Patents

Literature

57results about How to "Raise the level of competition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Planting method of five-pointed star loquats

InactiveCN105453985AImprove Intrinsic Nutritional QualityRaise the level of competitionCultivating equipmentsGreen environmentPest control

The invention provides a planting method suitable for five-pointed star loquats. The method comprises the steps of orchard construction, fertilizer and water management, deep plowing of soil, drainage and irrigation and intercropping of a young orchard, shaping and pruning, flower and fruit retention and fruit management, pest control and prevention, soil management, shaping and pruning and fruit management. The planting method is beneficial for improving the internal nutrition quality of loquats, green and environmentally friendly, the quality is good, the fruit competition grade is improved, high quality and high yield are achieved, greening environment is achieved, and a traditional industry is revitalized.

Owner:LIUYANG LONGGENG FRUIT PLANTING SPECIALIZED COOP

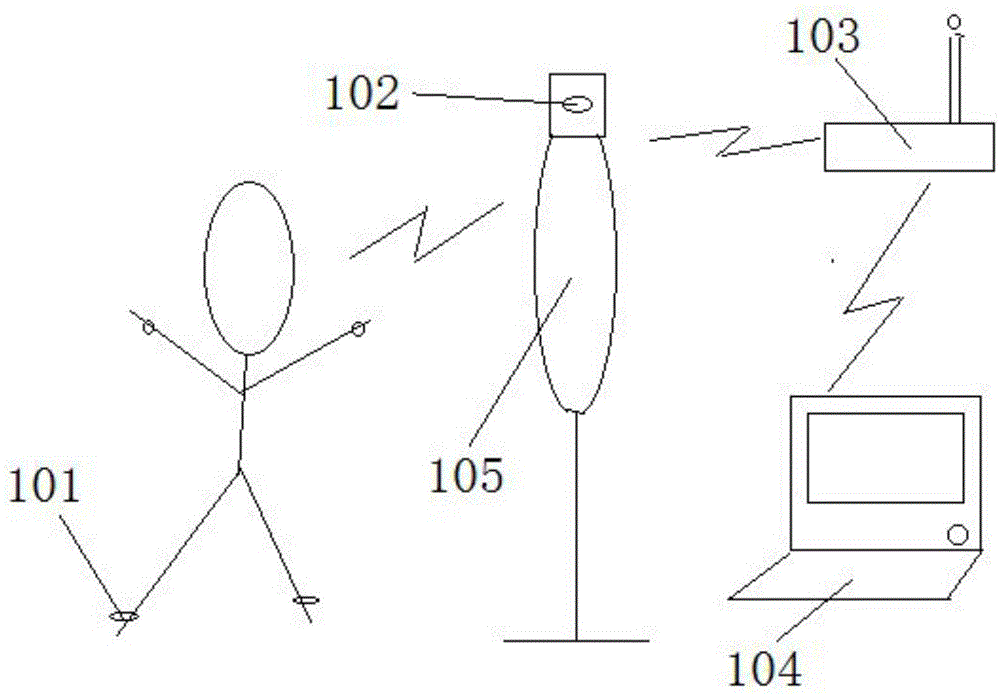

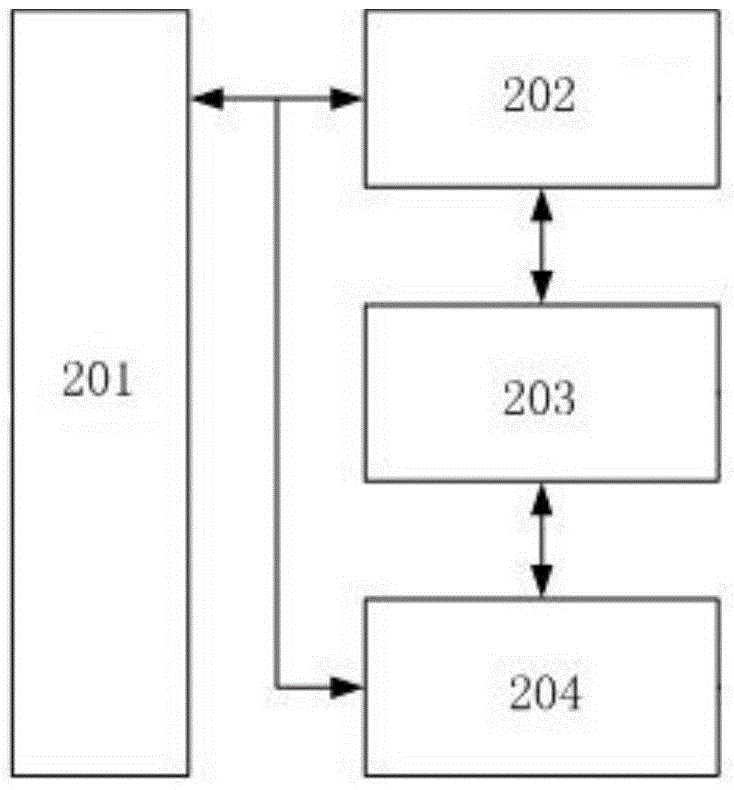

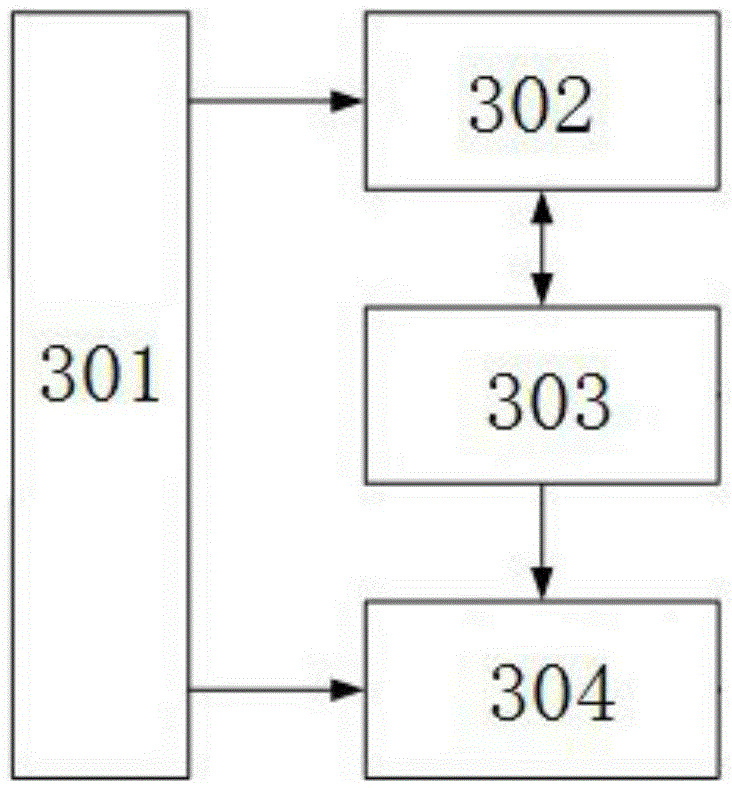

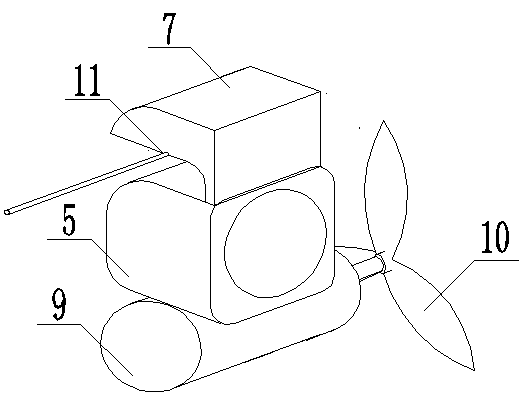

Acceleration sensor based digital fighting evaluation system

InactiveCN105536228AReduce distractionsMeet simultaneous measurement needsDiagnostic recording/measuringSensorsMotion sensingSimulation

The invention discloses an acceleration sensor based digital fighting evaluation system which comprises a central computer, a WIFI wireless router, a striking signal guide system and a motion information acquisition system; a measured person wears boxing gloves and sports shoes provided with the motion information acquisition system based on a gene motion sensing unit, the motion information of the measured person is captured, the obtained information is sent to the striking signal guide system mounted on a vertical sandbag in a WIFI mode, the striking signal guide system conducts screening and analyzing according to the obtained data information and sends the analyzed data to the central computer through the WIFI wireless router in a WIFI mode, and the central computer feeds the training data of the measured person to the measured person in real time. By means of the acceleration sensor based digital fighting evaluation system, the training level of the fighting trainees can be displayed in a quantitative mode, the potential motion ability of the trainees can be stimulated, action influences of the trainees are reduced to the maximum degree, and online evaluation of multiple persons can be achieved simultaneously.

Owner:ANHUI BEIDOU YITONG INFORMATION TECH CO LTD

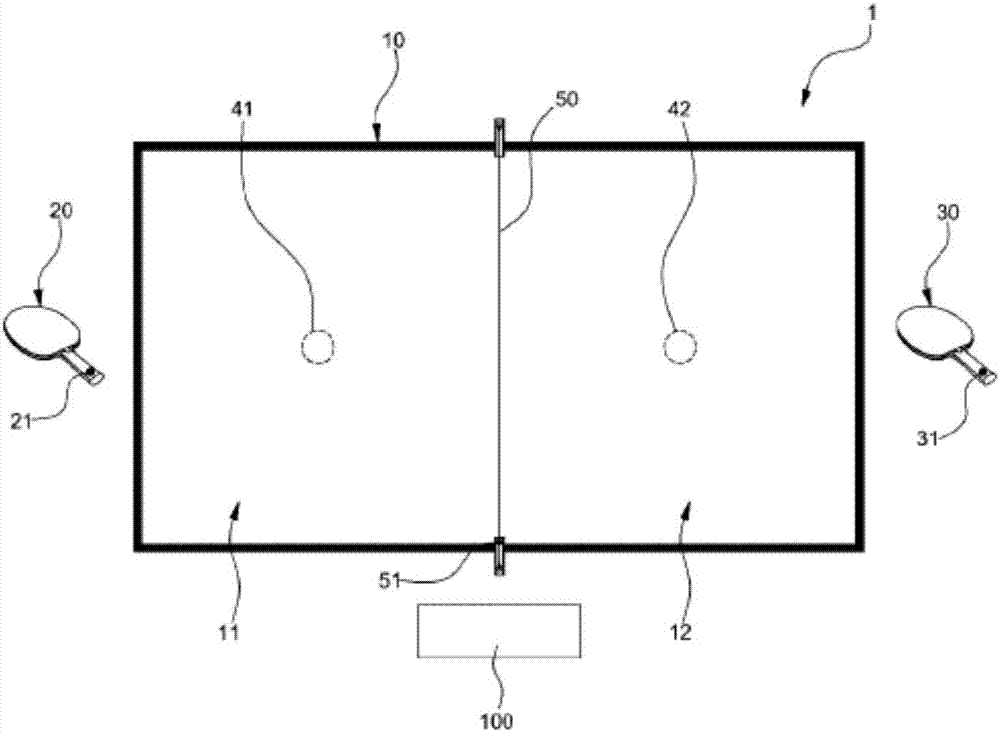

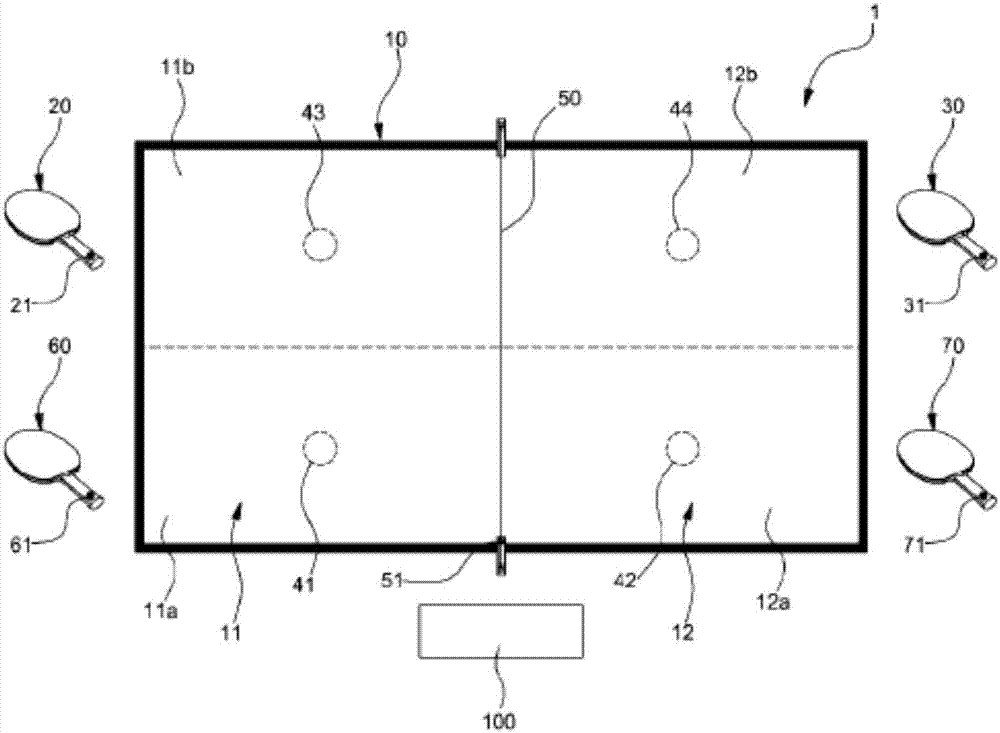

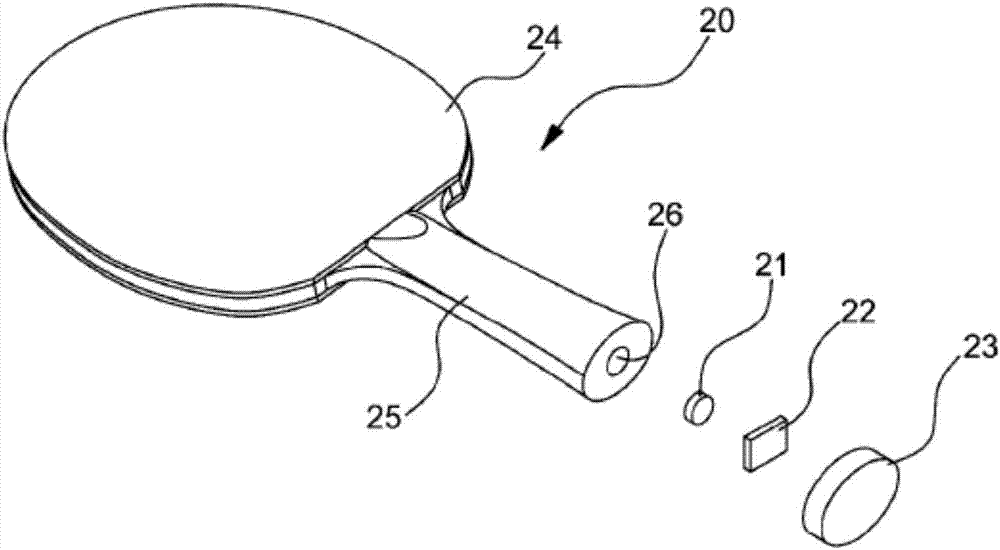

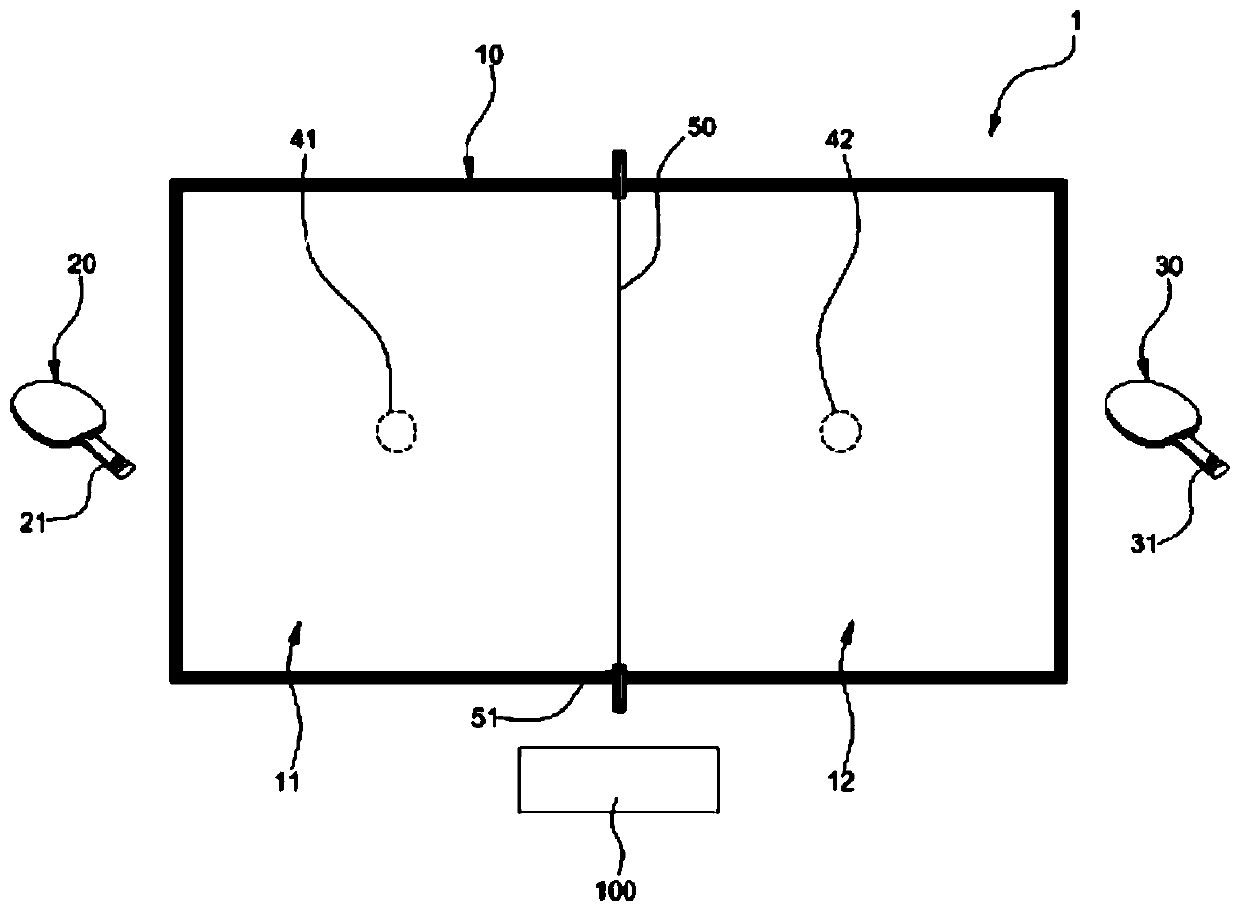

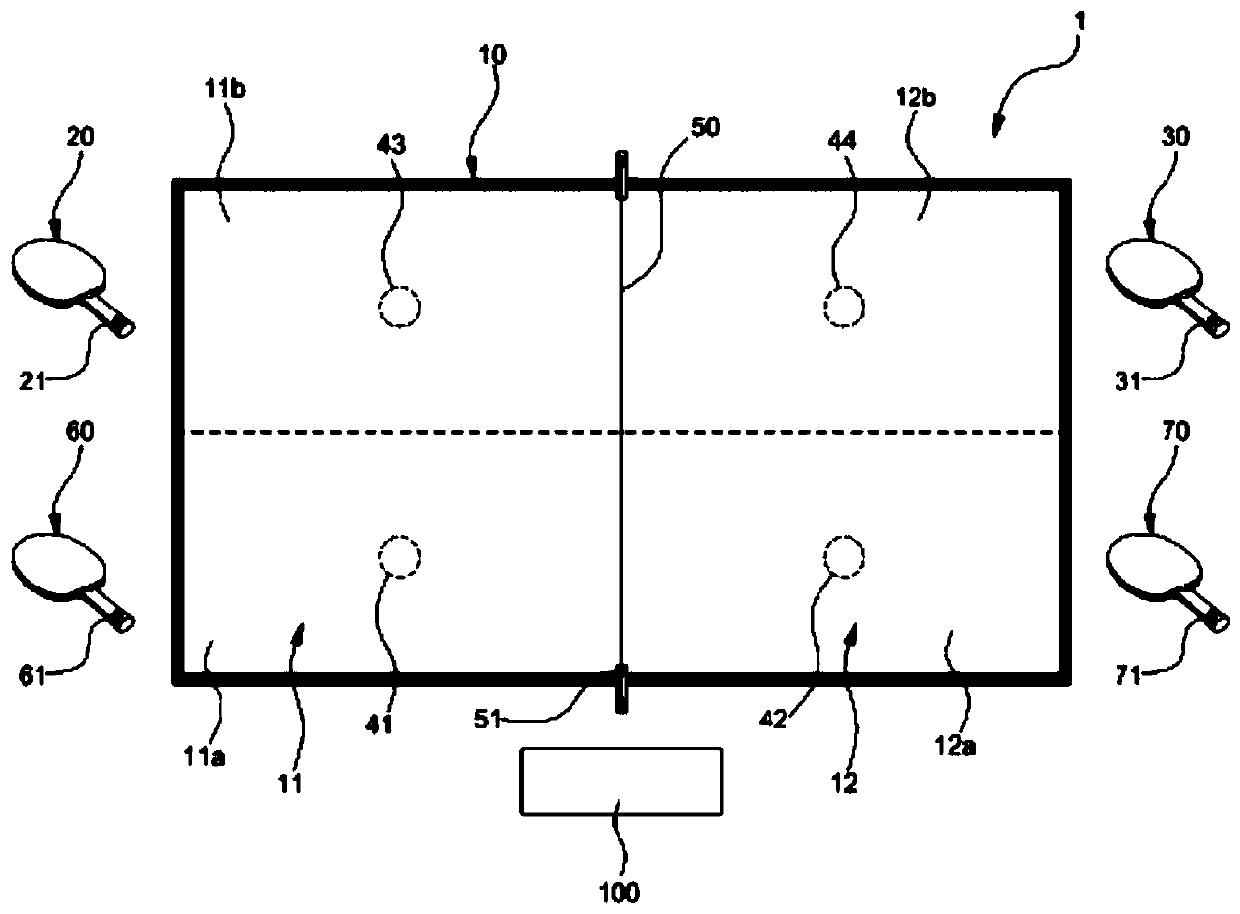

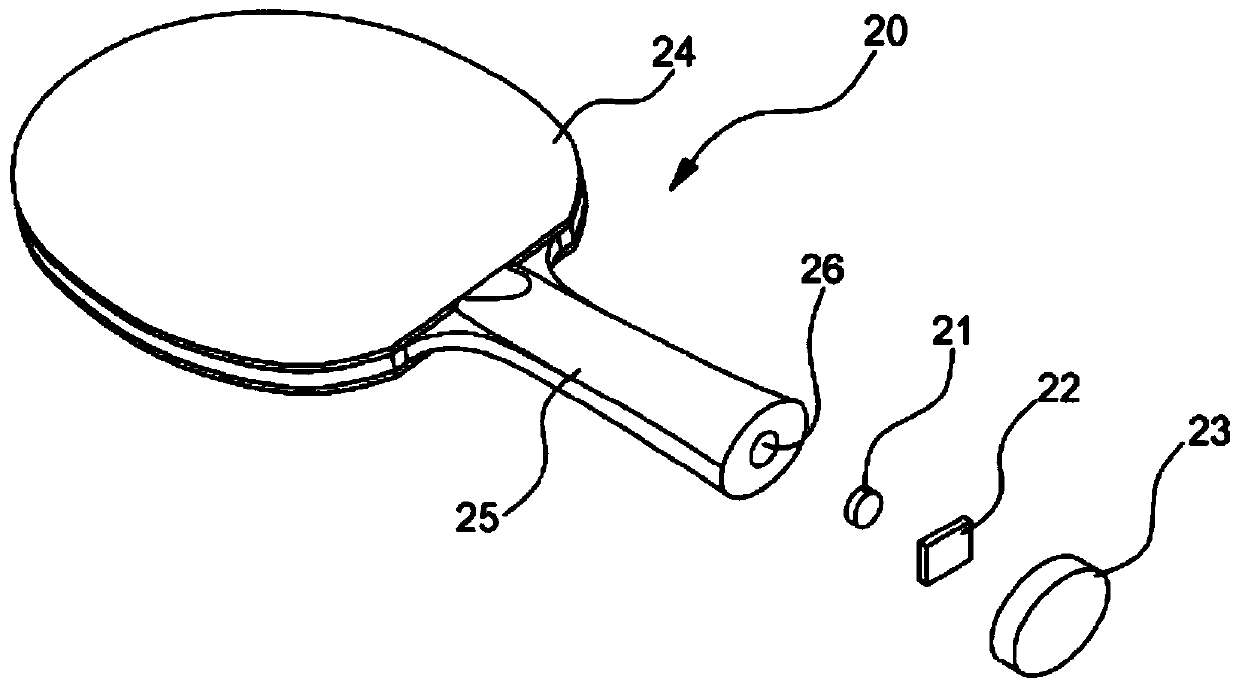

System for executing table tennis game comprising multiple impact sensors, and method for displaying table tennis game score using same

ActiveCN106999752AImprove the level of table tennis competitionRaise the level of competitionGymnastic exercisingRacket sportsComputer graphics (images)Computer engineering

The present invention relates to a system for executing a table tennis game, and a method for displaying a table tennis game score using the same and, more specifically, to a system for executing a table tennis game, and a method for displaying a table tennis game score using the same, the system comprising a score calculation terminal which receives a sensing signal of a collision with a table tennis ball from impact sensors installed in a racket and in respective zones of a table tennis table, and calculates and displays the table tennis game score according to the input pattern of the received sensing signal.

Owner:YEOU ELECTRONICS

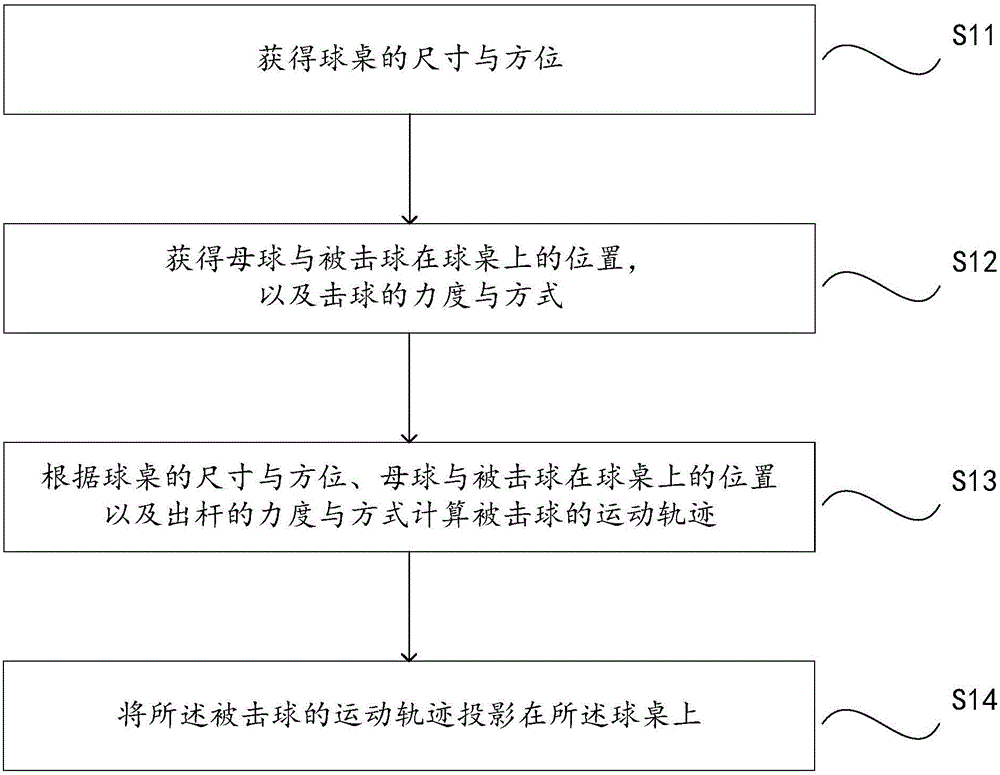

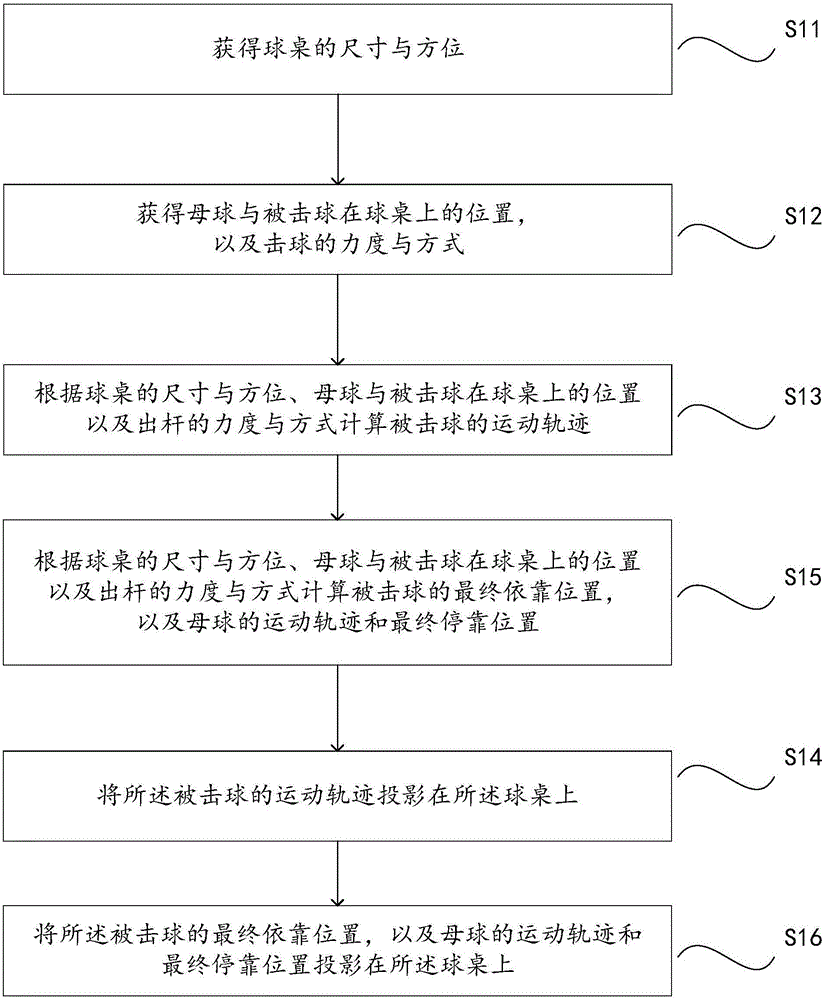

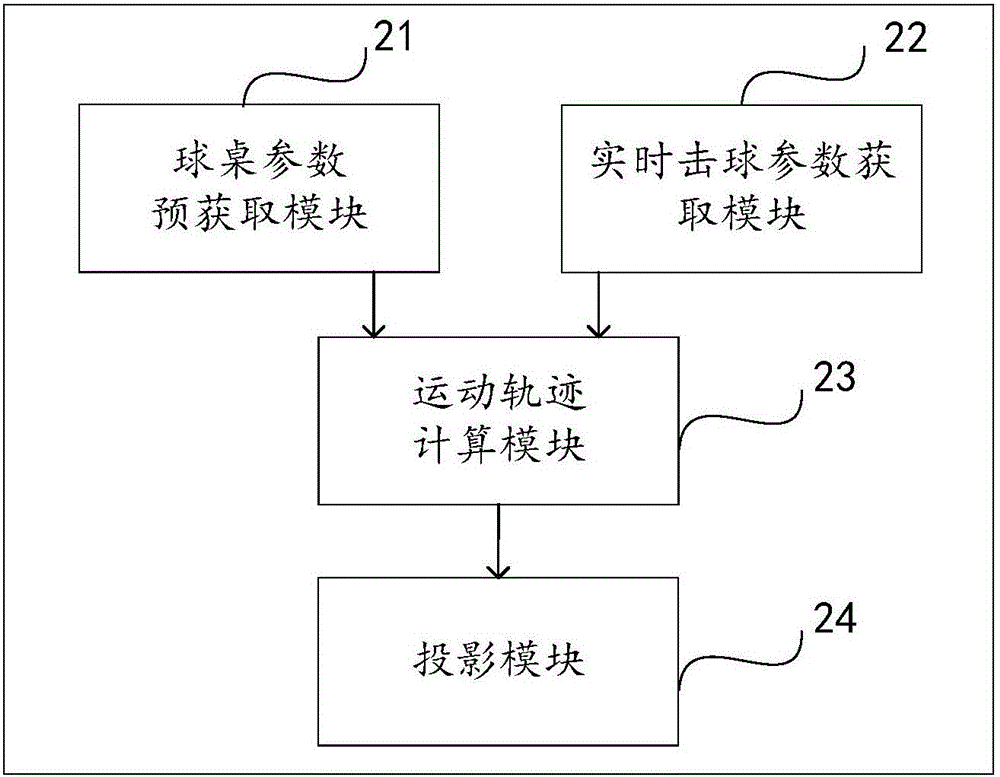

Billiard movement track real-time projection method, device and equipment

InactiveCN105879371AEffective Fast Competitive LevelRaise the level of competitionPicture reproducers using projection devicesBilliardsBilliard ballEngineering

The invention provides a billiard movement track real-time projection method which comprises the following steps: obtaining the size and direction of a table; obtaining the positions of a cue ball and the hit ball on the table as well as the ball hitting power and way; calculating the movement track of the hit ball according to the size and direction of the table, the positions of the cue ball and the hit ball on the table and the ball hitting power and way; and projecting the movement track of the hit ball on the table. In the invention, a user can get aware of the ball hitting result relatively accurately before the ball hitting action actually happens, the result of current ball hitting policy can be predicted, and the ball hitting policy can be adjusted in time according to the movement track projection, thus sufficient sports fun can be brought to the billiard players, and the competitiveness of the billiard players can be improved effectively and quickly. The invention also provides corresponding billiard movement track real-time projection device and equipment.

Owner:LETV HLDG BEIJING CO LTD +1

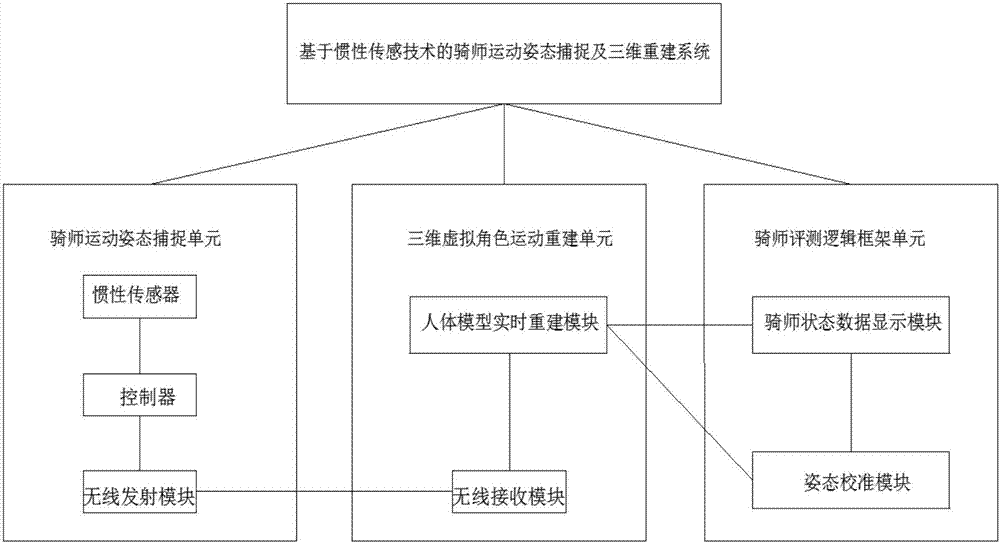

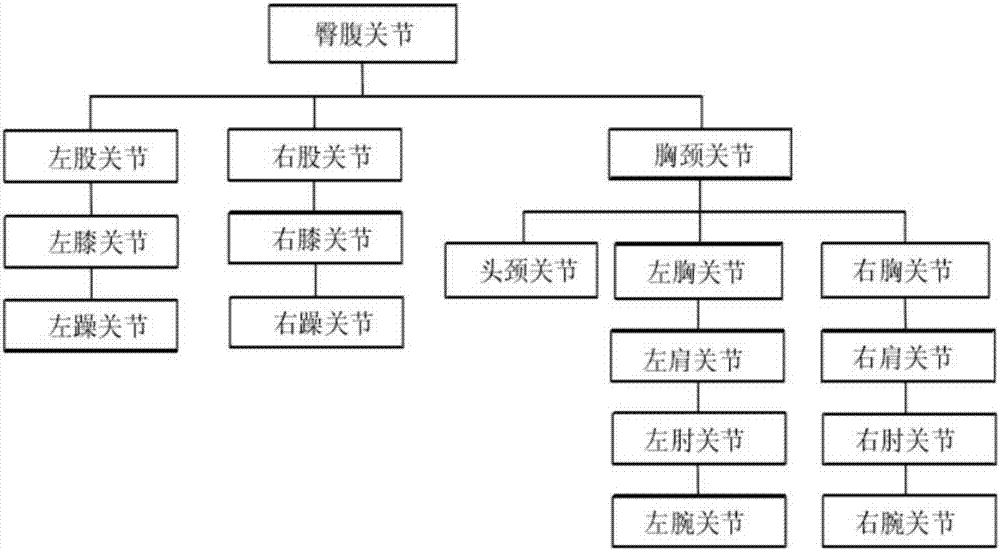

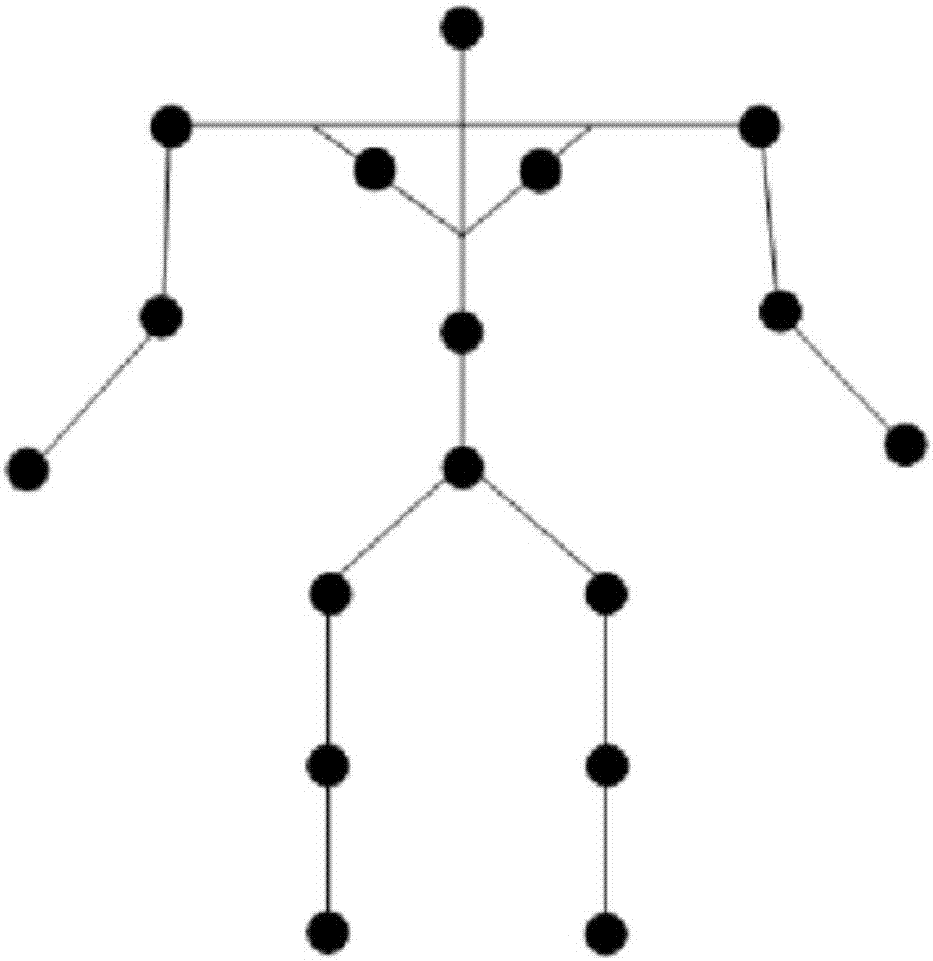

Reinsman motion posture capturing and three-dimensional reconstruction system based on inertial sensing technology

ActiveCN107330967APrecise positioningShorten recovery timeNavigation by speed/acceleration measurements3D modellingData displaySimulation

The invention discloses a reinsman motion posture capturing and three-dimensional reconstruction system based on the inertial sensing technology, and the system comprises a reinsman motion posture capturing unit which comprises a plurality of inertial sensors distributed on the body of a reinsman, a controller, and a wireless transmitting module for data output; a three-dimensional virtual character motion reconstruction unit which comprises a wireless receiving module for receiving the information, and a human body model real-time reconstruction module connected with the wireless receiving module; and a reinsman evaluating logic frame unit which is connected with the human body model real-time reconstruction module and comprises a reinsman state data display module and a posture calibration module. According to the invention, the system prestores the standard motion postures of the Chinese reinsman, drives the movement of the virtual three-dimensional model through the data of sensor posture analysis, finds out the wrong postures of the reinsman, carries out the targeted adjustment, achieves the coupling research of the human and horse motion postures, and improves the score of a sportsman.

Owner:WUHAN BUSINESS UNIV

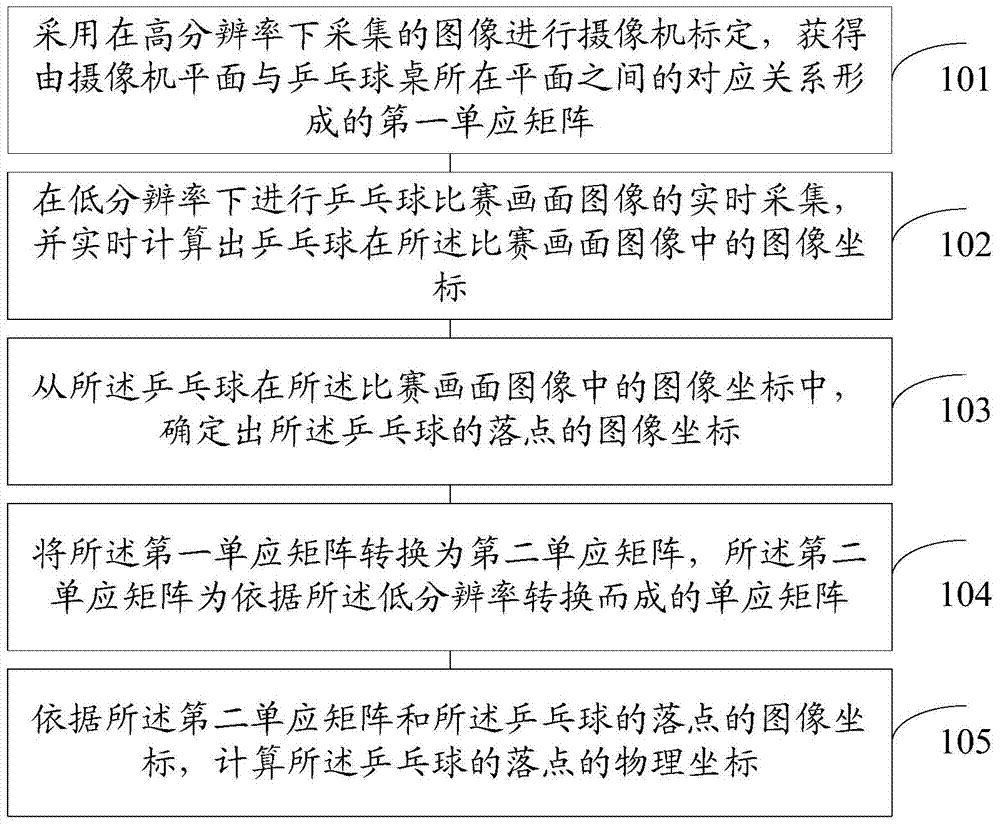

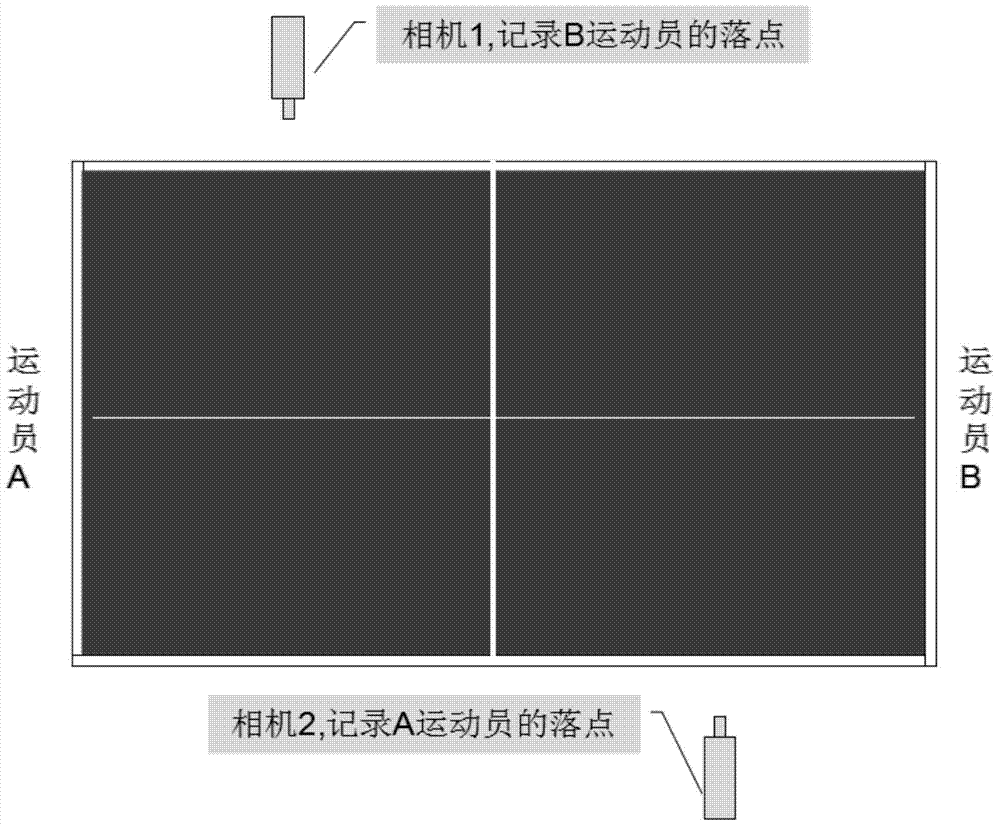

Method and system for determining ping-pong ball drop point data in video images

The invention discloses a method and system for determining ping-pong ball drop point data in video images. The method comprises the steps that an image which is collected under high resolution is used for camera calibration, and the corresponding relation between a camera plane and a plane where a ping-pong table is placed is acquired to form a first homography matrix; table tennis competition images under low resolution are collected in real time, and the image coordinates of a ping-pong ball in the competition images are calculated in real time; the image coordinates of drop points of the ping-pong ball are determined from the image coordinates of the ping-pong ball in the competition images; the first homography matrix is converted into a second homography matrix; and the physical coordinates of the drop points of the ping-pong ball are calculated according to the second homography matrix and the image coordinates of the drop points of the ping-pong ball. The method and system for determining the ping-pong ball drop point data in the video images lower the cost, improve the precision of measuring of the drop points of the ping-pong ball, and are more suitable for television relaying of table tennis competitions.

Owner:北京新奥特智慧体育创新发展有限公司

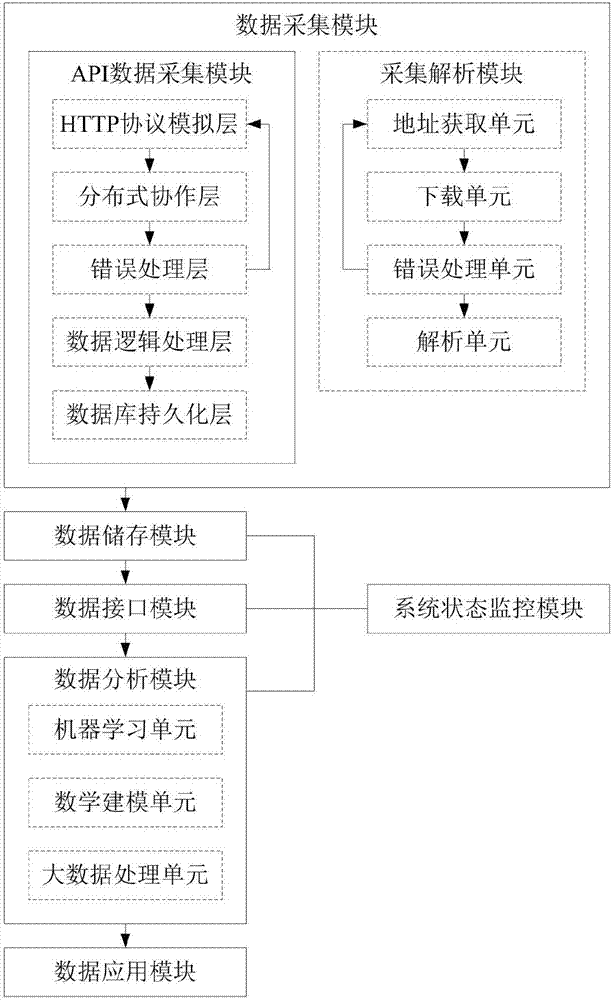

Game data processing system and processing method

InactiveCN106878409ARaise the level of competitionData switching networksData processing systemStatistical analysis

The invention discloses a game data processing system and processing method. The game data processing system comprises a data acquisition module consisting an API data acquisition module and an acquisition parsing module, a data storage module connected with the data acquisition module electrically, and a data analysis module being connected with the data storage module electrically and being used for a statistic analysis of API data and a game process parameter and generating an analysis result. According to the processing system and the processing method, the official API data can be collected and the video data of a match video can be analyzed, so that more source data of the game can be collected; and directive data can be obtained based on the statistic analysis, so that players can understand and analyze the game well, the competitive levels of the players can be improved and the professional progress of the electronic sports can be promoted.

Owner:深圳市莫二科技有限公司

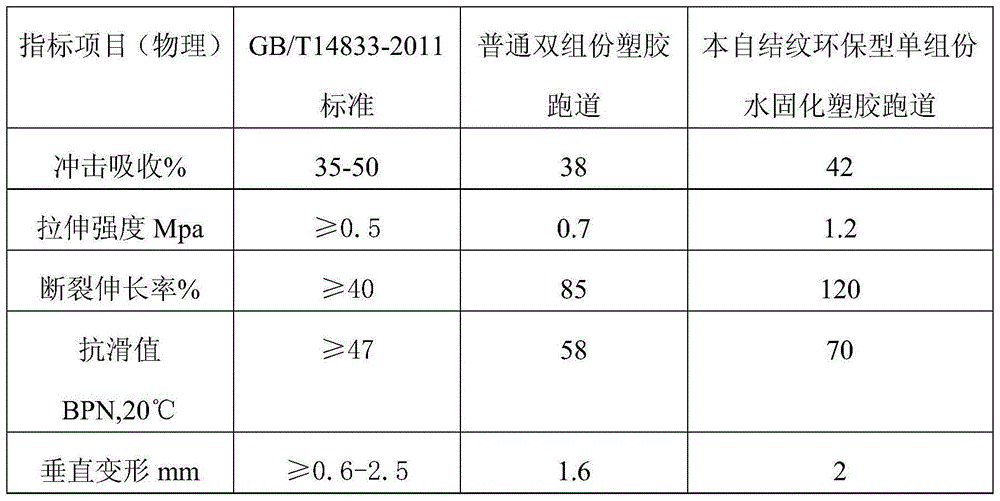

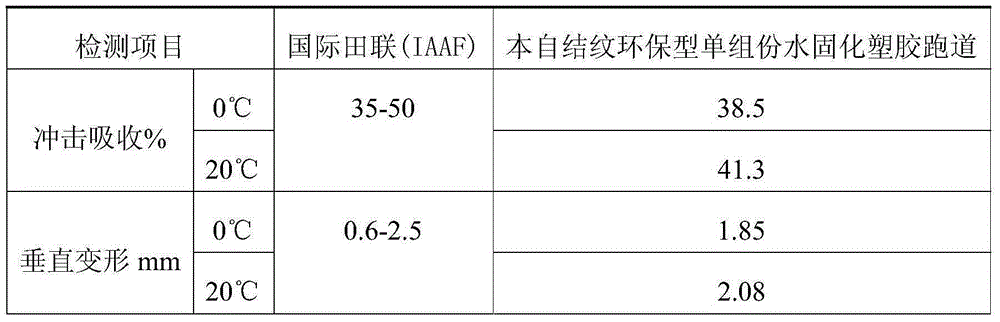

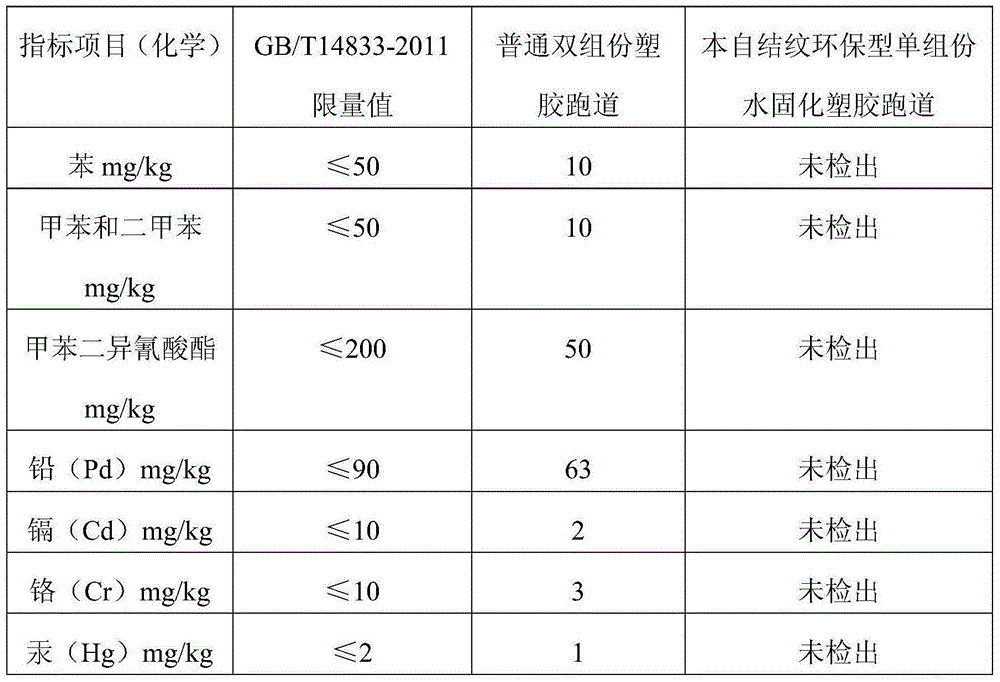

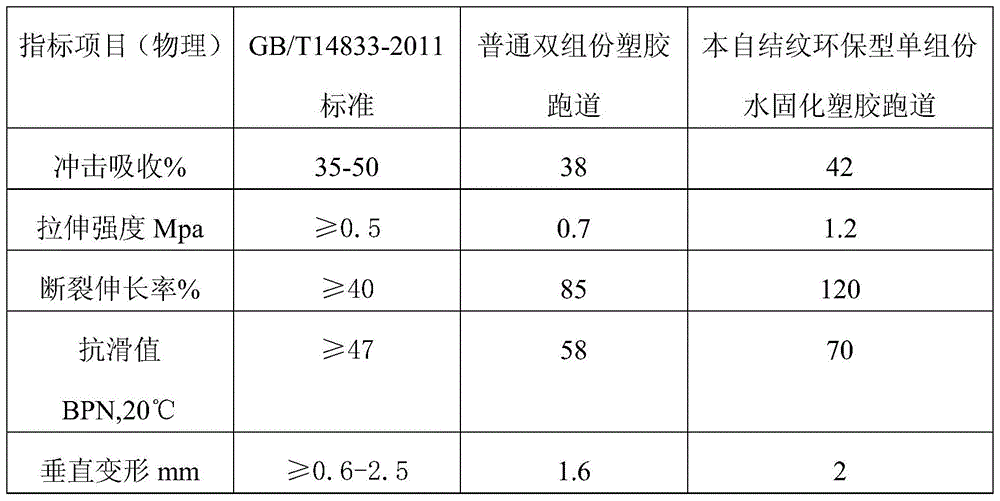

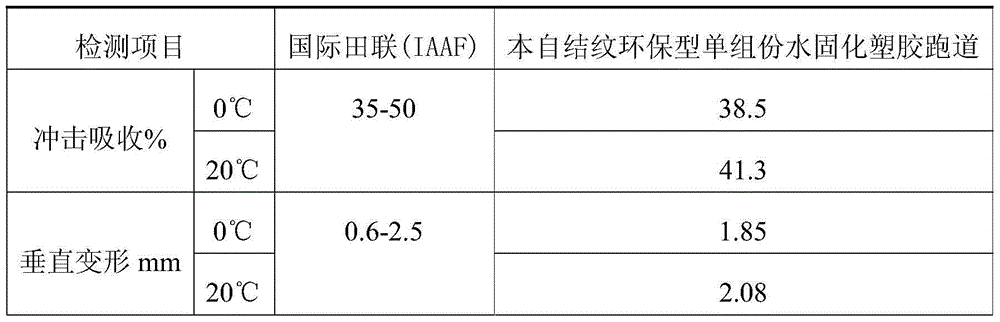

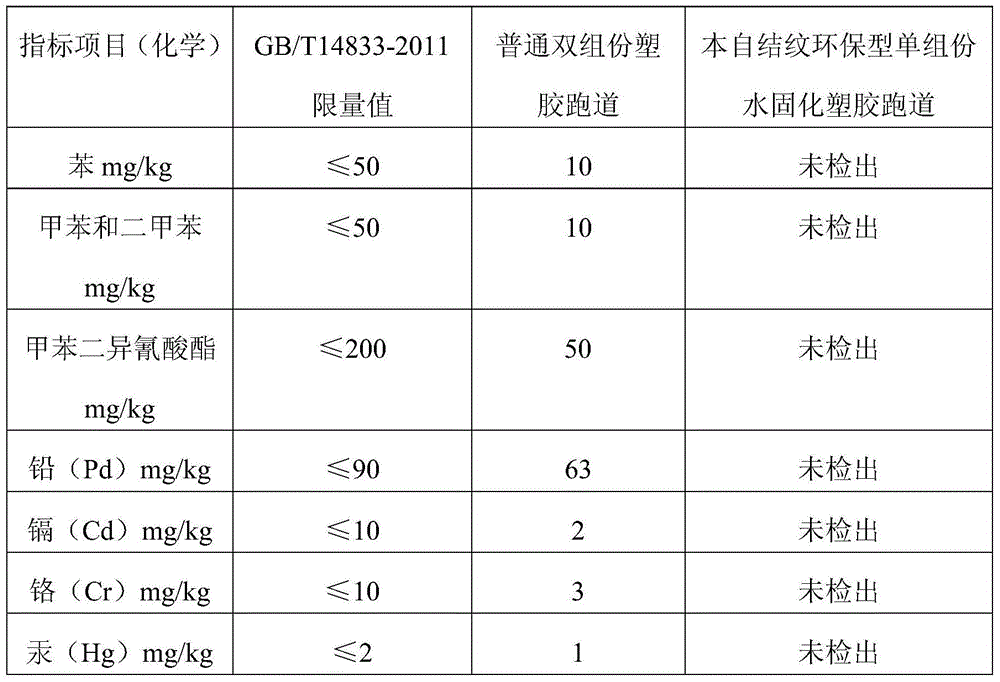

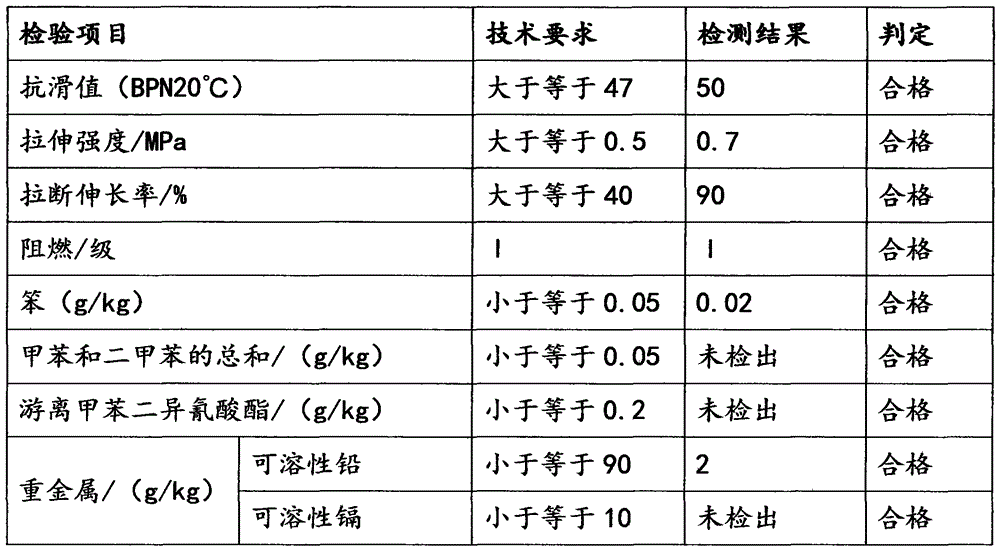

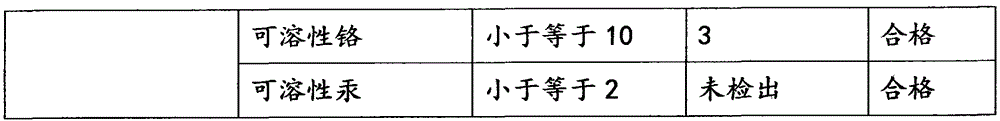

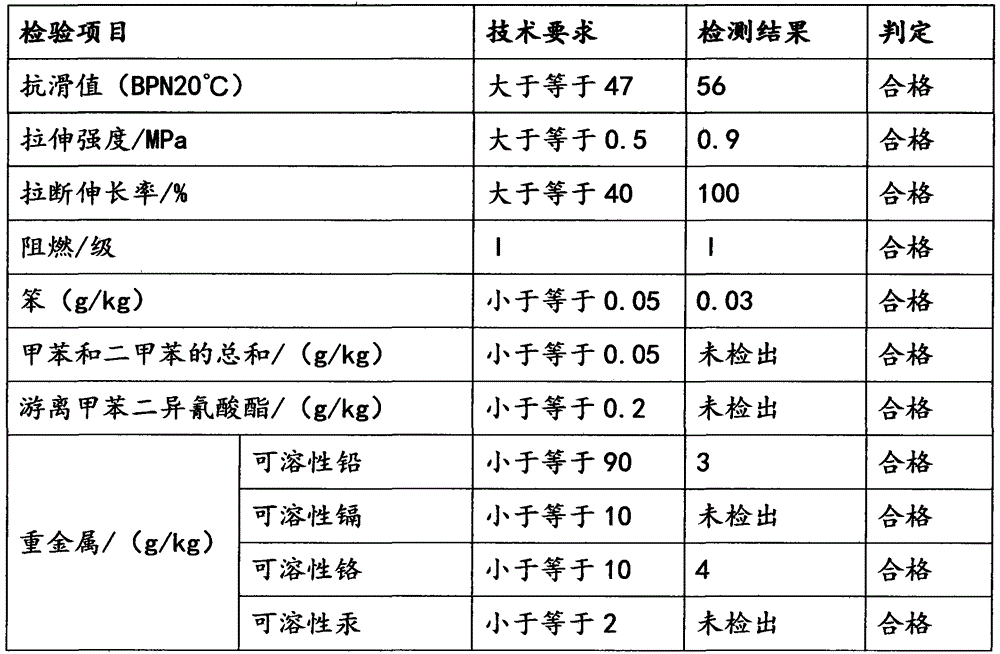

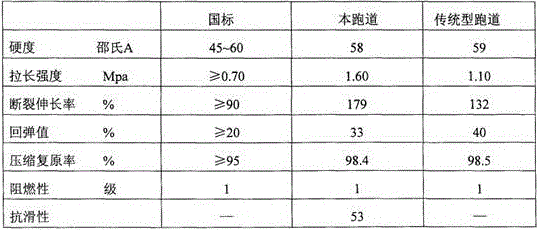

Laying method of automatic texture formation particle-free environmentally-friendly plastic track

The invention discloses a laying method of an automatic texture formation particle-free environmentally-friendly plastic track. The method comprises the following steps: S21, laying a substrate layer: mixing an environmentally-friendly single-component water solidified plastic track material with black micelles according to a weight ratio of 1:4-6, and laying the substrate layer on a dry and solidified cement base or asphalt base; S22, laying a reinforcing layer: spreading a layer of the black micelles on the dry and solid base layer, and lying the environmentally-friendly single-component water solidified plastic track material to cover the substrate layer; and S23, laying an automatic texture formation layer: uniformly mixing 10-12 parts of an automatic texture formation finish, 1-3 parts of EPDM particle rubber powder and 3-6 parts of quartz sand to form an automatic texture formation layer material, fully stirring, and spraying the obtained material on the dry and solidified reinforcing layer. The track has the advantages of environmentally friendly material, no shedding of particles, good durability, plump and uniform surface textures, high tensile strength and long service life, and all performance indexes of the track accord with technical requirements of International Association of Athletics Federations and GB / T14833-2011.

Owner:广州帝森康体设备有限公司

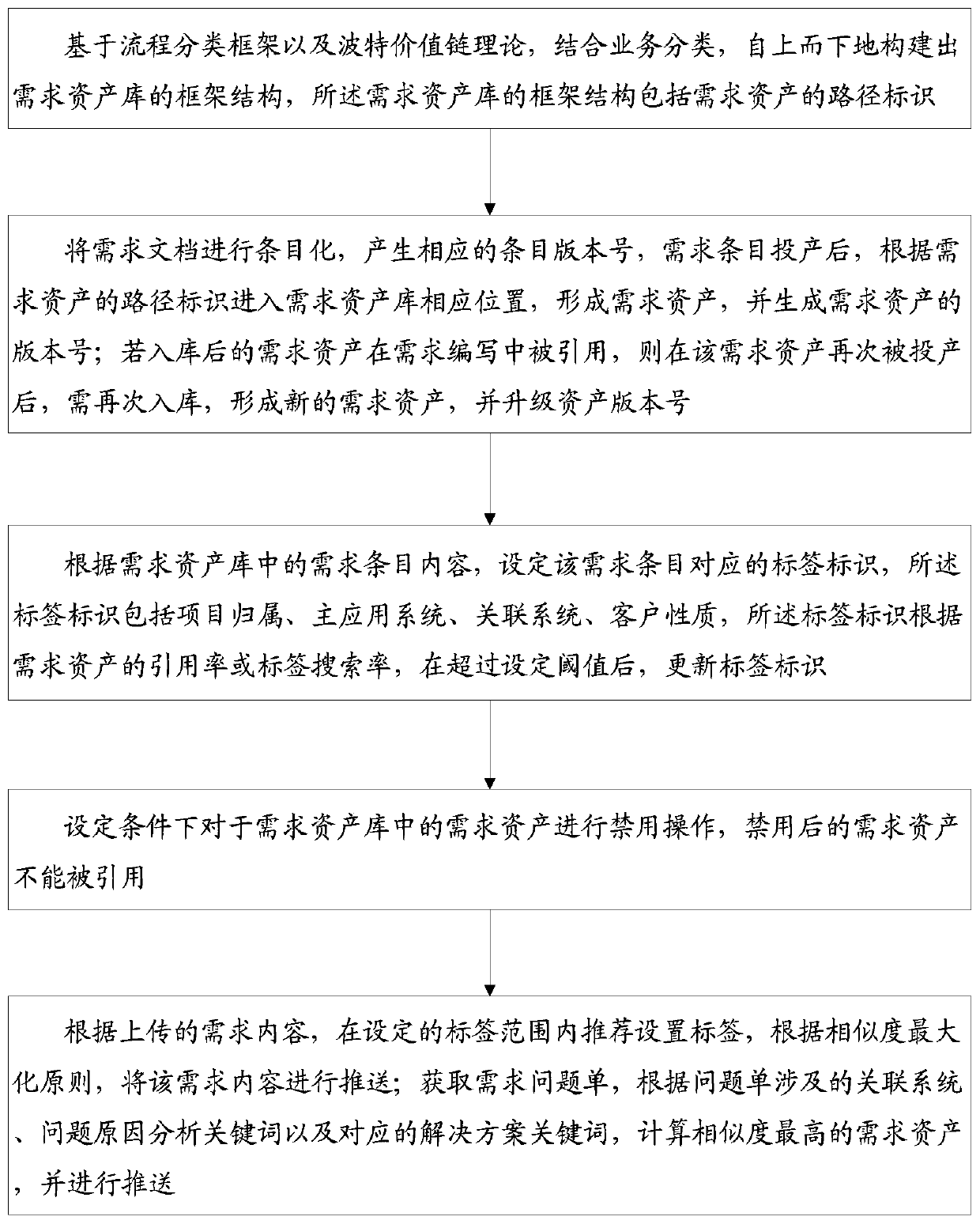

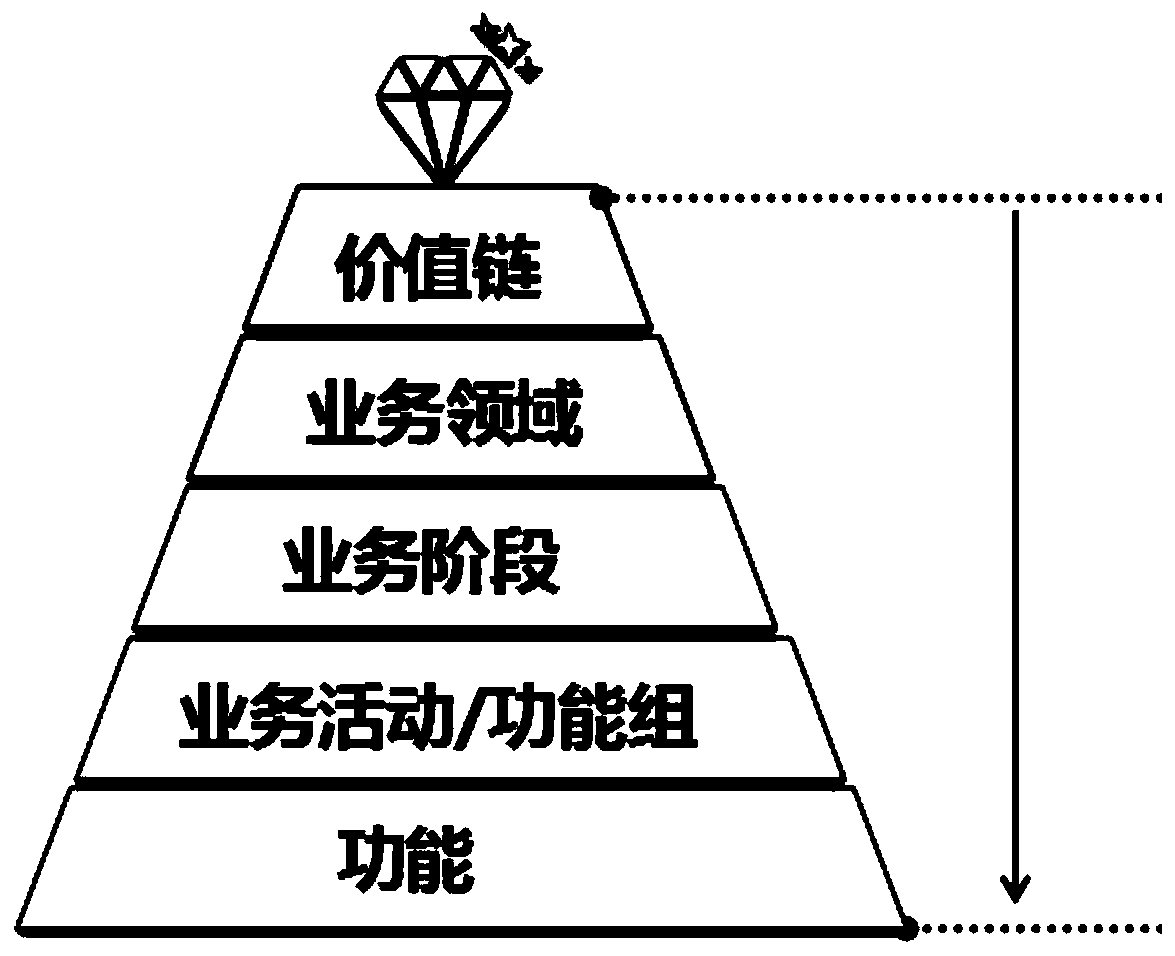

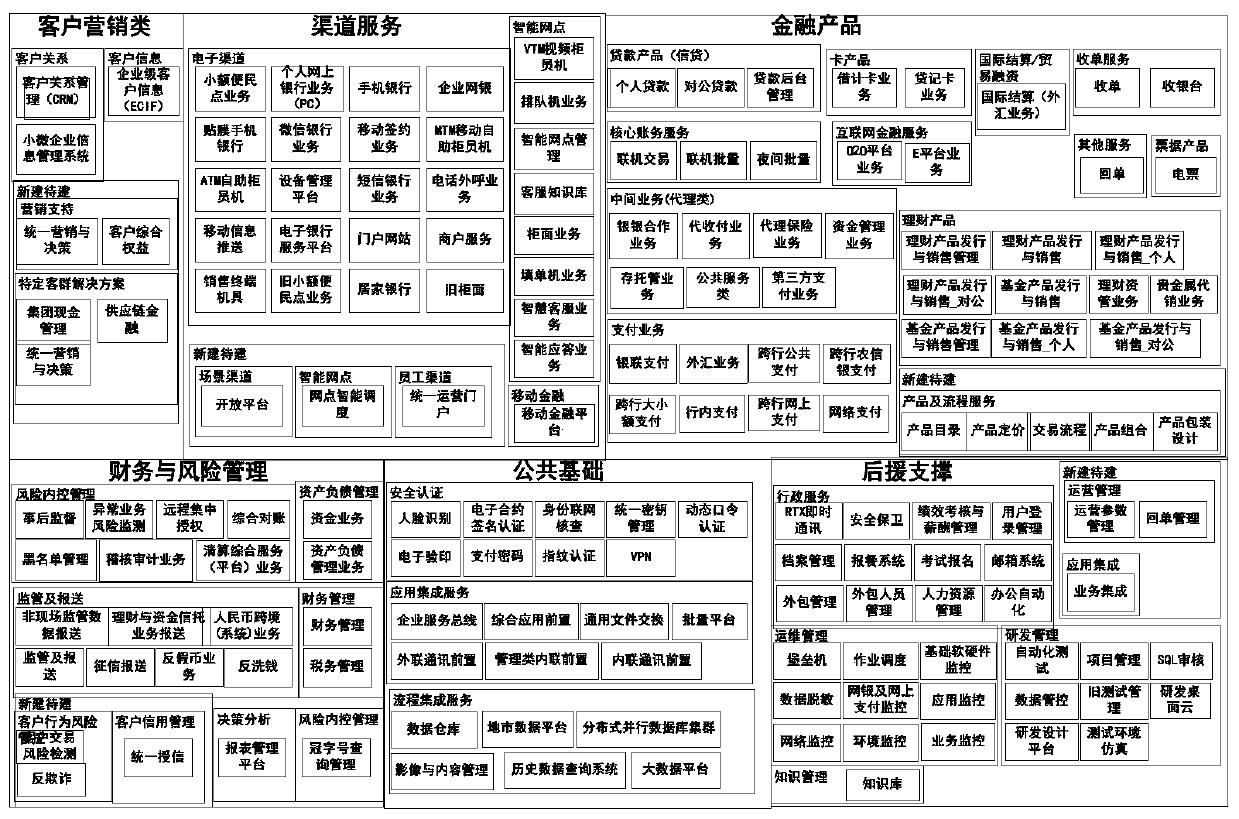

Banking service demand asset management method and system

ActiveCN110704574ARaise the level of competitionImprove writing efficiencyMetadata text retrievalFinanceOperations researchOperations management

The invention provides a banking service demand asset management method, which is characterized in that a framework structure of a demand asset library is constructed from top to bottom by combining service classification on the basis of a process classification framework and a Baud value chain theory, and the framework structure of the demand asset library comprises a path identifier of demand assets; the demand document is entries to generate corresponding entry version numbers, and after the demand entries are put into production, the demand entries enter the corresponding positions of thedemand asset library according to the path identifiers of the demand assets to form the demand assets and generate the version numbers of the demand assets; if the demanded assets put into storage arequoted in demand writing, putting the demanded assets into storage again after the demanded assets are put into production again to form new demanded assets, and upgrading asset version numbers; theinvention also provides a banking service demand asset management system, which can be applied to banking enterprise-level service demand asset management, especially under a two-level legal person system, and considers the homogenization and individuation of demands through the reuse of demand assets.

Owner:FUJIAN RURAL CREDIT UNION

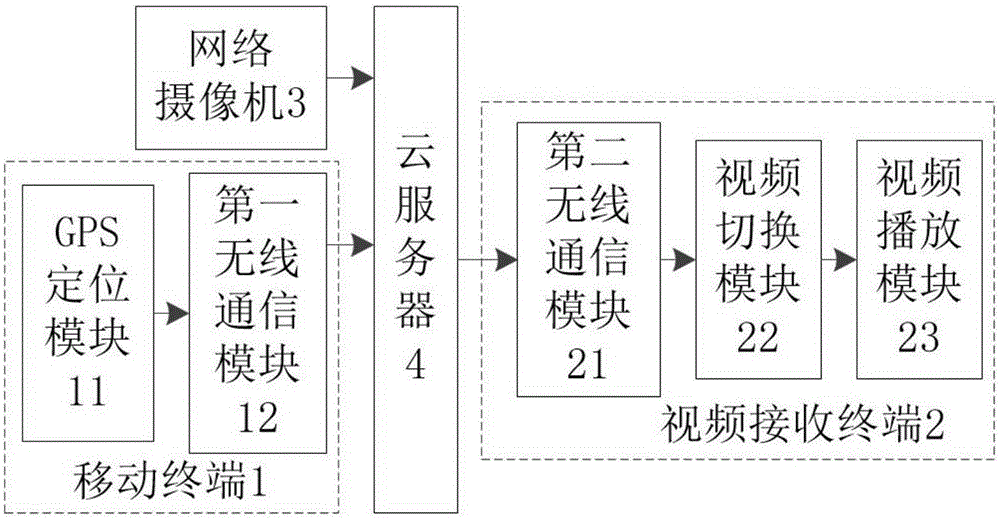

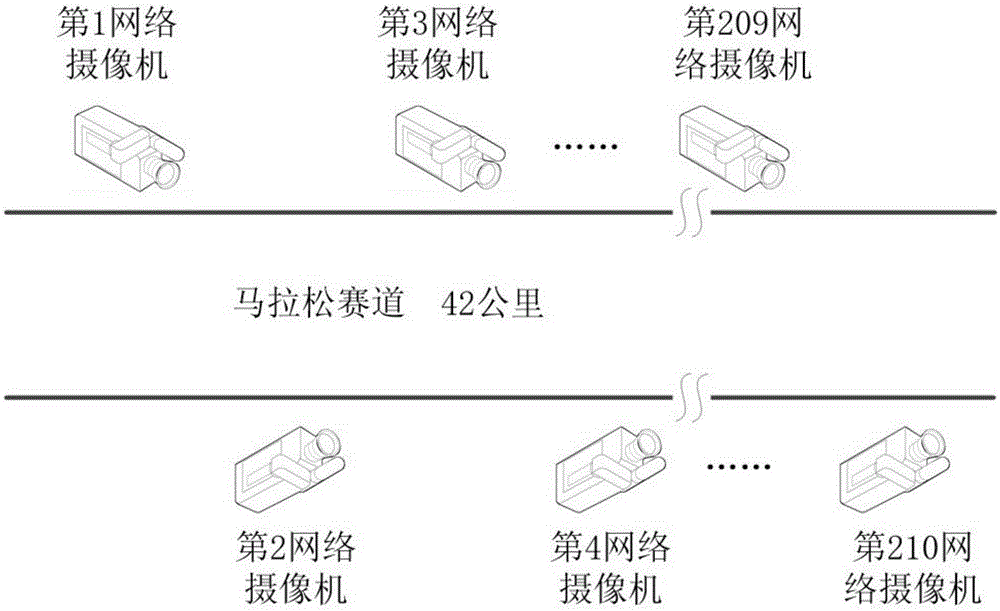

Personal video real-time live broadcast method and system for runway

InactiveCN105187846AImprove interactivityRaise the level of competitionClosed circuit television systemsSelective content distributionNetwork cameraReal-time computing

The invention relates to a personal video real-time live broadcast method and system for a runway. The live broadcast system comprises a mobile terminal, a video receiving terminal, network cameras and a cloud server, wherein the mobile terminal comprises a GPS (Global Positioning System) positioning module and a first wireless communication module; the video receiving terminal comprises a second wireless communication module, a video switching module and a video playing module; a plurality of network cameras are crossly arranged on both sides of the runway; the GPS positioning module is used for transmitting position information of sportsmen to the video receiving terminal through the first wireless communication module and the cloud server; the network cameras are used for transmitting shot videos to the video receiving terminal through the cloud server; the second wireless communication module is used for transmitting both the position information and the videos to the video switching module; and the video switching module is used for switching the videos to videos shot by the network cameras in sections where the sportsmen are positioned in real time, and playing the videos. The method and the system have the advantage that shooting can be performed on each sportsman.

Owner:SHANGHAI HUWEIHAN INFORMATION TECH CO LTD

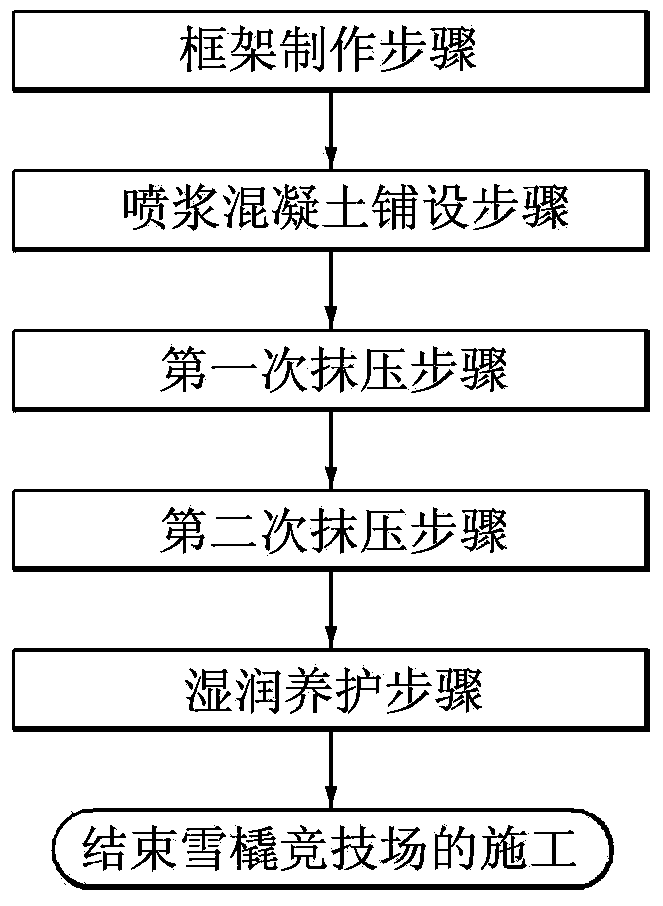

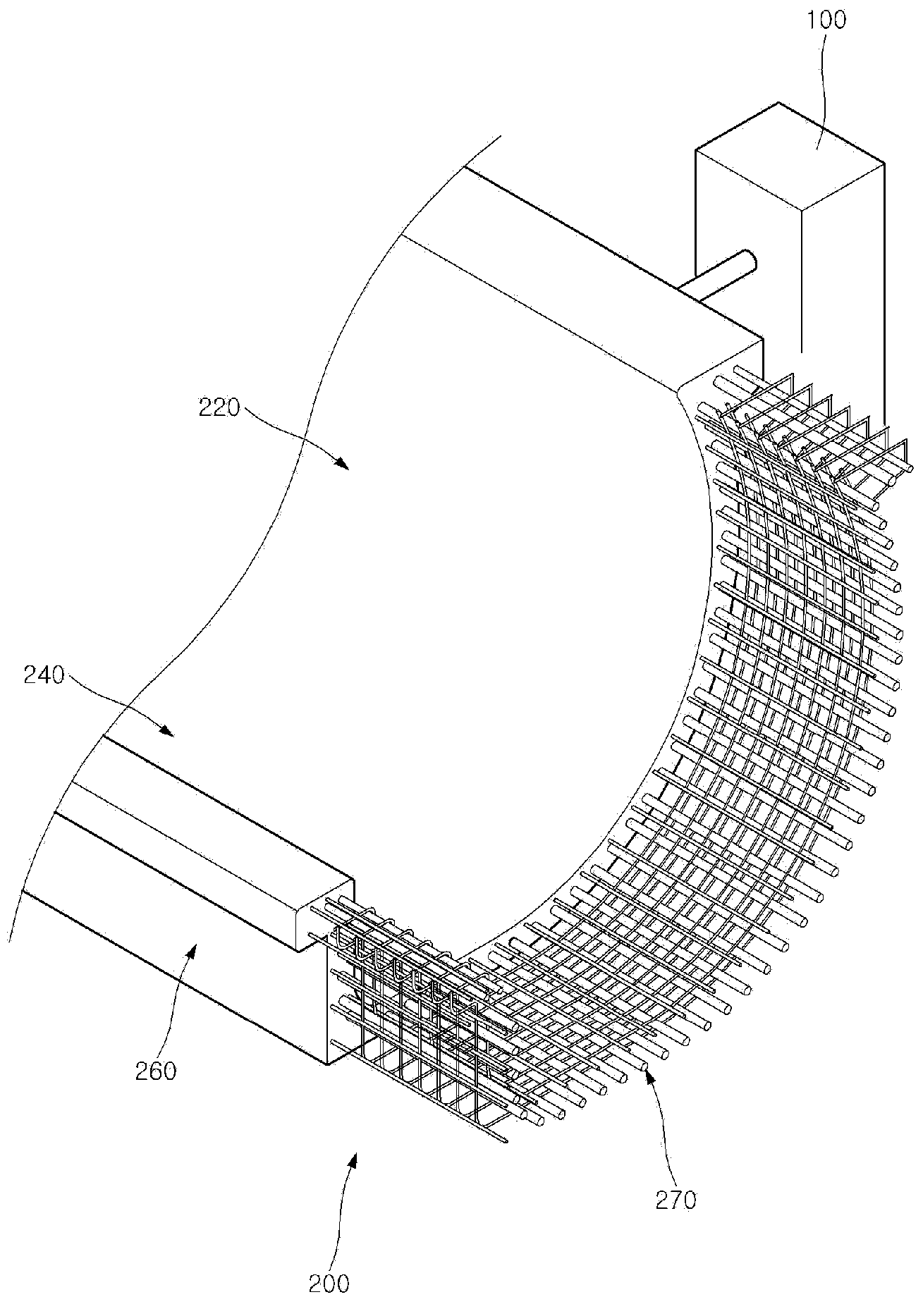

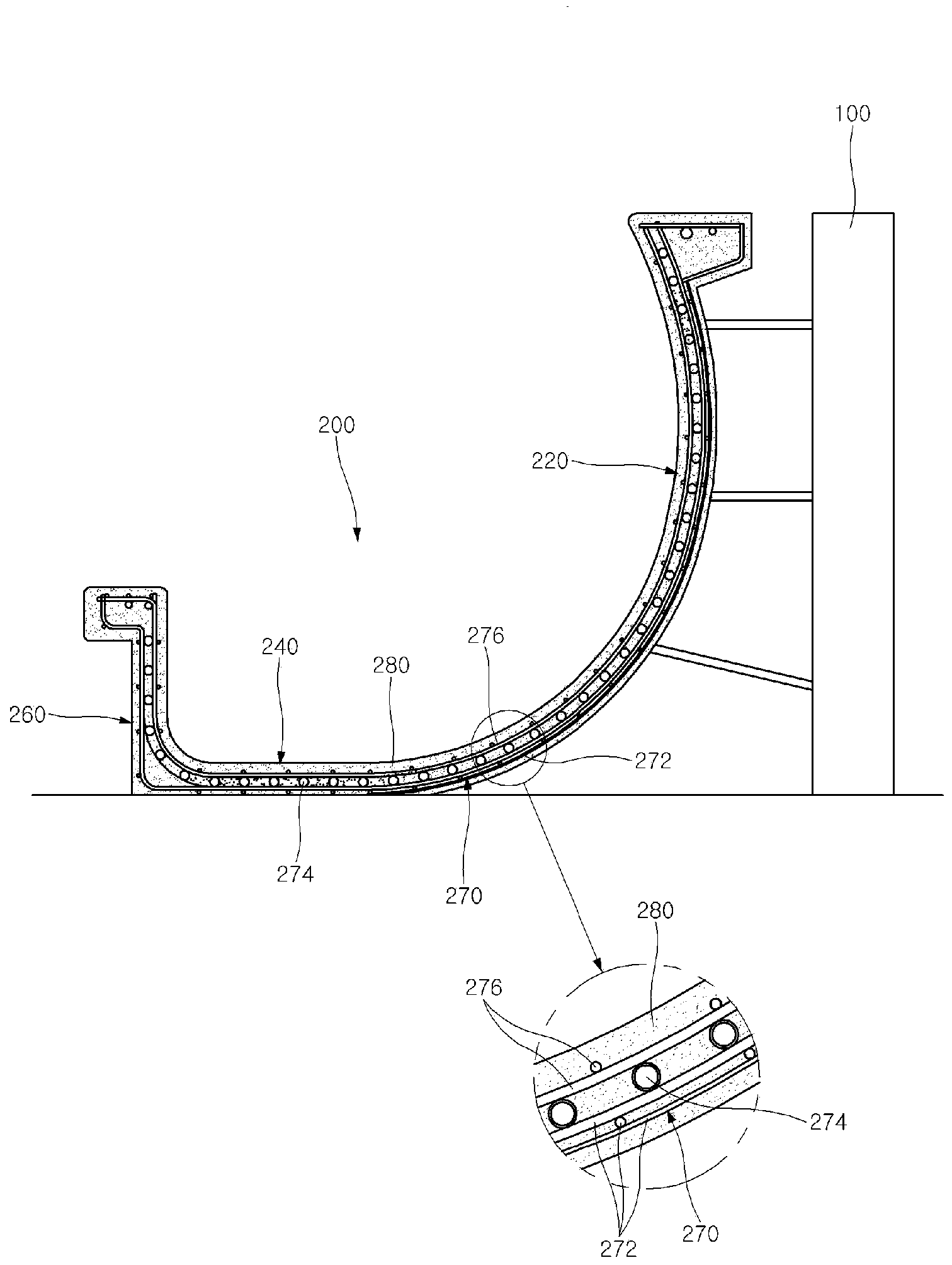

Method for constructing a bobsleigh course using a high-performance wet-type shotcrete composition

InactiveCN103906552AGood construction performanceHigh compressive strengthSki bindingsTunnel liningRough surfaceShotcrete

The present invention relates to a method for constructing a bobsleigh course using a high-performance wet-type shotcrete composition, and more particularly, to a method of constructing a bobsleigh course that uses a high-performance wet-type shotcrete composition which includes silica fumes and AE material, and which has increased pumpability prior to being deposited due to the presence of a superabundant amount of air, and increased shootability after being deposited since the amount of air present is decreased, thus imparting high constructability, high strength, and high durability to the composition. To this end, the method comprises: a framework-forming step of fixing a wire-mesh formwork, positioning a cooling pipe, strengthening adherence and holding strength, and installing a curvature-maintaining pipe; a shotcrete-laying step of laying the shotcrete composition; a first surface-finishing step of setting a curved surface and performing finishing using plastering; a second surface-finishing step of performing a rough surface finishing; and a wet curing step of performing wet curing.

Owner:KNU IND COOPERATION FOUND +1

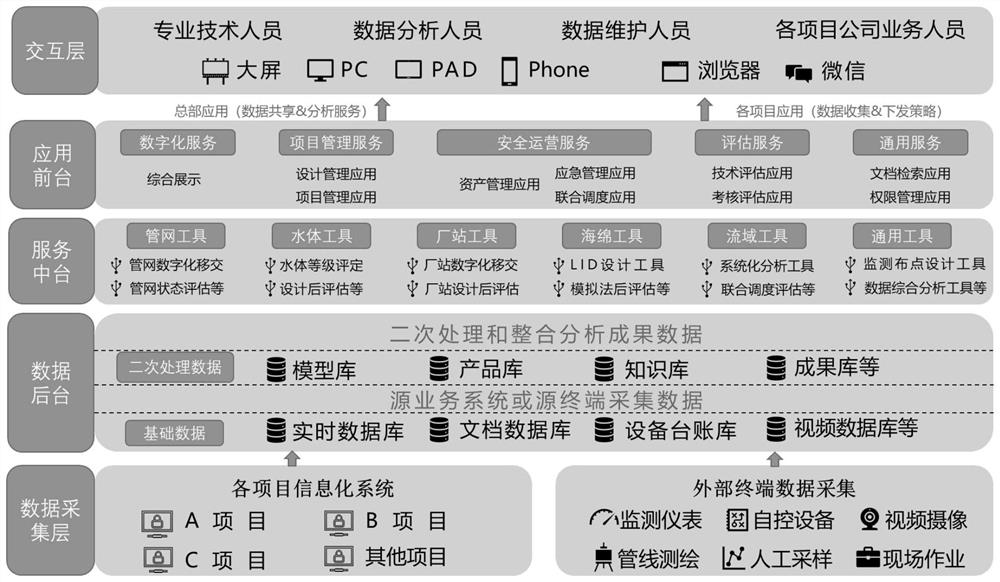

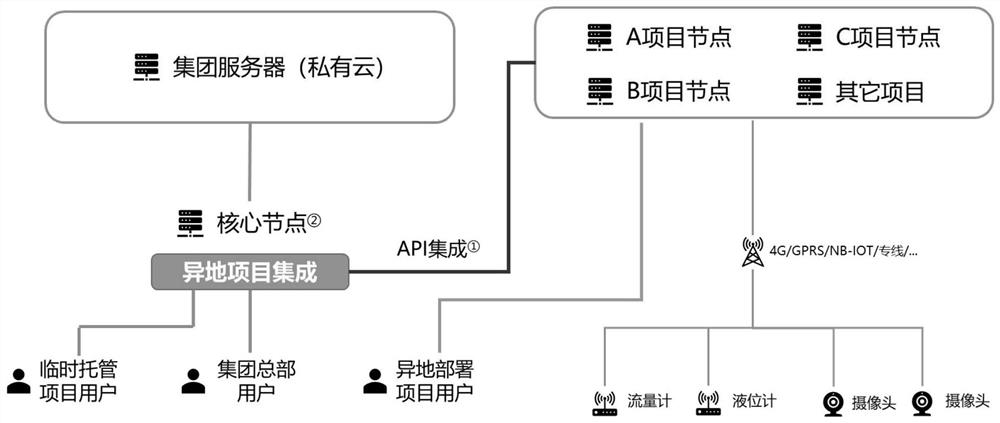

Intelligent water affair data center station based on distributed cloud architecture

PendingCN112232635ARaise the level of competitionStrong correlationResourcesInformatizationData center

An intelligent water affair data center station based on a distributed cloud architecture comprises a data collection layer, a data background layer, a service center station layer, a foreground application layer and an interaction layer, wherein the data collection layer has standardized access to data of an informatization system of each regional project in an API mode and collects data of external terminal equipment; wherein the data background layer comprises a basic database and a secondary processing database, the service center station layer processes basic data collected by a data background through a data processing tool, and the foreground application layer comprises a comprehensive display application, a project management service, a safe operation service, an evaluation serviceand a universal service. The interaction layer comprises a browser, a WeChat applet and a WeChat official account. Interaction tools comprise a large screen, a computer, a tablet personal computer and a mobile phone. According to the invention, standardized acquisition, storage, management, analysis, mining, sharing, exchange, display and application of water affair data of group-level-project-level multi-management-level projects can be realized.

Owner:NORTH CHINA MUNICIPAL ENG DESIGN & RES INST

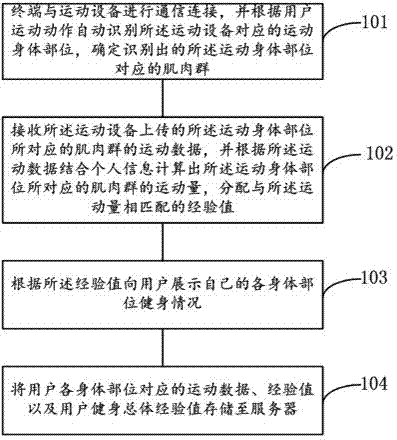

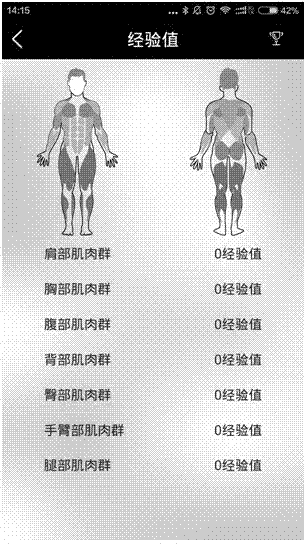

Body building method and system based on muscle group race

InactiveCN107185214AAdd funRaise the level of competitionGymnastic exercisingExercise equipmentPhysical exercise

The invention discloses a body building method and system based on a muscle group race. By means of the method, in the body building process, a user terminal is combined with corresponding fitness equipment, obtained motion data is more accurate, the exercise intensity of various parts of the body can be more intuitive to understand through empirical values, and people can reasonably design pertinent body-building plans and achieve the goal of body building. By means of the body building method, nationwide fitness programs are conveniently achieved. Moreover, the empirical values can be obtained through constant physical exercises and can reflect the health index to a certain extent, and users thus have healthy physiques and own a more confident life.

Owner:XIAMEN COWELL IND

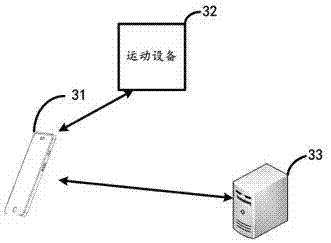

Toe correction device

InactiveCN107072803APrevent diseasePromote healthDevices for pressing relfex pointsDiseaseVaricose veins

The present invention relates to a toe correction device and, more specifically, to a toe correction device, which: by inserting correction protrusions between toes to prevent the deformation of the toes (phalanges and metatarsals) and correcting the deformed toes simultaneously, can correctly hold the toes which are the foundation of the whole body, thereby correcting and improving the body shape and physical constitution, thus promoting health improvement; can prevent and treat diseases, such as varicose veins or toe deformation including hallux valgus; and can correct the body shape.

Owner:WHBS有限公司

Laying method of self-knotted grain-free environment-friendly plastic runway

The invention discloses a laying method of an automatic texture formation particle-free environmentally-friendly plastic track. The method comprises the following steps: S21, laying a substrate layer: mixing an environmentally-friendly single-component water solidified plastic track material with black micelles according to a weight ratio of 1:4-6, and laying the substrate layer on a dry and solidified cement base or asphalt base; S22, laying a reinforcing layer: spreading a layer of the black micelles on the dry and solid base layer, and lying the environmentally-friendly single-component water solidified plastic track material to cover the substrate layer; and S23, laying an automatic texture formation layer: uniformly mixing 10-12 parts of an automatic texture formation finish, 1-3 parts of EPDM particle rubber powder and 3-6 parts of quartz sand to form an automatic texture formation layer material, fully stirring, and spraying the obtained material on the dry and solidified reinforcing layer. The track has the advantages of environmentally friendly material, no shedding of particles, good durability, plump and uniform surface textures, high tensile strength and long service life, and all performance indexes of the track accord with technical requirements of International Association of Athletics Federations and GB / T14833-2011.

Owner:广州帝森康体设备有限公司

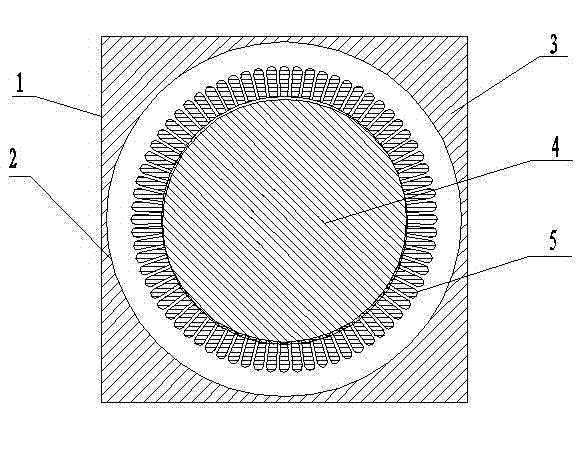

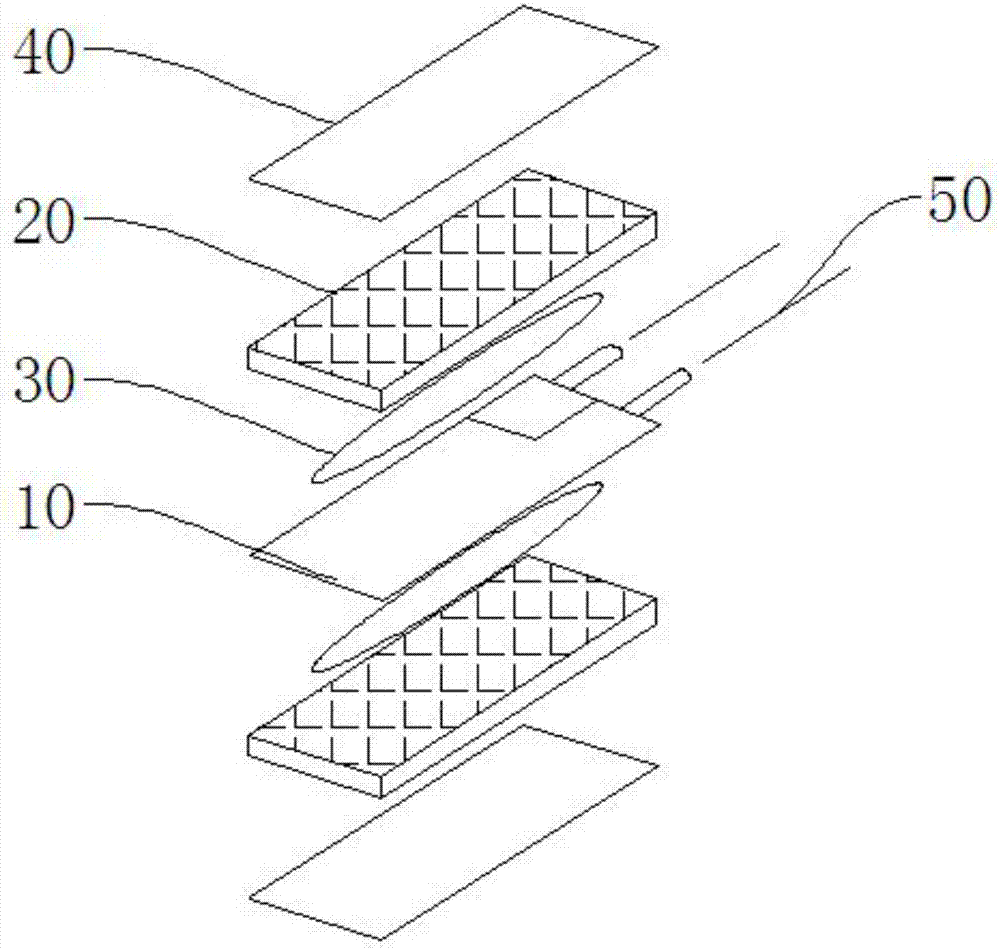

Silicon pu type plastic court

ActiveCN104846717BProtect the jointsReduce the risk of injuryGround pavingsPolyurea/polyurethane coatingsEngineeringBall tennis

The invention relates to a synthetic court, and in particular relates to a silicon PU type synthetic court which is suitable for various competition places, is high in elasticity, has anti-abrasion and anti-skid and anti-aging effects, is integrally molded, is uniform in surface layer thickness and is colorful and is used for solving the technical problems in the prior art. The silicon PU type synthetic court comprises a basic layer, a waterproof layer, a silicon PU elastic layer and a cover finishing coat protection layer, wherein the silicon PU elastic layer consists of a leveling layer and a reinforcement layer. The silicon PU type synthetic court can be widely applied to basketball, tennis ball and badminton ball places with various fundamental planes, various indoor and outdoor leisure areas, gymnasiums, gymnasium activity places and the like.

Owner:GUANGZHOU SHENGBANG SPORTS GROUND MATERIAL CO LTD

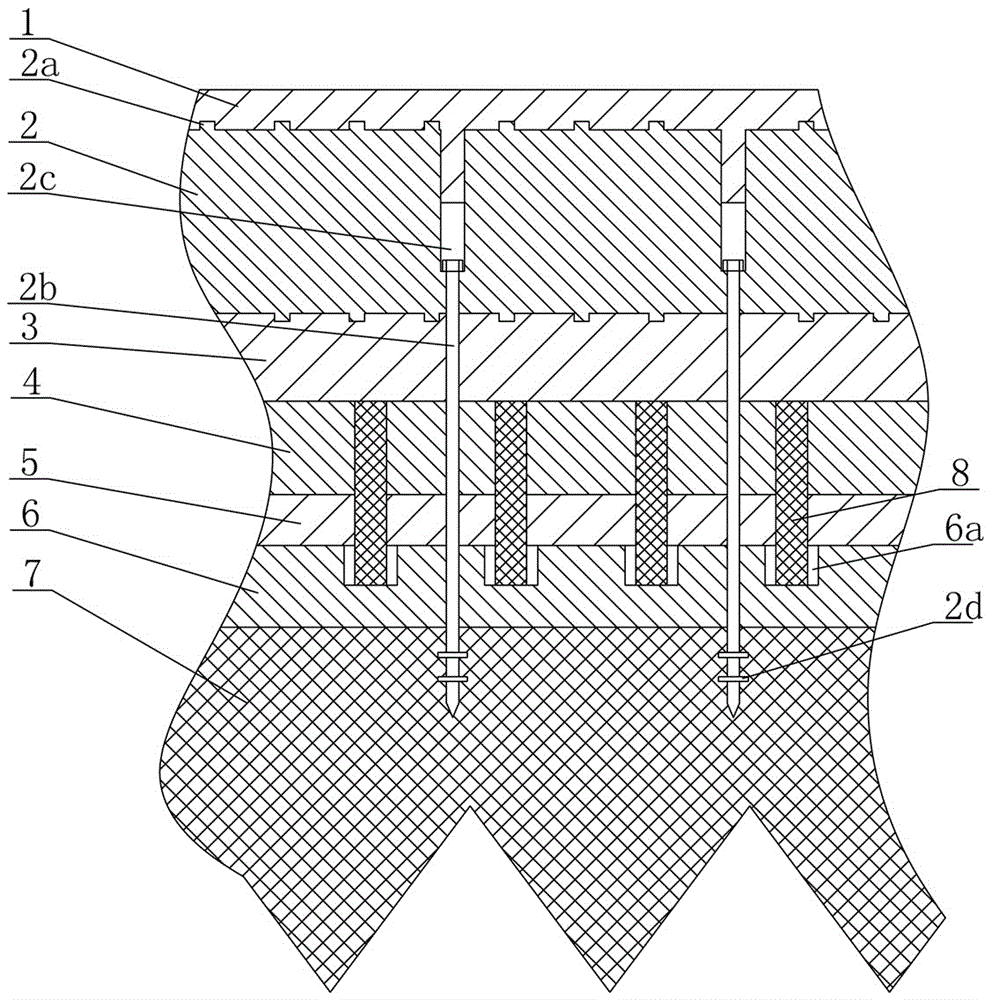

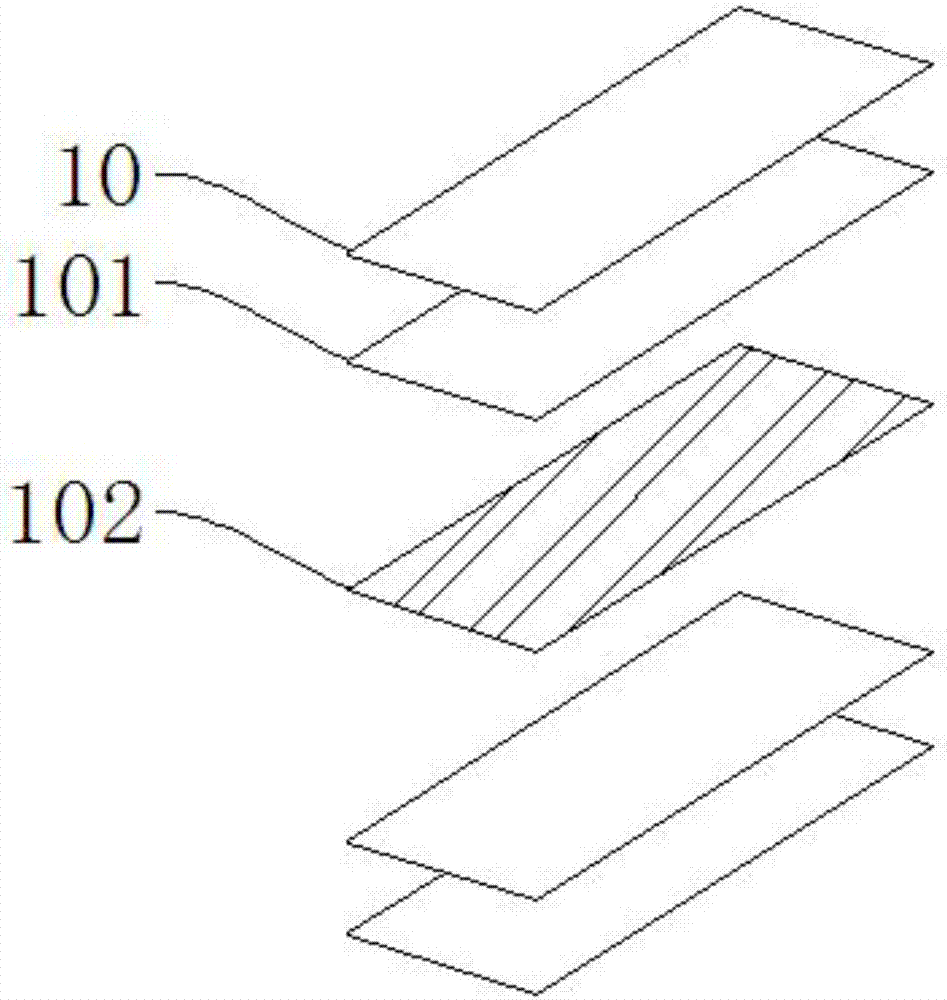

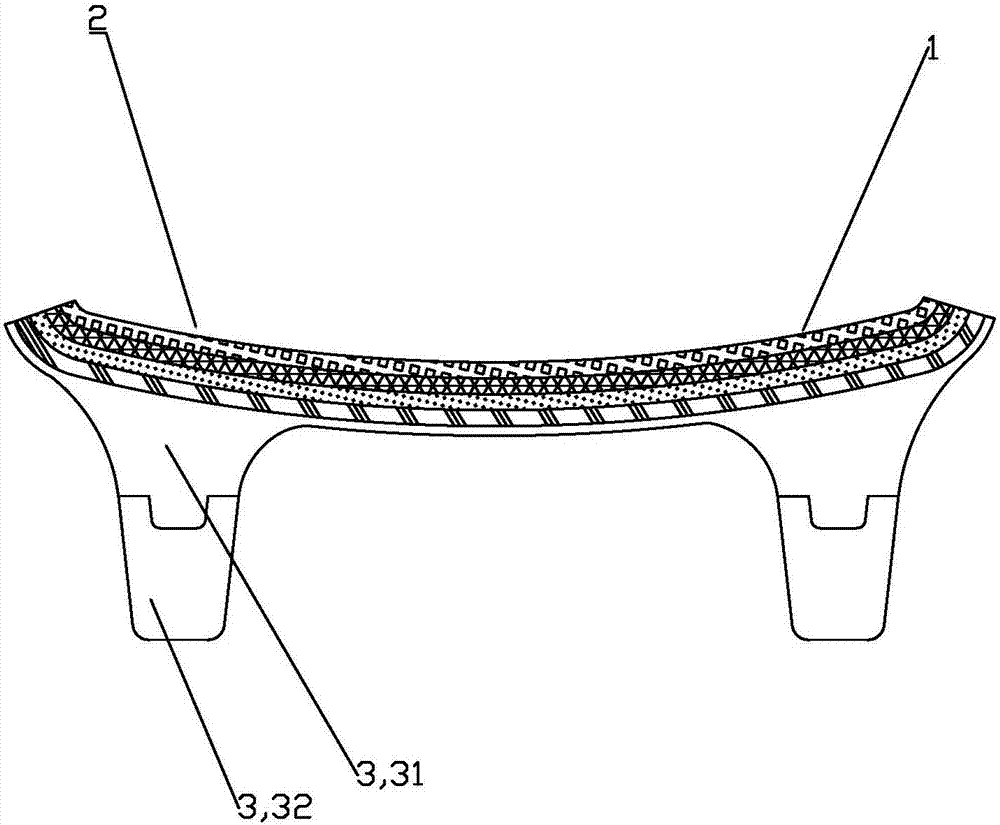

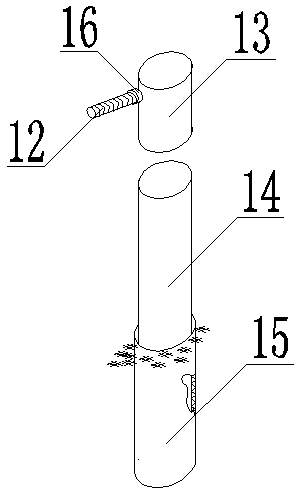

SBS elastomer environment-friendly runway

The invention provides an SBS elastomer environment-friendly runway and belongs to the technical field of plastic runways. The SBS elastomer environment-friendly runway comprises connecting nails and plastic elastic columns and further comprises an abrasion-resisting layer, a buffer layer, a priming coat, a first geotextile layer, a thin film layer and a second geotextile layer which are sequentially arranged from top to bottom. Inwards-sunken connecting holes are formed in the buffer layer, and the bottom diameters of the connecting holes are smaller than the top diameters of the connecting holes; the connecting nails sequentially penetrate into the buffer layer, the priming coat, the first geotextile layer, the thin film layer and the second geotextile layer, and the bottom ends of the connecting nails are inserted in a pure soil layer; and the plastic elastic columns are vertically arranged and penetrate into the first geotextile layer and the thin film layer. According to the SBS elastomer environment-friendly runway, the connecting nails are arranged so that the buffer layer, the priming coat, the first geotextile layer, the thin film layer and the second geotextile layer can be connected into a whole, use of glue is avoided, and the environmental friendliness of the runway is improved; and the runway is further provided with the plastic elastic columns, the negative impact of the connecting nails on the runway elasticity is eliminated, and the plastic pavement has appropriate elasticity accordingly.

Owner:浙江动动恰体育科技有限公司

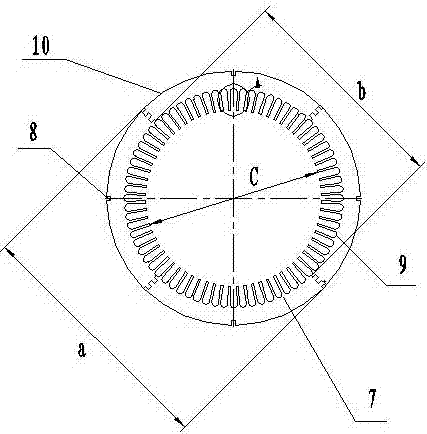

Processing method of motor stator end plate

The invention discloses a processing method of a motor stator end plate. The processing method of the motor stator end plate comprises the steps of (1) cutting a bar stock; (2) using a dedicated die to carry out blanking on arc-shaped blocks with locating grooves; (3) carrying out circle splicing, carrying out two-sided burn-in on splicing connectors through welding rods, and carrying out polishing to achieve smoothness; (4) using an outer circle and the locating grooves to carry out locating, and punching groove profiles. When the processing method of the motor stator end plate is adopted, due to the facts that an original complete circle structure is replaced by an arc-shaped splicing structure, cutting of a square stock is changed into cutting of the bar stock, and an inner circle does not need to be cut, and waste of the area of an inner disk is avoided; due to the fact that the amount of waste produced through blanking of the arc-shaped blocks is much smaller than that of waste produced through cutting of the outer circle, waste of steel plate materials is reduced by about 70%, the use ratio of the materials is greatly improved, and the profit and the competition level of enterprises are greatly improved; in addition, due to the facts that the outer circle and the locating grooves are simultaneously used for locating and punching of the groove profiles, and the groove profiles can be directly punched through a high-speed notching press, the notching speed is high, operation can be carried out through only one person, the punching speed is increased to 300-400 times per minute from 70-80 times per minute of the traditional technology, production efficiency is high, and the requirement for mass rapid production can be met.

Owner:JIANGSU TONGDA POWER TECH

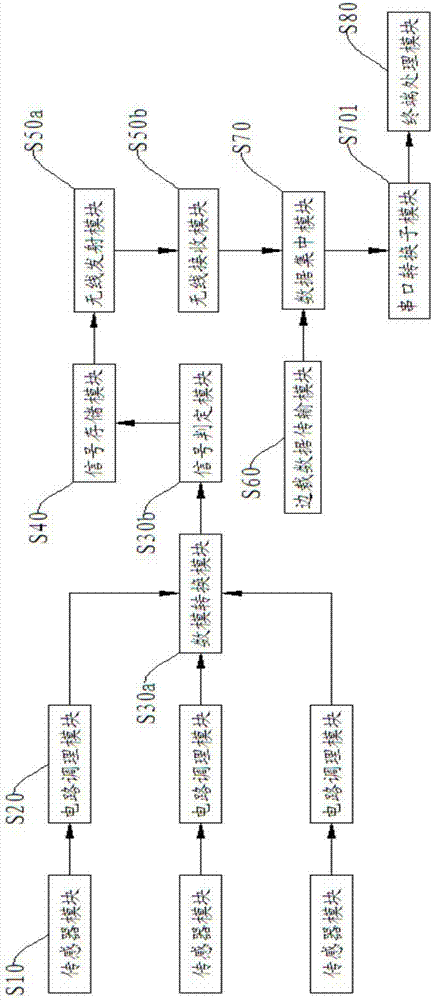

Sensor and signal collecting and processing system for wushu free combat electronic protector

PendingCN107045775AClear senseLess prone to misjudgmentTransmission systemsSport apparatusElectricityComputer module

The invention discloses a sensor for a wushu free combat electronic protector. The sensor comprises a piezoelectric film layer, wherein two pressure-sensitive films are clamped in the piezoelectric film layer; a silver nano-film layer for reducing the resistivity is also arranged between the two pressure-sensitive films; buffer layers are arranged on the upper surface and the lower surface of the piezoelectric film layer; a vacuum filling layer is arranged between each buffer layer and the piezoelectric film layer; a flexible shielding layer coating the whole piezoelectric film layer is arranged on the outer surface, far away from the piezoelectric film layer, of each buffer layer. The invention further discloses a signal collecting and processing system for the wushu free combat electronic protector; and the signal collecting and processing system comprises a sensor module, a circuit conditioning module, a digital-to-analogue conversion module, a signal judgment module, a wireless transmitting module and a wireless receiving module. The sensor is sensitive in sensing, is capable of sensing a pressure signal in an omnibearing manner, and is not easy to bend; meanwhile, according to the signal collecting and processing system, the fairness and the objectivity of the game are ensured, the requirements of free combat action techniques are improved and the competitiveness is indirectly improved.

Owner:CHENGDU KINESIOLOGY UNIVERSITY

Table tennis game execution system and table tennis game score display method

ActiveCN106999752BRaise the level of competitionGymnastic exercisingRacket sportsComputer graphics (images)Simulation

Owner:YEOU ELECTRONICS

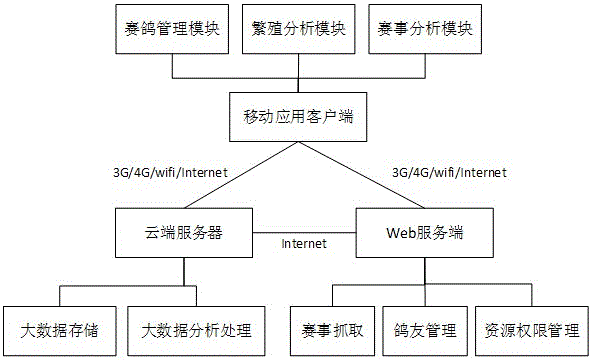

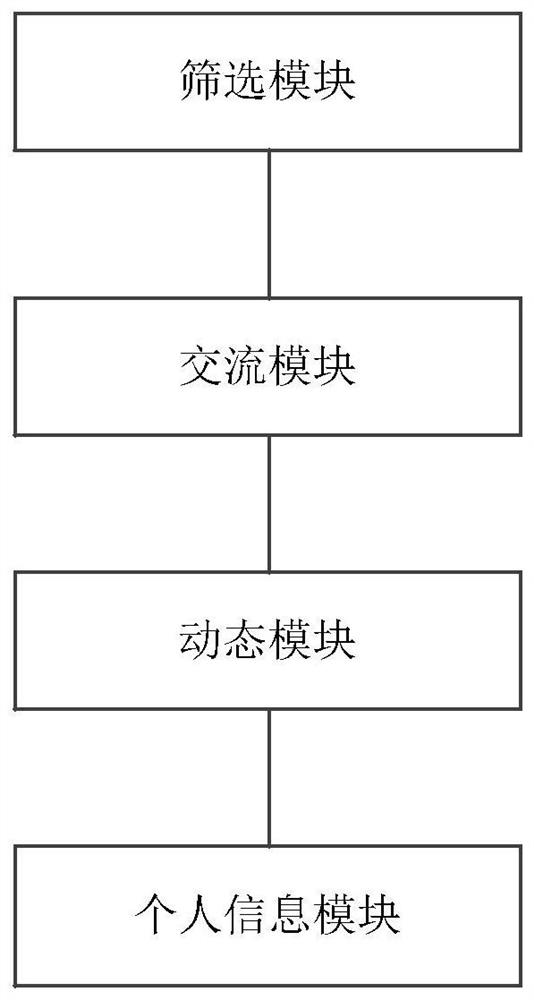

Carrier pigeon competition management and competition analysis system based on mobile terminal

InactiveCN105046411ARaise the level of competitionEfficient managementResourcesWeb serviceClient-side

The present invention provides a technical scheme of a carrier pigeon competition management and competition analysis system based on a mobile terminal. The scheme is that the carrier pigeon competition management and competition analysis system based on the mobile terminal comprises a mobile application client, a cloud server and a web server; the mobile application client is interacted with the cloud server and the web server via a wireless network, the web server real-timely obtains the information in the network and stores the information in the cloud server, and the mobile application client can obtain the information from the cloud server and the web server, display the information, record the carrier pigeon information and upload the recorded information to the cloud sever to store. According to the scheme, the system can manage the carrier pigeon information effectively, promotes to improve the carrier pigeon species, analyzes the competition data, provides forceful foundation for the pigeon friend competition, and enables the carrier pigeon competition level of our country to be improved.

Owner:SICHUAN ZHIHUA SOFTWARE TECH CO LTD

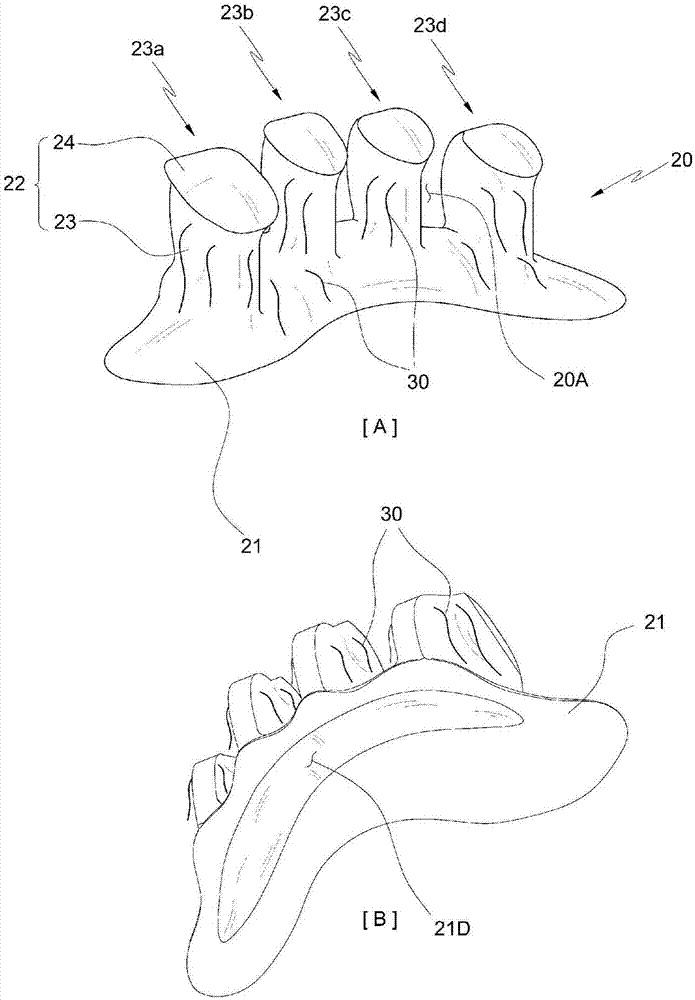

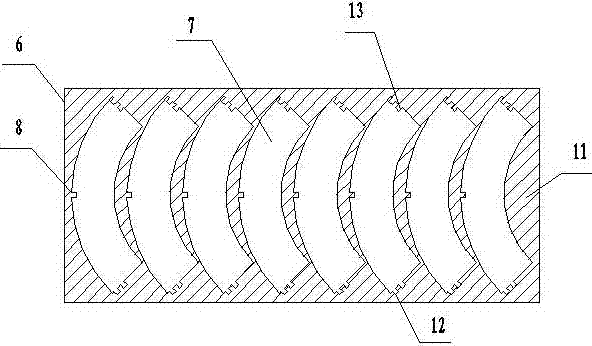

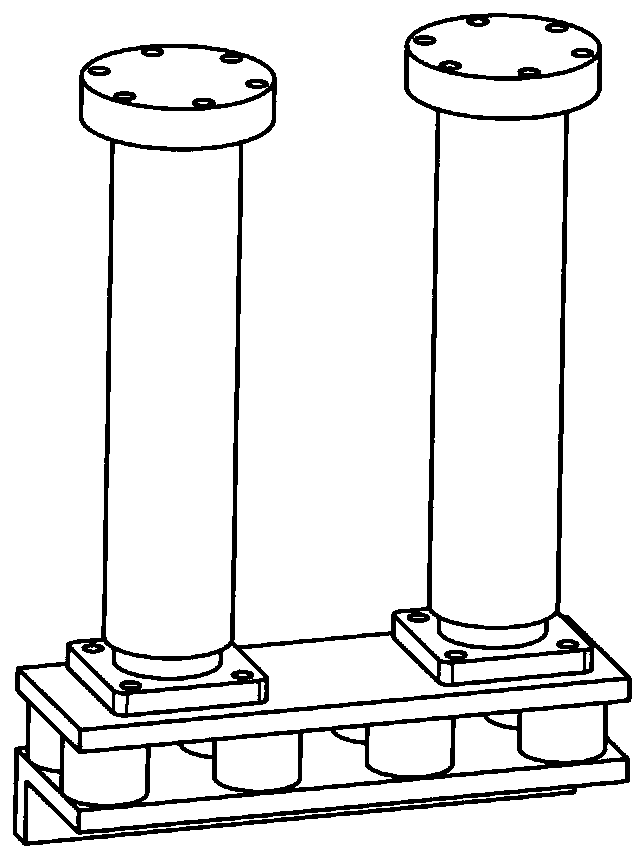

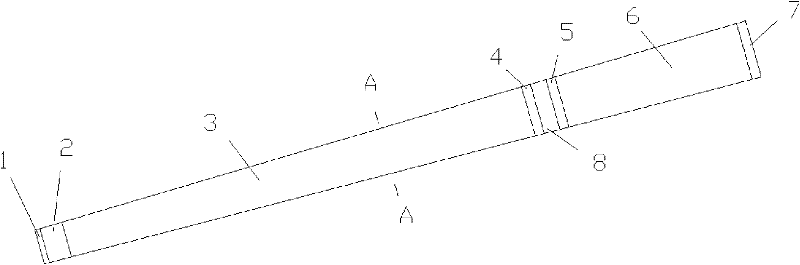

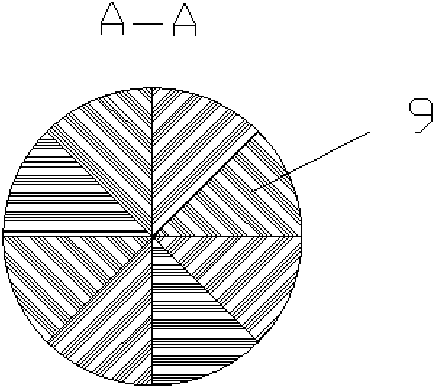

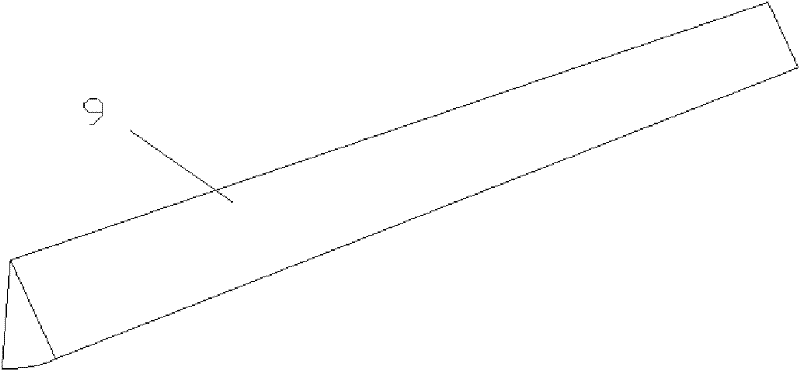

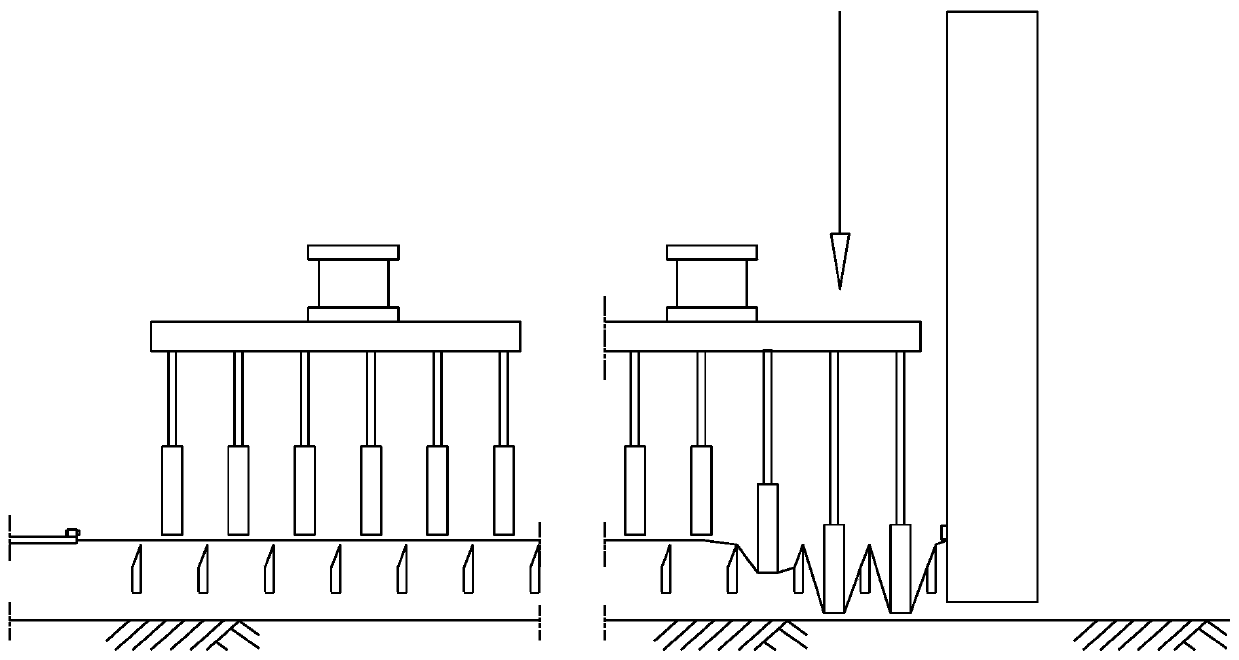

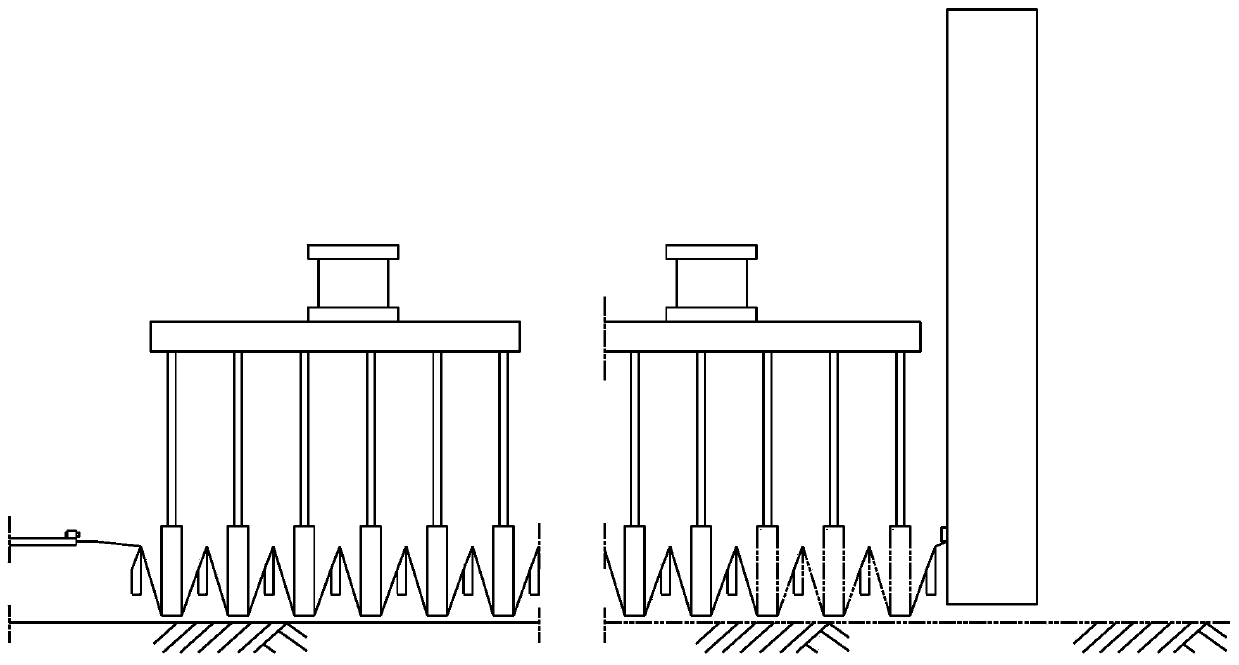

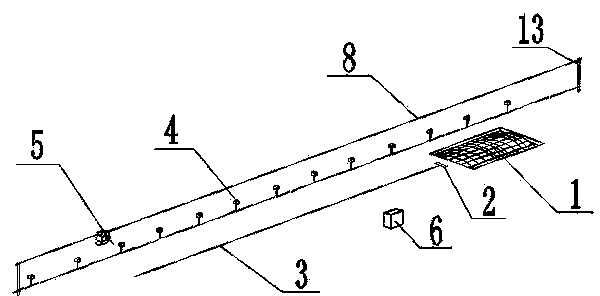

Silk planting needle mechanism of lawn artificial silk planting machine

ActiveCN111485339ATargetedSimple structureTufting apparatusGround pavingsAgricultural engineeringLawn

The invention relates to a component structure of a lawn artificial silk planting machine. All rows m-column silk planting needles (8) in a working section are arranged on one silk planting needle support (29) and are connected with a vertical linear vibrator (28) through a vibration unit (27), the upper part is fixedly connected with a horizontally arranged upper cross beam (26), the left side and the right side are connected with extension rod ends of electric cylinders (25) which are vertically arranged on a rack (9); the left side and the right side of a lower cross beam (32) which is horizontally arranged are fixed to the rack (9), two guide columns (31) are vertically fixed to the left side and the right side, and guide sleeves (30) arranged above the guide columns (31) in a sleevingmode are fixed to the silk planting needle support (29); and the lower ends of the silk planting needles (8) are positioned in pipes of corresponding silk pressing pipes (7). A silk planting needle mechanism of the lawn artificial silk planting machine can achieve operation rapidly and conveniently, pertinence is high, the structure is simple, standard and universal parts are adopted, manufacturing, assembling and maintaining are easy, the artificial silk planting machine can be rapidly and widely popularized, the mass is benefited, and physical exercise development is promoted.

Owner:BEIJING TEAMRUN TECH DEV CO LTD

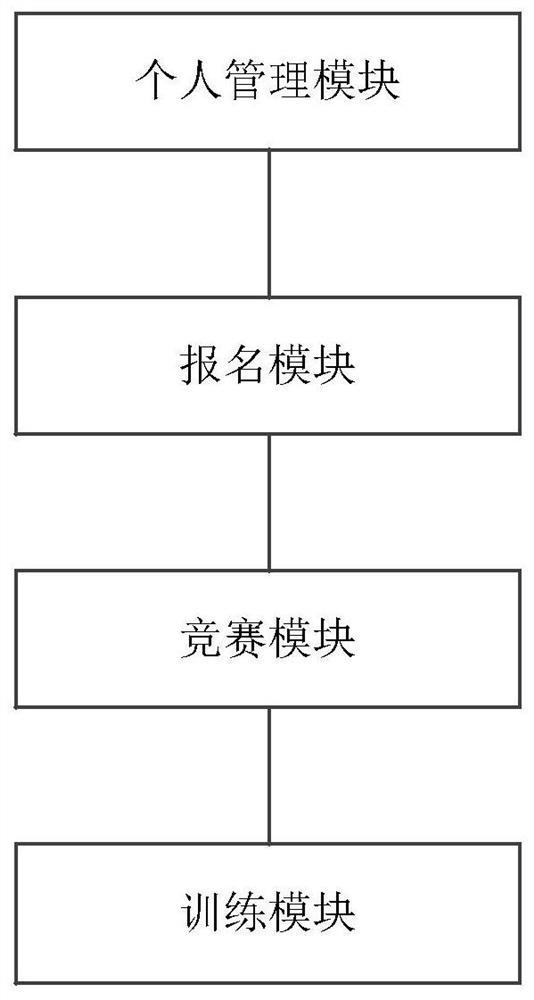

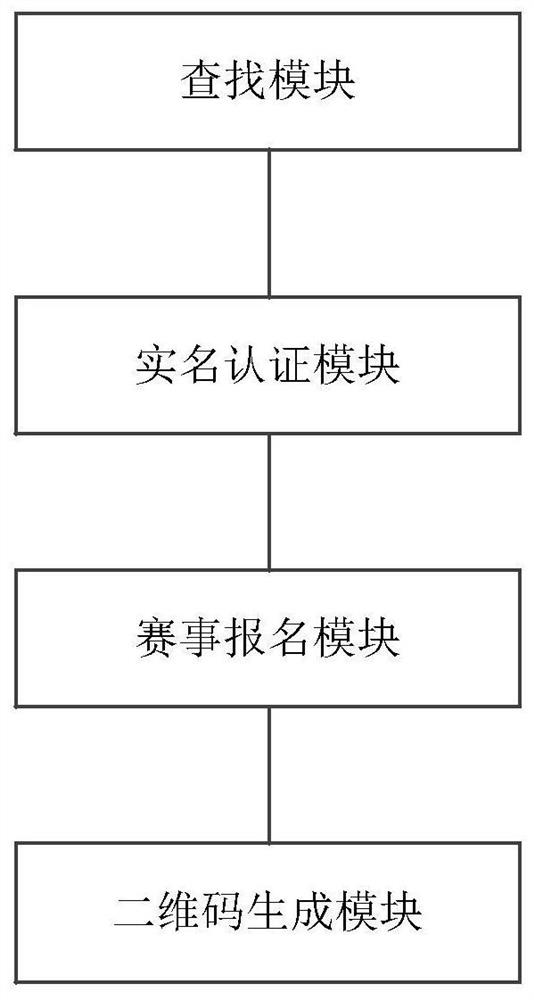

Timing and scoring system for iBoat racing training

The invention discloses a timing and scoring system for iBoat racing training. The timing and scoring system comprises a personal management module, an application module, a racing module and a training module, and the personal management module is used for managing personal activities of a user; the application module is used for searching a match to be participated and performing application; the competition module is used for opening competition referee and athlete channels of a competition when the competition is about to be reported, checking application information and field requirementreports by the referee and the athlete through a two-dimensional code, realizing participating in the competition, recording the competition and obtaining scores in real time; and the training moduleis used for establishing a training team through a friend group, completing training and recording training data. Data during training can be presented, the problem that the training cannot be completely repeated is solved, the training is simpler and more efficient, the racing boat competition can be recorded and judged, scores can be obtained in real time, and the competition is simpler.

Owner:南京风之曲科技文化有限公司

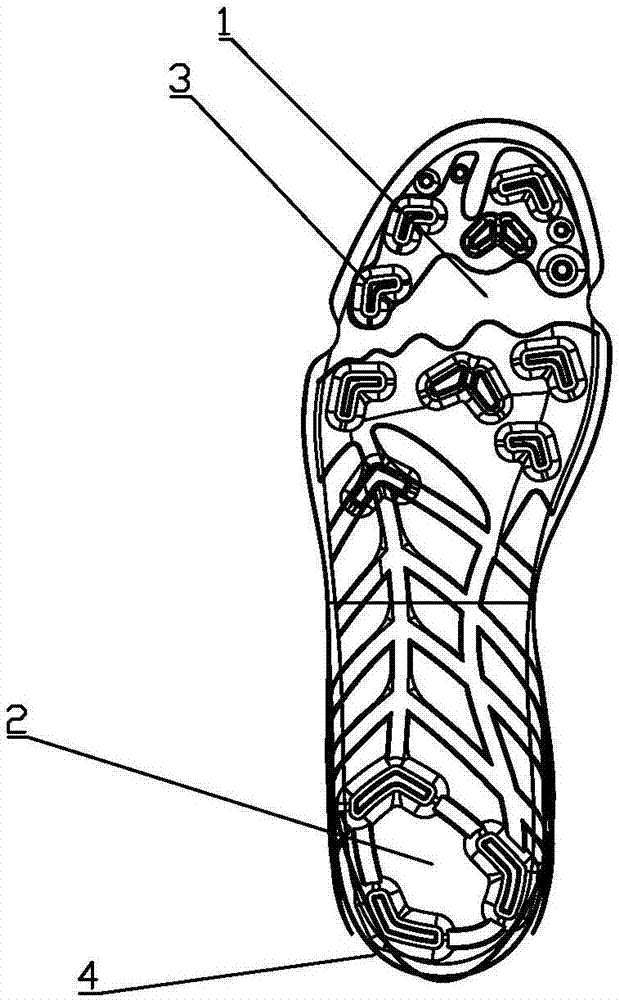

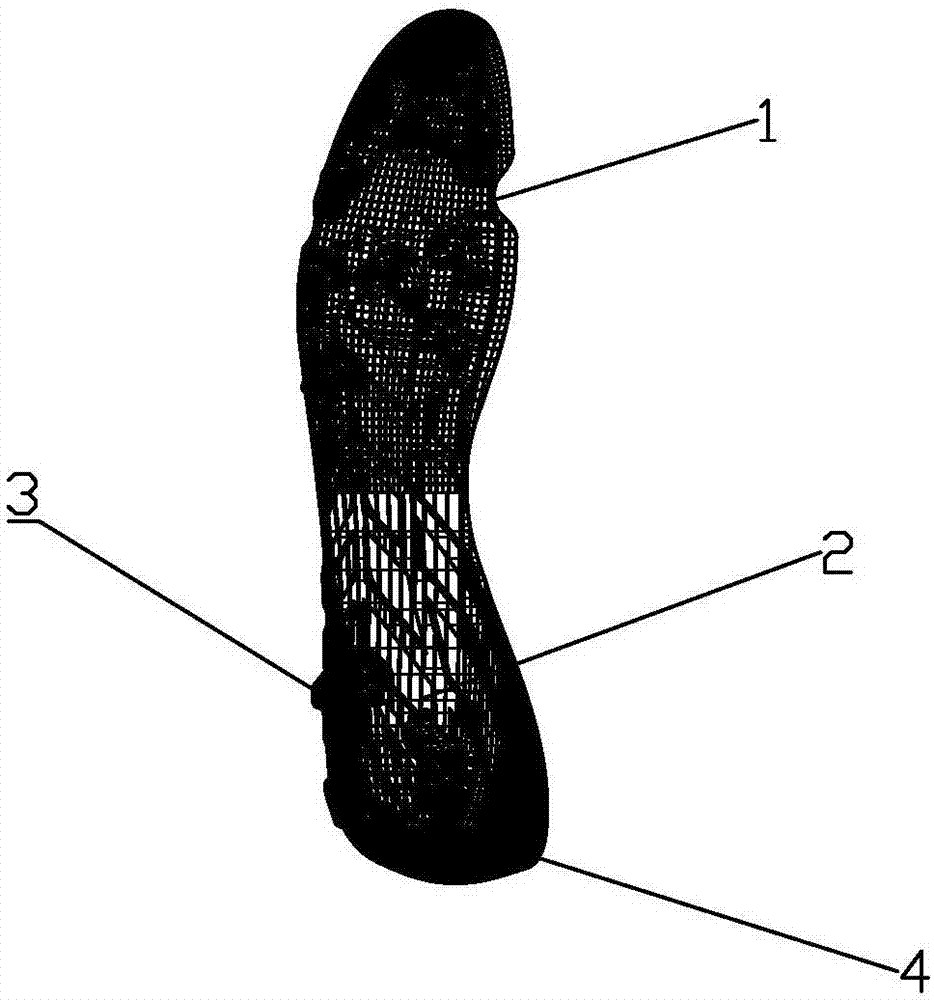

Soccer spike sole

The invention discloses a soccer spike sole which comprises a large base plate face. The large base plate face is composed of a shoe toe plate and a shoe heel. A plurality of spikes are uniformly arranged at the bottoms of the shoe toe plate and the shoe heel. The edge of the exterior of the shoe heel extends upwards to form a rear packet. The large base plate face, the spikes and the rear packet are formed by internally combining and molding thermosetting epoxy resin matrix composites. The soccer spike sole has the advantages of being good in strength, durable, capable of preventing a user from being injured and the like.

Owner:ZHONGSHAN FUDA SPORTS EQUIP

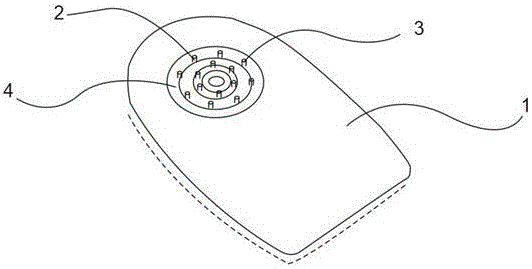

Healthcare decompression pad capable of correcting plantar fasciitis

InactiveCN106074953ARelieve fatigueReduce the risk of injuryAntipyreticAnalgesicsLycopodium clavatum sporeCactus

The invention discloses a healthcare decompression pad capable of correcting plantar fasciitis. The decompression pad is characterized in that the decompression pad is made of one-step-formed gel, a traditional Chinese medicine ointment ring is arranged at the heel position of the decompression pad to form an outer ring, latex columns are evenly distributed on the periphery in the traditional Chinese medicine ointment ring, nano silver particles for massaging the heel are arranged at the tops of the latex columns, and the traditional Chinese medicine components in the traditional Chinese medicine ointment ring are prepared by, by weight, 5-10 parts of fresh cactus, 10-30 parts of radix clematidis, 5-20 parts of angelica sinensis, 7-25 parts of panax notoginseng, 10-30 parts of lycopodium clavatum, 1-3 loofah sponges, 10-30 parts of Eucommia ulmoides, 5-10 parts of semen cuscutae, 5-10 parts of ramulus cinnamomi, 1-3 parts of coconut oil, 1-2 parts of vitamin E and 500-1000ml of rice vinegar. The healthcare decompression pad has the advantages that the decompression pad is suitable for relieving heel pain and heel spurs and suitable for people with plantar fasciitis, people whose heels ache easily and foot lovers with high healthcare consciousness; the healthcare decompression pad is designed according to human body figure, the contact area between the planta pedis and the decompression pad is increased, the decompression latex columns can absorb shock, and the shock absorbing effect is further enhanced due to the fact that density of the material of the whole decompression pad is large.

Owner:鄢海军

Bamboo-made deformation-resisting cue

The invention discloses a bamboo-made deformation-resisting cue, comprising a cue body, which is conical cue body formed by the steps of gluing and hot-press shaping, by mold, a plurality of axially arranged bamboo sheets with the same quality and consistent specification, wherein the bamboo sheet, which is subject to cooking at high temperature, removal of original juice, sugar and protein of bamboo, disinfestation, bleaching and drying, is Mao bamboo. The bamboo-made deformation-resisting cue according to the invention, capable of maintaining vertical axis center and free from bending and deformation, settles the problem of inferior bending and deformation properties of the cue, enhances competition level of billiard ball players and ensures fair competition.

Owner:周凯

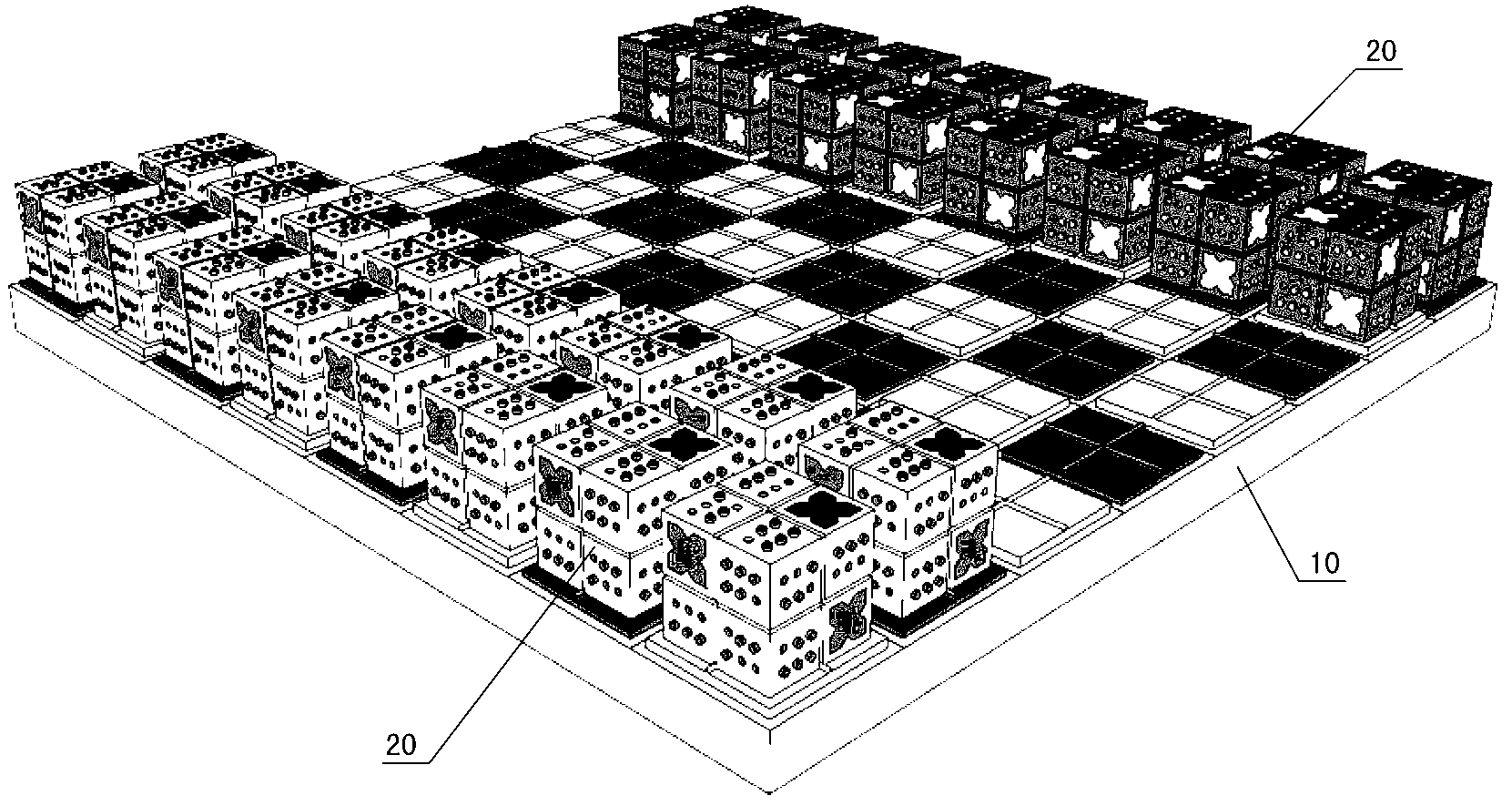

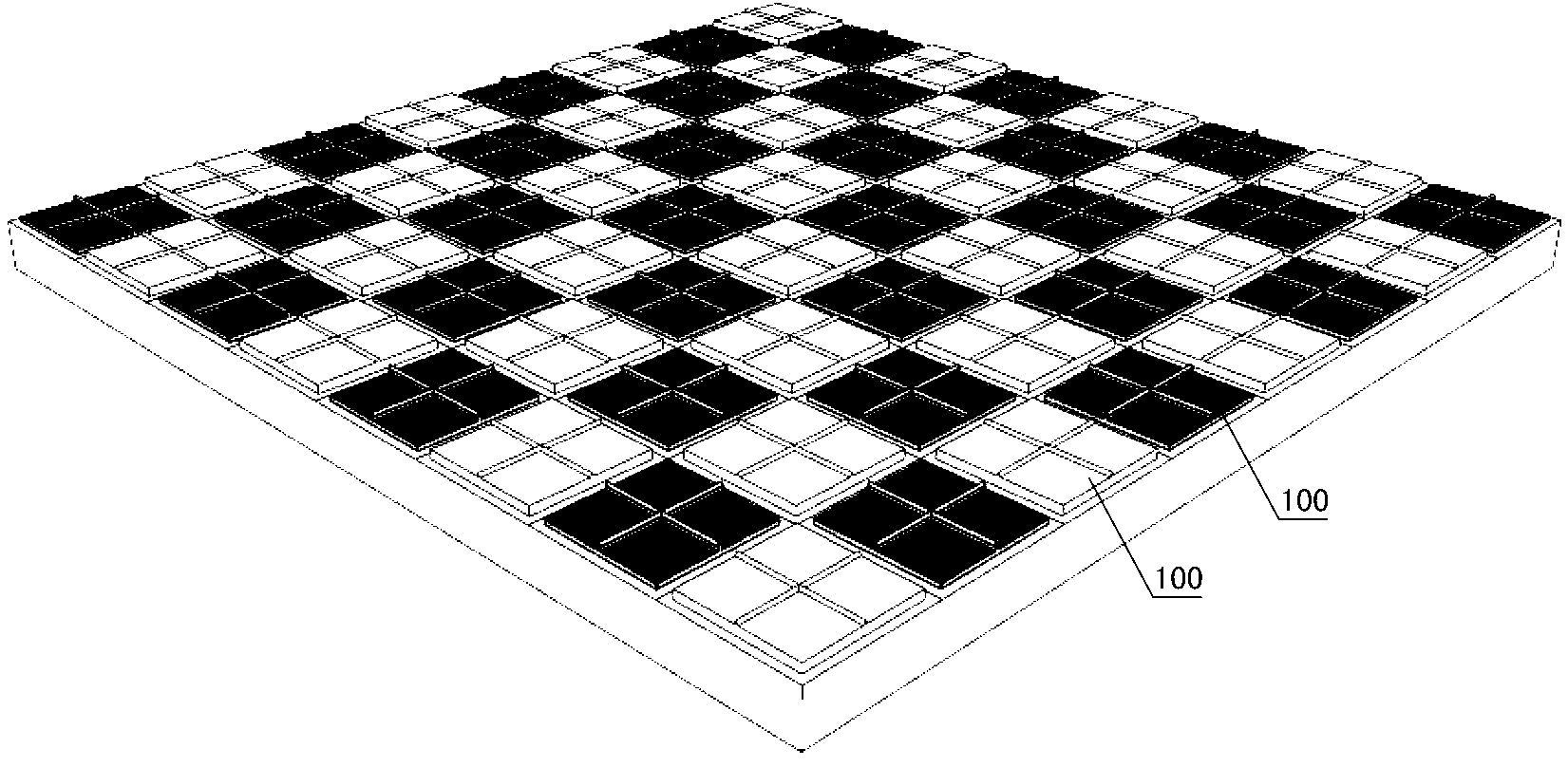

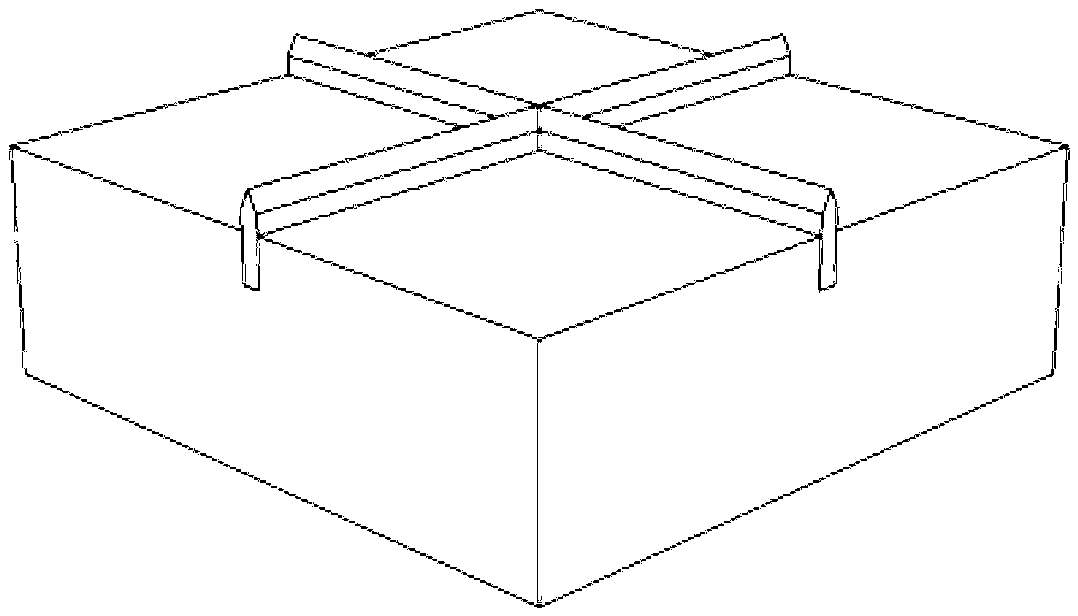

Barrier-free chess

The invention belongs to the field of game entertainment, and particularly discloses a barrier-free chess. The barrier-free chess provided by the embodiment of the invention adopts the nature that the magnetic pole of a magnetic device arranged in a chessboard checker and the magnetic pole of a magnetic device in a plane formed by all chess pieces are repellent if the magnetic poles are the same or attracted mutually if the magnetic poles are opposite, and opposite Braille representing chessboard checker colors are arranged in a chessboard color Braille indicating zone in a plane formed by two opposite chess pieces, with opposite magnetic poles, on an identical barrier-free chess piece, so that the visually impaired can not only distinguish chess pieces through touch of hands during use, but also know colors of the chessboard checker where a chess piece is positioned from the chess piece through the touch of hands, and the barrier-free chess is convenient for the visually impaired to use, enables the visually impaired to be able to use the chess without barriers, improves the entertainment, and is also beneficial to the improvement of the competitive level of the visually impaired.

Owner:SUZHOU YUNDU NETWORK TECH

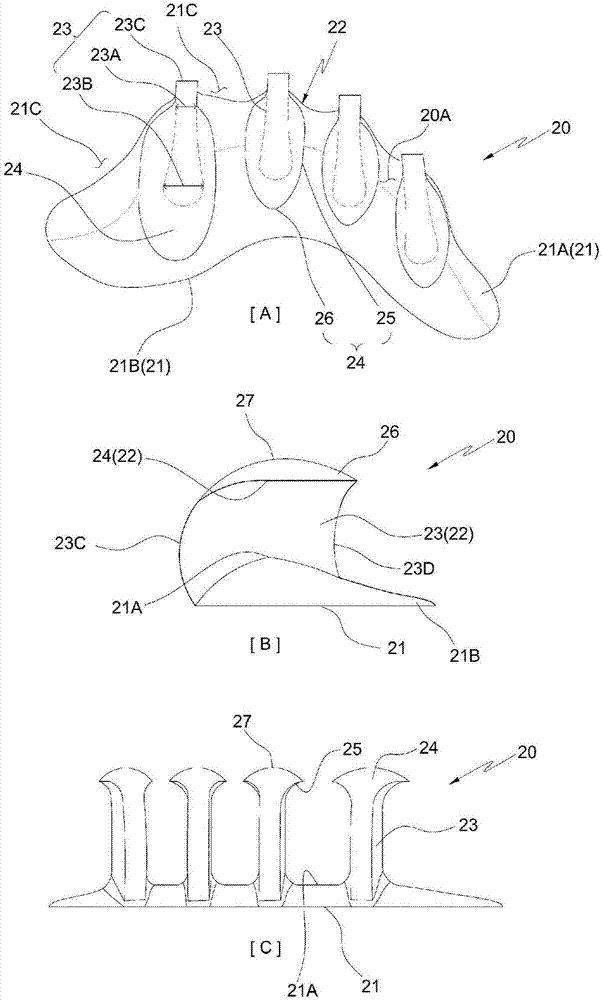

Silk pressing device applied to mixed lawn silk planting machine

ActiveCN111517162AEasy to implementStrong targetingFilament handlingSevering to form staple fibresPolymer scienceEngineering

The invention provides a silk pressing device applied to a mixed lawn silk planting machine. N rows of vertical silk pressing pipe row frames are arranged on a rack, m silk pressing pipes are vertically fixed to the lower surface of each silk pressing pipe row frame, silk pressing pipe pushing mechanisms are installed on the two sides of the n rows of vertical silk pressing pipe row frames, the silk pressing pipe row frames are synchronously driven by the silk pressing pipe pushing mechanisms on the two sides to move up and down along the rack, and the silk pressing pipe row frames move downwards one by one to drive the silk pressing pipes to be pressed downwards row by row with the position close to a clamping component on the rack as the starting point. The device is compact in structureand ingenious in design, the transverse area occupied by the device body is greatly reduced, transportation is convenient, and the design requirement is met.

Owner:BEIJING TEAMRUN TECH DEV CO LTD

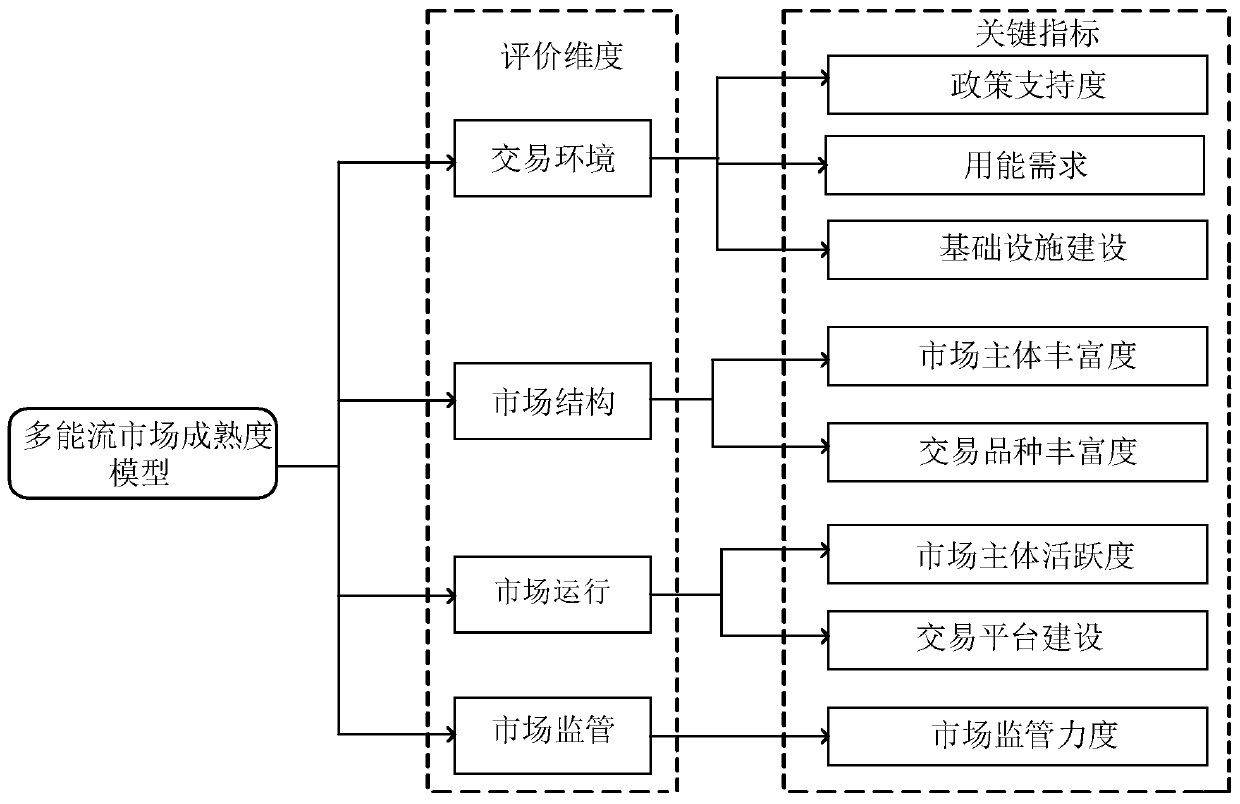

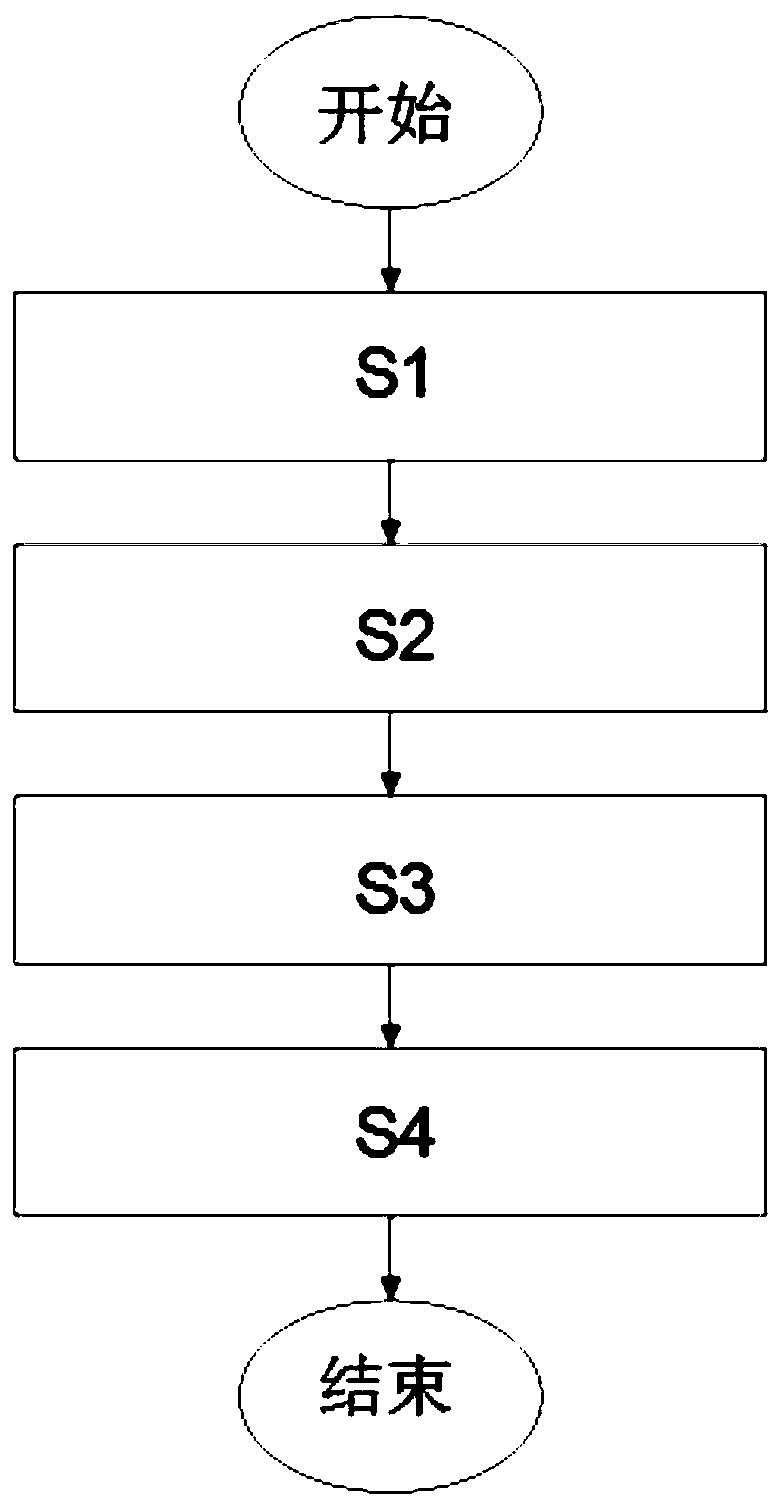

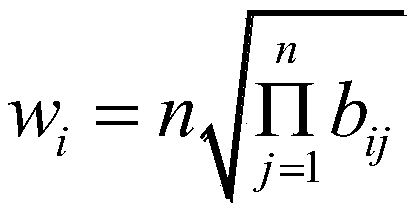

Regional multi-energy-flow market maturity evaluation method based on fuzzy comprehensive evaluation

PendingCN111382955ARaise the level of competitionOptimize market operationsResourcesIndex systemData mining

The invention discloses a regional multi-energy-flow market maturity evaluation method based on fuzzy comprehensive evaluation, belongs to the technical field of energy markets, and particularly relates to a regional multi-energy-flow market maturity evaluation method. The method comprises the following steps in sequence: S1, constructing a regional multi-energy flow market maturity evaluation index system; wherein the maturity evaluation index system is composed of evaluation dimensions and key indexes; S2, defining the evaluation dimension in S1 as a control layer and the key index as an index layer, and sequentially determining the weights of the control layer and the index layer based on an analytic hierarchy process; S3, establishing an evaluation set, and quantifying each key index of the index layer in the step S2 by adopting the idea of fuzzy mathematics so as to determine the grade evaluation of each key index; and S4, converting the evaluation set in S3 into scores to obtaina comprehensive evaluation result of the multi-energy-flow market maturity; based on fuzzy comprehensive evaluation, the maturity of the multi-energy-flow market can be well evaluated.

Owner:STATE GRID JILIN ELECTRIC POWER COMPANY LIMITED +3

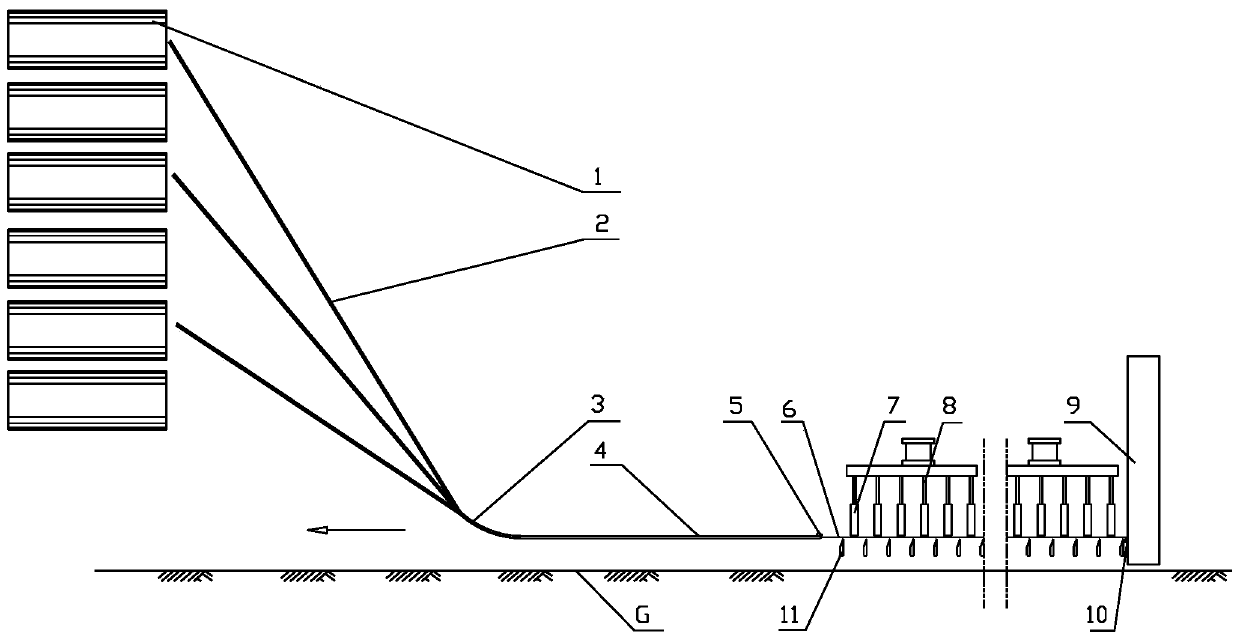

Accurate training device for long jump athletes

ActiveCN103357139ARaise the level of competitionReduce mistakesJumping apparatusLong jumpEngineering

The invention relates to a long jump training device, in particular to an accurate training device for long jump athletes. The accurate training device for the long jump athletes comprises a sand pit, a take-off board and a running approach runway, and is characterized in that a plurality of step cameras are arranged on one sides of the sand pit and the running approach runway; accompanying video cameras are arranged above the step cameras; the step cameras are connected with a computer combination. The accurate training device for the long jump athletes has the benefits that training of the athletes at ordinary times can be continuously standardized, so that the athletes can be well trained during hundreds of or thousands of times of training at ordinary times, competition level of the athletes can be greatly improved, the athletes can make outstanding performance for each-time long jump, errors are reduced, competition time can be further shortened, structure is simple, erection is convenient, operation is convenient, and the accurate training device is a greater assistant of the athletes in peacetime training.

Owner:德州云川机电设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com