Die attach systems, and methods of attaching die to substrate

A technology of die and substrate, applied in the field of die attach system and attaching die to substrate, which can solve the problems of speed accumulation and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] As used herein, the term "die" is intended to refer to any structure that includes (or is configured to include in a later step) a semiconductor chip or die. Exemplary "die" elements include: bare semiconductor dies including bare LED semiconductor dies, semiconductor tubes on substrates (e.g., leadframes, PCBs, carriers, semiconductor chips, semiconductor wafers, BGA substrates, semiconductor components, etc.) core, packaged semiconductor device, flip chip semiconductor device, die embedded in a substrate, and others.

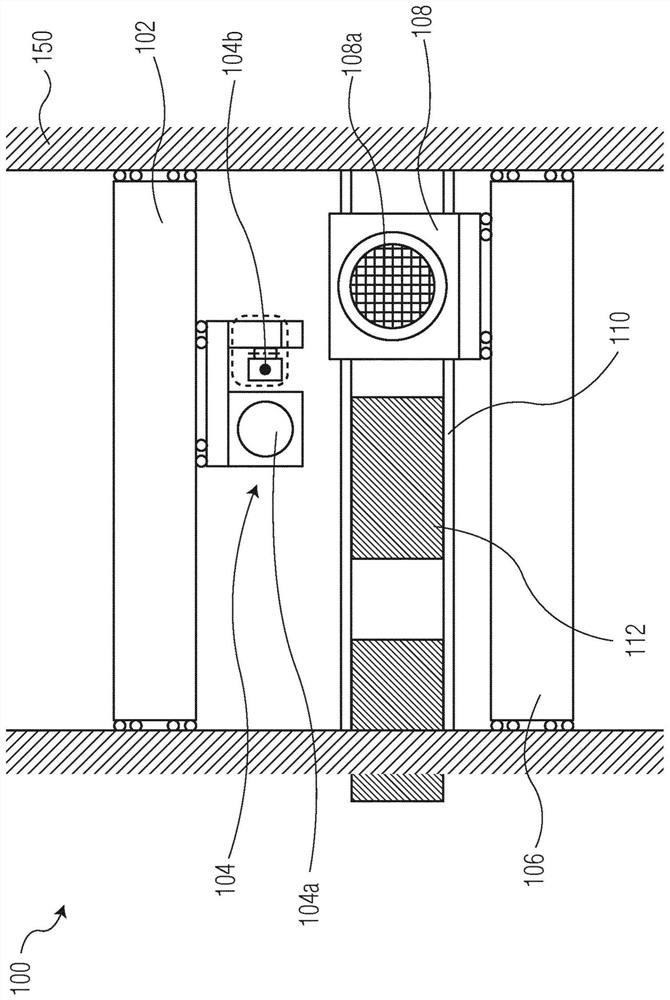

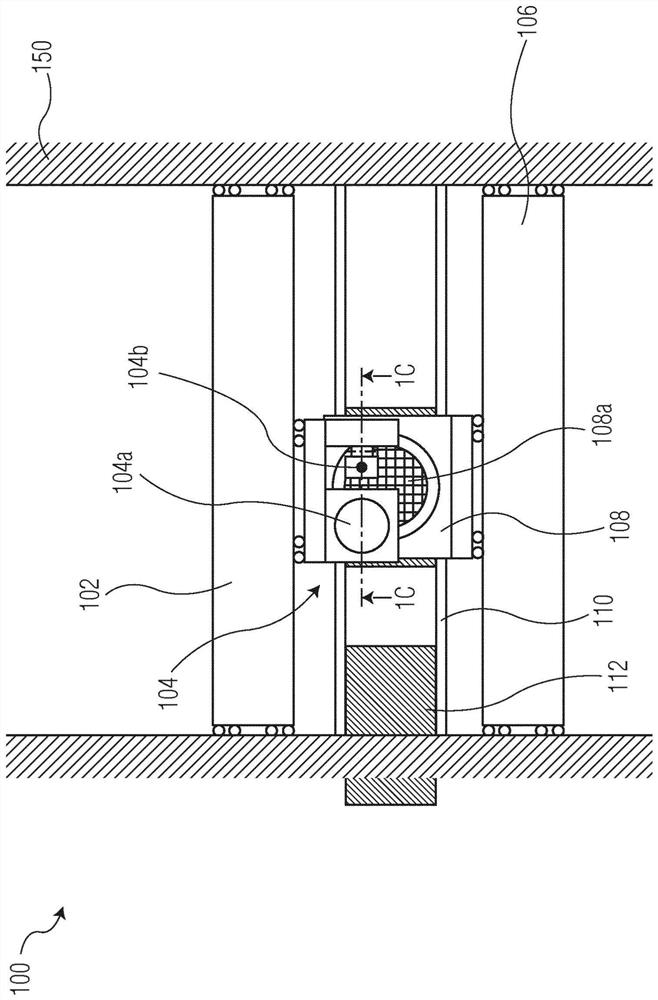

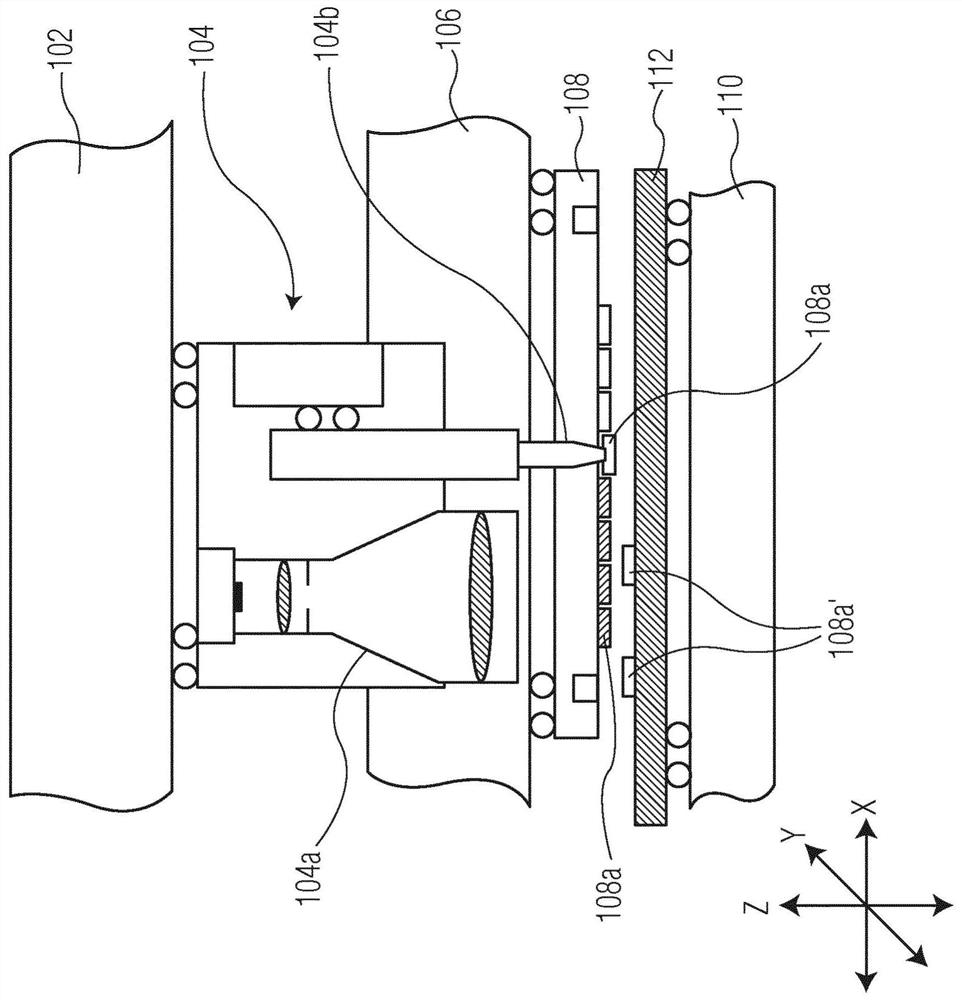

[0020] According to certain exemplary embodiments of the present invention, there is provided a die attach system comprising an inventive arrangement for supporting a solder tip or a die supply. Such devices include: (i) a long stroke portion supporting a short stroke axis; and (ii) a short stroke portion supporting a solder tip or die supply. For example, during a bonding sequence, the long travel axis may travel at a constant speed relative to the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com