Optical cable laid in sewer line and laying method thereof

An optical cable and pipeline technology, which is applied to the optical cable laid in the sewer pipeline and the laying field thereof, can solve the problems of complex installation structure, troublesome construction and laying, increased cost of laying optical cables, etc. Effects of Communication Transmission Characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

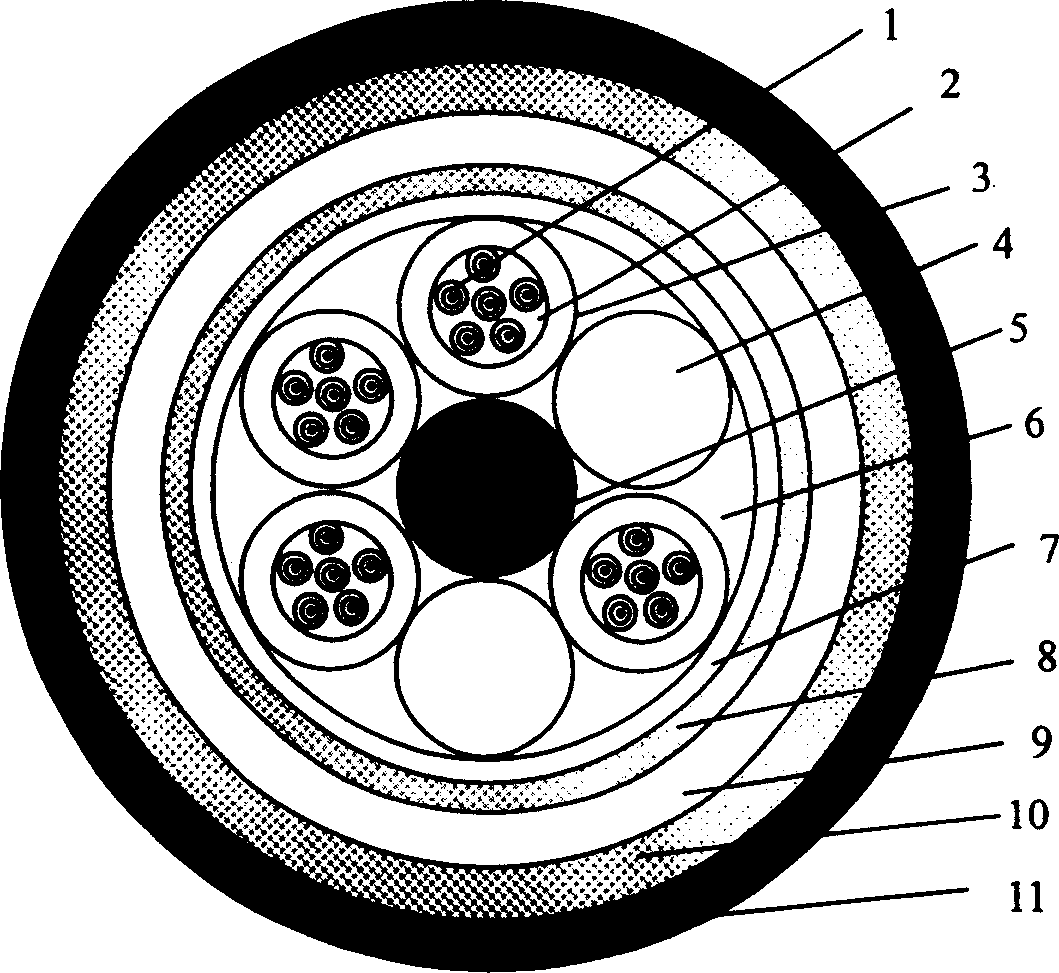

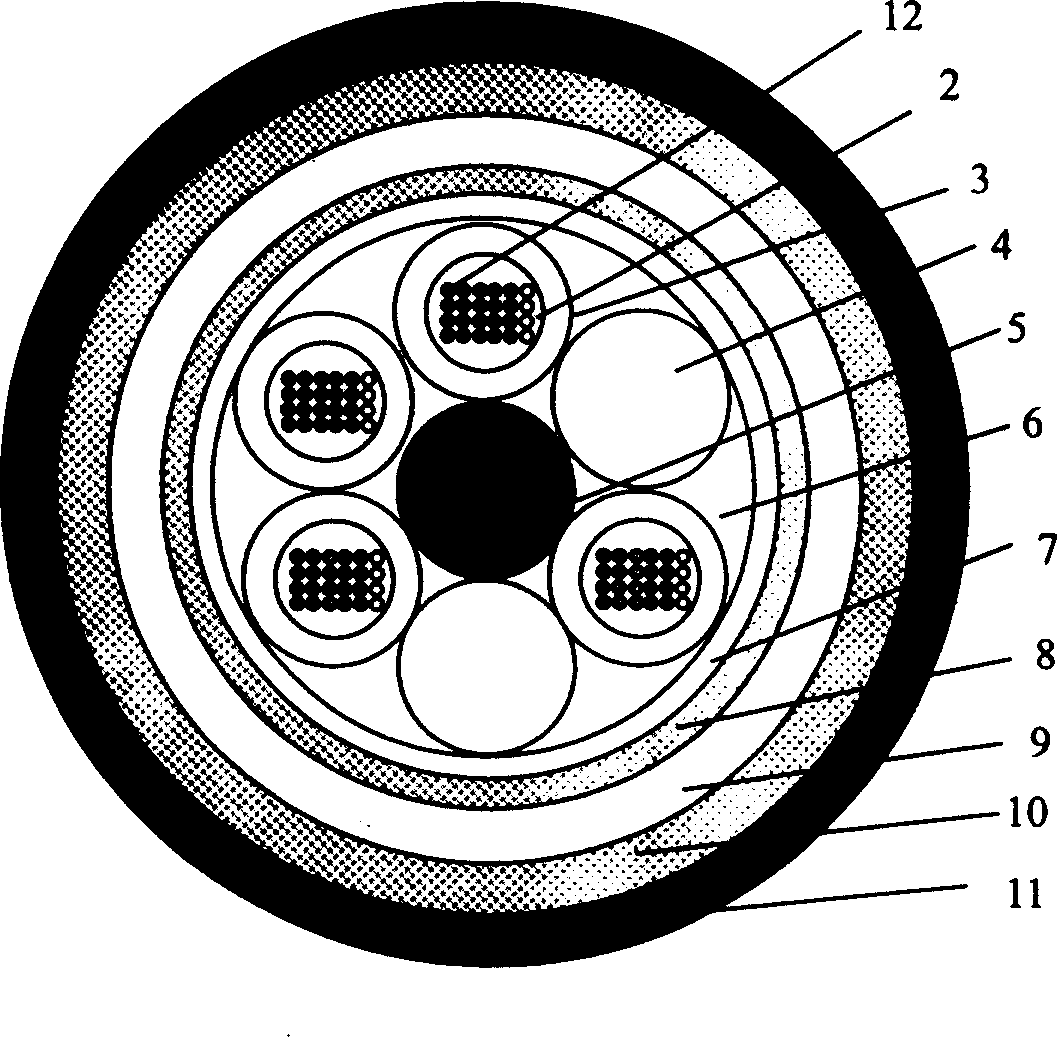

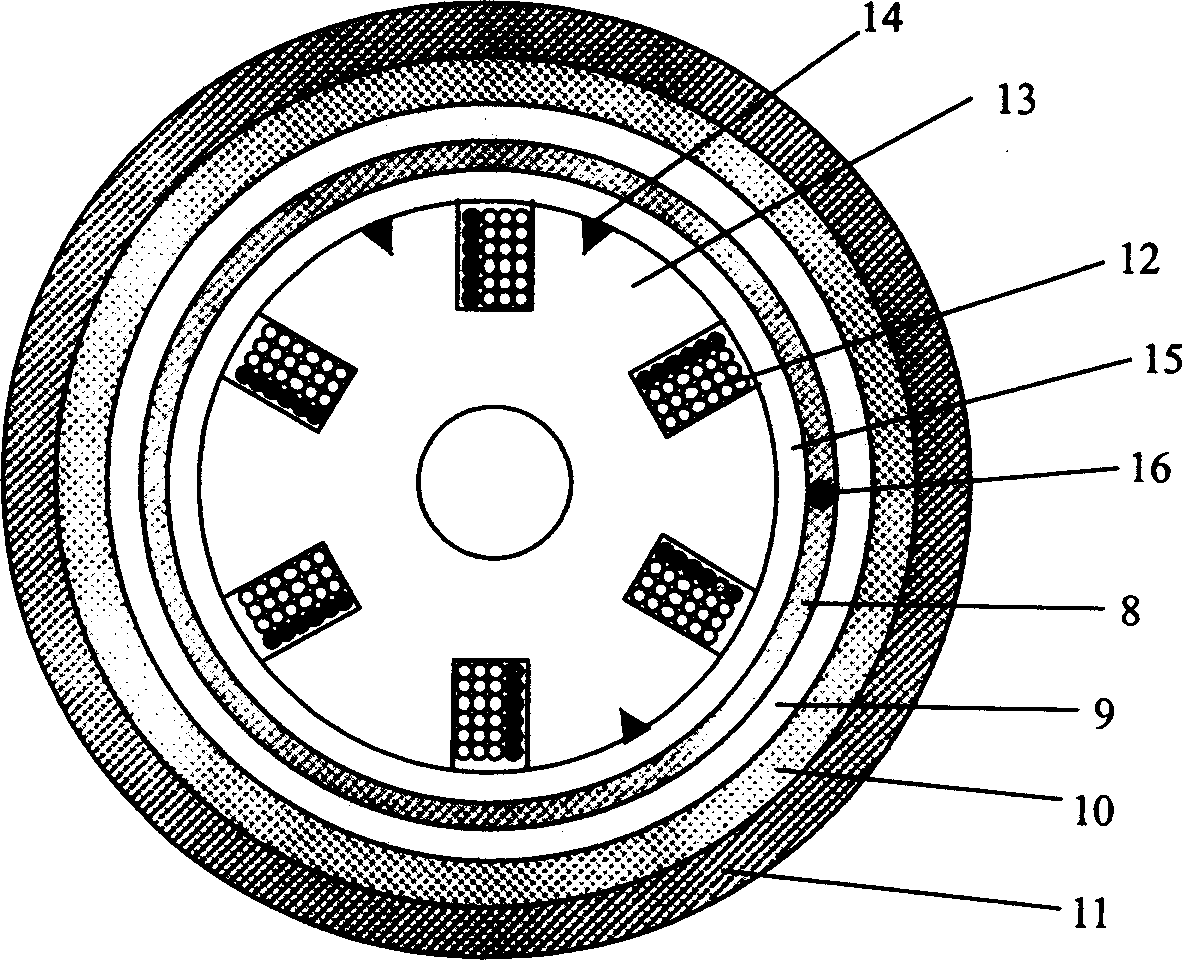

[0023] The structure of the first embodiment of the optical cable of the present invention is as follows: figure 1 As shown, the optical fiber 1 is set in the loose tube 3 and filled with water-blocking fiber paste 2, and multiple loose tubes are twisted around the periphery of the central strength member 5. When the number of loose tubes is insufficient, the corresponding filling rope 4 can be used Instead, the stranded loose tubes are filled with cable paste 6, and the outside is wrapped with cable ties 7 to form a layer-stranded optical cable core, and a metal strip 8 is wrapped around the core, and the metal strip can be an aluminum strip or a steel strip , wrap along the longitudinal direction, wrap the inner sheath 9 outside the metal strip, and set the fiber reinforcement 10 on the periphery of the inner sheath. The fiber reinforcement is made of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com