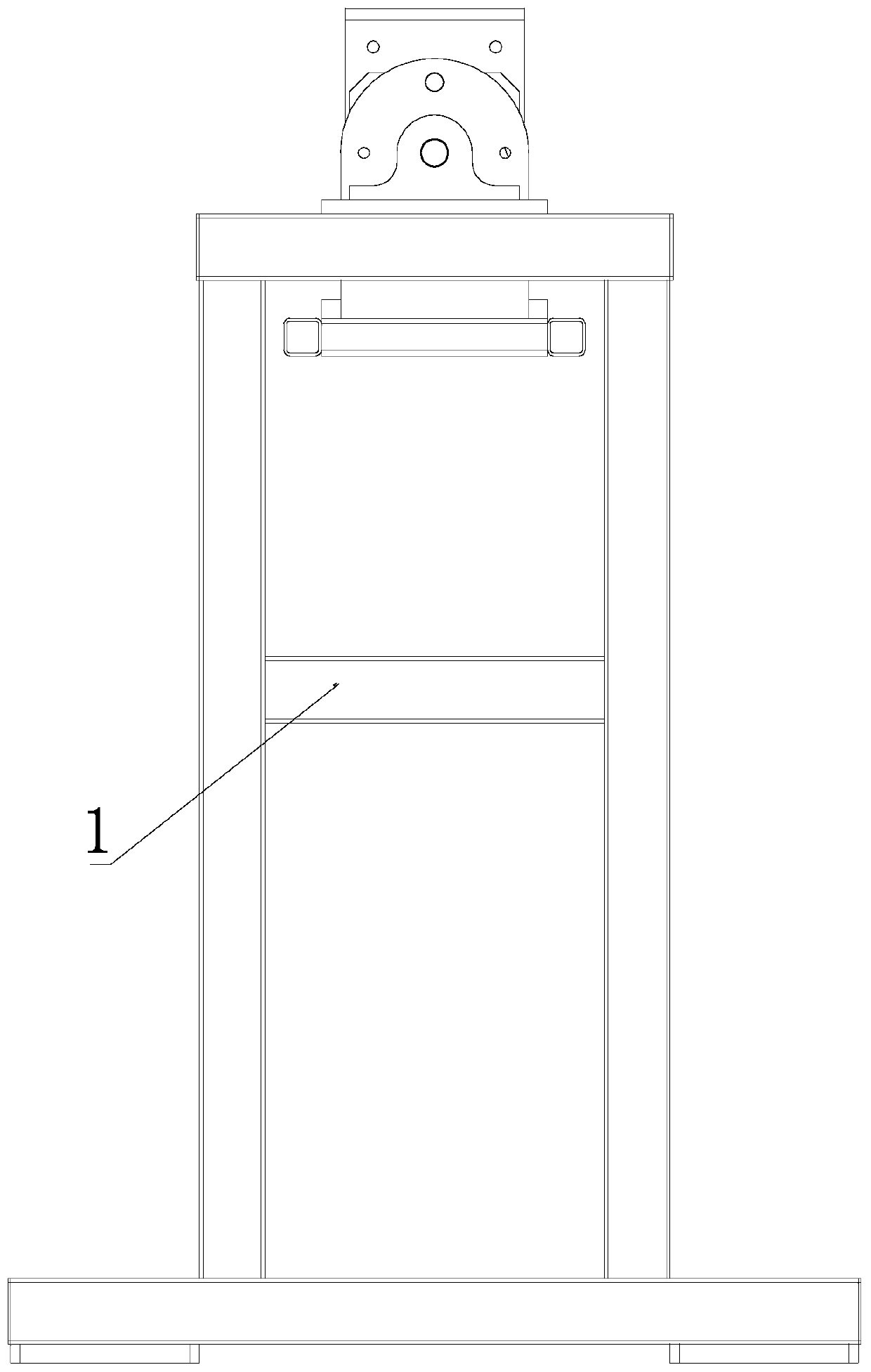

Steel structure welding and clamping device for building

ActiveCN111390470AEasy clampingEasy to weldWelding/cutting auxillary devicesAuxillary welding devicesArchitectural engineeringWelding

The invention discloses a steel structure welding and clamping device for a building. The device comprises a protection cover and two supporting vertical plates, a driving mechanism and a lifting mechanism are mounted in the protection cover, a supporting plate is mounted on the top of the protection cover, a strip hole is formed in the supporting plate, the two supporting vertical plates penetrate through the strip hole, extend into the protection cover, and are matched with the driving mechanism, the lifting mechanism is mounted above the driving mechanism and is mounted between the two supporting vertical plates, the two ends of the lifting mechanism are mounted on the two supporting vertical plates, a clamping mechanism is mounted on the inner side of each supporting vertical plate, asteel structure can be clamped, welding precision is ensured, under the effect of the driving mechanism, the steel structure can be driven to rotate, a worker can conveniently weld the steel structure, the lifting mechanism can lift the steel structure required to be clamped to the same horizontal plane of the clamping mechanism, the clamping mechanism can conveniently clamp the steel structure, and the work efficiency can be improved.

Owner:BEIJING TIANHENG CONSTR

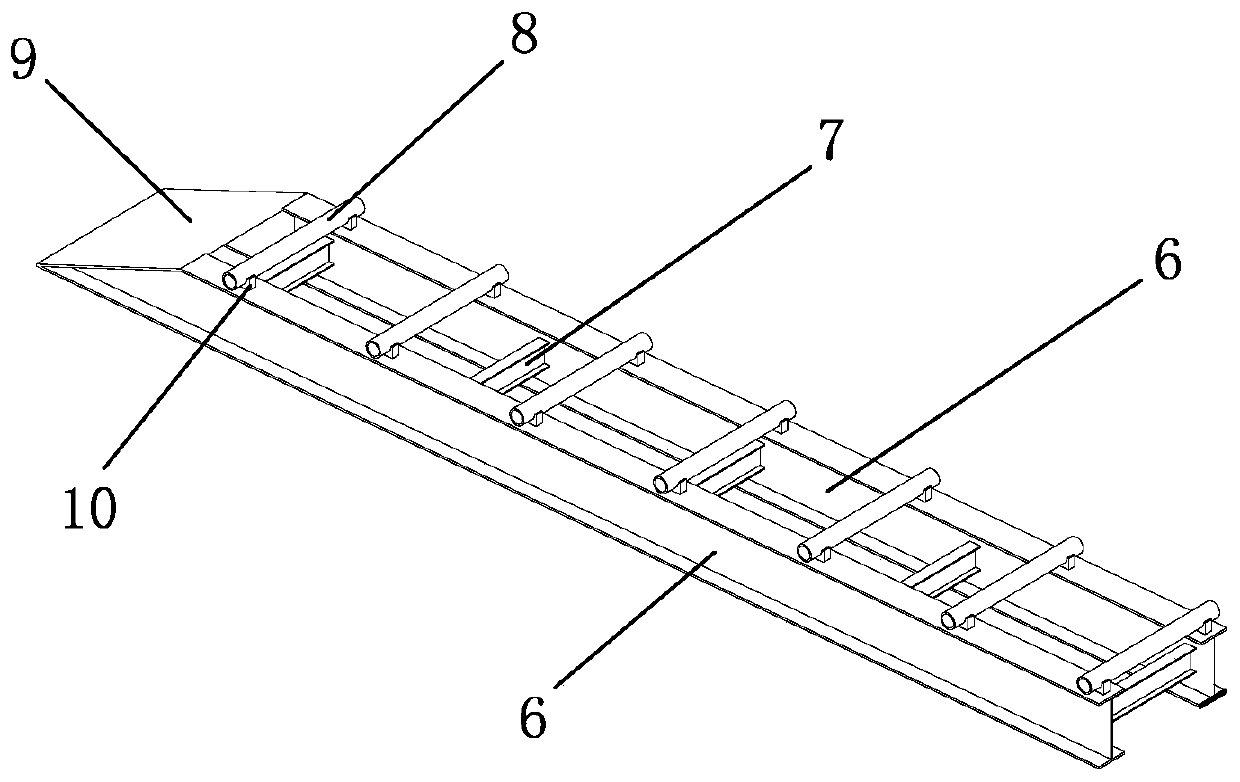

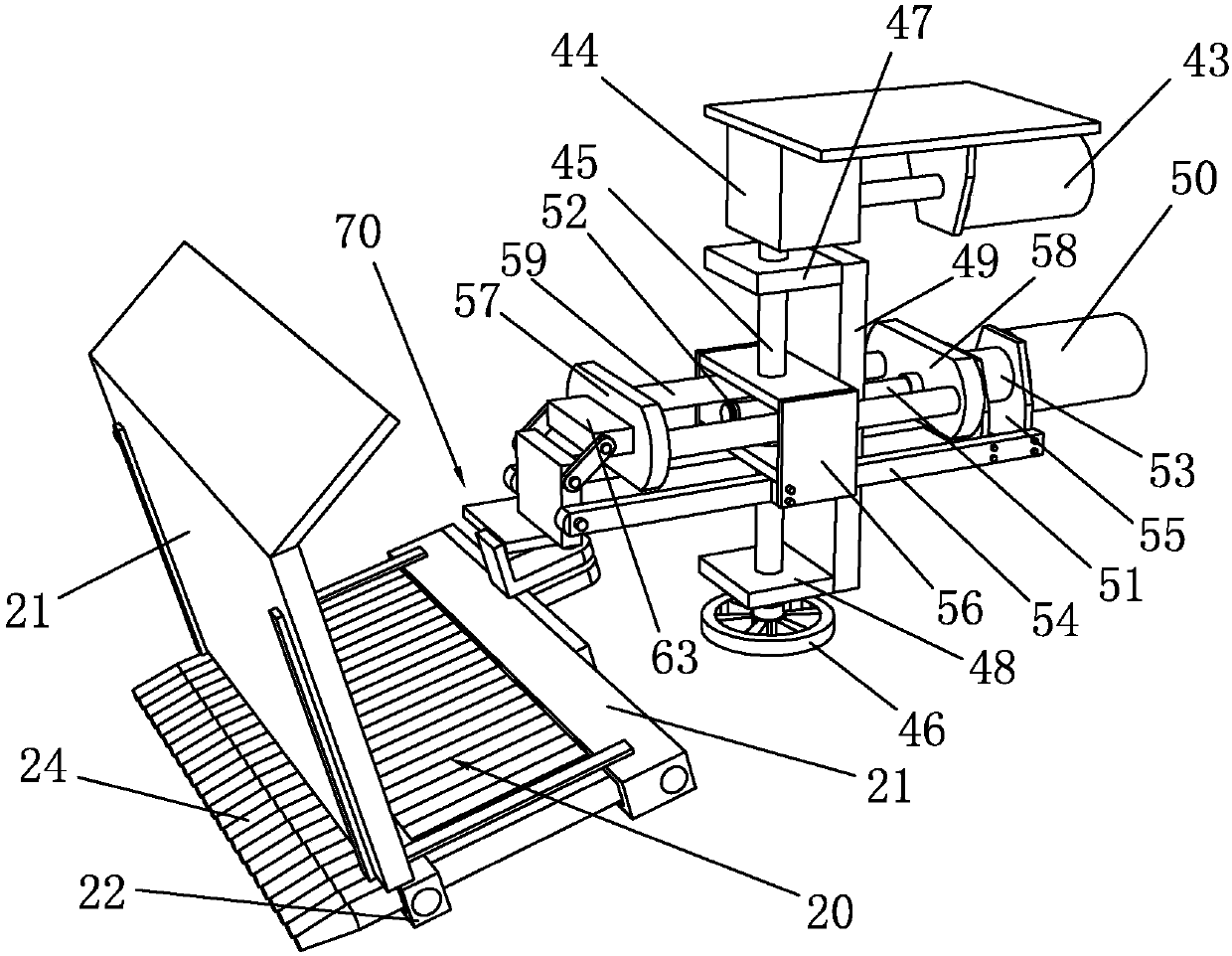

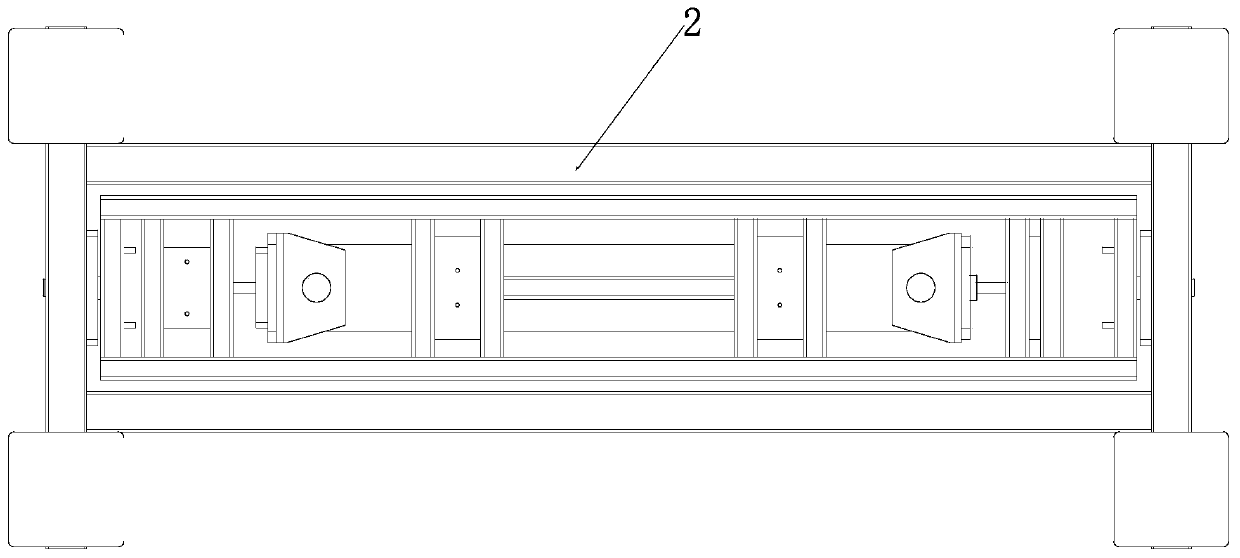

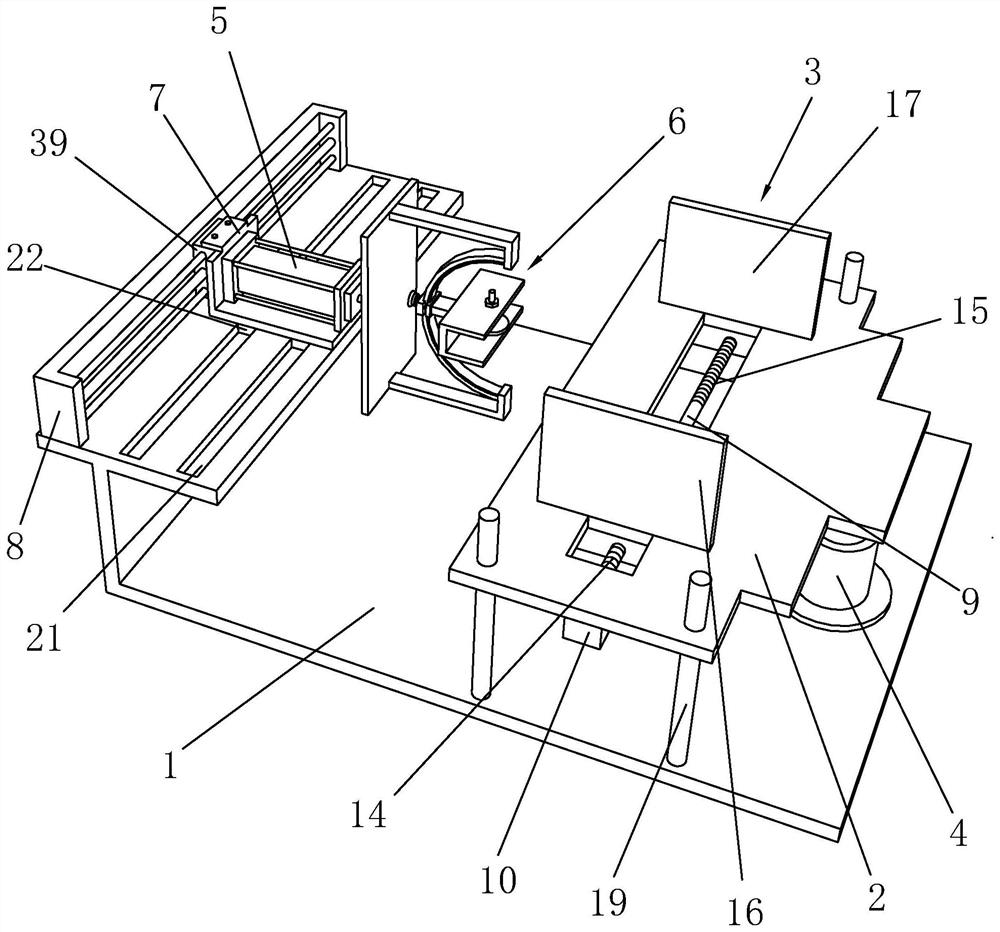

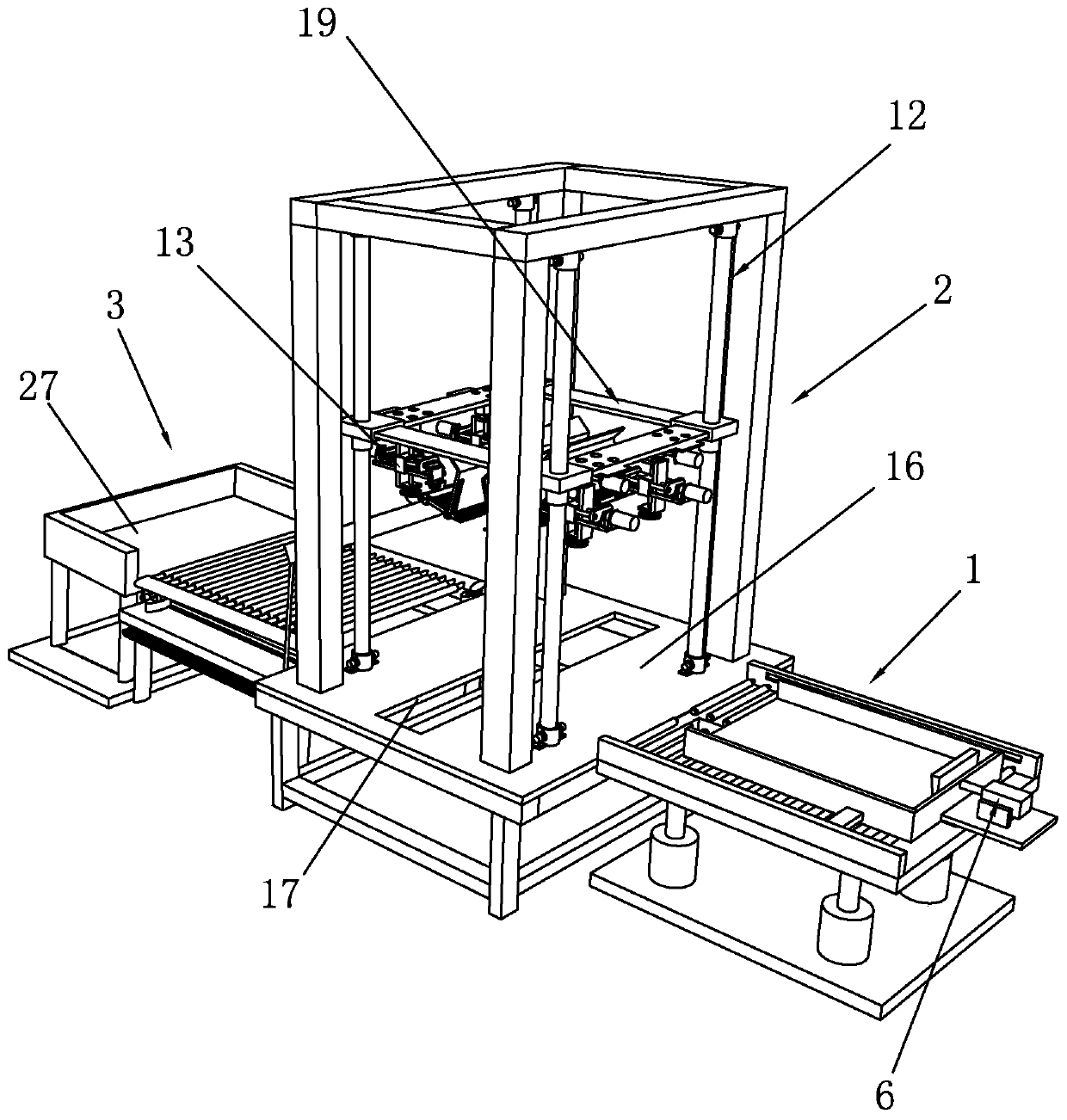

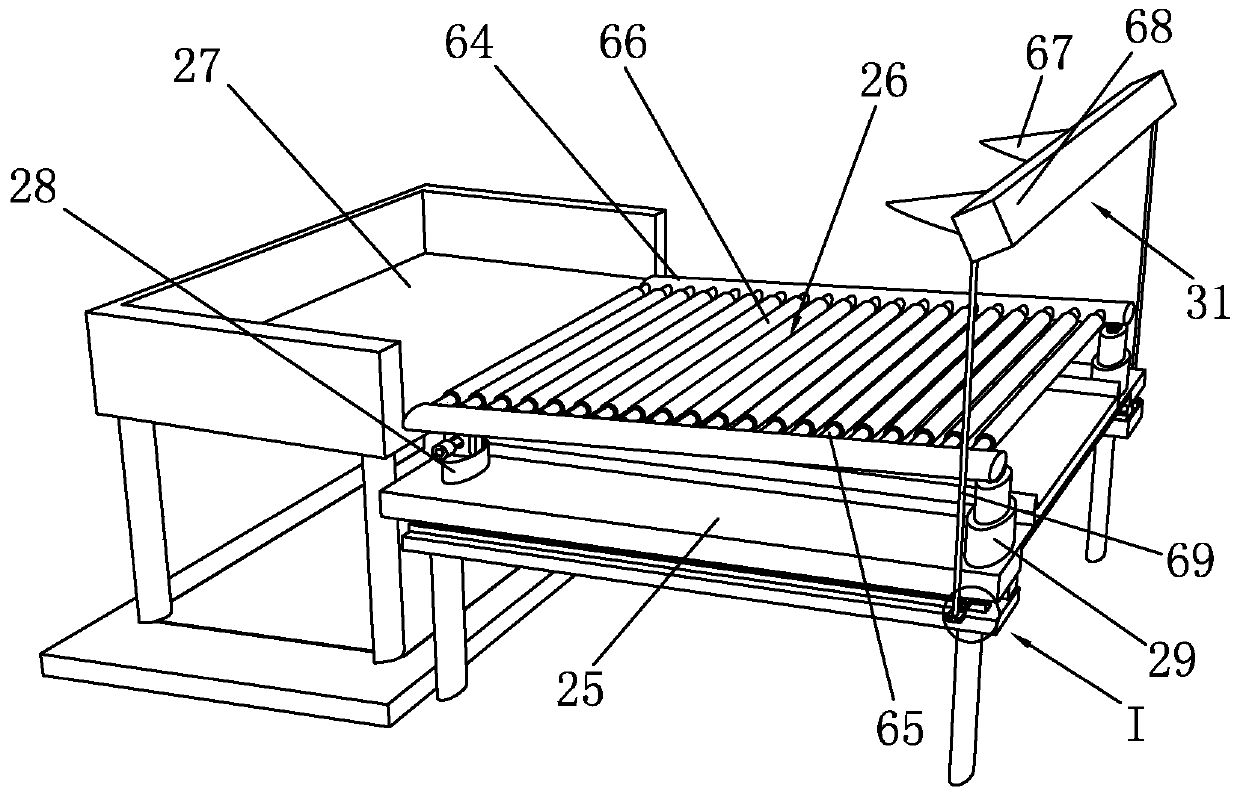

Linear flame welding machine and welding method thereof

ActiveCN107717171AEasy to handleIncrease feeding rateGas flame welding apparatusOperation safetyOperations security

The invention discloses a linear flame welding machine. The linear flame welding machine comprises a feeding mechanism, a welding mechanism and a discharging mechanism; the feeding mechanism comprisesa feeding table, a storing table and a pushing device; the welding mechanism comprises a welding room supporting frame and welding assemblies; each welding assembly comprises a welding head set, a longitudinal adjusting assembly and a transverse adjusting assembly; and the discharging mechanism comprises a discharging table, a material conveying device and a material table. A welding method comprises the following steps of (1) feeding of welded workpieces; (2) adjustment of the height of the welding assemblies; (3) adjustment of the position of the welding head sets; (4) welding; and (5) discharging of the welded workpieces. The linear flame welding machine is ingenious and reasonable in structural design, and convenient and rapid to use and operate, achieves automatic treatment operationof workpiece feeding and discharging through the feeding mechanism and the discharging mechanism, relieves labor intensity, improves operation safety performance, can conduct welding on the workpieces at the same time through design of the multiple welding assemblies, effectively increases the welding rate, and improves the work efficiency.

Owner:XINCHANG KECHUANG AUTOMATION EQUIP

Welding technology for manual argon arc welding of thick plate titanium material

InactiveCN104057185AReduce the difficulty of welding operationGuarantee welding qualityArc welding apparatusWelding/soldering/cutting articlesTitaniumEngineering

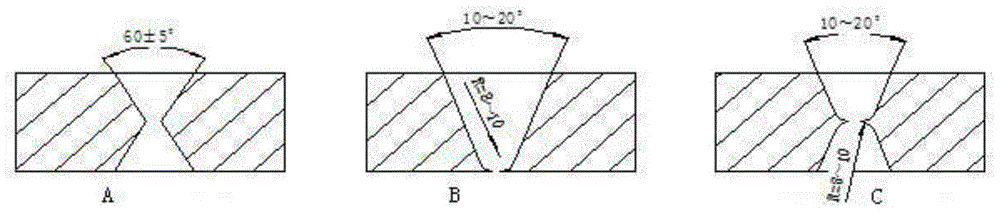

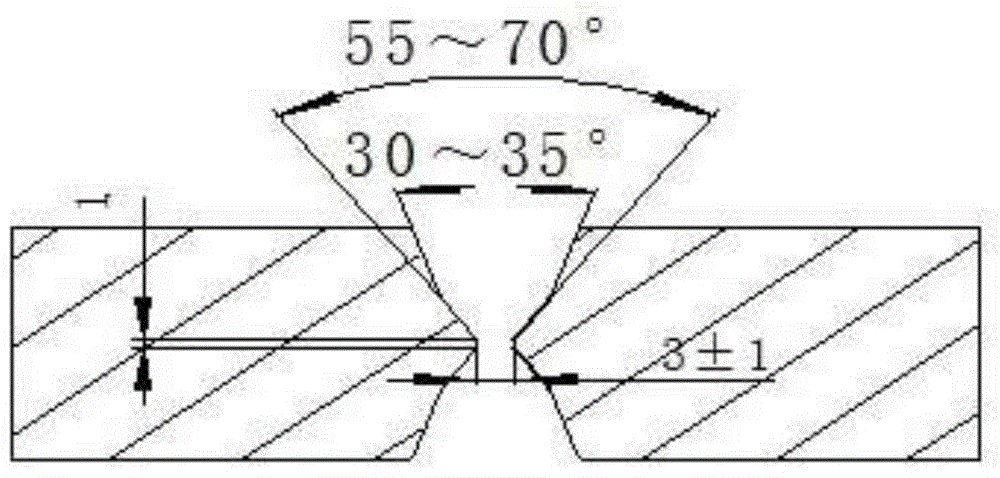

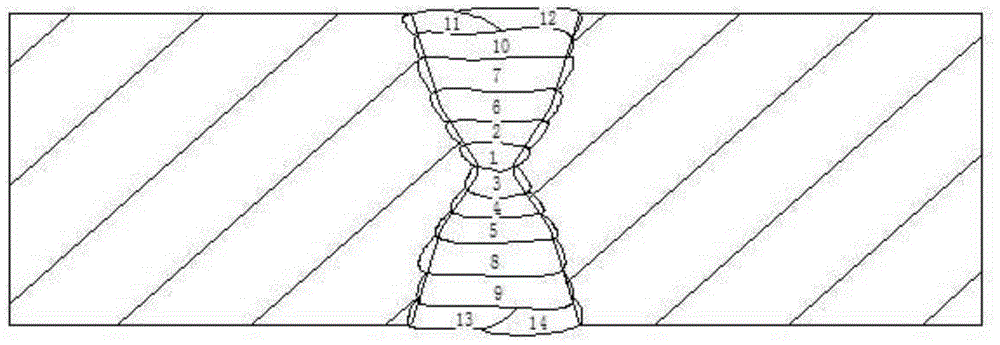

The invention discloses a welding technology for manual argon arc welding of a thick plate titanium material. The welding technology comprises the following steps: 1) cleaning welding wires, the surface of a groove and two sides of the groove; 2) adopting a double V-shaped groove, setting the angle of the lower section of the groove to be 55-70 degrees, and setting the angle of the upper section of the groove to be 30-35 degrees; 3) determining welding parameters, and welding. The application range of welding technology for manual argon arc welding of the titanium material is enabled to be further enlarged, and is particularly suitable for welding the titanium material of more than or equal to 20mm. The angle of the lower section of the groove is 55-70 degrees, so that a sufficient welding operation space is ensured, the defects of incomplete fusion, incomplete penetration and the like are prevented from being generated, and the welding quality is guaranteed; the angle of the upper section of the groove is 30-35 degrees, so that the metal filling volume is effectively reduced, and the difficulty requirements of improved groove processing technology is greatly reduced compared with U-shaped and double U-shaped grooves.

Owner:LUXI IND EQUIP

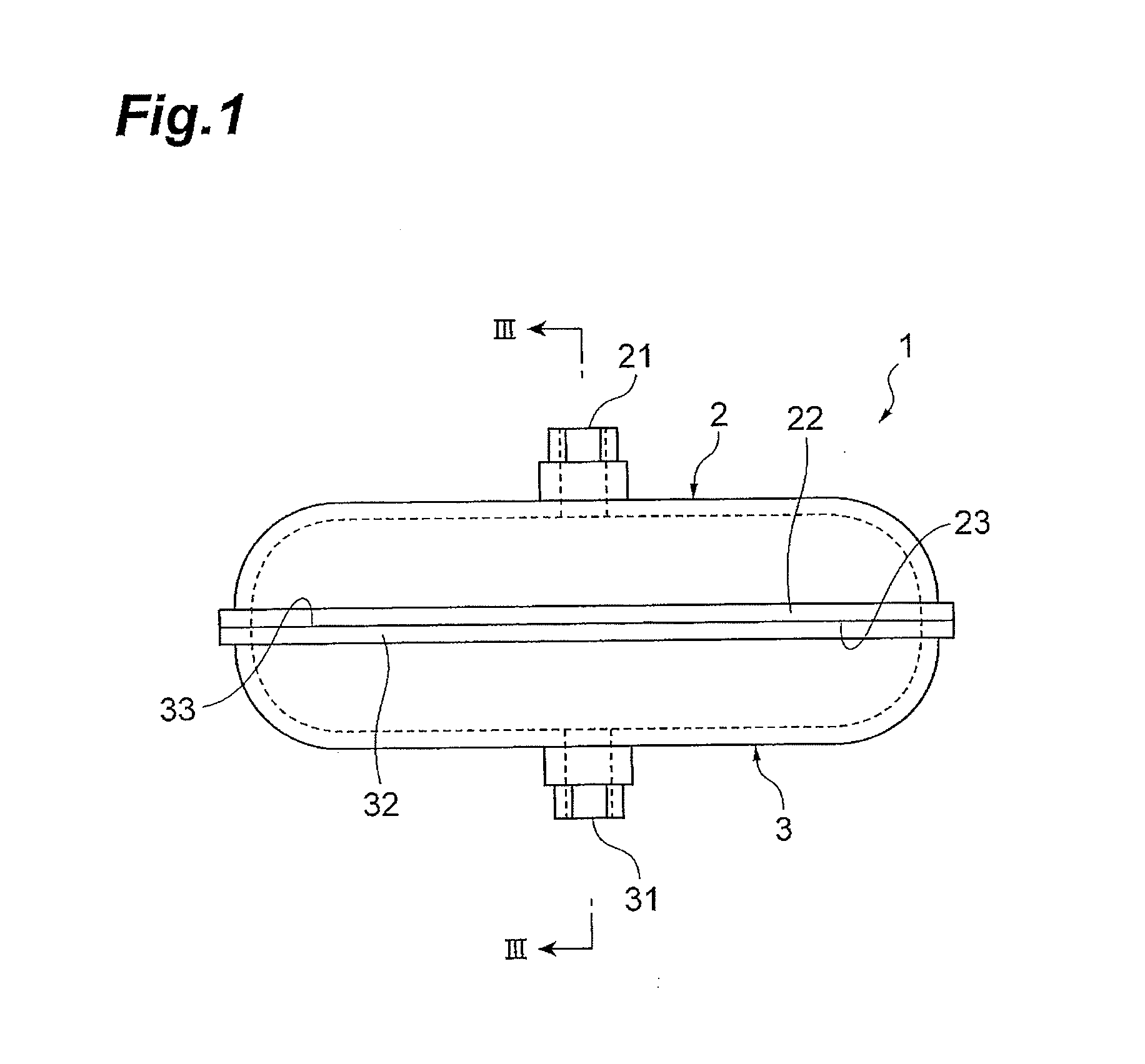

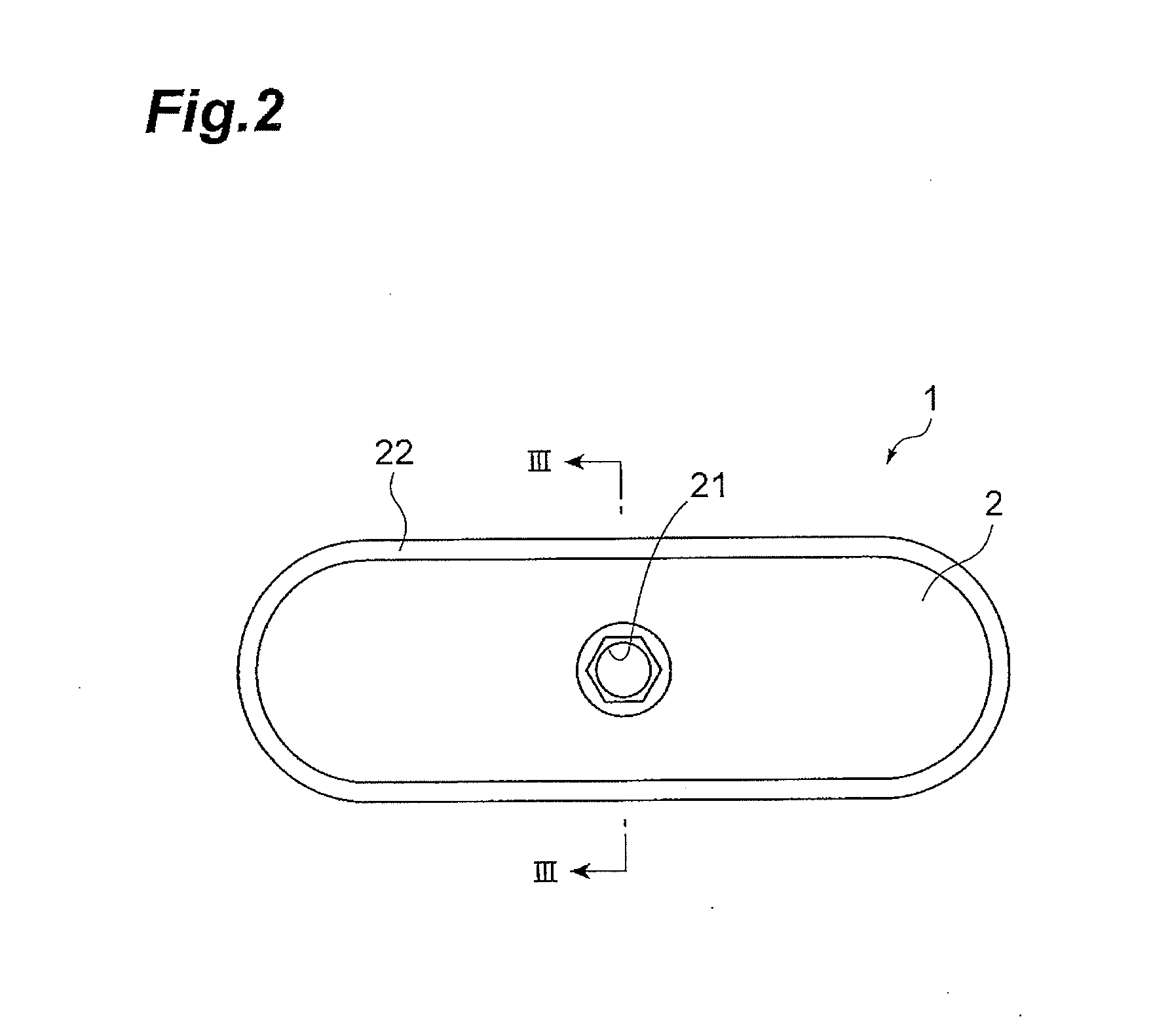

Welding method and weld

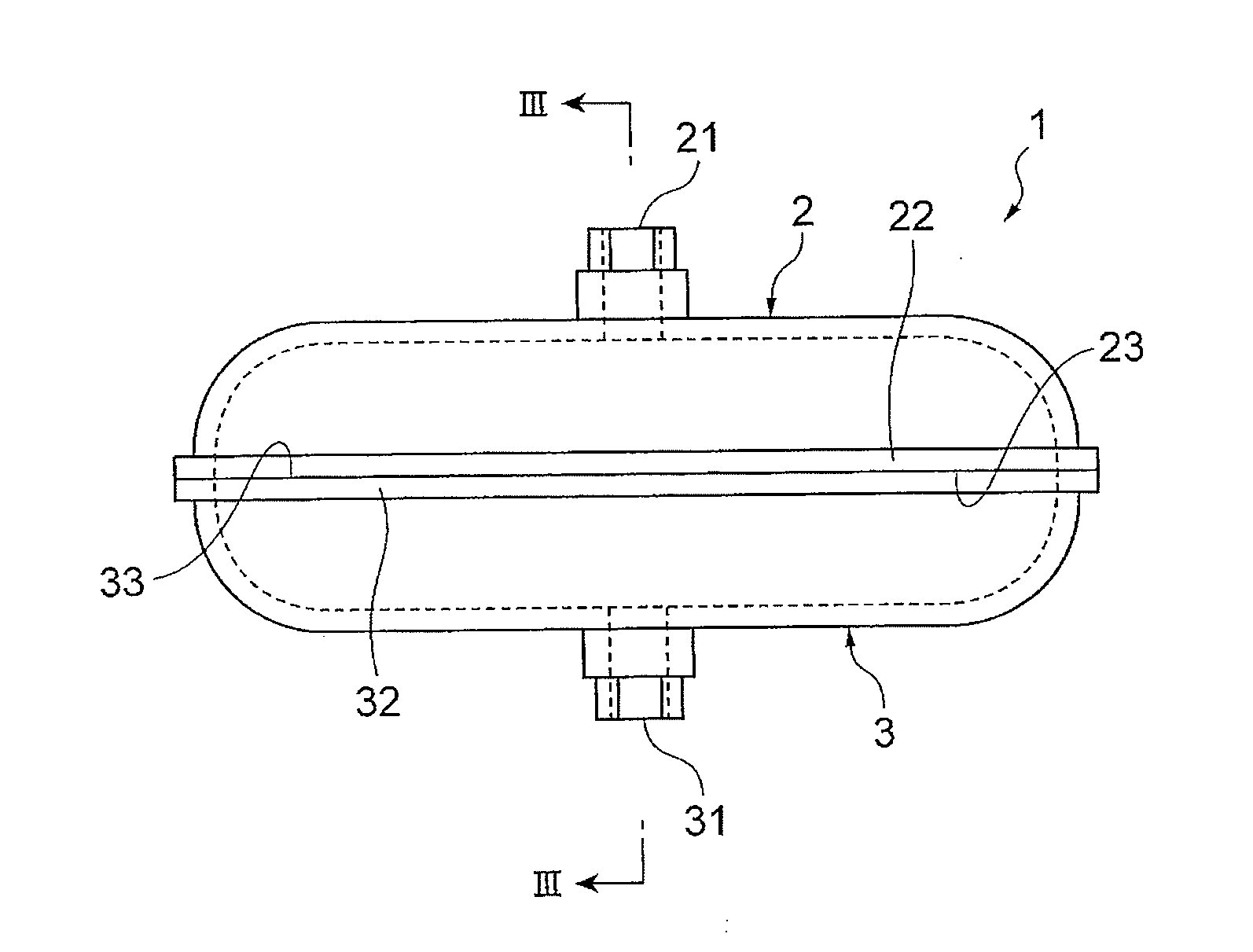

InactiveUS20150183155A1Fast welding speedEnhance layeringLamination ancillary operationsLaminationLaser lightWeld seam

Provided is a welding method for welding a first resin layer and a second resin layer, the method including interposing a metal layer having pores formed therein, between the first resin layer and the second resin layer; irradiating at least one of the first resin layer and the second resin layer with laser light; thereby causing the melted resin to penetrate through the metal layer; and thus welding the first resin layer and the second resin layer.

Owner:ASAHI KASEI CHEM CORP

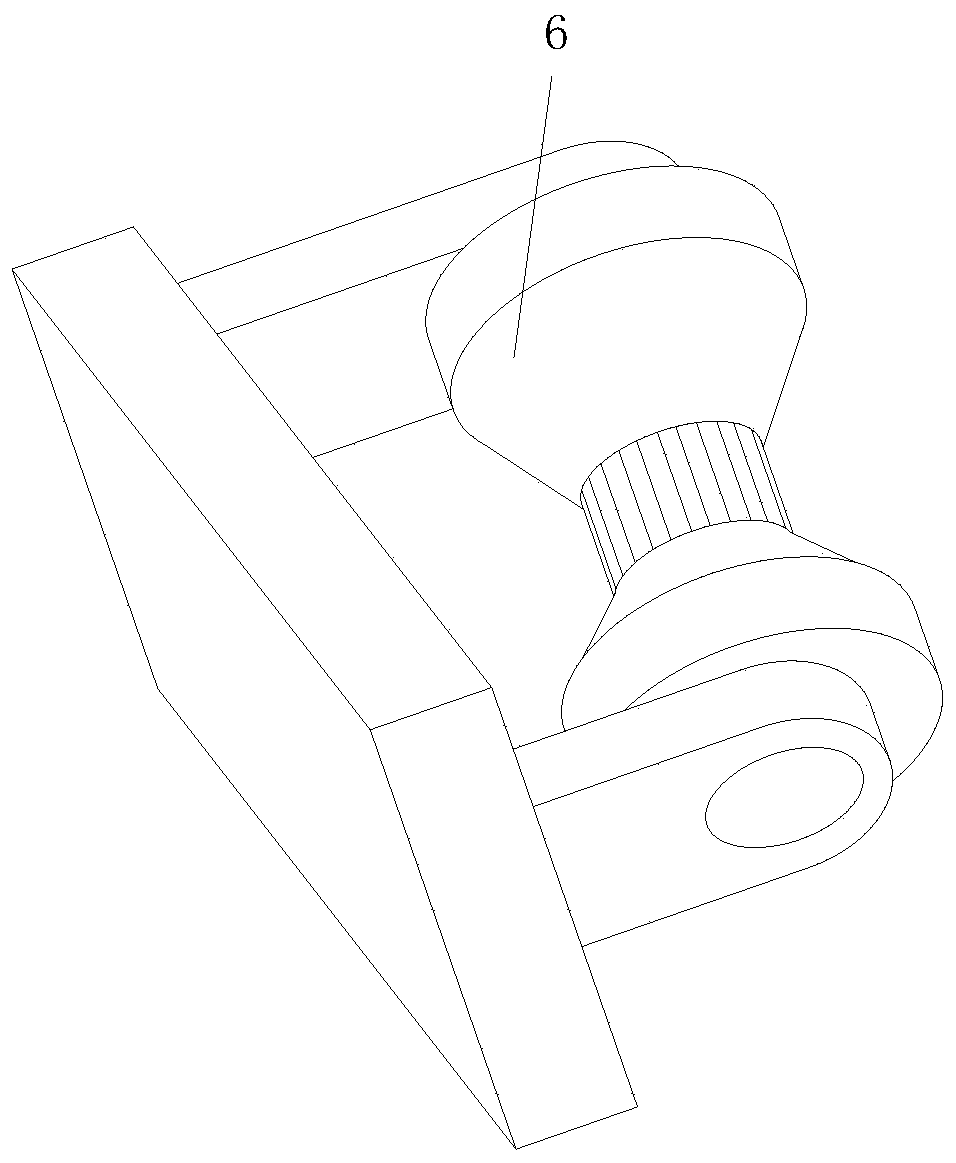

Robot intelligent welding production line

ActiveCN110394573ATo achieve the purpose of beating and removingAchieve the effect of autonomyWelding/cutting auxillary devicesAuxillary welding devicesSlagBall screw

The invention relates to the technical field of welding production lines, in particular to a robot intelligent welding production line. The robot intelligent welding production line comprises a mounting box, a movable plate, a supporting plate, a connecting rod, a knocking head, a contact roller, a drive motor, a cam, a reset spring, dustproof clustered hair, a ball nut, a ball screw, a drive motor, a chip removal hopper, a rotary motor and a clamp. The movable plate is located in the mounting box, the middle position of the left side of the top of the movable plate is fixedly connected with the bottom of the supporting plate, the left end of the connecting rod is fixedly connected with the top of the right side of the knocking head, and the right end of the connecting rod stretches into the mounting box. The purpose that welding slag at the welding position is knocked away through the knocking head is achieved, thus, a manual removing manner is replaced, the whole process and automatic welding supplement each other, a manual participation working manner is reduced, the whole welding line achieves an autonomous effect, then the labor intensity is reduced, and the welding rate is increased.

Owner:中山叁迪智能设备有限公司

Water soluble scaling powder core leadless solder wire

InactiveCN1927524AEasy to cleanLow costWelding/cutting media/materialsSoldering mediaWater solubleCorrosion

The invention relates to a water-soluble welding flux leadless solder wire without, corrosion and bittern. Wherein, it is formed by Cu at 0.5-1, Ni at 0.02-0.1, P at 0.005-0.1, and the left is Sn. The invention has better welding quality, wetting property, bright crystal, better flow ability and better reliability.

Owner:天津市宏远电子有限公司

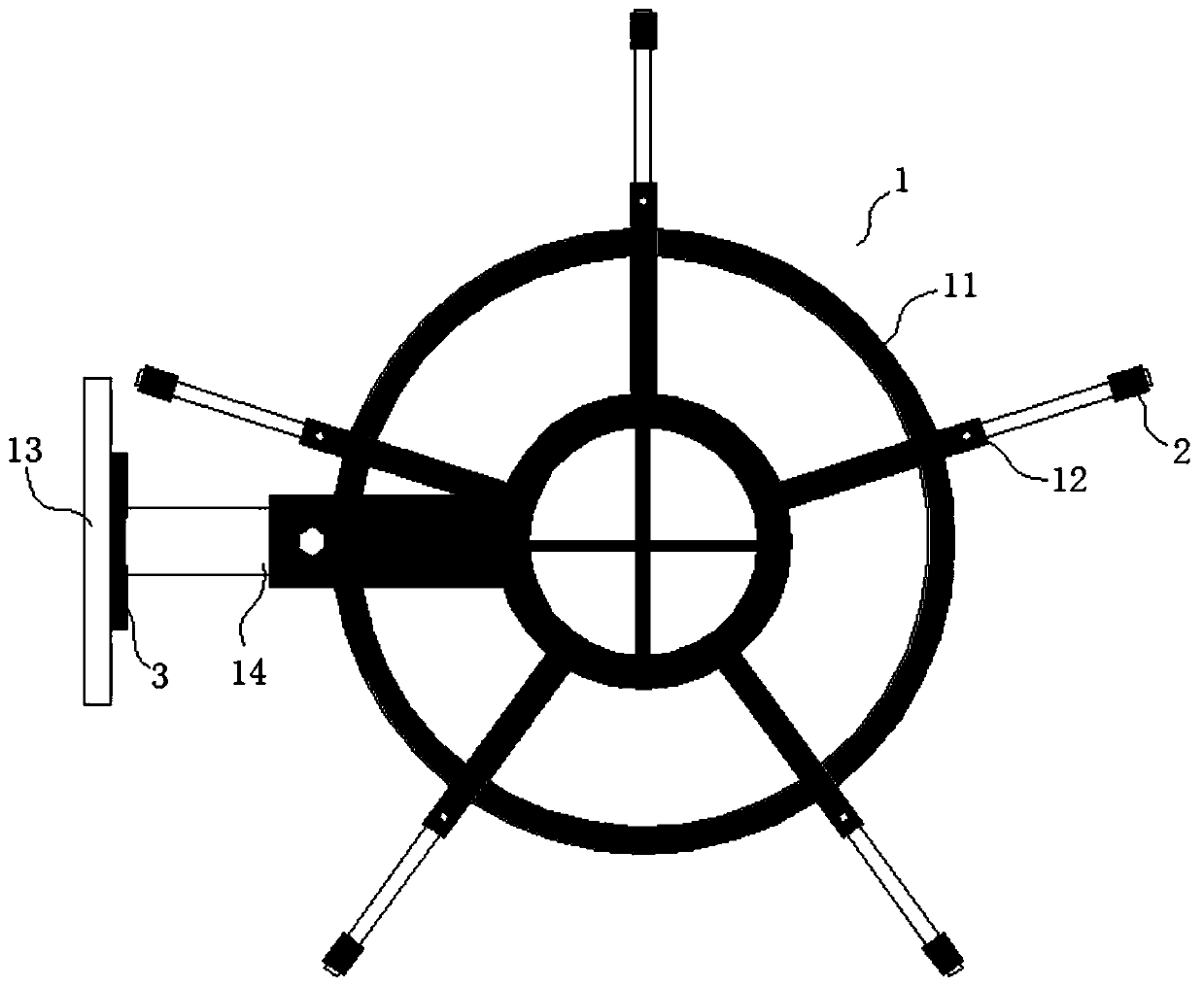

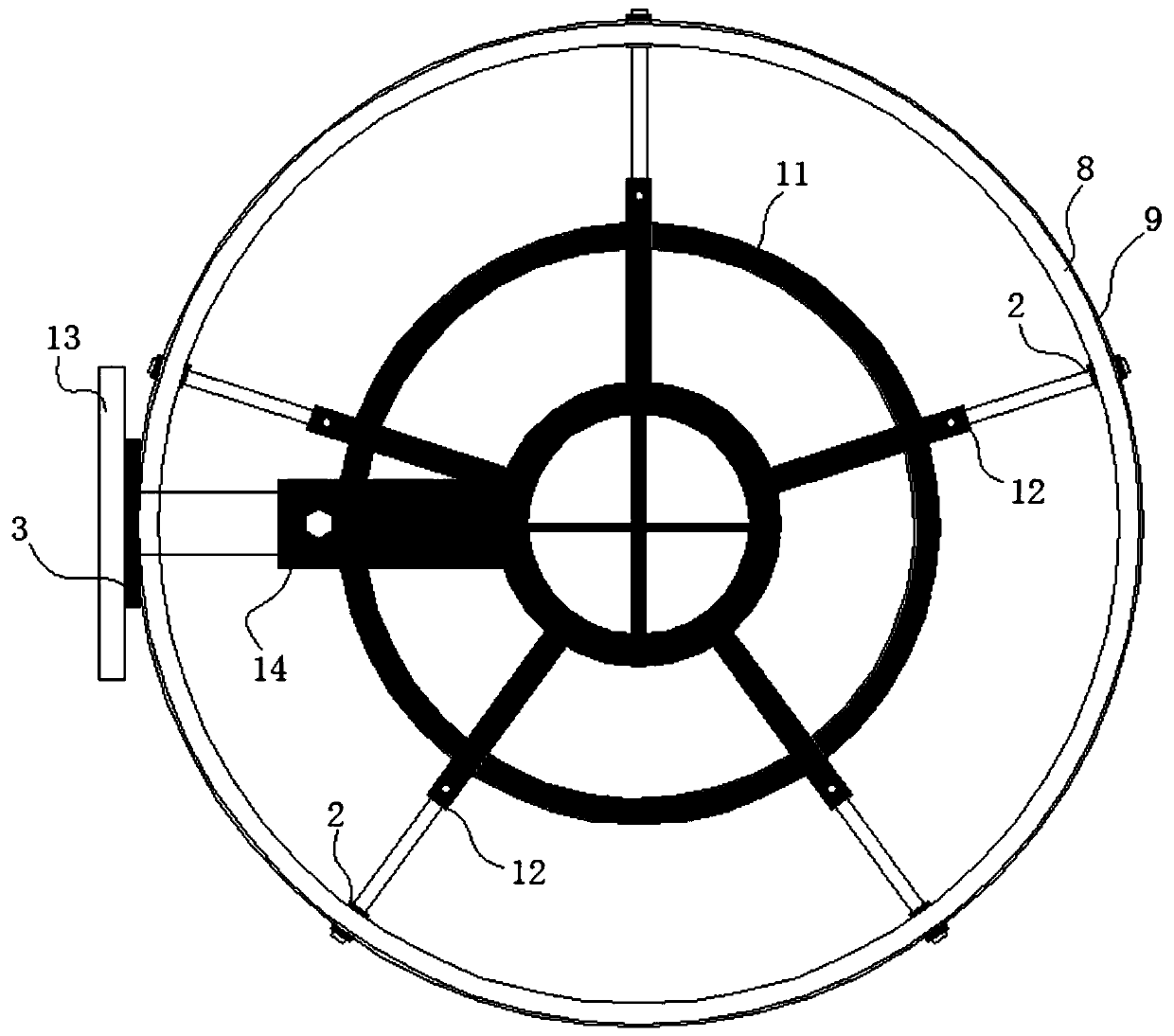

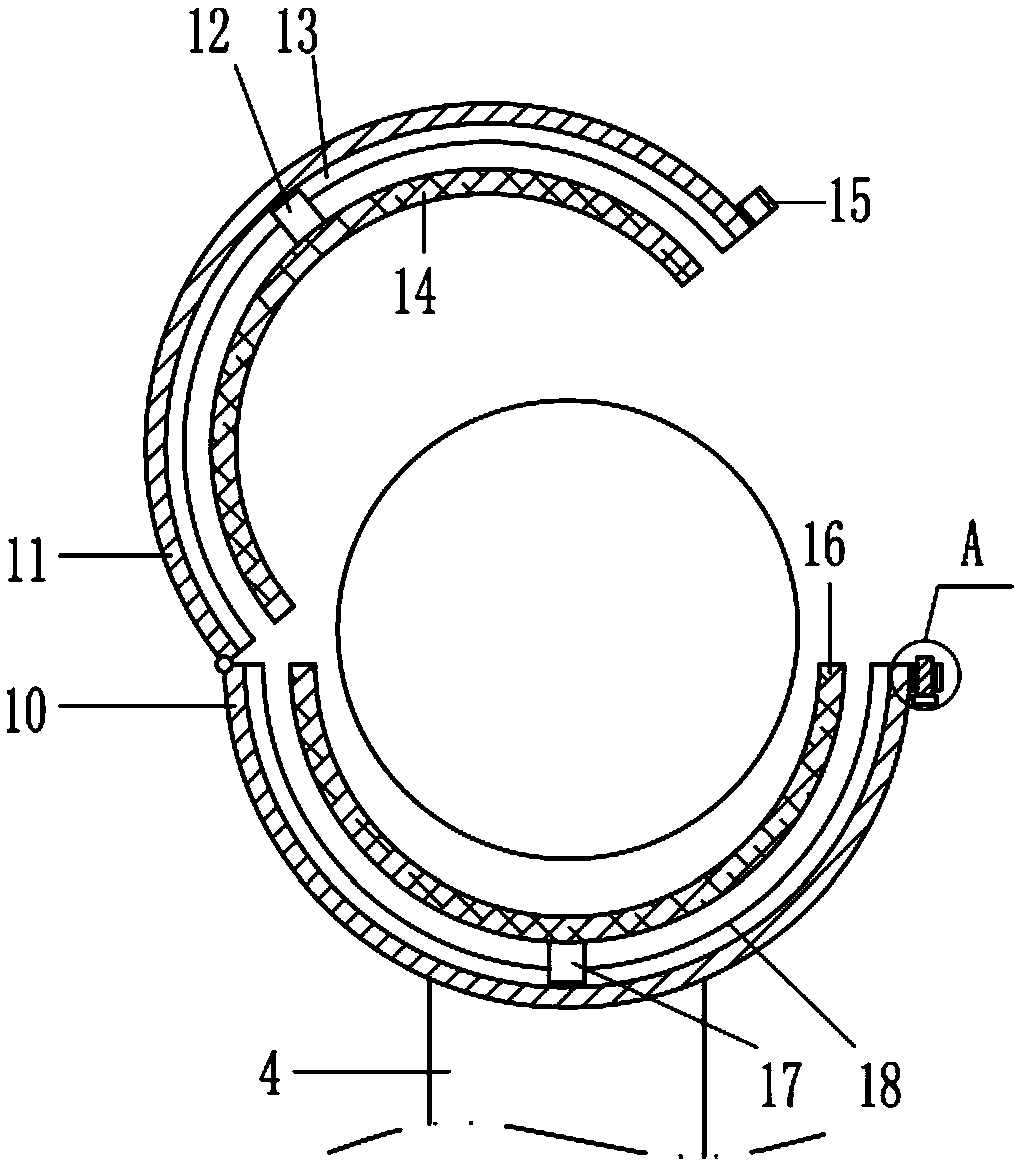

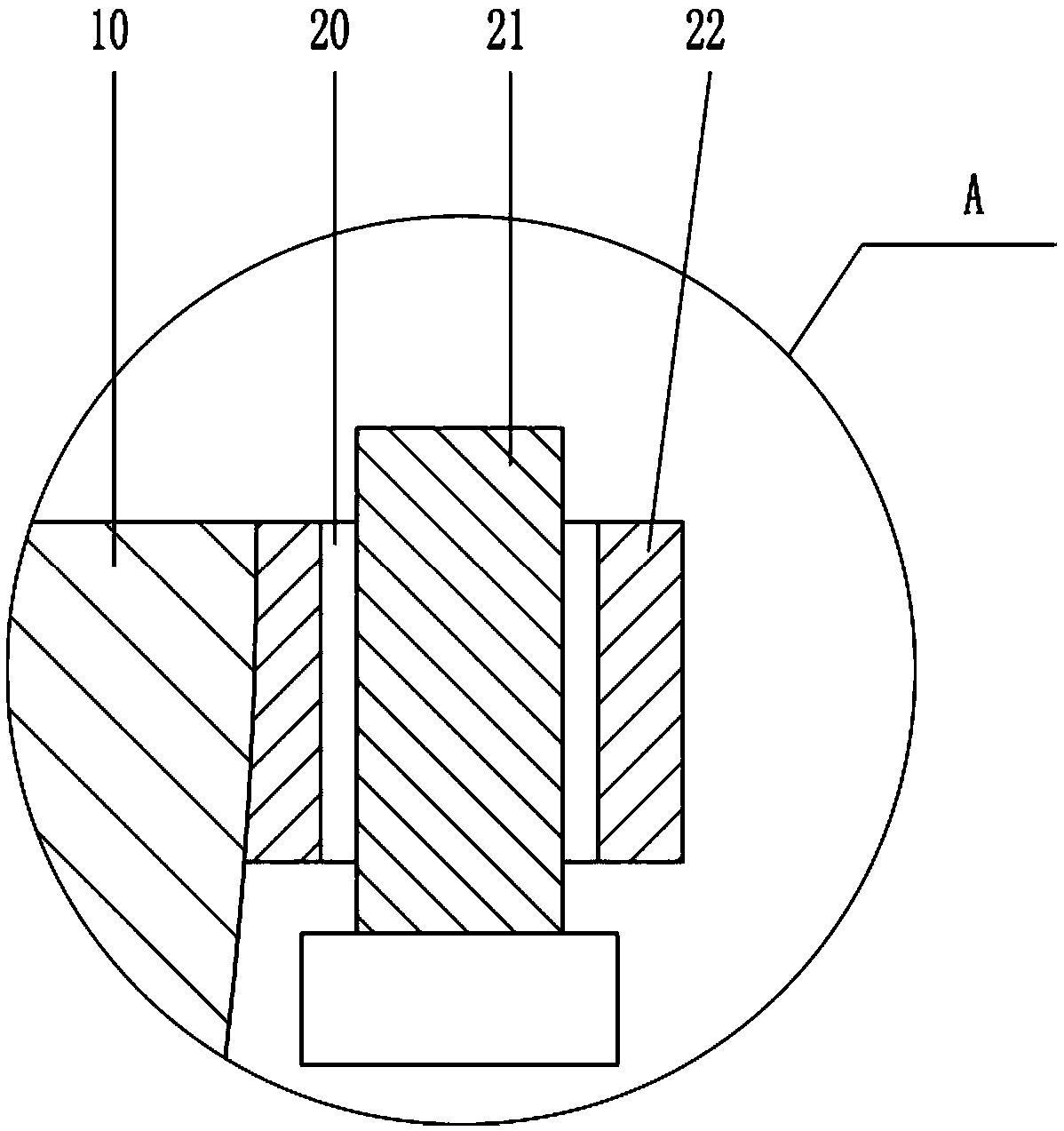

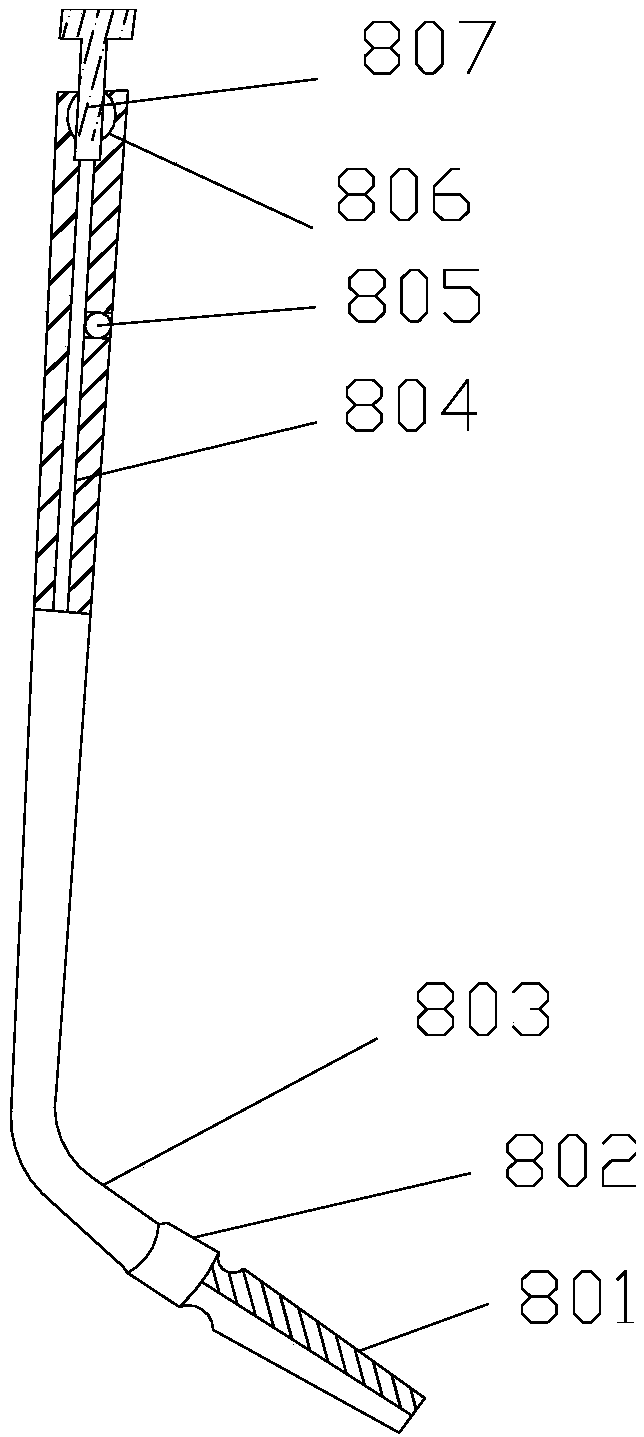

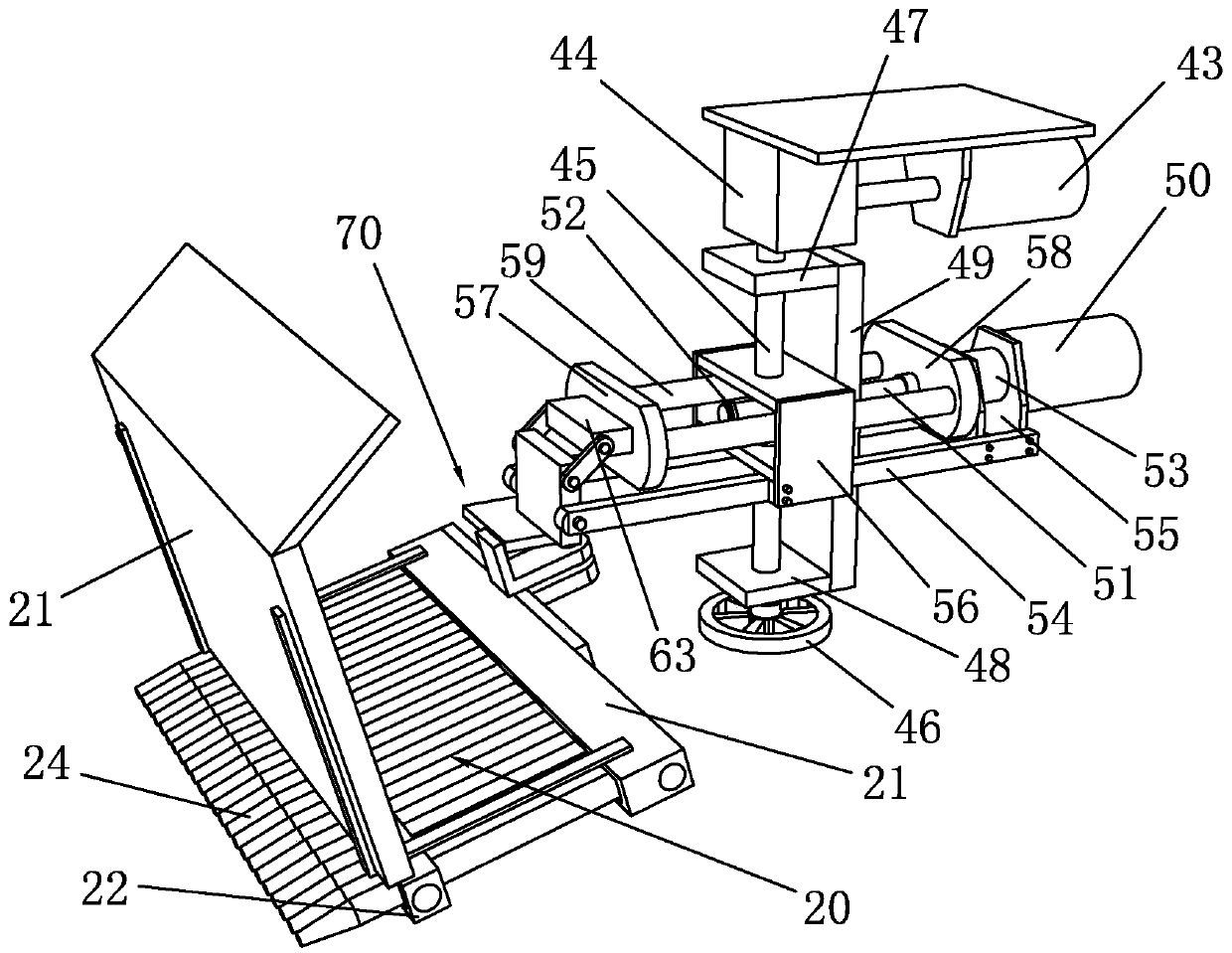

Stiffening ring welding device for large penstock

PendingCN111360481AThe turning process is stable and reliableImprove welding speedWelding/cutting auxillary devicesAuxillary welding devicesPenstockHydraulic ram

The invention discloses a stiffening ring welding device for a large penstock. The welding device comprises a supporting frame, wherein the supporting frame comprises a horizontal part and a verticalpart which are connected to each other; and the horizontal part comprises an annular fixing part and a plurality of carrier roller telescopic arms which are connected with the annular fixing part andarranged in a radial mode, each of the carrier roller telescopic arms is provided with a carrier roller, and the carrier rollers are used for being connected with the end face of a penstock in an abutting mode so as to support the penstock. The device is composed of a hydraulic oil cylinder, a roller frame, the self-made carrier rollers and the like, other steel structures are assembled through equipment and tools in a steel pipe factory, the site construction condition is reasonably considered at the beginning of design, and the device is stable and reliable in the steel pipe turnover process. In the welding process, the welding speed can be effectively increased, the overturning working condition is completed through the hydraulic oil cylinder, the rotating working condition is completedthrough cooperation between the roller frame and the carrier rollers, and the device can be overturned and rotated. The device can be suitable for penstocks with different diameters.

Owner:SINOHYDRO ENG BUREAU 4

Pipeline special robot

ActiveCN108747185AEasy to weldReduce workloadWelding/cutting auxillary devicesAuxillary welding devicesEngineeringBuilding construction

The invention belongs to the field of pipeline construction, and particularly relates to a pipeline special robot. According to the pipeline special robot, the pipeline joint can be easily and comprehensively welded, the welding efficiency is improved, and the labor intensity of workers is relieved. The pipeline special robot comprises a mounting plate, a first supporting seat, a first semicircular supporting plate, a second supporting seat, a mounting rod, a welding gun, a first sliding block, a first semicircular sliding rail, a first semicircular fixing sleeve, a nut, a second semicircularfixing sleeve, a second sliding block, a second semicircular sliding rail, a screw rod, a fixing block and the like; and the first semicircular supporting plate is fixedly connected to one side part of the mounting plate through the first supporting seat, and the second semicircular supporting plate is fixedly connected to the other side part of the mounting plate through a fourth supporting seat.According to the pipeline special robot, the effects that the large pipeline can be comprehensively welded, and the workload of workers during welding is reduced are achieved.

Owner:ZHEJIANG SHUREN UNIV

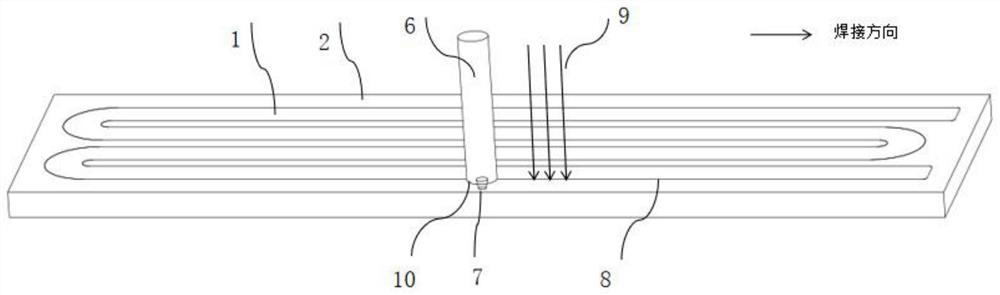

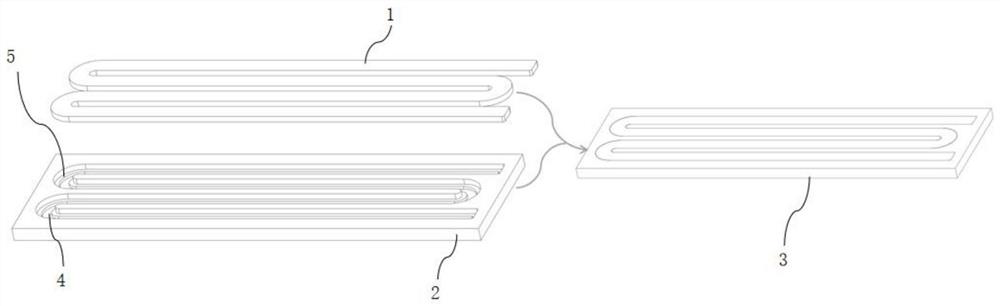

Preparation method of waterway backboard for target material

ActiveCN112045309AImprove welding efficiencyQuality improvementLaser beam welding apparatusNon-electric welding apparatusStructural engineeringErbium lasers

The invention discloses a preparation method of a waterway backboard for a target material. The preparation method is characterized by comprising the following steps that (1) a T-shaped groove is machined in a copper backboard body, and the T-shaped groove comprises a cover plate groove and a water groove which are arranged from top to bottom; (2) a cover plate is placed on the cover plate groove,and a to-be-welded waterway copper backboard is obtained; (3) a welding workpiece is fixed to a rigid tool; (4) a laser device is arranged above the to-be-welded waterway copper backboard; (5) spot welding is conducted on the to-be-welded waterway copper backboard; (6) primary welding is conducted; and (7) secondary welding is conducted, specifically, a welding needle is gradually rotated into ajoint, a focus is located at the joint between the copper backboard body and the cover plate, then a stirring friction head and the laser device are started at the same time, and the stirring frictionhead and the focus are fed synchronously in the welding direction according to the same feeding amount. According to the preparation method of the waterway backboard for the target material, the welding efficiency of the waterway backboard for the target material is improved, and the service life of the stirring friction head is prolonged.

Owner:FUJIAN ACETRON NEW MATERIALS CO LTD

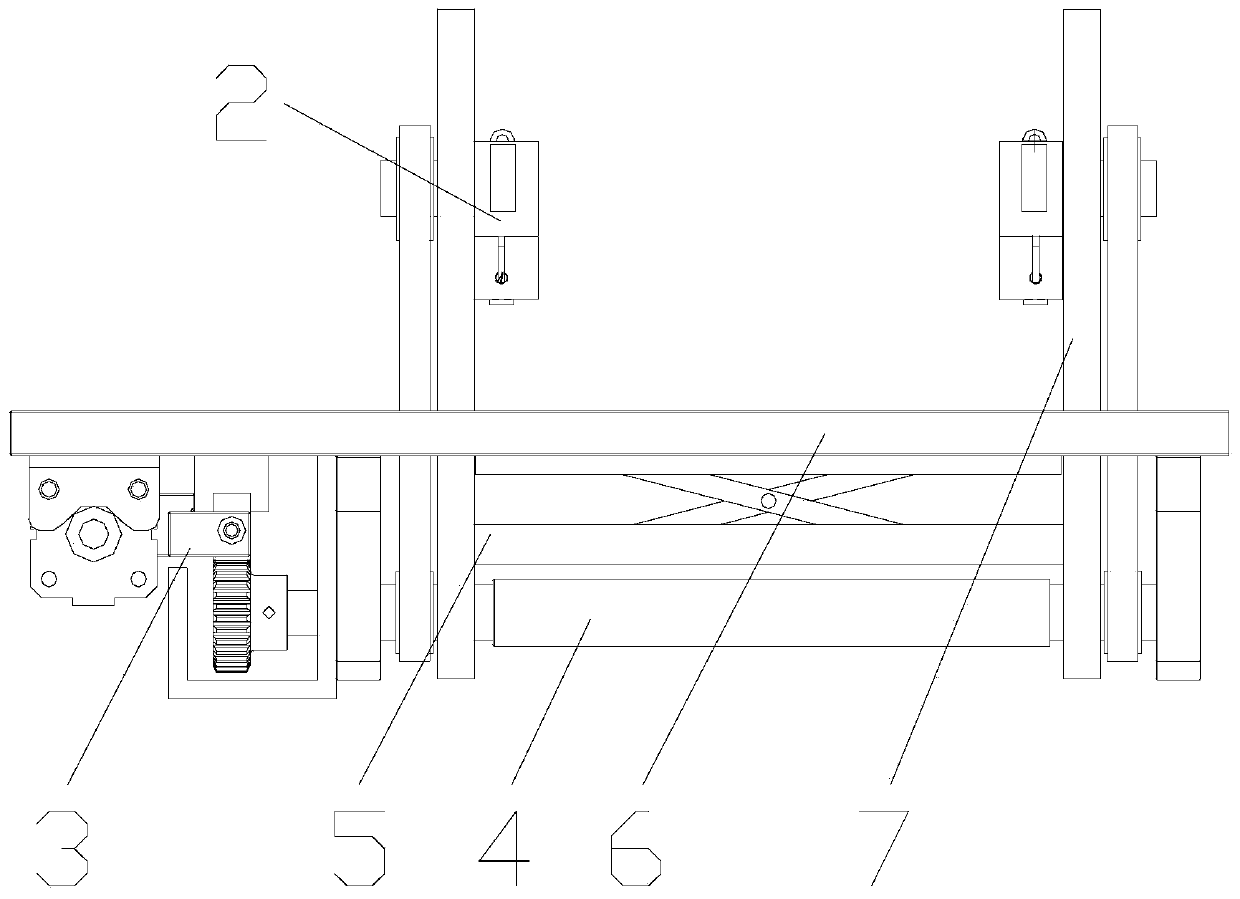

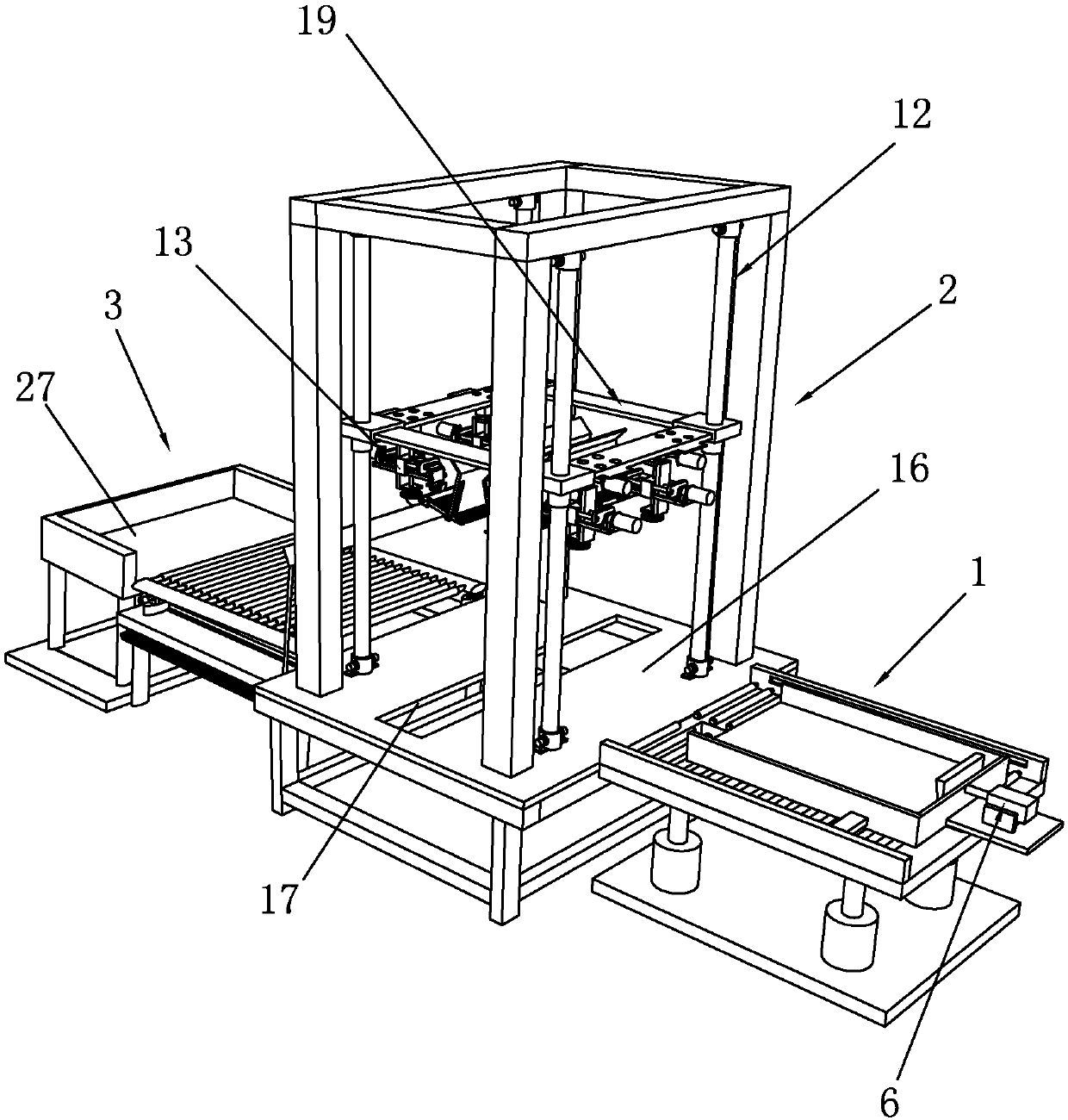

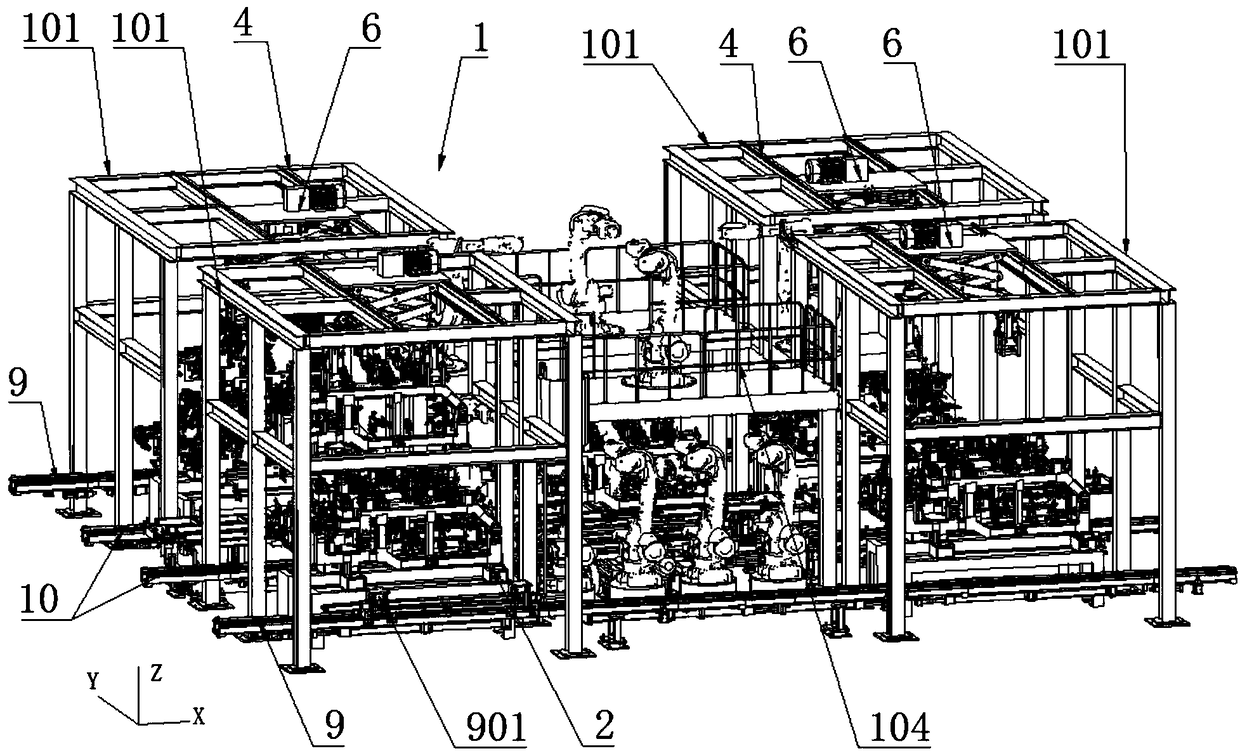

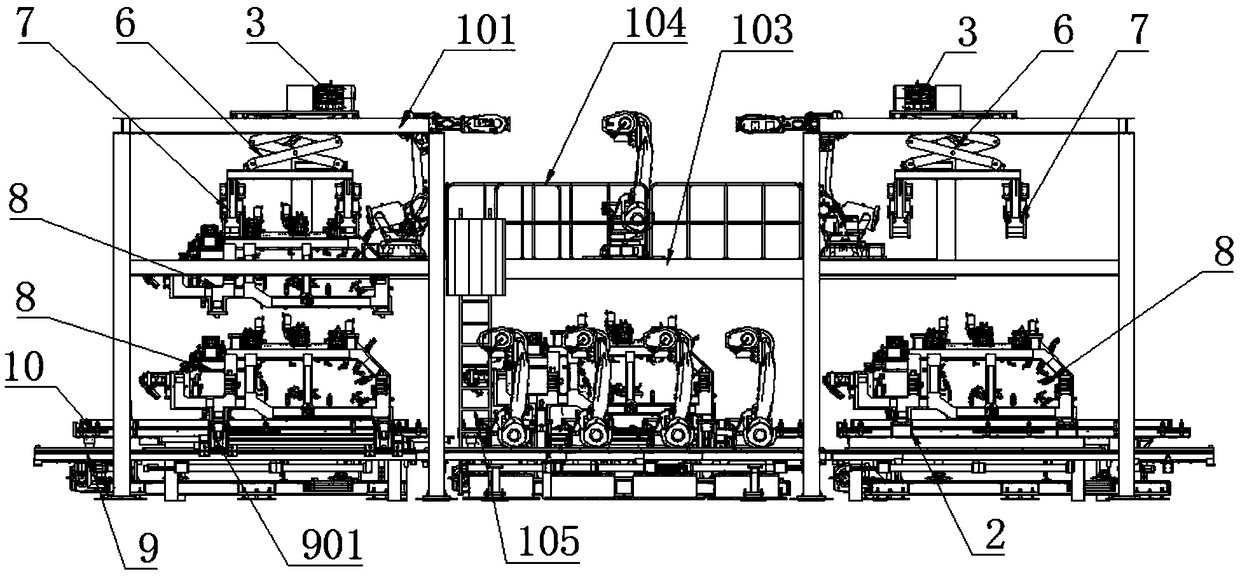

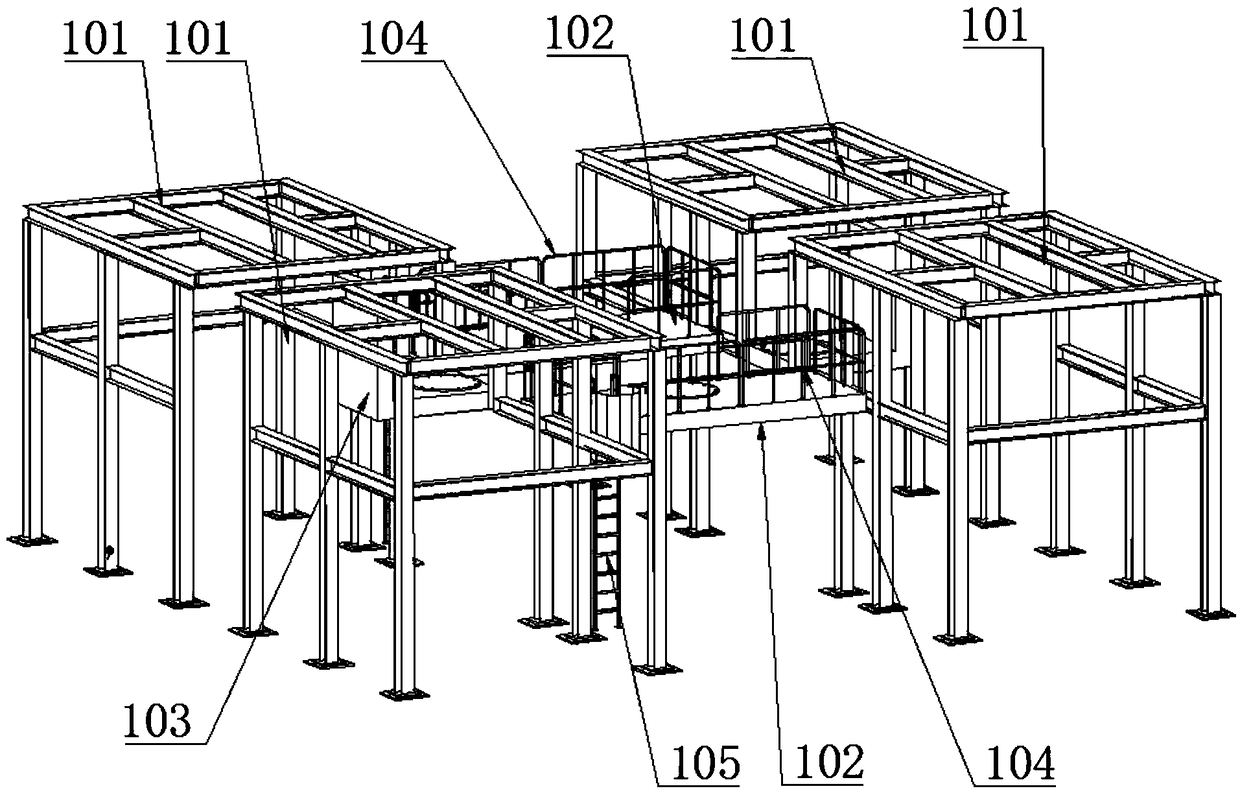

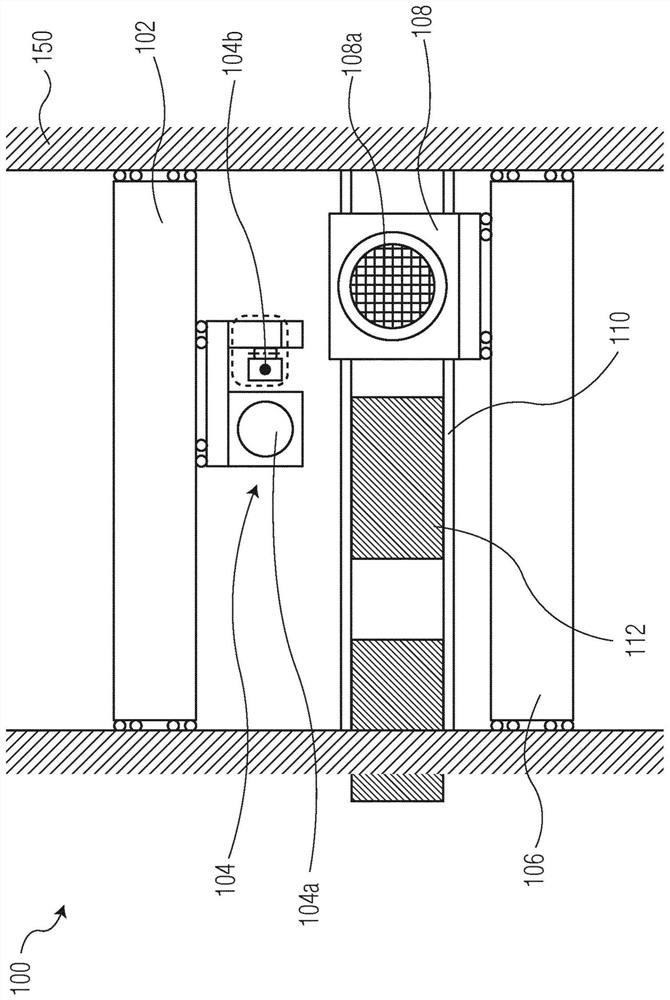

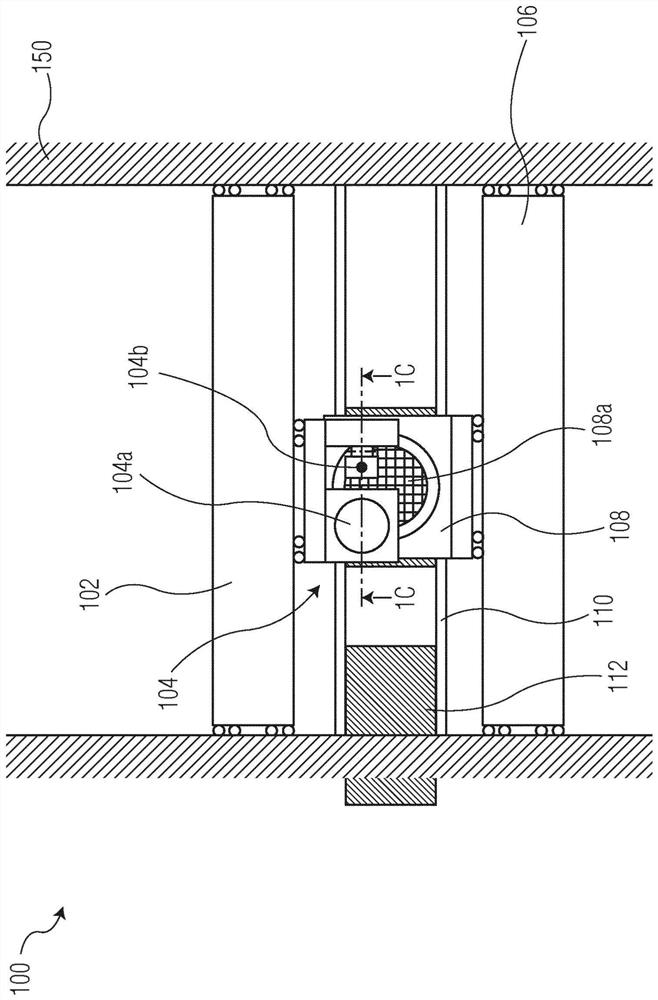

Aerial operation clamp library access device for white vehicle body welding

InactiveCN108857246AReasonable structureCompact structureWelding/cutting auxillary devicesAuxillary welding devicesEngineeringHeavy weight

The invention discloses an aerial operation clamp library access device for white vehicle body welding. The aerial operation clamp library access device for white vehicle body welding comprises a welding platform consisting of multiple uniformly arranged supporting frames, an X-directional vehicle body delivery track, a clamp positioning seat and an X-directional clamp delivery track, wherein theX-directional vehicle body delivery track, the clamp positioning seat and the X-directional clamp delivery track are arranged below the supporting frames, the supporting frames are provided with clampswitching mechanisms, each clamp switching mechanism comprises two Y-directional running guide rails arranged at the top of the corresponding supporting frame, a shear fork lifting machine capable ofsliding is supported on the two Y-directional running guide rails, a Y-directional running mechanism driving the shear fork lifting machine to slide in the Y direction is arranged between the shear fork lifting machine and the supporting frame, and the lower end of the shear fork lifting machine is provided with a clamp gripper mechanism for gripping vehicle body side clamps. The aerial operationclamp library access device adopts the design of the shear fork lifting machines and is easy to control and operate and capable of gripping vehicle clamps of heavier weights, transferring larger weight loads and controlling operation precision, and the overall stability and control precision of the aerial operation clamp library access device are improved.

Owner:广州德恒汽车装备科技有限公司

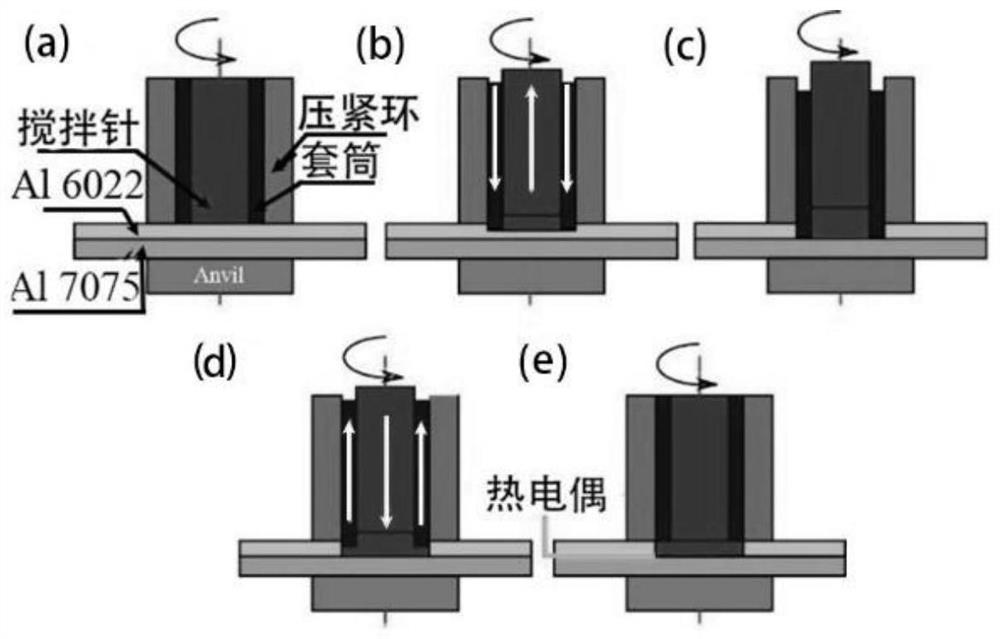

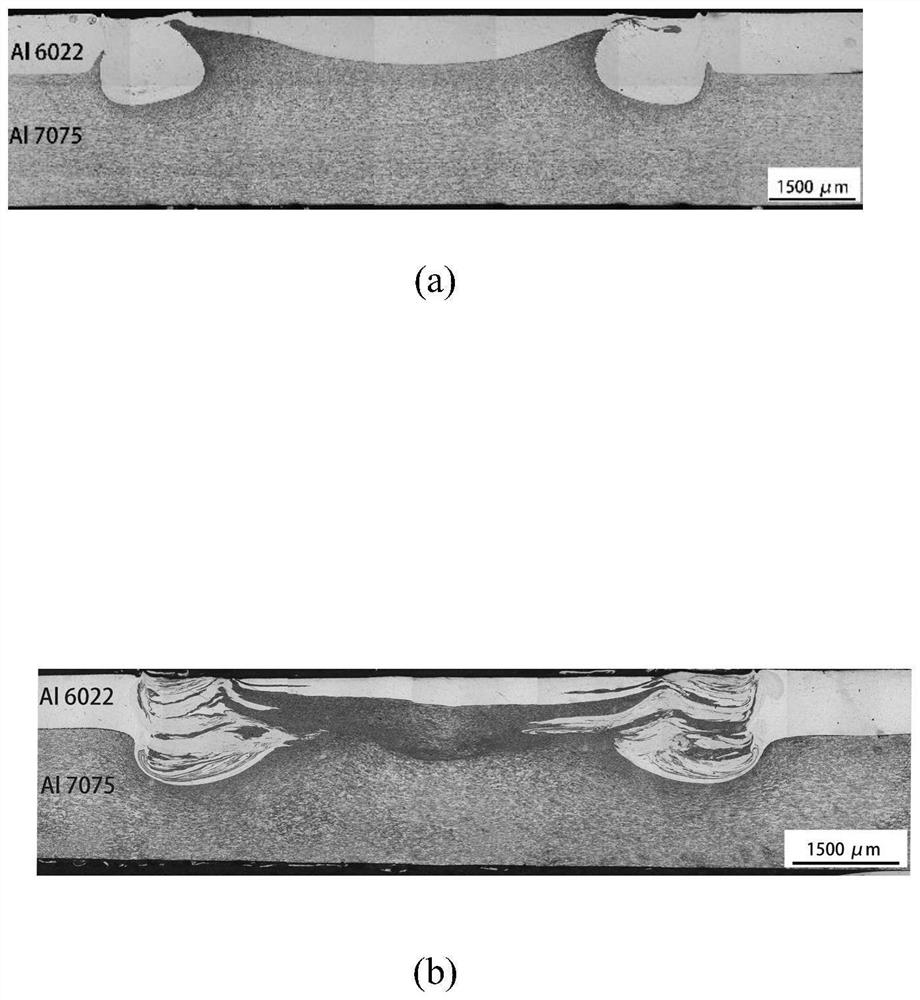

Method for improving welding efficiency of backfill type friction stir spot welding

PendingCN113369670AIncrease downforceIncrease heat input rate and heat utilization rateNon-electric welding apparatusSpot weldingMaterials science

The invention provides a method for improving the welding efficiency of backfill type friction stir spot welding. The problems of long welding time, low welding efficiency and unfavorable industrial production in the prior art are solved. According to the method, the pressing speed of a sleeve in the pressing stage of the sleeve is improved in the welding process of traditional backfill type friction stir spot welding, and the pressing speed is 80-520 mm / min. According to the method, the downward pressing speed of a stirring head is increased, downward pressing force is increased, the heat input rate and the heat utilization rate are increased, meanwhile, the welding insertion time is shortened, heat cannot be dissipated into the surrounding environment in time, the sleeve is pressed downwards, a stirring needle is squeezed back, materials in a cavity are dynamically recrystallized, finally backfilling is conducted, and a defect-free compact-structure welding joint is formed.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

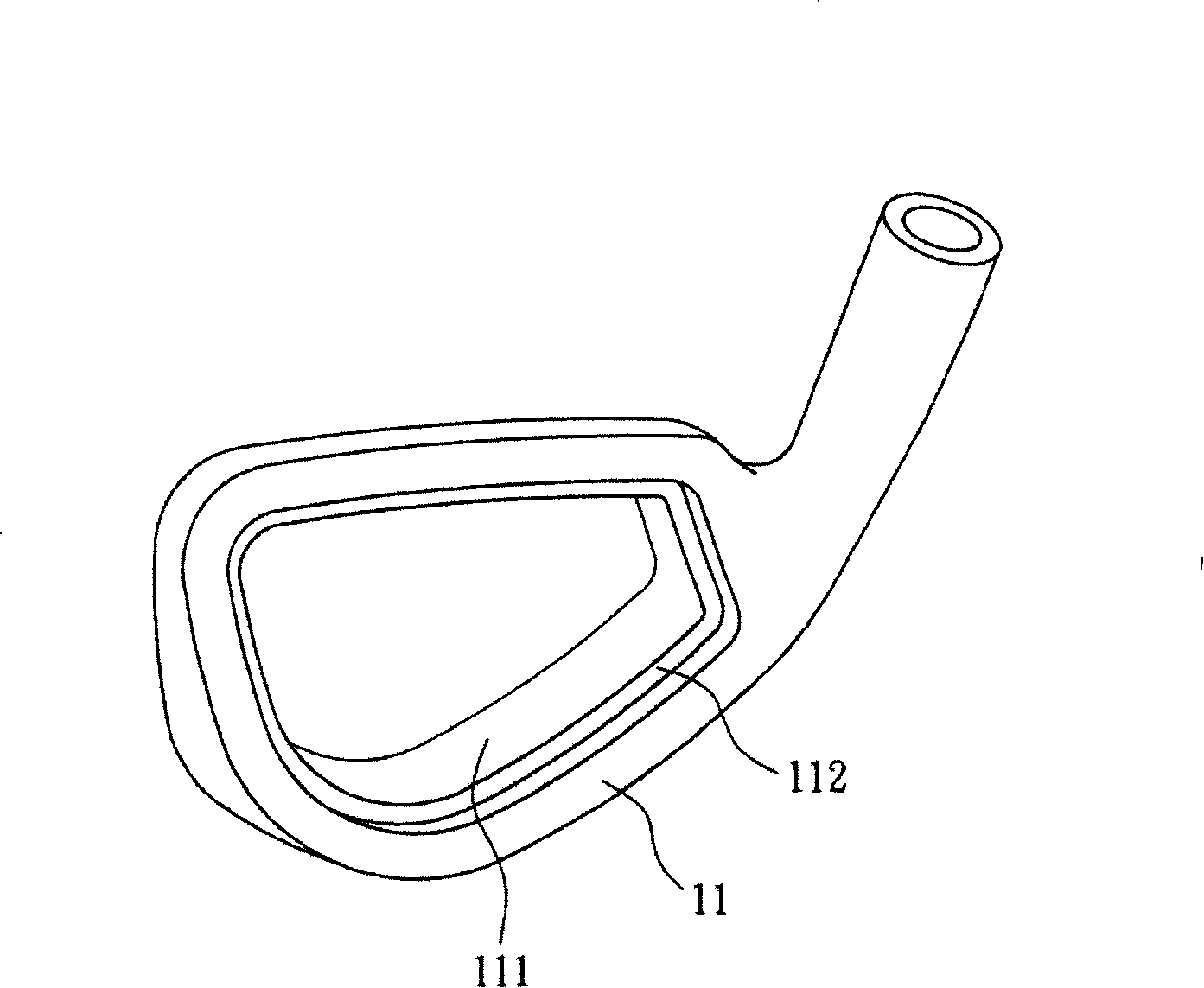

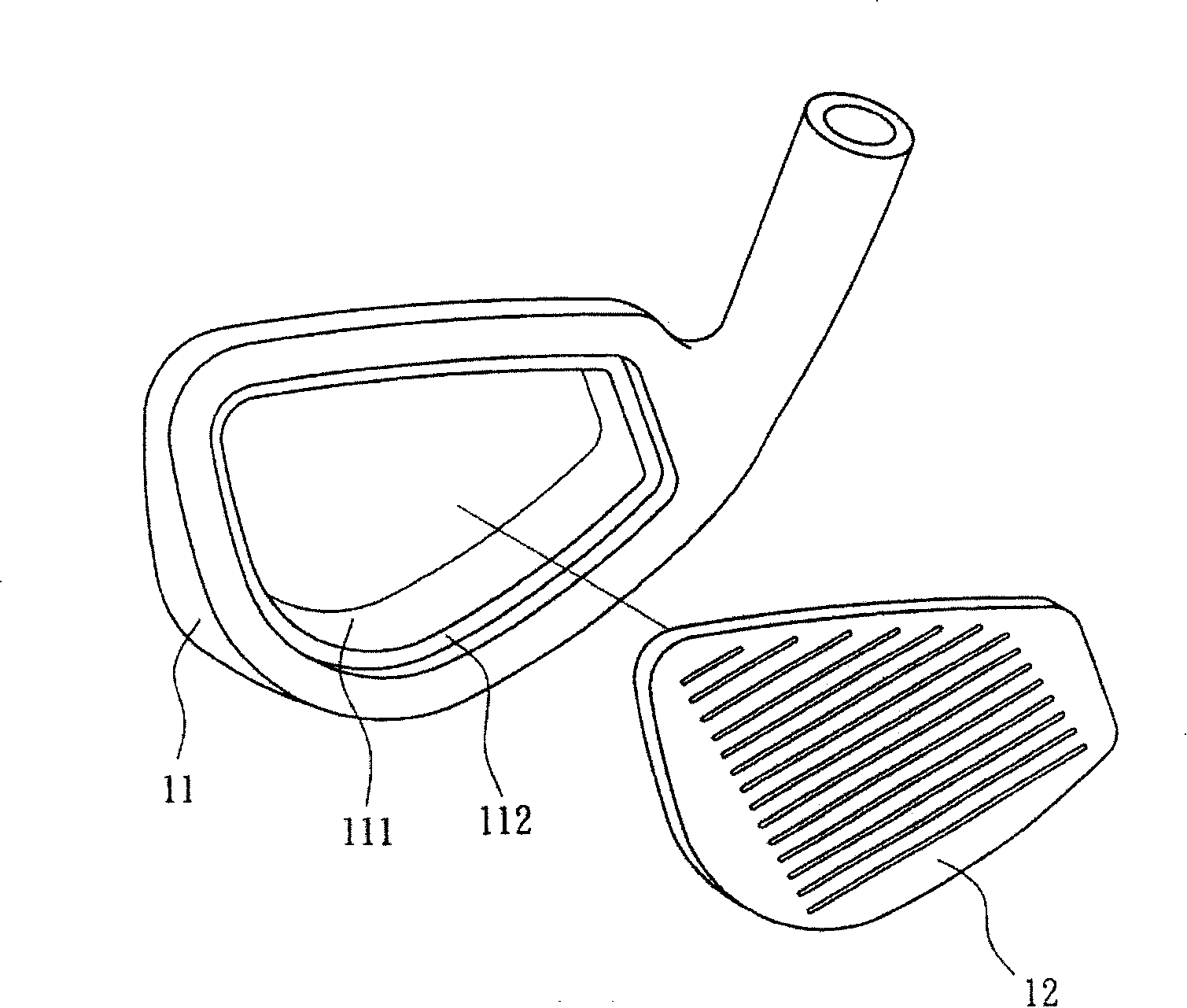

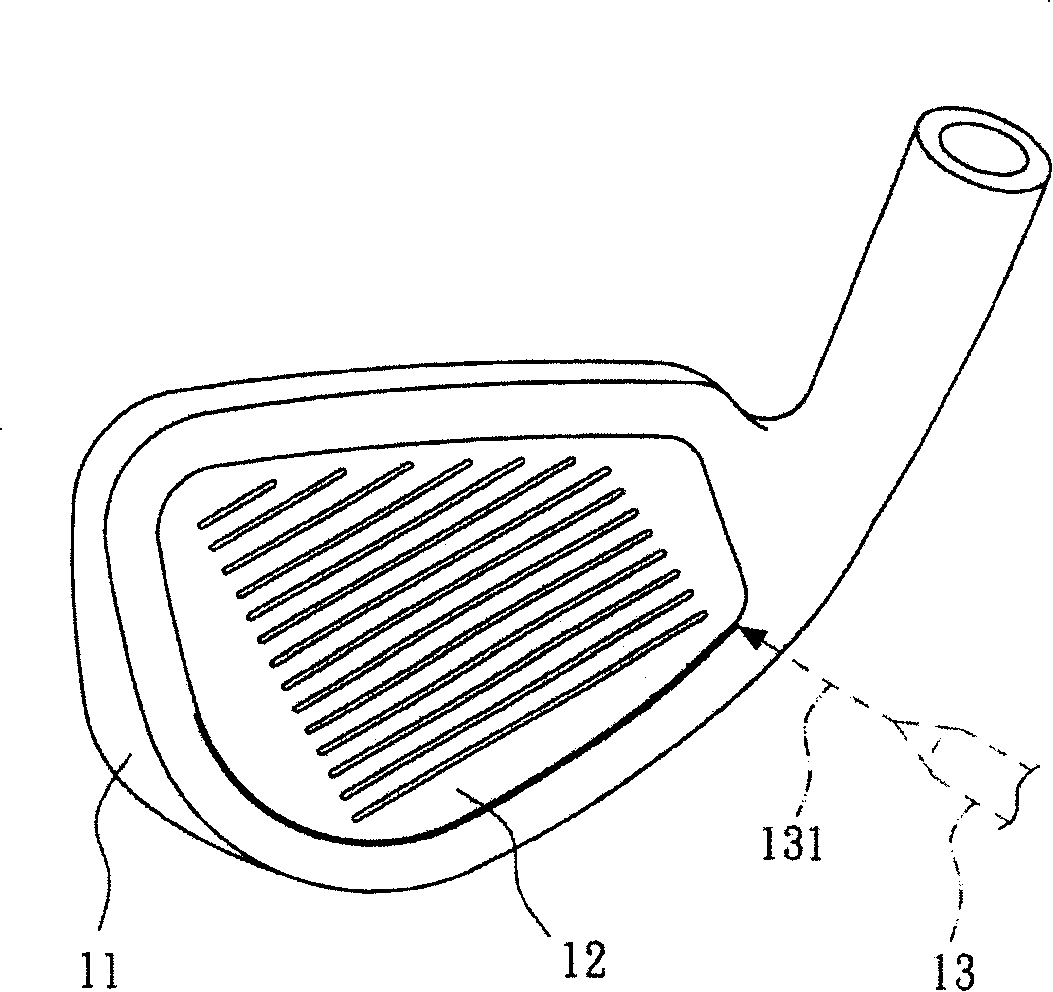

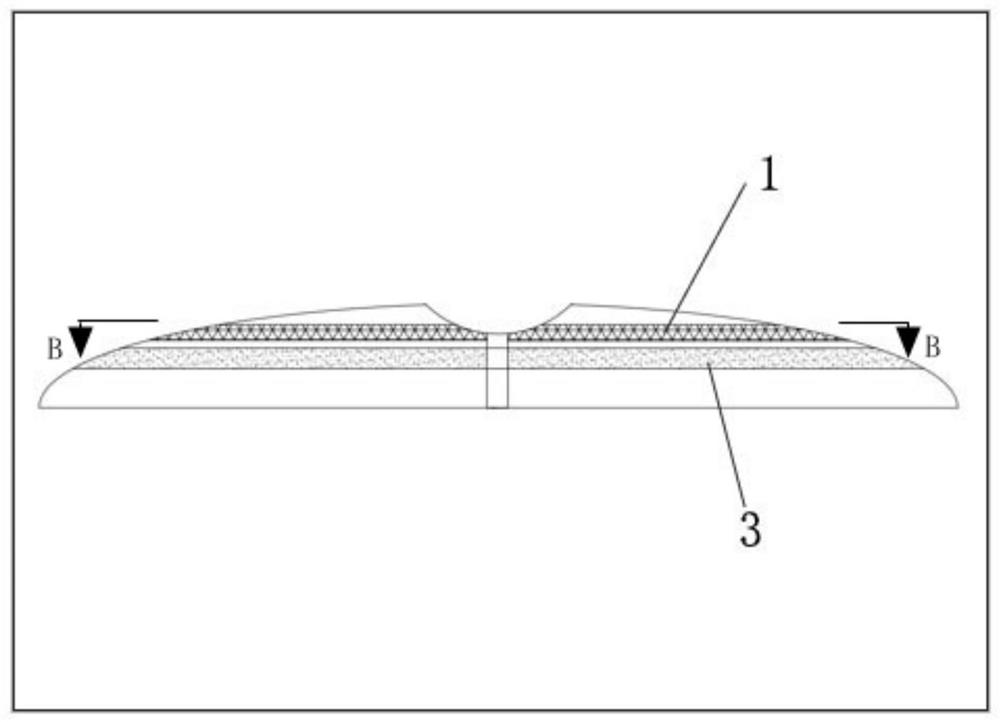

Golf club and welding method thereof

InactiveCN101195069AImprove welding speedIncrease productivityWelding/cutting media/materialsSoldering mediaEngineeringGolf club

The invention relates to a golf head and a welding method. The welding method comprises arranging a metal plate in an opening hole of a metal body, wherein the shape of the metal plate is matched with the shape of the opening hole, then respectively contacting a first electric pole and a second electric pole with the back surface of the metal body and the top surface of the metal plate, wherein the shape of the first electric pole and the second electric pole are respectively matched with the shape of the bake surface and the top surface, finally conducting electric current through the first electric pole and the second electric pole, and connecting the metal plate and the metal body through the mode of electric-resistance weld. The welding method of the invention is utilized which greatly increases welding speed, raises productivity, and increases the connecting intensity of the weld, simultaneously, a golf head which is welded has high smoothness, and the subsequent processing cost can be reduced.

Owner:METAL INDS RES & DEV CENT

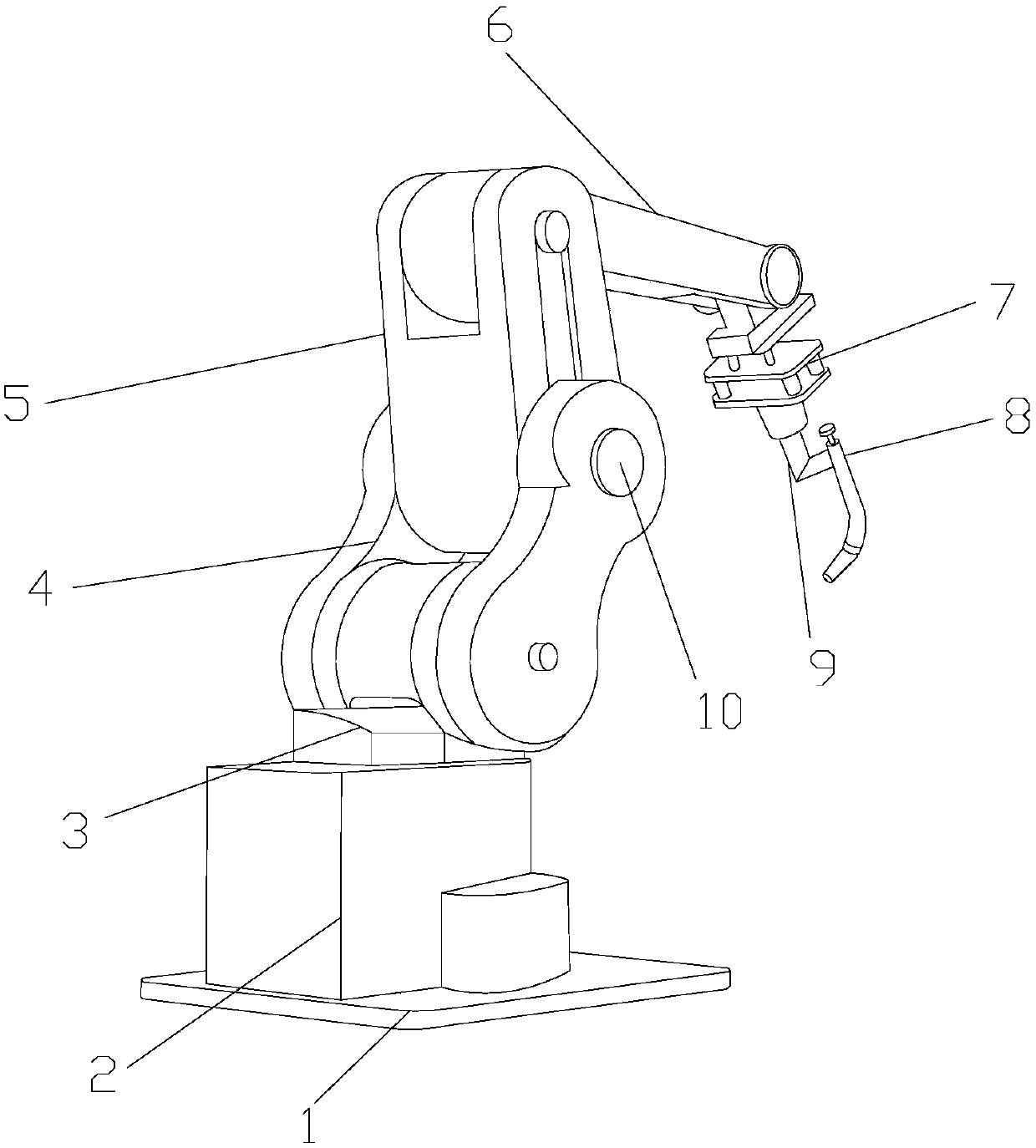

High-accuracy car welding robot

InactiveCN107584235AImprove welding precisionIncrease shrinkage rateProgramme-controlled manipulatorWelding/cutting auxillary devicesEngineeringAtmospheric pressure

The invention discloses a high-accuracy car welding robot. The high-accuracy car welding robot structurally comprises a chassis, a base, a wiring box, a front arm, an upper arm, a small arm, a rotaryflange disc, a welding gun, a connecting plate and a rotary shaft, wherein the upper end of the chassis is laminated with the lower end of the base; the wiring box is arranged at the upper end of thebase; and the upper arm is embedded and connected in the front arm which is connected with the rotary shaft. The high-accuracy car welding robot disclosed by the invention has the advantages that theleft side of the welding gun is welded with the right side of the connecting plate, and by mechanical movement of the front arm, the upper arm and the small arm, the welding robot can move in all directions; by rotation of the rotary flange disc, the welding gun can carry out all-directional welding; the size of the air pressure in a mixed gas pipe is controlled by the tightening degree of an oxygen handwheel, and then the speed of shrinkage of an injection pipe is accelerated, so that the welding speed of a welding nozzle is accelerated; and the welding speed of the welding gun can be controlled when a worker uses a tin-welding robot, so that the welding accuracy of the robot is improved.

Owner:HUBEI HAILIAN TECH CONSULTATION CO LTD

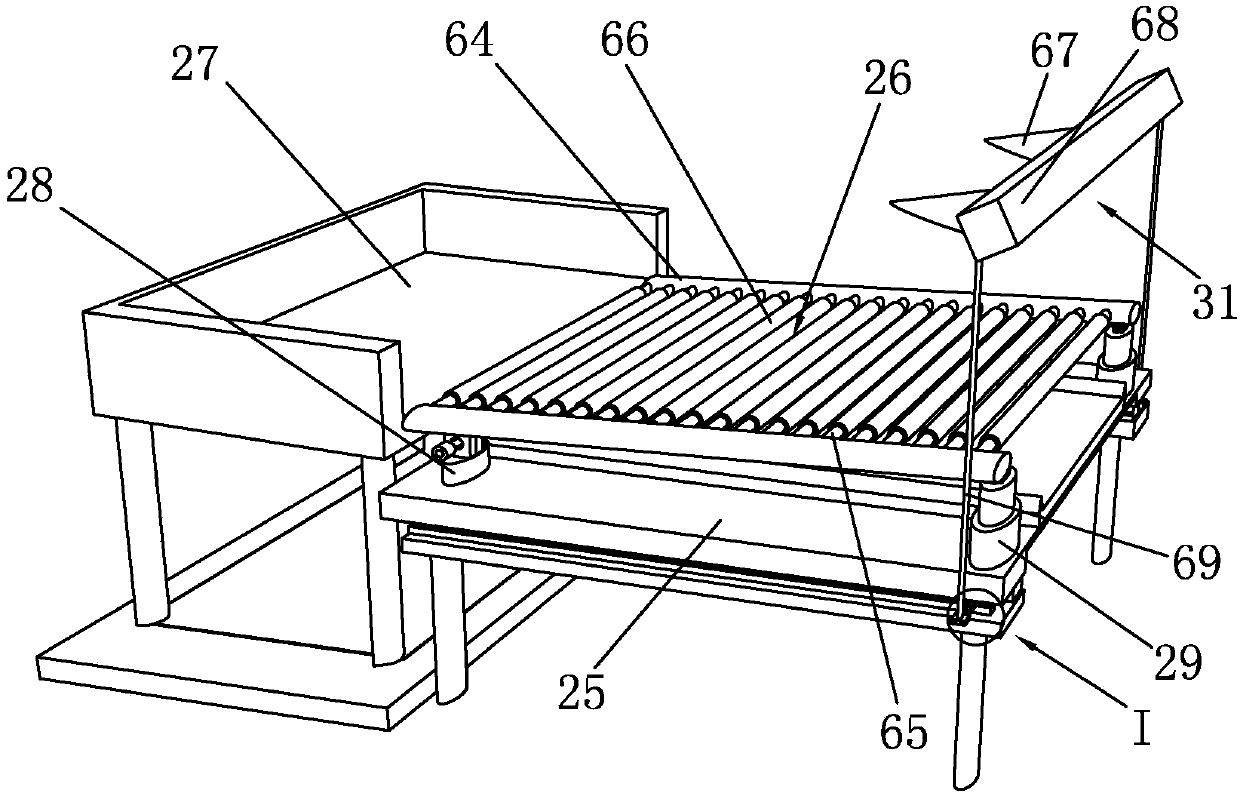

Semitrailer beam welding tool and welding process thereof

InactiveCN109986272AGuaranteed pair clearanceGuaranteed welding sizeWelding/cutting auxillary devicesAuxillary welding devicesArchitectural engineeringAir cylinder Press

The invention belongs to the technical field of aluminum alloy welding, and relates to a semitrailer beam welding tool and a welding process thereof. The tool comprises a tool fixing frame, a turnoversupport rotationally arranged on the tool fixing frame, an air cylinder pressing device and a connecting groove fixing end limiting device, wherein the air cylinder pressing device and the connectinggroove fixing end limiting device are fixedly arranged at the two ends of the turnover support, a to-be-assembled-and-welded welding beam wing plate is clamped between the air cylinder pressing device and the connecting groove fixing end limiting device, and a plurality of beam turnover limiting blocks used for clamping the to-be-assembled-and-welded welding beam wing plate are fixedly arranged on the turnover support. The tool solves the problems that in the prior art, when a semitrailer framework cross beam is independently welded, grouping errors are prone to occur, and the welding efficiency is low.

Owner:LIAONING ZHONGWANG SPECIAL VEHICLE MFG

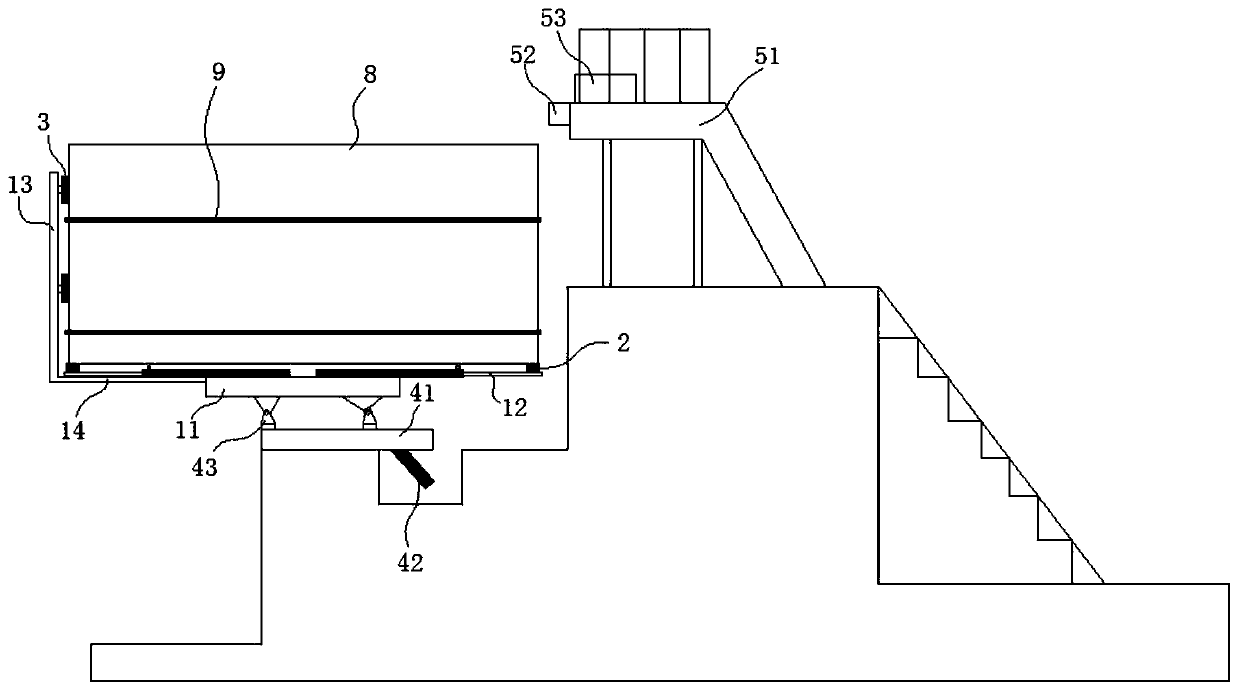

Stream oil tank processing equipment

PendingCN111619130AImprove welding speedPrecise positioningDomestic articlesProcess engineeringChain drive

The invention discloses stream oil tank processing equipment. Speed chains in the equipment comprise an upper speed chain and a lower speed chain. The upper speed chain and the lower speed chain are arranged on a circular processing body in a sleeving manner. A first lifting unit and a second lifting unit of a lifting module are arranged at two ends of the circular processing body. An oil tank isplaced on a tool plate module, the first lifting unit conveys an unprocessed oil tank to the circular processing body, the oil tank is driven by the upper speed chain and is positioned and detected bya tool plate detection module, a blocking mechanism blocks the oil tank to stay in a preset position, a manipulator welds and processes the oil tank, and the second lifting unit conveys the processedoil tank to an appointed area. According to the stream oil tank processing equipment, a welded part is positioned precisely by means of the tool plate detection module and the positioning mechanism on the tool plate module, so that the welding quality is improved and the welding speed is improved.

Owner:深圳市远望工业自动化设备有限公司

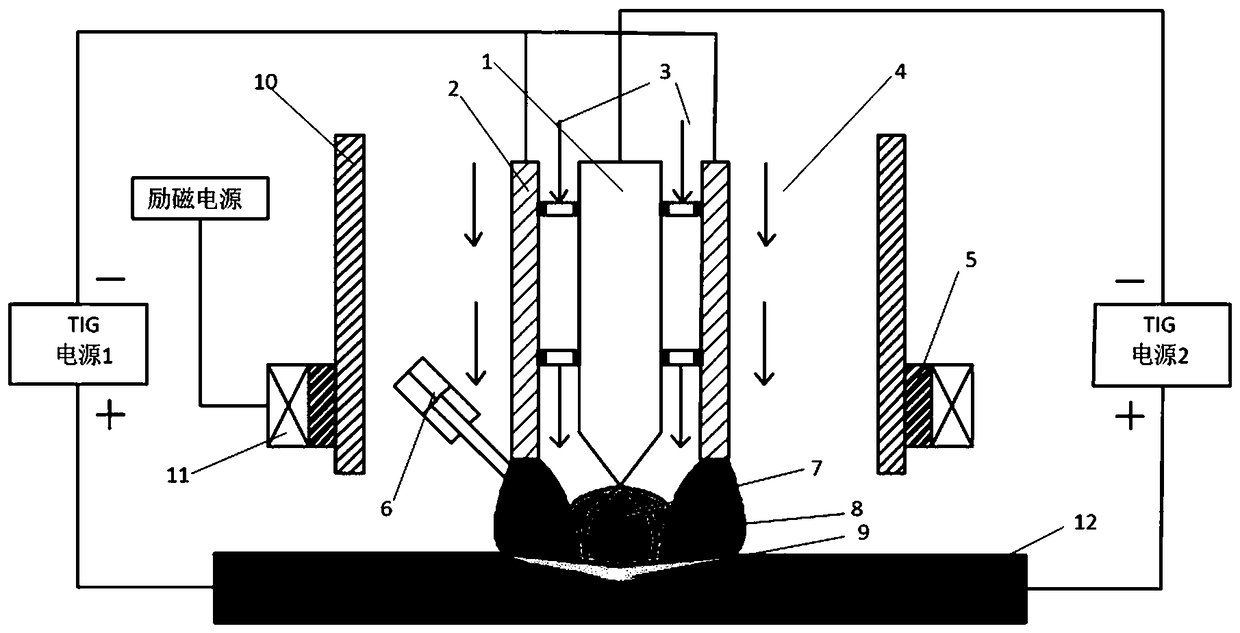

Welding method for gas-magnetic combined control double-tungsten-electrode TOPTIG

The invention discloses a welding method for a gas-magnetic combined control double-tungsten-electrode TOPTIG. The welding method comprises the following steps of 1, fixing a work piece to be welded on a welding fixture; 2, setting the welding parameters, specifically the welding current is 50-200 A, the welding speed is 120-400 mm / min, the wire feeding speed is 50-900 mm / min, the included anglesof a welding wire and tungsten electrodes are both 15 DEG-30 DEG, and the air flow of an inner hole of the hollow tungsten electrode is 5-15 L / min; and 3, starting a controlling switch, firstly aerating shielding gas, energizing an electromagnetic coil, then sequentially performing arcing of the ordinary tungsten electrode and the hollow tungsten electrode, controlling the two arcs to be coupled to reduce air blow between the two tungsten electrodes by adjusting the air flow of the inner hole of the hollow tungsten electrode and changing the intensity of the access current of the electromagnetic coil 2.0 to 3.0 s after igniting arcs, feeding the welding wire in highest temperature region under the arc action, and moving a welding torch along the welding line for the welding of the work piece. By means of the welding method, double-tungsten-electrode arc coupling is adopted for welding, so that the arc heat is increased, the welding wire melts more quickly, the welding rate is improved,and the high speed and high efficiency welding is achieved.

Owner:JIANGSU UNIV OF SCI & TECH

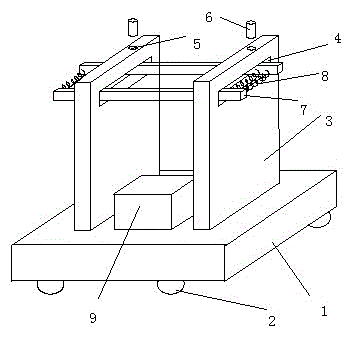

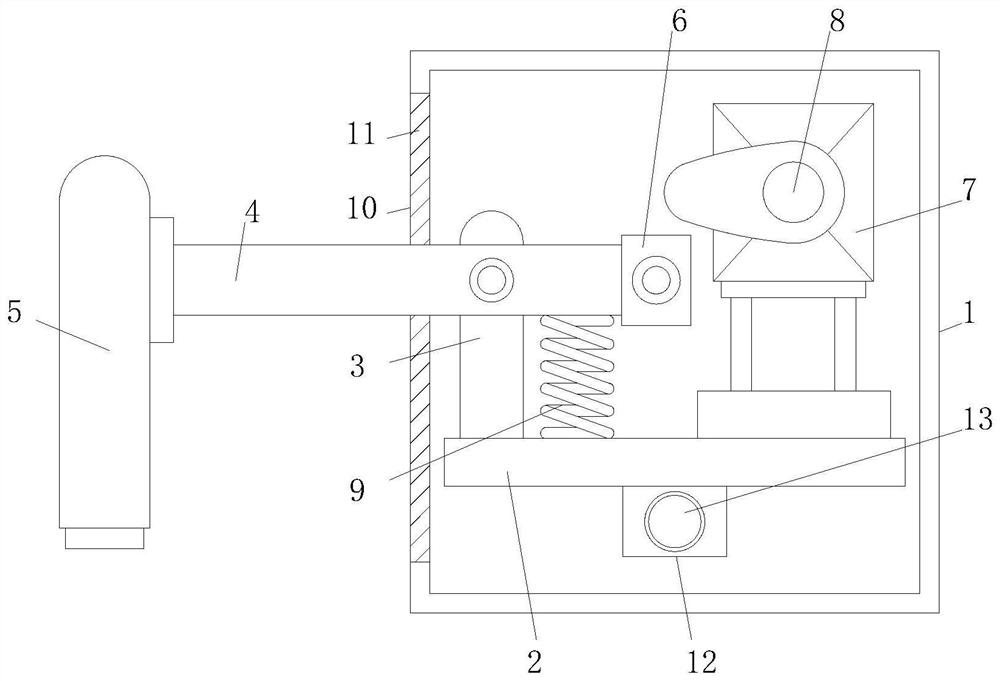

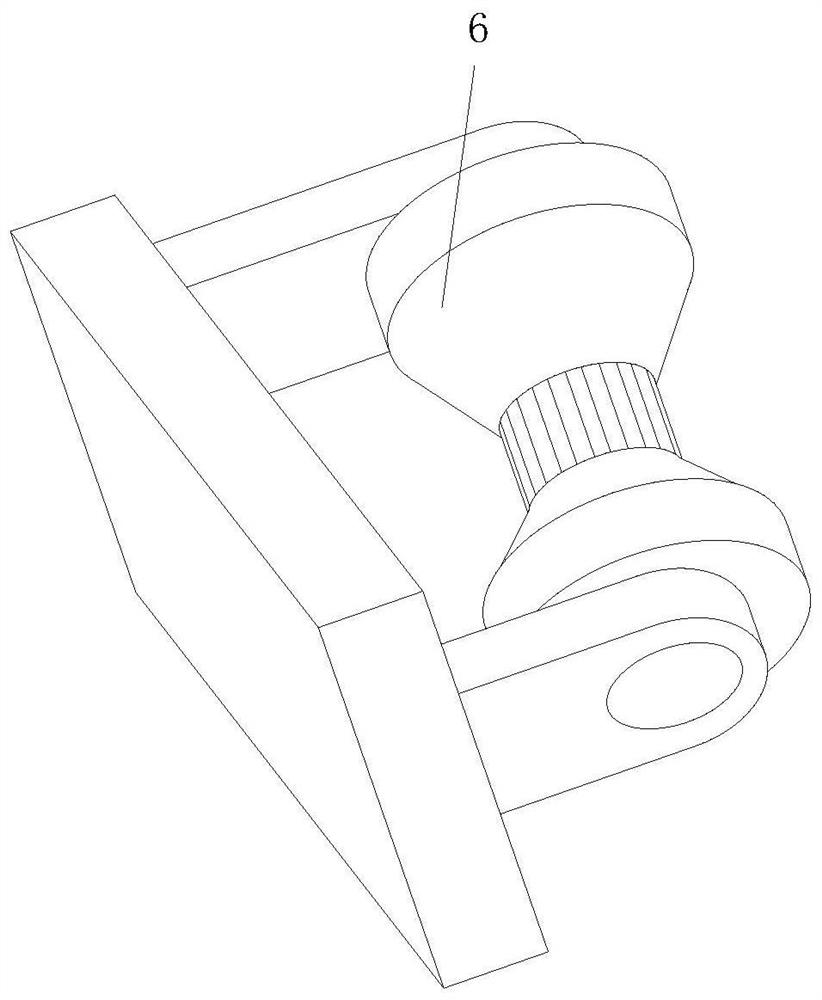

Welding clamp

ActiveCN105108410AIncrease flexibilityReduce the burden onWelding/cutting auxillary devicesAuxillary welding devicesEconomic benefitsMaterial resources

The invention discloses a welding clamp. The welding clamp comprises a base. Multiple universal wheels with brakes are arranged at the lower portion of the base. A pair of symmetrically-arranged supporting plates is arranged on the base. Each supporting plate is provided with penetrating openings formed in the width direction of the supporting plate and a clamping assembly penetrating through the two penetrating openings, wherein the two ends of the clamping assembly are located in the two penetrating openings respectively, the two ends of the clamping assembly are provided with first penetrating holes respectively, the top of the supporting plate is provided with second penetrating holes matched with the first penetrating holes, and the clamping assembly is positioned on the supporting plate in the mode that inserted pins penetrate through the second penetrating holes and the first penetrating holes. The welding clamp is high in flexibility and wide in application range, and is applied to various workpieces to be welded, manpower and material resources are greatly reduced, the welding speed is increased, large economic benefits are brought to manufacturers, good application prospects are achieved, and the welding clamp is worthy of popularization.

Owner:昆山斯格威电子科技有限公司

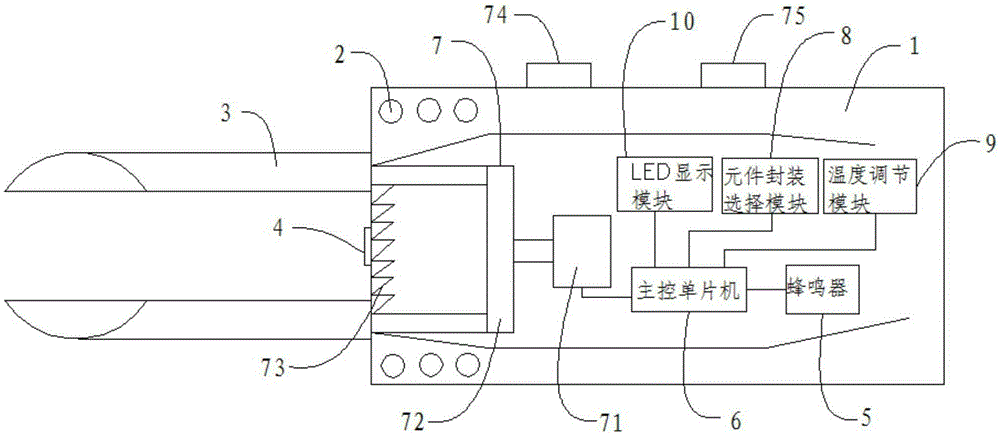

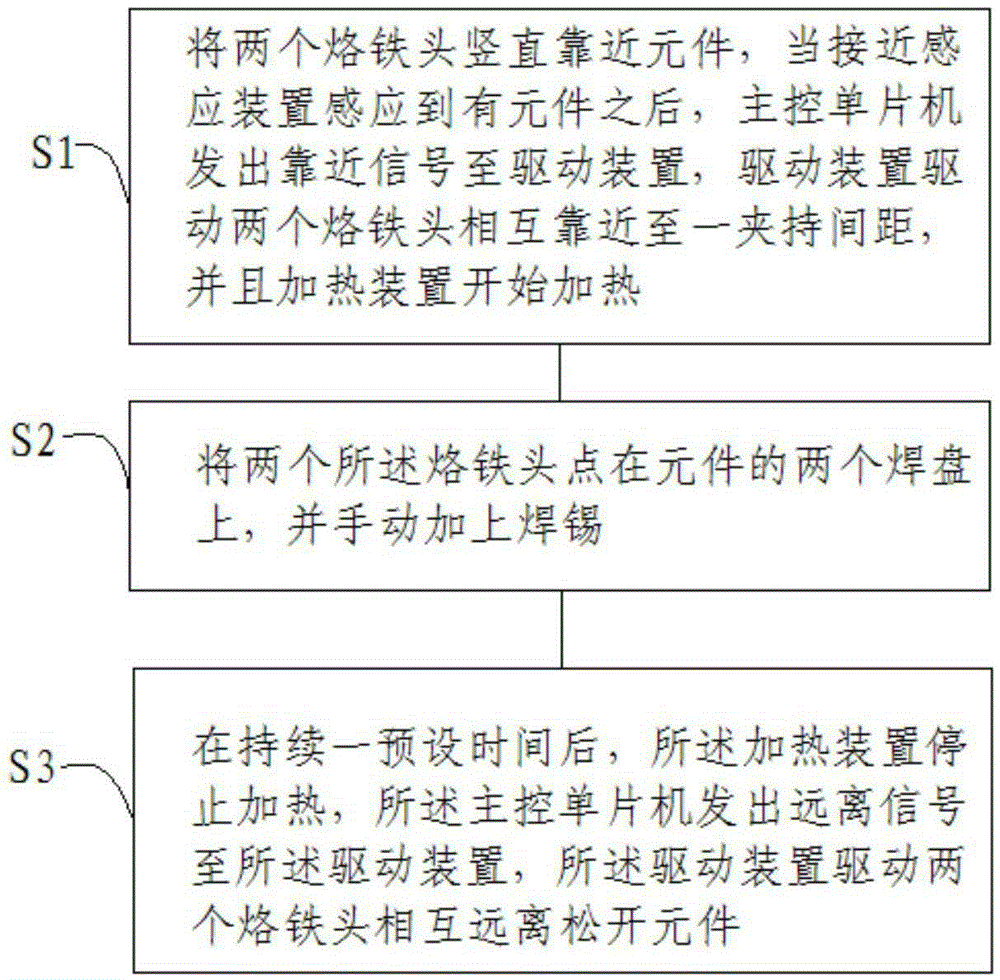

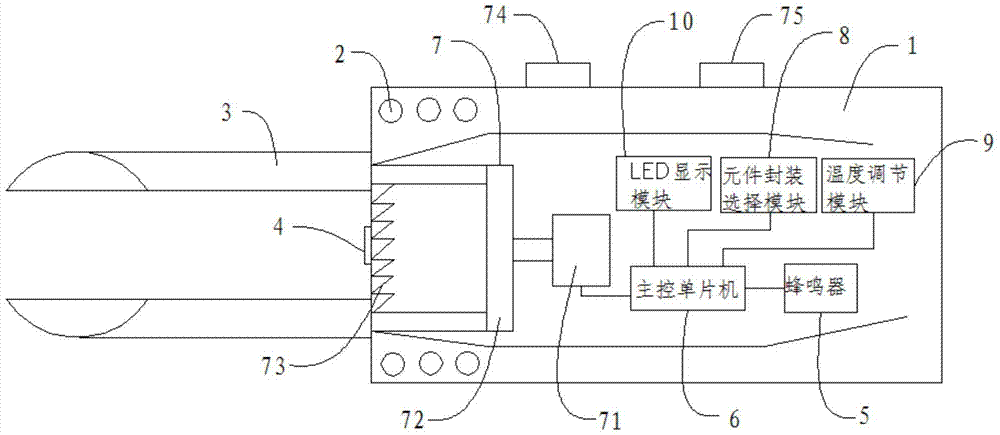

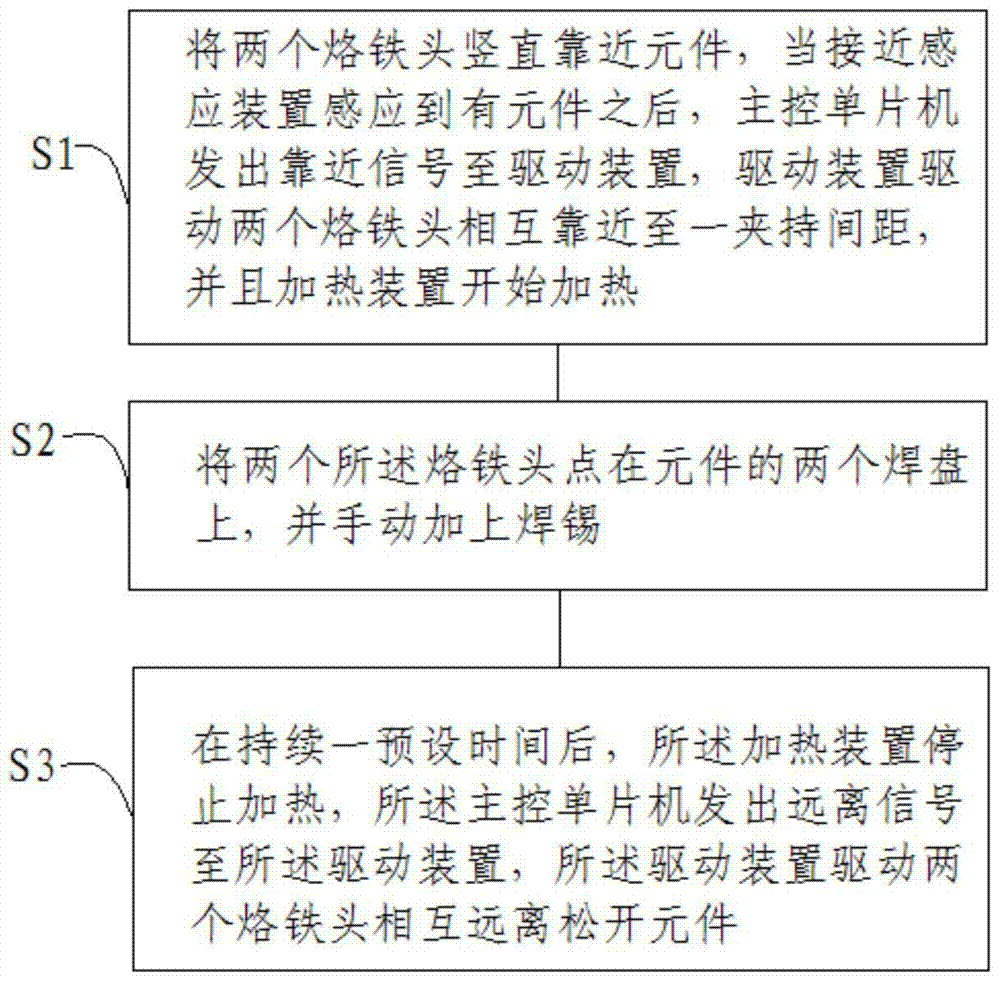

Fully-automatic welding gun and using method thereof

ActiveCN105252101ALower requirementImprove welding speedSoldering bitsHeating appliancesEngineeringFully automatic

The invention provides a fully-automatic welding gun and a using method thereof. The welding gun comprises a welding gun body, wherein a heating device is arranged inside the welding gun body; two movable soldering iron heads and a proximity sensing device are arranged on the outer end surface at one side of the welding gun body; the two movable soldering iron heads are symmetrically arranged; a master control single chip microcomputer and a drive device which are connected with each other are further arranged inside the welding gun body; the master control single chip microcomputer is connected with the proximity sensing device; the master control single chip microcomputer is used for sending a proximity signal or a far-away signal to the drive device; and the drive device is used for driving the two movable soldering iron heads to get close to each other or to be far away from each other according to the proximity signal or the far-away signal. The fully-automatic welding gun can combine the actions of fixing an element and welding an element in primary welding, so that welding velocity is improved. Moreover, the fully-automatic welding gun realizes fully-automatic welding and reduces requirements on a welding staff.

Owner:湖州帷幄知识产权运营有限公司

Auxiliary device for manufacturing direct-current motor controller shell and manufacturing method thereof

PendingCN111843260AEasy to move back and forthLimit up and down movementWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMotor controller

The invention discloses an auxiliary device for manufacturing a direct-current motor controller shell. The device comprises a support frame, the device further comprises a workbench, a clamping assembly is arranged on the workbench, the bottom surface of the workbench is connected with a lifting column, a pushing air cylinder is arranged at the top of the support frame, the end part of a piston rod of the pushing air cylinder is connected with an angle adjusting assembly, and the pushing air cylinder is connected with a sliding block of a rodless cylinder through a bracket. A manufacturing method of the auxiliary device for manufacturing the direct-current motor controller shell comprises the following steps of (1) preparing a shell body and a mounting plate; (2) welding operation of the mounting plate and the shell body; and (3) quality detection. According to the device and the method, through the auxiliary device, welding positions and angles between the mounting plate and the shellbody are accurately adjusted, the welding quality between the mounting plate and the shell body is guaranteed, the actual disassembly of a subsequent controller is facilitated, clamping and limitingare always carried out on the shell body and the mounting plate in the welding process, the displacement of the shell body and the mounting plate in the welding process is effectively prevented, and the actual welding operation is facilitated.

Owner:嵊州市三吉电子有限公司

Fluorescent hot-melt gasket as well as preparation method and application thereof

ActiveCN113563662AConvenient laying and constructionImprove welding speedUnderground chambersSynthetic resin layered productsPolymer sciencePolyolefin

The invention belongs to the technical field of waterproof coiled material construction, and discloses a fluorescent hot-melt gasket as well as a preparation method and application thereof. The fluorescent hot-melt gasket is a fluorescent blending hot-melt gasket or a fluorescent interlayer hot-melt gasket; the fluorescent hot-melt gasket is prepared from the following components: polyolefin resin, an antioxidant, stearic acid amide and fluorescent master batch; and the fluorescent master batch comprises the following components: polyolefin resin, heavy calcium carbonate, a fluorescent agent and a coupling agent. Compared with a traditional hot-melt gasket, the fluorescent hot-melt gasket has the advantages that the welding speed can be remarkably increased, and the welding accuracy is guaranteed.

Owner:YUEYANG ORIENTAL YUHONG WATERPROOF TECH

Double-spot welding gun mechanism

InactiveCN107971617AImprove welding speedImprove work efficiencyResistance electrode holdersEngineeringSpot welding

The invention discloses a double-spot welding gun mechanism. The double-spot welding gun mechanism comprises a fixed welding gun, a movable welding gun, guide grooves, guide rails and supporting profile steel. The double-spot welding gun mechanism is characterized in that the fixed welding gun is fixed to a working table through a fixed welding gun support and a fixed welding gun bottom plate, themovable welding gun is fixed to the movable welding gun bottom plate through a movable welding gun support, the guide grooves are fixed to the lower portions of the two sides of the movable welding gun bottom plate, and the section of each guide groove is of a C-shaped structure; and the guide grooves are buckled to the outer sides of the guide rails, the guide rails are fixed to the two sides ofthe supporting profile steel, a transmission mechanism for driving the movable welding gun bottom plate to move is further fixed to the movable welding gun bottom plate, and a runway used for allowing the transmission mechanism to walk is fixed to the upper portion of the supporting profile steel. The double-spot welding gun mechanism has the advantages that the working efficiency is high, and the stability is good.

Owner:HEFEI CHANGQING MACHINERY

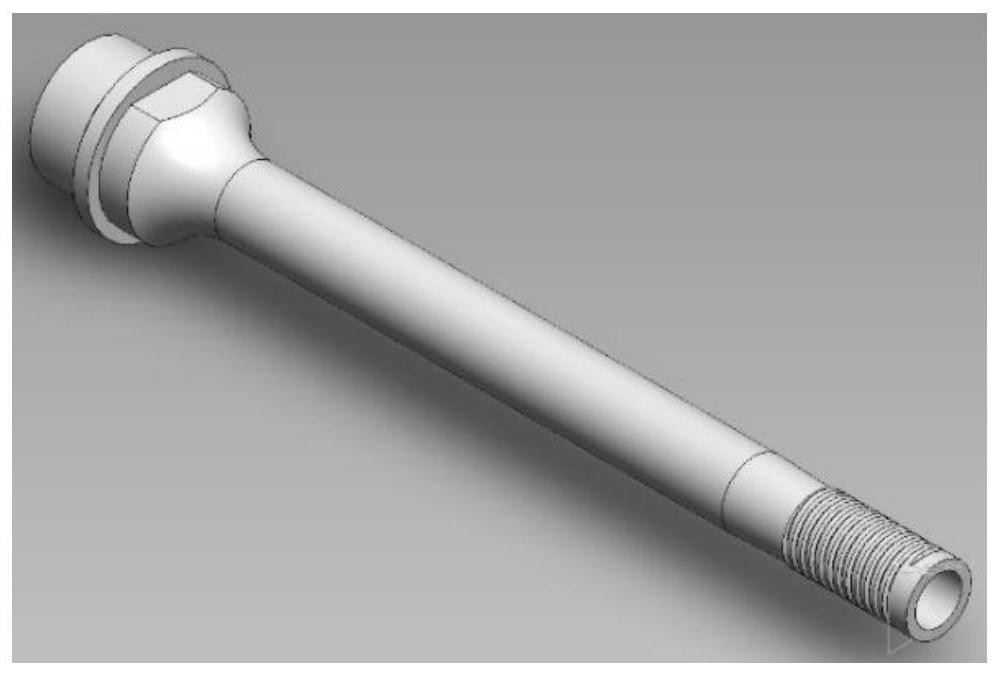

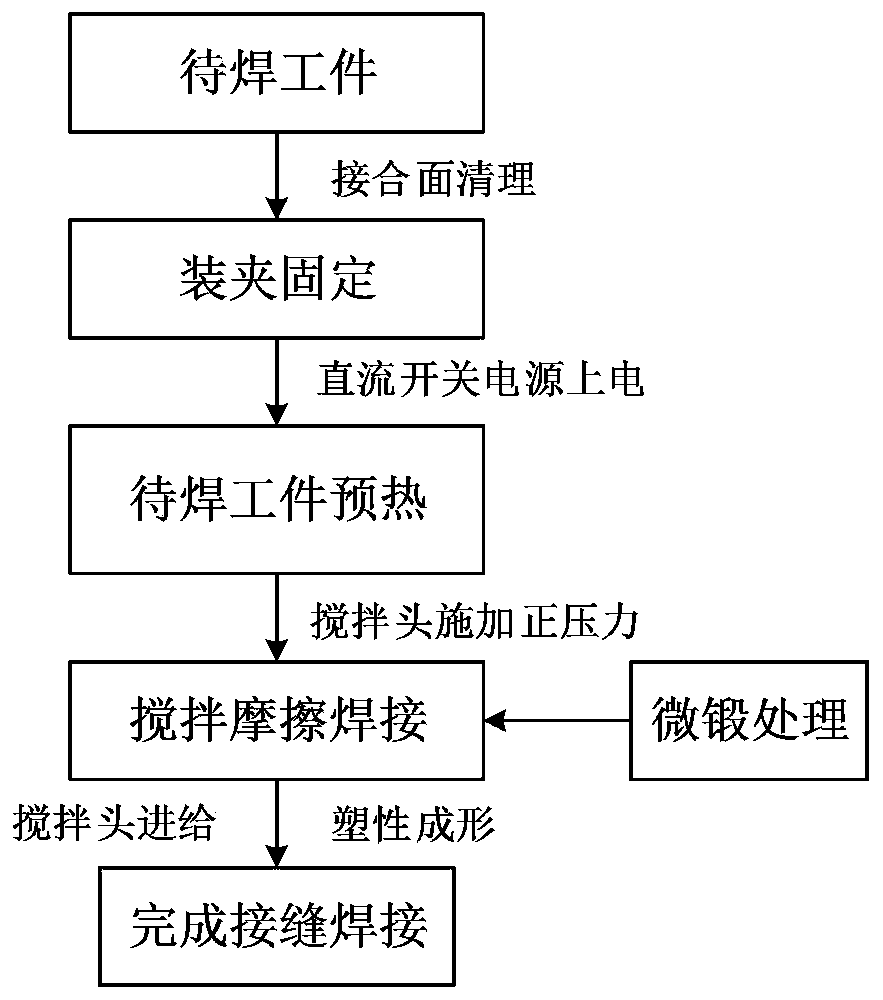

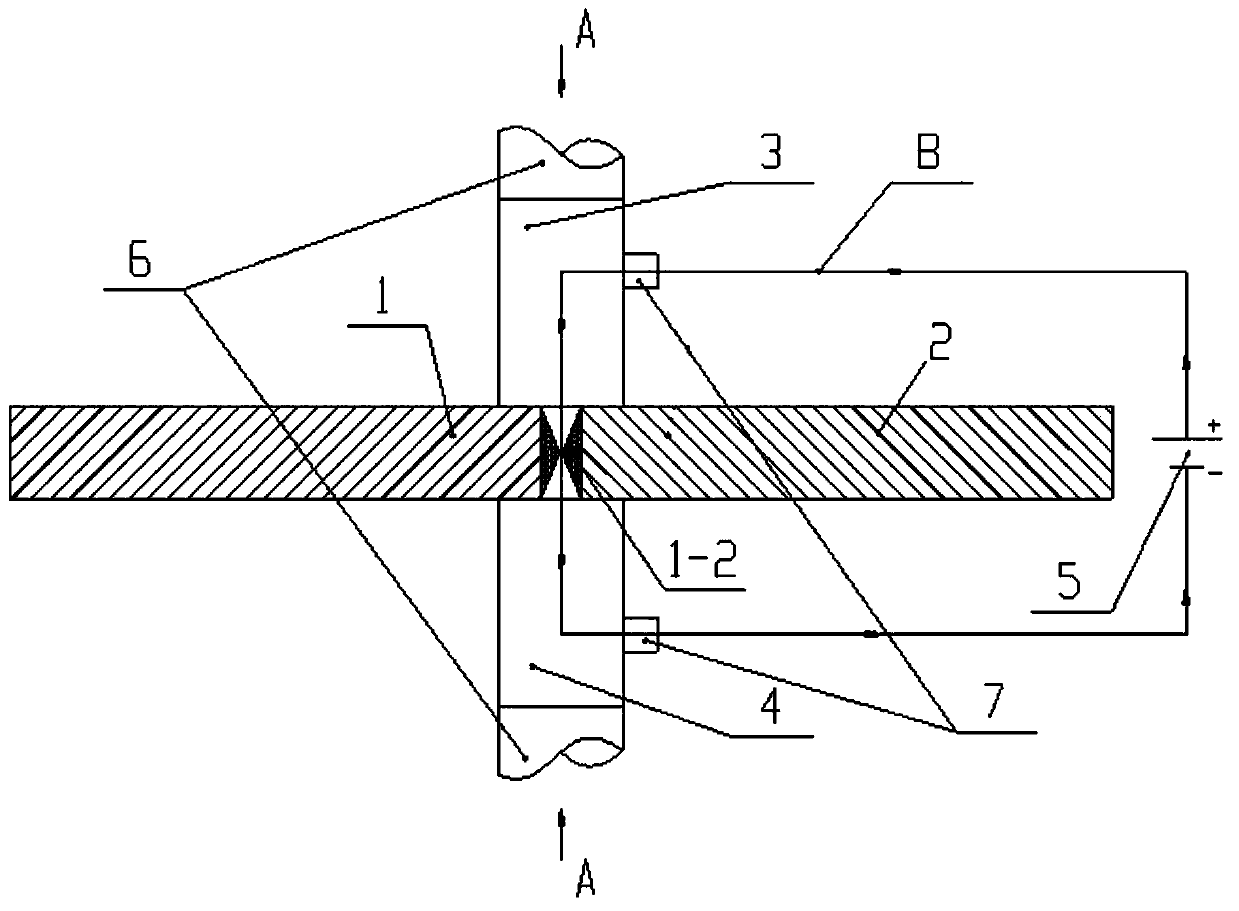

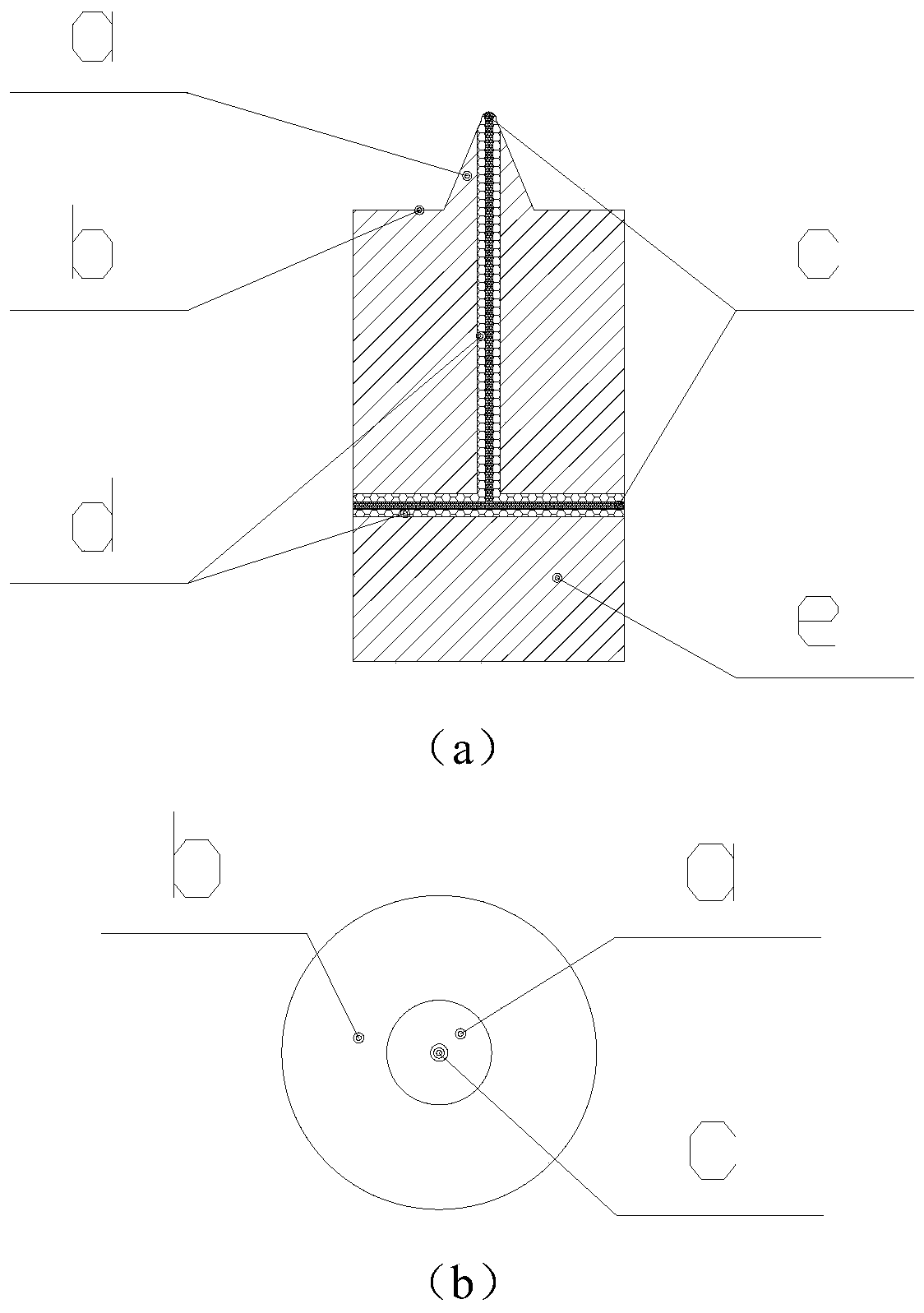

A Stirring Head Power Supply Assisted Composite Biaxial Friction Stir Welding Method

ActiveCN107199394BRefined grain structureQuality improvementNon-electric welding apparatusFriction weldingHigh density

The invention discloses a stirring head power supply-assisted composite double-shaft friction stir welding method. The method comprises the steps that stirring friction heads are adopted as electrodes of a resistor heat source, high-density currents are provided for the interior of a to-be-welded workpiece through a direct-current switch power supply, and the resistor-assisted heat source is provided for the stirring heads rotating at a high speed in the friction stir welding process; the stirring heads rotating at the high speed are inserted into the two sides of a joint, and upsetting pressure is exerted to metal at the joint through a shaft shoulder, so that the metal material at the joint is softened; the metal structure at the joint achieves a plasticizing state under the stirring effect through the stirring heads, and meanwhile micro-forging treatment is conducted on the plasticized metal by adopting an ultrasonic vibration exciter, so that metal structure crystalline grains at the joint are refined; the stirring heads do forward feeding motion in the direction of the joint, a cavity formed after a stirring needle moves is continuously filled with the plasticized metal under the stirring and extruding effect of the stirring heads, and the plasticized metal is gradually cooled and solidified to form a welding joint. According to the method, wear of the stirring heads is reduced, the welding thickness is increased, the welding speed is increased, and welding defects are reduced.

Owner:XI AN JIAOTONG UNIV

Manufacturing method of copper-plastic pipe

The invention discloses a manufacturing method of a copper plastic pipe. The copper plastic pipe comprises a copper pipe; the copper pipe is coated with a fiberglass mesh; the outside of the fiberglass mesh is sprayed with high-temperature-resistant epoxy glue; a layer of aluminum tube is arranged outside the copper pipe sprayed with the high-temperature-resistant epoxy glue; a PPR material is formed outside the aluminum tube by injection molding. Thus, the manufacturing method of the copper plastic pipe, which has the advantages of smooth circumferential surface, complete smooth weld joints, heat preservation, large bearing capacity and high injection efficiency, is provided.

Owner:NINGBO YONGXIANG COPPER PIPELINE

A kind of fully automatic welding torch and using method thereof

ActiveCN105252101BLower requirementImprove welding speedSoldering bitsHeating appliancesSingle chipProximity sensing

The invention provides a fully-automatic welding gun and a using method thereof. The welding gun comprises a welding gun body, wherein a heating device is arranged inside the welding gun body; two movable soldering iron heads and a proximity sensing device are arranged on the outer end surface at one side of the welding gun body; the two movable soldering iron heads are symmetrically arranged; a master control single chip microcomputer and a drive device which are connected with each other are further arranged inside the welding gun body; the master control single chip microcomputer is connected with the proximity sensing device; the master control single chip microcomputer is used for sending a proximity signal or a far-away signal to the drive device; and the drive device is used for driving the two movable soldering iron heads to get close to each other or to be far away from each other according to the proximity signal or the far-away signal. The fully-automatic welding gun can combine the actions of fixing an element and welding an element in primary welding, so that welding velocity is improved. Moreover, the fully-automatic welding gun realizes fully-automatic welding and reduces requirements on a welding staff.

Owner:湖州帷幄知识产权运营有限公司

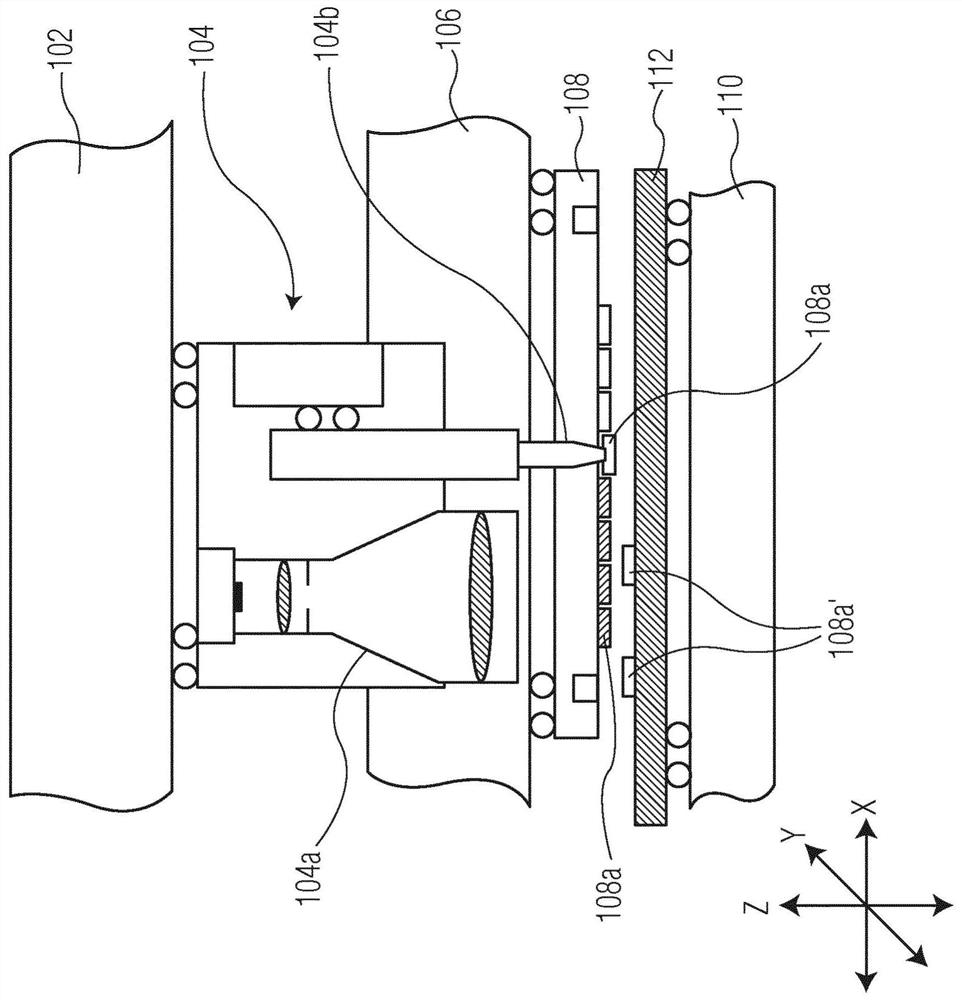

Die attach systems, and methods of attaching die to substrate

PendingCN112805817AImprove welding speedSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

A die attach system is provided. The die attach system includes a support structure for supporting a substrate; a die supply source including a plurality of die for attaching to the substrate; a bond head for bonding a die from the die supply source to the substrate, including a bond tool for contacting the die during a transfer from the die supply source to the substrate; a first motion system for moving the bond head along a first axis; and a second motion system, independent of the first motion system, for moving the bond tool along the first axis.

Owner:安必昂公司

A robotic intelligent welding production line

ActiveCN110394573BTo achieve the purpose of beating and removingAchieve the effect of autonomyWelding/cutting auxillary devicesAuxillary welding devicesSlag (welding)Electric machine

The present invention relates to the technical field of welding production line, in particular to a robotic intelligent welding production line, which includes a mounting box, a movable plate, a support plate, a connecting rod, a beating head, a contact roller, a driving motor, a cam, a return spring, and a dust-proof cluster. hair, ball nut, ball screw, drive motor, chip removal bucket, rotating motor and fixture, the movable plate is located inside the installation box, and the middle position on the left side of the top of the movable plate is fixedly connected with the bottom of the support plate. The left end of the connecting rod is fixedly connected to the top on the right side of the beating head, and the right end of the connecting rod extends to the inside of the installation box. The invention achieves the purpose of knocking and removing the welding slag at the welding place by the beating head, thereby replacing the manual removal method, and the whole process complements the automatic welding, reduces the manual participation in the work mode, and makes the whole welding line autonomous The effect, which in turn reduces the labor intensity and improves the welding speed.

Owner:中山叁迪智能设备有限公司

A kind of linear flame welding machine and its welding method

ActiveCN107717171BReasonable structural designIncrease feeding rateGas flame welding apparatusOperation safetyOperations security

The invention discloses a linear flame welding machine. The linear flame welding machine comprises a feeding mechanism, a welding mechanism and a discharging mechanism; the feeding mechanism comprisesa feeding table, a storing table and a pushing device; the welding mechanism comprises a welding room supporting frame and welding assemblies; each welding assembly comprises a welding head set, a longitudinal adjusting assembly and a transverse adjusting assembly; and the discharging mechanism comprises a discharging table, a material conveying device and a material table. A welding method comprises the following steps of (1) feeding of welded workpieces; (2) adjustment of the height of the welding assemblies; (3) adjustment of the position of the welding head sets; (4) welding; and (5) discharging of the welded workpieces. The linear flame welding machine is ingenious and reasonable in structural design, and convenient and rapid to use and operate, achieves automatic treatment operationof workpiece feeding and discharging through the feeding mechanism and the discharging mechanism, relieves labor intensity, improves operation safety performance, can conduct welding on the workpieces at the same time through design of the multiple welding assemblies, effectively increases the welding rate, and improves the work efficiency.

Owner:XINCHANG KECHUANG AUTOMATION EQUIP

Wire-added welding method of manual electric arc welding

InactiveCN101704155AReduced heat input rateImprove deposition efficiencyArc welding apparatusShielded metal arc weldingEngineering

The invention discloses a wire-added welding method of manual electric arc welding. By a method of adding a welding wire during welding, the problems of large efficiency and deformation during the repair welding of the manual electric arc welding are solved. Meanwhile, the problems of large gaps and difficult welding when mother materials are assembled can also be solved.

Owner:CHANGCHUN RAILWAY VEHICLE FACILITIES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com