Silk planting needle mechanism of lawn artificial silk planting machine

A technology of silk planting and silk needles, applied in the field of artificial silk planting machinery, can solve the problems that hinder the use and promotion of artificial silk planting machinery, it is difficult to enjoy superiority, and it takes a long time to improve skills and competition levels and promote development. , easy-to-make effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The present invention will be described in detail below in conjunction with the accompanying drawings.

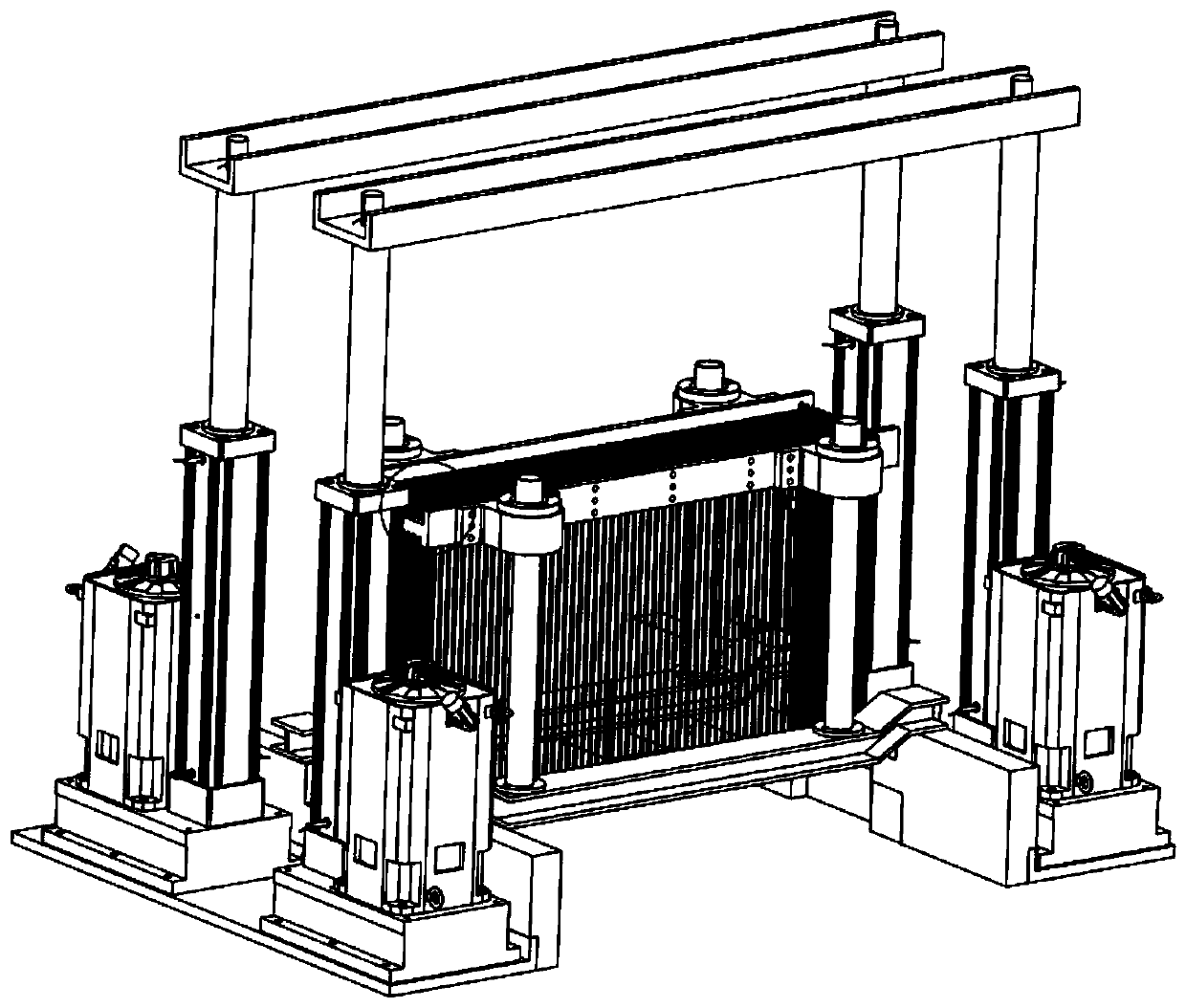

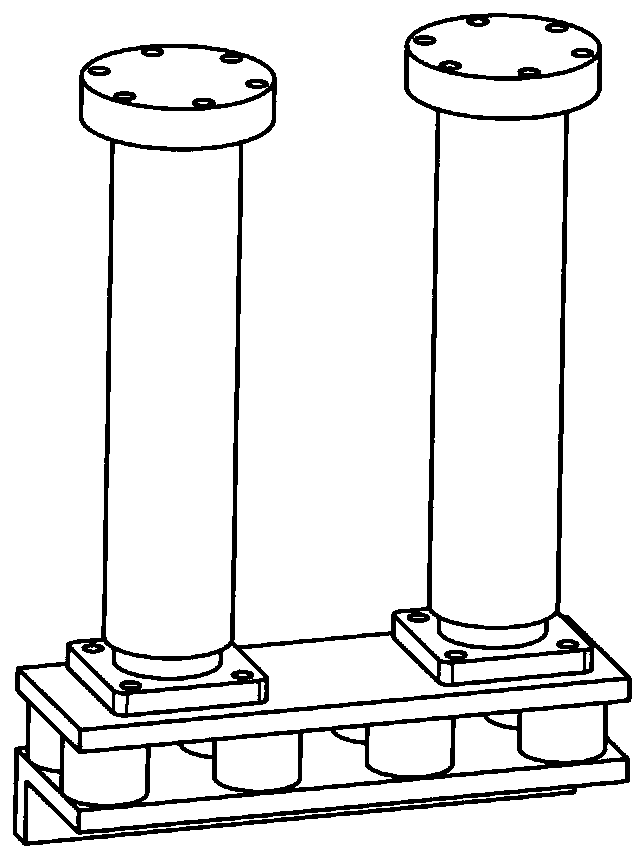

[0076] A silk-planting needle mechanism of a lawn artificial silk-planting machine,

[0077] Each silk-planting cycle of the silk-planting machine plants a rectangular lawn with front and rear n rows and horizontal m-column clusters,

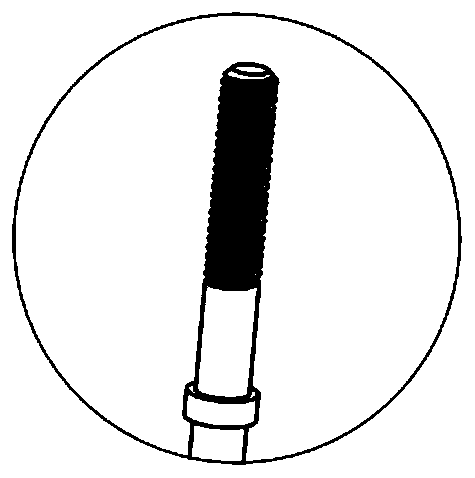

[0078] The silk planting machine is pulled out from the m bundles of fiber spindles 1 in the feeding area, sent horizontally to the other side to be fixed, and then pressed down by n rows of m columns of wire pressing tubes 7 row by row to bend the fiber filaments 6 into After the u-shape, cut off at a certain position and enter the vibration pressing program of the silk-planting needles; n rows of silk-planting needles 8 are a whole section, or divided into two or more sections before and after and moved downward synchronously; the whole section here , or divided into two or more segments before and after are collectively referred to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com