Top protection structure applied to wind power tower drums after hoisting two vertical sections and paving method thereof

A technology for wind power towers and protective structures, which is used in wind power generation, mechanical equipment, wind turbines, etc. It can avoid the corrosion and damage of salt spray, the laying construction is simple, and the protection effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific examples.

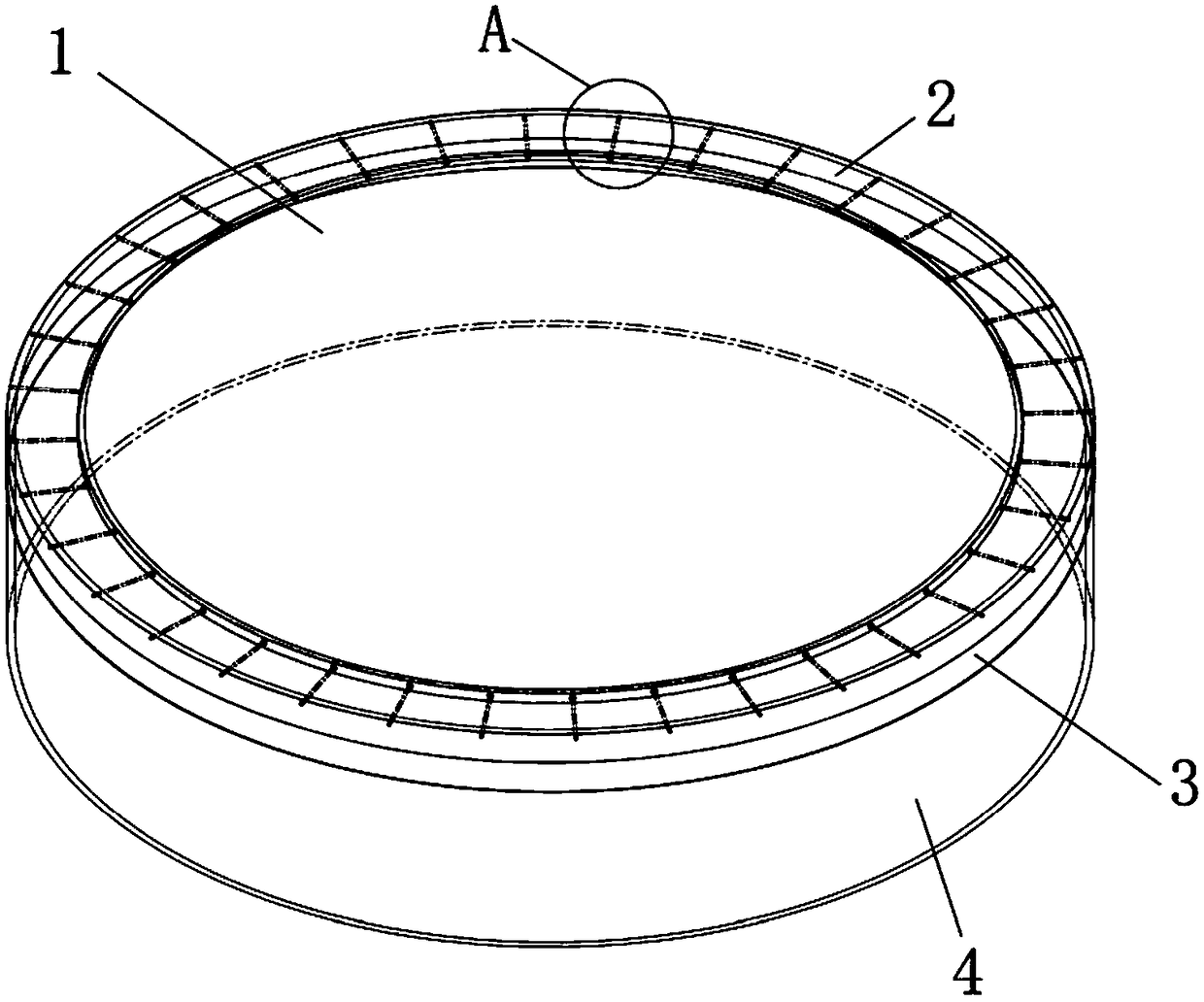

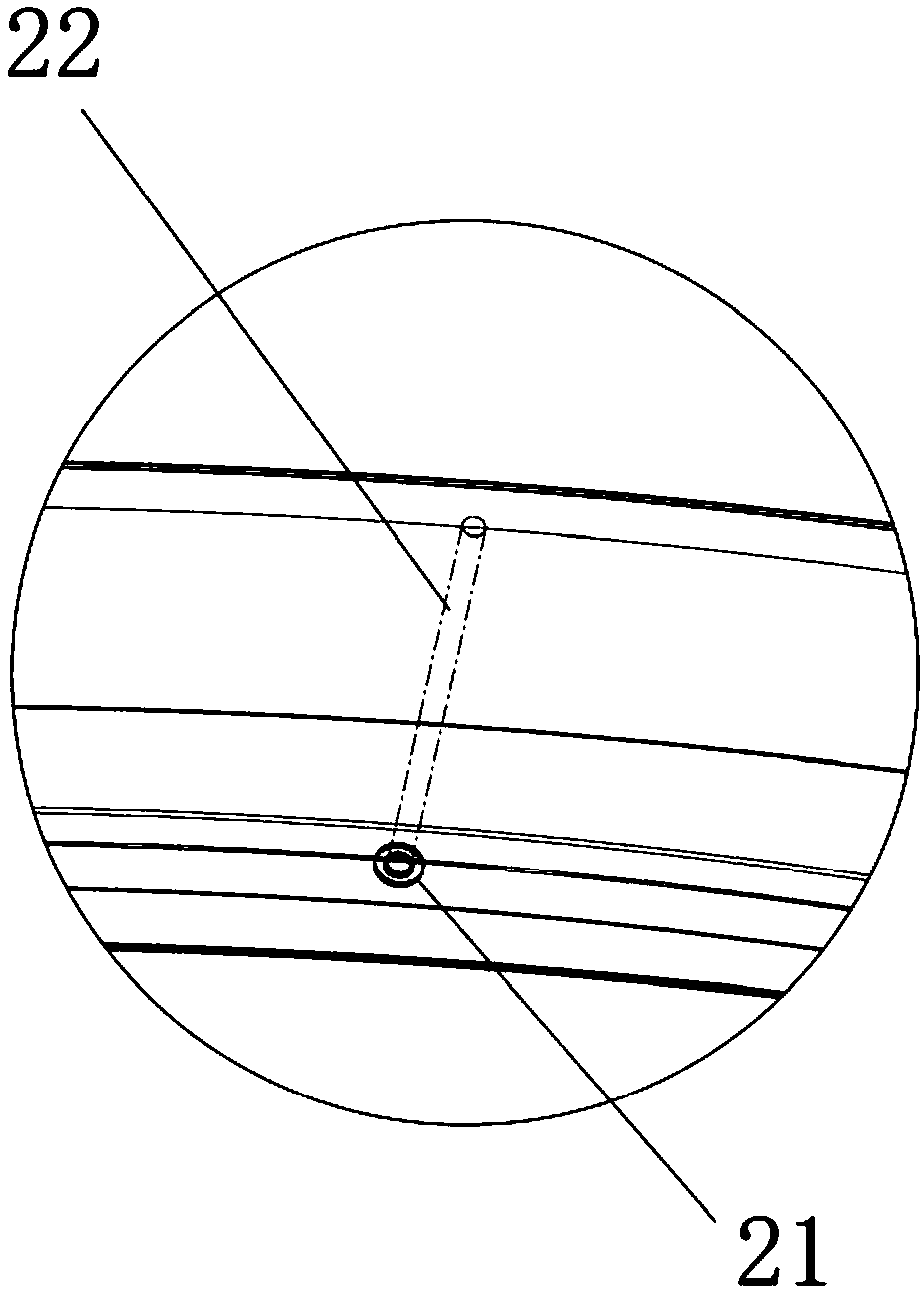

[0027] The top protection structure provided by this embodiment after the wind power tower is hoisted and erected in two sections can be effectively used in offshore wind power installation projects and land installation wind power projects in the top protection protection after the wind turbine tower is hoisted and erected in two sections, and is suitable for 1.5MW-6.0MW and other offshore and onshore high-power wind turbines (with different tower diameters) are used for top protection after hoisting and erecting two tower sections. Such as Figure 1 to Figure 6 As shown, the top protective structure includes three parts: a rainproof tarpaulin cover 1, a stainless steel awning ring rainproof tarpaulin 2, and a stretched rubber rainproof tarpaulin 3. Wherein, the rainproof tarpaulin cover 1 is made of polyvinyl chloride plastic-coated canvas with a thickness of 1-2mm and a di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com