Medium-voltage fire-proof cable

A fire-resistant cable and medium-voltage technology, which is applied in the direction of insulated cables, cables, circuits, etc., can solve the problems that fire-resistant structures are only applicable and difficult to medium-voltage cables, etc., and achieve small laying space, lighten the burden, and good fire and heat insulation performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

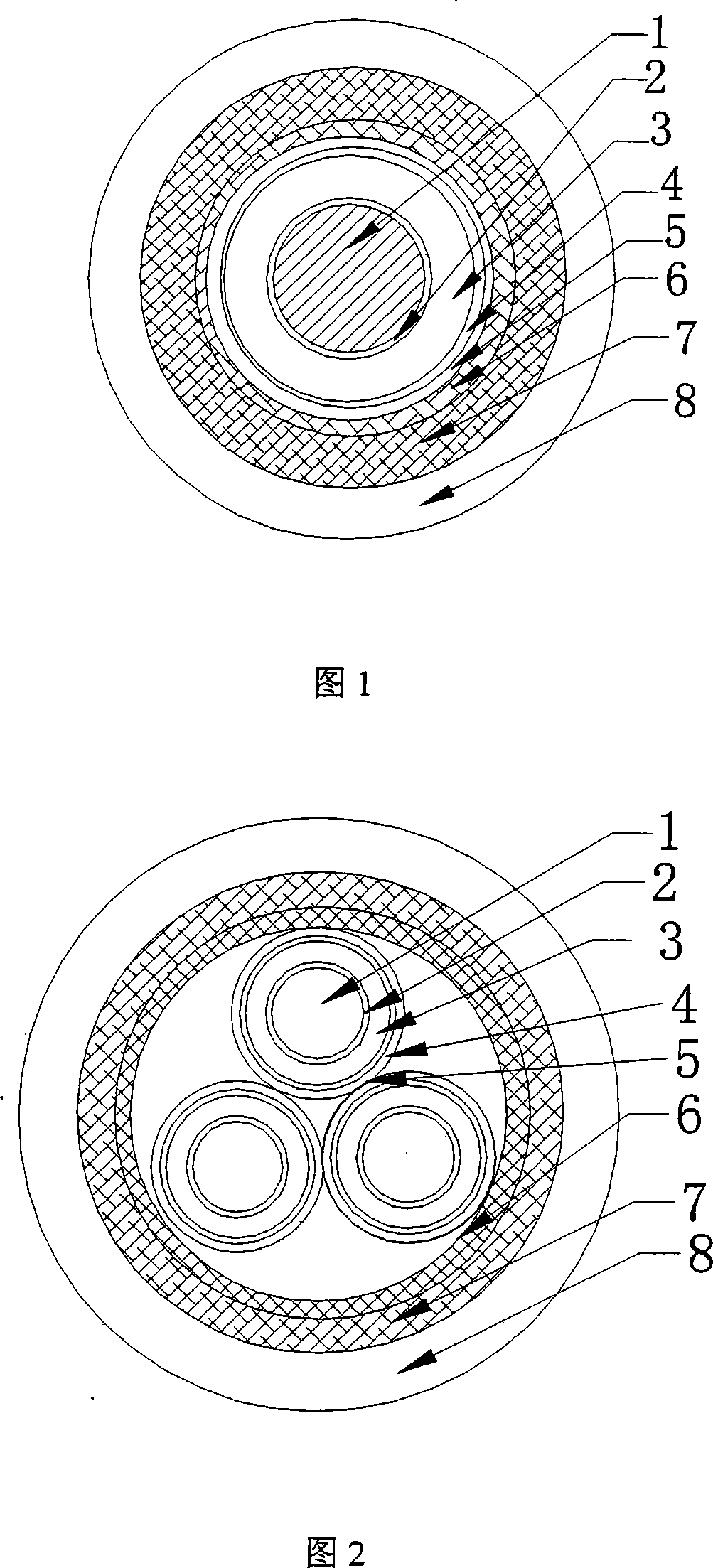

[0031] Embodiment 1: see figure 1 , the medium-voltage single-core fire-resistant cable of the present invention, its structure from the center to the outside is: fine copper wire stranded conductor 1, conductor shield 2, cross-linked polyethylene insulation 3, insulation shielding layer 4, copper tape or copper wire braided shield 5. 2mm thick glass fiber braided wrapping heat insulation layer 6, 3.5mm thick thermosetting elastomer fireproof heat insulation layer 7, outer sheath 8.

[0032] Among them, the thermosetting elastomer fire-resistant and heat-insulating layer is composed of 30wt% silicone rubber, 25wt% talcum powder, 30wt% white carbon black, 8wt% boron-containing 500°C medium and low temperature frit, and 7wt% peroxide vulcanizing agent. The rubber material is extruded and wrapped outside the wrapped heat insulation layer 6 by a rubber extruder, and finally formed by vulcanization.

Embodiment 2

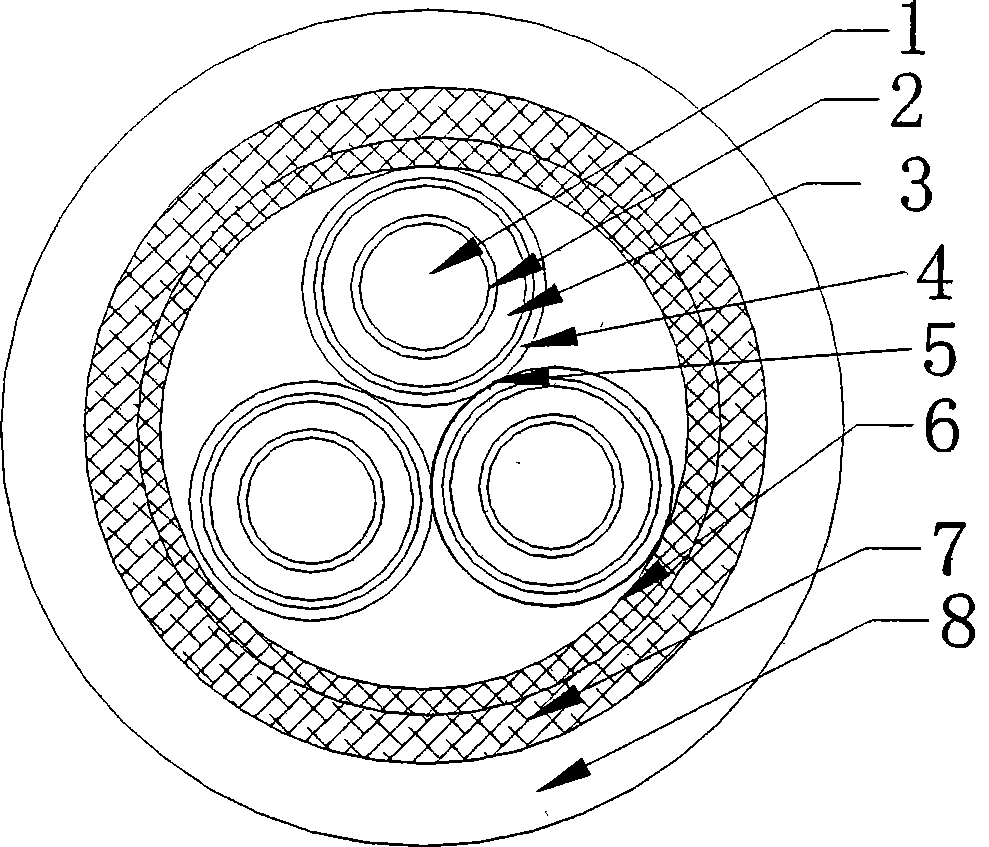

[0033] Example 2: see figure 2 , as in Example 1, wherein the cable core is composed of three insulated wire cores of medium-voltage structure twisted, the heat insulation layer 6 is made of glass fiber tape and asbestos laminated and wrapped to a thickness of 1.5mm, and the extruded thermosetting elastomer is fire-resistant and heat-insulated The thickness of the layer is 3mm, and the composition is: 38wt% silicone rubber, 45wt% clay filler, 10wt% medium and low temperature frit, 7wt% peroxide vulcanizing agent.

Embodiment 3

[0034] Embodiment 3: As mentioned above, wherein the thermal insulation layer 6 is composed of basalt fiber tape wrapping, and the thermosetting elastomer refractory thermal insulation layer is composed of: 45wt% silicone rubber, 40wt% white carbon black filler, 10wt% medium and low temperature frit, 5 wt% platinum chloride compound.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com