Fluorescent hot-melt gasket as well as preparation method and application thereof

A hot-melt gasket and fluorescent technology, which is applied in chemical instruments and methods, shaft equipment, mining equipment, etc., can solve problems such as inconvenient visibility and inaccurate welding of hot-melt gaskets, so as to improve welding speed and ensure precision sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] According to the present invention, preferably, the preparation method of the fluorescent masterbatch includes: mixing and stirring the components included in the fluorescent masterbatch: LDPE resin, heavy calcium carbonate, fluorescent agent and coupling agent, and sending them into the extrusion In the device, the phosphor masterbatch is obtained through cooling, molding and pelletizing.

[0040] According to the present invention, preferably, the stirring speed of the stirring is 100-150 r / min, and the stirring time is 8-12 min.

[0041] According to the present invention, preferably, the extrusion device is a twin-screw extruder, the barrel temperature of the twin-screw extruder is 165-180°C, the mold temperature is 180-185°C, and the screw speed is 200-220r / min.

[0042] According to the present invention, preferably, the particle size of the fluorescent masterbatch is 2-3 mm.

[0043] The second aspect of the present invention provides the preparation method of...

Embodiment 1

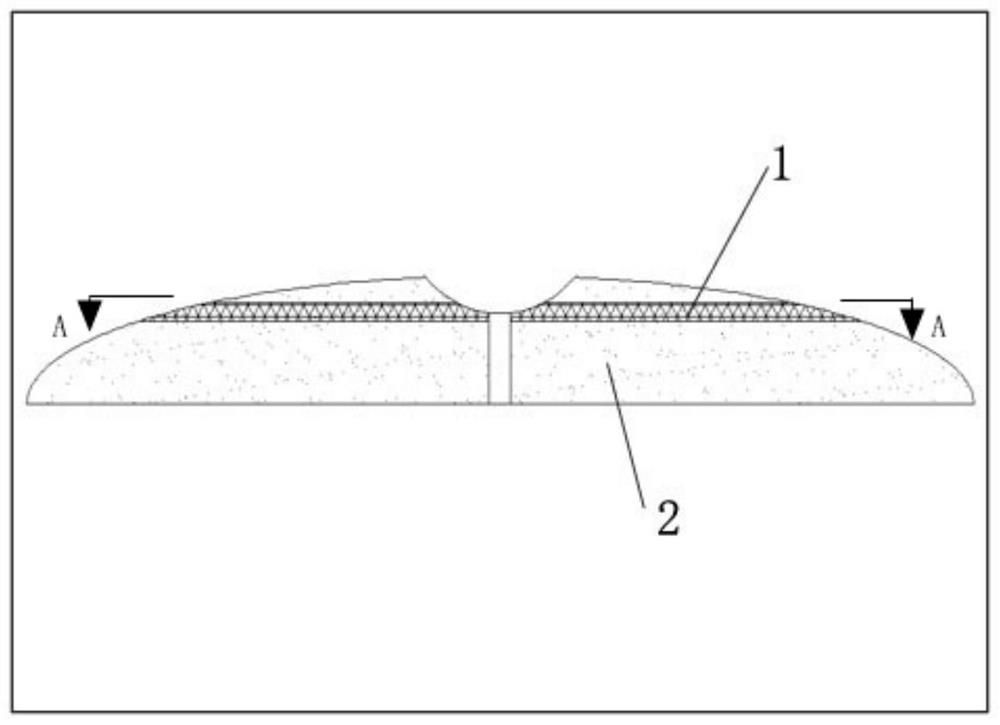

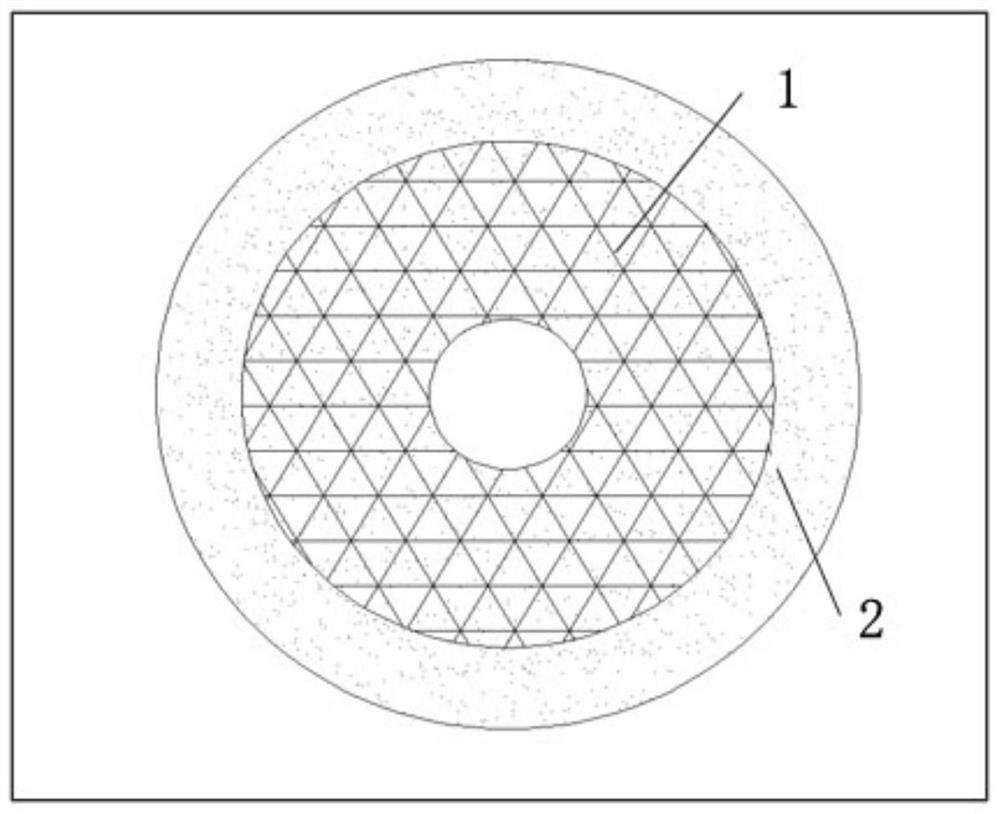

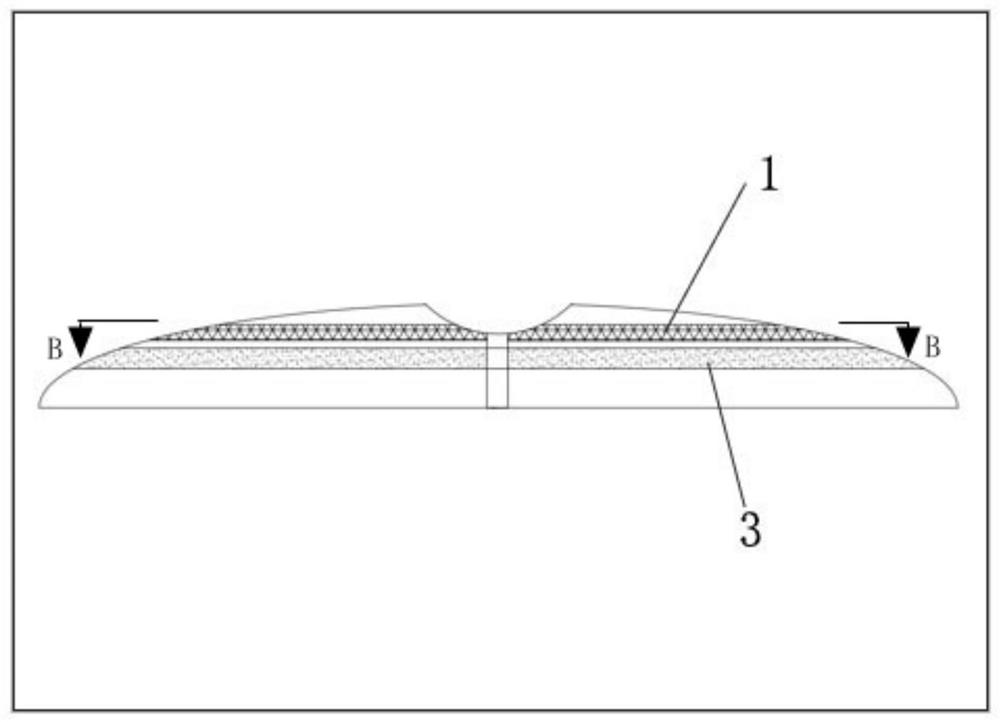

[0066] This embodiment provides a fluorescent hot-melt gasket, which is a fluorescent blended hot-melt gasket or a fluorescent interlayer hot-melt gasket;

[0067] In terms of the total weight percentage of the fluorescent hot-melt gasket, the fluorescent hot-melt gasket includes the following components in weight percent: LDPE resin 60%, HDPE resin 30%, antioxidant 1.0%, hard acid Amide 0.2% and fluorescent masterbatch 10%;

[0068] In terms of the total weight percentage of the fluorescent master batch, the fluorescent master batch includes the following components in weight percentage: 70% of LDPE resin, 15% of heavy calcium carbonate, 15% of fluorescent agent and 1.0% of coupling agent.

[0069] The particle size of described heavy calcium carbonate is 800 orders;

[0070] The fluorescent agent is a boroaluminate fluorescent agent whose model is RTS-60;

[0071] The coupling agent is a titanate coupling agent.

[0072] Wherein, the preparation method of the fluorescent ...

Embodiment 2

[0078] This embodiment provides a fluorescent hot-melt gasket, which is a fluorescent blended hot-melt gasket or a fluorescent interlayer hot-melt gasket;

[0079] In terms of the total weight percentage of the fluorescent hot-melt gasket, the fluorescent hot-melt gasket includes the following components in weight percent: LDPE resin 65%, HDPE resin 20%, antioxidant 1.0%, hard acid Amide 0.2% and fluorescent masterbatch 15%;

[0080] In terms of the total weight percentage of the fluorescent master batch, the fluorescent master batch includes the following components in weight percentage: 75% of LDPE resin, 10% of heavy calcium carbonate, 15% of fluorescent agent and 1.0% of coupling agent.

[0081] The particle size of described heavy calcium carbonate is 800 orders;

[0082] The fluorescent agent is a boroaluminate fluorescent agent whose model is RTS-60;

[0083] The coupling agent is a titanate coupling agent.

[0084] Wherein, the preparation method of the fluorescent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com