Double-spot welding gun mechanism

A dual-spot welding and welding torch technology, applied in the direction of resistance electrode base, electrode features, etc., can solve the problems of inability to realize multi-spot welding and affect the speed, and achieve the effect of good movement stability, improved work efficiency, and improved welding speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

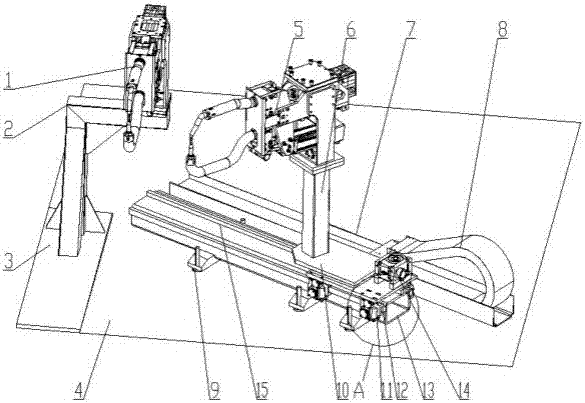

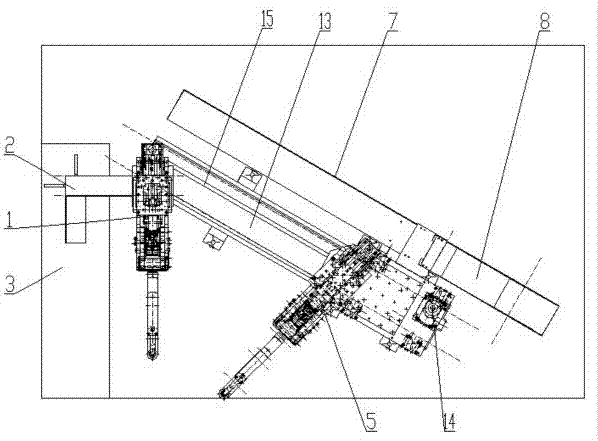

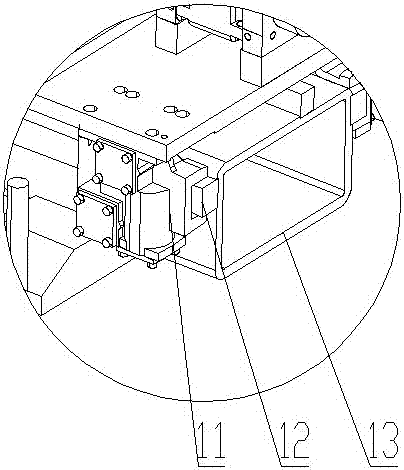

[0014] see figure 1 , figure 2 , image 3 , a two-point welding torch mechanism, including a fixed welding torch 1, a moving welding torch 5, a guide groove 11, a guide rail 12, and a supporting profile steel 12; On the platform 4, the mobile welding gun 5 is fixed on the mobile welding gun base plate 10 through the mobile welding gun bracket 6, and the lower parts of both sides of the mobile welding gun base plate 10 are fixed with guide grooves 11, and the cross section of the guide groove 11 is a C-shaped structure , the guide groove 11 is buckled on the outside of the guide rail 12, the guide rail 12 is fixed on both sides of the supporting steel 13, and the transmission mechanism 14 for driving the mobile welding gun base plate 10 to move is also fixed on the mobile welding gun base plate 10, so A runway 15 for the transmission mechanism 14 is fixed on the top of the supporting steel 13 .

[0015] A wire slot 7 is provided on the side of the supporting section steel 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com