Ocean high voltage-resistant and anti-corrosion cable convenient for replacement and maintenance

A corrosion-resistant and high-voltage-resistant technology, which is applied in the field of marine high-voltage and corrosion-resistant cables, can solve problems such as poor cable resistance to pressure and corrosion, hidden dangers to marine life safety, and reduced service life of cables, so as to achieve good corrosion resistance and use The effect of long life and easy and fast positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

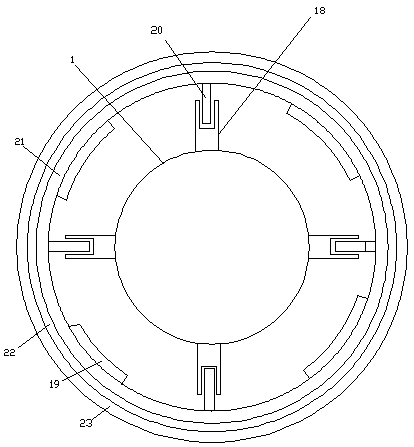

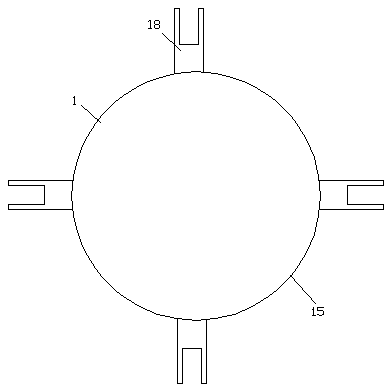

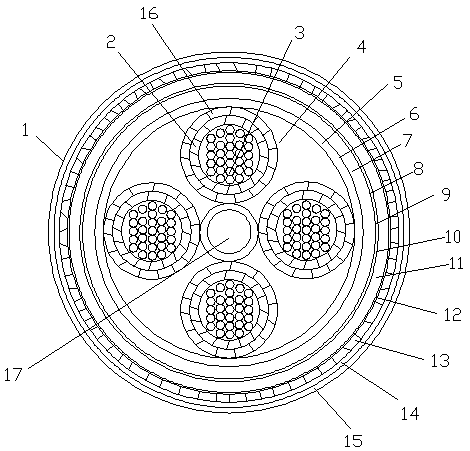

[0022] see Figure 1-3 , the present invention provides a technical solution: a marine high-voltage and corrosion-resistant cable that is easy to replace and maintain, including a cable body 1 and a cable channel 21, an oil channel 17 is provided in the middle of the cable body 1, and multiple channels are provided on the outside of the oil channel 17. Each core shielding layer 16, the inside of the core shielding layer 16 is provided with an aluminum-plastic film wrapping tape 2, and the inside of the aluminum-plastic film wrapping tape 2 is provided with a plurality of cores 3, between the plurality of core shielding layers 16 The space is filled with a resin insulating layer 4, and the outside of the resin insulating layer 4 is sequentially covered with an insulating shielding layer 5, a first braid 6, an alloy sheath 7, a second braid 8, a reinforcement layer 9, a first lining 10, Anti-corrosion layer 11, anti-moth layer 12, second lining layer 13, armor 14 and outer prote...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com