Patents

Literature

37results about How to "Promote green construction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

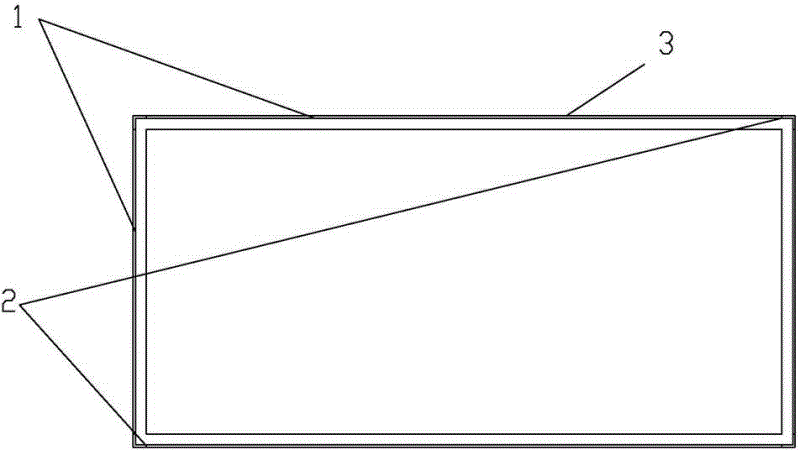

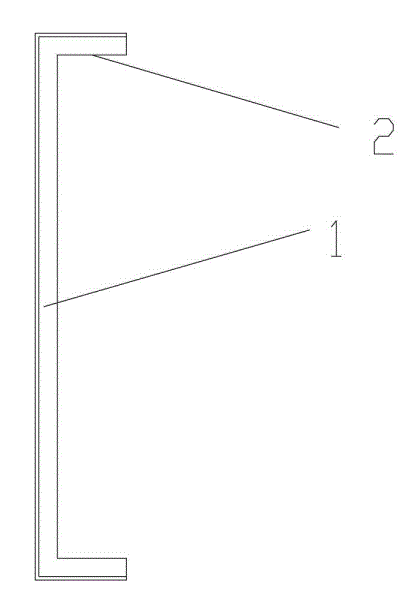

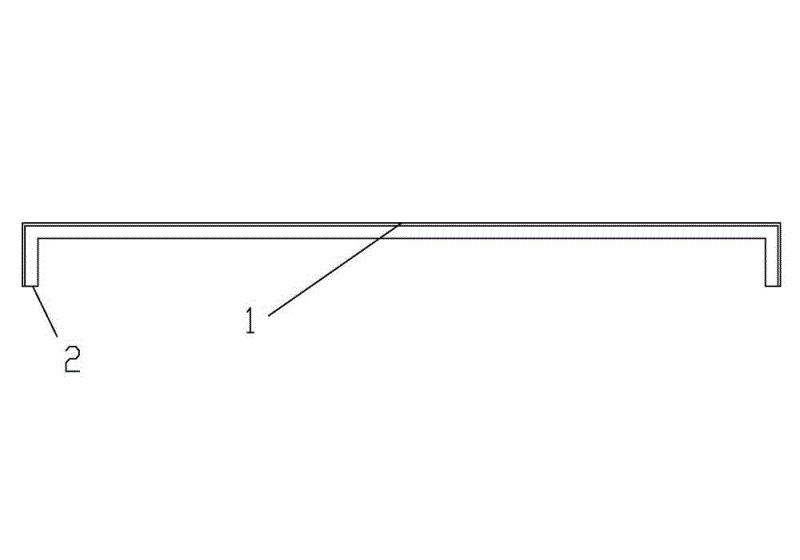

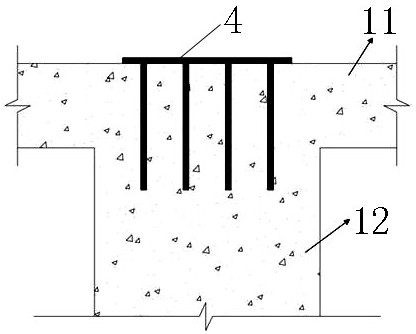

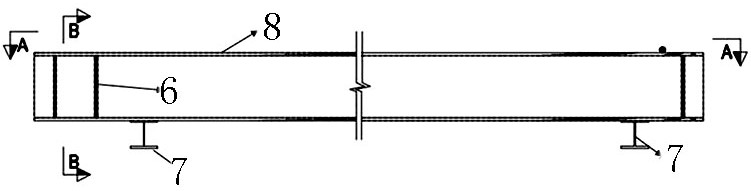

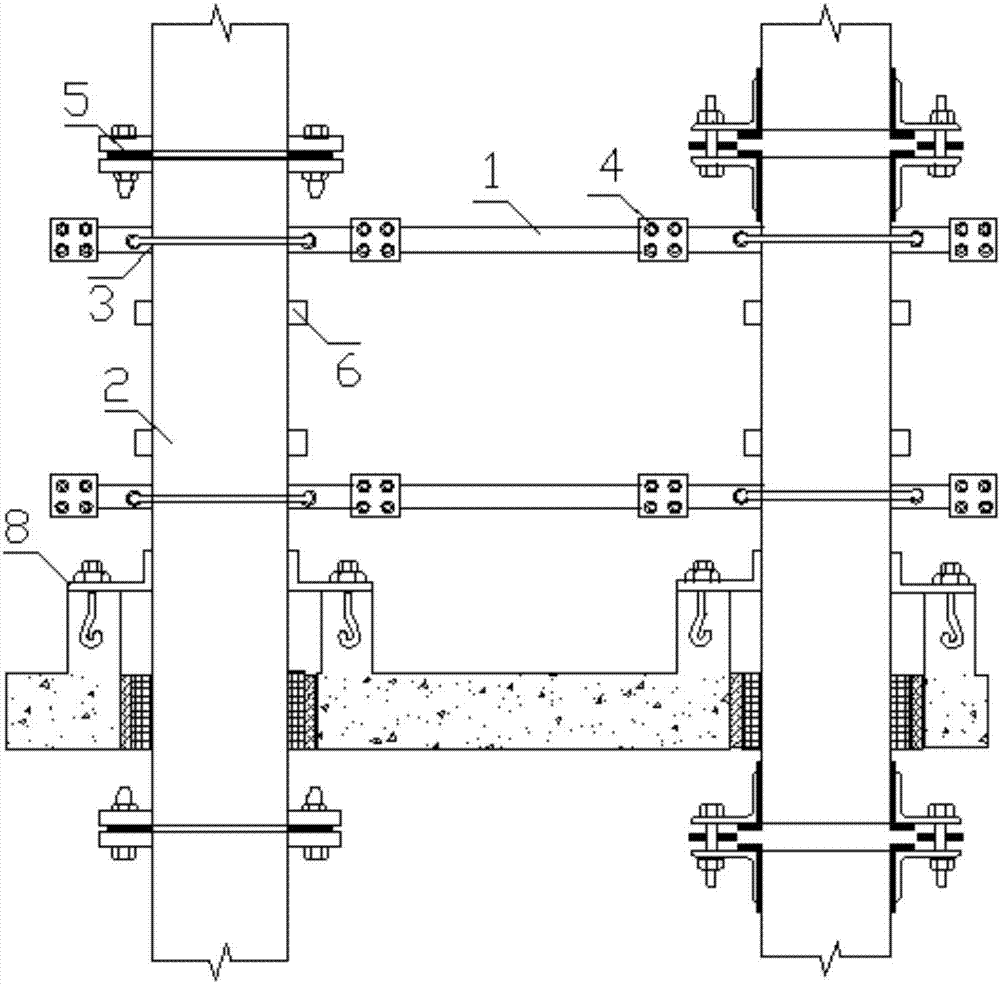

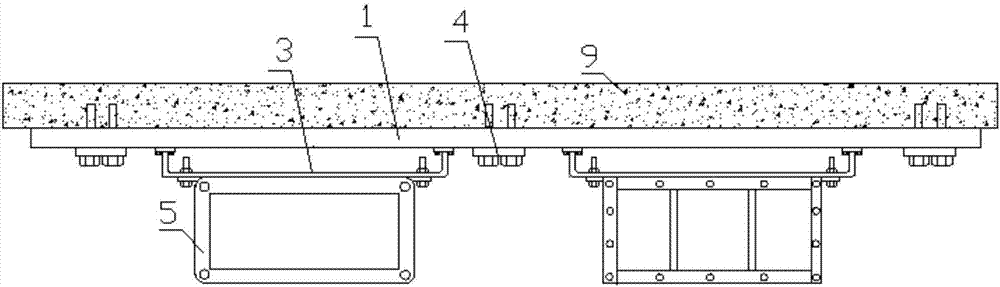

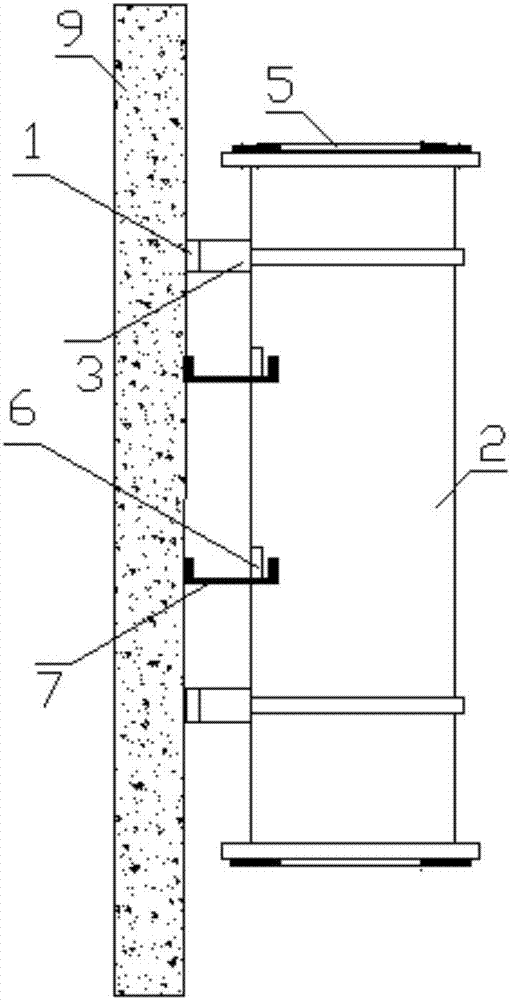

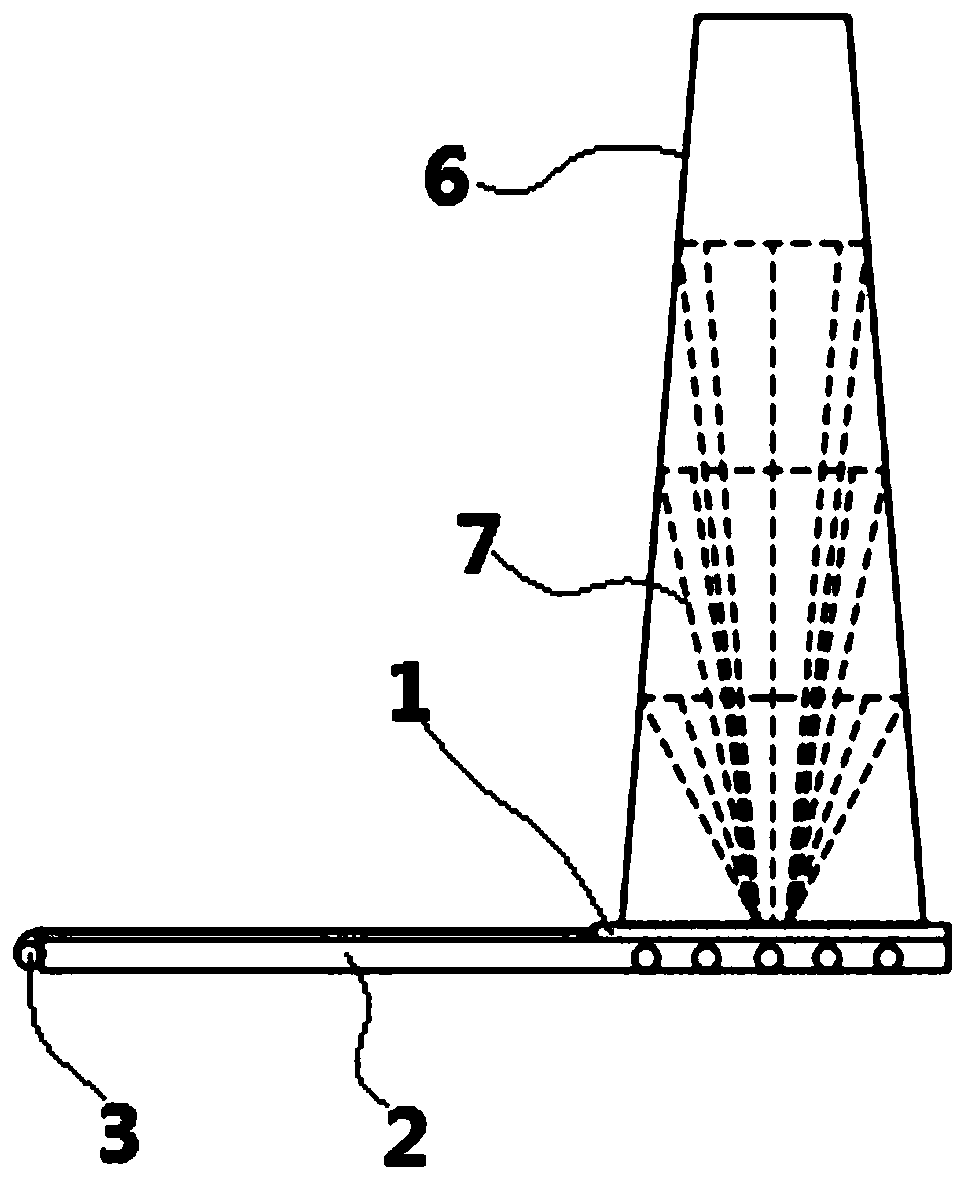

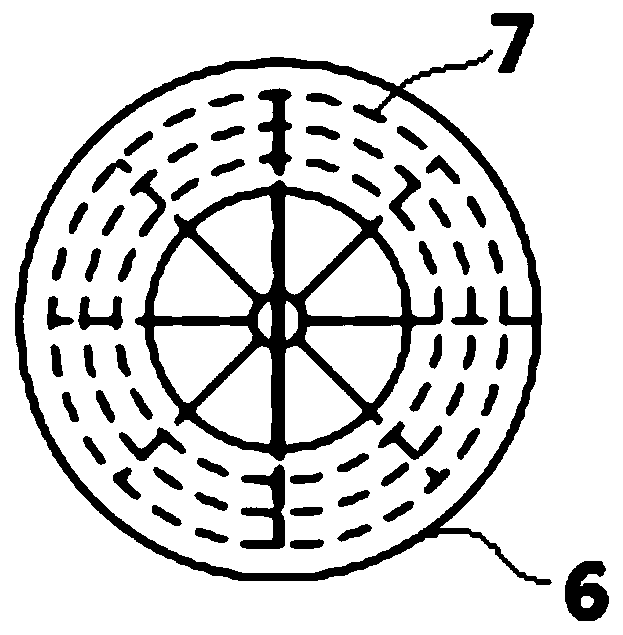

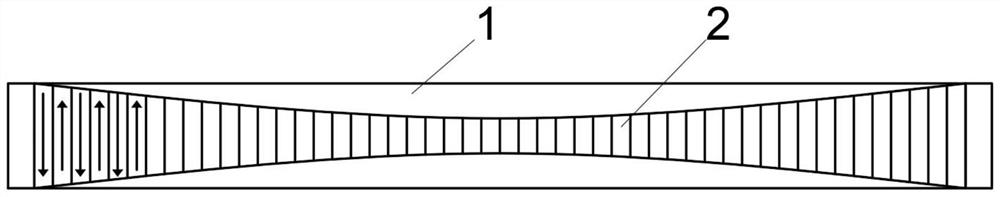

Split mounting type prefabricated reinforced concrete construction temporary road

InactiveCN102619152AAvoid being vulnerable to damageReduce construction wasteTemporary pavingsRebarReinforced concrete

The invention discloses a split mounting type prefabricated reinforced concrete construction temporary road, which comprises a box type member, wherein a reinforced concrete box type member is arranged in the box type member; reinforcement of the reinforced concrete box type member is welded and fixed to the box type member; four angular points of the reinforced concrete box type member are provided with omega-shaped lifting rings respectively; and water discharge holes are also formed at the omega-shaped lifting rings. The split mounting type prefabricated reinforced concrete construction temporary road has the beneficial effects that: through development of the split mounting type prefabricated reinforced concrete construction temporary road, a reinforcement welding net, angle steel and concrete are formed into a whole, so that the performances of the steel and the concrete are fully utilized, particularly, the periphery of the construction temporary road is protected by using the angle steel, and the unavailability due to corner stripping caused by collision or other reasons during use of the construction temporary road is avoided; and a temporary road module is manufactured by using a shaped steel mould, and meanwhile, a special formwork and a strengthening system are matched, so that the construction quality of the corner part and the entire temporary road is effectively guaranteed.

Owner:ZHONGTIAN CONSTR GROUP

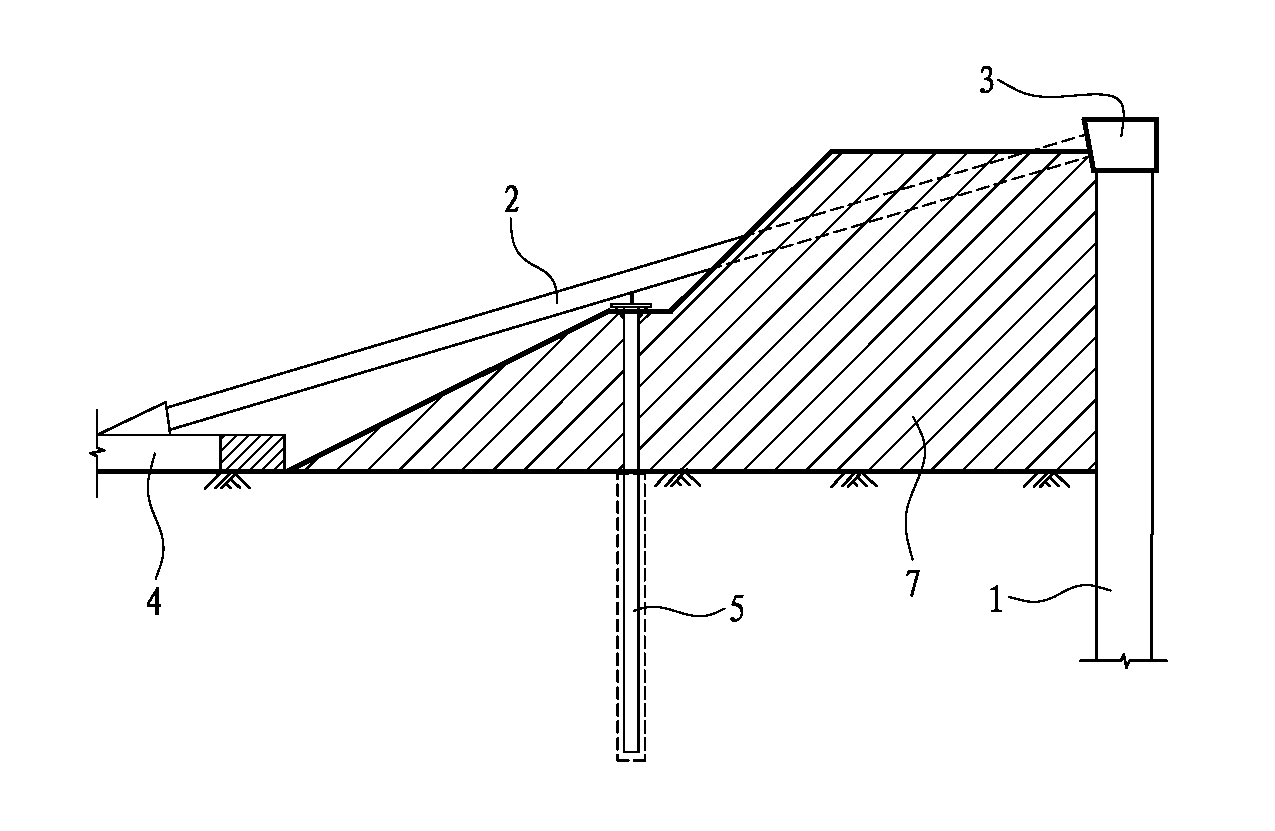

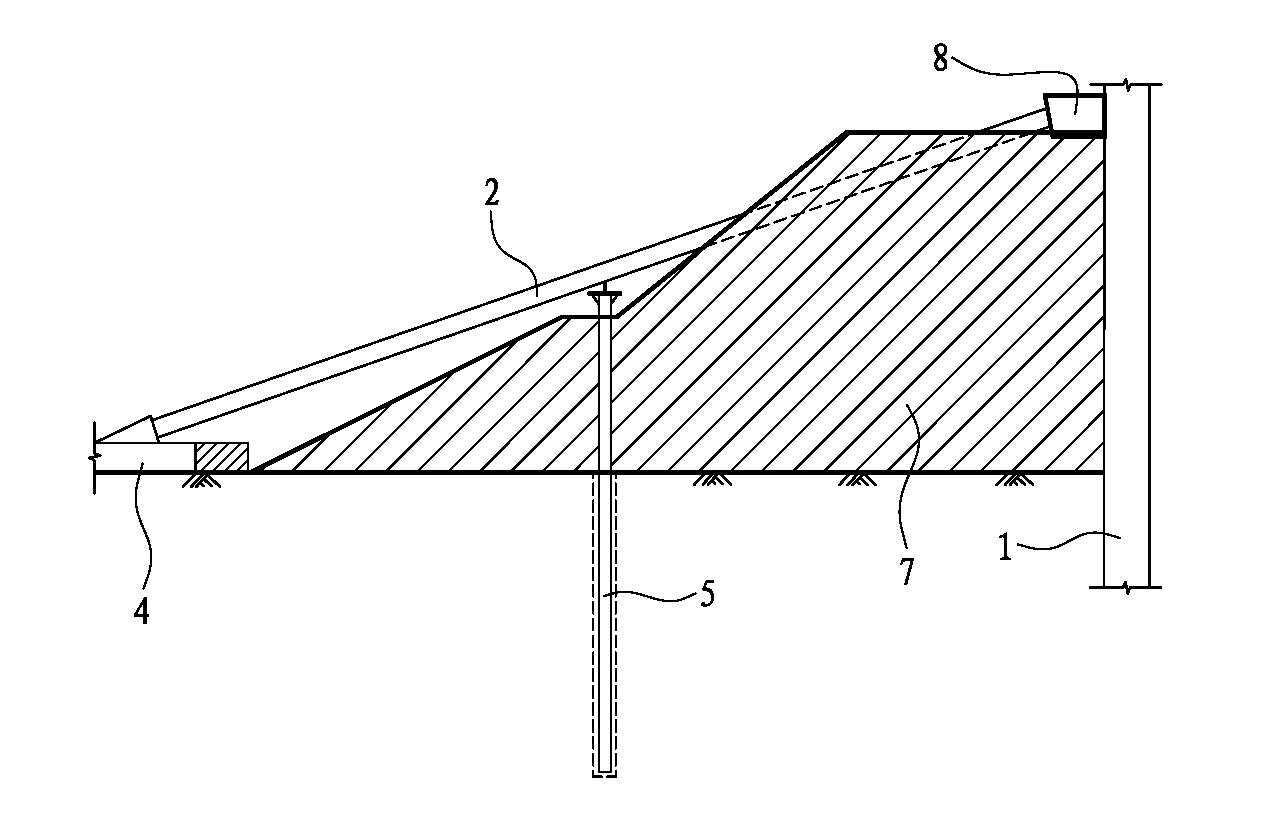

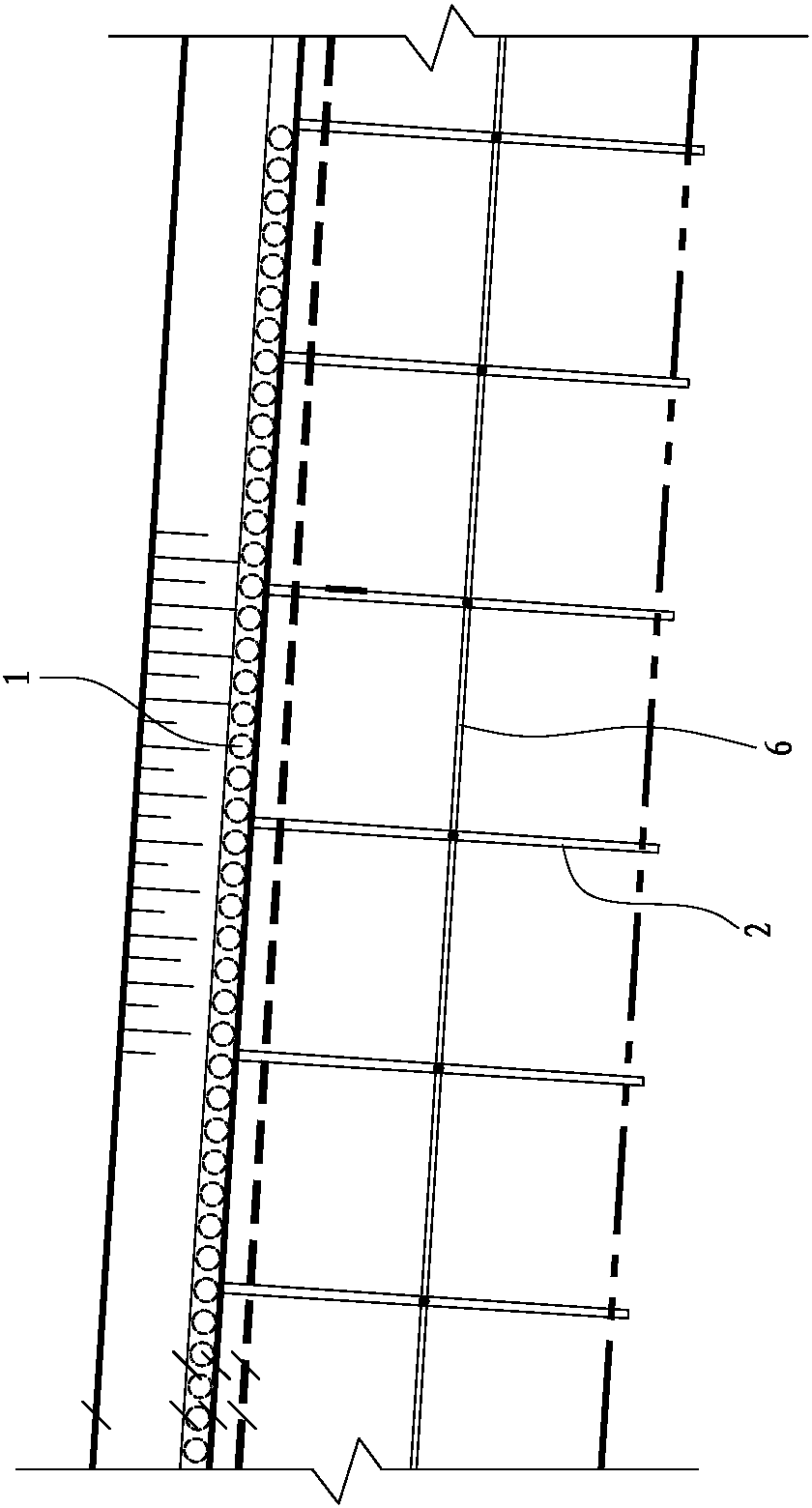

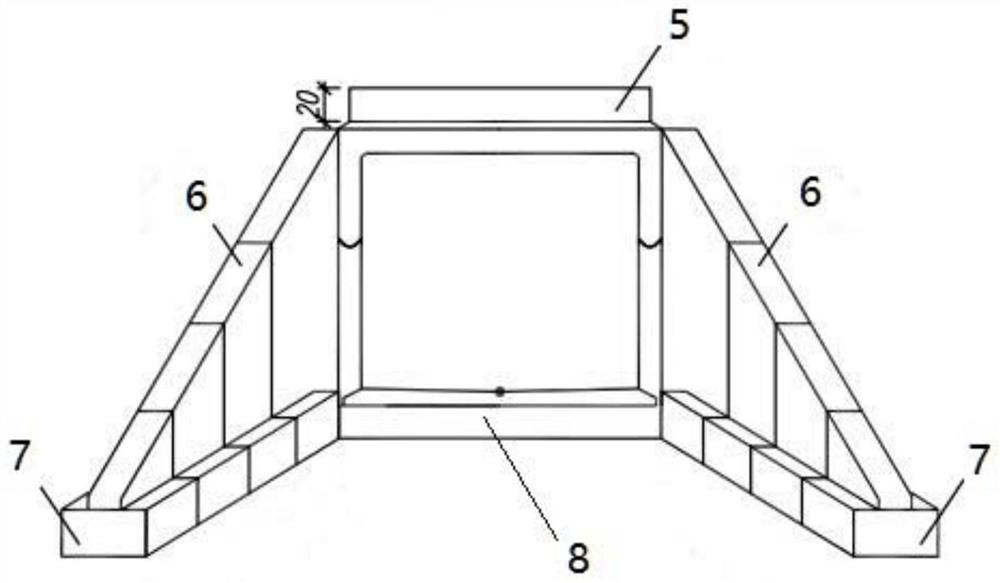

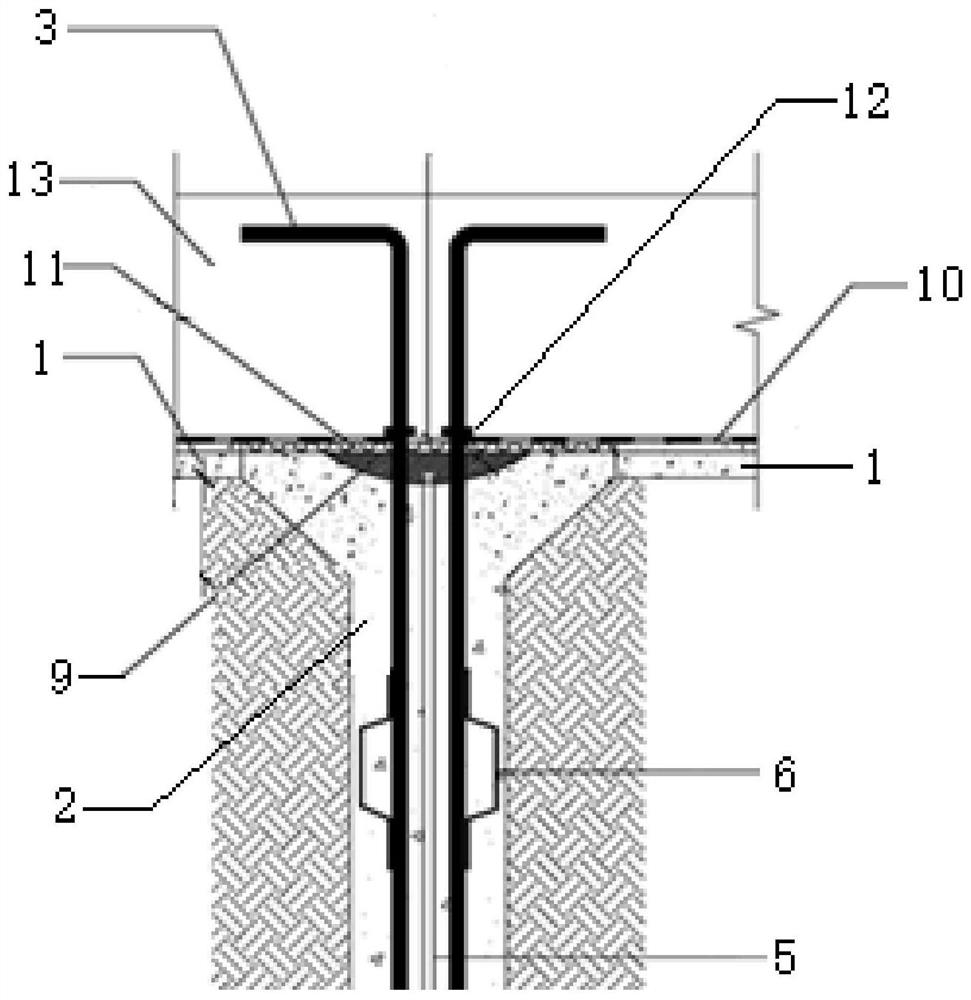

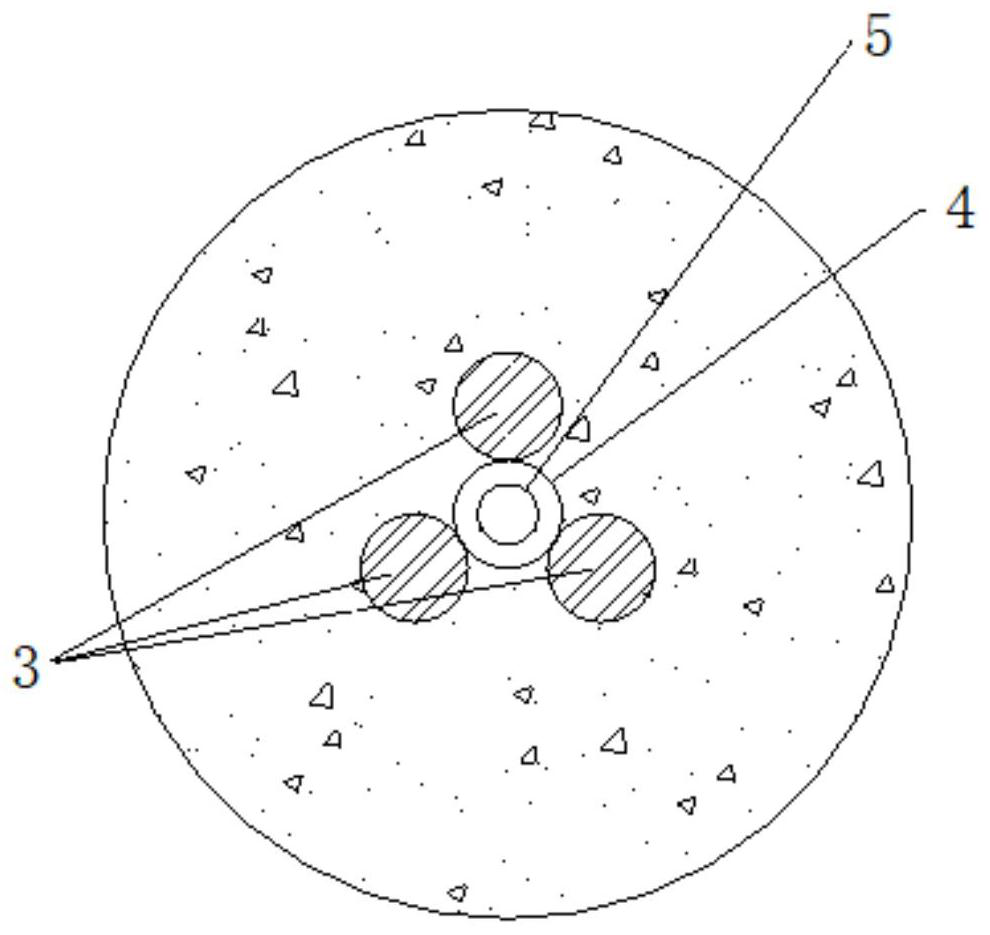

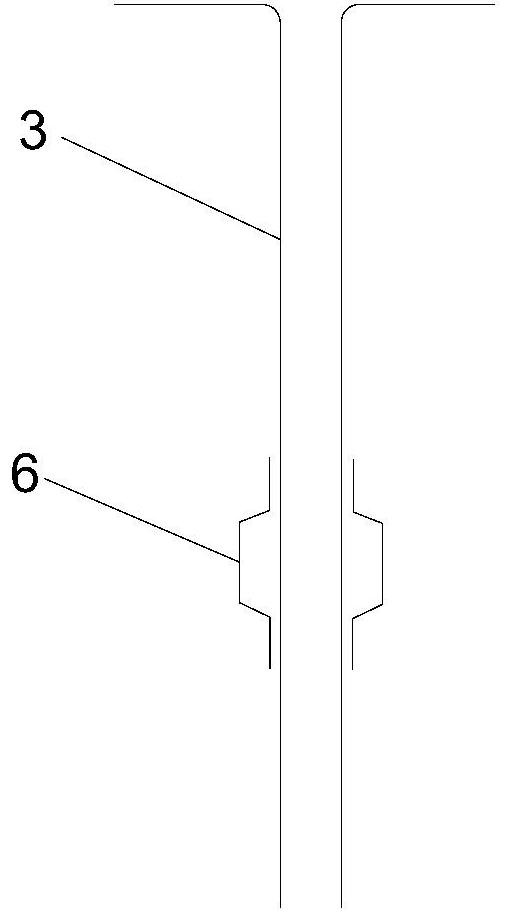

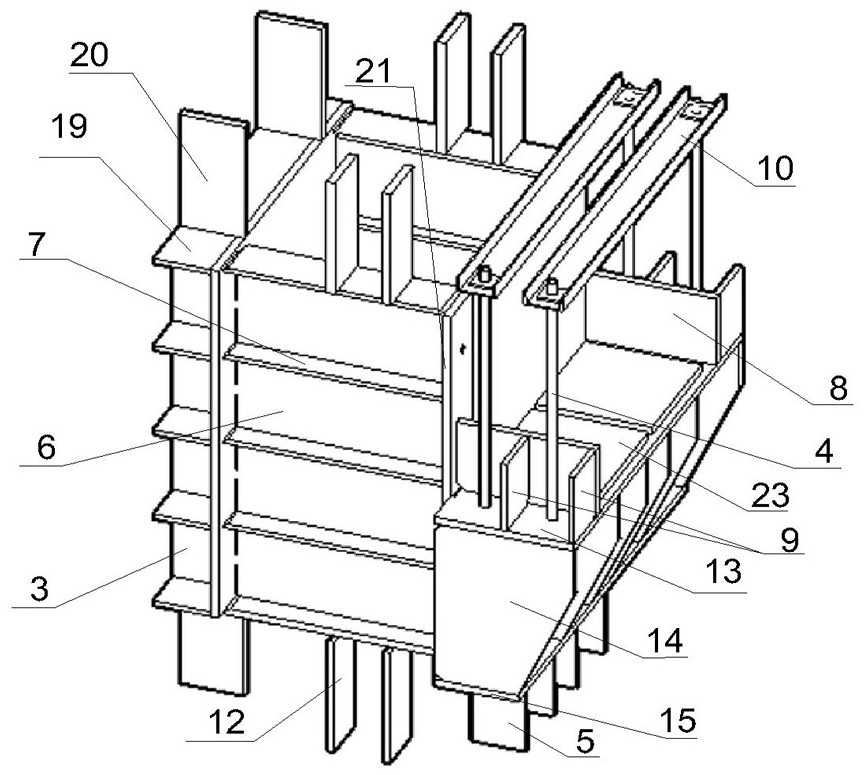

Inner oblique beam supporting structure for oversized-area deep foundation pit and construction method

The invention discloses an inner obliquely beam supporting structure for an oversized-area deep foundation pit. The inner oblique beam supporting structure comprises a pouring pile and an inner oblique beam, wherein the pouring pile is arranged at the edge of the foundation pit, the upper end of the inner oblique beam is fixedly connected with a top beam or a waist beam arranged on the pouring pile, and the lower end of the inner oblique beam is fixedly connected with a basement base board. The invention further discloses a construction method for the supporting structure. The construction method comprises the following steps of constructing a fender post, constructing the pouring pile in the fender post, excavating earth in a graded mode to the elevation of a cushion layer of the top beam, constructing the reinforced concrete top beam and maintaining the reinforced concrete top beam to the design strength, excavating earth in a graded mode to the design elevation of the pit bottom except earth outside a reversed stereobate, constructing basement base boards except basement base boards outside the reversed stereobate, constructing a branch oblique beam supporting seat, constructing the inner oblique beam, and excavating and removing the reversed stereobate. A deep foundation pit inner support constructed according to the supporting structure and the construction method is reliable in technique, convenient to operate, obvious in benefit and capable of meeting requirements for energy conservation and environment protection.

Owner:FUJIAN JIULONG CONSTR GRP CO LTD

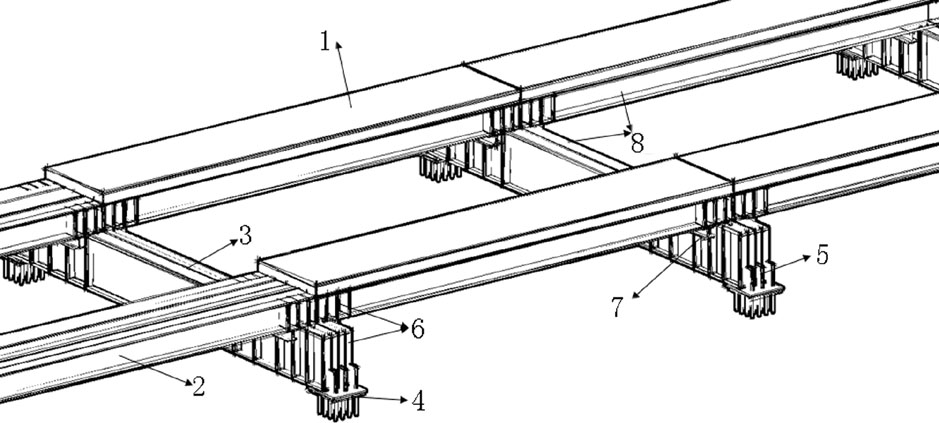

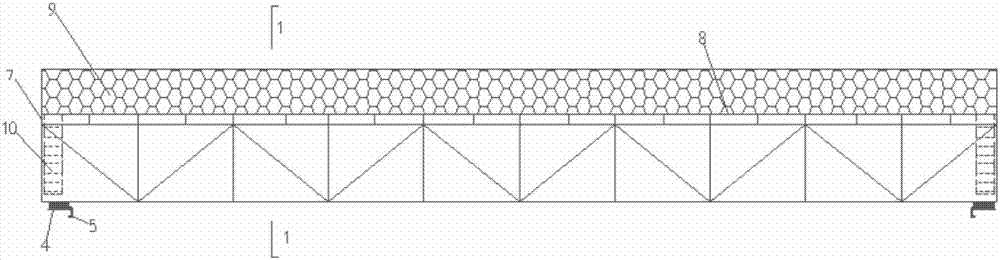

Concrete floor walking trestle device for large crawler crane and mounting method thereof

PendingCN112211085AReduce the amount of hardening measuresSimple structureBridge erection/assemblyTravelling bridgesFloor slabArchitectural engineering

Owner:中冶(上海)钢结构科技有限公司

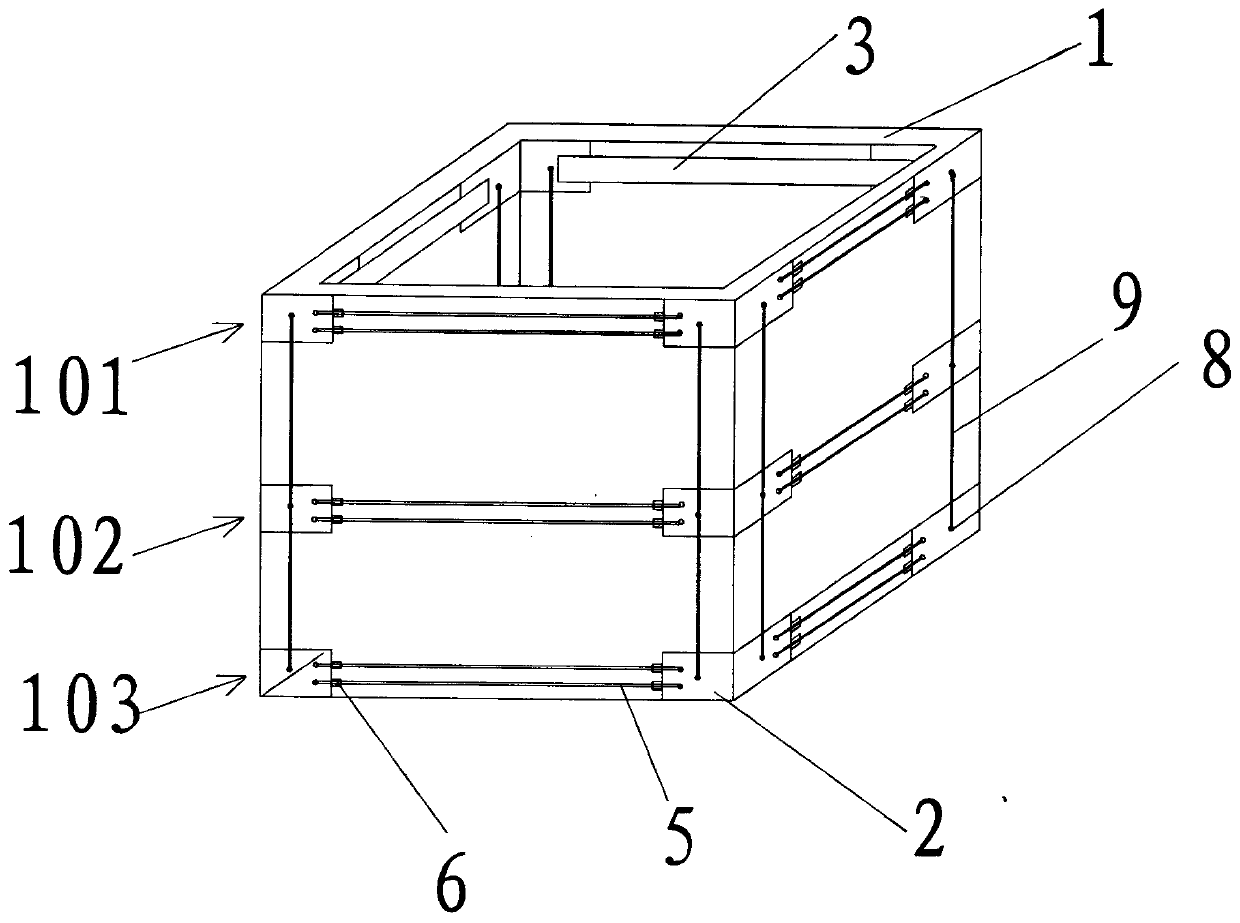

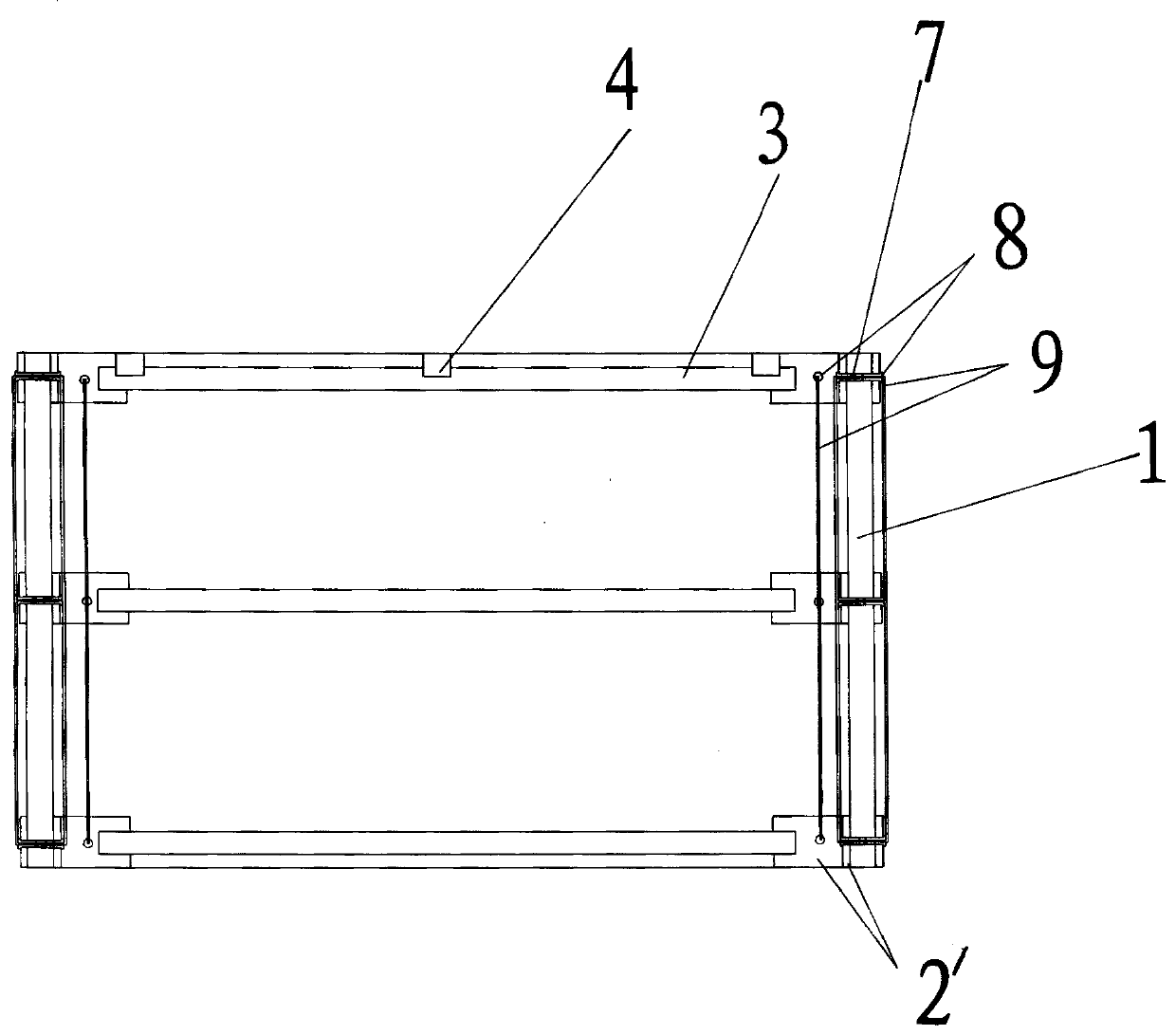

Integrated air duct system and mounting method thereof

InactiveCN107143989AReduce restrictionsEasy to installDucting arrangementsLighting and heating apparatusWaste management

The invention provides an integrated air duct system and a mounting method thereof. The integrated air duct system comprises a plurality of integrated air duct modules, wherein each integrated air duct module comprises a common bracket and a plurality of air duct units; an air duct fixing device and a bracket fixing device are arranged on each common bracket at intervals; the air duct units are fixedly arranged on the corresponding common bracket side by side through the corresponding air duct fixing device; the two ends of each air duct unit are equipped with connecting devices; the common brackets are fixedly arranged on a building structure through the bracket fixing devices; and adjacent integrated air duct modules are connected through a connecting device of the corresponding air duct units. According to the integrated air duct system provided by the invention, the integrated air duct modules can be connected with various air duct units according to needs in a plant to form customizable standard modules, and the customizable standard modules are finally transported to a construction site to subject to integral hoisting and mounting, so that the integrated air duct system is formed.

Owner:SHANGHAI INSTALLATION ENG GRP

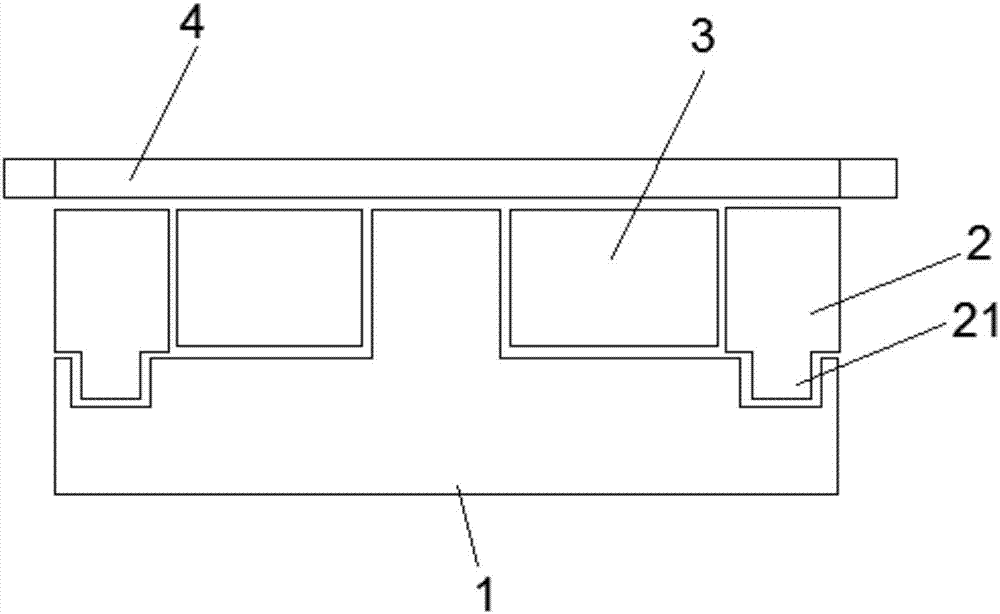

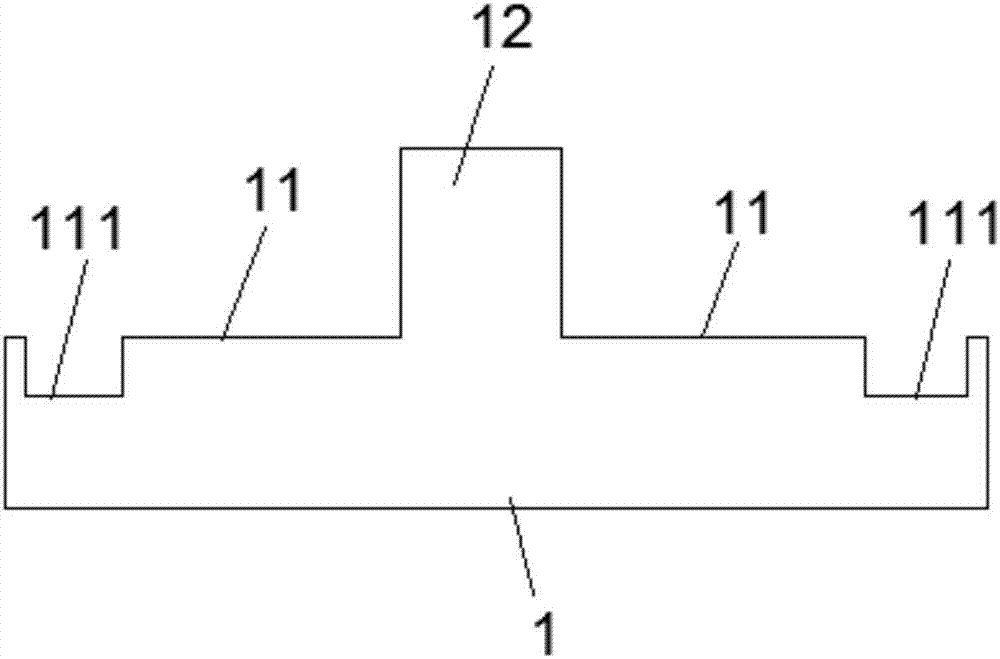

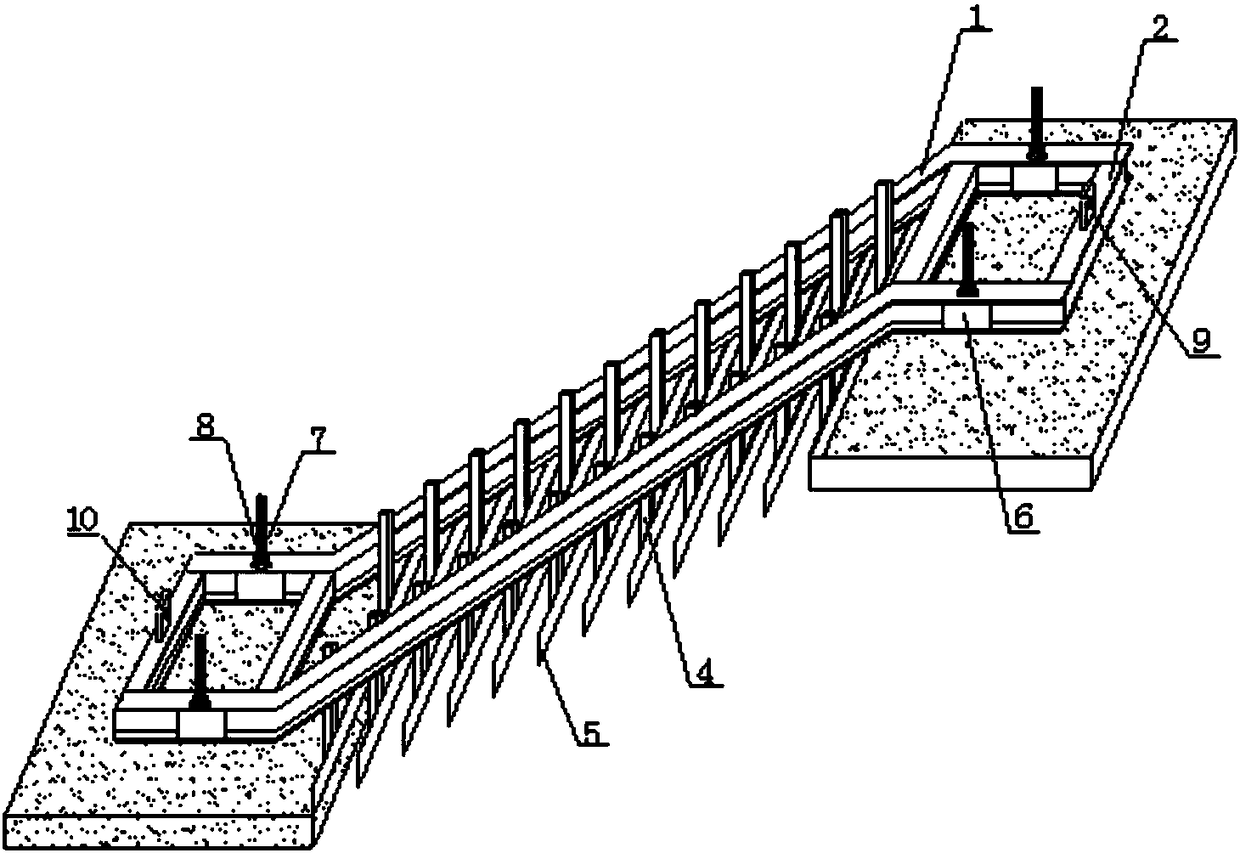

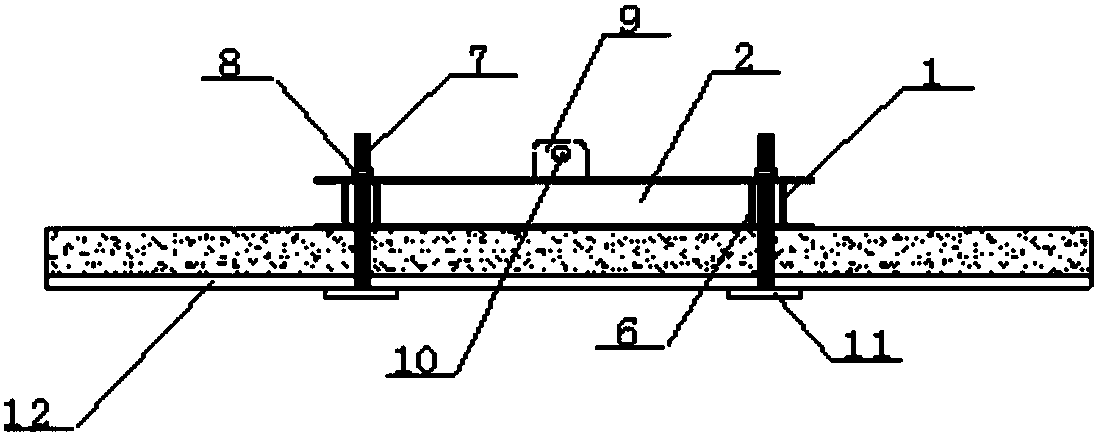

Precast concrete road system and construction method

ActiveCN108004866AEasy to replaceImprove the level of civilized constructionSingle unit pavingsPaving gutters/kerbsRoad surfaceBasic block

The invention discloses a precast concrete road system and a construction method and relates to the technical field of road construction. The road system comprises a basic layer, a curb layer, a filling layer and a pavement layer; the basic layer is paved with concrete precast basic blocks with reversed-T-shaped longitudinal sections; the curb layer is paved with rectangular solid concrete precastcurb blocks; the filling layer is paved with precast filling blocks of a box-shaped structure; and the pavement layer is laid at the top of a structure composed of a vertical layer of the basic layer, the curb layer and the filling layer, and the pavement layer is paved with concrete precast pavement board blocks. By the adoption of the system, the basic layer is paved with the multiple basic blocks in an attached and crossed mode, the curb layer is paved with the multiple curb blocks in an attached and crossed mode, the filling layer is paved with the multiple filling blocks in an attached and crossed mode, the pavement layer is paved with the multiple pavement board blocks in an attached and crossed mode, the system is convenient to transport, easy to lay, short in site construction time, high in construction efficiency, capable of being reused, easy to replace after being damaged and small in construction waste.

Owner:马晓鹤

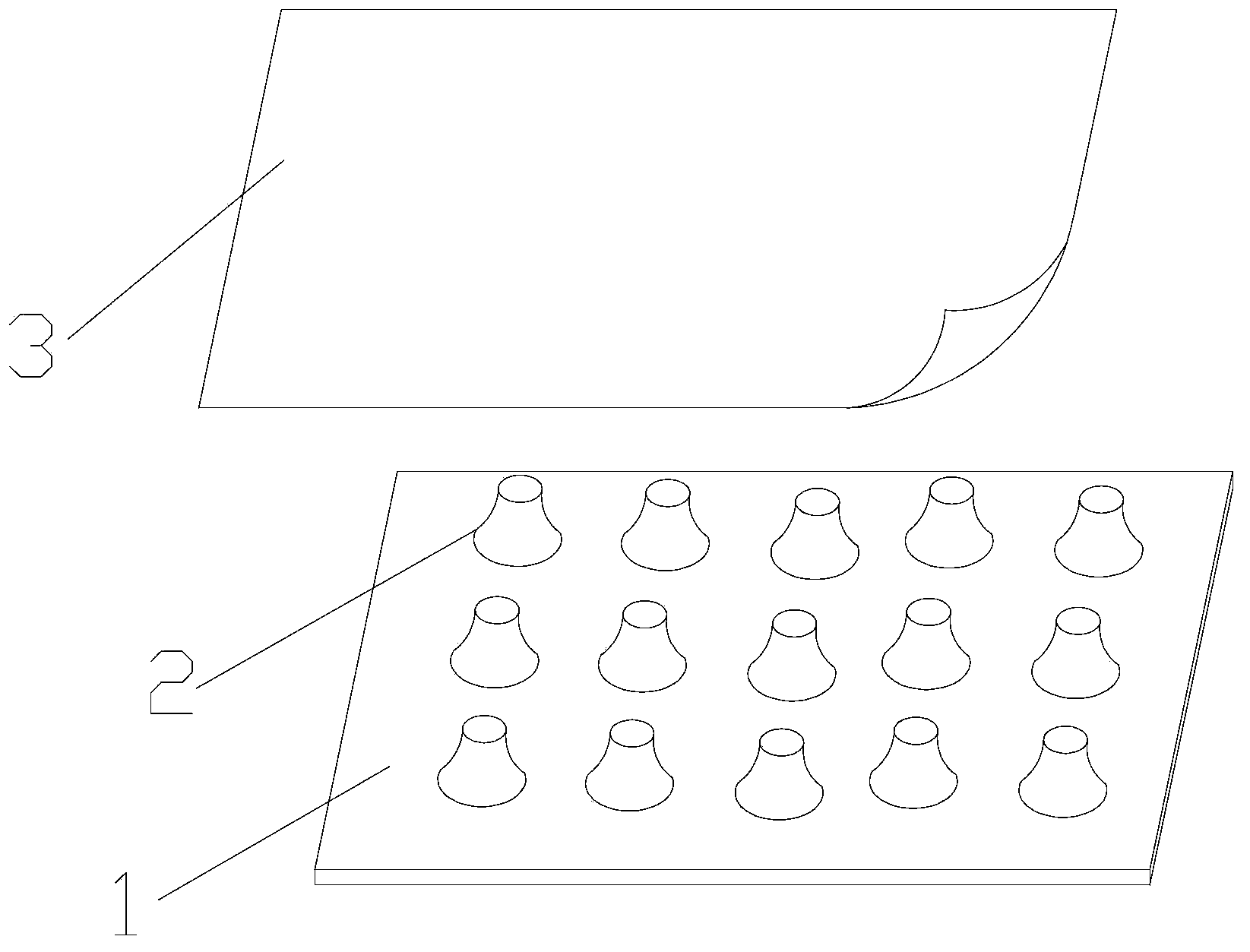

Environment-friendly drain board

InactiveCN104120707AHigh strengthImprove ductilitySoil preservationMicrometerMelamine formaldehyde resin

The invention provides an environment-friendly drain board which comprises a board body and a filtering layer arranged on the board body in a covering mode. A plurality of hollow protrusions are arranged on the board body. The board body is made of melamino-formaldehyde resin, and the distributing rate of the hollow protrusions on the board body is larger than 80%. The filtering layer is made of geotechnical cloth, and the hole diameter of the geotechnical cloth ranges from 20 micrometers to 180 micrometers. The filtering layer and the board body can be combined in a bonding or heat sealing mode. The environment-friendly drain board has the advantages of being good in drain effect, low in machining cost, degradable, environmentally friendly and free of pollution, and saving energy.

Owner:TIANJIN DINGYI MACHINERY MFG

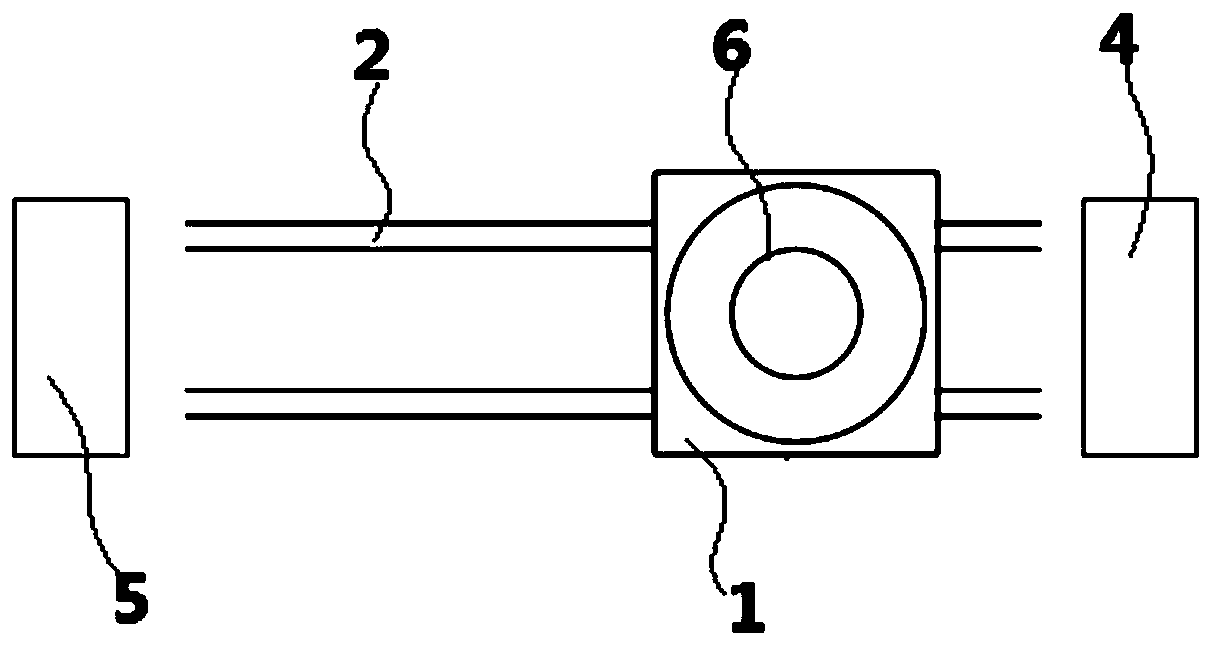

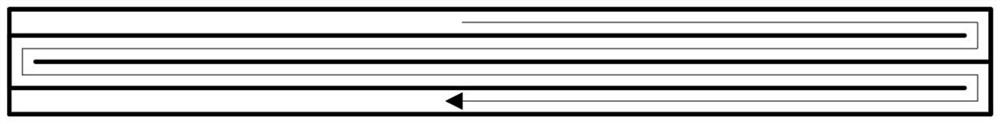

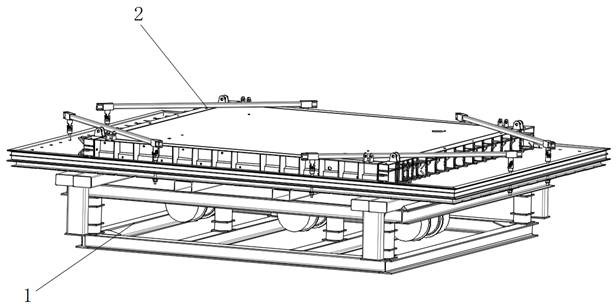

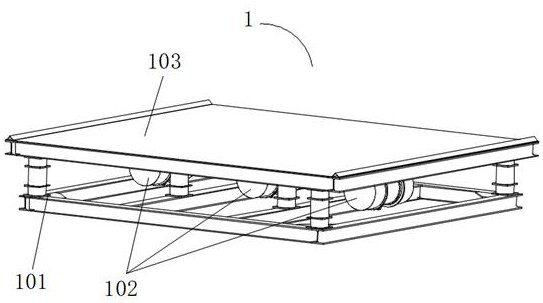

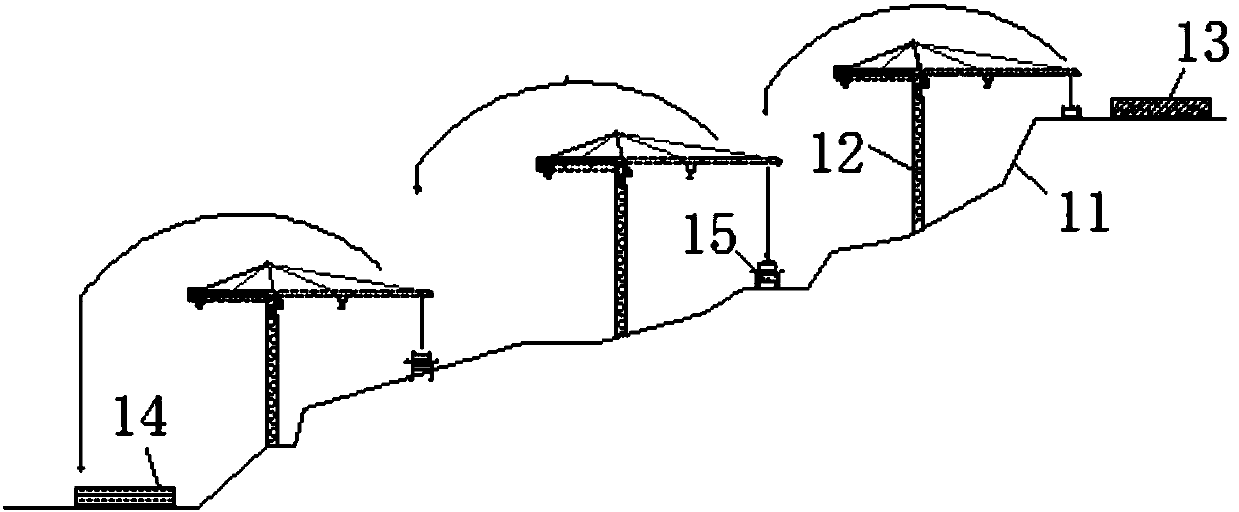

Fabricated wind power tower quick assembling device and construction method

PendingCN111336071AClear functionReduce cross workWind motor supports/mountsPortable liftingArchitectural engineeringTower

The invention discloses a fabricated wind power tower quick assembling device and construction method. The fabricated wind power tower quick assembling device comprises an assembling table and transporting tracks and is mounted in a site, the site comprises an assembling area and a plurality of to-be-lifted areas, and the transporting tracks are formed between the assembling area and all the to-be-lifted areas. The assembling table is arranged in the assembling area, towers are assembled on the assembling table, and the towers and the assembling table slide to all the to-be-lifted areas alongthe transporting tracks. The fabricated wind power tower quick assembling device and construction method have the beneficial effects that site function division is clear, the use cost of a truck cranein the assembling process is lowered, the area occupied by the site is decreased, the assembling quality is easier to control, the space for track transferring is saved, reliability is high, the lifting efficiency is advantageously improved, and green construction is facilitated.

Owner:CHONGQING UNIV

Green formwork system construction method

PendingCN113958138AReduce usageEasy to remove in advanceForms/shuttering/falseworksBuilding material handlingArchitectural engineeringRebar

The invention discloses a green formwork system construction method, and belongs to the technical field of building construction. The method comprises the following steps of preparation before construction, formwork system erection, steel bar binding, concrete pouring and two-time formwork removal. The erection size of a formwork system is standardized, formworks are standardized, the erection efficiency and stability of the formwork system are improved, the standard formworks are utilized, circulation is fast, investment is small, only one layer of formwork needs to be prepared, the formwork can be rapidly erected from the periphery to the upper layer, circulation materials are prevented from being idle, the use of the materials is reduced, and green construction and environment protection are facilitated. According to the formwork system, a top plate early-dismantling column head is additionally arranged at the top of a vertical rod, the formworks can be conveniently dismantled in advance, and the use amount of the formworks and the circulation materials is reduced. The method is suitable for common multi-layer and high-rise cast-in-place concrete structure buildings, is particularly suitable for underground garages, plants and other projects with large single-layer area and few layers, and can also be applied to formwork erection of post-cast strips.

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD

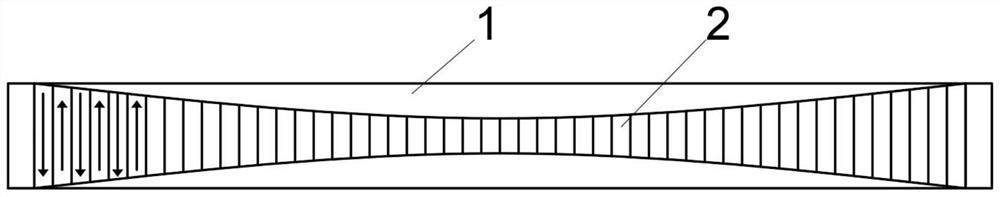

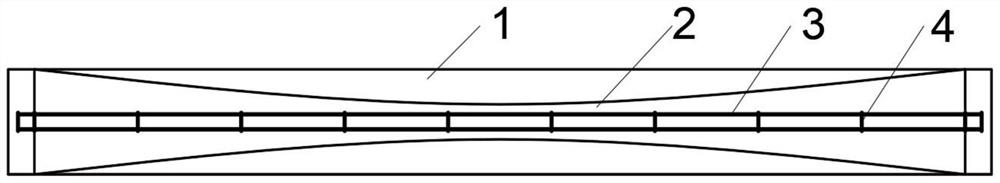

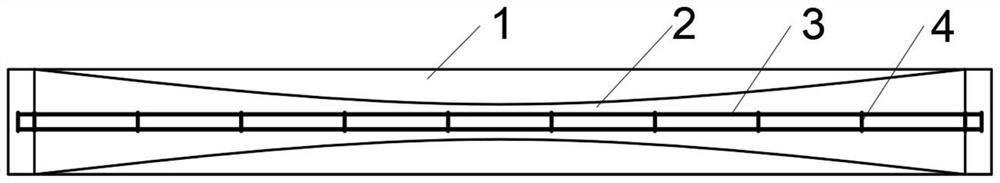

3D printing method of concrete special-shaped beams without web reinforcement

ActiveCN112343343AAvoid shear damageImprove adhesionAdditive manufacturing apparatusCeramic shaping apparatusShaped beamConstruction engineering

The invention discloses a 3D printing method of concrete special-shaped beams without web reinforcement. A concrete special-shaped beam member without the web reinforcement comprises a rectangular flange layer, a curved web layer, a bent reinforcing mesh layer and an external concrete cover in sequence from top to bottom. The 3D printing method is characterized by comprising the following steps ofprinting the rectangular flange layer and the curved web layer in sequence by adopting a 3D concrete printing technique, then manually arranging the reinforcing mesh layer, and finally, printing theconcrete cover by adopting the 3D concrete printing technique. According to the method, through modeling optimization, concrete is arranged according to the stress condition of the beam, so that the using amount of concrete materials is reduced, and reinforcing steel bars are laid in the printing direction in a printing process, so that the inconvenience in construction due to post installation ofhorizontal bars is avoided, additionally, the problem of bonding of the reinforcing steel bars and the concrete during post installation is solved, and the construction is simplified.

Owner:SOUTHEAST UNIV

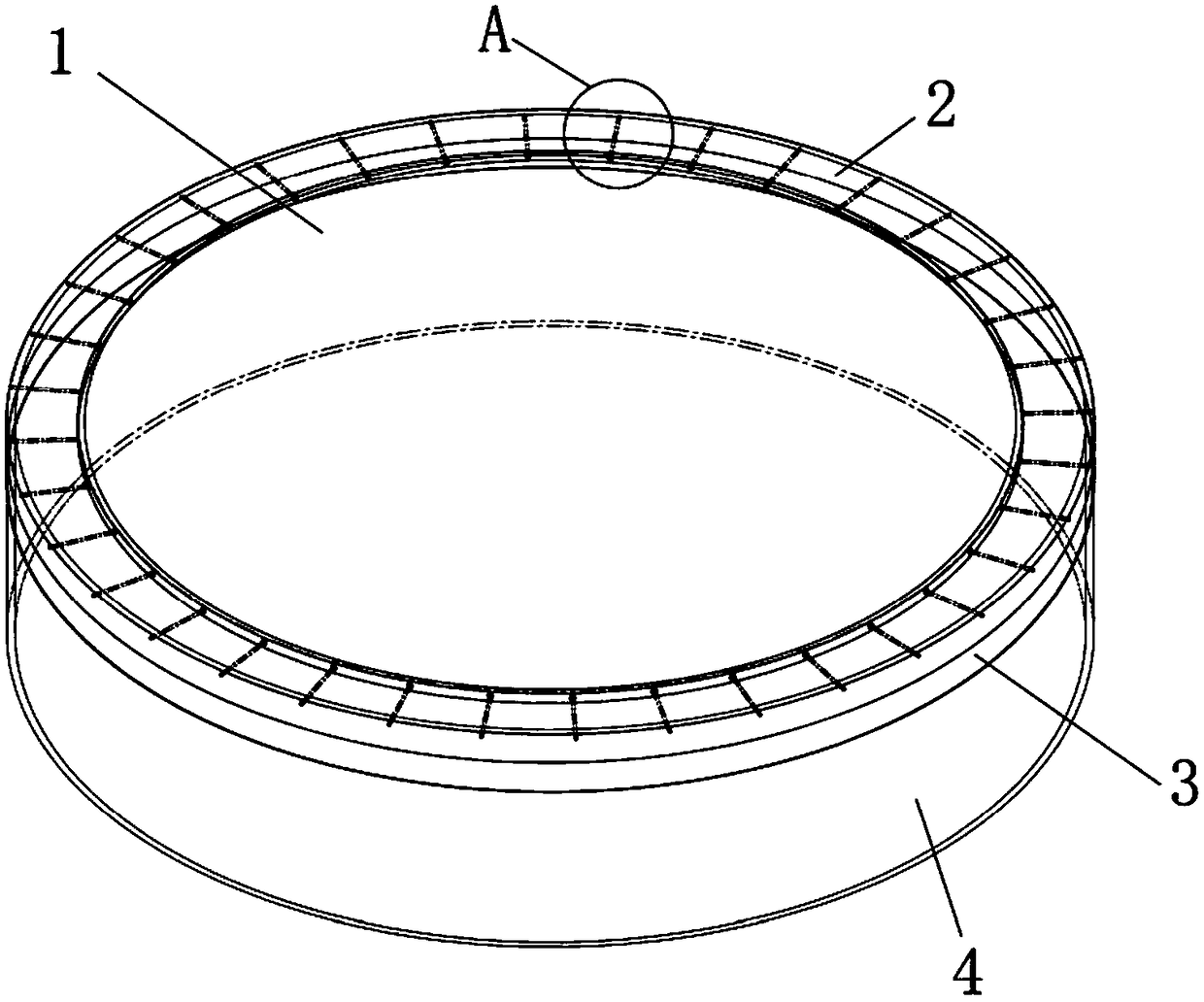

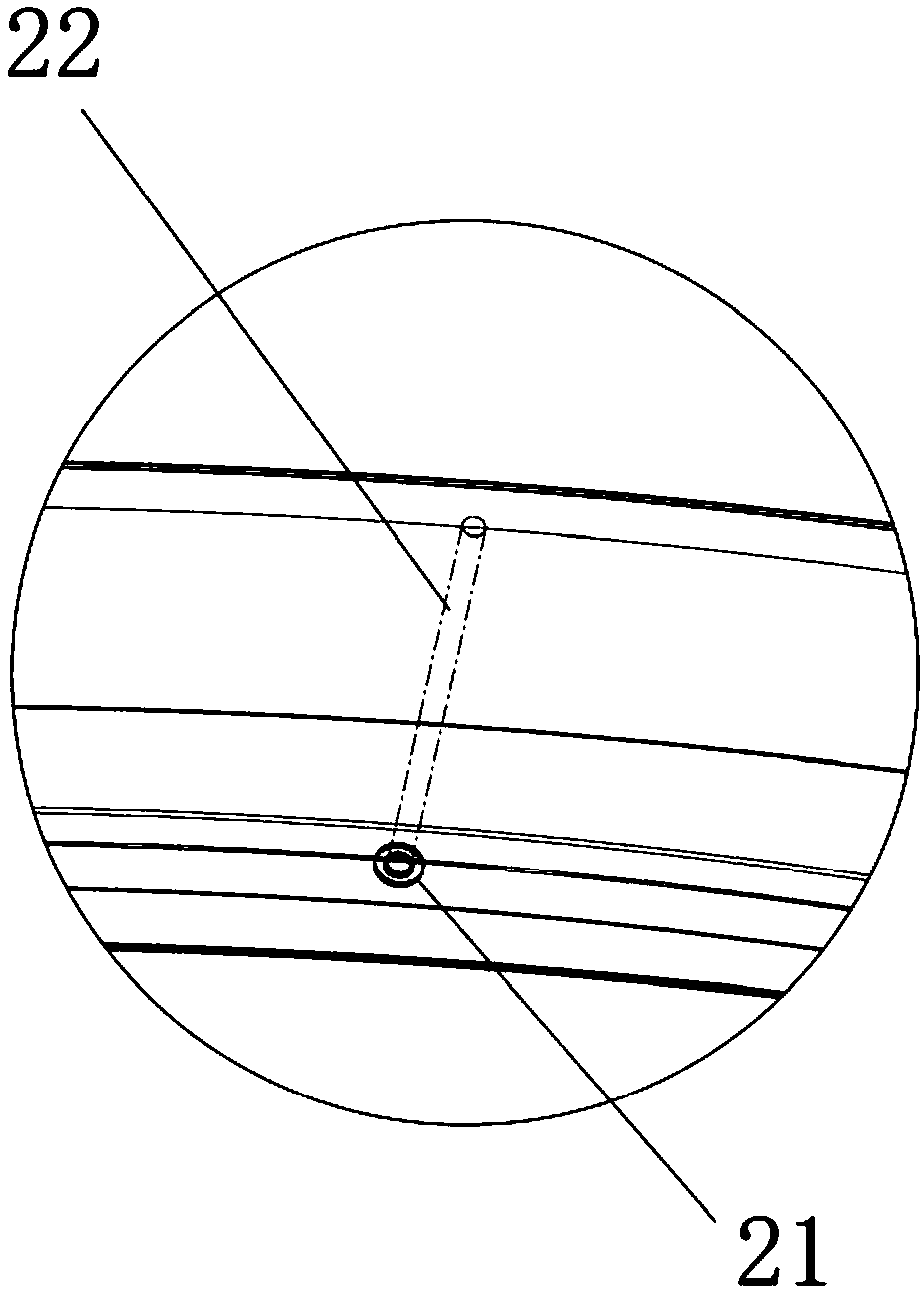

Top protection structure applied to wind power tower drums after hoisting two vertical sections and paving method thereof

PendingCN108386327ALow costEasy constructionMachines/enginesWind energy generationElectricityEngineering

The invention discloses a top protection structure applied to wind power tower drums after hoisting two vertical sections and a paving method thereof. The top protection structure comprises a rainproof tarpaulin hood, a stainless steel awning ring rainproof tarpaulin and a tensile rubber rainproof tarpaulin, wherein the rainproof tarpaulin hood is a circular hood with shape and size which are matched with that of the top of a second tower drum section; the stainless steel awning ring rainproof tarpaulin is sewed on the inner layer of the rainproof tarpaulin hood; a plurality of stainless steelawning rings are embedded at the edge of the stainless steel awning ring rainproof tarpaulin; one end of a hemp rope is fixedly fastened in one hole of each of the plurality of stainless steel awningrings; the tensile rubber rainproof tarpaulin is vertically sewed on the circumference edge of the rainproof tarpaulin hood to form a straight drum shape; tensile rubber bands are sewed on the innerlayer of the tensile rubber rainproof tarpaulin; through the sewed tensile rubber bands, the tensile rubber rainproof tarpaulin is clung to the surface of the circular outer wall of the top of the second tower drum section during paving. The top protection structure has operability and practical significance to the protection problems such as rainwater resistance, sand and dust resistance and corrosion resistance and the like of wind power plants after hoisting two vertical tower drum sections.

Owner:GUANGDONG MINGYANG WIND POWER IND GRP CO LTD

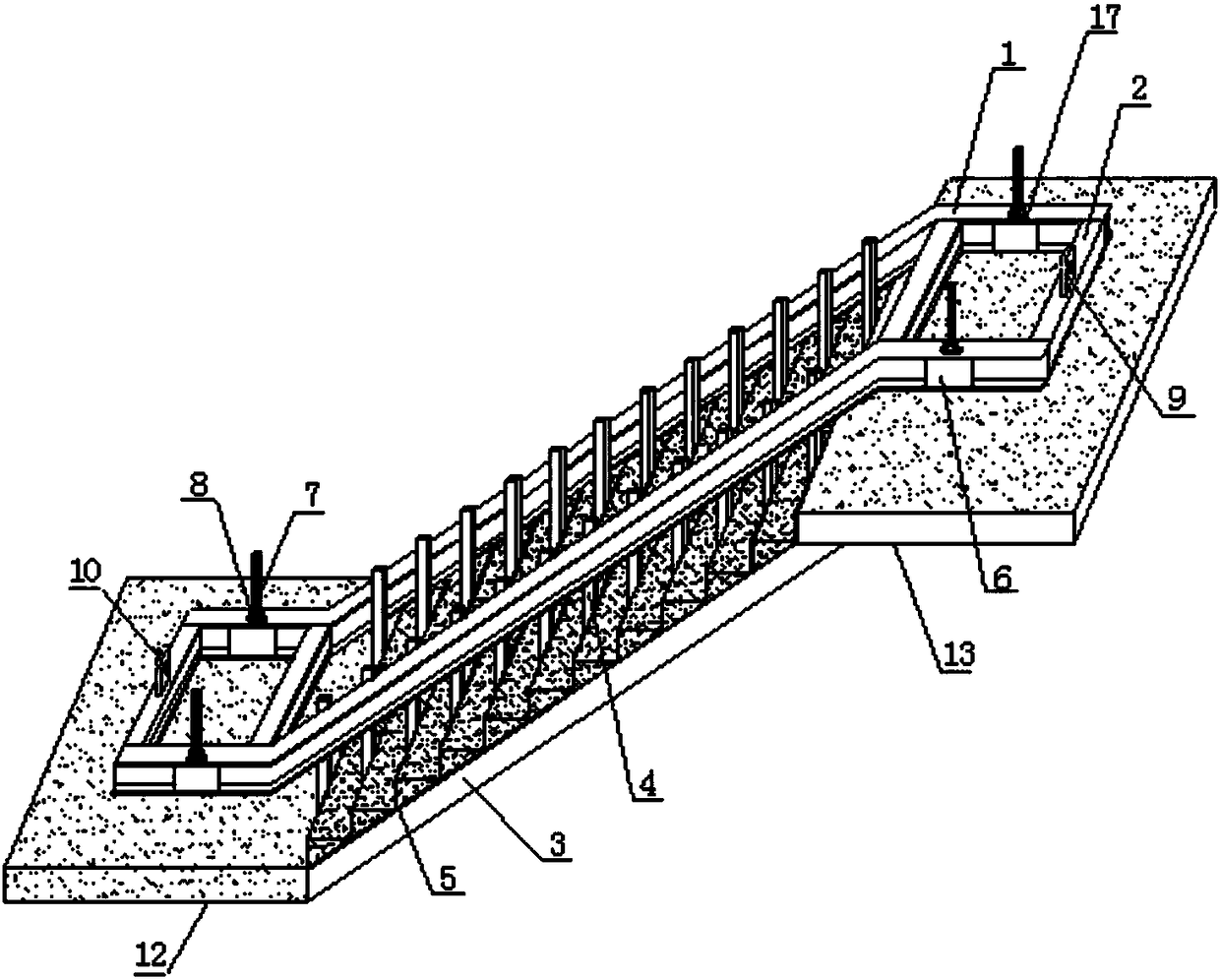

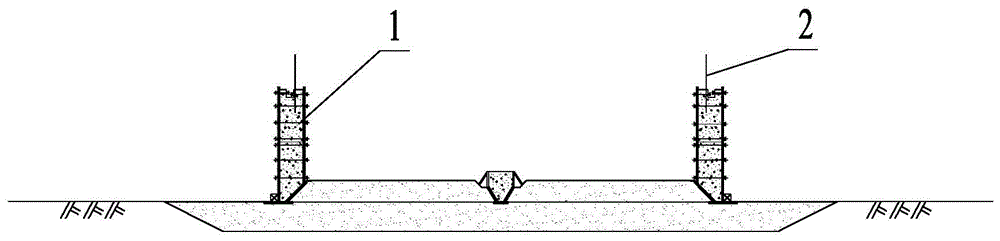

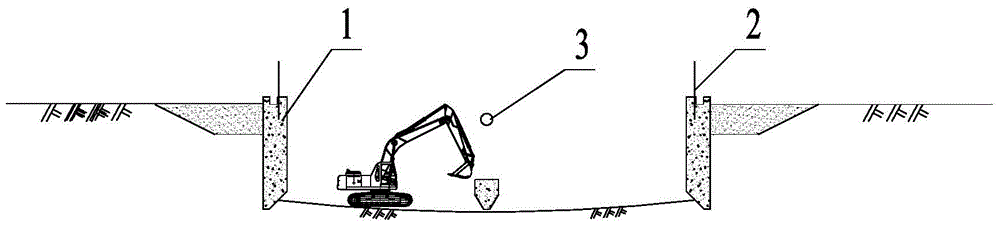

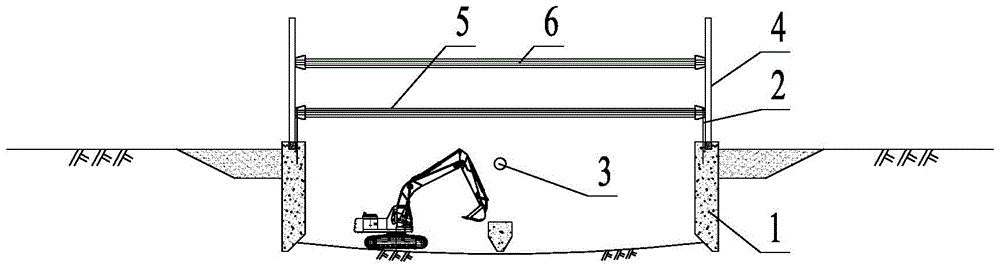

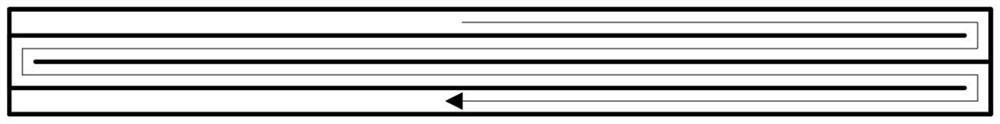

Prefabricated installation construction method for fabricated box culvert

The invention discloses an assembly type box culvert prefabrication installation construction method, an assembly type box culvert comprises a plurality of mutually connected box culvert sections and holes at two ends, each box culvert section comprises a top plate, a bottom plate and side walls, two ends of each top plate are respectively spliced with the side walls, the bottoms of the two side walls are in cast-in-place connection, a cast-in-place part is the bottom plate, and a cast-in-place part is connected with the bottom plate; the top plates, the bottom plate and the two side walls form a box-shaped channel, supporting feet protruding outwards are arranged at the bottoms of the side walls, two connectors of the top plates and the side walls are in an elbow shape and are freely hinged, and when different box-shaped culvert sections are connected, the top plates are connected through bent bolts. Prefabrication can be performed in the field in advance, the construction time is greatly shortened, the construction period is shortened, and civilized and green construction is promoted; during excavation construction, the working face is small, and damage and pollution to ground surface underground water and soil are greatly reduced; the quality of the culvert can be effectively improved, the appearance and the percent of pass of a protective layer are greatly improved, and good economic and social benefits are achieved.

Owner:CHINA FIRST HIGHWAY ENG

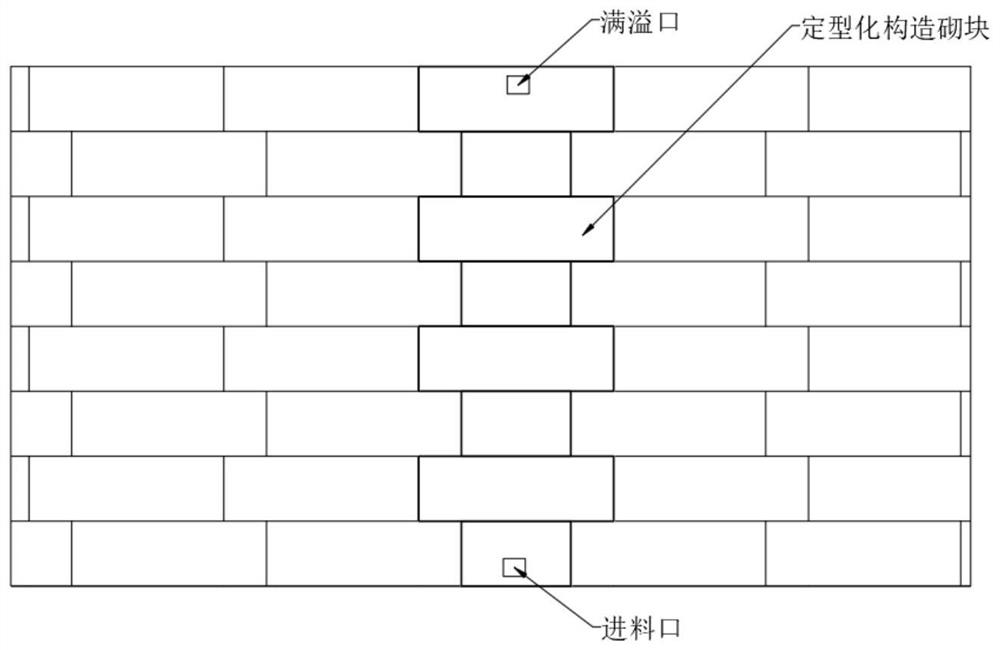

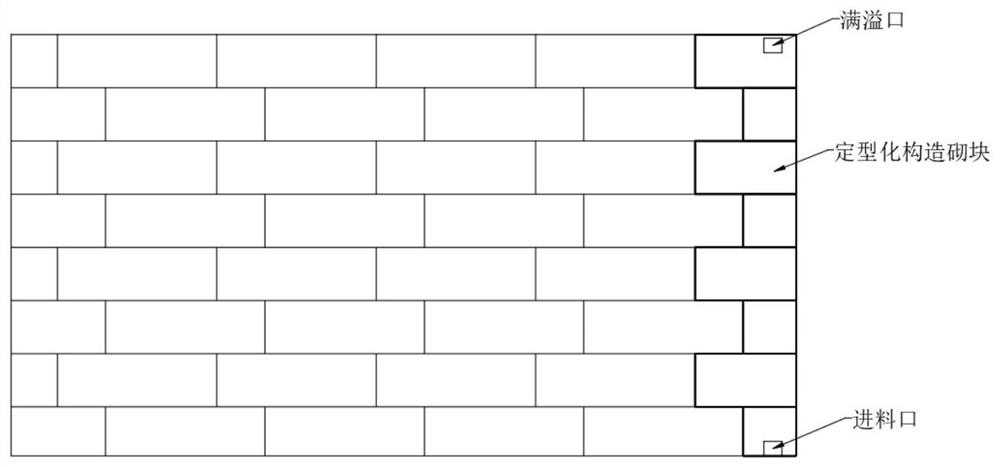

Construction method for assembling integral ring beam, lintel, waist beam and constructional column

InactiveCN112982735AImprove molding qualityAppearance quality is easy to controlStrutsWallsArchitectural engineeringUltimate tensile strength

The invention discloses a construction method for assembling an integral ring beam, a lintel, a waist beam and a constructional column. The construction method comprises the following steps that S1, shaped constructional building blocks matched with building blocks used for wall engineering at the ring beam, the lintel, the waist beam and the constructional column are selected; and S2, the shaped constructional building blocks matched with the ring beam are in a C-shaped section shape, and the multiple shaped constructional building blocks are spliced and matched with a wall. After the shaped constructional building blocks are built, a constructional column shell with good appearance quality is formed and can also be used as a constructional column formwork, in the abovementioned way, the process of a branch constructional column formwork in a traditional construction method is omitted, use of woodworking labor force and turnover materials is avoided, and meanwhile the construction quality is guaranteed; and due to the fact that the constructional building blocks are high in self weight and self strength and the lateral supporting force of the built wall is large, the strength and stability of the formwork are reliable along with increase of the strength of masonry mortar, and the requirement for pouring fine aggregate concrete into the formwork from top to bottom is met.

Owner:THE FOURTH OF CHINA EIGHTH ENG BUREAU

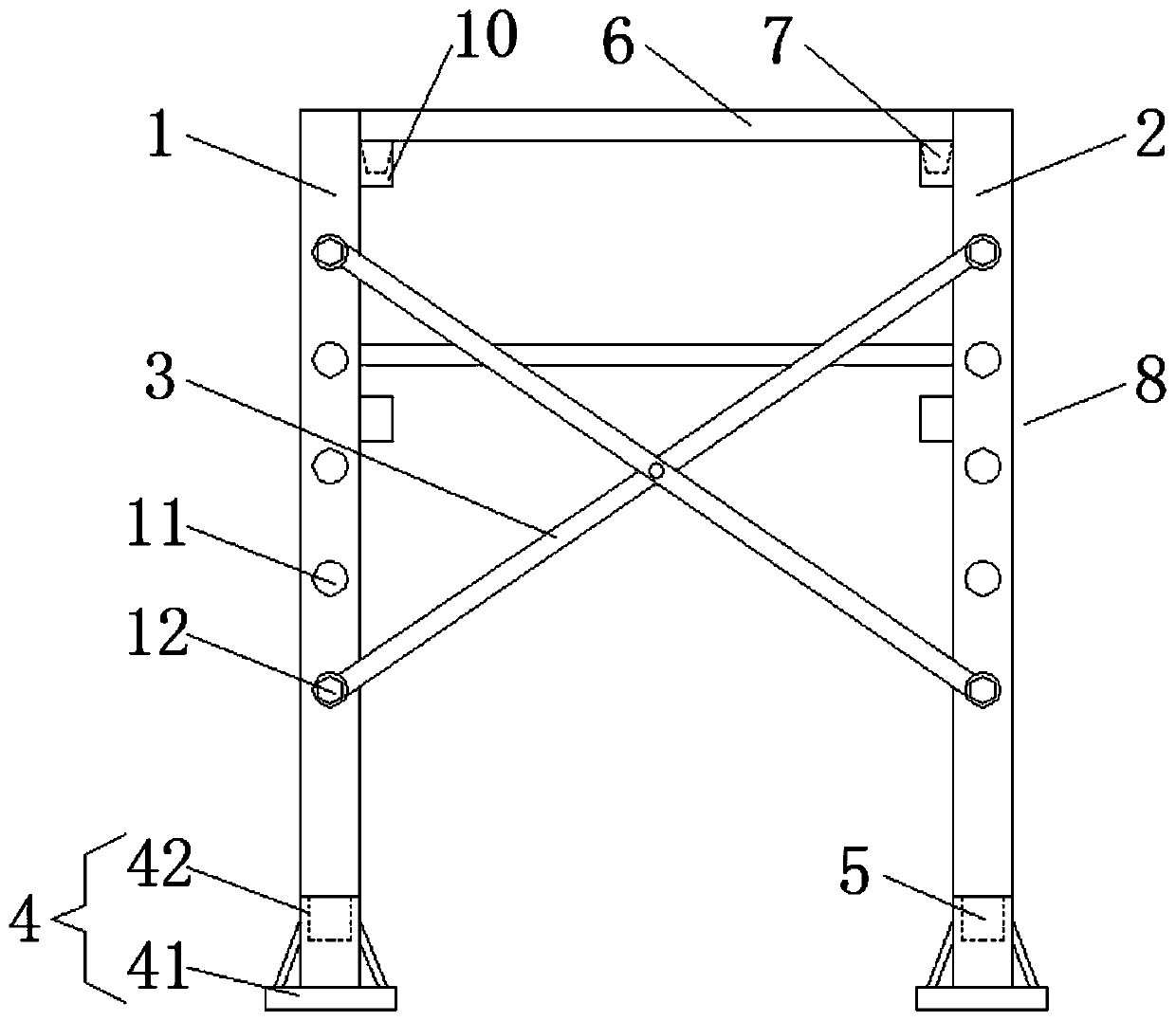

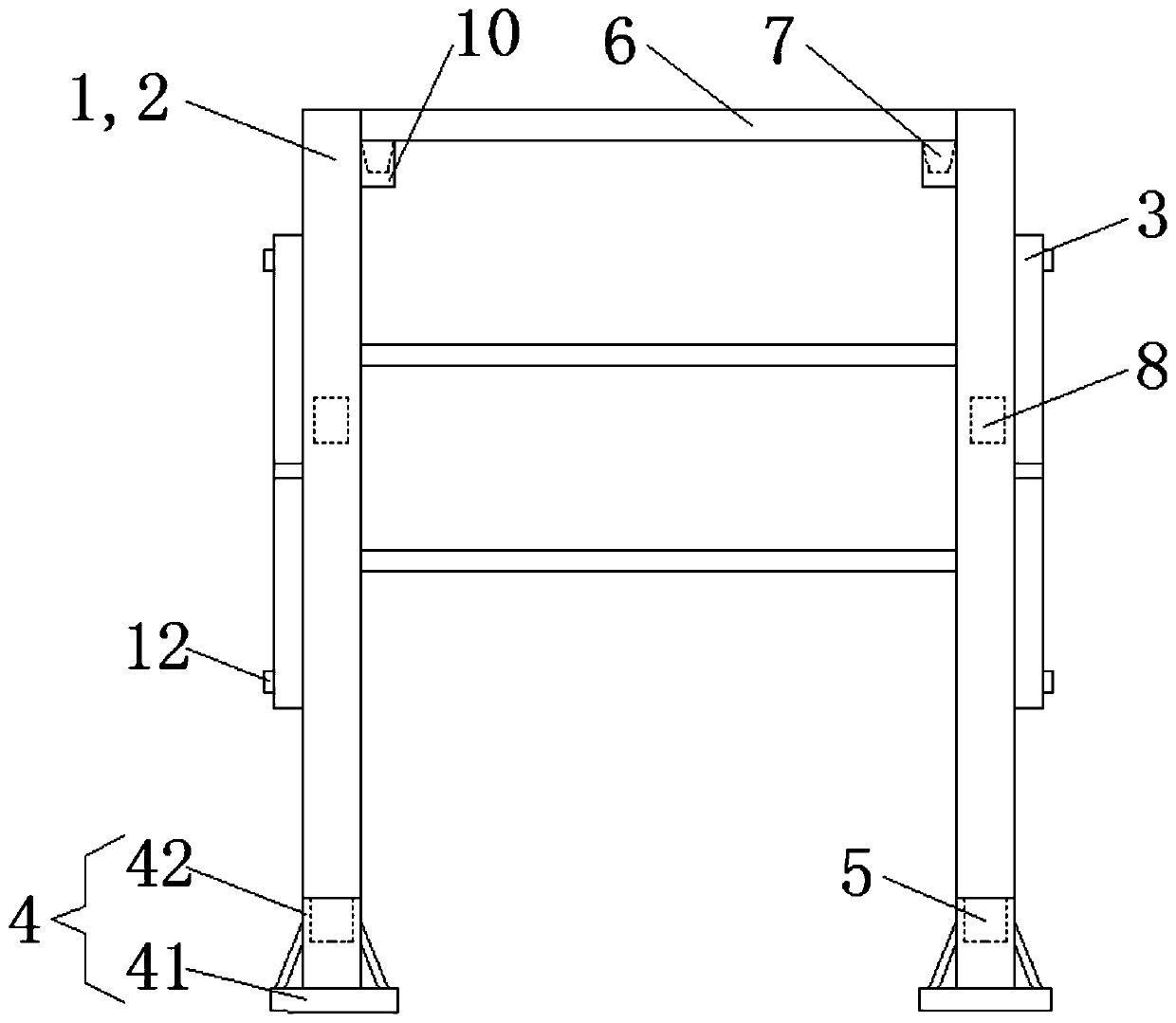

Stair steel framework for building

InactiveCN108193874AScientific and reasonable structureEasy to useForms/shuttering/falseworksForming/stuttering elementsBuilding constructionStairs

Owner:于海松

Foldable inner frame device for coke oven masonry construction and construction method

PendingCN111005546ALess clean upImprove protectionBuilding material handlingScaffold accessoriesArchitectural engineeringCoke burner

The invention provides a foldable inner frame device for coke oven masonry construction and a construction method. The device comprises moving supports and a base. Transversely adjacent moving supports are connected through connecting pieces, and longitudinally adjacent moving supports are connected through pin shafts. The moving supports comprise frame-shaped front supports and rear supports andcross-shaped hinged connecting rods arranged in the middle. The base comprises a bottom plate and a base support, wherein the base support is of a cylindrical structure, and the base support is connected with the lower end of an upright post of the lowermost moving support through a pin shaft. A pedal is arranged above the uppermost moving support and is correspondingly connected with the upper ends of the front supports and the rear supports. Through modular assembly and scaffold erection, no hole needs to be reserved in a wall body for supporting, later repair work is reduced, mounting and disassembly are easy, the safety coefficient is high, the overall occupied space of the structure of the device is small, a plurality of working faces can be used for work at the same time or in turn,waste cleaning work after masonry is relieved.

Owner:TIANJIN 20 CONSTR

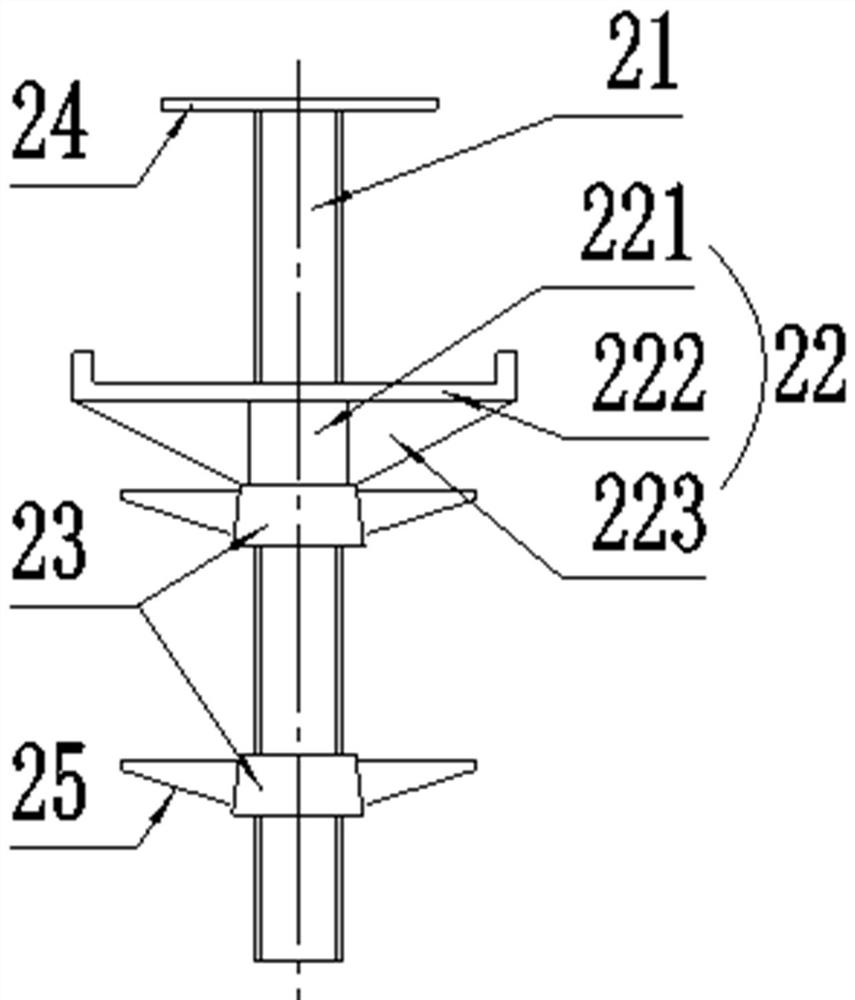

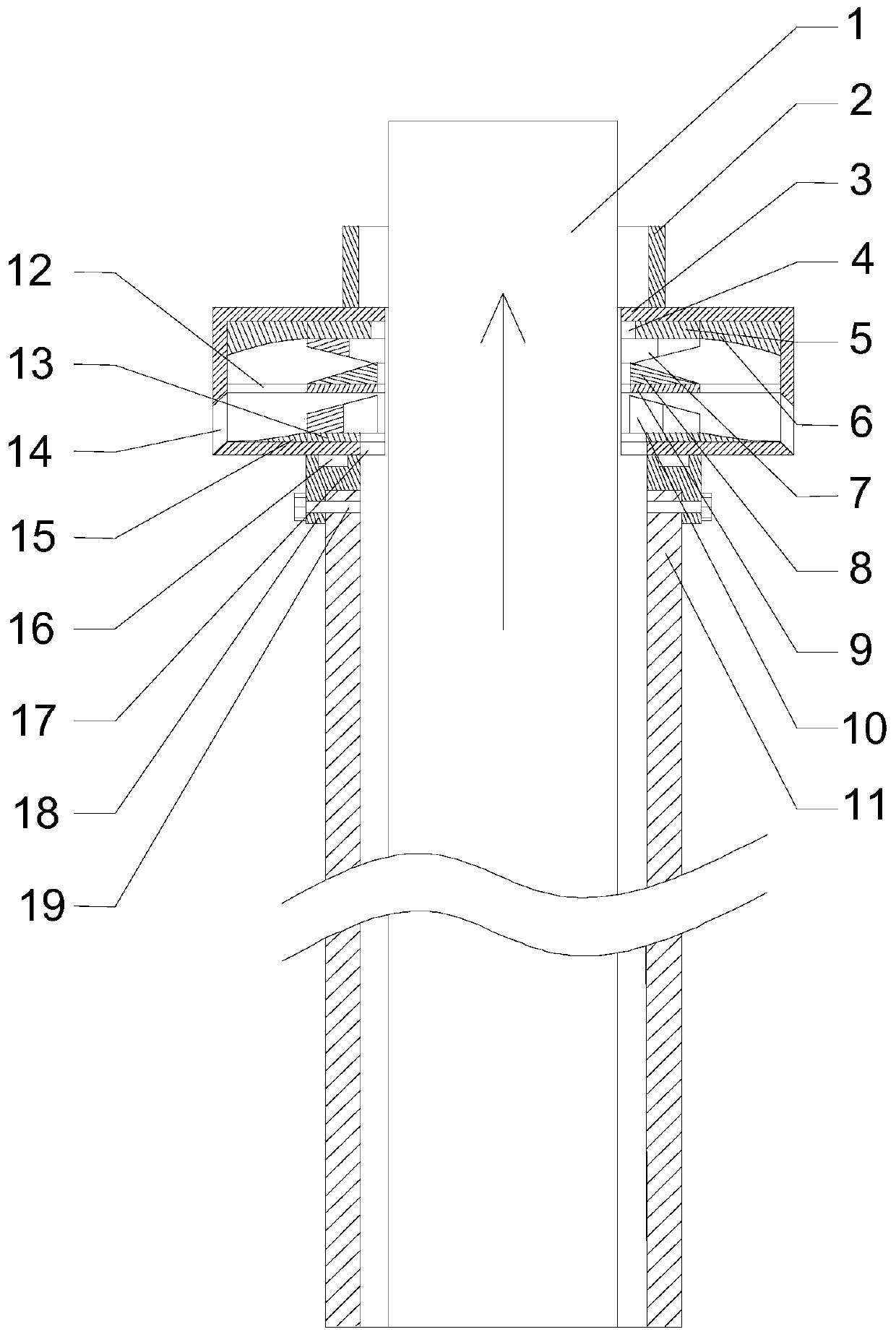

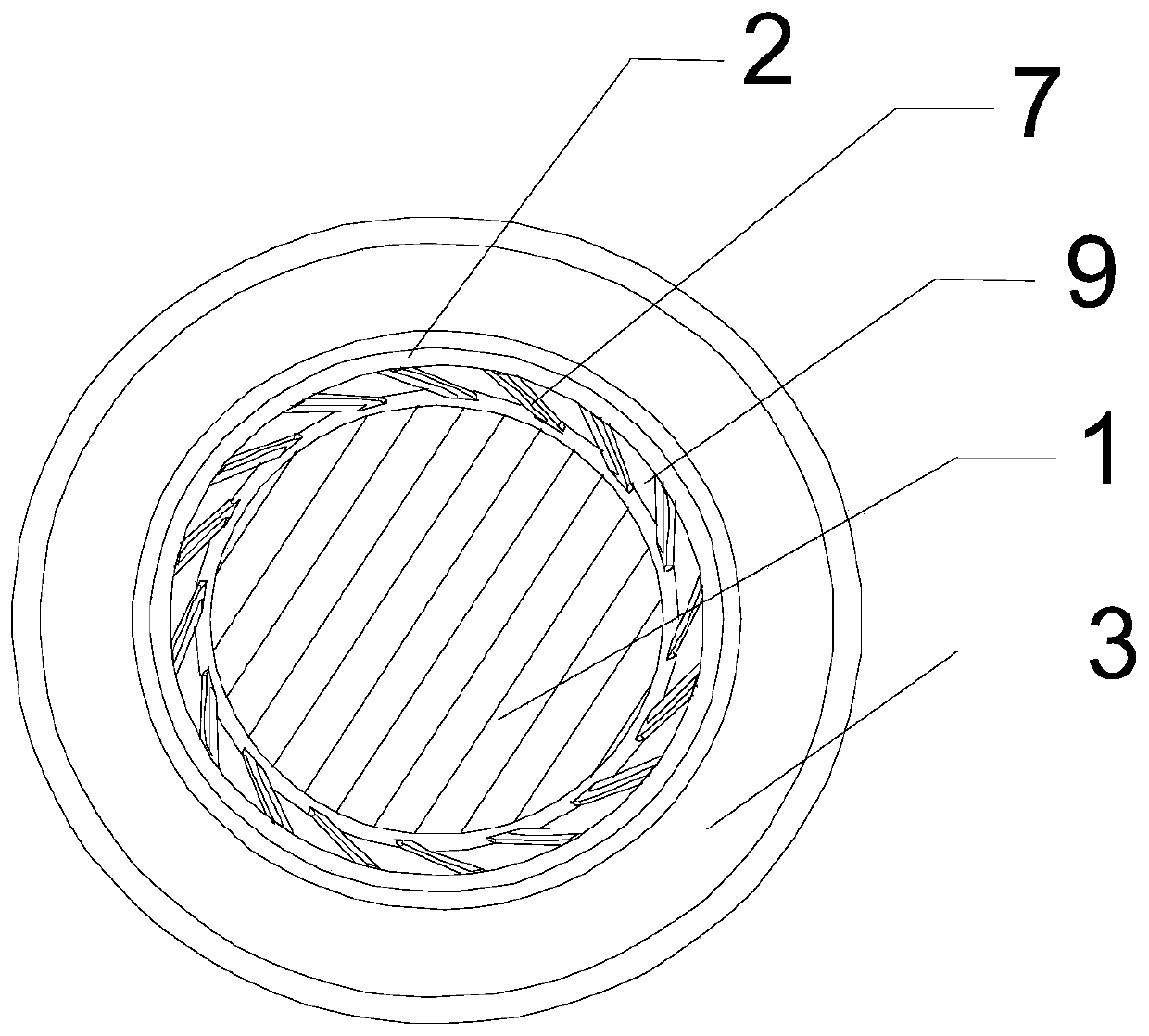

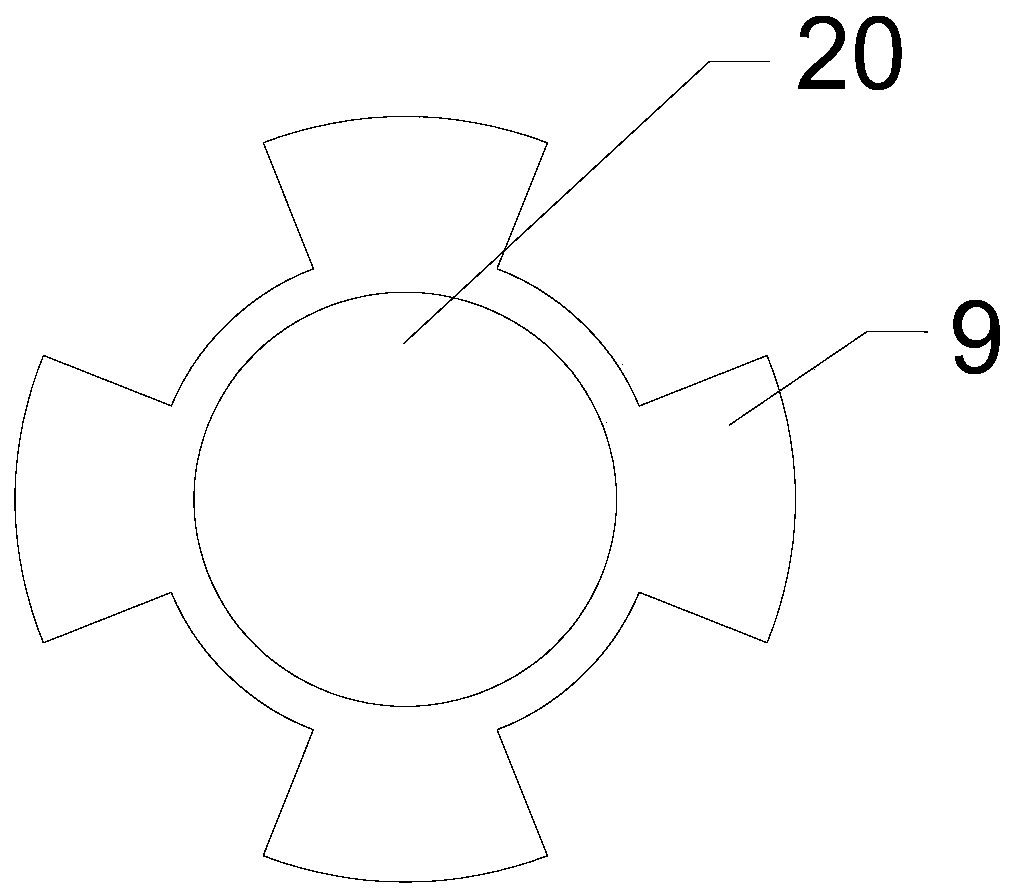

A barrier-free cleaning device for abandoned piles

ActiveCN110258562BReduce labor intensityReduce lifting capacityBulkheads/pilesStructural engineeringMechanical engineering

The invention discloses a barrier-free cleaning device for an abandoned pile. The barrier-free cleaning device comprises a shell with a cylindrical cavity formed in the inner part, an upper sleeve tube is arranged on the upper surface of the shell, an upper through hole communicating with the sleeve tube is formed in the upper wall of the shell, a lower through hole corresponding to the upper through hole is formed in the lower wall of the shell, a round support plate is fixed to the middle of the hollow cavity of the shell, a penetrating hole for the abandoned pile to penetrate is formed in the middle of the support plate, a plurality of slag discharging holes are formed in the upper surface of the support plate in the radial direction of the support plate, an upper ring seat coaxially arranged with the upper through hole is arranged on the upper wall of the hollow cavity, a plurality of upper scraping blades are arranged on the bottom surface of the upper ring seat in the radial direction of the ring seat, a plurality of discharging holes are evenly formed in the side surface of the shell between the support plate and the lower wall of the cavity, and a lower sleeve tube is further arranged on the lower part of the shell. Soil stuck to the outer wall of the abandoned pile is cleaned by using the barrier-free cleaning device, the jacking-up weight is effectively decreased, meanwhile the labor intensity of works is relieved, and the jacking-up efficiency is improved.

Owner:甘肃九州岩土工程有限公司

Rapid precipitation construction method for anti-floating anchor rod

The invention discloses a rapid precipitation construction method of an anti-floating anchor rod. The rapid precipitation construction method is applied to sandy mudstone with abundant underground fissure water, and comprises the following steps that firstly, earth excavation and manual bottom picking are carried out; then concrete cushion layer pouring is carried out; hole forming operation is preferentially carried out on anchor holes around a serious water gushing part after the pouring is completed; after the hole is formed, a self-sucking pump is put down, water in the formed hole is discharged outwards through the self-sucking pump, and precipitation treatment is carried out on an area with serious water seepage and water gushing; hole forming operation is carried out on the position with serious water gushing after treatment is completed, and an anti-floating anchor rod which is made in advance is put down after hole forming is completed; and then grouting is carried out on the anchor hole, and after grout is solidified, waterproof treatment is carried out on the anti-floating anchor rod. According to the rapid precipitation construction method of the anti-floating anchor rod, existing anchor holes are used for precipitation, the well point precipitation and drainage mode adopted at present is replaced, the well point precipitation and drainage hole forming cost is saved, and the safety of the bearing capacity of a base is guaranteed.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

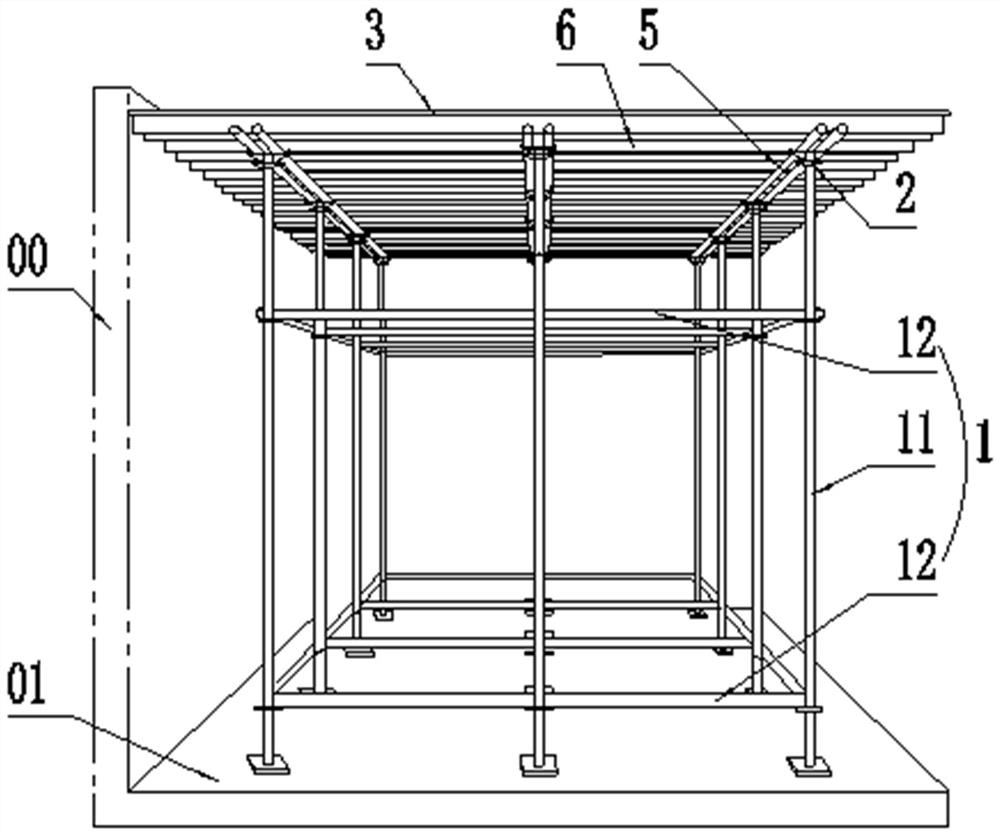

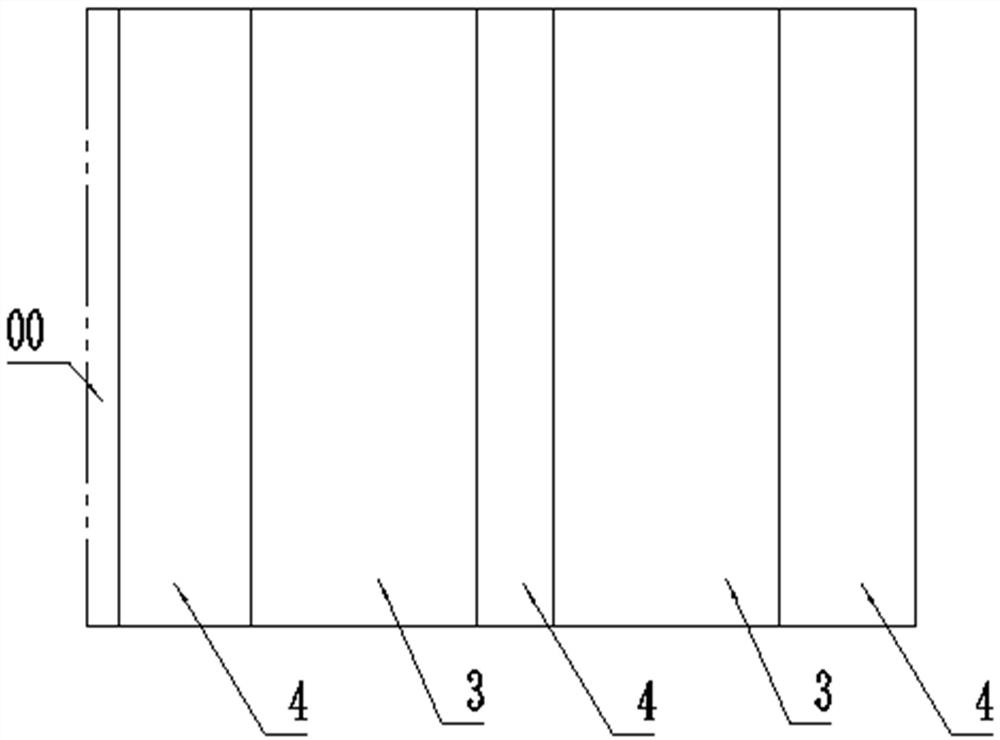

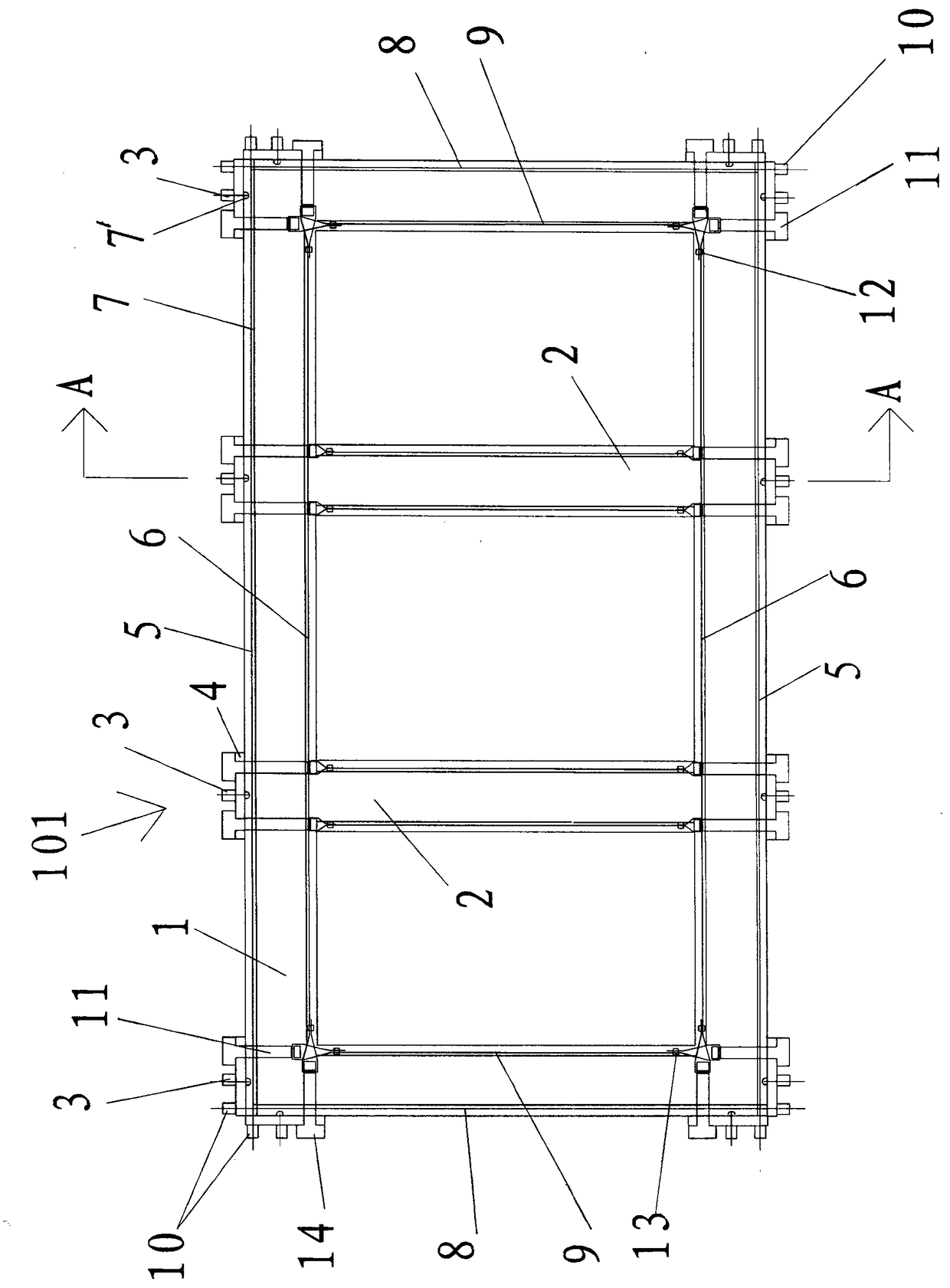

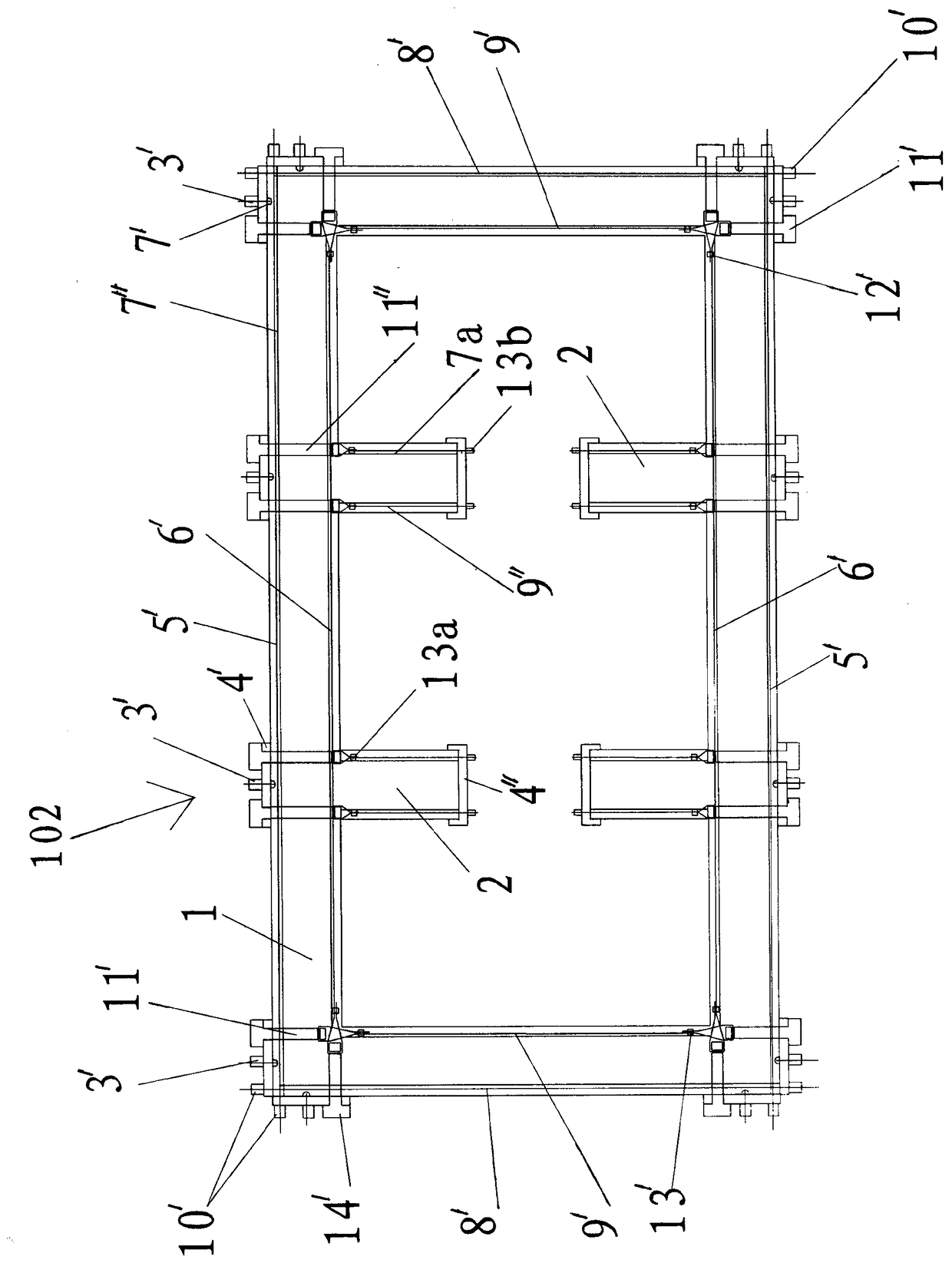

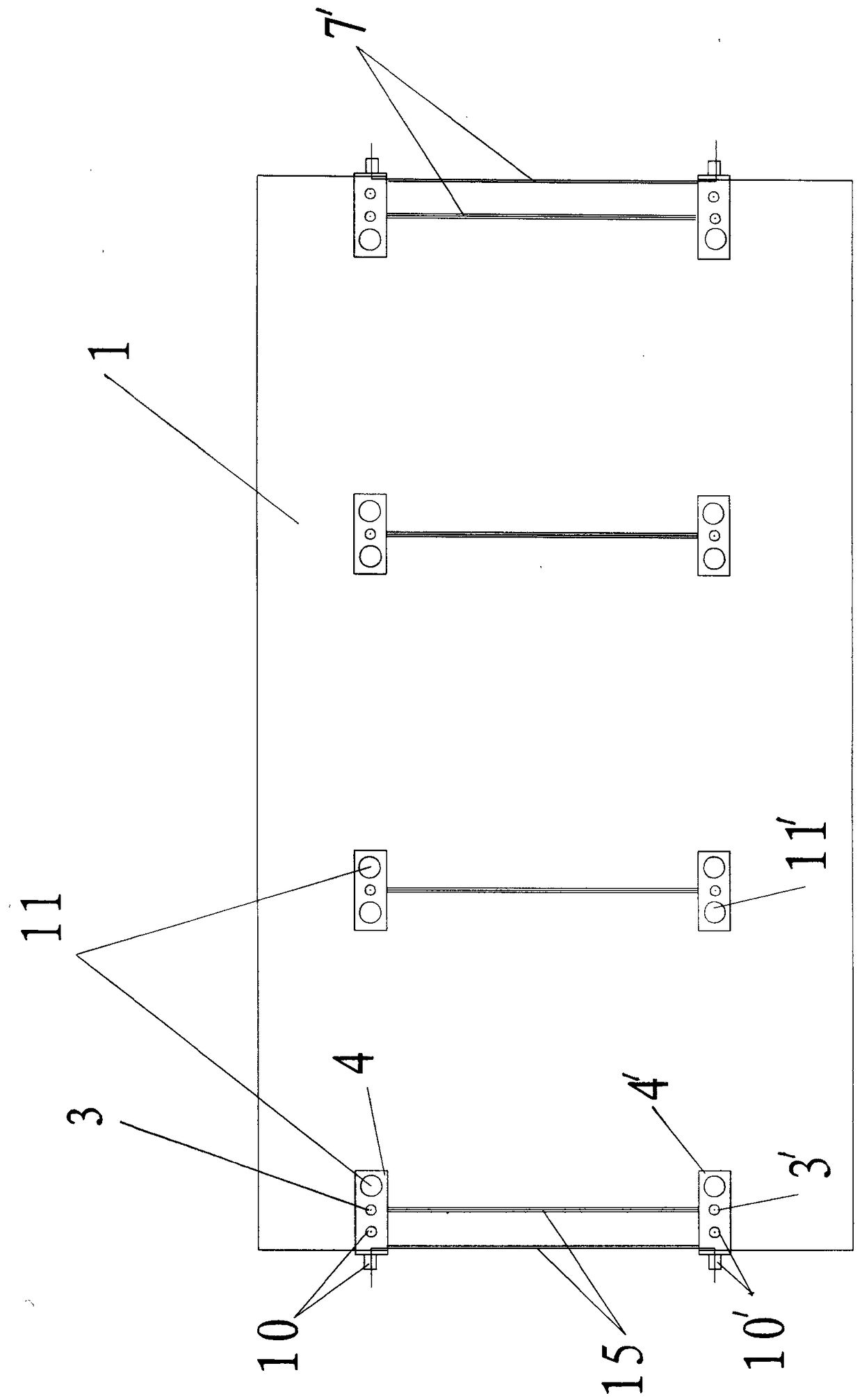

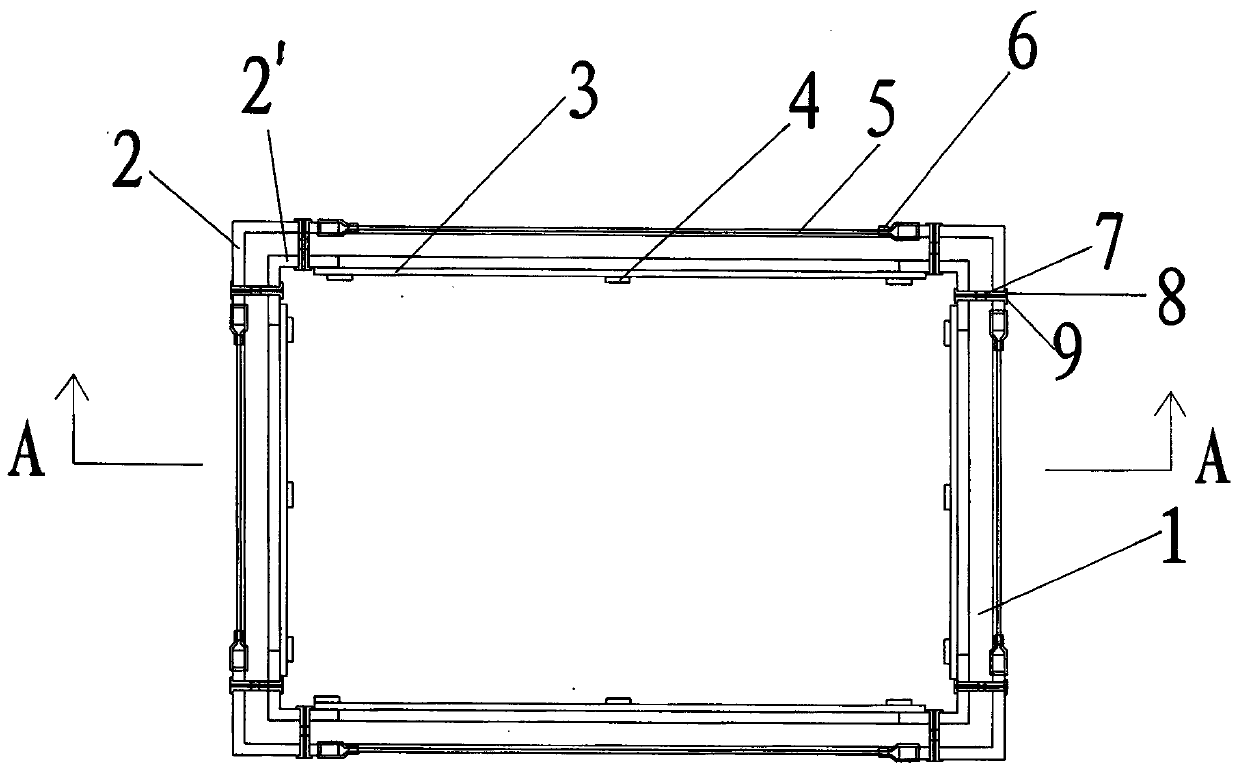

Lining mounting construction device and method for movable steel roof face

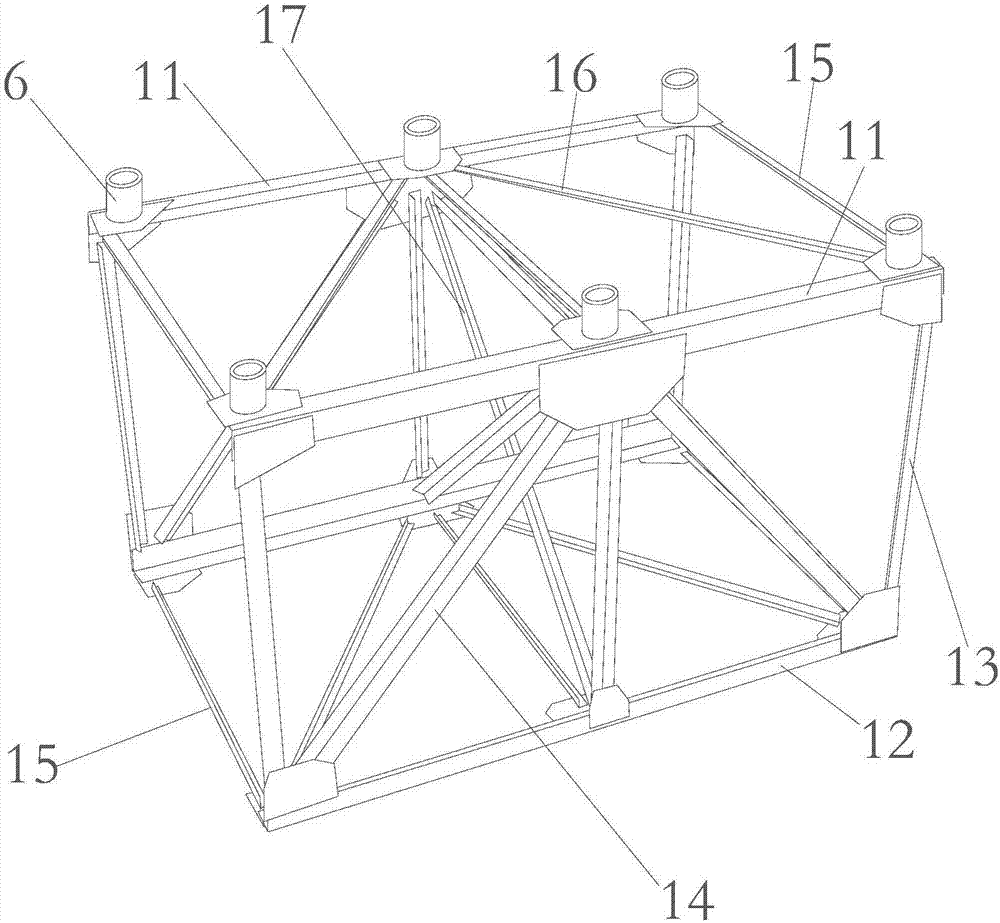

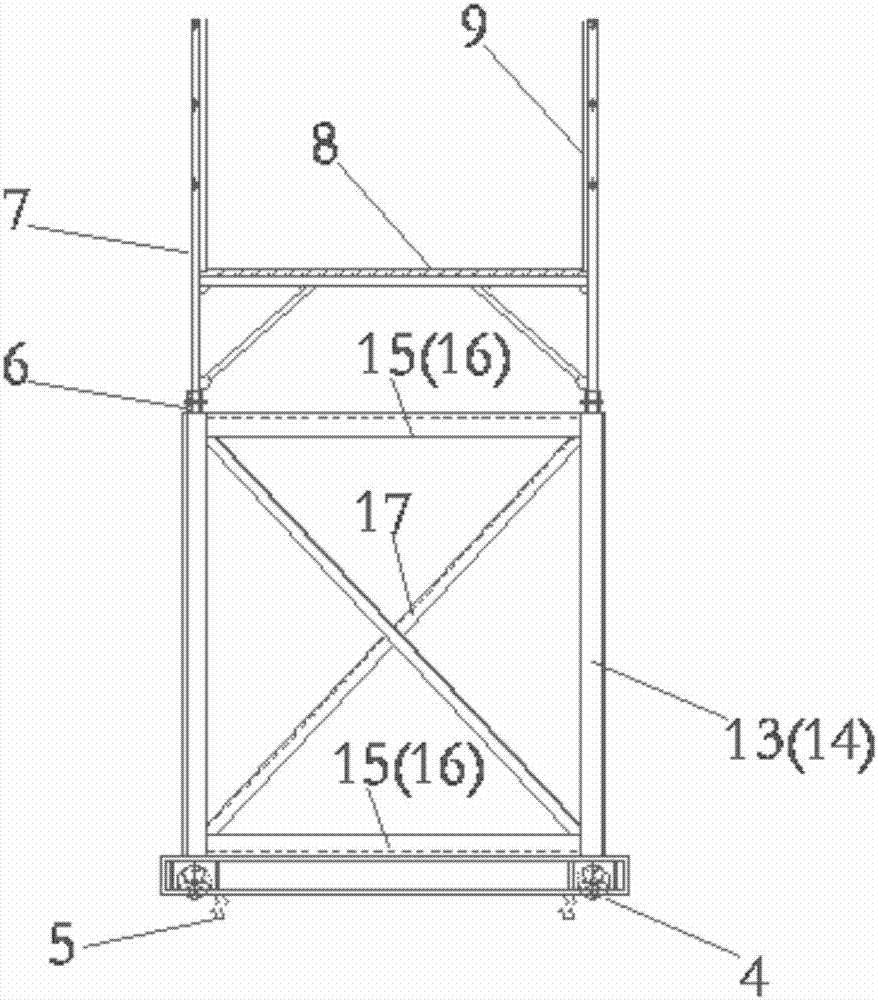

InactiveCN107514145ASpeed up the installation processGuaranteed installation qualityBuilding material handlingScaffold accessoriesDiagonalArchitectural engineering

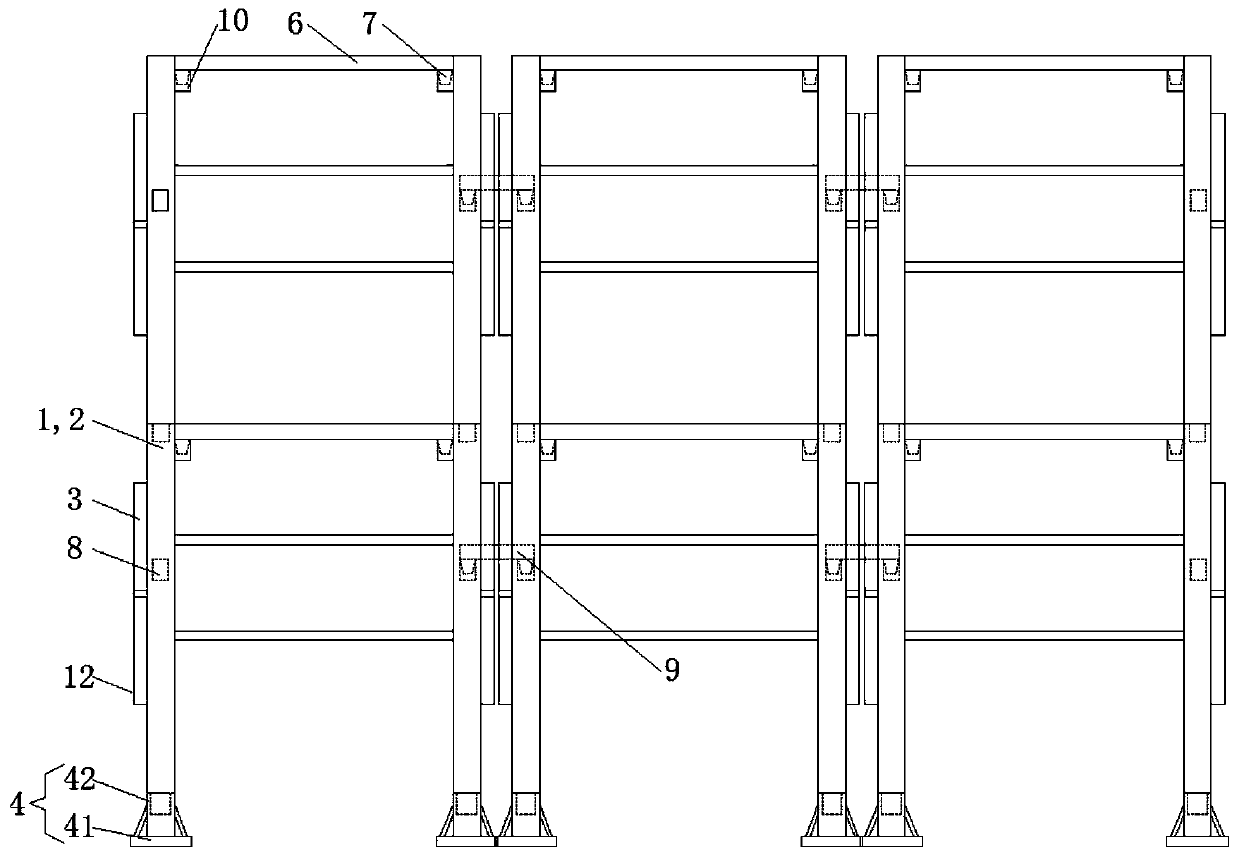

The invention relates to a lining mounting construction device for a movable steel roof face. The lining mounting construction device comprises factory building steel columns, crane beams, electric driving guiding wheels and vertical pipe mounting sleeves, wherein the crane beams are mounted on the factory building steel columns, and a space truss system of the electric driving guiding wheels is mounted on the crane beams, so that the flatness of a whole moving construction platform is ensured; the space truss system is of cuboid frame structure formed by truss upper chords, truss lower chords, vertical truss web members and truss upper-lower-chord transversely-horizontal supports, truss inclined web members and truss upper-lower-chord transversely-horizontal inclined supports are correspondingly arranged on the diagonal lines of all the planes of the cuboid frame, and truss vertical and transverse inclined supporting rods are arranged on the plane in the middle of the cuboid frame; and climbing ladders are arranged on the left side and the right side of the space truss system, and the vertical pipe mounting sleeves are evenly arranged on the front side and the rear side of the upper end of the space truss system at intervals and are used for mounting of platform vertical pipes. The lining mounting construction device for the movable steel roof face is convenient to mount and disassemble, and quickening of the mounting progress of steel roof face lining plates is facilitated.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

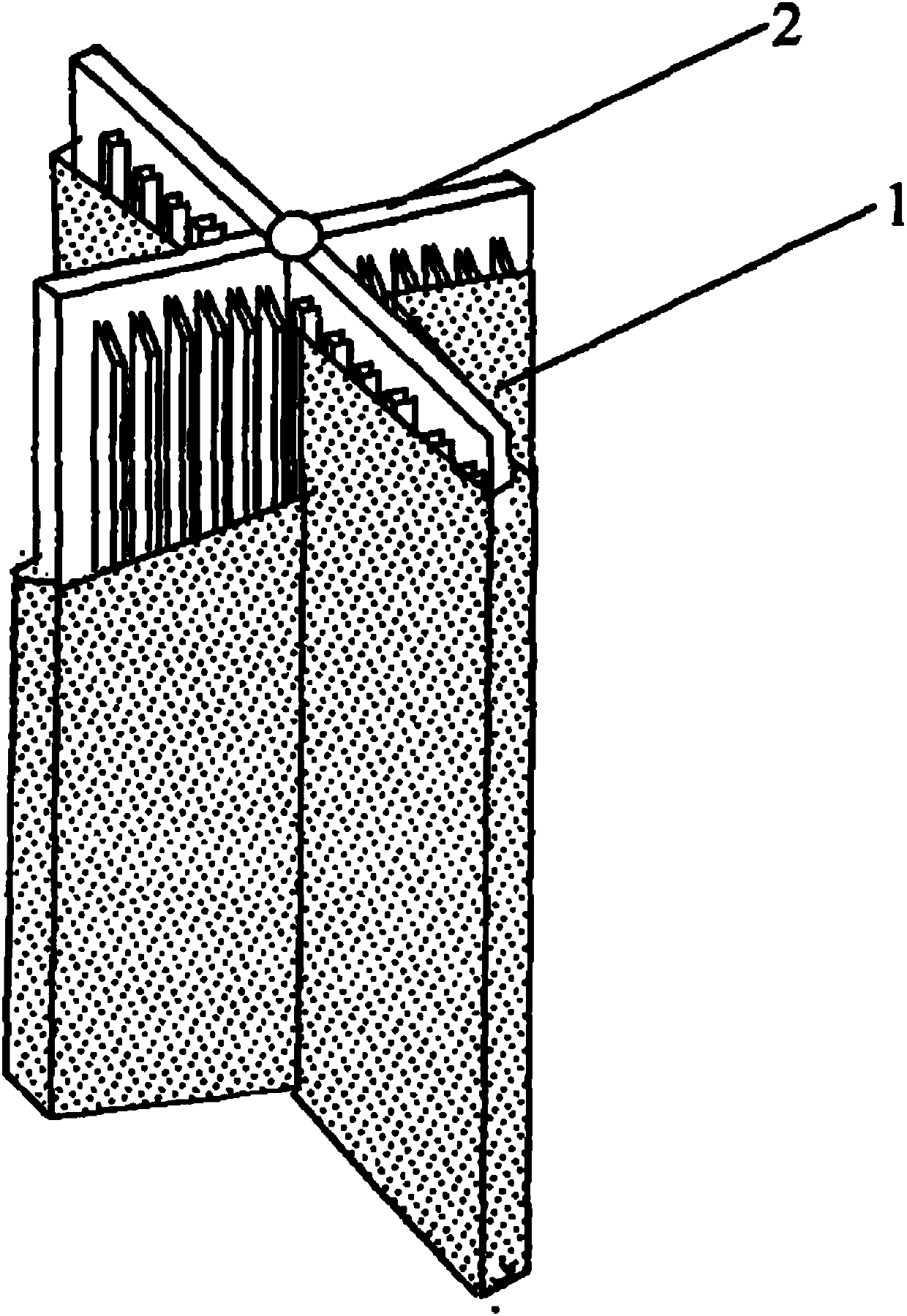

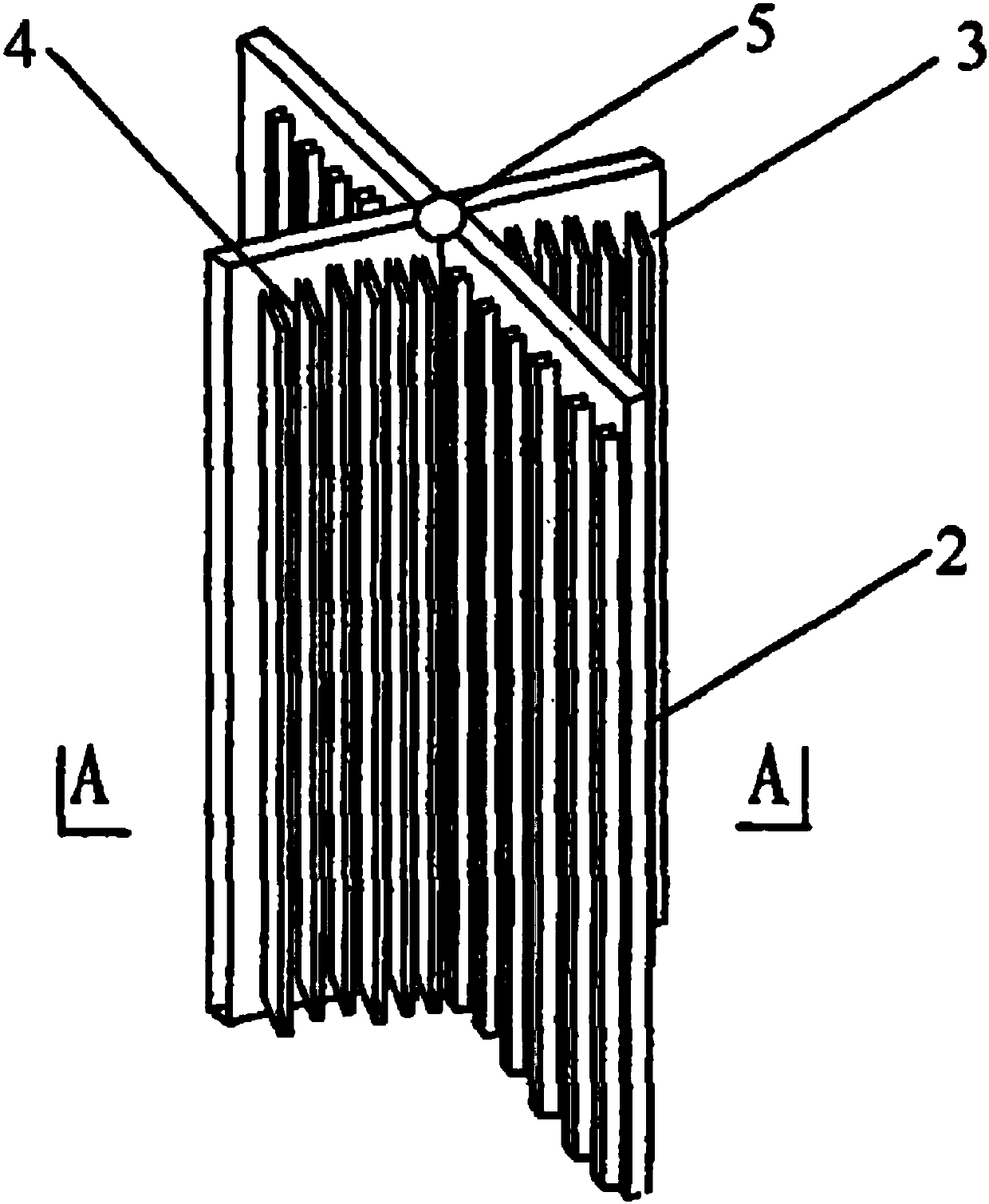

Novel plastic drainage plate

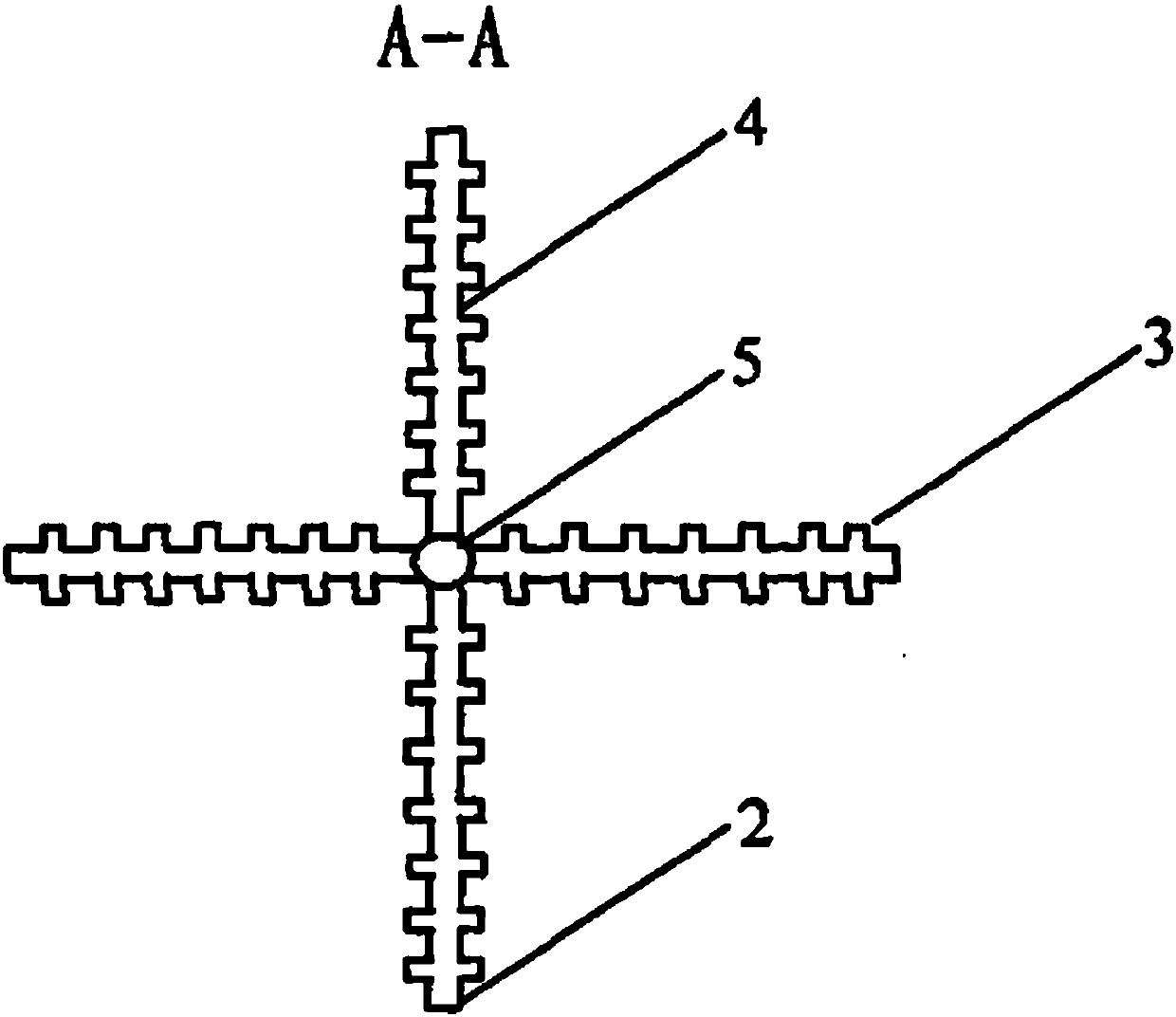

InactiveCN107905210AImprove bending resistanceReduce cloggingSoil preservationCruciformPlastic materials

The invention relates to a plastic drainage board used in the treatment of soft soil foundation, which is a new type of plastic drainage board. The new type of plastic drainage board is composed of a cross-shaped core board and a filter membrane, wherein the cross-shaped core Composed of , protrusions, drainage channels, and a cross-shaped joint center, this new type of high-efficiency anti-bending plastic drainage board can prevent bending and clogging in the soil, increase the contact area with the soil to accelerate drainage, and is very environmentally friendly. That is, with the cylindrical joint point as the center, paste the surface of the cross-shaped core plate and the filter membrane, which can increase the strength of the plastic drainage plate and prevent bending and clogging; Channels increase the number of drainage paths, which is conducive to the drainage of water; the materials used in the new type of high-efficiency and anti-bending plastic drainage boards are degradable materials, which will degrade and disappear after a period of time, which is conducive to the redevelopment and utilization of land.

Owner:慈溪市舒润卫浴实业有限公司

Oversized prefabricated fair-faced concrete hanging plate and manufacturing and mounting process

PendingCN114809512AWill not deformSo as not to damageCovering/liningsCeramic shaping apparatusCrack resistanceArchitectural engineering

The oversized prefabricated fair-faced concrete hanging plate comprises a prefabricated fair-faced concrete hanging plate body, part of a back-attached steel frame is pre-embedded in the prefabricated fair-faced concrete hanging plate body, and a plurality of main keel pre-embedded holes and secondary keel pre-embedded holes are distributed in the back-attached steel frame. According to the prefabricated fair-faced concrete hanging plate, the double-layer two-way steel bars are combined with the channel steel primary and secondary keels in the prefabricated fair-faced concrete hanging plate body, so that the hanging stress of the hanging plate body is met, and the hanging stress of the hanging plate body is improved; meanwhile, the longitudinal rigidity, the transverse rigidity and the surface crack resistance of the hanging plate body are guaranteed, and it is guaranteed that the prefabricated fair-faced concrete hanging plate is not deformed or damaged in the transportation and hoisting processes.

Owner:ZHEJIANG CONSTR ENG GRP CO LTD

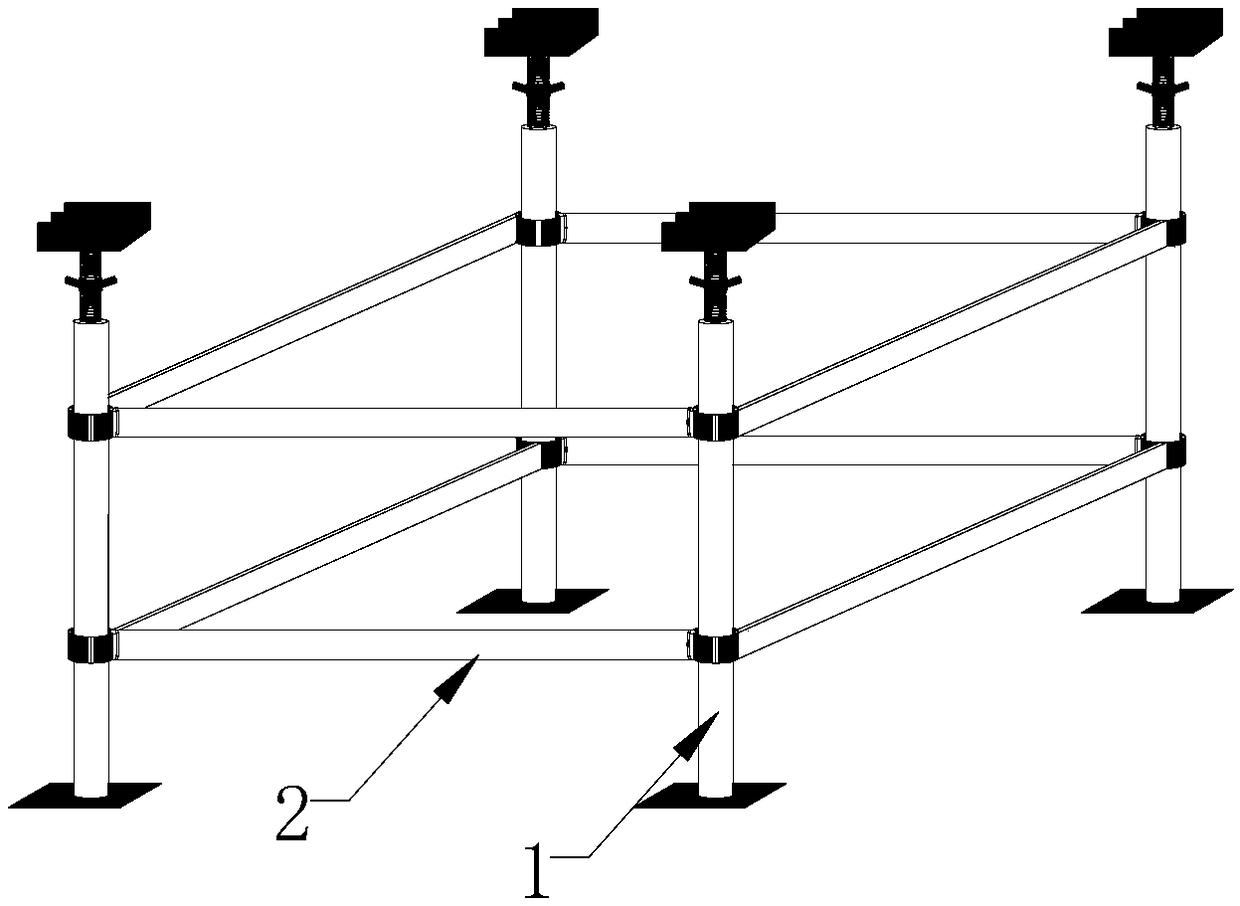

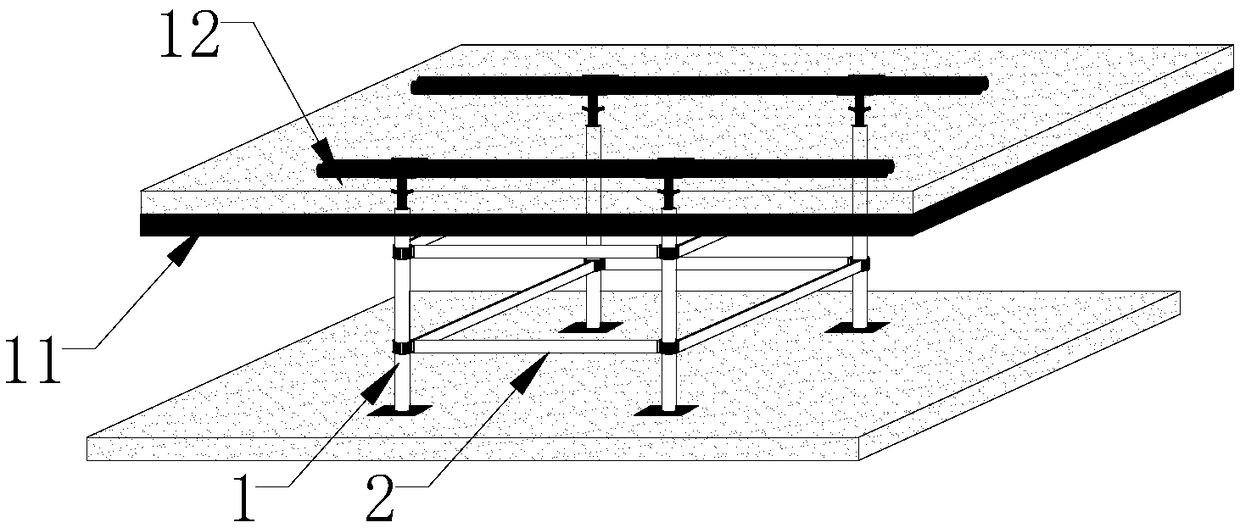

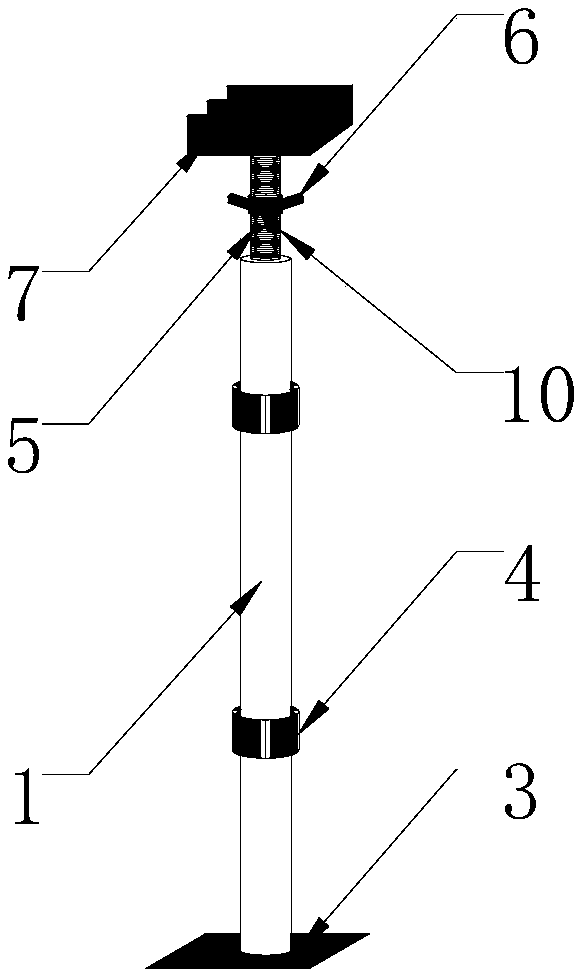

Adjustable steel supporting system for building construction, and installation and use methods thereof

InactiveCN108729688AReduce steel consumptionReduce in quantityShoresSupporting systemMaterial handling

The invention discloses an adjustable steel supporting system for building construction, and installation and use methods thereof. The adjustable steel supporting system comprises four supporting rodsand eight cross rods; the two ends of the cross rods are respectively connected with the supporting rods; two buckles are respectively arranged on each of the four supporting rods; the two ends of the cross rods are respectively fixed on the buckles; a bottom supporting plate is arranged at the bottom end of each of the supporting rods, a lead screw is arranged at the top end, and a top support is arranged at the top end of the lead screw; plugs are respectively arranged at the two ends of each of the cross rods, and an oblique installation port is formed in each of the plugs. The adjustablesteel supporting system disclosed by the invention has the benefits that the adjustable steel supporting system is less in steel consumption compared with a bowl-buckle type scaffold and a steel pipescaffold, the number of the supporting rods on a mould supporting field is less, the operation space is large, personnel passage and material handling are facilitated, the field is easy to manage, theconstruction speed is accelerated, the resource consumption rate is also reduced while the construction efficiency is improved, and the green construction on a site construction site is favorably promoted.

Owner:徐晓胜

Construction Method of Combined Cofferdam Suitable for Deep Foundation Pit in Weak Geology

ActiveCN104988930BAvoid pollutionMeet the structural stress requirementsExcavationsBulkheads/pilesCofferdamRebar

The invention discloses a construction method of a combined cofferdam suitable for a weak geology deep foundation pit and relates to the field of bridge construction. The construction method includes the following steps that the construction position of the concrete cofferdam is set out and positioned; base replacement is conducted on the construction position; supporting sole timber and steel blade feet are laid, rebars are tied, the concrete cofferdam is poured, and anchor rebars are installed on the top face of the concrete cofferdam; a first inner support is installed in the concrete cofferdam; the concrete cofferdam is made to sink; steel plate piles are installed on the top face of the concrete cofferdam, a second inner support is installed in the steel plate piles, the second inner support is fixed to the anchor rebars, and a third inner support is installed above the second inner support; the concrete cofferdam is made to sink continuously to design elevation. The combined cofferdam can meet the structural stress requirement; environmental pollution of construction waste, dust, noise and the like generated when the concrete cofferdam is detached is avoided; green construction is facilitated; construction progress is effectively accelerated; the construction cost is saved.

Owner:CHINA RAILWAY MAJOR BRIDGE ENG GRP CO LTD

A method of 3D printing concrete special-shaped non-web reinforcement beam

ActiveCN112343343BAvoid shear damageImprove adhesionAdditive manufacturing apparatusCeramic shaping apparatus3d printArchitectural engineering

The invention discloses a method for 3D printing concrete special-shaped non-web reinforcement beams. The concrete special-shaped non-web reinforcement beam members sequentially include a rectangular flange layer, a curved web layer, a curved steel mesh layer, and an external concrete protection layer from top to bottom. part; it is characterized in that the method is: using 3D printing concrete technology to sequentially print a rectangular flange layer and a curved web layer; then manually arranging the curved reinforcement layer; finally using 3D printing concrete technology to print the concrete protection layer. The method of the invention optimizes the shape, sets the concrete according to the stress of the beam, saves the amount of concrete materials, lays the steel bars along the printing direction during the printing process, avoids the construction inconvenience caused by the post-installation of the horizontal bars, and solves the problem at the same time. The problem of bonding between steel bars and concrete during installation simplifies construction.

Owner:SOUTHEAST UNIV

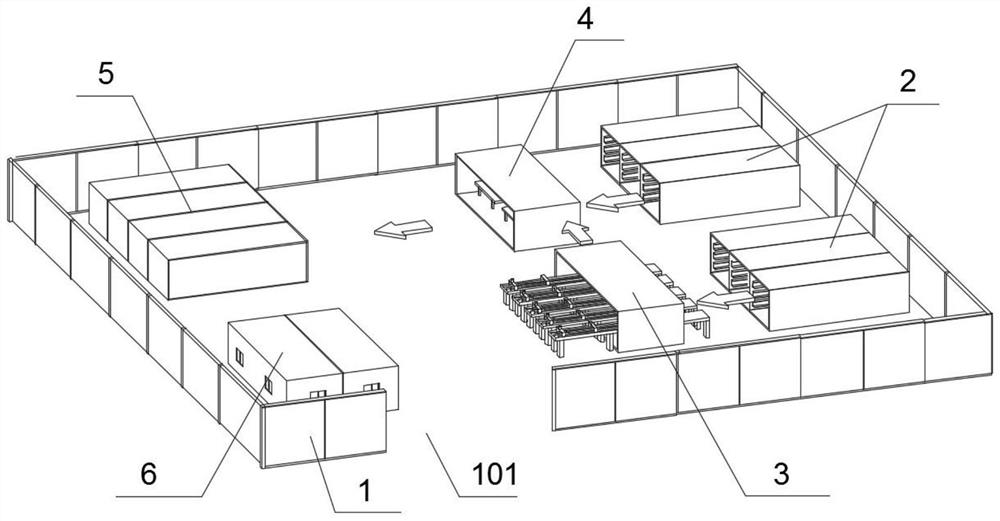

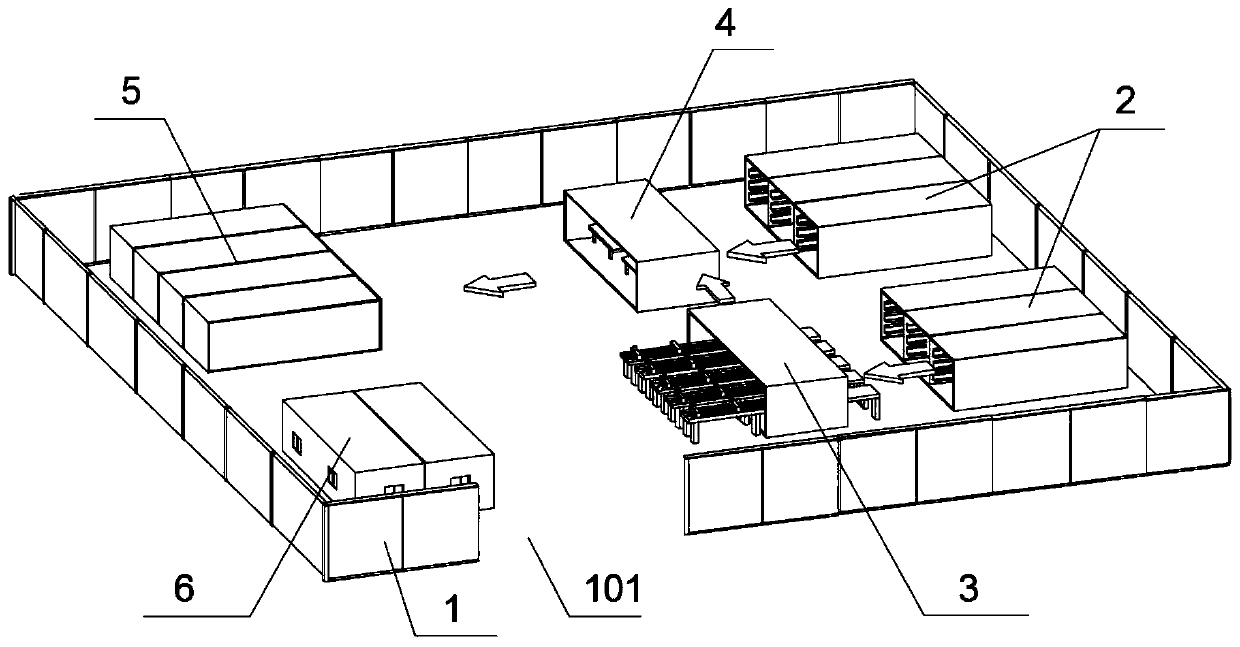

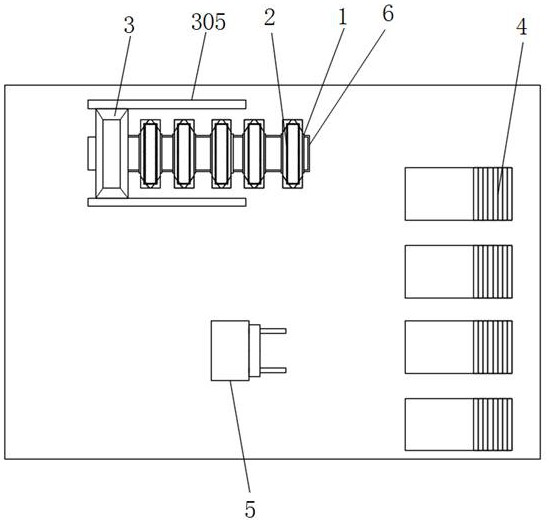

A support and hanger green construction integrated system

ActiveCN111502355BAvoid placingReduce pollutionWork tools storageIndustrial buildingsPunchingAssembly line

The invention relates to a green construction integrated system for support and hangers, which includes an enclosure wall and an accessory storage station, a processing workstation, an assembly workstation, a finished product storage station and an office mobile workstation arranged in the enclosure wall. The enclosure wall is assembled from multiple sets of prefabricated enclosures. There is an entrance and exit on one side of the fence, and an office mobile workstation is set at the entrance and exit of the fence. A finished product storage station is set on one side of the office mobile workstation, and an assembly workstation is set on the opposite side of the finished product storage station. The assembly workstation is used for assembling steel parts. A processing workstation is set on the side, and the processing workstation is used for punching, cutting and welding operations on the steel parts, and an accessory storage station is set at one end of the processing workstation and the assembly workstation, and the accessory storage station is used for storing the steel accessories. The production and assembly of the support and hanger is centralized to avoid the problem of placing various equipment and accessories everywhere. The assembly line is used to process and assemble the support and hanger, which effectively improves the assembly efficiency.

Owner:江苏安赫智能装备科技有限公司

Supporting hanger green construction integration system

ActiveCN111502355AAvoid placingReduce pollutionWork tools storageIndustrial buildingsSoftware engineeringStructural engineering

The invention relates to a supporting hanger green construction integration system. The supporting hanger green construction integration system comprises an enclosure wall, an accessory storage station, a processing workstation, an assembly workstation, a finished product storage station and an office moving workstation, wherein the accessory storage station, the processing workstation, the assembly workstation, the finished product storage station and the office moving workstation are arranged in the enclosure wall. The enclosure wall is formed by assembling a plurality of groups of prefabricated enclosure blocking pieces. One side of the enclosure wall is provided with an access opening provided with the office moving workstation. One side of the office moving workstation is provided with the finished product storage station. The assembly workstation is arranged opposite the finished product storage station and is used for assembling a profile steel fitting. One side of the assemblyworkstation is provided with the processing workstation used for punching, cutting and welding the profile steel fitting. One end of the processing workstation and one end of the assembly workstationare respectively provided with a fitting storage station used for storing profile steel fittings. The production and assembly of supporting hangers are centralized, so that the problem that a plurality of sets of equipment and accessories are placed at any place is avoided. The supporting hangers are processed and assembled in a streamline mode, so that the assembly efficiency is effectively improved.

Owner:江苏安赫智能装备科技有限公司

Earthen kiln folk house wall prestressed reinforcement structure

ActiveCN109281489AImprove securityExtended service lifeBuilding repairsEngineeringStructural engineering

The invention discloses an earthen kiln folk house wall prestressed reinforcement structure. The earthen kiln folk house wall prestressed reinforcement structure is provided with outer walls, inner walls, an upper layer reinforcement ring installed on the upper portion of the outer walls and the inner walls, a lower layer reinforcement ring installed on the lower portion of the outer walls and theinner walls, a plurality of vertically arranged prestressed anchor cables connecting the upper layer reinforcement ring and the lower layer reinforcement ring, a plurality of first anchor heads installed at the upper layer reinforcement ring for anchoring the upper ends of the prestressed anchor cables, a plurality of second anchor heads installed at the lower layer reinforcement ring for anchoring the lower ends of the prestressed anchor cables and a plurality of grooves corresponding to the multiple prestressed anchor cables. According to the earthen kiln folk house wall prestressed reinforcement structure, steel plates are used for drawing wall bodies of an earthen kiln folk house by using the prestressed anchor cables, so that horizontal and vertical reinforcement of the inner walls and the outer walls of the earthen kiln folk house is realized, the wall bodies have higher strength and integrity, the stability of the wall bodies of the earthen kiln folk house is increased, and thesafety of the earthen kiln folk house is improved; and the earthen kiln folk house wall prestressed reinforcement structure is convenient, practical and easy to operate, all materials used are conventional and economical, energy saving and environmental protection are achieved, and the earthen kiln folk house wall prestressed reinforcement structure is suitable for large-scale overall reinforcement of the earthen kiln folk house.

Owner:王维玉

A reinforcement system for the overall structure of traditional earthen kiln dwellings and its construction technology

The invention discloses a traditional earthen kiln folk house overall structure reinforcement system and construction technology. The reinforcement system is provided with wall bodies, a kiln roof, upper, middle and lower layer reinforcement rings, nylon ropes, limiting glue-stopping plugs and a kiln roof support frame. The upper, middle and lower layer reinforcement rings are all provided with external L-shaped steel plates, steel strands, anchorage devices, internal L-shaped steel plates and in-wall supporting steel plate bars. According to the traditional earthen kiln folk house overall structure reinforcement system and construction technology, the external L-shaped steel plates are used for performing pre-stressed drawing on the outer wall bodies by using the steel strands, and the internal L-shaped steel plates are adopted in walls and the in-wall supporting steel plate bars are welded to form the upper, middle and lower layer reinforcement rings; and through holes in the wall bodies are tied by the nylon ropes, and finally the overall reinforcement of the wall bodies of an earthen kiln is achieved, so that the wall bodies have higher strength and integrity. The reinforcementof the kiln roof is achieved through the kiln roof support frame. The traditional earthen kiln folk house overall structure reinforcement system and construction technology effectively improve the safety of earthen kiln folk houses, and is convenient, practical and easy to operate, all materials used are conventional and economical, energy saving and environmental protection are achieved, and thetraditional earthen kiln folk house overall structure reinforcement system and construction technology are suitable for large-scale overall reinforcement of the earthen kiln folk houses.

Owner:王维玉

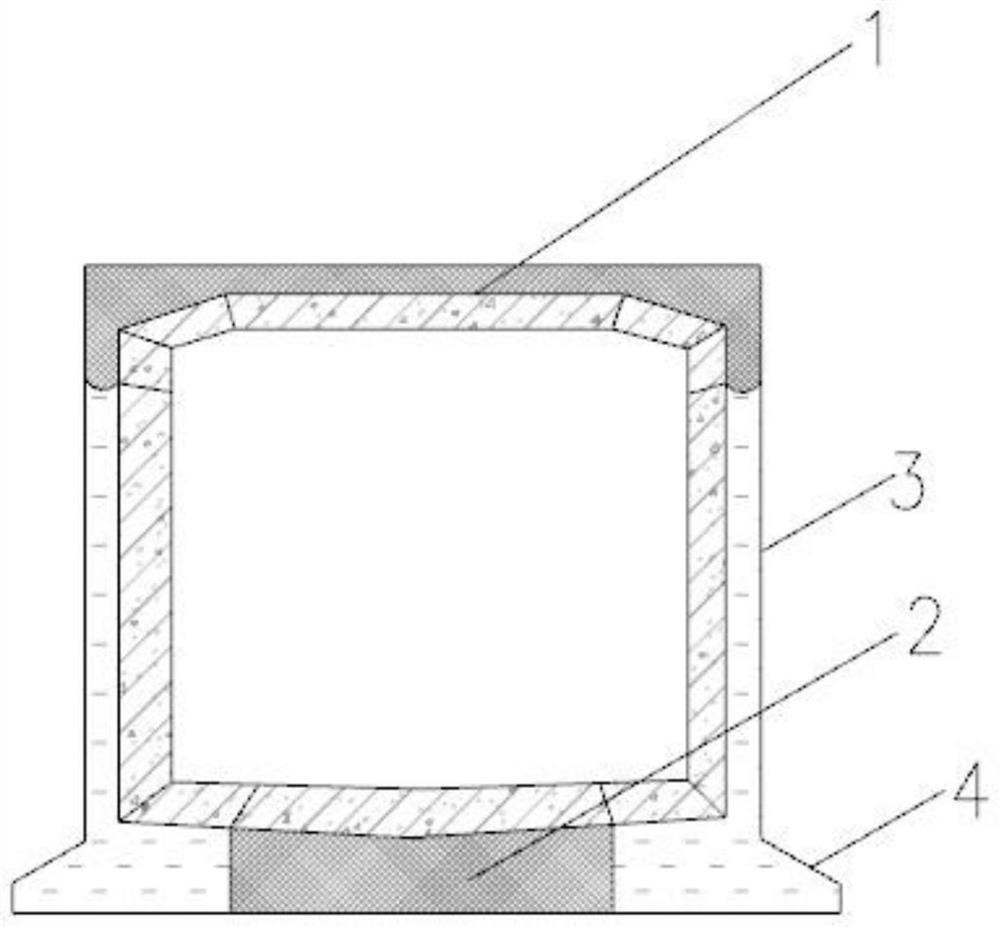

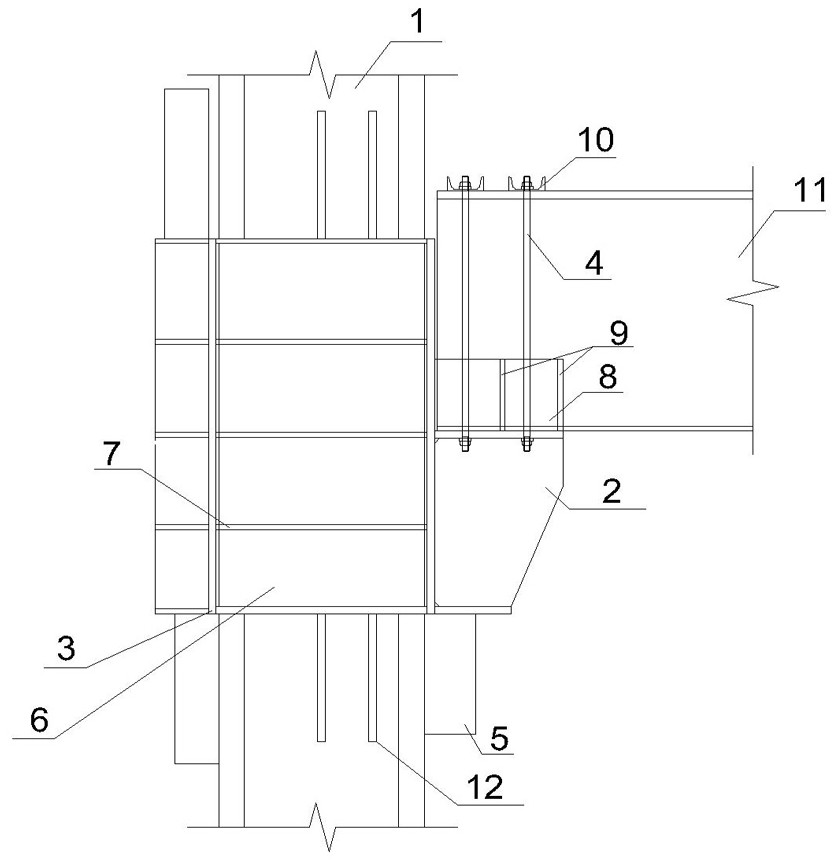

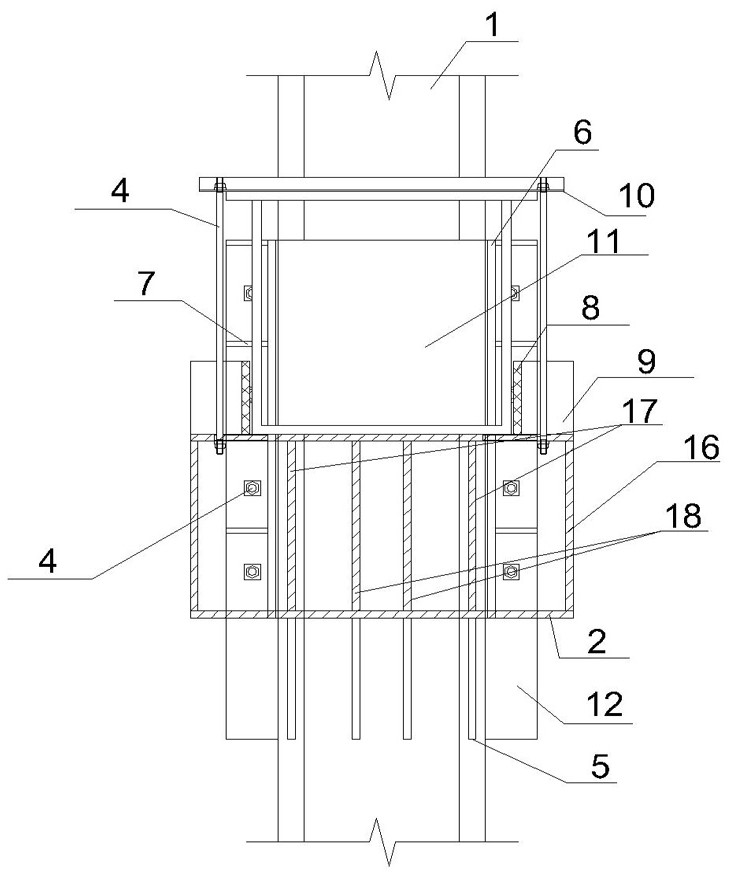

Hoop, beam-column connection structure including the hoop, and construction method thereof

ActiveCN113463773BSolve slippageFirmly connectedBuilding constructionsBraced frameArchitectural engineering

The invention discloses a hoop, a beam-column connection structure comprising the hoop and a construction method thereof. The inner end face of the hoop abuts against the outer end face of an existing column, and one end of a box-shaped steel beam is socketed in the pre-socketed steel beam. stay in the groove, and the other end is set on the support short column; the bottom of the underground structure roof is provided with a support frame, and the support frame is formed by connecting vertical concrete support columns and horizontal concrete support columns; the support short column is set above the underground structure roof to support The bottom of the short column is inserted at the intersection of the vertical concrete support column and the horizontal concrete support column, and is coaxial with the vertical concrete support column of the supporting frame; the existing column vertically passes through the roof of the underground structure and extends out of the roof of the underground structure for at least 20cm. The invention makes the installation of the box-shaped steel beam and the existing column more convenient, solves the technical problem of low strength of the existing beam-column connection node, provides a beam-column connection structure with a more stable structure, and provides a powerful foundation for the establishment of the tower crane conversion foundation. condition.

Owner:BEIJING NO 3 CONSTR ENG +1

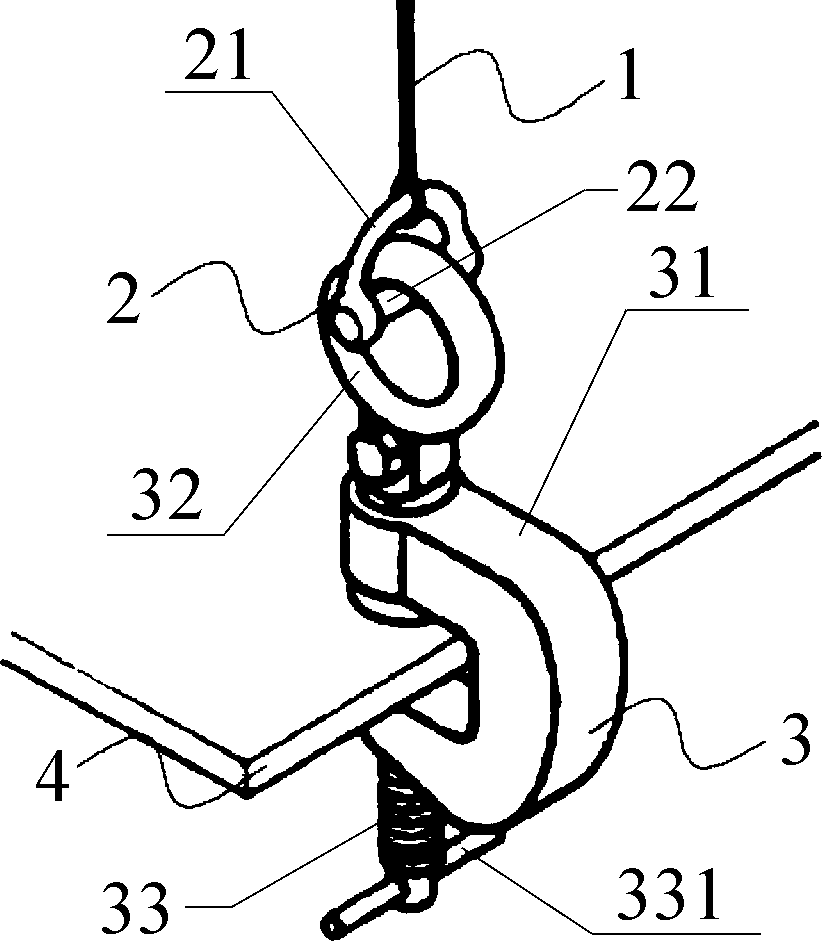

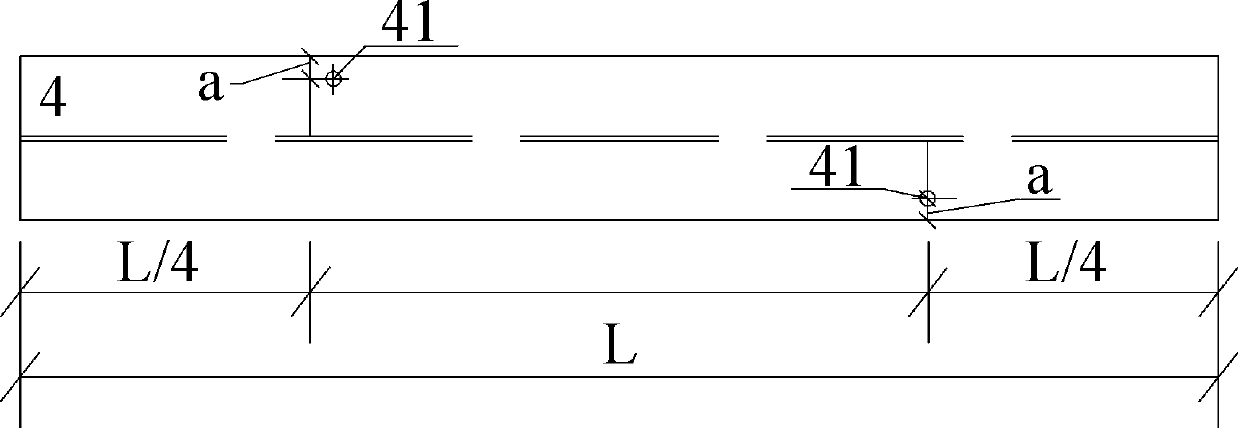

Construction node for H-shaped steel beam hoisting and using method of construction node

PendingCN109592555AReduce the risk factorMeasures to reduce hoisting toolingBuilding material handlingLoad-engaging elementsArchitectural engineeringCalipers

The invention relates to the field of load hanging elements or devices for transmitting lifting force to objects, in particular to a construction node for H-shaped steel beam hoisting and a using method of the construction node. The construction node for the H-shaped steel beam hoisting comprises a steel wire rope (1) and is characterized by further comprising a shackle ring (2) and a bolt lockinghanging clamp (3); the bolt locking hanging clamp (3) comprises a caliper (31), a hanging ring (32) and a fastening bolt (33); and the shackle ring (2) and the hanging ring (32) are interlocked, andone end of the steel wire rope (1) is tied on the shackle ring (2). The invention provides a using method of the construction node for the H-shaped steel beam hoisting, and is characterized by comprising the following steps of a, forming holes, b, hoisting, and c, plugging holes. The construction node is simple in structure, convenient to use, low in construction time consumption, safe and reliable.

Owner:SHANGHAI BAOYE GRP CORP

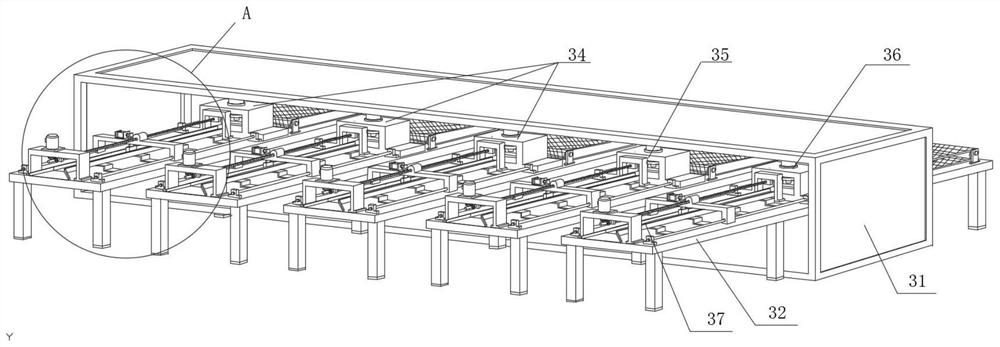

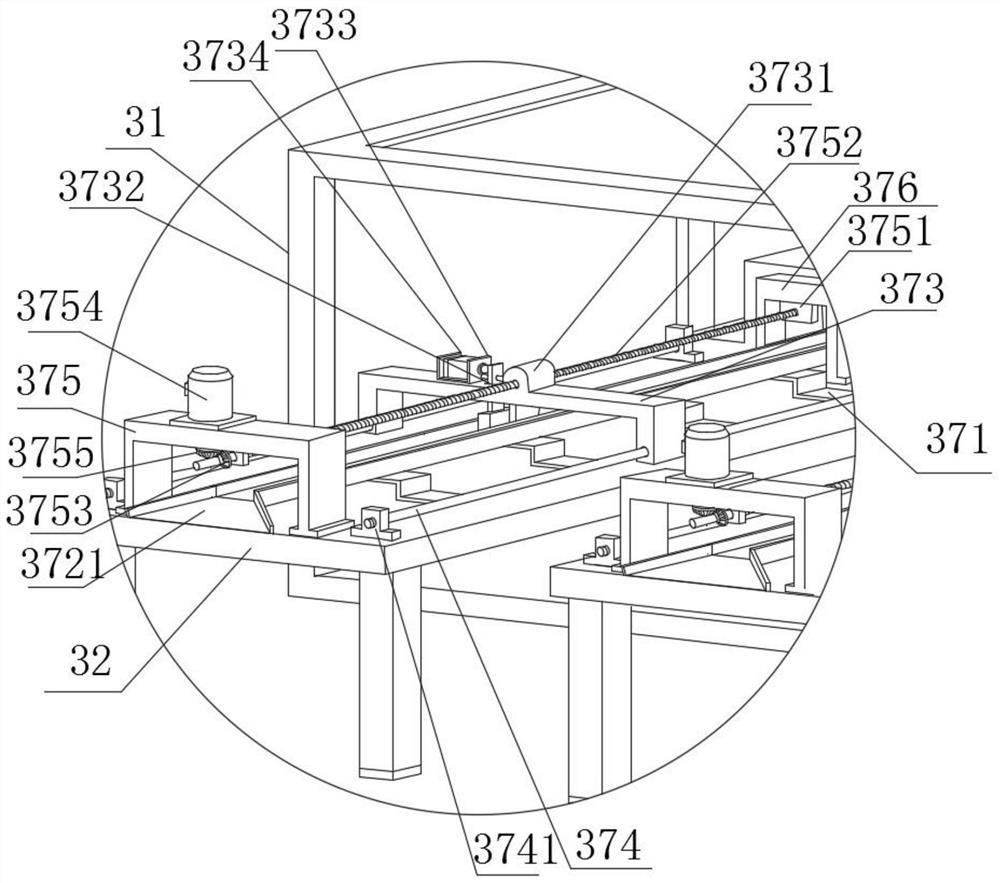

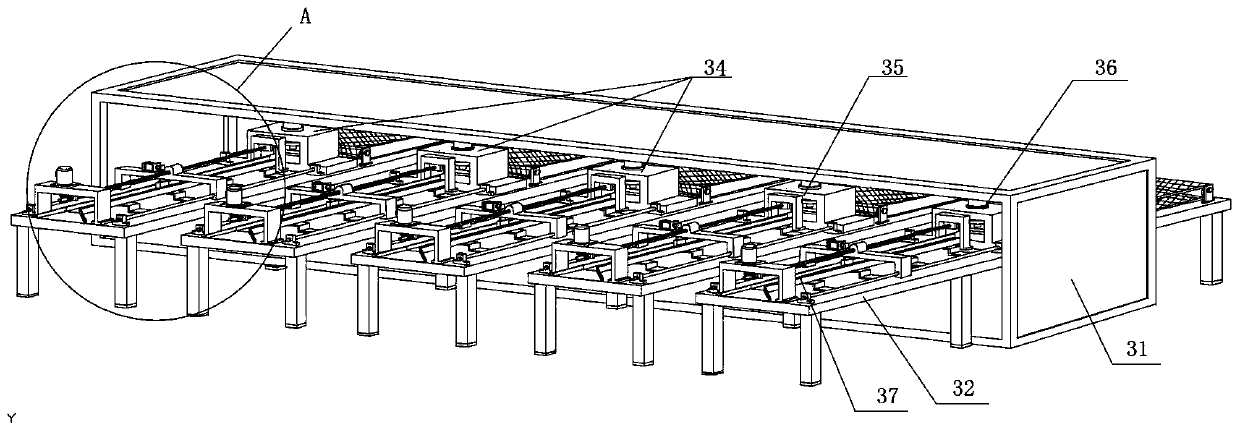

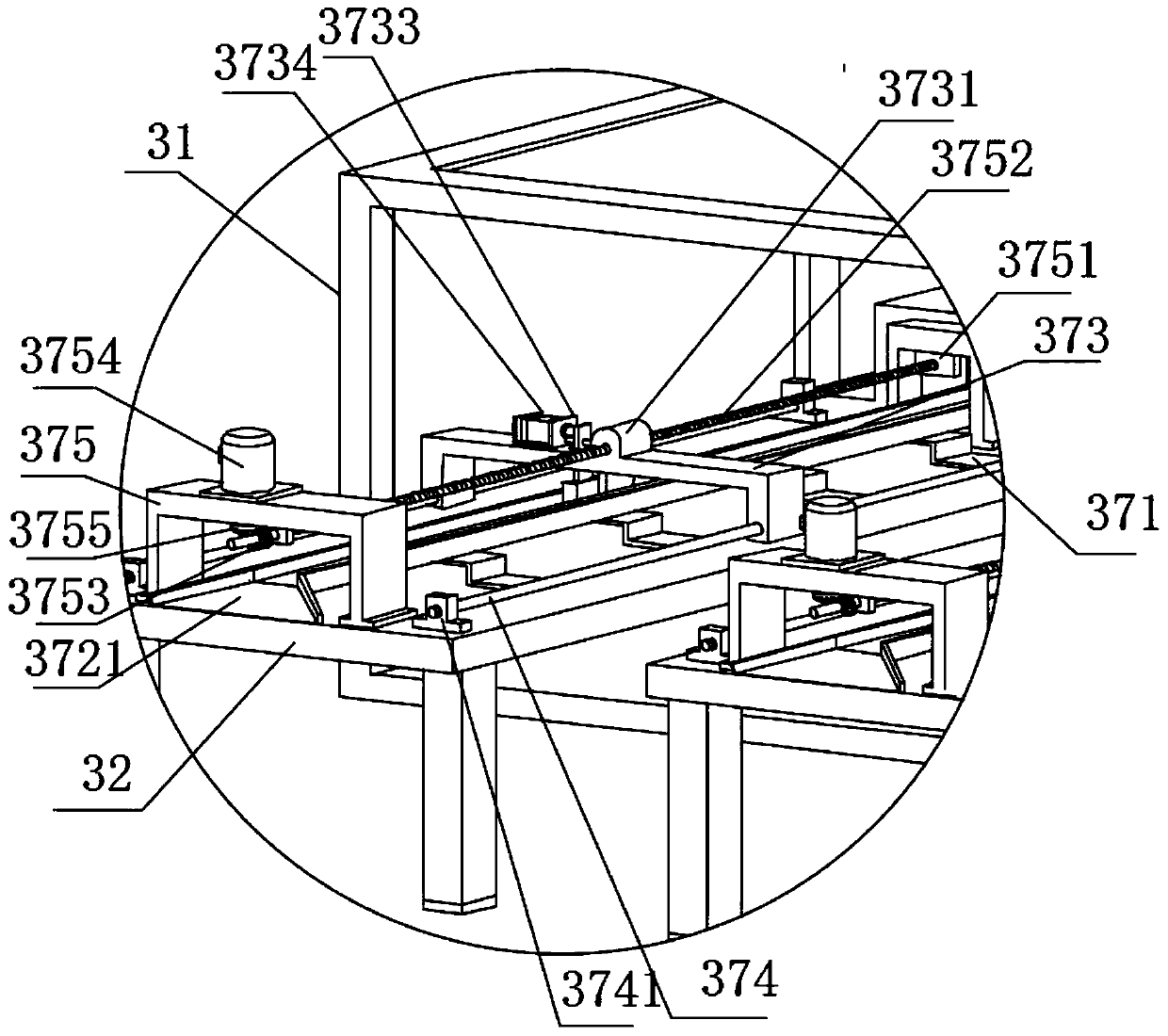

Nomadic building prefabricated PC component production line and method

PendingCN112792977AConducive to parallel constructionControllable prefabrication cycleCeramic shaping plantsProduction lineConstruction engineering

The invention discloses a nomadic building prefabricated PC component production line and method. The nomadic building prefabricated PC component production line is arranged on a construction site and comprises a material distribution area and a steam curing area, a vibration table and a mold table assembly arranged on the vibration table are flatly laid in the material distribution area, and a material distribution device is arranged above the mold table assembly; a plurality of foldable oxygen steaming rooms are flatly laid in the steam curing area; and the nomadic building prefabricated PC component production line further comprises a transfer mechanism which is used for transferring and stacking the mold table assembly. According to the design, the construction site is reasonably utilized for producing prefabricated PC components on site, the prefabricating period can be reasonably arranged along with the building construction process, parallel construction is facilitated, the construction period is controllable, and the production efficiency is high; in addition, resources of the construction site are reasonably used, the site construction cost is saved, and green construction is facilitated; and in addition, the cost input caused by long-distance transportation of the prefabricated components is avoided, building assembly can be carried out after the prefabricated components are prefabricated on site, the prefabricated components are not prone to being damaged, and the safety and reliability of a building are effectively guaranteed.

Owner:贵州中昇东浩科技有限公司

A tower crane relay lifting storage rack device

ActiveCN106193102BSolve transportation problemsEasy to makeFoundation engineeringBuilding constructionsArchitectural engineeringTower crane

The invention relates to a device for conveying accommodating frames through tower crane relaying. The device comprises bodies, wherein each body comprises movable foundations, steel pipe stand columns and square steel pipe cross beams, the movable foundations are fixed on a foundation, embedded bolts are arranged at upper ends of the movable foundations, the steel pipe stand columns are mounted at upper ends of the movable foundations, springs are arranged at lower ends inside the steel pipe stand columns, round steel plates are arranged at top ends of the springs, supports are arranged on two sides of lower ends of the square steel pipe cross beams, diameters of the supports correspond to those of the steel pipe stand columns, round steel pipes are arranged at lower ends of the supports, diameters of the round steel pipes are smaller than those of the steel pipe stand columns, the square steel pipe cross beams are mounted on the steel pipe stand columns by the aid of the round steel pipes, and the round steel pipes are pressed against the round steel plates inside the steel pipe stand columns. The device is simple to manufacture and easy to mount, the whole set of device can be recycled, green construction is facilitated, the device is provided with shock-absorbing devices, the service life can be prolonged, safe construction is facilitated, and the problem about transportation of hillside construction materials is solved.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com