SBS elastomer environment-friendly runway

An elastomer and environment-friendly technology, applied in the direction of roads, roads, pavements, etc., can solve problems such as high production costs, human skin burns, and long production and processing processes, so as to improve elasticity and cushioning effects, improve competition levels, reduce The effect of risk of injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

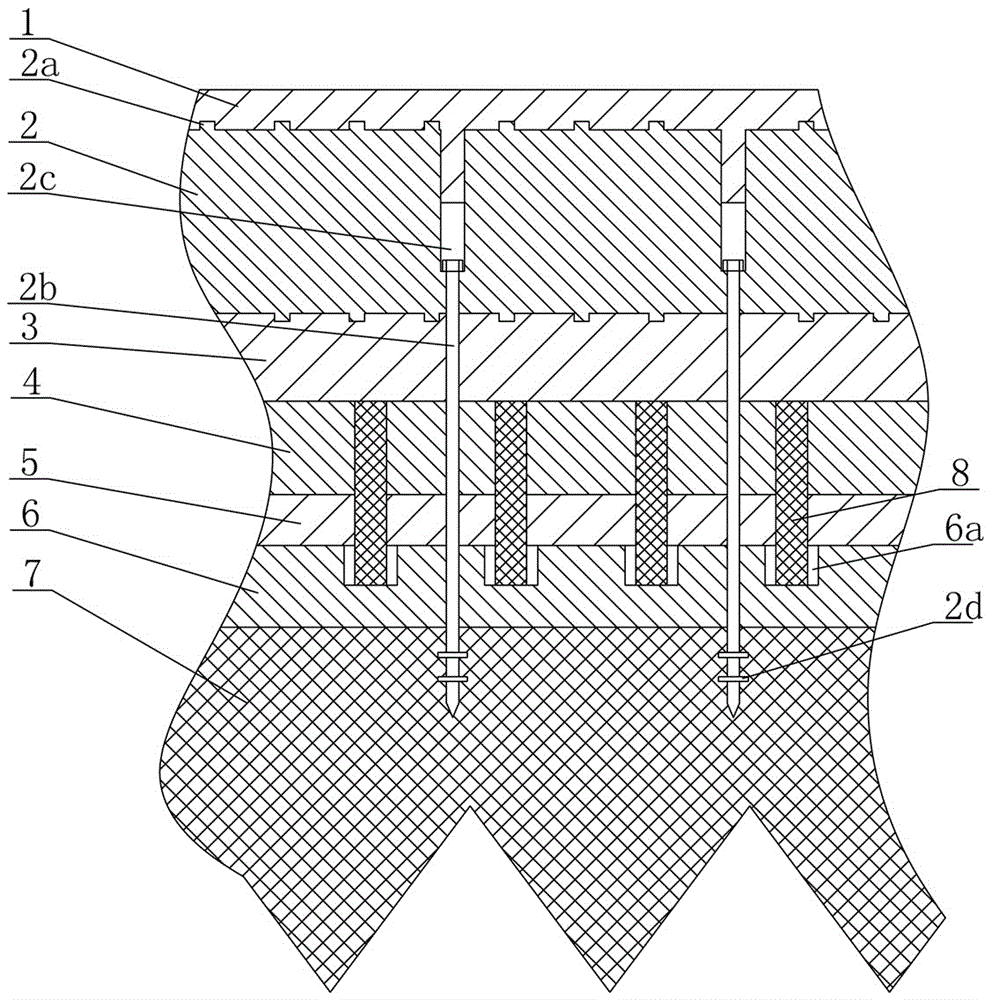

[0020] An SBS elastomer environment-friendly runway includes a wear-resistant layer 1, a buffer layer 2, a primer layer 3, a first geotextile layer 4, a film layer 5, and a second geotextile layer 6 arranged sequentially from top to bottom.

[0021] The second geotextile layer 6 is laid on the plain soil layer 7 . After the plain soil layer 7 is leveled and compacted, the second geotextile layer 6 is laid. The first geotextile layer 4 is composed of geotextiles, which has the characteristics of corrosion resistance and good water permeability, and isolates the upper and lower layers to keep materials from being lost or mixed, and improve the bearing capacity of the runway.

[0022] The film layer 5 is laid on the second geotextile layer 6 . The film layer 5 is composed of polymer cement waterproof coating. Polymer cement waterproof coatings are commerciall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com