Pipeline special robot

A technology of robots and pipes, which is applied in the direction of auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of high labor intensity in handling pipes, increase the labor burden of staff, and low welding efficiency, so as to facilitate comprehensive welding, Effect of reducing workload and improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

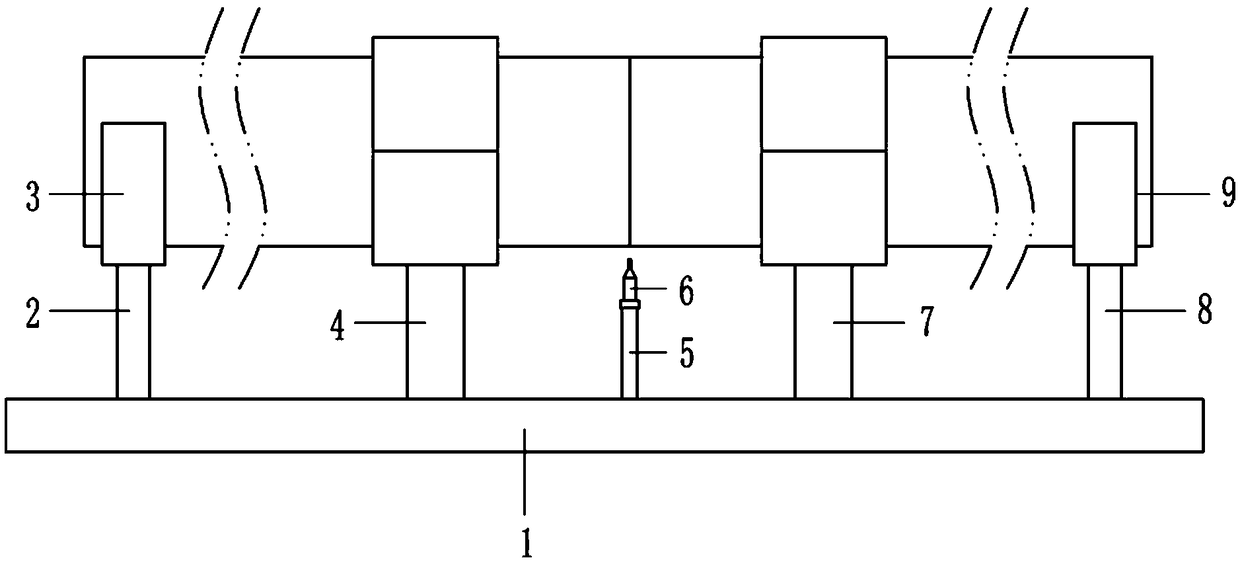

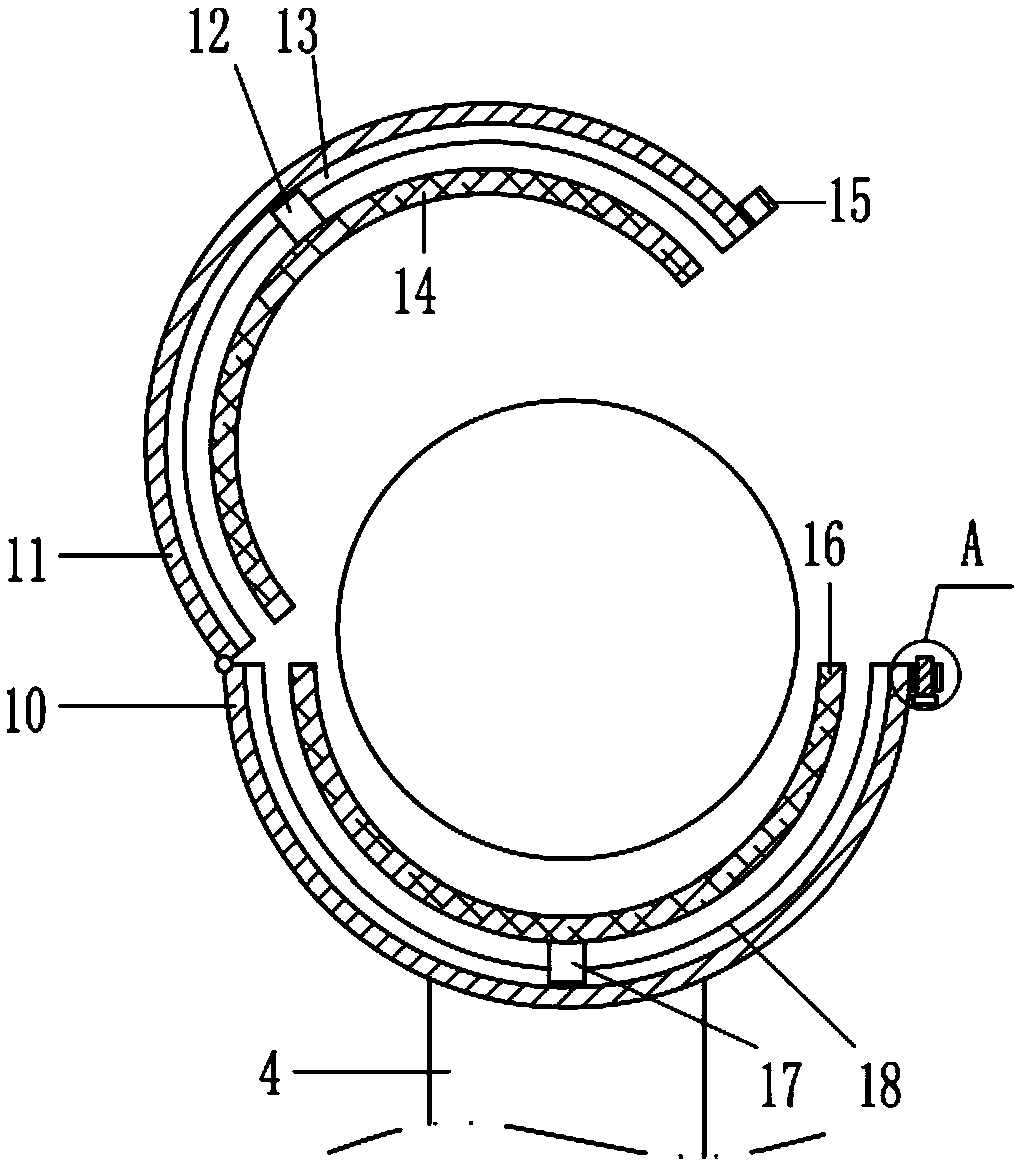

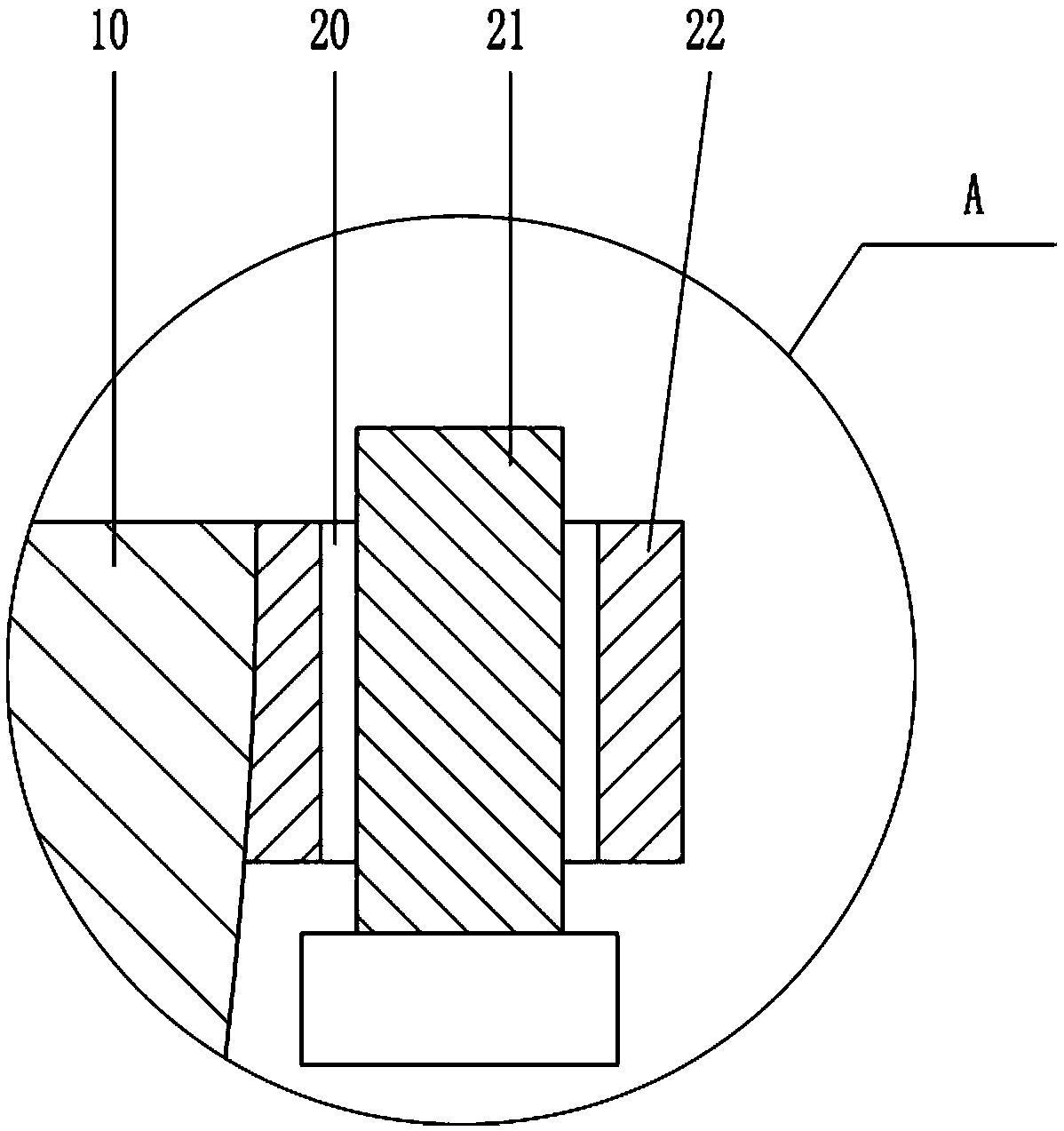

[0027] A pipeline-specific robot, such as Figure 1-8 As shown, it includes a mounting plate 1, a first support base 2, a first semicircular support plate 3, a second support base 4, a mounting rod 5, a welding torch 6, a third support base 7, a fourth support base 8, a Two semicircular supporting plates 9, the first semicircular jacket 10, the second semicircular jacket 11, the first slider 12, the first semicircular slide rail 13, the first semicircular fixed sleeve 14, Nut 15, second semicircular fixed sleeve 16, second slide block 17, second semicircular slide rail 18, screw rod 21 and fixed block 22; On one side of the mounting plate 1, the second semicircular support plate 9 is fixed to the other side of the mounting plate 1 through the fourth support seat 8; the second support seat 4 is fixed to the mounting plate 1 close to the first support seat 2, the third supporting seat 7 is fixed on the side of the mounting plate 1 close to the fourth supporting seat 8, the weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com