Patents

Literature

60results about How to "Convenient laying and construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

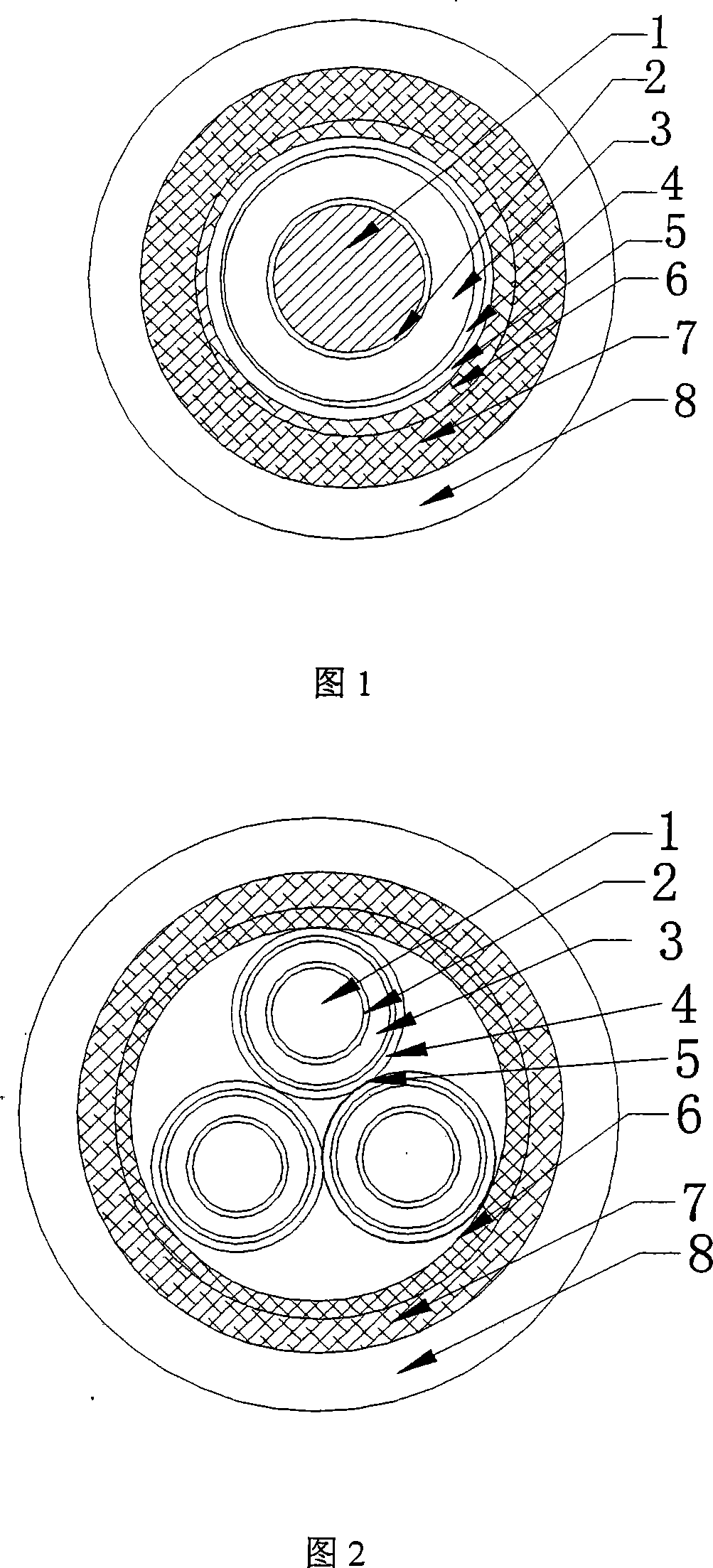

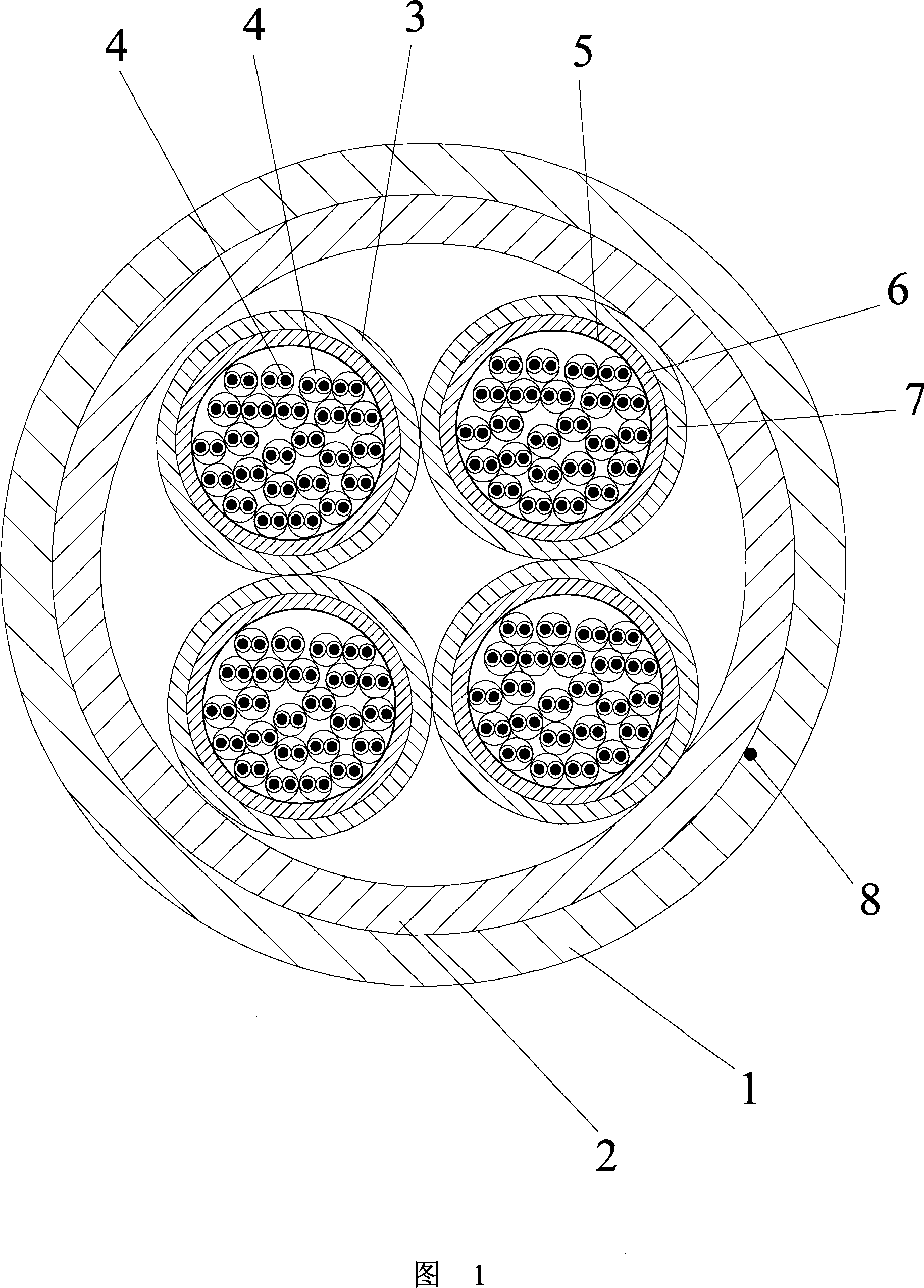

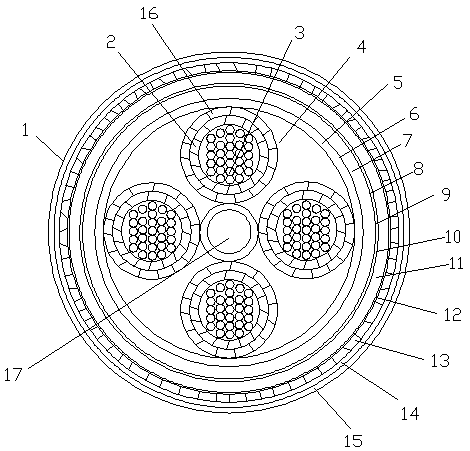

Medium-voltage fire-proof cable

ActiveCN101169993AGood tensile strengthGood fire and heat insulation performanceInsulated cablesInsulated conductorsThermal insulationCable transmission

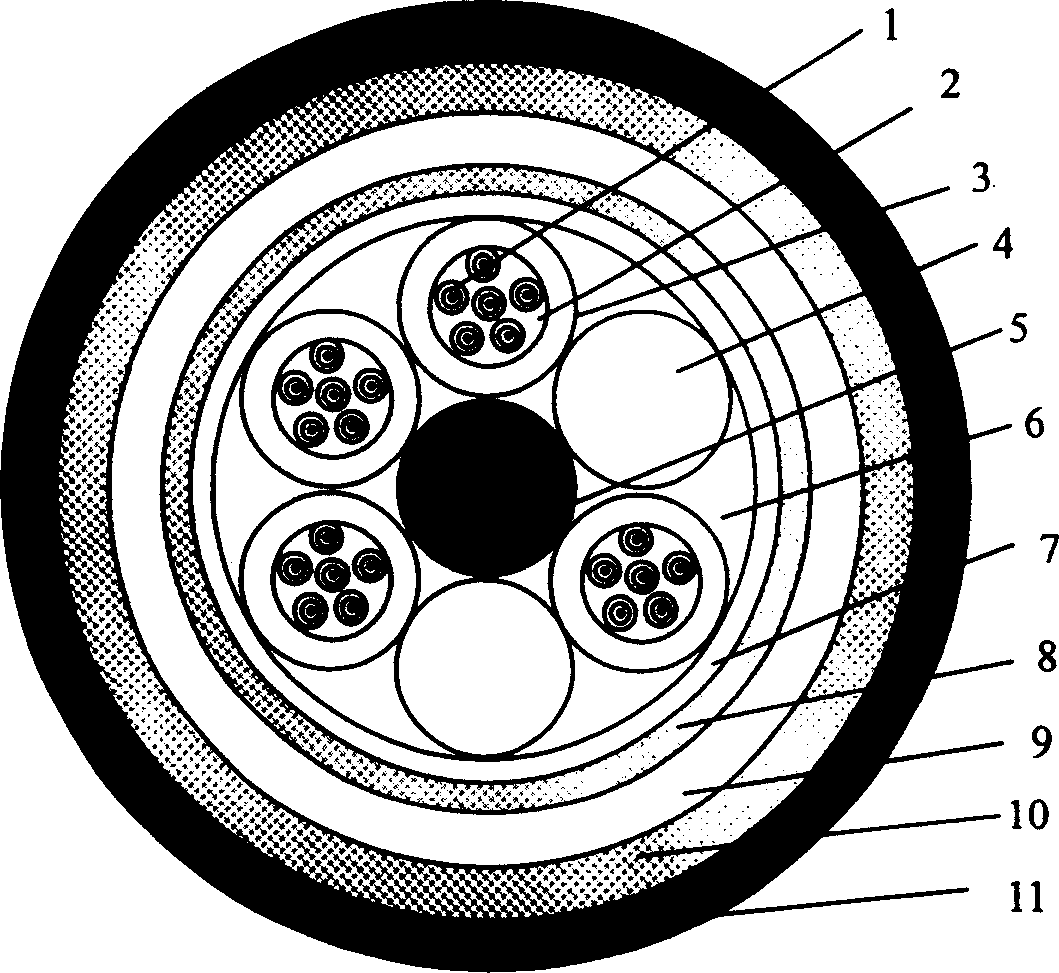

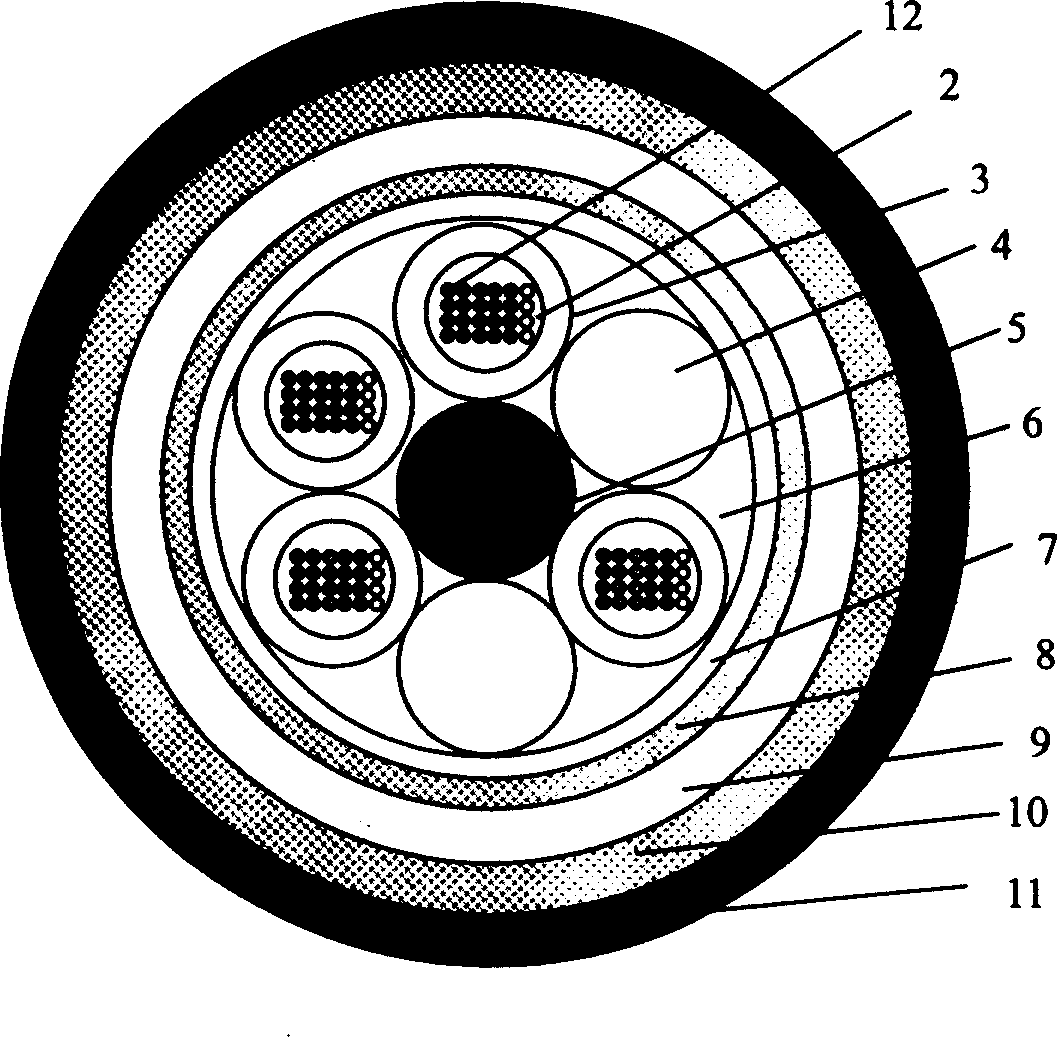

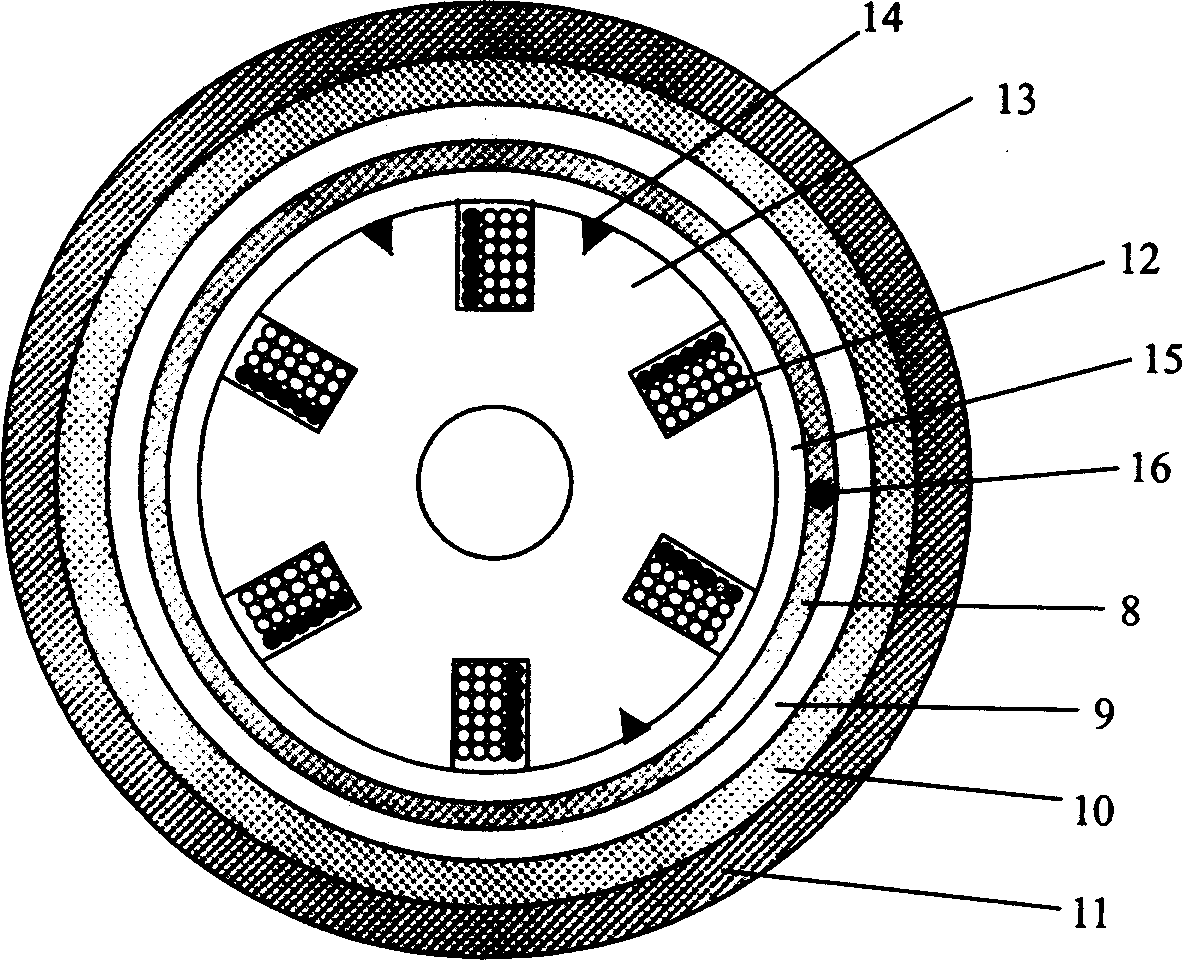

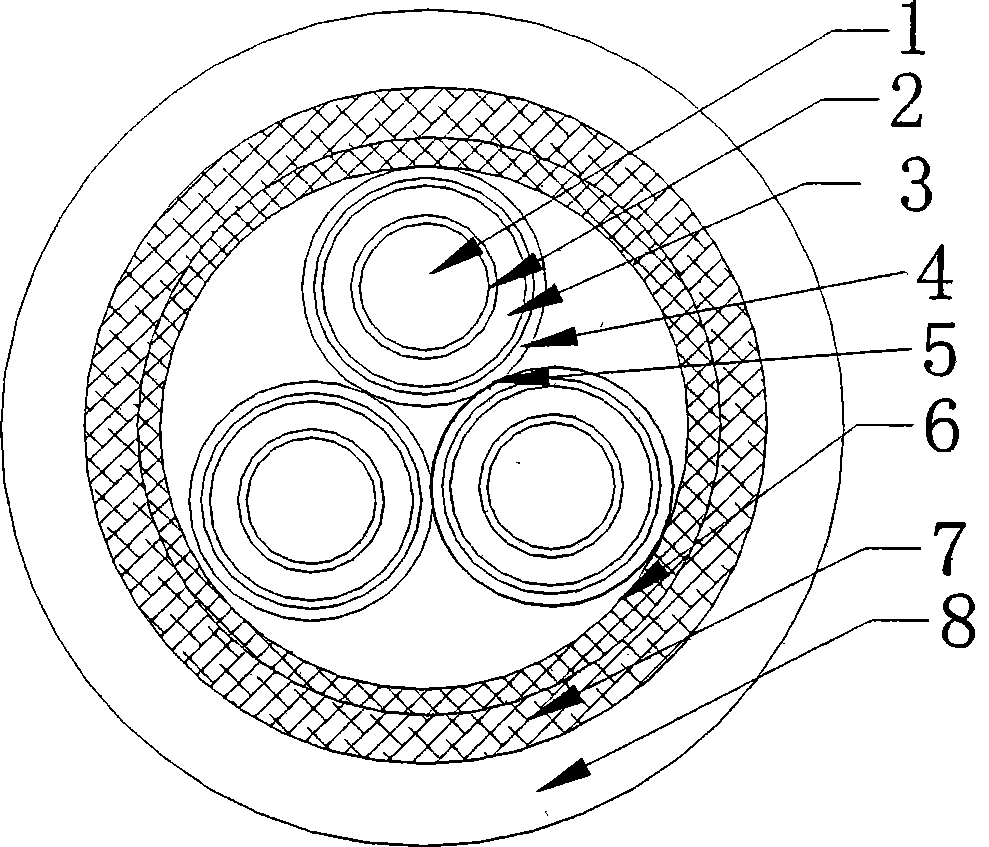

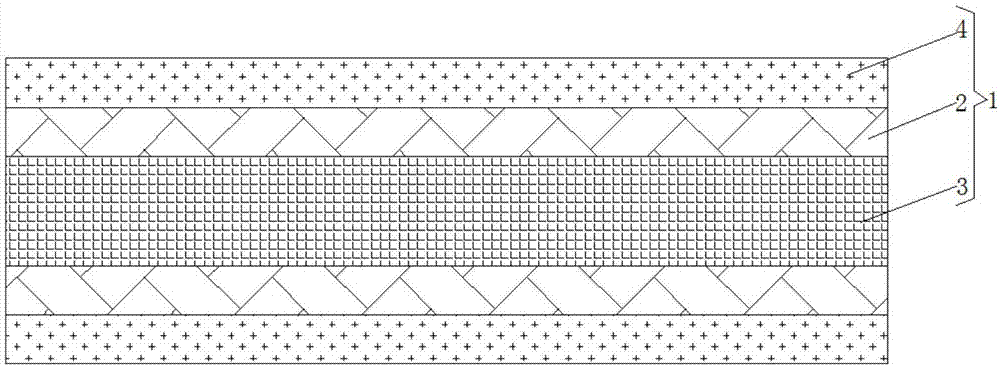

The invention relates to a medium-voltage power transmission fire-resistant cable, which is characterized in that the outer fire-resistant layer of the medium-voltage cable core is made of fire-resistant inorganic fiber heat insulation layer on the inner side, and the outer side is a soft thermosetting elastomer for normal use. The composite fire-resistant and heat-insulating layer of the heat layer, the thermosetting elastomer, is composed of 30-50wt% silicon-based elastic material, 40-60wt% inorganic filler, 5-15wt% medium and low temperature frit, 4-10wt% vulcanizing agent, It is made by mixing extrusion molding and vulcanization. The composite fire-resistant and heat-insulating layer is a relatively soft sheath material when it is not exposed to flames, which can ensure good bending performance of the refractory structure in normal conditions, and quickly transforms into a shell-and-tube refractory and heat-insulating structure when it encounters fire or high temperature. In the fire-fighting environment, it can still maintain a certain period of time without being damaged, effectively preventing damage to the inner insulation caused by flames or high temperatures. When the flame temperature of the outer layer is 850°C, the temperature of the inner insulation surface is lower than 180°C. This fire-resistant and heat-insulating structure can be applied according to conventional cable production methods, and the production efficiency is extremely high.

Owner:FAR EAST CABLE +2

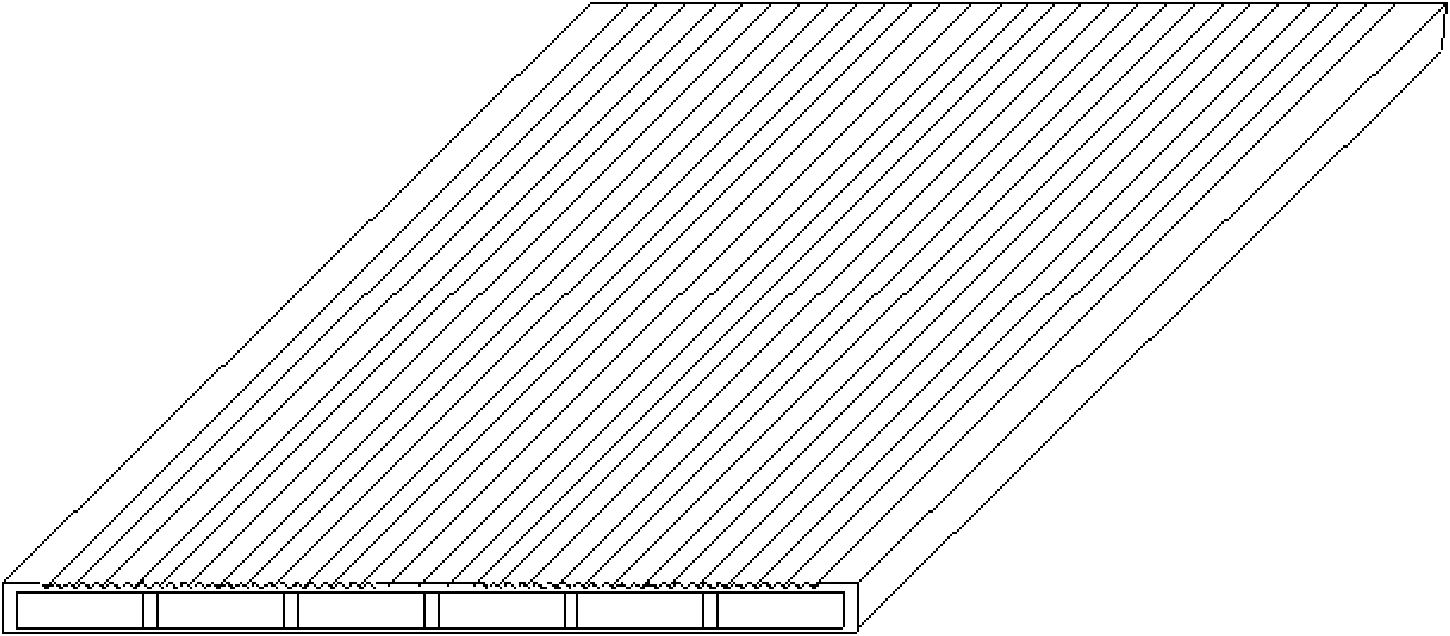

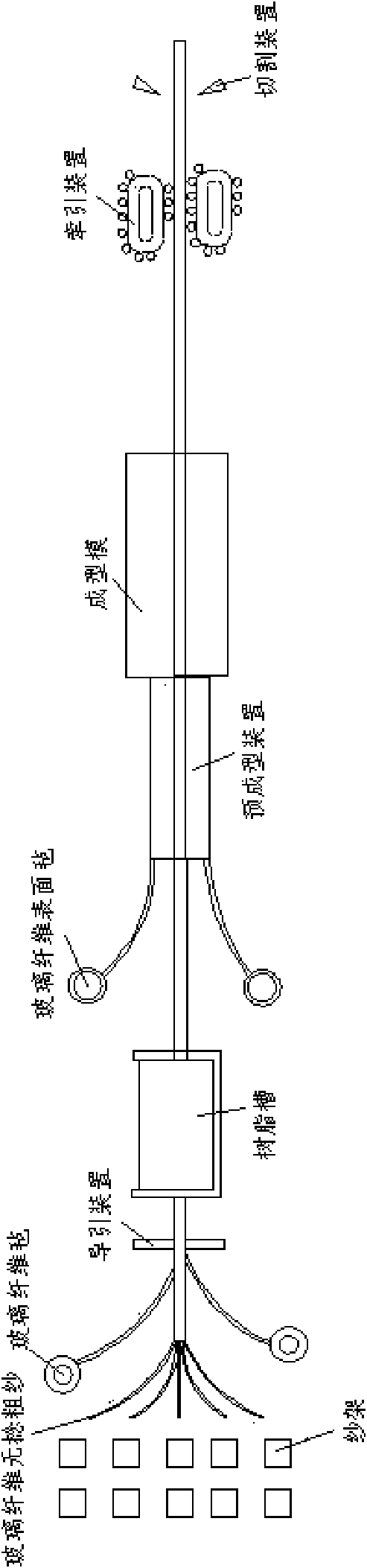

Glass fiber reinforced plastic cable channel cover plate and production method thereof

InactiveCN101672044AImprove corrosion resistanceStrong anti-agingArtificial islandsUnderwater structuresPolyvinyl alcoholEngineering

The invention relates to a glass fiber reinforced plastic cable channel cover plate and a production method thereof. The cover plate is a rectangular hollow belly structure, longitudinal stiffening ribs are arranged in the hollow belly of the cover plate and the upper surface of the cover plate is provided with strip-shaped antiskid grains; the invention comprises the following raw materials: unsaturated polyester resin, curing agent, packing, polyvinyl alcohol solution, pigment, fiberglass roving and fiberglass felt; the invention comprises the following steps: (1) arranging a tooling equipment on an extrusion molding machine; (2) mixing and pouring the raw materials in a resin tank; and (3) inducing the fiberglass roving and the fiberglass felt through immersion, a performing device, a forming device, curing and cutting. The cover plate has high strength, smooth surface, neat and beautiful appearance, corrosion resistance of alkali, acid, petrol and the like, aging resistance, long service life without pulverization, discoloration, crack, deformation and the like. The invention ensures the safe operation of cables and prolongs the service life of the cables.

Owner:醴陵市万通新型材料有限公司

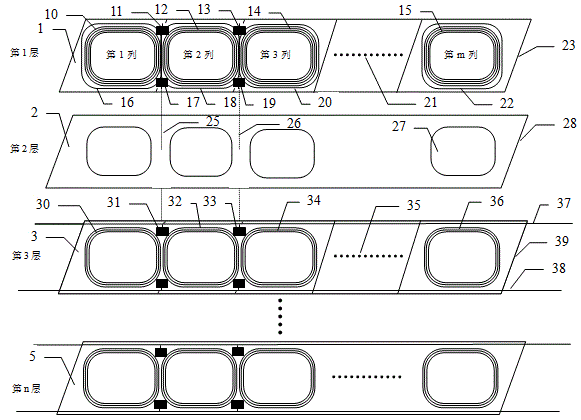

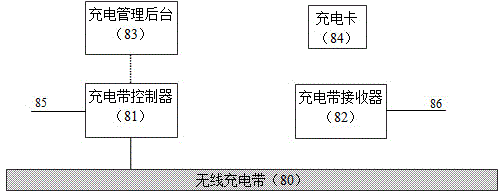

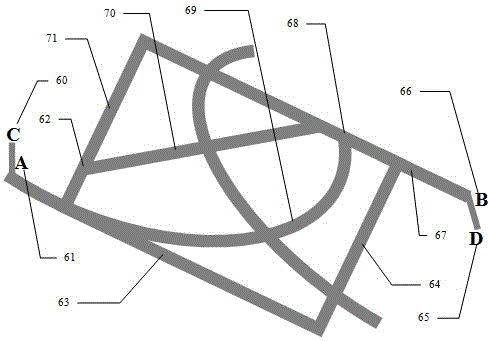

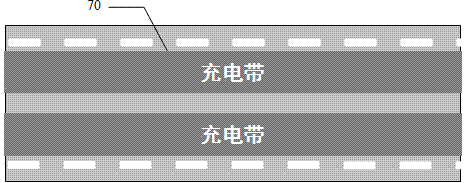

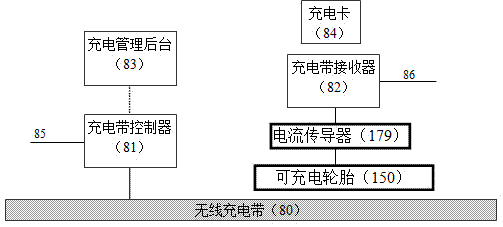

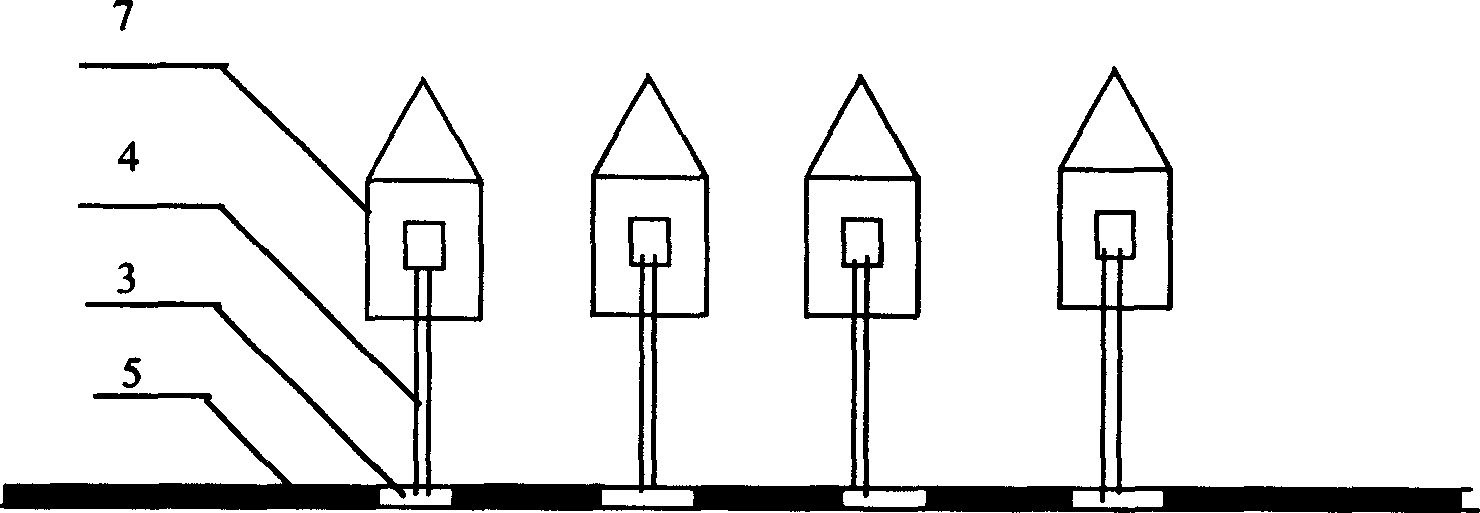

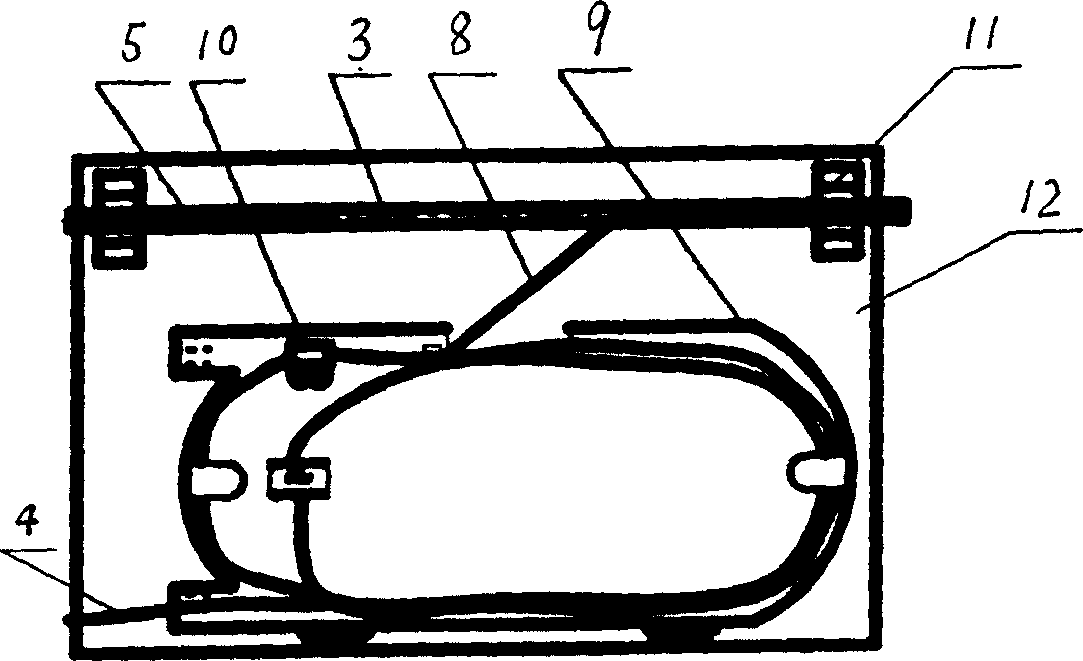

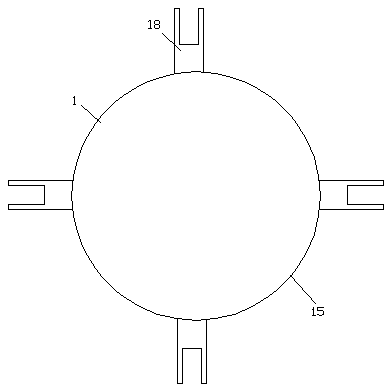

Automatic-focusing wireless charging belt system and full-automatic laying device for wireless charging belt

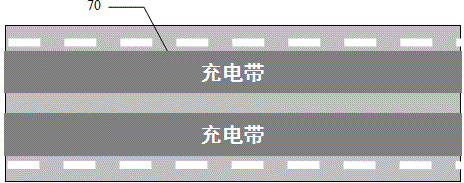

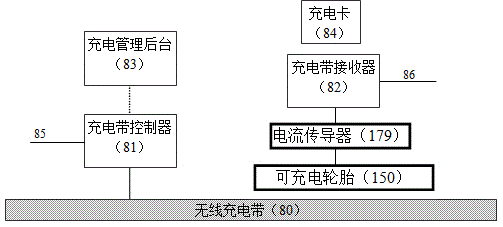

PendingCN104578240AEasy to seepEasy to pasteBatteries circuit arrangementsElectromagnetic wave systemControl systemElectric vehicle

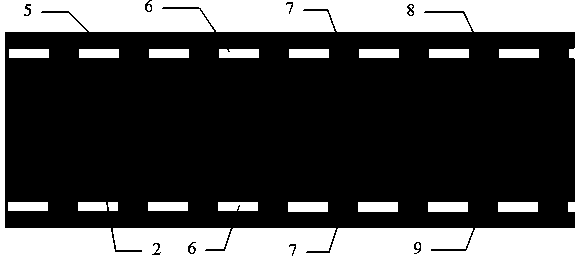

The invention provides an electromagnetic automatic-focusing wireless charging belt technology for charging an electric vehicle during running, a wireless charging belt control system, a technology implementation method, and a full-automatic laying construction device and method for the wireless charging belt. The wireless charging belt system comprises a wireless charging belt, a charging belt controller, a charging belt receiver, a charging card and a charging management background. The wireless charging belt is a belt-shaped object sealed by a high-strength plastic or rubber or alloy sealed casing, the width of the belt-shaped object is 20-350 cm, the thickness of the belt-shaped object is smaller than 5 cm, and the longest length of the belt-shaped object can be thousands of kilometers. The wireless charging belt is characterized in that the latest techniques of dynamic electromagnetic emission arrays and static electromagnetic emission arrays are firstly adopted, the wireless charging belt automatically focuses electromagnetic charging flows on a receiving antenna which is positioned at the bottom of the electric vehicle or in a chargeable tire, so that the wireless charging efficiency is effectively improved. The charging belt has the functions of water prevention, dust prevention, water seepage prevention, and ventilation, the charging belt is ultrathin, and the charging belt can be laid by the full-automatic laying construction device fully automatically.

Owner:刘跃进

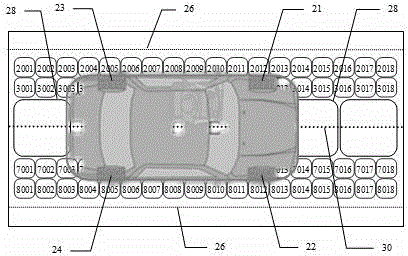

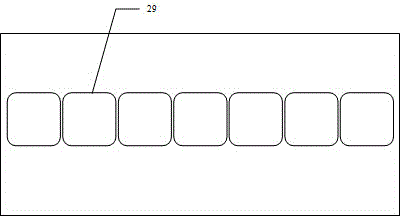

Wireless charging belt system for providing charging, positioning, navigation and automatic driving for electric vehicle

PendingCN105529751ALess crowdedImprove traffic capacityNear-field transmissionBatteries circuit arrangementsElectromagnetic couplingResonance

The invention discloses a multifunctional wireless charging belt system which can support wireless multimode automatic charging, automatic positioning, automatic navigation and automatic driving for an electric vehicle during driving and combine intelligent traffic control and communication entertainment as a whole. The system comprises micro blocks and a positioning and navigation technology, wherein the micro blocks divide a road surface into blocks of fixed shapes and are arranged according to sequence numbers; and according to the positioning and navigation technology, the position of the vehicle is determined according to the position of a micro block where a vehicle tire is, and the driving speed and the direction of the vehicle are determined according to the distance between micro blocks and the numbers of the micro blocks passed by the vehicle in a unit time. A technology and a method of sending and receiving information while charging is carried out through electromagnetic resonance or an electromagnetic coupling charging system are also provided. Through the system, the vehicle can be automatically charged; the vehicle can automatically acquire real-time road traffic information, road traffic light information and front-rear vehicle information; the vehicle can automatically select the best way, regulate the best speed and arrive at a destination safely along a road guiding line indication lamp on the road.

Owner:刘跃进

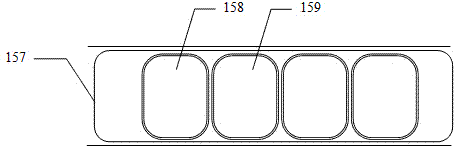

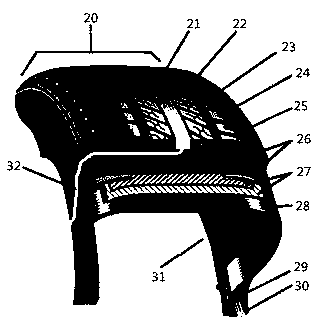

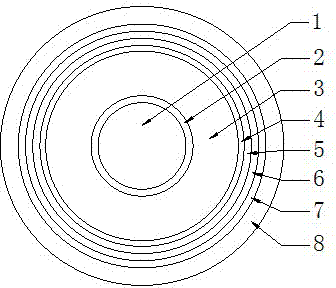

Electric vehicle-used rechargeable tire and tire-type wireless charging belt system

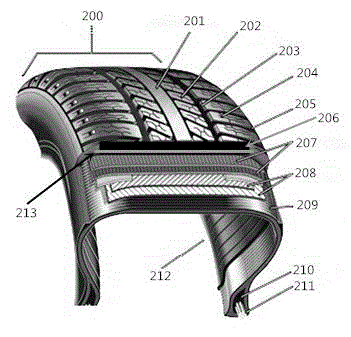

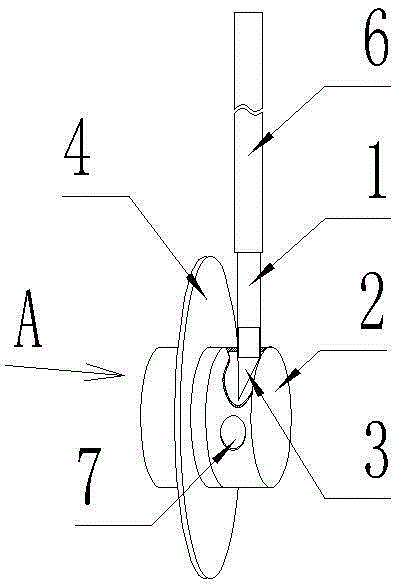

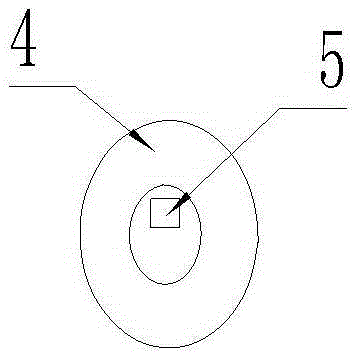

InactiveCN104333145AImprove battery lifeImprove charging efficiencyTyre partsBatteries circuit arrangementsCharge currentCoil array

The invention provides a rechargeable tire and a tire-type wireless charging belt system which can support the rechargeable tire to charge the electric vehicle in high-speed driving or stopping process, and belongs to the field of new-energy vehicles. The rechargeable tire uses the charging receiving antenna coil array technology and the multi-layer receiving antenna coil dislocation array group technology, wireless charging current sent by the tire-type wireless charging belt system can be effectively received, and the rechargeable tire is tightly attached to the tire-type wireless charging belt, thereby effectively improving the wireless charging efficiency and reducing harmful electromagnetic radiation. According to the ultra-thin tire-type wireless charging belt technology, the design and production technology method and the laying, installation and construction method, the production and construction efficiency can be effectively improved, the cost is reduced, laying construction is extremely simple, and the wireless charging technology can be quickly executed in a large area.

Owner:刘跃进

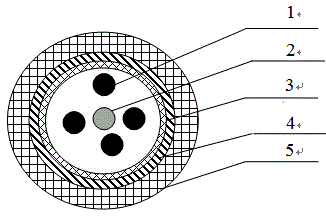

Optical cable laid in sewer line and laying method thereof

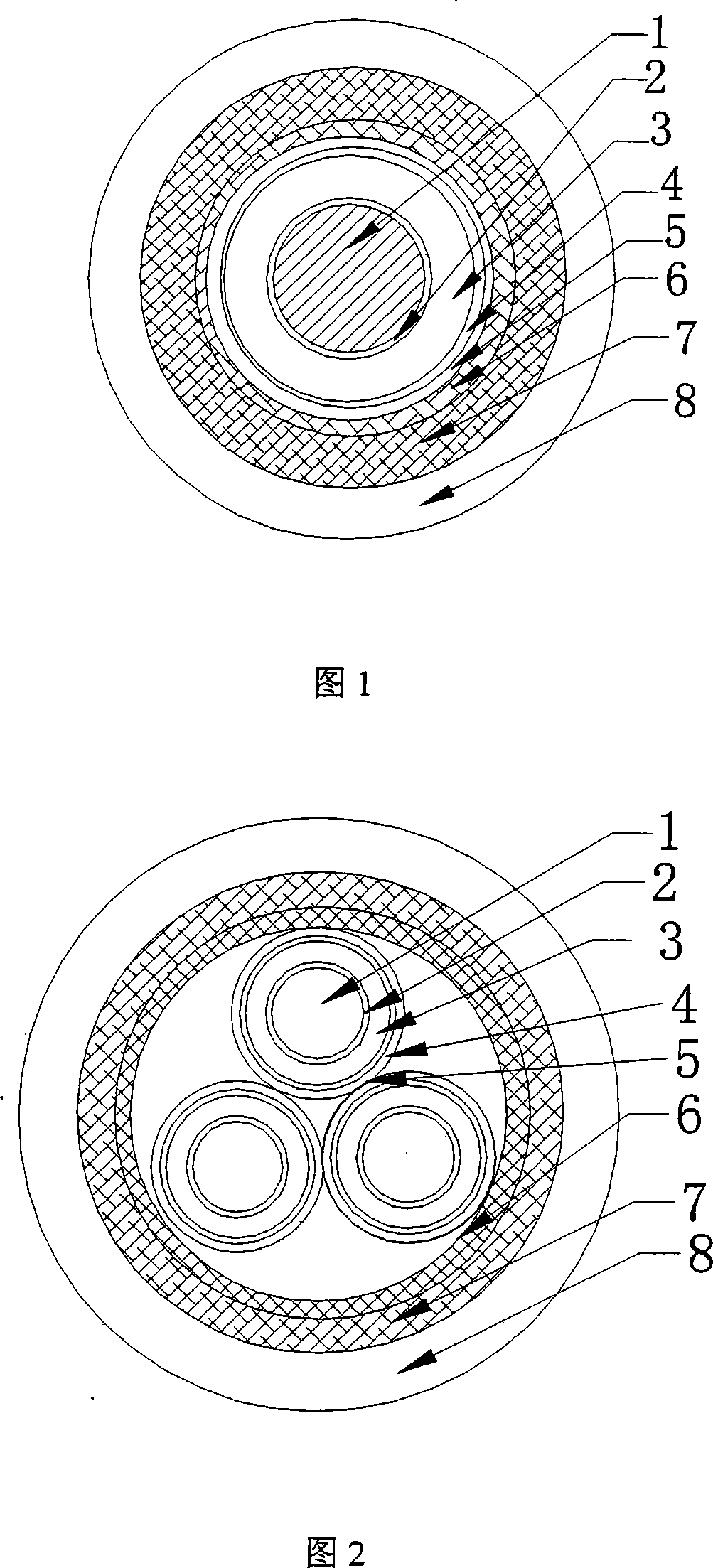

ActiveCN1542484AHigh tensile strengthImprove corrosion resistanceOptical fibre/cable installationFiberEngineering

The optical cable includes cable core, metal belt coating the cable core, inner sheath outside the metal belt, reinforcing fiber part outside the inner sheath and outer sheath outside the reinforcing fiber part. The optical cable has very high tensile strength for direct hanging inside sewer without needing other support, has two layers of sheath and added ratproof and ant resisting additive resulting in raised performance of resisting corrosion, moisture, rat and ant for use in harsh environment, and has simple installation structure and thus lowered laying cost.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

Medium-voltage fire-proof cable

ActiveCN101169993BReduce the burden onImprove fire and heat insulation performanceInsulated cablesInsulated conductorsFiberFrit

The invention relates to a middle-voltage power transmission fire-resistant cable, which is characterized in that a fire-resistant layer out of a middle-voltage cable core includes an inner fire-resistant inorganic fiber thermal insulating layer, and an outer composite fire-resistant thermal insulating layer, which is a soft thermosetting elastic body in normal use and is a fire-resistant thermalinsulating layer when exposed to fire, wherein the thermosetting elastic body consists of 30-50wt percent silicon-based elastic material, 40-60wt percent inorganic filling material, 5-15wt percent middle- and low-temperature frit, and 4-10wt percent vulcanizing agent and is prepared by mixing, extruding, shaping and vulcanizing. The composite fire-resistant thermal insulating layer is a soft protective material for ensuring the good bending property of the fire-resistant structure under normal condition, can change to tubular fire-resistant thermal insulating structure when exposed to fire orhigh temperature and can not be damaged for a certain time in fire environment so as to effectively prevent the flame or high temperature from damaging the inner insulating layer. When the outer flame temperature is 850DEG C, the surface temperature of the inner insulating layer is less than 180DEG C. The fire-resistant thermal insulating structure can be applied in common cable protection mannerand has very high production efficiency.

Owner:FAR EAST CABLE +2

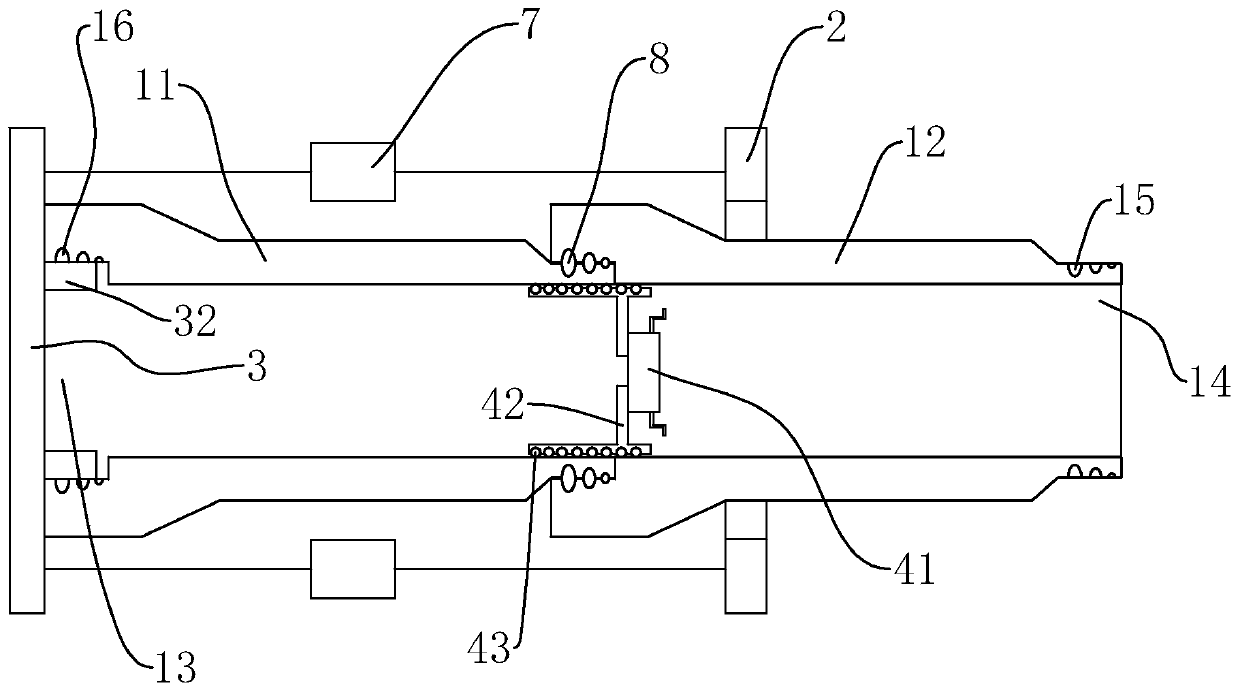

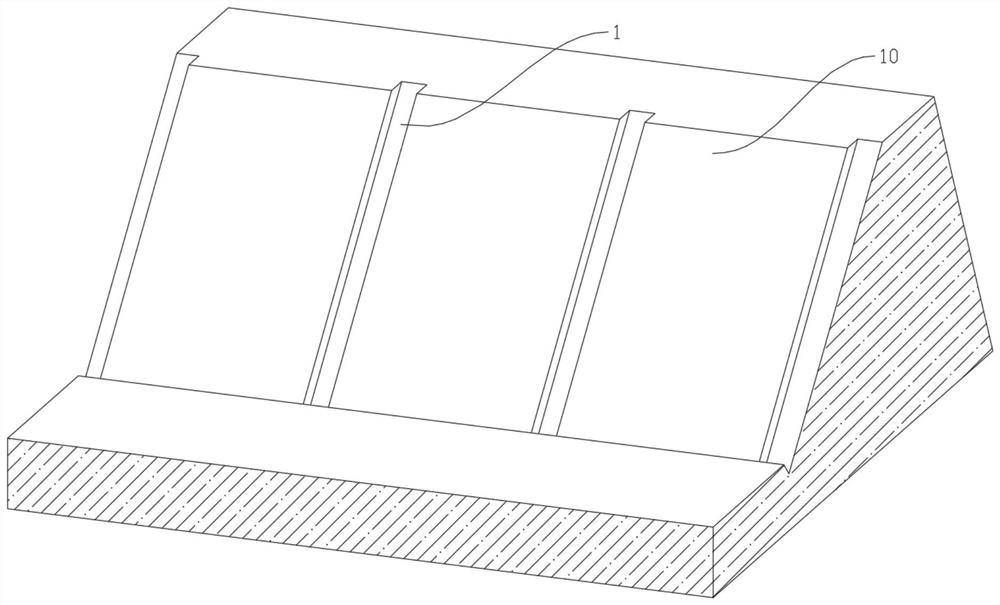

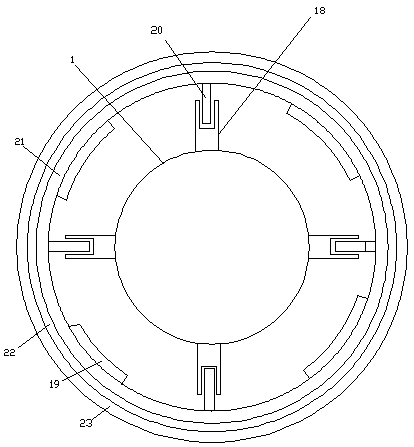

Plastic double-wall winding corrugated pipe forming device

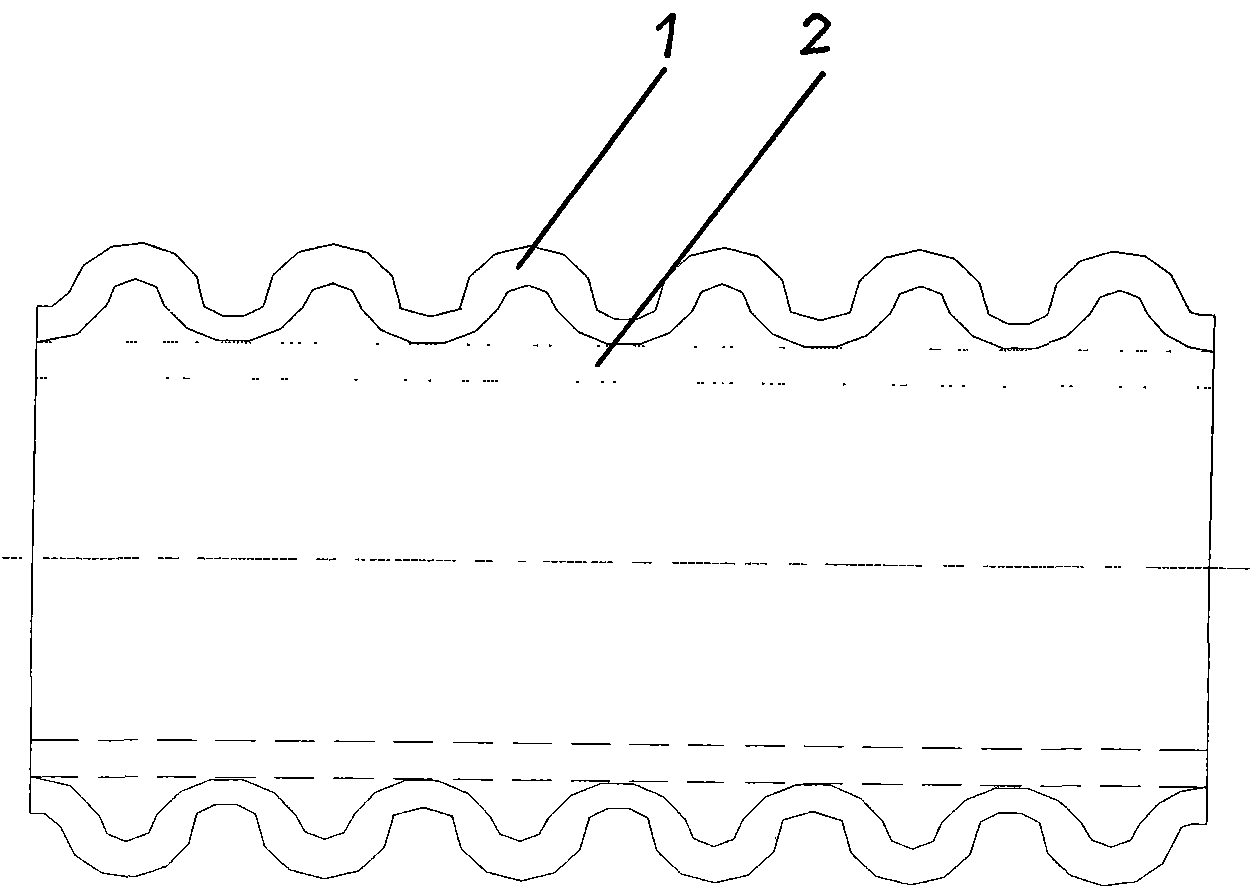

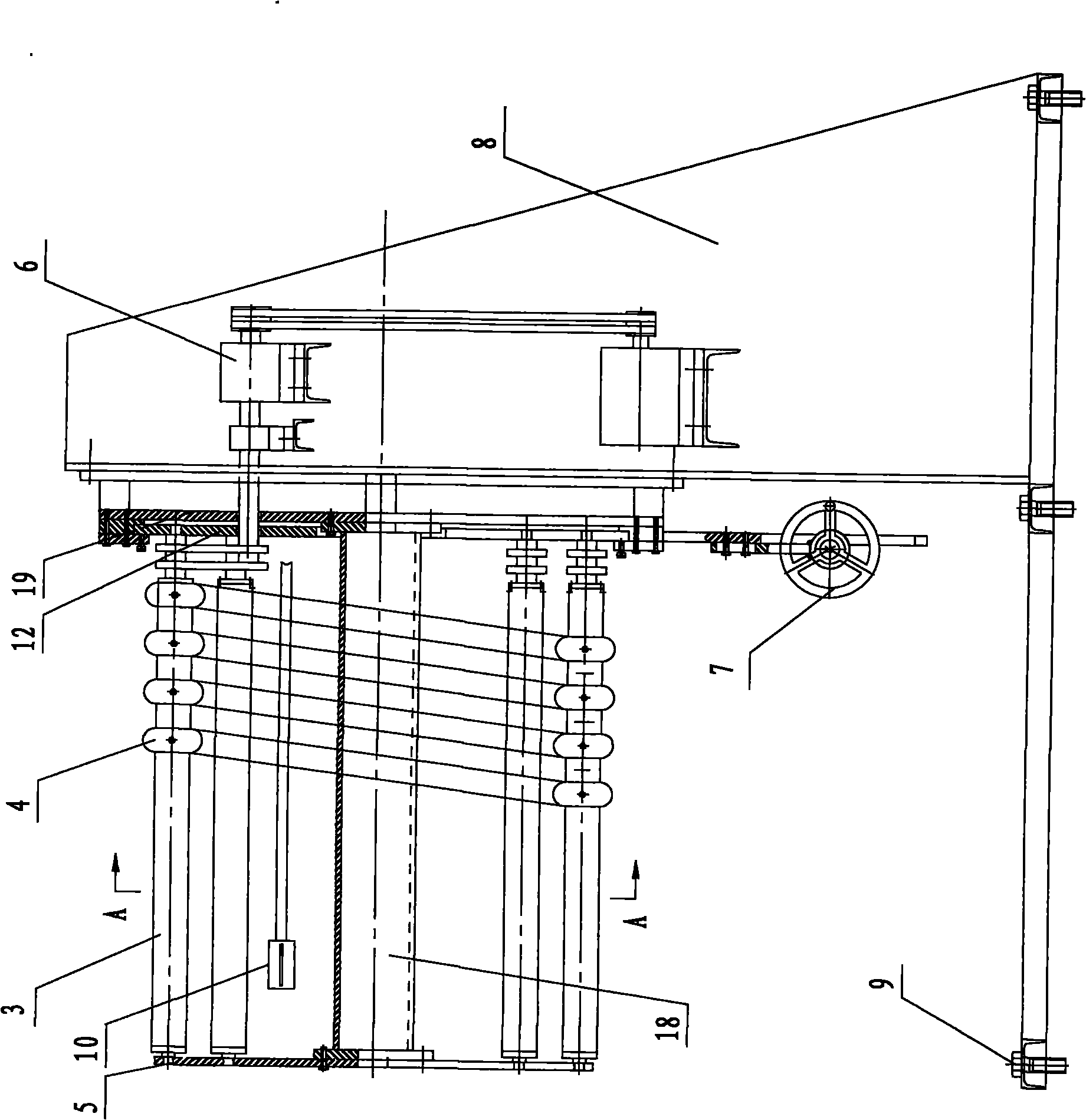

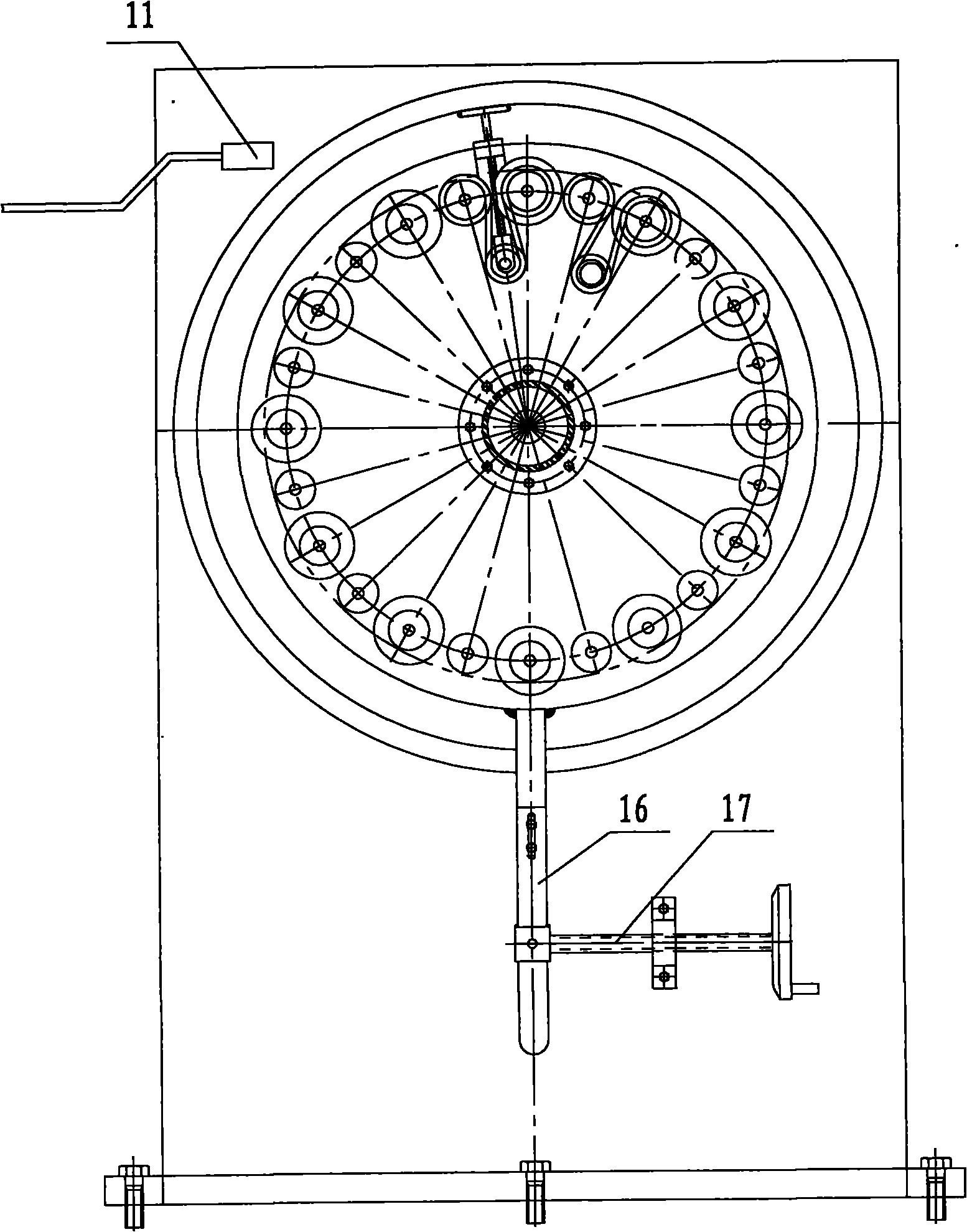

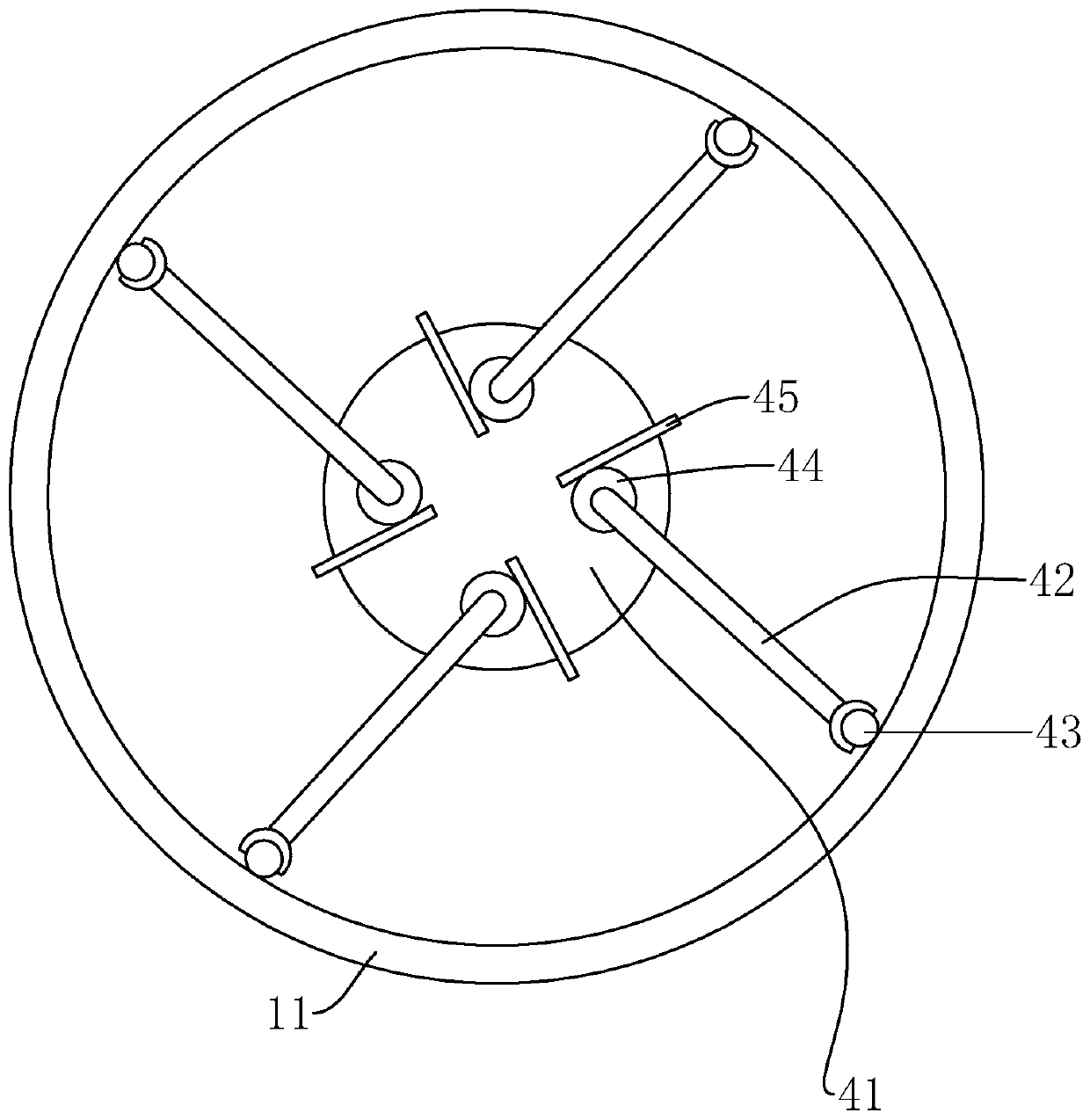

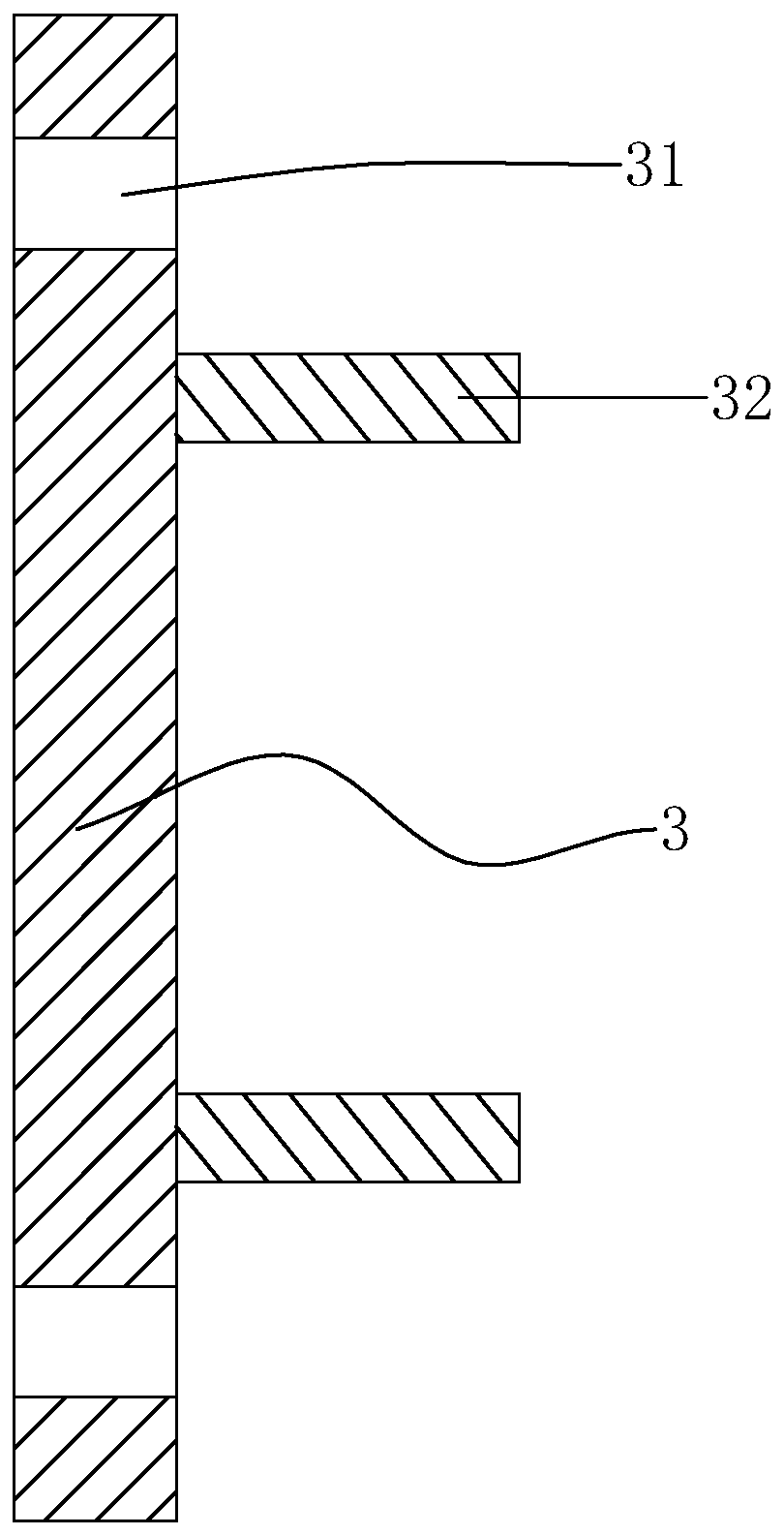

The invention belongs to the technical field of forming of plastic double-wall corrugated pipes, in particular to a plastic double-wall winding corrugated pipe forming device. The invention solves the problems that the existing plastic double-wall corrugated pipe die sucking type forming mode is not suitable for production of large-caliber tubular products, and the steel belt supporting and winding type forming mode leads the product quality and the service life to be unstable. The device of the invention comprises an uplifting and winding device, and the uplifting and winding device comprises a circular stick group; the circular stick group consists of a plurality of circular sticks which are uniformly distributed and arranged into a circle, have the same diameter and can independently rotate at a constant speed in the same direction; the excircle of the circular stick group is matched with the inner diameter of a plastic double-wall winding corrugated pipe; a plurality of supporting wheels forming uplifted spiral trajectories are arranged at the rear part of the circular stick group; an outer die head is arranged at the exterior of the rear part of the circular stick group; and an inner die head is arranged at the interior of the front part of the circular stick group. The invention has the beneficial effects of improving the production efficiency, shortening the processing cycle, greatly reducing the usage of equipment, and effectively reducing the manufacturing cost of the plastic double-wall corrugated pipe.

Owner:杨荣

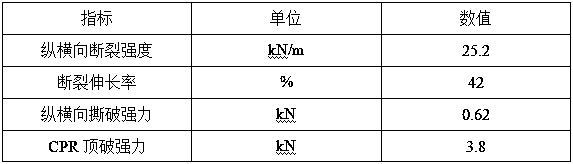

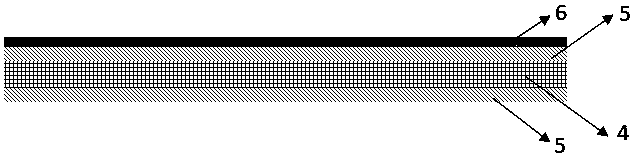

Non-asphalt-based reaction type pre-paving macromolecular self-adhesion adhesive film waterproof coiled material

InactiveCN107267083AAvoid pollutionAvoid Fire HazardsFilm/foil adhesivesPolymer scienceCrack resistance

The invention discloses a non-asphalt-based reactive pre-paved polymer self-adhesive film waterproof coiled material, which includes a waterproof coiled material body, and the waterproof coiled material body includes a resin polymer sheet, a polymer waterproof base layer and a self-adhesive membrane. Adhesive outer layer, the outer surface of the polymer waterproof base layer is fixedly connected with the resinous polymer sheet, and the outer surface of the resinous polymer sheet is fixedly connected with the self-adhesive outer layer. The non-asphalt-based reactive pre-paved polymer self-adhesive film waterproof membrane has super bonding performance, the peel strength is 2-3 times that of ordinary self-adhesive membranes, high tear resistance, waterproof and impermeable It has strong performance and hydrolysis resistance, and has a skin-like waterproof effect, which is conducive to popularization and use. It has excellent toughness, strong elasticity, stress crack resistance, softness, and high toughness. Poor, low tear strength, poor waterproof and impermeable performance and hydrolysis resistance, which is not conducive to popularization and use.

Owner:淮安市大有塑纤有限公司

Natural air conditioner

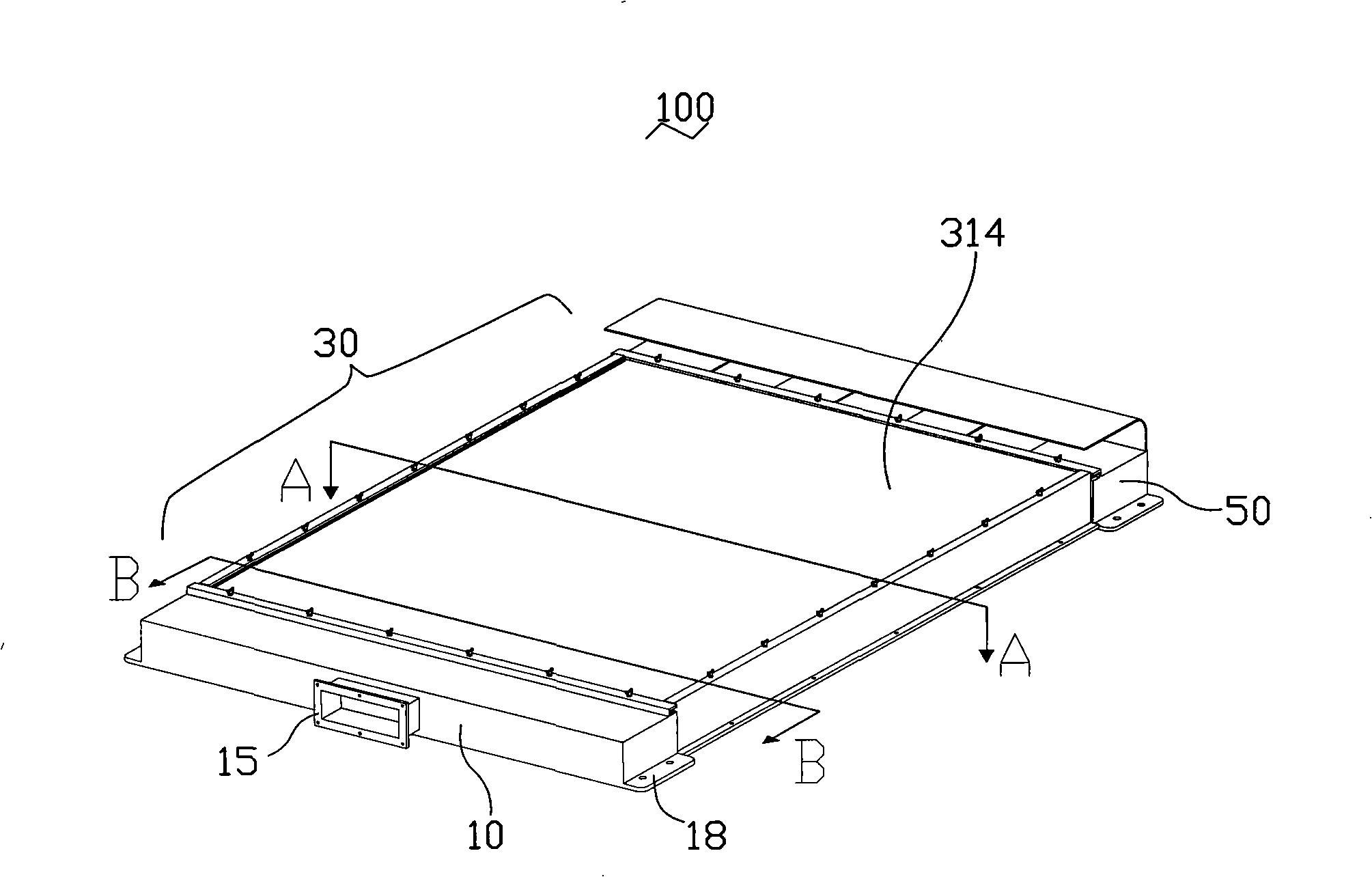

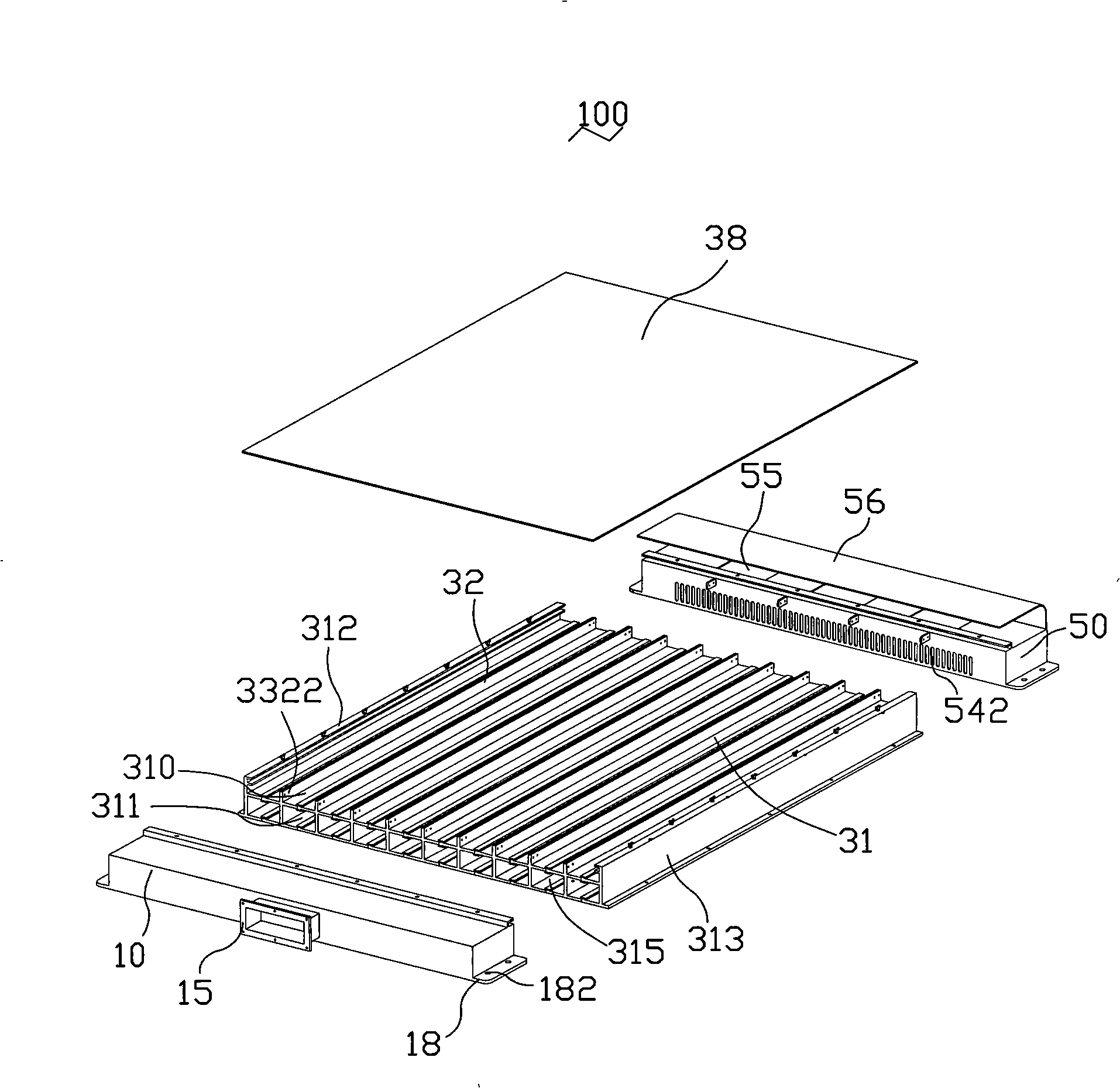

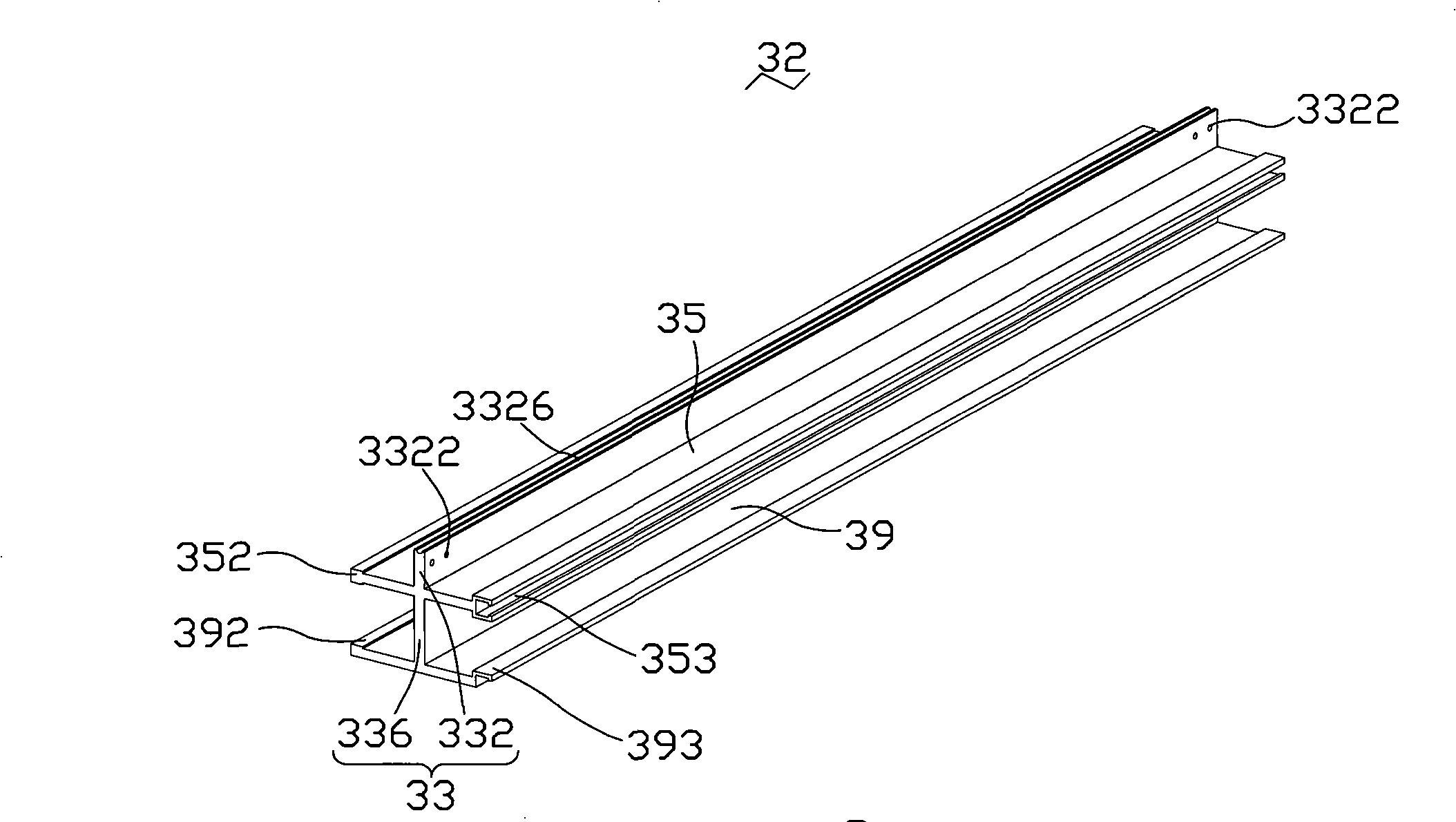

InactiveCN101319820ASimple structureLow priceSolar heating energySolar heat devicesCollector deviceEngineering

The invention relates to a modularization natural air conditioning device by using solar energy to heat air, mainly comprises a heat collector, an inlet part and an outlet part. The heat collector comprises a transparent cover plate on the upper part and a heat absorption component on the lower part. The heat absorption component comprises a plurality of modularization heat absorption units. The heat absorption unit is an integrated forming part comprising a support plate, a heat absorption plate and a bottom plate. The efficacy of the transverse expansion and laying can be reached by locking and locating structures arranged on a plurality of heat absorption plates and the bottom plate.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

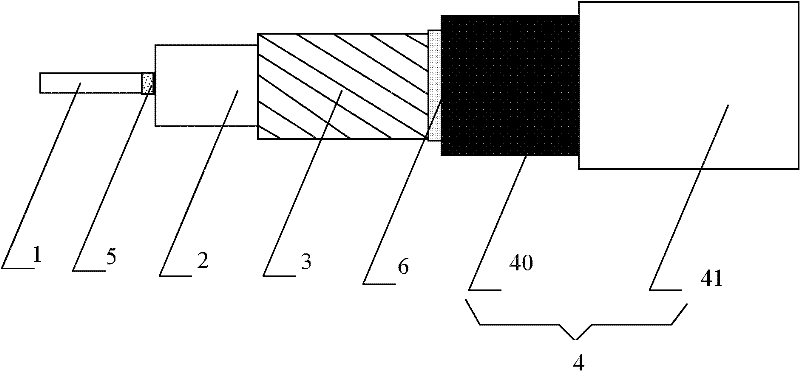

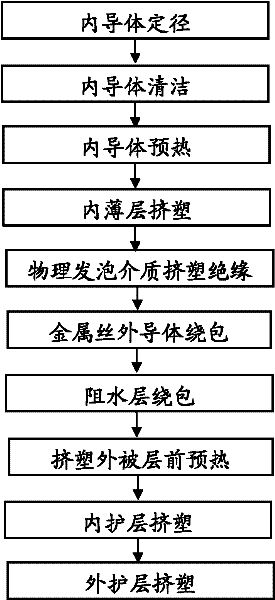

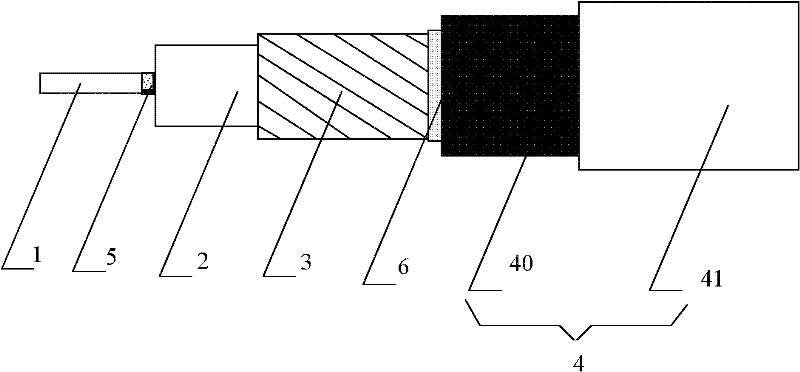

Leakage coaxial cable of lapped braided outer conductor and production technology thereof

InactiveCN102361145AReduce weightGood electrical conductivityWaveguidesLeaky-waveguide antennasBlocking layerPolymer

The invention relates to a leakage coaxial cable of a lapped braided outer conductor and a production technology thereof. The cable is formed by an internal conductor, an insulating layer, an outer conductor and an outer-coating layer from inside to outside and in a multilayer structure. An inner thin layer, which is used for bonding the internal conductor and the insulating layer and has waterproof and moistureproof functions, is arranged between the internal conductor and the insulating layer. The outer-coating layer is in a double-layer structure and is composed of an inner protection layer and an outer protection layer; more particularly, the inner protection layer is manufactured by continuous enclosed extrusion processing by polymer sheathing compounds with weather ability; and the outer protection layer is manufactured by the continuous enclosed extrusion processing by flame-retardant polymer sheathing compounds. Besides, a water-blocking layer, which is formed by smoothly lapping the outer conductor with a layer of thin polyester film or a water-blocking yarn and has moistureproof and anticorrosion functions, is arranged between the inner protection layer and the outer protection layer of the outer-coating layer; and the outer conductor is formed on the insulating layer by uniformly lapping and braiding a plurality of sparse metal wires along a same direction.

Owner:ZHUHAI HANSEN TECH CO LTD

Sewage pipeline laying process

ActiveCN110285261AEasy constructionPipe butt joint sealing is goodPipe laying and repairEngineeringSewage

The invention discloses a sewage pipeline laying process which sequentially comprises the steps of excavating a tunnel, laying a base, laying pipelines and refilling. According to pipeline laying, pipeline connection is carried out by adopting a sequential butt-joint way, the previous pipeline is firstly fixed before the next pipeline is laid, and each pipeline is provided with a socket and a spigot. The pipeline butt-joint way comprises the following steps of (1) excavating a working pit at the butt-joint part of a fixed pipeline and a pipeline to be installed; (2) installing a push plate on the socket part of the pipeline to be installed, wherein the push plate is abutted against the end surface of the socket of the pipeline to be installed; (3) installing a clamping hoop on the outer wall of the fixed pipeline, wherein the inner diameter of the clamping hoop is smaller than the outer diameter of the socket of the pipeline; (4) hanging the pipeline to be installed into the tunnel, aligning axes of the pipeline to be installed and the fixed pipeline, and installing a chain block, wherein the clamping hoop and the push plate are connected to two ends of the chain block; and (5) sleeving a seal ring on the spigot part of the pipeline to be installed, and pulling the chain block so as to enable the spigot of the pipeline to be installed to be inserted into the socket of the fixed pipeline.

Owner:福建磊鑫(集团)有限公司

Novel magnetic conductive rubber and magnetic conductive tyre charging system used for charging electric automobile in operation

PendingCN105337334AImprove battery lifeImprove charging efficiencyBatteries circuit arrangementsElectromagnetic wave systemEngineeringConductive rubber

The invention discloses a novel magnetic conductive rubber material, a magnetic conductive tyre which is manufactured from the magnetic conductive rubber and enables an electric automobile in a high-speed driving state or a stop state to be automatically charged with high efficiency, and a magnetic conductive tyre charging system. According to the chargeable magnetic conductive tyre, the charging receiving coil array technology and the magnetic conductive rubber column array technology are used, electromagnetic coupling efficiency is effectively improved, charging efficiency reaches up to 95%, multiple electric automobiles can be simultaneously charged at one same road segment, so harmful electromagnetic radiation is reduced. The magnetic conductive rubber and the chargeable magnetic conductive tyre are a revolution for the electric automobile charging technology, and the technologies can be new directions for development and popularization of the electric automobile tyres and the electric automobiles.

Owner:刘跃进

Cable distance measuring instrument

ActiveCN105258663ASimple structureEasy to operateMeasurement devicesEngineeringBuilding construction

The invention discloses a cable distance measuring instrument and belongs to the electric power construction appliance technical field. The cable distance measuring instrument includes a distance measuring wheel and a rolling wheel seat; the distance measuring wheel rotates in the rolling wheel seat; the rolling wheel seat is provided with a handle; and the rolling wheel is provided with a counter. The distance measuring wheel rolls along the laying direction of a cable, so that the numerical value of the length of the required cable can be detected through the counter. Compared with an original cable estimation mode, the cable distance measuring instrument can assist in decreasing cable length errors and greatly improving cable measurement accuracy. The cable distance measuring instrument of the invention has the advantages of simple structure and convenient operation. With the cable distance measuring instrument adopted, the accuracy of secondary cable measurement can be improved, and cable laying construction can be facilitated.

Owner:STATE GRID CORP OF CHINA +2

Conductive road sign paint and conductive, magnetic and driving type electromagnetic tire

InactiveCN104356733AImprove battery lifeHigh charging transfer efficiencyTyre partsIn situ pavingsCurrent transducerLow voltage

The invention discloses a pavement marked line coating with conductivity, a pavement marked line coating with insulating property, a method for spraying a low-voltage conductive type charging belt by the conductive and insulating pavement marked line coatings and a conductive, magnetic, rechargeable and driving type electromagnetic tire. The invention also discloses a mobile charging belt system for supporting charging during running of an electric automobile. The system comprises the low-voltage conductive type charging belt sprayed by conductive road sign paint or the pavement marked line coating, a conductive type tire (or a conductive type rechargeable tire), a current transducer, a charging belt controller, a charging controller (or a charging control receiver), a charging management background and an IC (integrated chip) charging card.

Owner:刘跃进

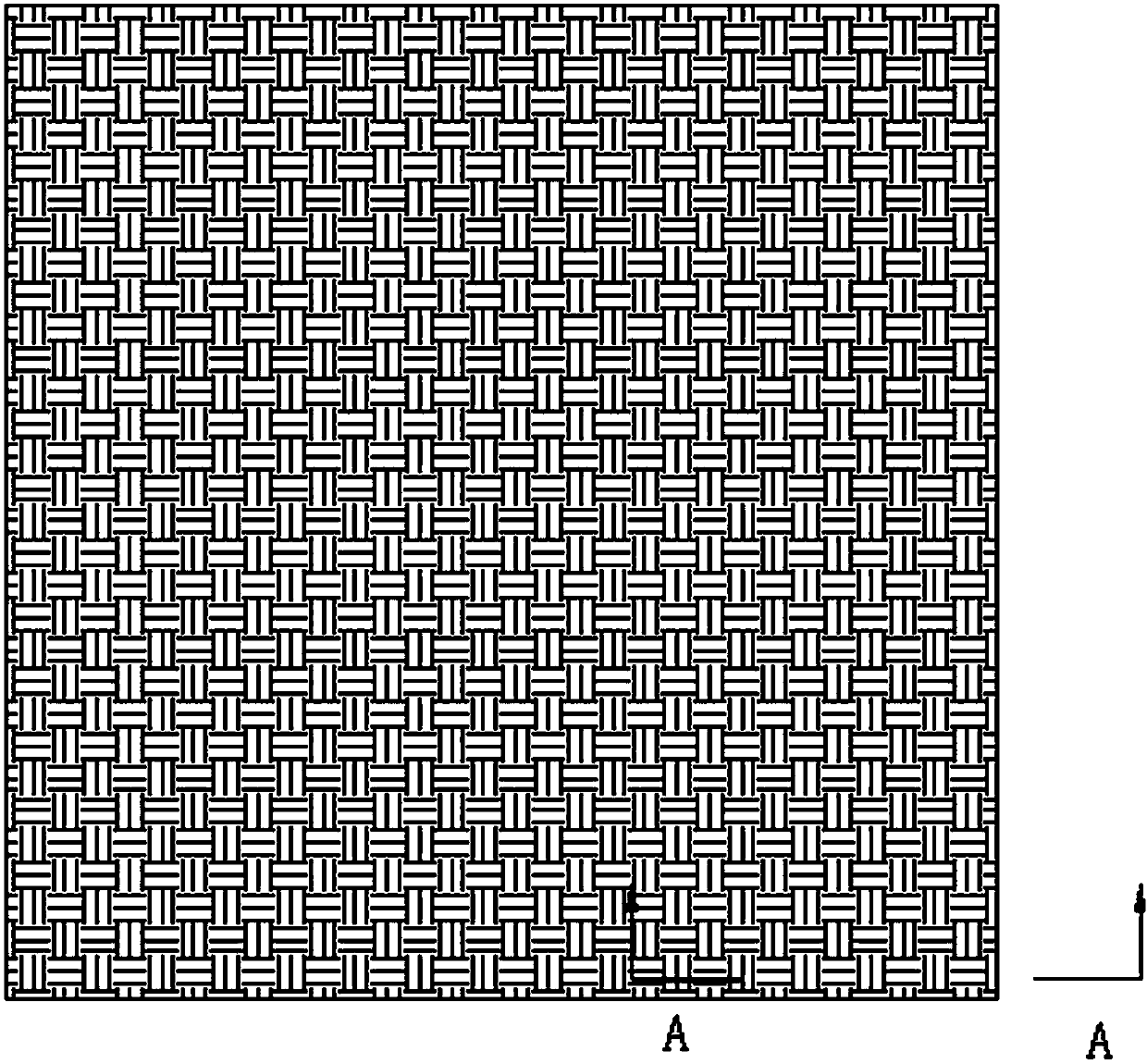

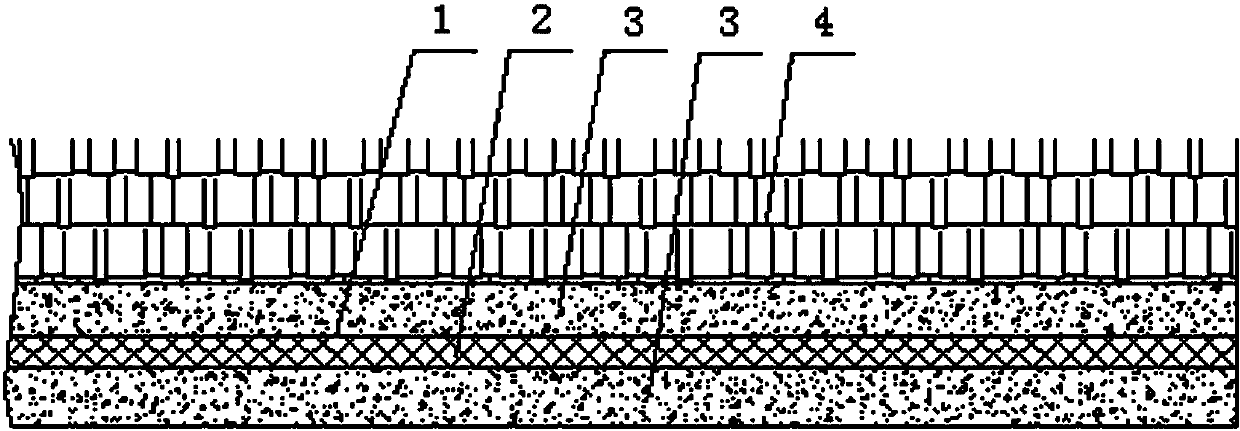

Carpet with electromagnetic shielding function

InactiveCN103462470AConvenient laying and constructionLow costFibre treatmentFloor carpetsMedical equipmentPolyvinyl chloride

The invention discloses a carpet with an electromagnetic shielding function, wherein the carpet is laid on the ground or floor. The carpet comprises a base fabric, and a tufted layer is set on the base fabric. The carpet is characterized in that fibers used by the tufted layer are metal blended fibers, and asphalt layers are coated on the front surface and the back surface of a nonwoven fabric to form the base fabric. The metal blended fibers contain metal fibers, the carpet has the electromagnetic shielding function after being woven or tufted, laying construction of the carpet is as same as that of a common carpet and is quite conveniently, asphalt can be recovered and then continued to be recycled after the produced carpet is scrapped, and cost is greatly reduced as compared with a traditional carpet with a base fabric made of nonwoven fabric and PVC (polyvinyl chloride) plastic composite materials. The carpet can be used in machine rooms with communications, instruments, meters, medical equipment and the like, and has the special function.

Owner:ZHEJIANG DALTON CARPET

Full-dry type access optical cable

InactiveCN105652400AFacilitate divergent continuationConvenient laying and constructionFibre mechanical structuresDirect to homeWater block

The invention relates to a full-dry type access optical cable which comprises an outer sheath and a sleeve. The full-dry type access optical cable is characterized in that tight tube optical fibers and a water blocking piece are laid in the sleeve, and a nonmetal reinforcing piece is arranged outside the sleeve. The full-dry type access optical cable has the advantages that the structure arrangement is simple and reasonable, the mechanical performance is good, the bending performance is high, and the full-dry type access optical cable can be conveniently laid in a corridor; the full-dry type full-medium structure is adopted, the optical cable without factice can be beneficial to divergence continuation, and construction laying, operation and use of the optical cable are facilitated; the loose tube structure of the tight tube optical fibers is adopted, enough buffer space is provided for the tight tube optical fibers, the performance of the cable is improved, divergent optical fibers are effectively protected, access construction is facilitated, and the FTTH direct-to-home requirement is met.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

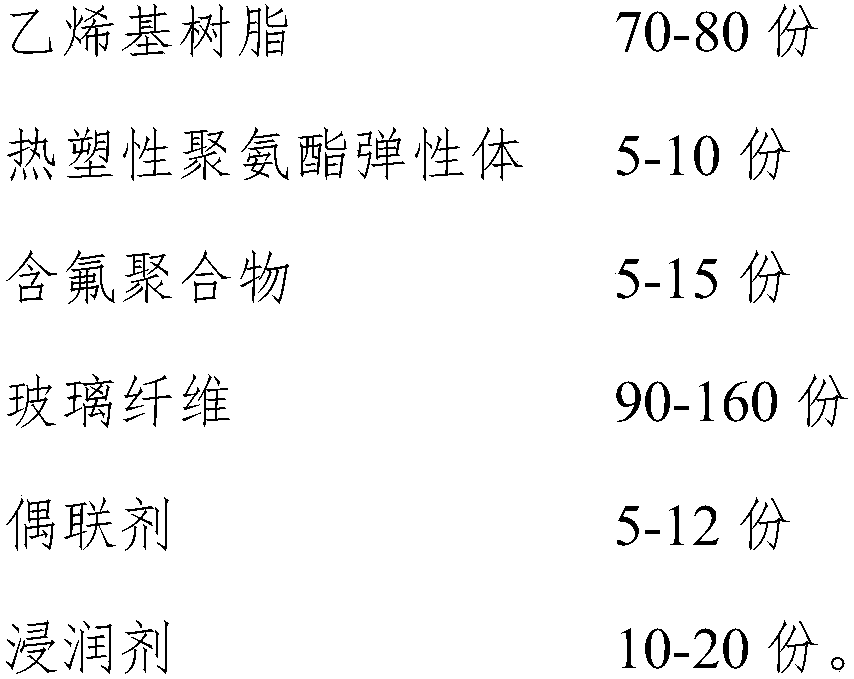

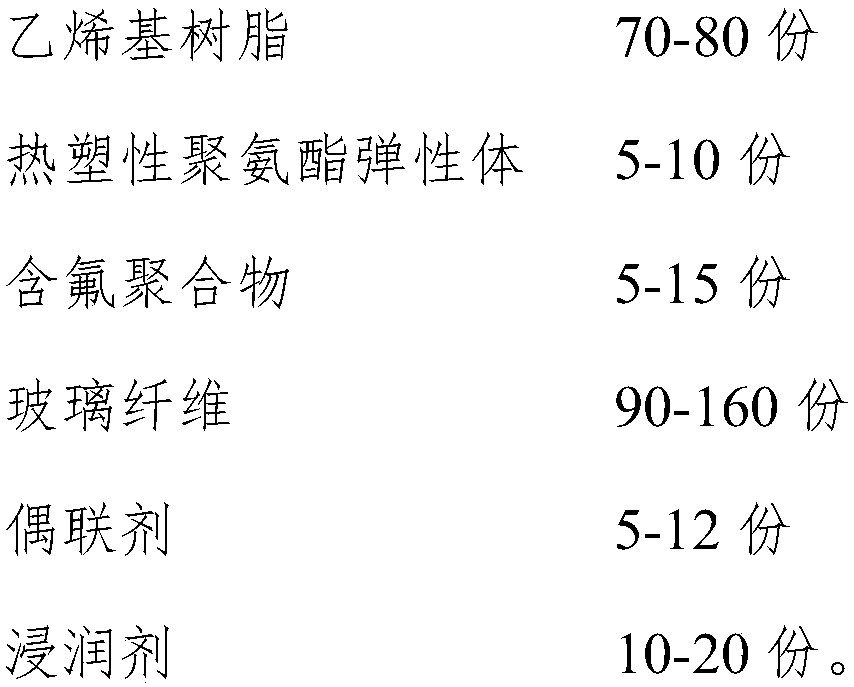

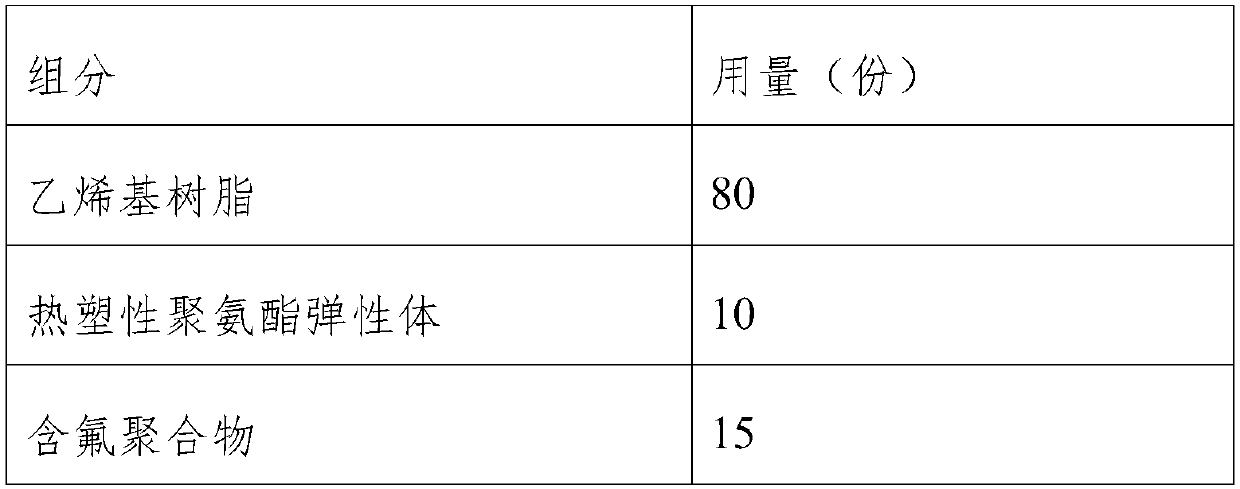

Glass fiber reinforced plastic round bar applied to lightweight all-dielectric aerial optical cable

InactiveCN107589507AHigh tensile strengthGood compatibilityFibre mechanical structuresGlass fiberWeather resistance

The invention discloses a glass fiber reinforced plastic round bar applied to a lightweight all-dielectric aerial optical cable. The glass fiber reinforced plastic round bar armors the outer layer ofa cable core and is manufactured from the following components: 70-80 parts of a vinyl resin, 5-10 parts of a thermoplastic polyurethane elastomer, 5-15 parts of a fluorine-containing polymer, 90-160parts of glass fibers, 5-12 parts of a coupling agent and 10-20 parts of an impregnating compound. According to the glass fiber reinforced plastic round bar applied to the lightweight all-dielectric aerial optical cable disclosed by the invention, glass fiber reinforced plastic is excellent in strength, corrosion resistance and weather resistance, and can meet the requirements on the lightweight all-dielectric aerial optical cable.

Owner:JIANGSU ETERN

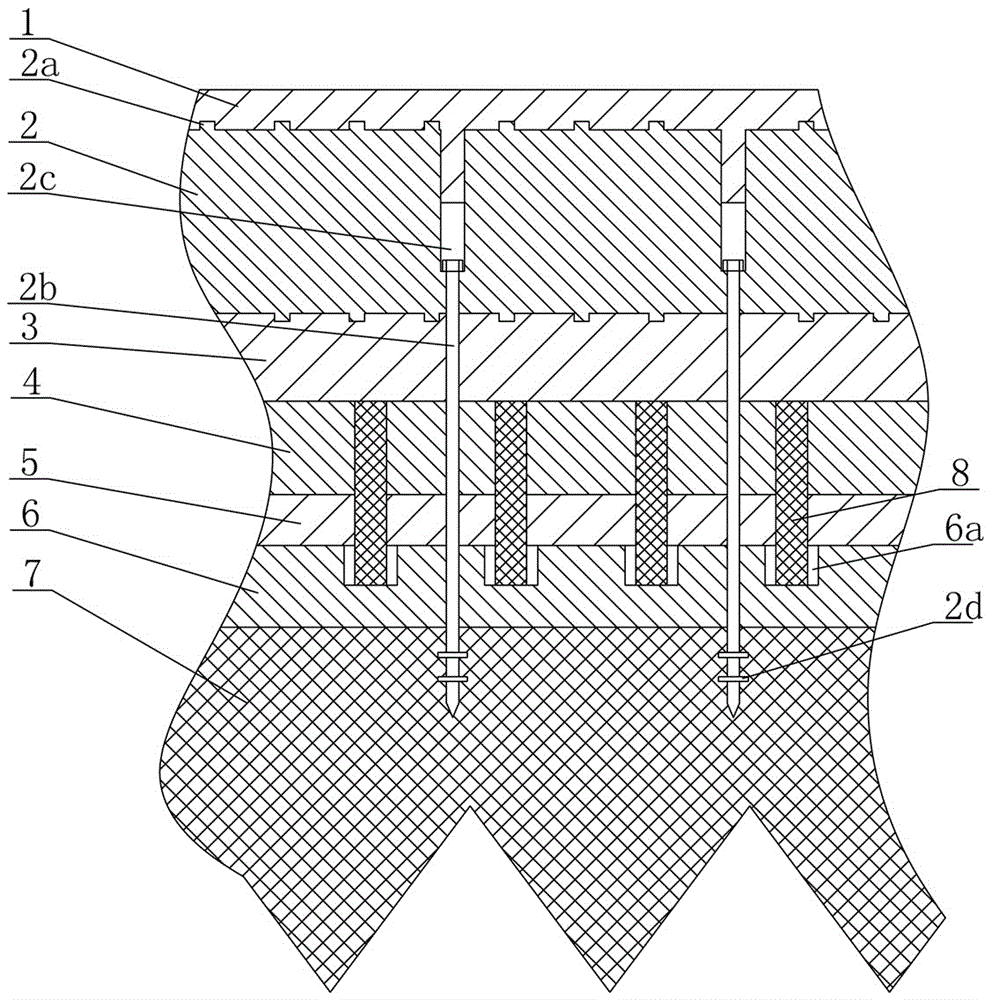

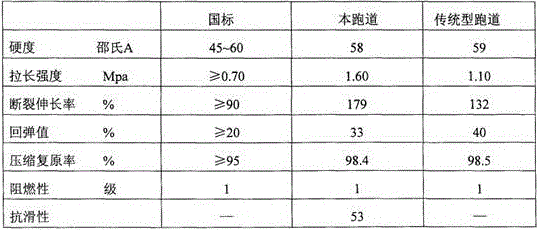

SBS elastomer environment-friendly runway

The invention provides an SBS elastomer environment-friendly runway and belongs to the technical field of plastic runways. The SBS elastomer environment-friendly runway comprises connecting nails and plastic elastic columns and further comprises an abrasion-resisting layer, a buffer layer, a priming coat, a first geotextile layer, a thin film layer and a second geotextile layer which are sequentially arranged from top to bottom. Inwards-sunken connecting holes are formed in the buffer layer, and the bottom diameters of the connecting holes are smaller than the top diameters of the connecting holes; the connecting nails sequentially penetrate into the buffer layer, the priming coat, the first geotextile layer, the thin film layer and the second geotextile layer, and the bottom ends of the connecting nails are inserted in a pure soil layer; and the plastic elastic columns are vertically arranged and penetrate into the first geotextile layer and the thin film layer. According to the SBS elastomer environment-friendly runway, the connecting nails are arranged so that the buffer layer, the priming coat, the first geotextile layer, the thin film layer and the second geotextile layer can be connected into a whole, use of glue is avoided, and the environmental friendliness of the runway is improved; and the runway is further provided with the plastic elastic columns, the negative impact of the connecting nails on the runway elasticity is eliminated, and the plastic pavement has appropriate elasticity accordingly.

Owner:浙江动动恰体育科技有限公司

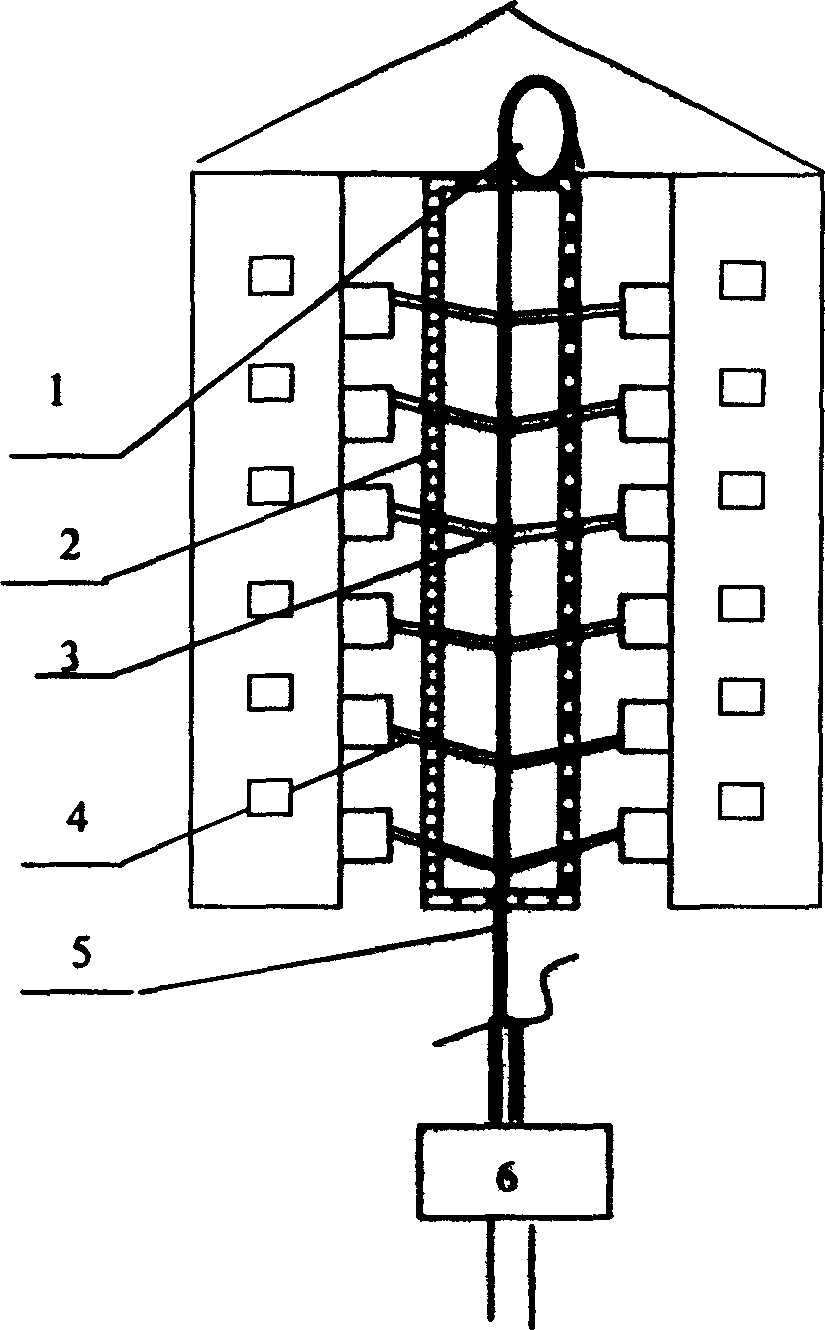

Optical cable laying and fiber distributing method for optical fiber to house

ActiveCN1617006AEasy to disagreeReduced cable consumptionOptical fibre/cable installationFiberEngineering

The method of distributing fibers to doors adopts skeletal flat optical cable with branching windows connected to optical cable joint box for withdrawing branching fiber band and converting into tail fiber to door. The cable core in the skeletal flat optical cable has no filled ointment for easy to construction, the skeletal flat optical cable can hold more fibers, and each optical cable may have several branching windows in different axial positions. The present invention has greatly reduced cable consumption, easy construction and low cost, and is favorable to distributing fibers to doors.

Owner:WUHAN YANGTZE OPTICAL TECH

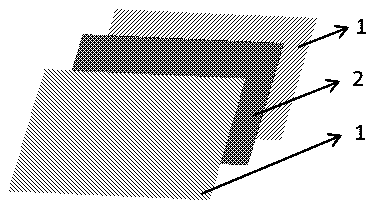

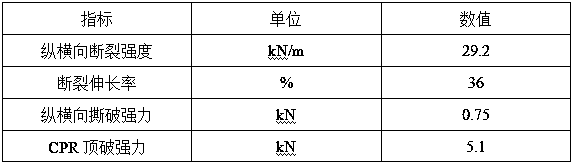

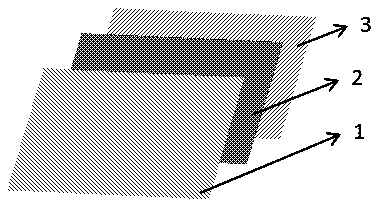

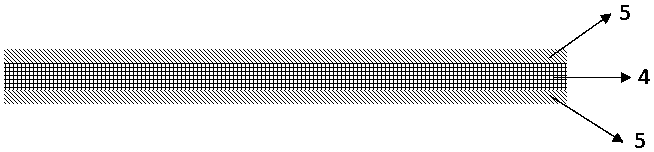

High-strength planting slope protection geotextile with sandwich structure and preparation method of high-strength planting slope protection geotextile with sandwich structure

InactiveCN108385272ASolve the problem of poor application layout restrictionsImprove fertilityExcavationsNon-woven fabricsGrowth plantFiber

The invention provides a high-strength planting slope protection geotextile with a sandwich structure and a preparation method of the high-strength planting slope protection geotextile with the sandwich structure. The geotextile comprises two short fiber geotextile layers, and a planting layer sandwiched between the two short fiber geotextile layers, and the short fiber geotextile layers and the planting layer are fixedly connected by a needle punching process and formed into a whole to form a sandwich structure. The preparation method comprises the following steps: firstly, pre-punching a fiber web by needles into a short fiber geotextile with higher strength, and then fixedly connecting the short fiber geotextile layers with the planting layer by the needle punching process, so that theupper and lower short fiber geotextile layers and the planting layer between them run through to form a sandwich structure. The geotextile layers are pre-punched by adopting the needle punching process, thereby improving the tensile strength and the deformation resistance of a material; the geotextile is not easily pierced or broken during use, and is solid and durable; the planting layer in the invention has higher fertility and water retention capacity, and provides a good environment for plant growth.

Owner:HENAN INST OF ENG

Novel landscape plank road

InactiveCN104195936AConvenient laying and constructionLow costBridge applicationsBridge structural detailsEngineeringStructural engineering

The invention relates to a novel landscape plank road. The novel landscape plank road comprises transverse supporting beams, longitudinal supporting beams and tempered glass. The transverse supporting beams and the longitudinal supporting beams are supported through corresponding supporting mechanisms, road surface installing grooves with the height equal to the thickness of the tempered glass are formed in the inner sides of the transverse supporting beams and the inner sides of the longitudinal supporting beams respectively, and the tempered glass is embedded in the road surface installing grooves in the transverse supporting beams and the longitudinal supporting beams to be laid on the transverse supporting beams and the longitudinal supporting beams; corresponding reinforcing ribs are arranged below the tempered glass in the transverse direction at intervals of 40 cm to 60 cm, and the reinforcing ribs are formed by wrapping foam filler with glass fiber reinforced plastic accumulation layers. Corresponding reinforcing rib installing grooves are distributed in the longitudinal supporting beams, and the two ends of each reinforcing rib are arranged in the corresponding reinforcing rib installing grooves in the longitudinal supporting beams. On the premise that the service life is guaranteed, the tempered glass is adopted as the road surface of the plank road, and thus tourists can enjoy the sight of landscape below.

Owner:CHENGDU JIAMEIJIA SCI & TECH

Flexible high-voltage direct-current cross-linked polyethylene insulation power cable

InactiveCN103794276AReduced short circuit current capacityEasy for construction and layingClimate change adaptationInsulated cablesCross-linked polyethyleneElectric field distortion

The invention discloses a flexible high-voltage direct-current cross-linked polyethylene insulation power cable which comprises a copper conductor located in the center of the power cable. The copper conductor is sequentially wrapped by an inner semi-conductive shielding layer, a cross-linked polyethylene insulation layer, an outer semi-conductive shielding layer, a metal shielding layer, a longitudinal waterproof layer, a radial waterproof layer and a polyethylene jacket layer. The flexible high-voltage direct-current cross-linked polyethylene insulation power cable is an extruding type monopolar cable and has the advantages of being small in size, high in intensity, light in weight, high in transmission capacity, superior in insulation level, easy to lay and the like, and the problems of insulation aging even the breakdown, caused by partial electric field distortion due to space charge accumulation in an insulation body, of a traditional cable and overstressing, caused by uneven pressure distribution due to temperature sensitivity, outside the insulation body of the traditional cable are solved.

Owner:WUXI GREAT WALL ELECTRIC WIRE & CABLE

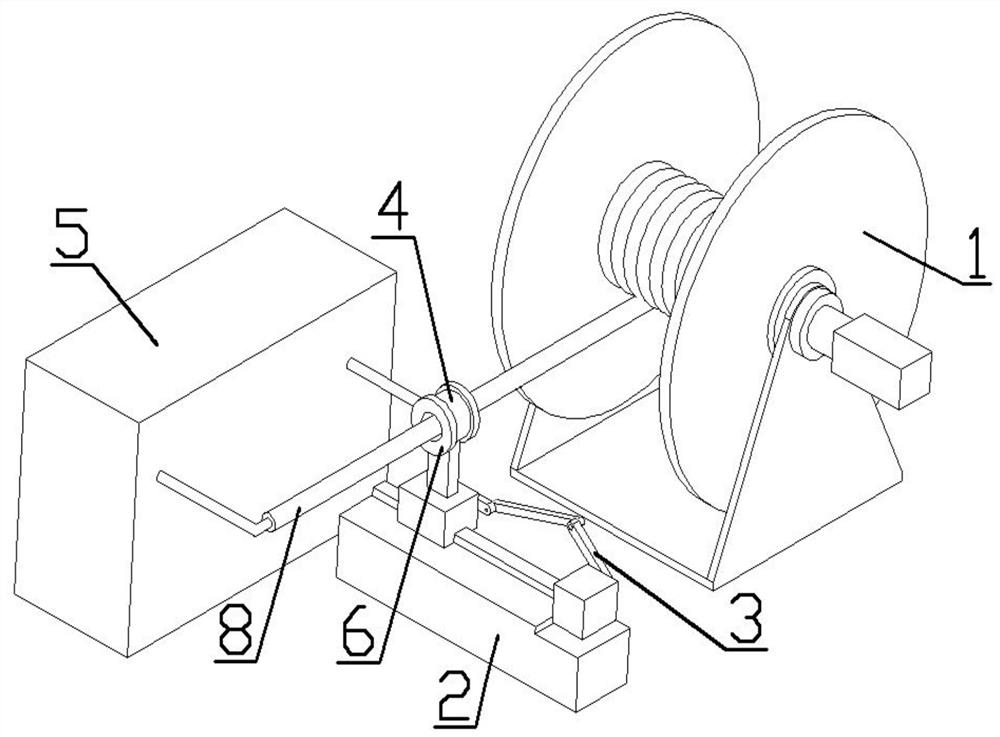

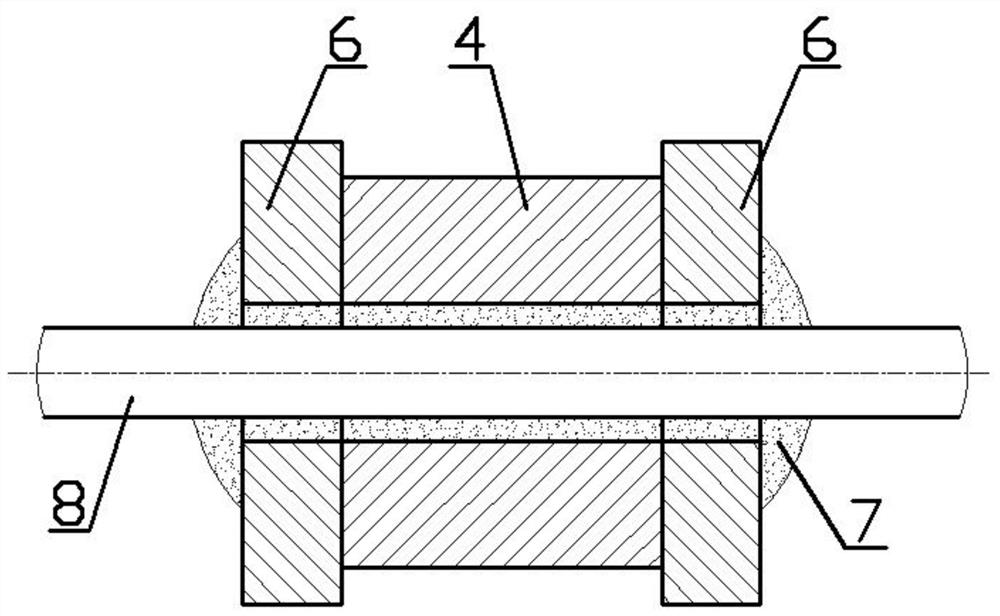

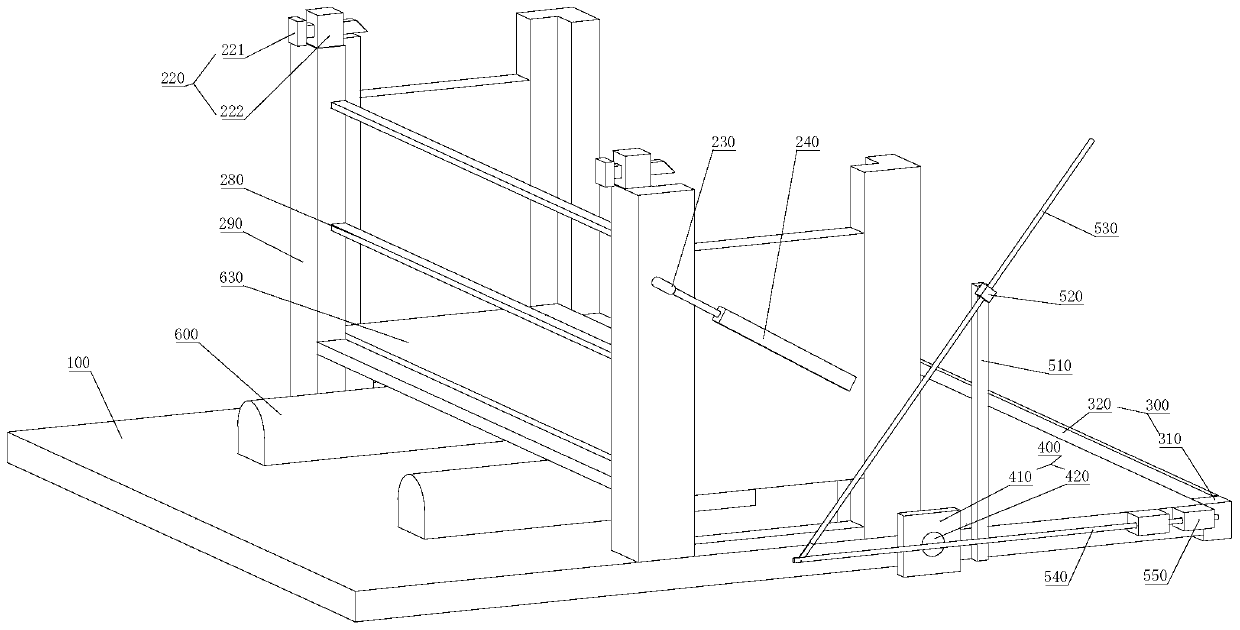

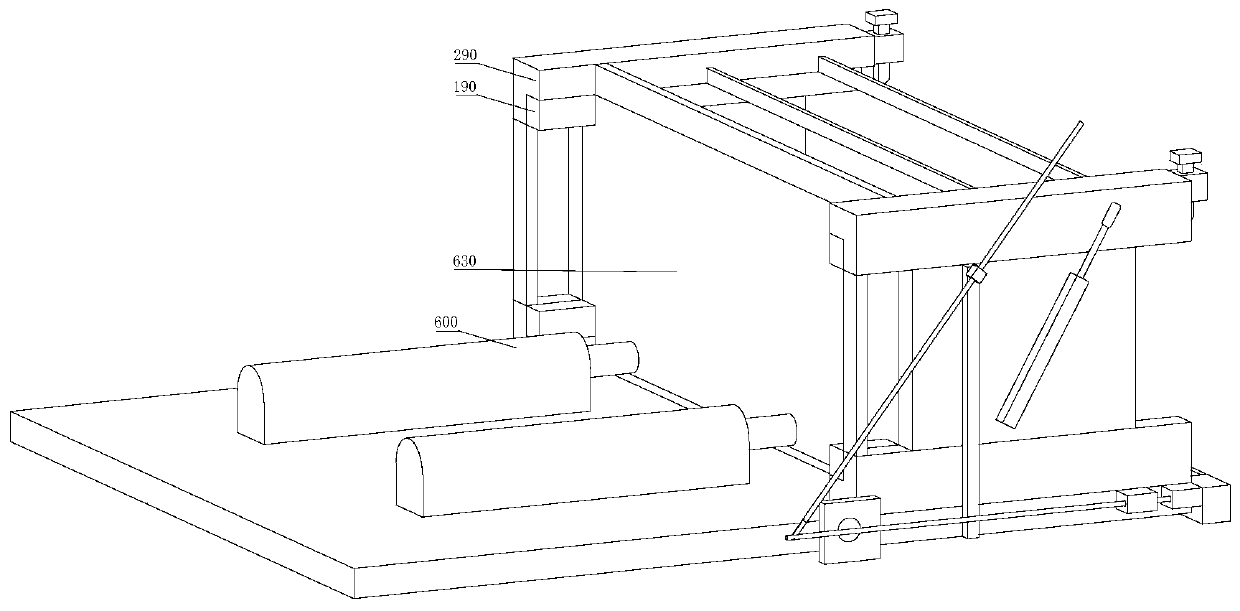

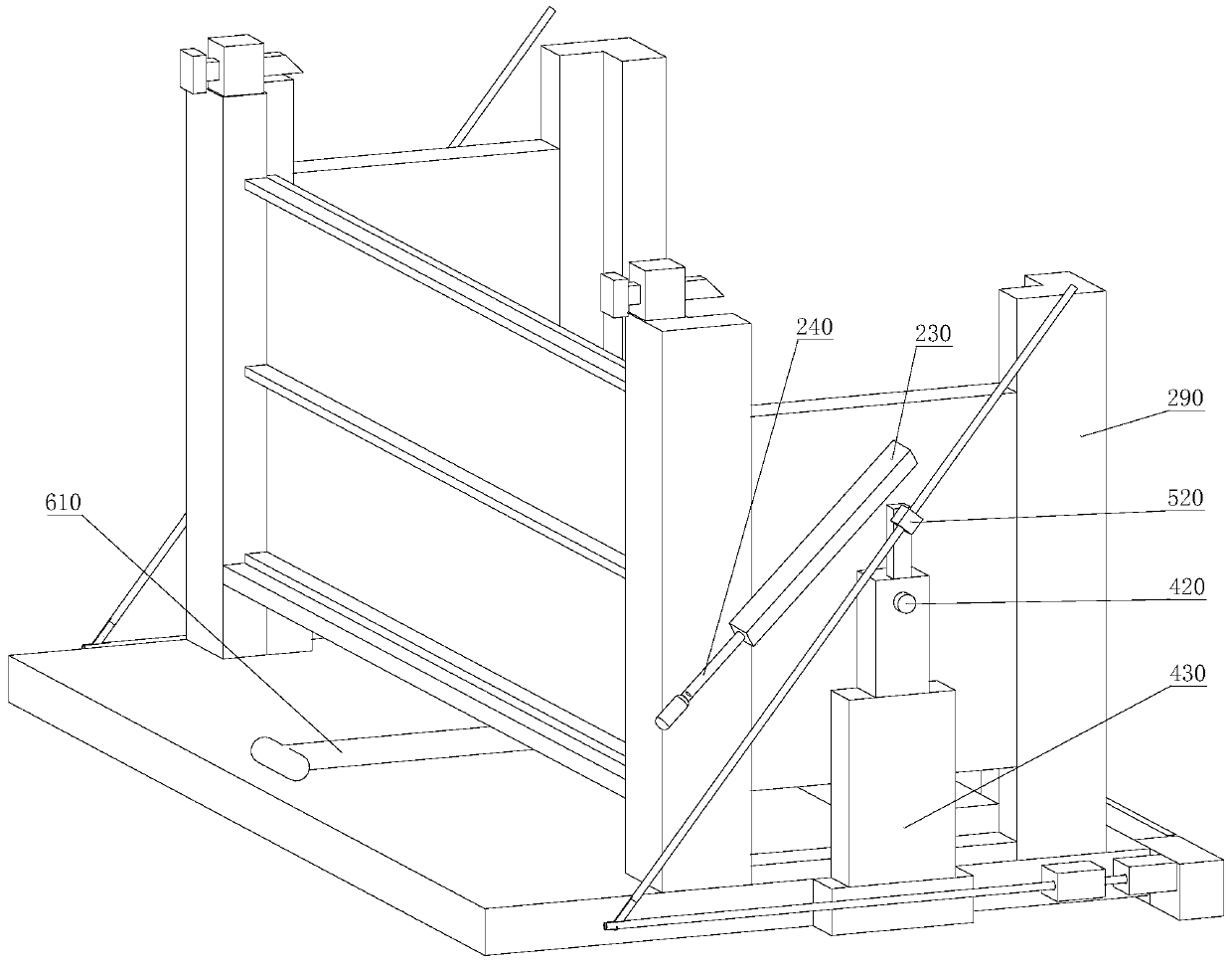

A withstand voltage test device for underground cable laying

ActiveCN110957675BAvoid draggingReduce labor intensityTesting dielectric strengthApparatus for laying cablesElectric machineStructural engineering

Owner:STATE GRID CORP OF CHINA +1

Anti-ageing vegetative slope-protection geotechnical cloth of sandwich structure and preparation method thereof

InactiveCN108360536AExtended service lifeRealize mechanized productionCellulosic plastic layered productsLaminationGrowth plantFiber

The invention relates to anti-ageing vegetative slope-protection geotechnical cloth of a sandwich structure and a preparation method thereof. The geotechnical cloth comprises an upper anti-ageing non-woven cloth layer, a vegetative layer and a lower anti-ageing non-woven cloth layer, wherein the upper and lower anti-ageing non-woven cloth layers and the vegetative layer are fixedly connected intoan integer through needling so as to form the sandwich structure. The preparation method of the geotechnical cloth comprises five steps of fiber web formation, pre-needling, coating, lapping and needling. The anti-ageing vegetative slope-protection geotechnical cloth provided by the invention improves ultraviolet ray resistance and ageing resistance of the material, prolongs the service life of geotechnical cloth, further has relatively good fertility and water retaining capacity, and is beneficial for creating a good plant growth environment.

Owner:HENAN INST OF ENG

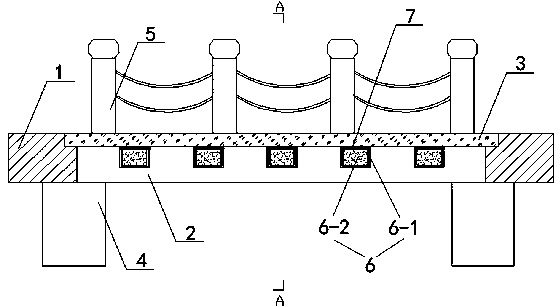

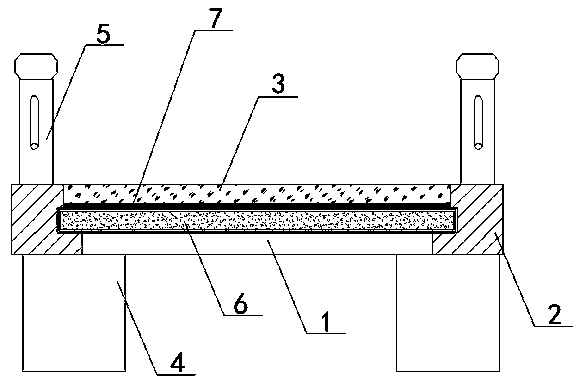

Cable trench cover plate laying device

ActiveCN111371056AConvenient laying and constructionReduce labor intensityCable installations on groundLifting framesEngineeringStructural engineering

Owner:国网山东省电力公司利津县供电公司 +1

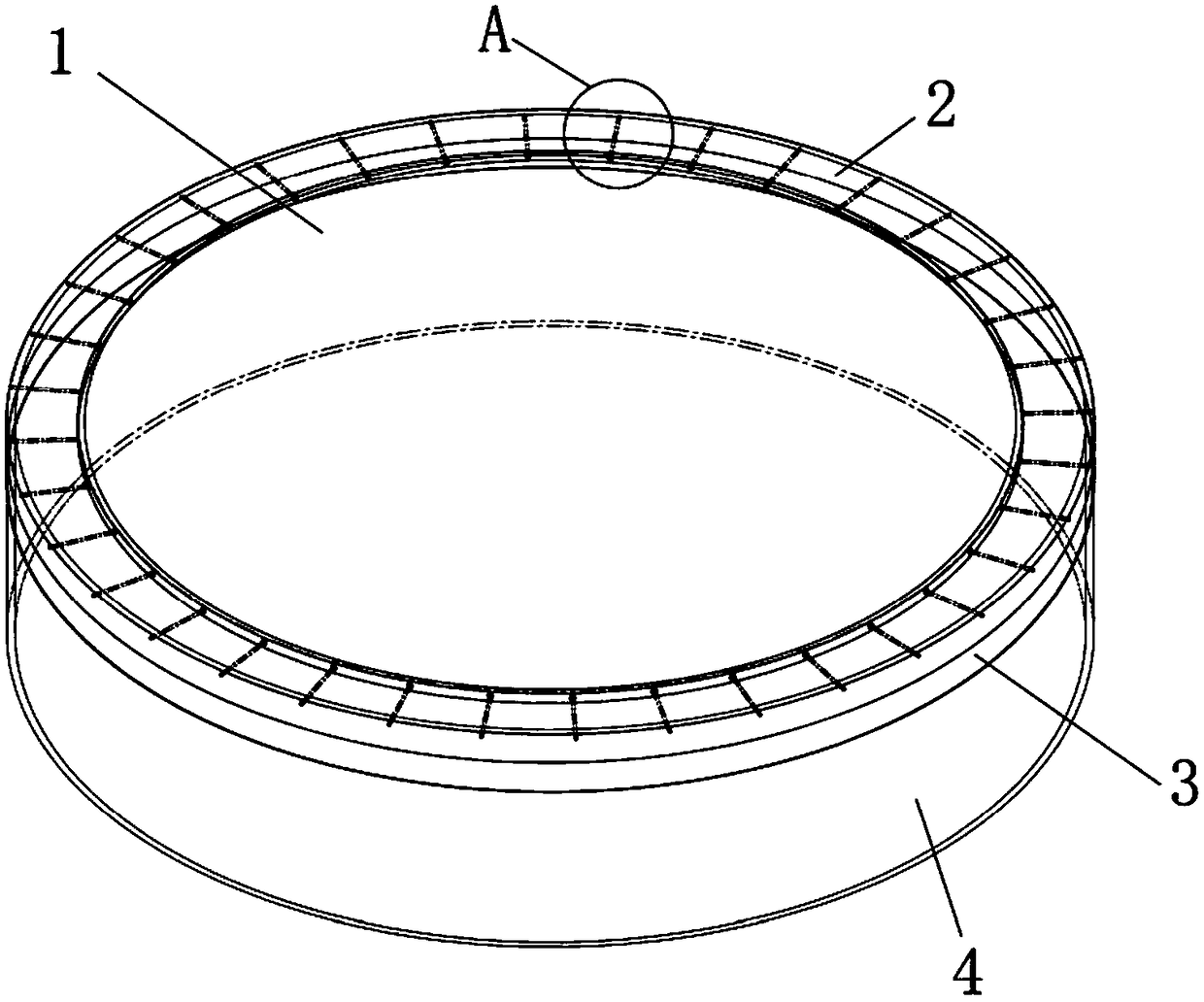

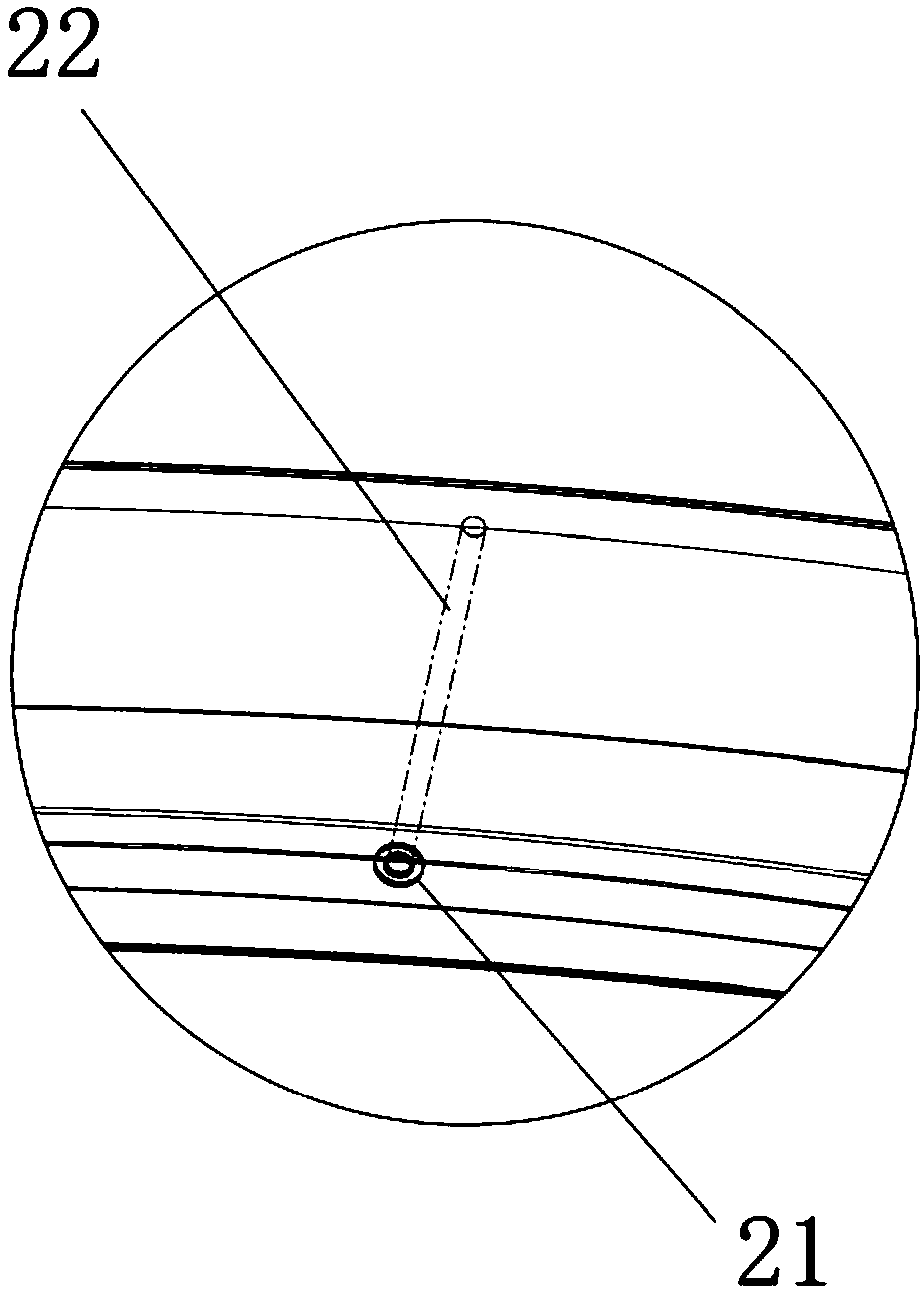

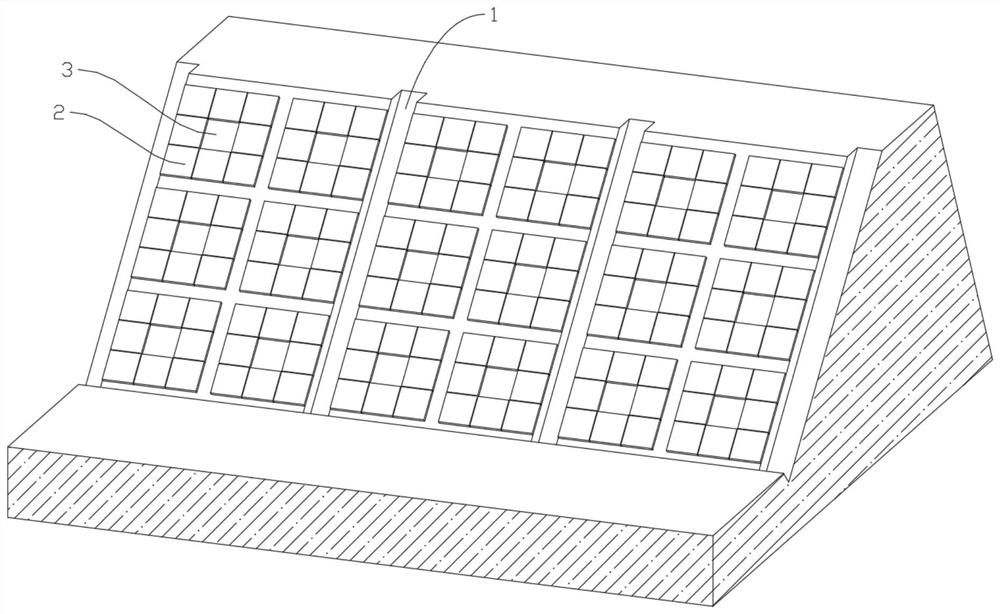

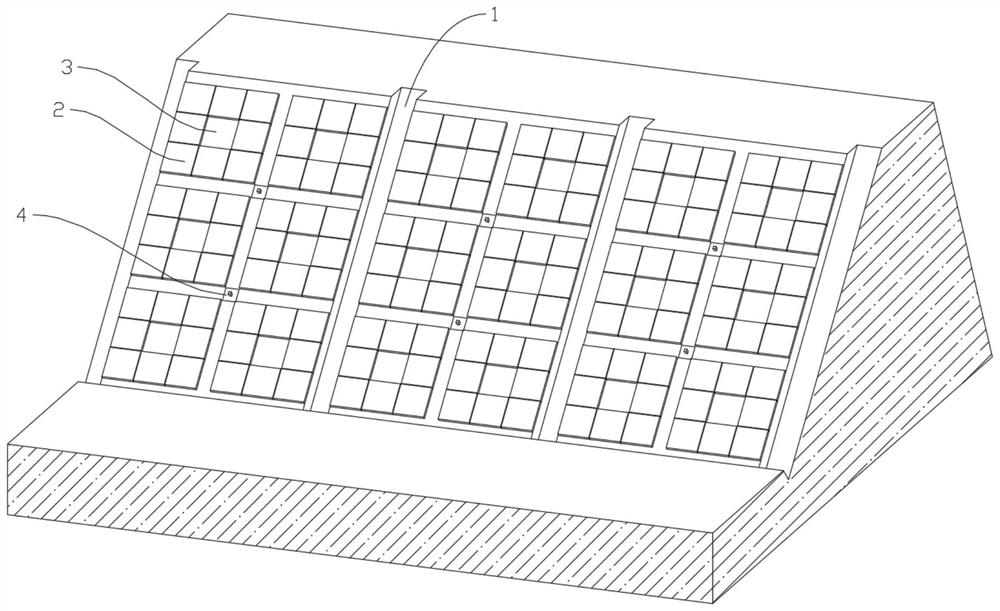

Top protection structure applied to wind power tower drums after hoisting two vertical sections and paving method thereof

PendingCN108386327ALow costEasy constructionMachines/enginesWind energy generationElectricityEngineering

The invention discloses a top protection structure applied to wind power tower drums after hoisting two vertical sections and a paving method thereof. The top protection structure comprises a rainproof tarpaulin hood, a stainless steel awning ring rainproof tarpaulin and a tensile rubber rainproof tarpaulin, wherein the rainproof tarpaulin hood is a circular hood with shape and size which are matched with that of the top of a second tower drum section; the stainless steel awning ring rainproof tarpaulin is sewed on the inner layer of the rainproof tarpaulin hood; a plurality of stainless steelawning rings are embedded at the edge of the stainless steel awning ring rainproof tarpaulin; one end of a hemp rope is fixedly fastened in one hole of each of the plurality of stainless steel awningrings; the tensile rubber rainproof tarpaulin is vertically sewed on the circumference edge of the rainproof tarpaulin hood to form a straight drum shape; tensile rubber bands are sewed on the innerlayer of the tensile rubber rainproof tarpaulin; through the sewed tensile rubber bands, the tensile rubber rainproof tarpaulin is clung to the surface of the circular outer wall of the top of the second tower drum section during paving. The top protection structure has operability and practical significance to the protection problems such as rainwater resistance, sand and dust resistance and corrosion resistance and the like of wind power plants after hoisting two vertical tower drum sections.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

River channel protection slope laying construction method for water conservancy project

The invention discloses a river channel protection slope laying construction method for a water conservancy project, and relates to the technical field of water conservancy projects. A river channel protection slope comprises a plurality of frame plates laid on a slope surface in an array mode; a plurality of bricks are arranged in each frame plate in an array mode; and a gap filling structure is arranged below a gap between every two adjacent frame plates. The river channel protection slope laying construction method comprises the following steps that step 1, the slope surface is divided into a plurality of units, and bricks are laid in each unit; step 2, a gap filling structure is laid between every two adjacent units; and step 3, the frame plates are laid and fixed in the units, the frame plates cover the gaps between the bricks, and the edges of the frame plates are in lap joint with the gap filling structures. In the method, a river bank slope is protected by the river channel protection slope, and river water pollution and turbidity caused by water and soil loss are avoided. Due to the fact that the frame plates are fixed, the bricks and the gap filling structures which are covered and pressed by the frame plates are also fixed on the slope surface, and the whole river channel protection slope is firm in laying and convenient to construct.

Owner:河南华安水利工程有限公司

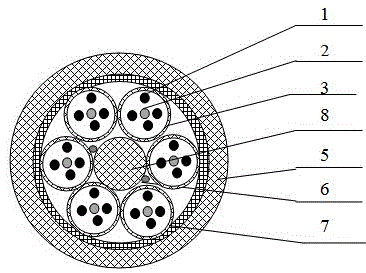

Multiple-core screen type broad band cable

InactiveCN101101803APrevent leakageAchieve shielding effectCables with twisted pairs/quadsMulticore cableEngineering

The invention is concerned with the multi-core screen broad-band cable, includes: the oversheath, the lapping in the oversheath, several sub-unit in the lapping. It is: each sub-unit includes several pair of cable that is set the stabbing out of it; the stabbing covers the lapping belt that is set screen layer out of it. The aluminum model aluminum belt screen layer can avoid the interfere between the sub-units effectively that can screen for the radiation and interfere from outside in order to satisfy the need of one tube with multi-core cable of the user.

Owner:JIANGSU ETERN

Ocean high voltage-resistant and anti-corrosion cable convenient for replacement and maintenance

InactiveCN109859891AExtended service lifeStrong pressure and corrosion resistanceInsulated cablesInsulated conductorsInsulation layerEngineering

The present invention discloses an ocean high voltage-resistant and anti-corrosion cable convenient for replacement and maintenance. The cable for ocean is fixed on a cable channel which is employed to have a secondary protection effect and facilitate replacement and maintenance, the laying construction is convenient, the cable is not completely in contact with the cable channel to have an effecton protection of the cable and improve the service life of the cable, the internal and external portions of the cable channel are coated with anti-corrosion coating, the anti-corrosion coating is coated with an asphalt coating layer at the outer side of the cable channel to have anti-corrosion and high voltage-resistant effects, the cable itself has high voltage-resistant and anti-corrosion performances, a titanium alloy sheath is employed in the cable, is better than a traditionally used titanium alloy sheath, is non-poisonous, high in intensity, good in anti-corrosion performance, not easy to break off and convenient for turning of the cable, and a resin insulation layer, a braided strap, a mothproof layer, a reinforcement layer, an anti-corrosion layer, a liner and an armour of the cable itself have a good protection effect on the cable core body so as to improve the service life of the cable on the ocean.

Owner:SHANGHAI MARITIME UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com