Improved triangular piston rotating type compression-expansion machine

A rotary compression and improved technology, applied in rotary piston engines, rotary or oscillating piston engines, mechanical equipment, etc., can solve problems such as poor sealing performance, consumption of lubricating oil, cylinder piston wear, etc., to reduce difficulty and cost, The effect of reducing friction loss and improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

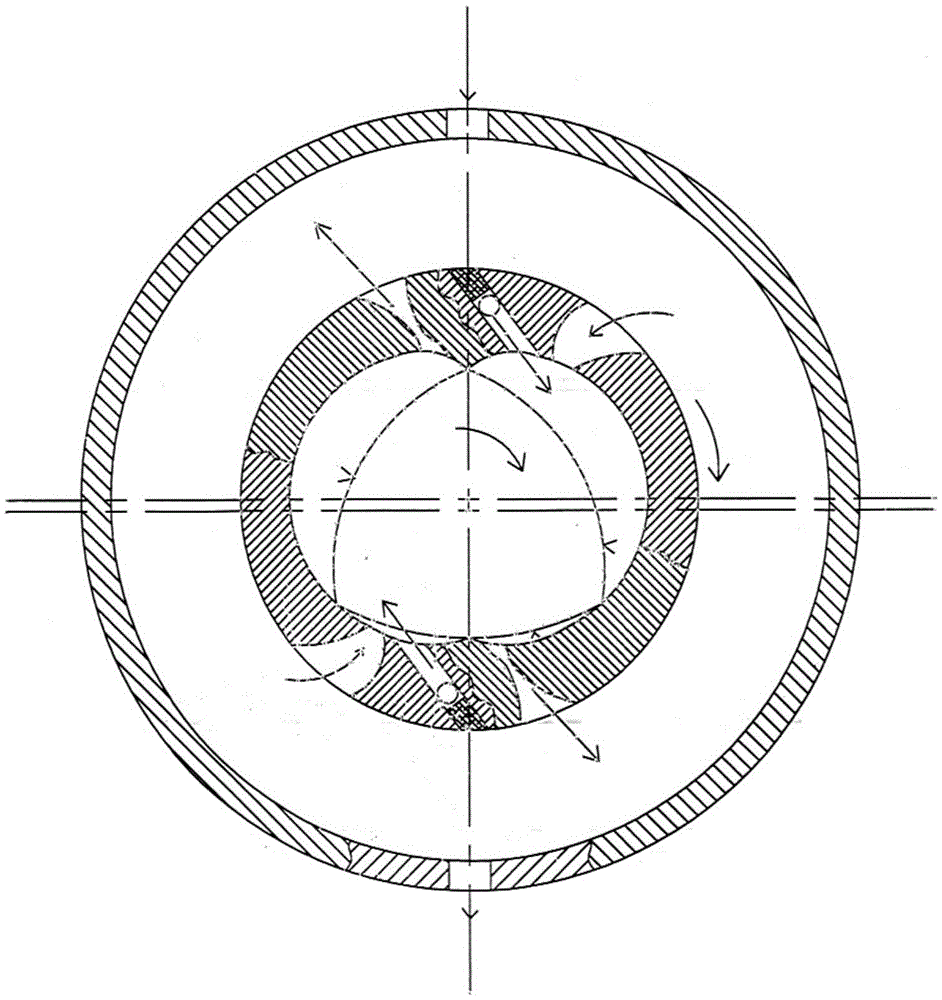

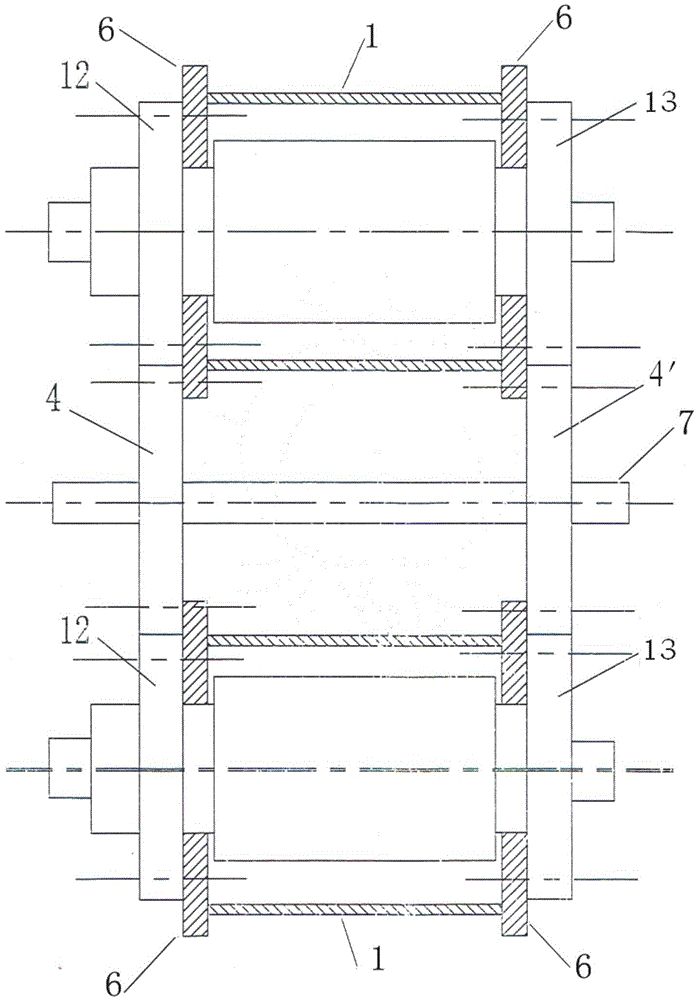

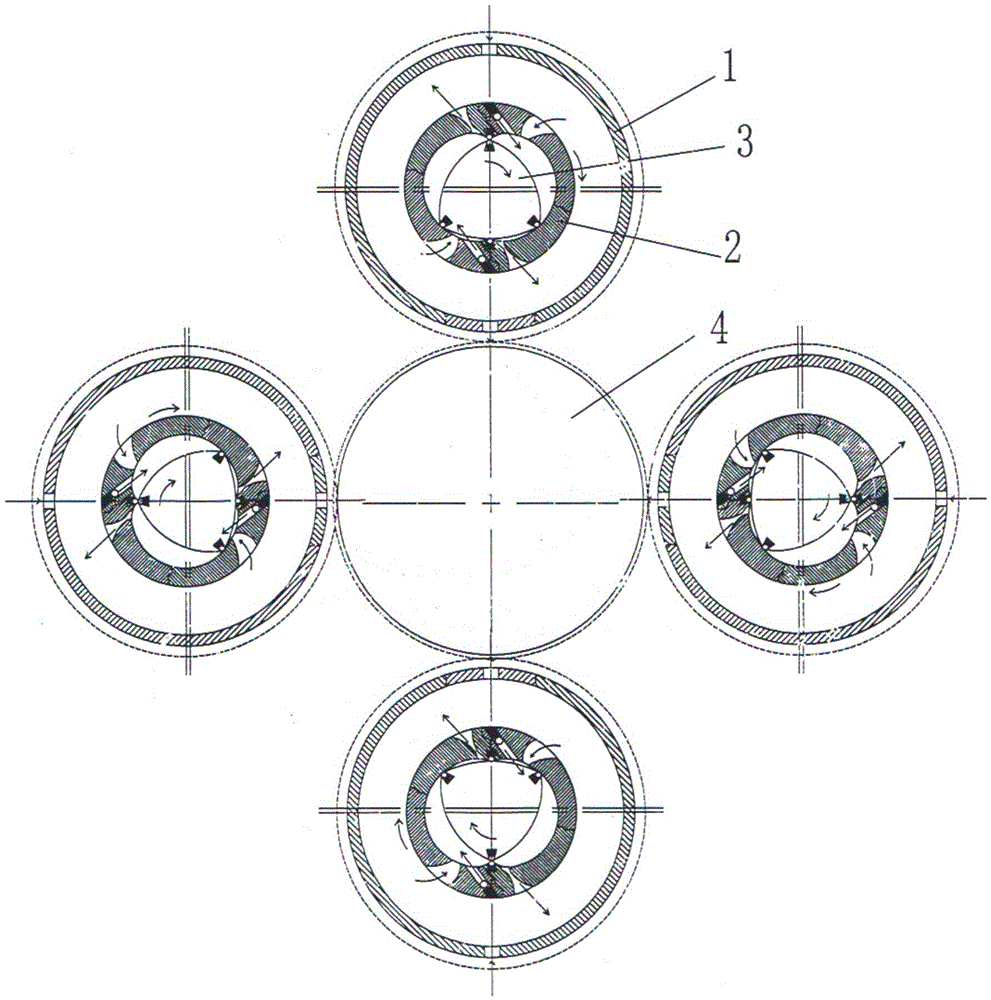

Embodiment 1

[0033] An improved triangular piston rotary compression expander, including power gears and four single-cylinder units, such as figure 2 , image 3 As shown, the four single-cylinder units are evenly arranged outside the power gear. The single-cylinder unit includes a sleeve, an outer rotor and an inner rotor located in the sleeve. There is a cavity inside the outer rotor, and two centrally symmetrical The inner wall of the cavity between the two convex ribs is a concave inner wall, the inner rotor is located in the cavity, and the outer wall of the inner rotor is provided with three raised edges, and the arc side is between two adjacent edges. In order to reduce the defects of sliding contact between the inner rotor and the outer rotor in the prior art, dovetail grooves are arranged on the edges, and elastic rolling components are arranged in the dovetail grooves. The notch width of the dovetail groove is smaller than the width of the bottom of the groove. The elastic rolli...

Embodiment 2

[0041] An improved triangular piston rotary compression expander, its structure is as described in Embodiment 1, the difference is that two ribs of the outer rotor are provided with dovetail grooves along the ribs, and elastic rolling components are arranged in the dovetail grooves. There are also elastic rolling assemblies on the two ribs on the inner wall of the outer rotor cavity, so that the ribs form rolling contact with the edges and the arc-shaped side wall of the inner rotor, and the edges form elastic rolling contact with the ribs and the concave inner wall of the outer rotor. , to further enhance the effect of rolling contact.

Embodiment 3

[0043] An improved triangular piston rotary compression expander, the structure of which is as described in Embodiment 1, the difference is that an elastic sealing ring is provided between the inner rotor, the outer rotor and the two end faces of the elastic rolling assembly and the outer rotor shaft, which can Apply high-pressure engine oil to the outer sides of the elastic sealing rings at both ends, and the flow direction of the high-pressure engine oil is as follows: Figure 6 indicated by the middle arrow. The sealing performance of the whole machine is enhanced by applying high-pressure oil to the outside of the elastic sealing rings at both ends.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com