Preparation method of waterway backboard for target material

A technology of back plate and waterway, which is applied in the field of target materials, can solve the problems of short service life of the friction stir head, reduce the quality of the stirring layer, and insufficient heat input, etc., and achieve the effect of increasing the welding rate, small deformation, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

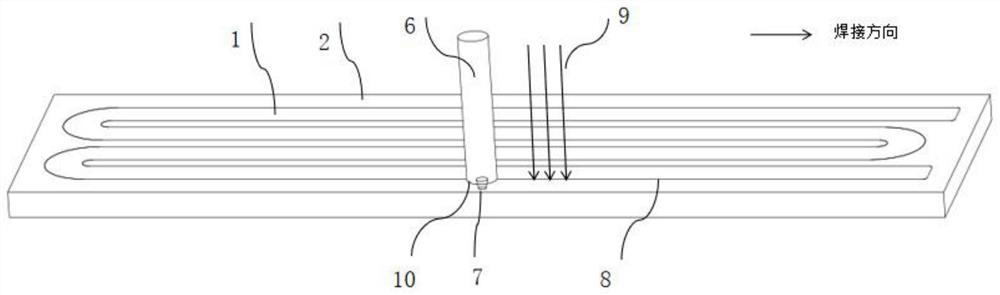

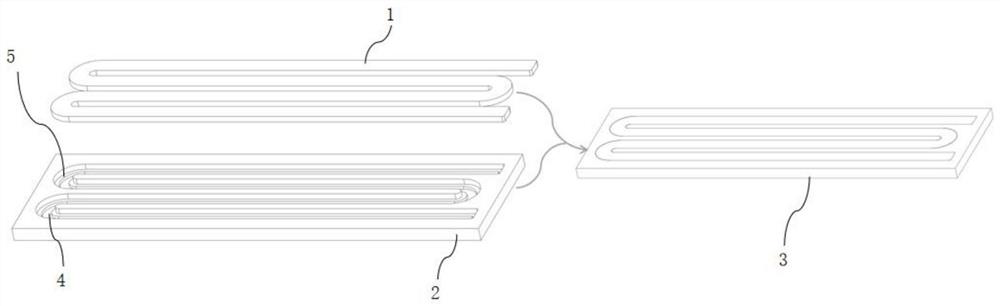

[0031] Such as Figure 1 to Figure 3 Shown: This embodiment provides a method for preparing a target waterway backplane, including the following steps:

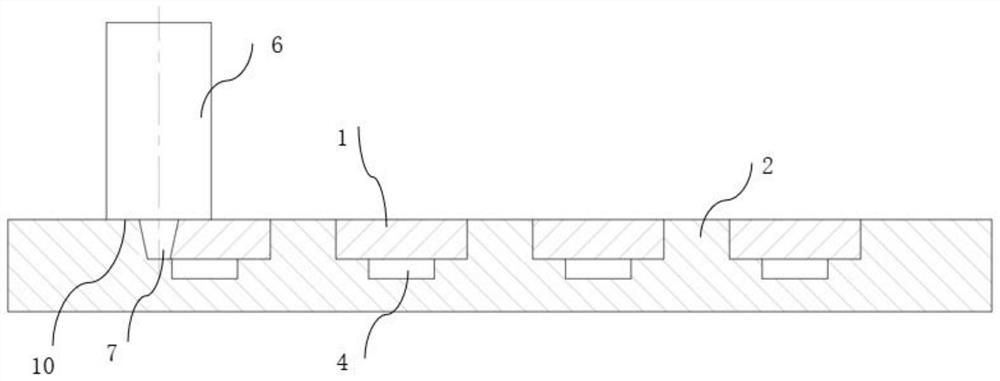

[0032] (1) Process a T-shaped groove on the copper backplane main body 2, the T-shaped groove includes a cover plate groove 5 and a water tank 4 arranged from top to bottom, the width of the cover plate groove 5 is greater than the width of the water tank 4; the copper backplane main body 2 Oxygen-free copper plate is used, the length is 500mm, the width is 150mm, the thickness is 20mm, and the hardness is 87HV;

[0033] (2) Place the cover plate 1 on the cover plate groove 5 to obtain the waterway copper back plate 3 to be welded. The cover plate 1 is also made of oxygen-free copper plate. The cover plate 1 matches the cover plate groove 5, and the cover plate 1 and the cover plate groove The gap between 5 is within 0.2mm, and then the cover plate 1 is pressed tightly with the pressure plate, so as to fix the cover plate 1 ...

Embodiment 2

[0043] Such as Figure 4 As shown, this example adopts a separate friction stir welding method, and the process flow and parameters are the same as in Example 1:

[0044] After the cover plate 11 is covered on the copper back plate main body 22, after spot welding and one-time welding, the welding needle 77 of the friction stir head 6 gradually rotates into the joint 8 of the copper back plate main body 22 and the cover plate 11, and the speed is 600r / min, feed rate: 230mm / min, the shoulder 1010 of the friction stirring head 6 extends to the contact surface and presses down 0.2-0.5mm, the welding pin 77 of the friction stirring head 6 after preheating is along the main body 22 of the copper backboard and the cover The fused seam 88 of the plate 11 moves and the welding needle 7 rotates to generate frictional heat, so that the temperature of the material at the seam 8 rises and plastic deformation occurs, and heat is generated by friction between the shoulder 1010 of the frict...

Embodiment 3

[0047] Such as Figure 4 As shown, in this example, on the basis of Example 2, the welding speed is reduced by about half compared with Example 2:

[0048] After the cover plate 11 is covered on the copper back plate main body 22, after spot welding and one-time welding, the welding needle 77 of the friction stir head 6 gradually rotates into the joint 8 of the copper back plate main body 22 and the cover plate 11, and the speed is 600r / min, feed rate: 130mm / min, the shoulder 1010 of the friction stirring head 6 extends to the contact surface and presses down 0.2-0.5mm, the welding pin 77 of the friction stirring head 6 after preheating is along the main body 22 of the copper backboard and the cover The fused seam 88 of the plate 11 moves and the welding needle 7 rotates to generate frictional heat, so that the temperature of the material at the seam 8 rises and plastic deformation occurs, and heat is generated by friction between the shoulder 1010 of the friction stir head 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com