Patents

Literature

65results about How to "Reduce cross work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

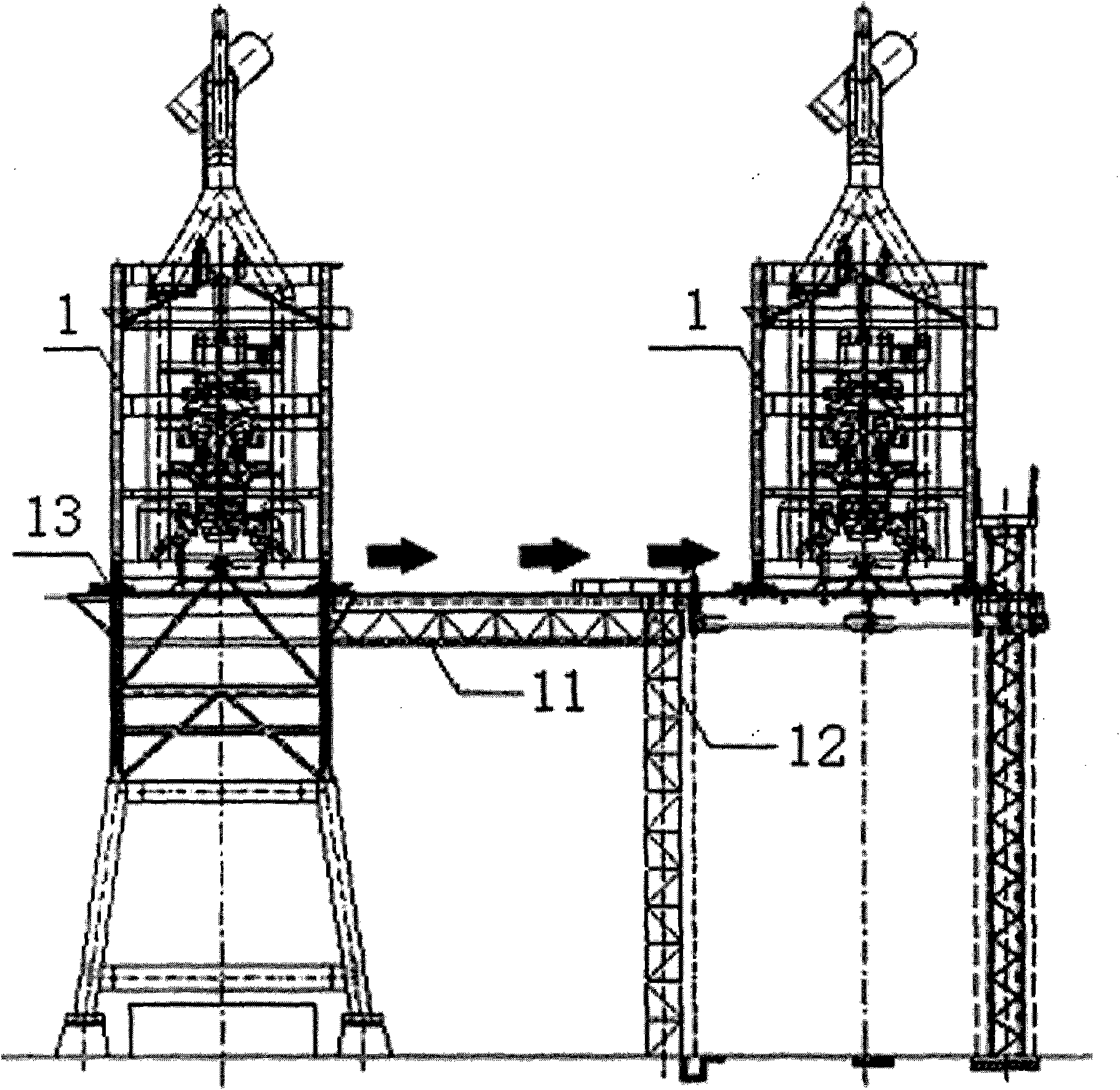

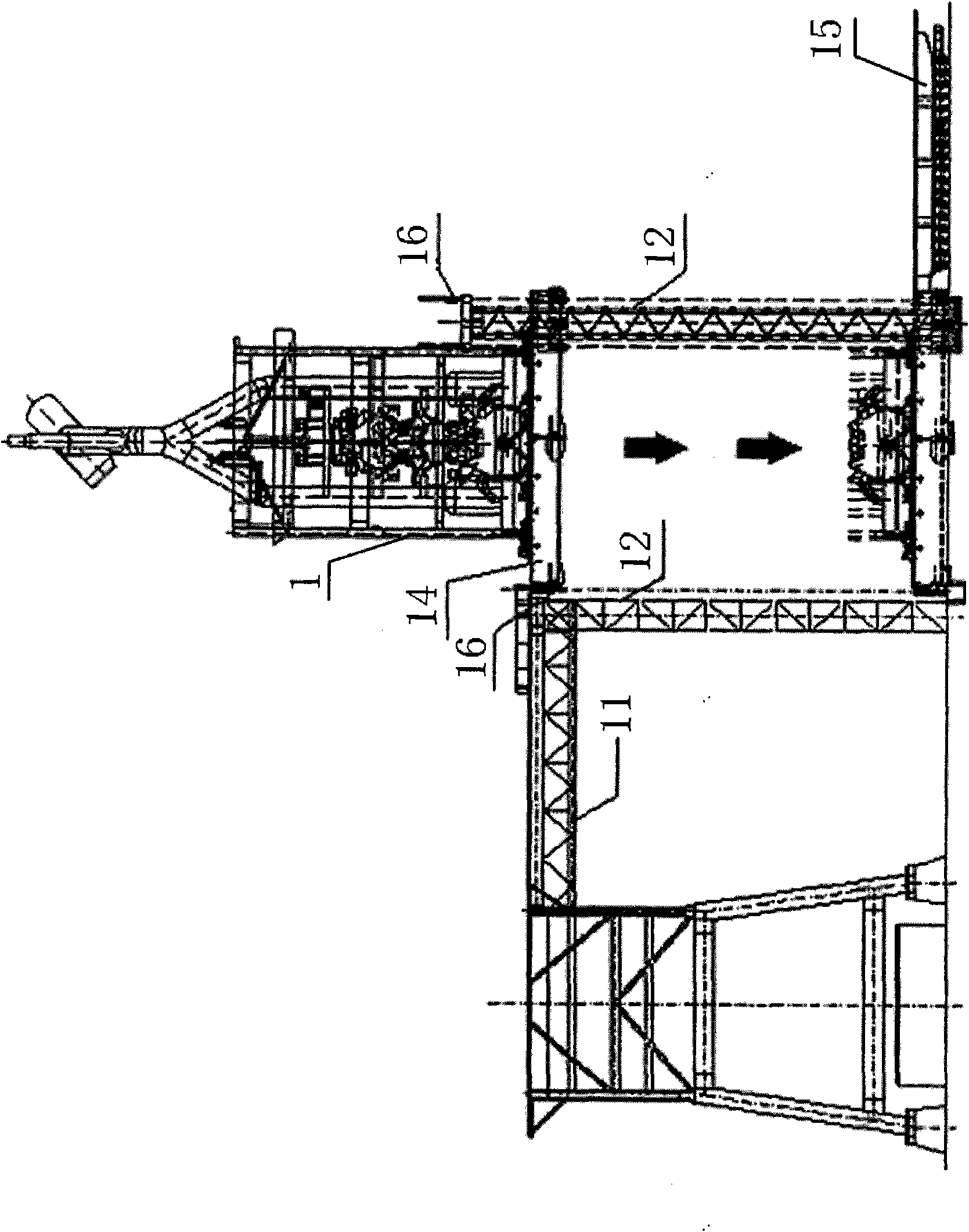

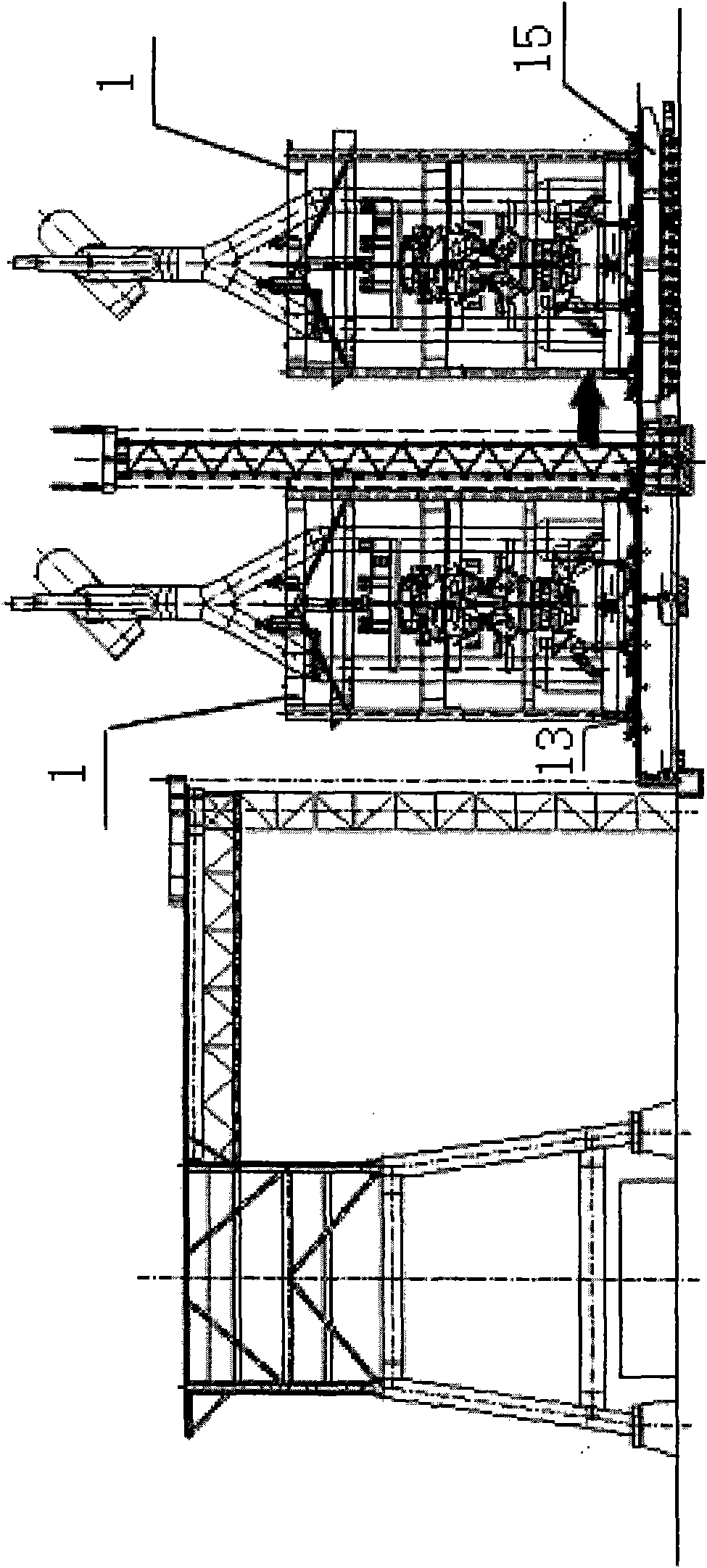

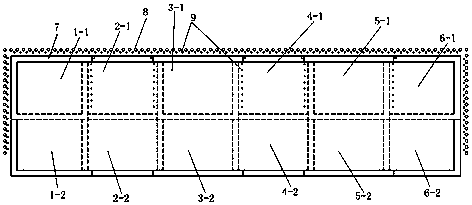

Modularized and integrative disassembling and installing methods for blast furnace

InactiveCN102146488ASatisfy construction safetyMeet construction requirementsBlast furnace componentsBlast furnace detailsCast houseBuilding construction

The invention relates to the installation method field of smelting equipment of iron, in particular relates to modularized and integrative disassembling and installing methods for a blast furnace. The modularized and integrative disassembling method for the blast furnace comprises: disassembling a furnace top system, disassembling a hot wind surrounding pipe, disassembling a layer beam and casting house platform and disassembling a furnace body. The modularized and integrative disassembling method is characterized in that when the furnace top system, the hot wind surrounding pipe, the layer beam and casting house platform and the furnace body are dissembled, the modularized and integrative disassembling method is adopted. The modularized and integrative insulating method for the blast furnace comprises: installing the furnace top system, installing the hot wind surrounding pipe, carrying out furnace body construction, carrying out layer beam and casting house platform construction and carrying out finished product groove construction and is characterized in that when the furnace top system, the hot wind surrounding pipe, the furnace body, the layer beam and casting house platform and the finished product groove are installed, the modularized and integrative installing method is adopted. According to the invention, construction efficiency is high, safety is high, and production cost is reduced.

Owner:SHANGHAI BAOYE CONSTR INDAL FURNACE ENG TECH

Secondary design construction method for low-pressure boiler small pipeline on the basis of BIM (Building Information Modeling) technology

InactiveCN106951637AIntuitive visualization of project progressDo a good job of progress controlGeometric CADSpecial data processing applicationsSocial benefitsField conditions

The invention discloses a secondary design construction method for a low-pressure boiler small pipeline on the basis of a BIM (Building Information Modeling) technology. The method comprises the following steps that: establishing the three-dimensional stereo models of all pipeline and equipment, and importing pipeline and equipment model and position data to carry out the collision detection of a three-dimensional stereo model graph; designing the starting point and the end point of the small pipeline, establishing the position data, and carrying out the collision detection of the three-dimensional stereo model graph on electric and thermal control equipment; according to a material bill provided by the BIM software technology, carrying out statistics on the type, the amount and the length information of each component of the boiler small pipeline; installing a small pipeline hanging bracket, and baiting and bending the small pipeline on the ground; and carrying out collision detection on an important position and a field condition, and guaranteeing a construction plan. According to the construction plan, construction simulation and progress simulation are carried out, each professional collision problem is coordinated to generate coordinated data to determine a reasonable construction scheme and construction period, a construction period is reduced in general, a great quantity of artificial, material, mechanical and equipment costs can be saved, and economic benefit and social benefit are obvious.

Owner:POWER CHINA HENAN ENG CO LTD

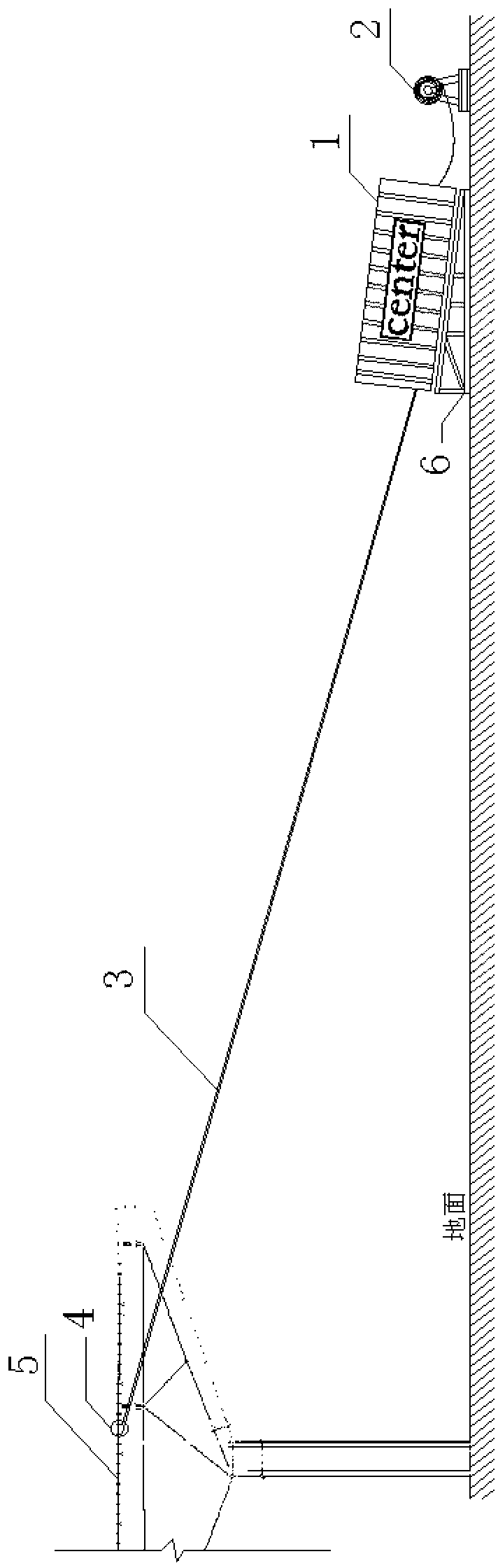

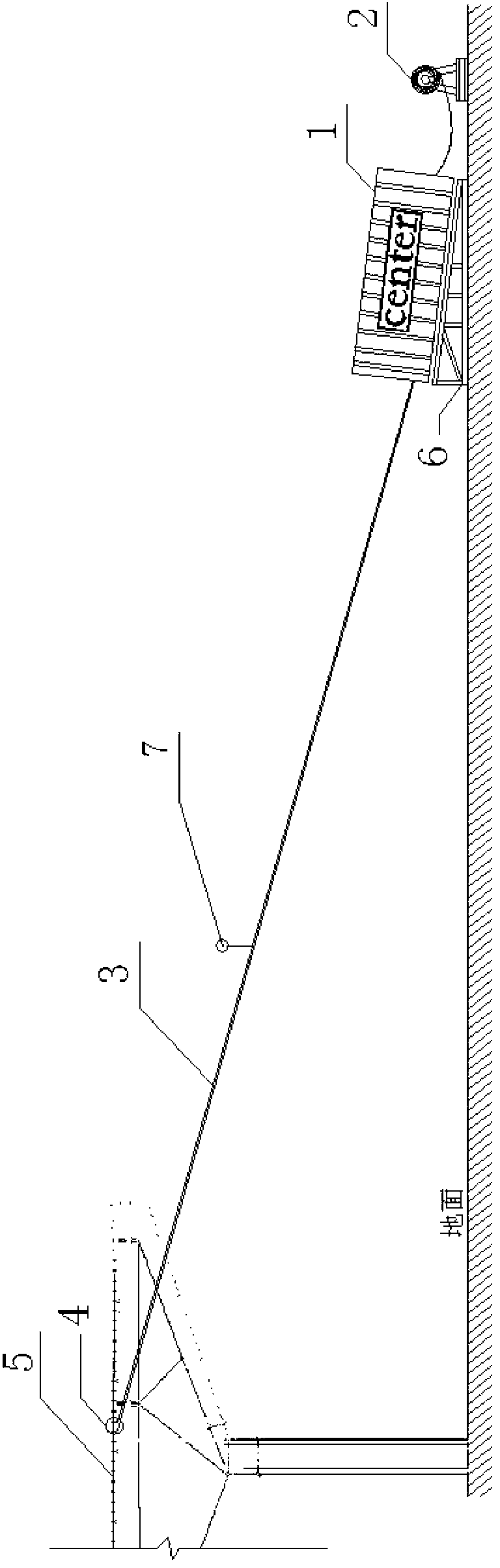

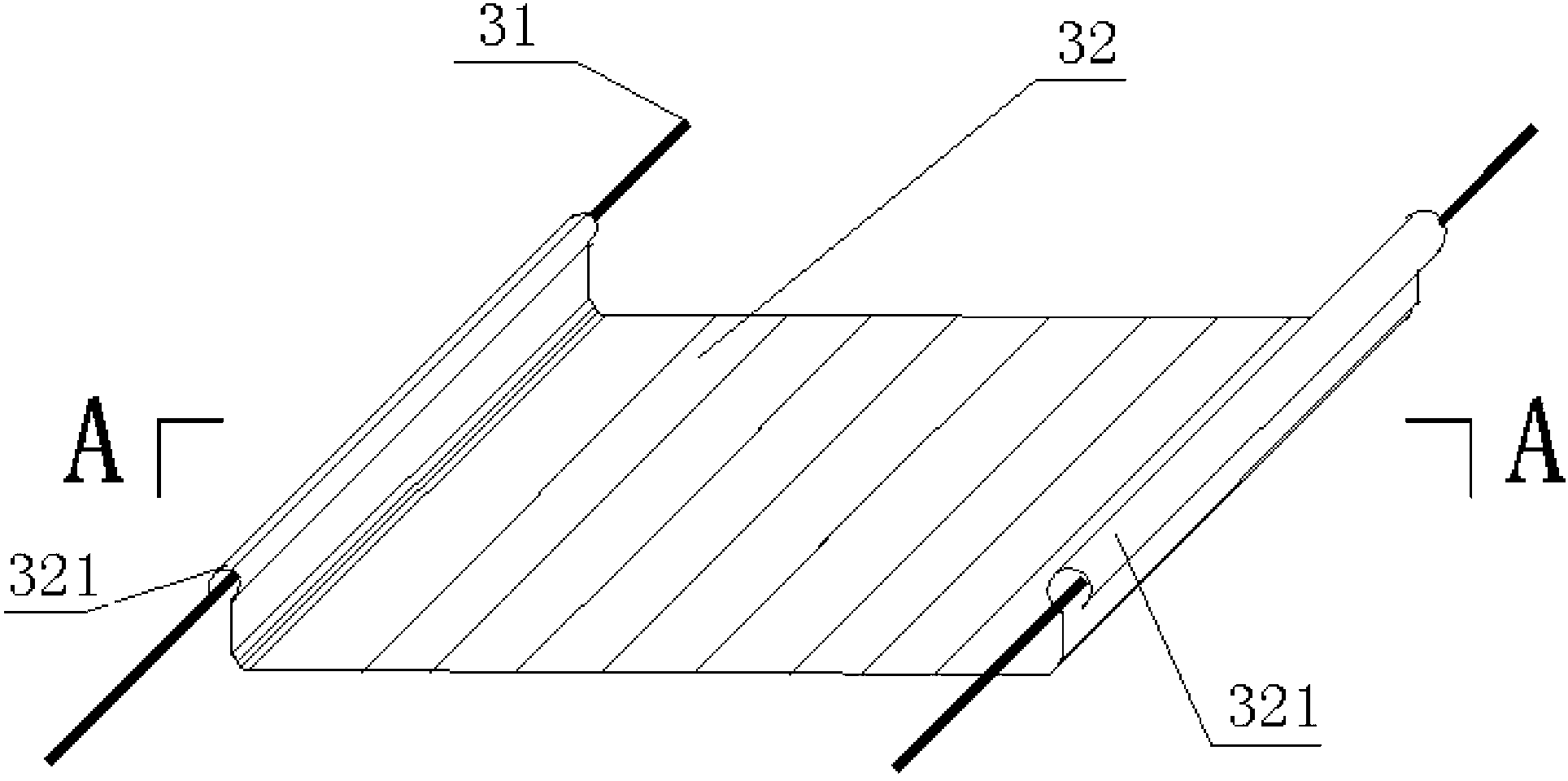

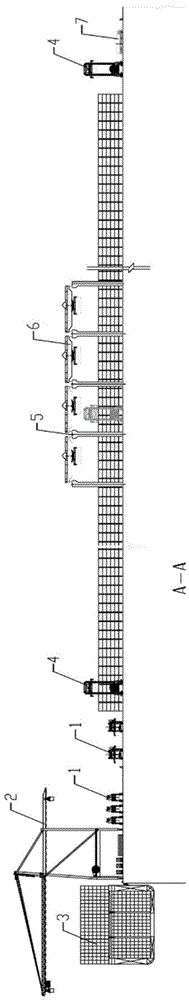

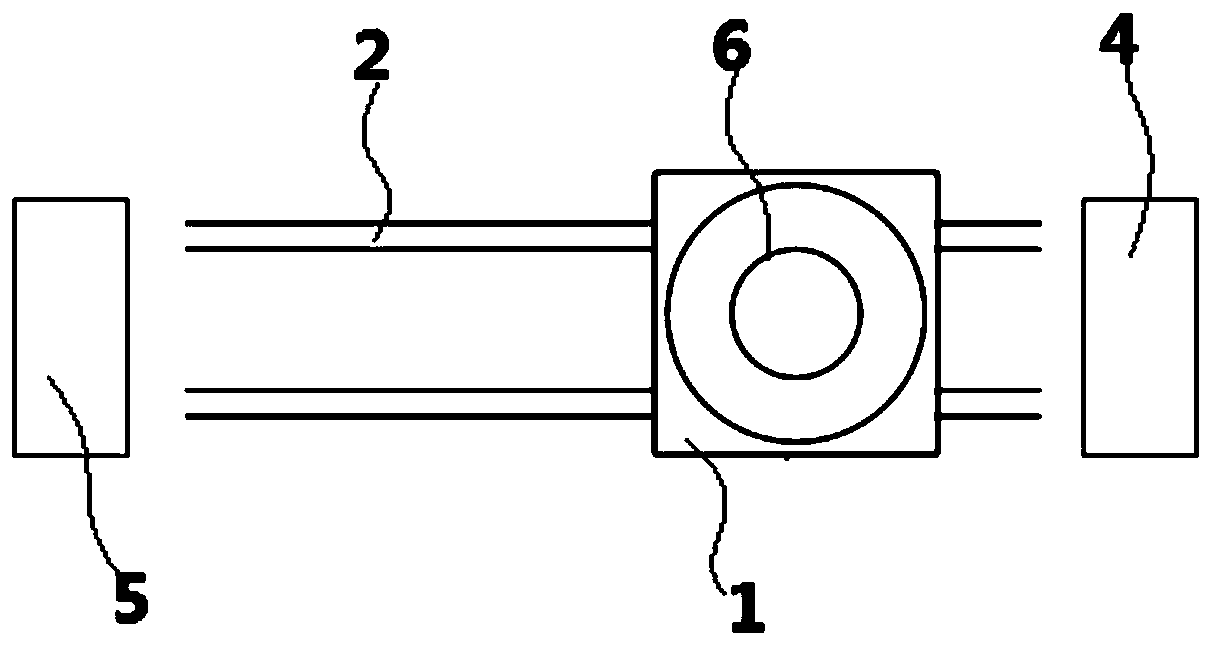

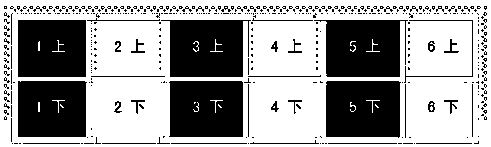

System and method for transporting roof board in air

ActiveCN103233559AShorten the transportation distanceFew linksRoof toolsBuilding constructionCivil engineering

The invention discloses a system for transporting a roof board in the air. The system comprises a sheet metal roll, a forming machine and a transporting device, wherein the forming machine is connected with the sheet metal roll and is used for manufacturing the sheet metal roll into a roof board in a required shape; the transporting device transports the manufactured roof board to a roof on which the metal roof board is to be mounted, and adopts a roof board conveying guide track; one end of the transporting device is connected with a reserved upper board opening on the roof, and the other end of the transporting device is arranged below a board outlet of the forming machine; a board outlet angle of the forming machine tends to be in accordance with an inclined angle of the roof board conveying guide track; and the roof board output by the board outlet of the forming machine falls on the roof board conveying guide track, board outlet thrust of the forming machine drives the roof board to be transported upwards along the roof board conveying guide track. According to the system and the method, the filed roof board manufacture in a construction site is realized, the air transportation is not affected by the building roof height, the length of a single rood board and an on-site condition, the transporting efficiency of the roof board is improved, and the manual labor and the hoisting device cost are reduced.

Owner:CENT INT GROUP

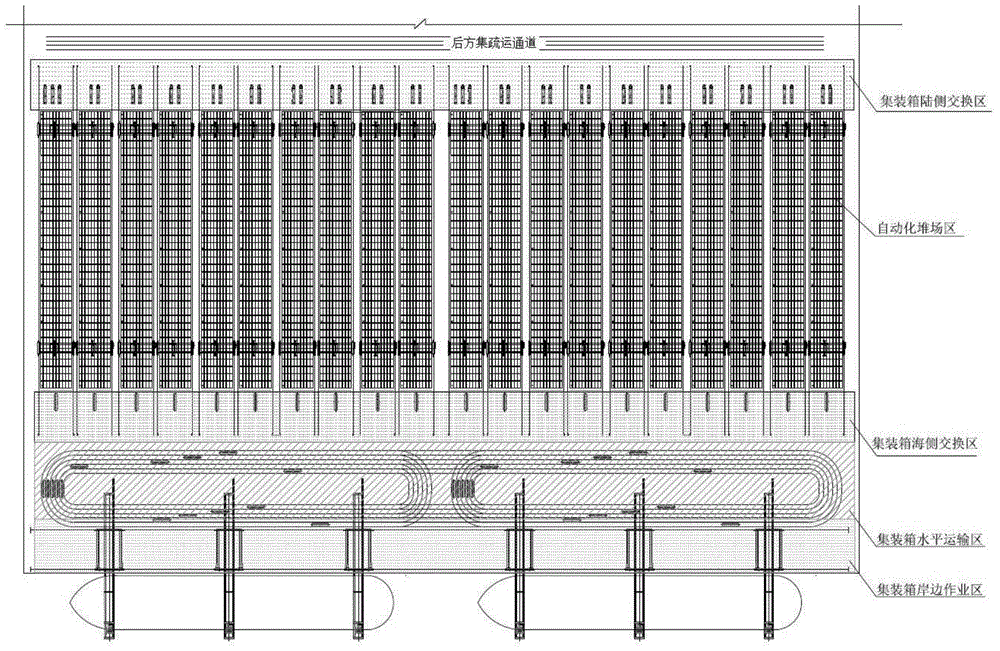

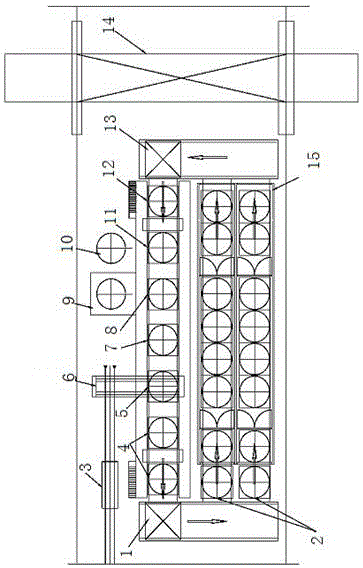

Automatic container wharf handling system and method for right-angled shoreline multi-berth arrangement

ActiveCN104986581AShorten the transportation distanceImprove loading and unloading efficiencyStorage devicesStraddleEngineering

The invention discloses an automatic container wharf handling system for right-angled shoreline multi-berth arrangement. The system is composed of a shore bridge, a straddle carrier, an ARMG and an overhead travelling crane subsystem. The overhead travelling crane subsystem is composed of a viaduct and an overhead travelling crane. The shore bridge is arranged on the front edge of a front face berth and the front edge of a side face berth. The shore bridge is used for perpendicularly and horizontally transporting containers from a container ship to a shoreside working area. An ARMG track of a container yard is arranged perpendicular to the front berth shoreline. The area, closely adjacent to the front face berth end, of the container yard is the front face berth end of the yard. The area, closely adjacent to a rear collecting and distributing channel, of the container yard is a yard land side end. The area, closely adjacent to the side face berth end of the yard, of the container yard is the side face berth end of the yard. According to the automatic container wharf handling system, cross operation possibly caused during joint operation of the front face berth and the side face berth can be reduced to a larger extent, meanwhile, the transportation distance of horizontal transportation equipment inside a side face berth port is decreased, and therefore the handling efficiency and the energy-saving level of the whole system are improved.

Owner:CCCC THIRD HARBOR CONSULTANTS

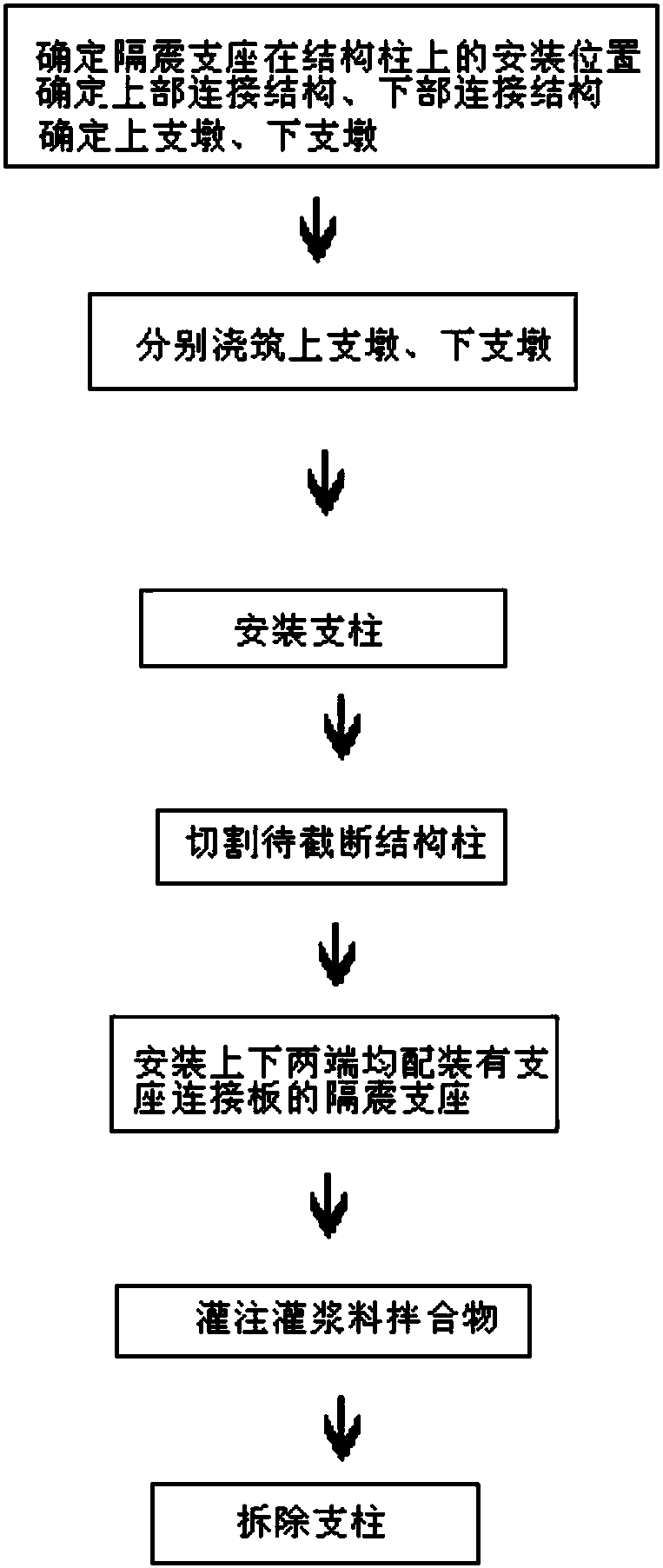

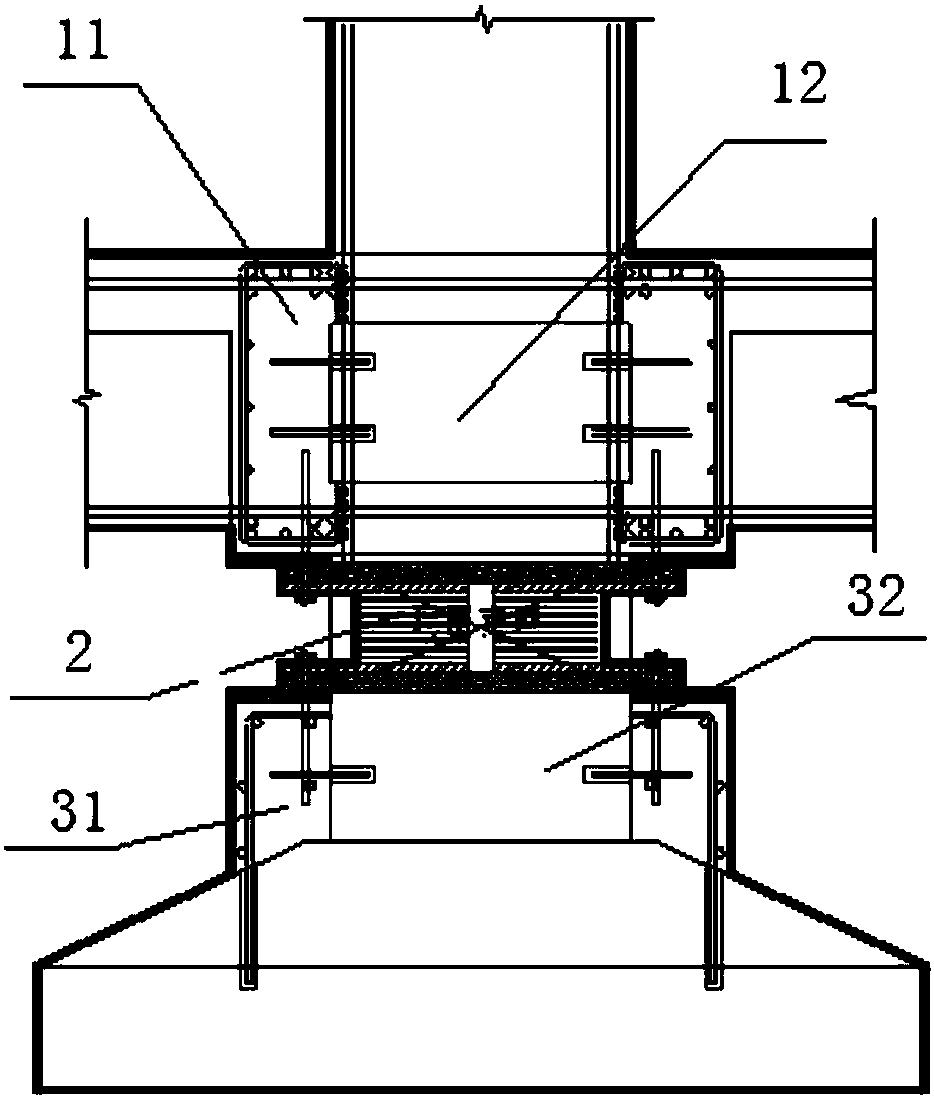

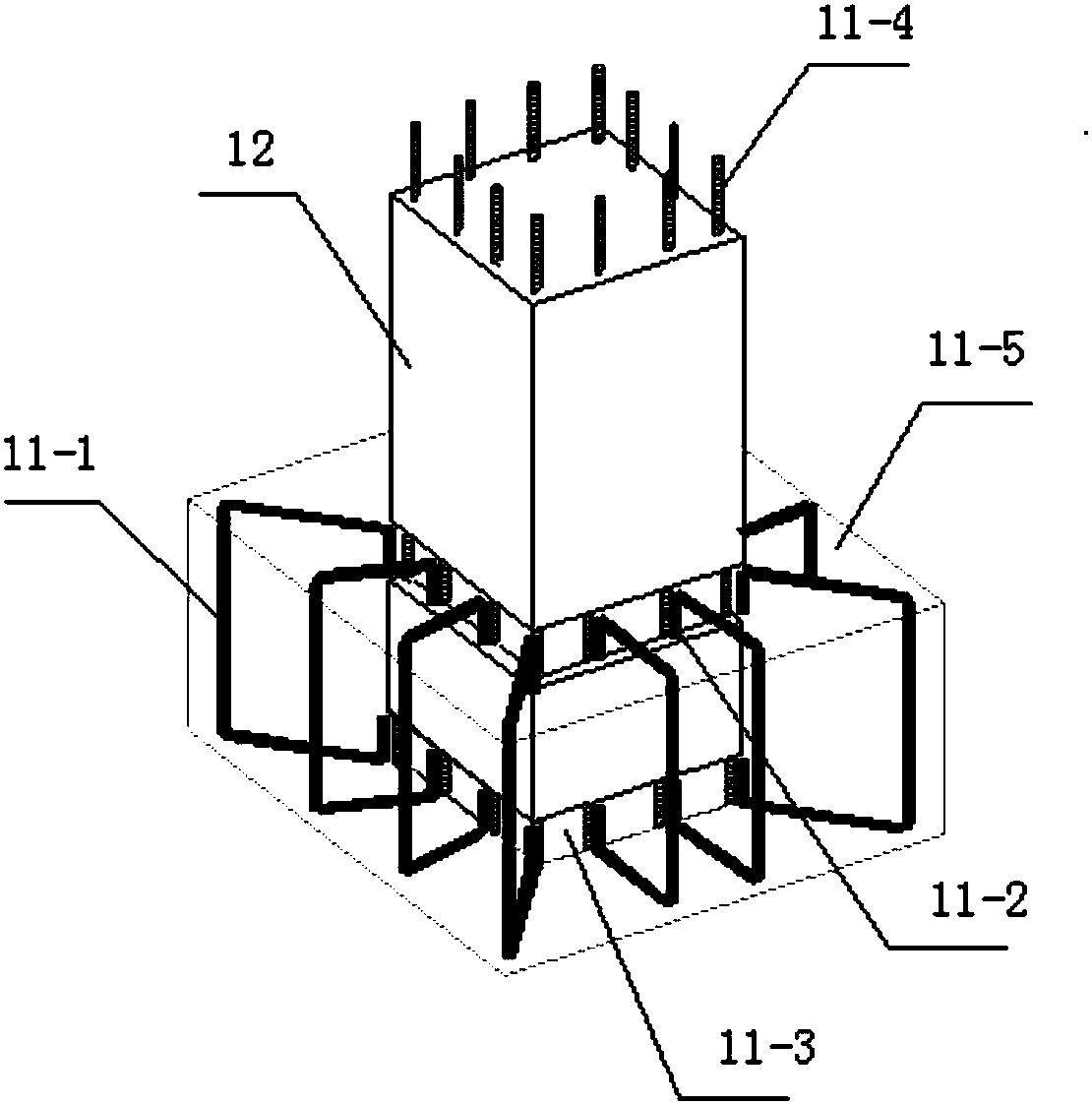

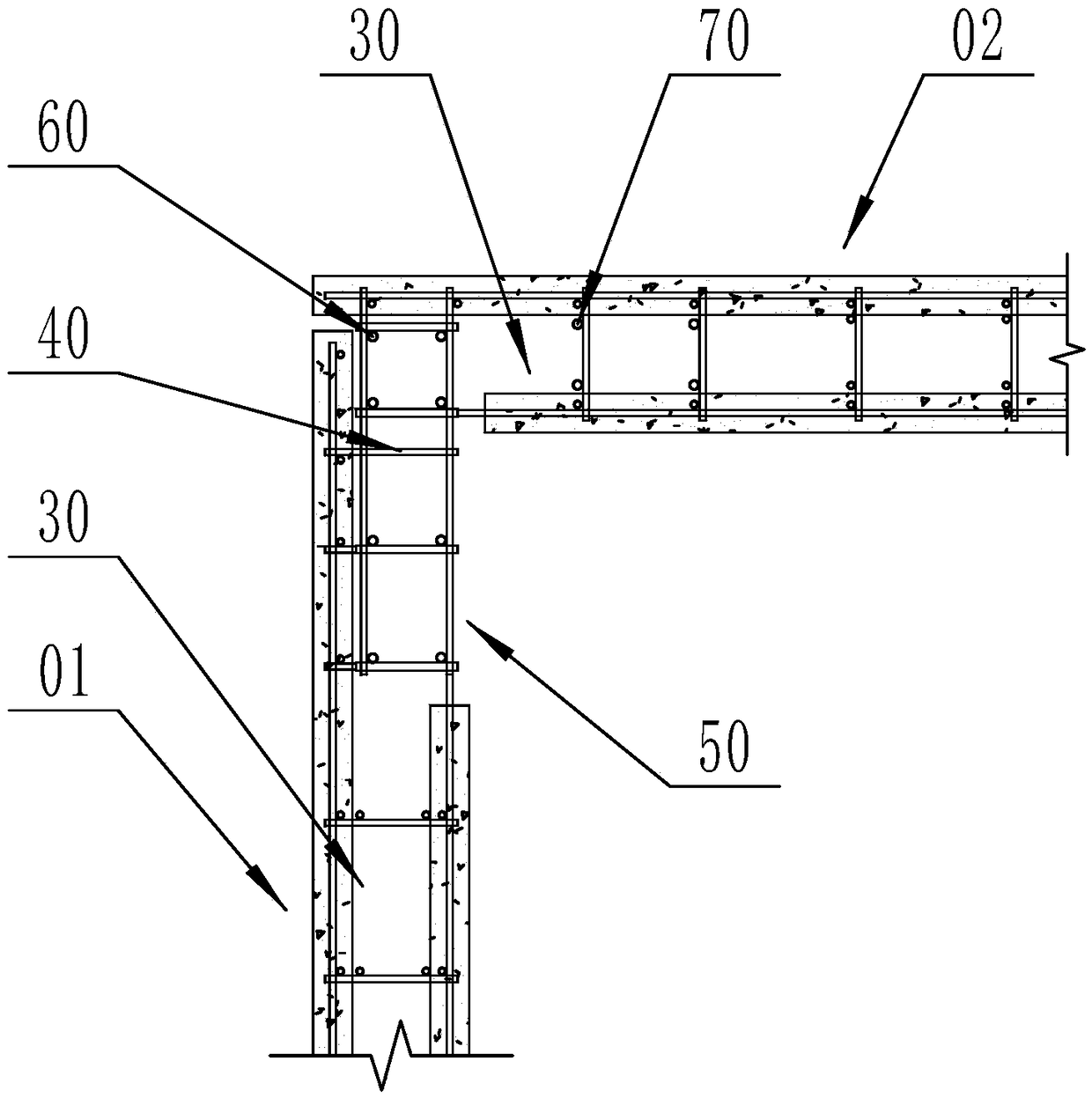

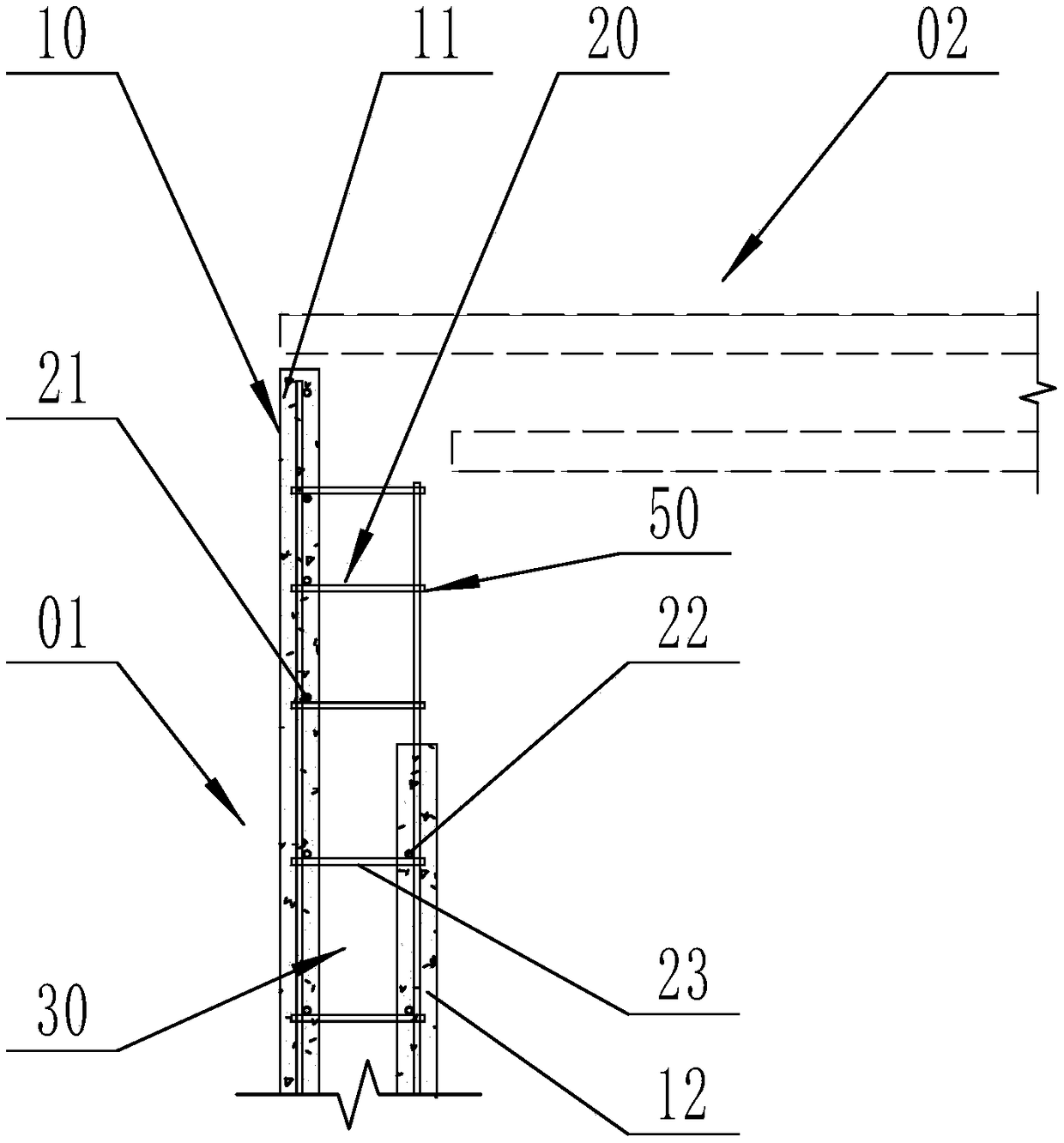

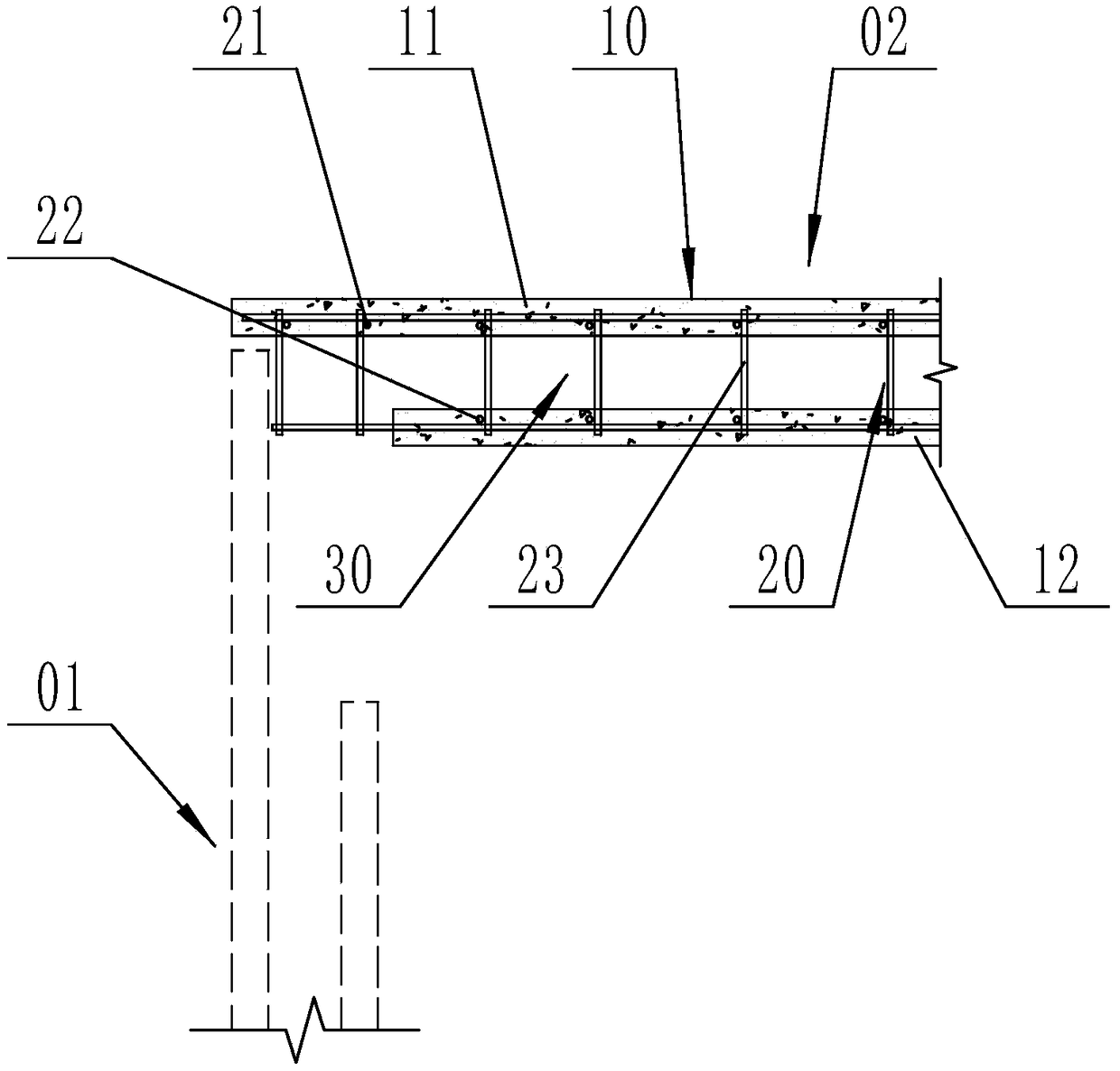

Existing building shock isolation reinforcement construction process

ActiveCN107724559AImprove construction levelSolve the real problemBuilding repairsProtective buildings/sheltersButtressIsolation layer

The invention discloses an existing building shock isolation reinforcement construction process which includes the steps: firstly, constructing a lower buttress; secondly, constructing an upper buttress; finally, cutting a structure column and mounting a shock isolation bearing in a shock isolation layer space. In addition, in order to consolidate normal implementation of the shock isolation reinforcement construction process, a specific upper buttress structure, a shock isolation bearing mounting structure and an underpinning structure are designed. By the aid of the construction process, themounting quality of the shock isolation bearing can be improved, manufacturing cost is reduced, and total construction time is greatly shortened.

Owner:南京百西思建筑科技有限公司

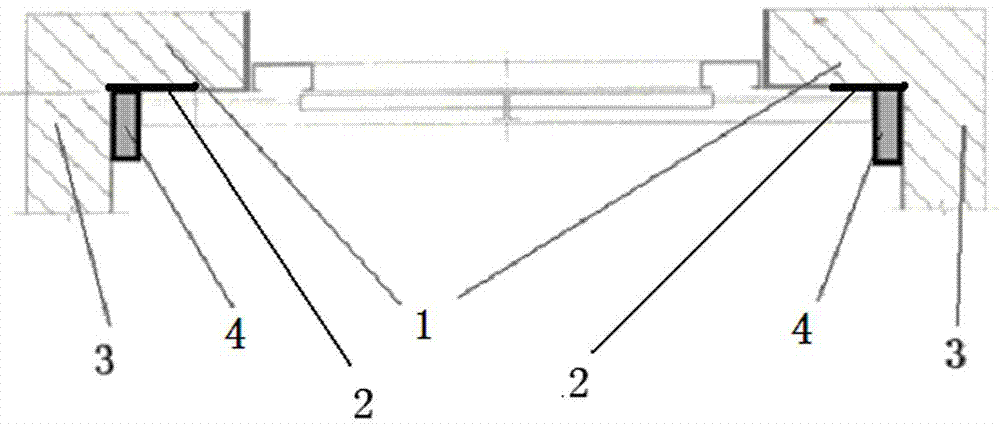

L-shaped wall connecting structure and assembly type building structure system

The invention relates to the technical field of assembly type buildings and particularly relates to an L-shaped wall connecting structure and an assembly type building structure system. The L-shaped wall connecting structure comprises prefabricated walls; each prefabricated wall comprises a wall shell and a moulding reinforcement cage; two prefabricated walls are provided, a first prefabricated wall and a second prefabricated wall; one side of the first prefabricated wall is vertical to one side of the second prefabricated wall to form an L shape; the L-shaped wall connecting structure comprises a connection reinforcing mesh; one end of the connection reinforcing mesh is connected with the moulding reinforcement cage of the first prefabricated wall, and the other end of the connection reinforcing mesh is connected with the moulding reinforcement cage of the second prefabricated wall. The L-shaped wall connecting structure provided by the invention has the advantages of simple structure and convenience in construction; the formwork quantity is greatly reduced, and the construction efficiency is improved. Moreover, through in-place casting of concrete for the prefabricated wall on the construction site, comprehensive performance of the wall is equivalent to that of common cast-in-place concrete structure.

Owner:SANY CONSTR TECH CO LTD

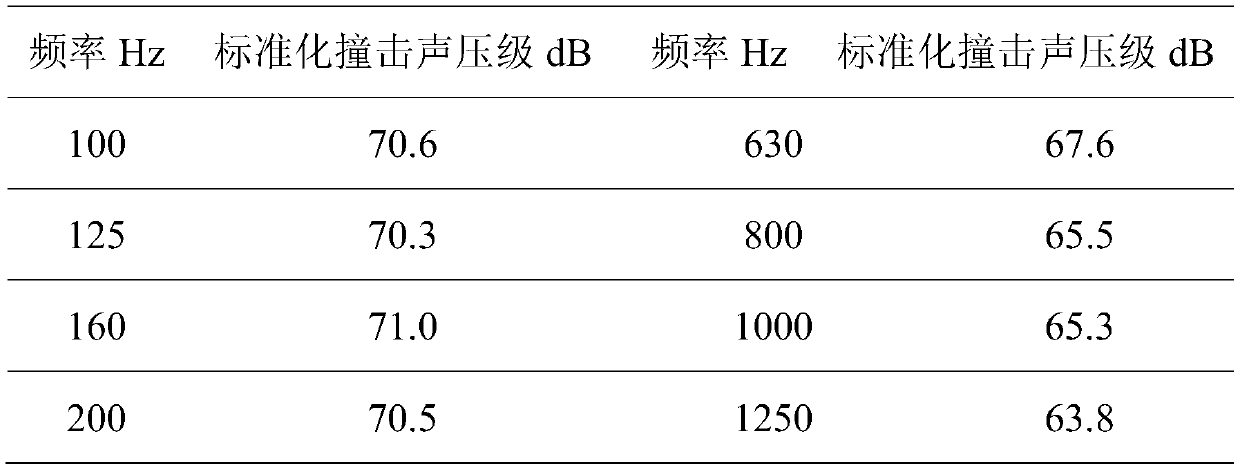

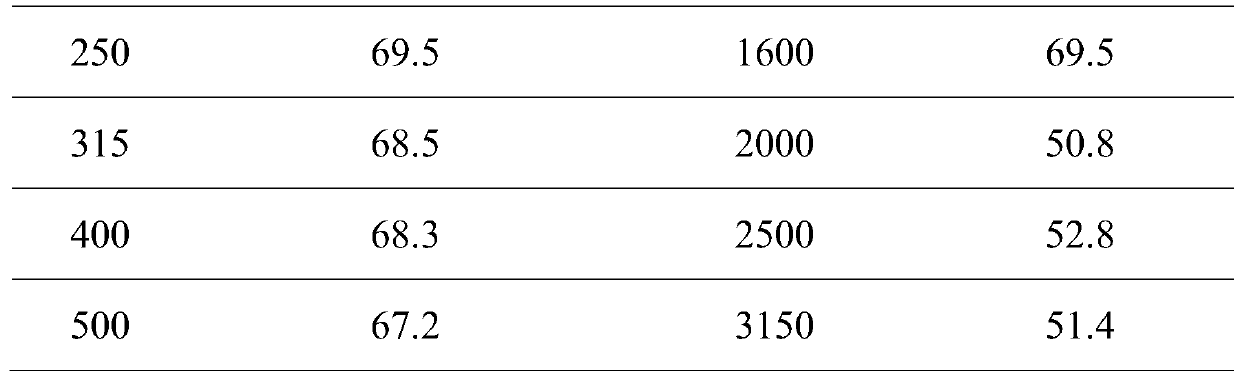

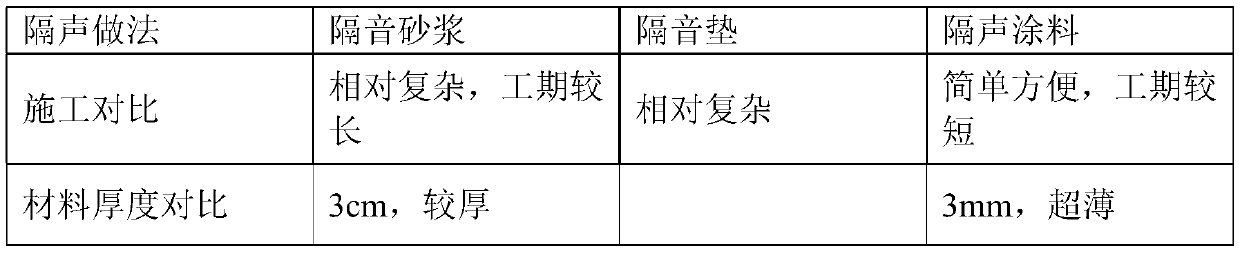

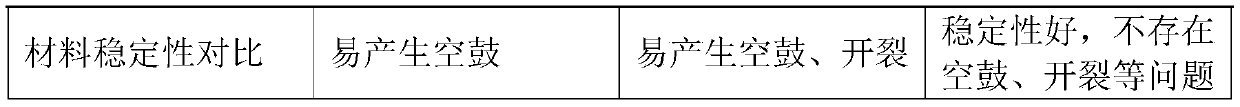

Water-based sound insulation coating for ground sound insulation and shock absorption, and preparation method thereof

PendingCN110951347AImprove liquidityGood film formingFireproof paintsCellulose coatingsFiberEngineering

The invention belongs to the technical field of coatings, and particularly relates to a water-based sound insulation coating for ground sound insulation and shock absorption, and a preparation methodthereof. The coating comprises an emulsion, a filler, aggregates, a halogen-free flame retardant, a defoaming agent, a bactericide, a thickening agent, a dispersing agent and deionized water, and further comprises rubber particles and rubber fibers. The coating of the invention has better flowability, film-forming property, sound insulation property, damping property and shock absorption propertythan coatings in the prior art, and is better than other sound insulation coatings with the same thickness; the sound insulation coating can achieve A1-level fire prevention, and has the advantages ofenvironmental friendliness, no pollution, good protecting effect on buildings, good adhesive force, good permeability, good compatibility with a base material, and no crack; the production technologyof the coating has the advantages of simplicity, easiness in implementation, improvement of the performances of the coating through reasonable dispersion and mixing of all the components, simplicityin construction operation, avoiding of node treatment with complex procedures, reduction of cross operation, reduction of the procedures of other traditional floor sound insulation methods by at least50%, and high cost performance.

Owner:广州协堡建材有限公司

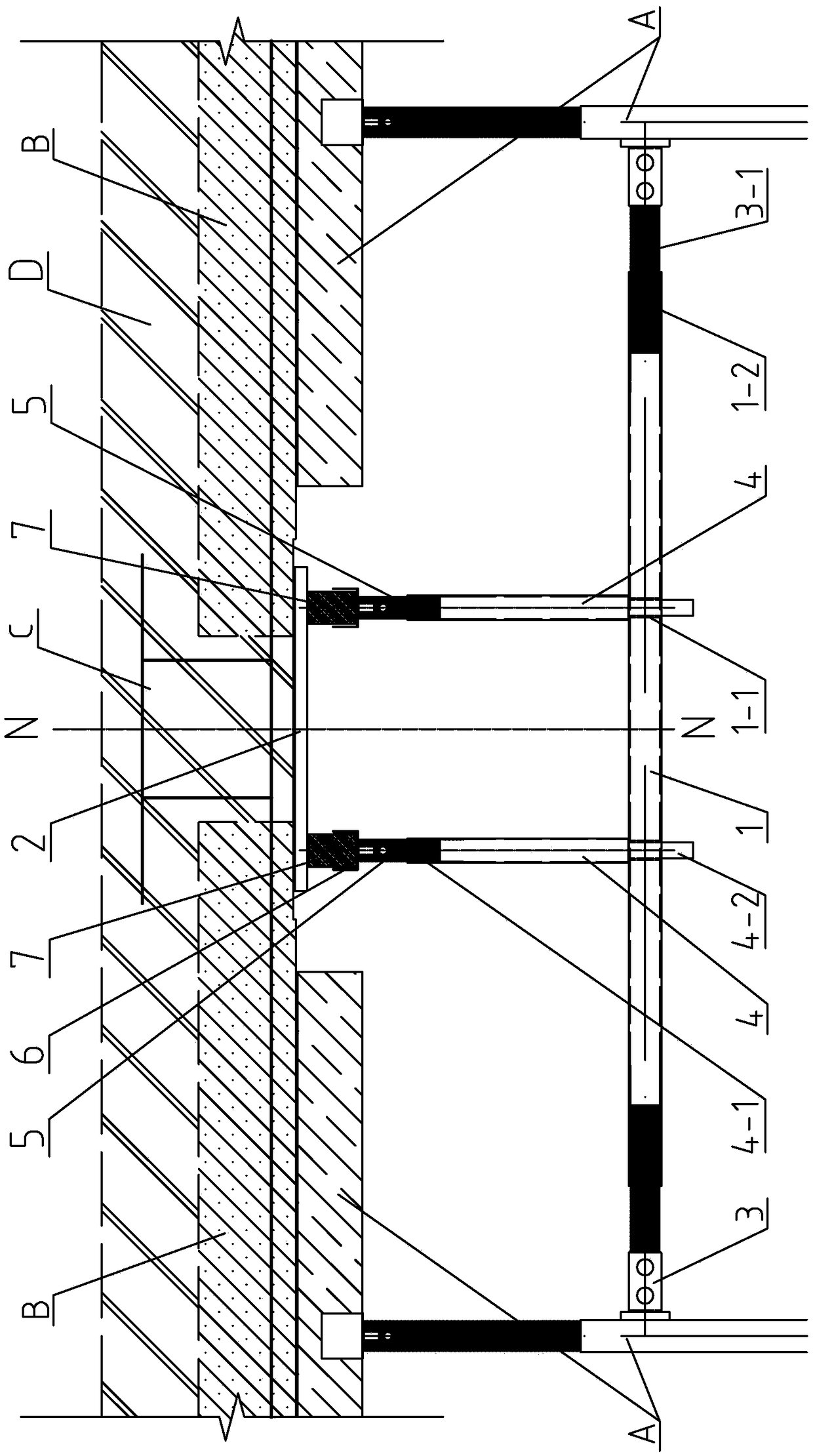

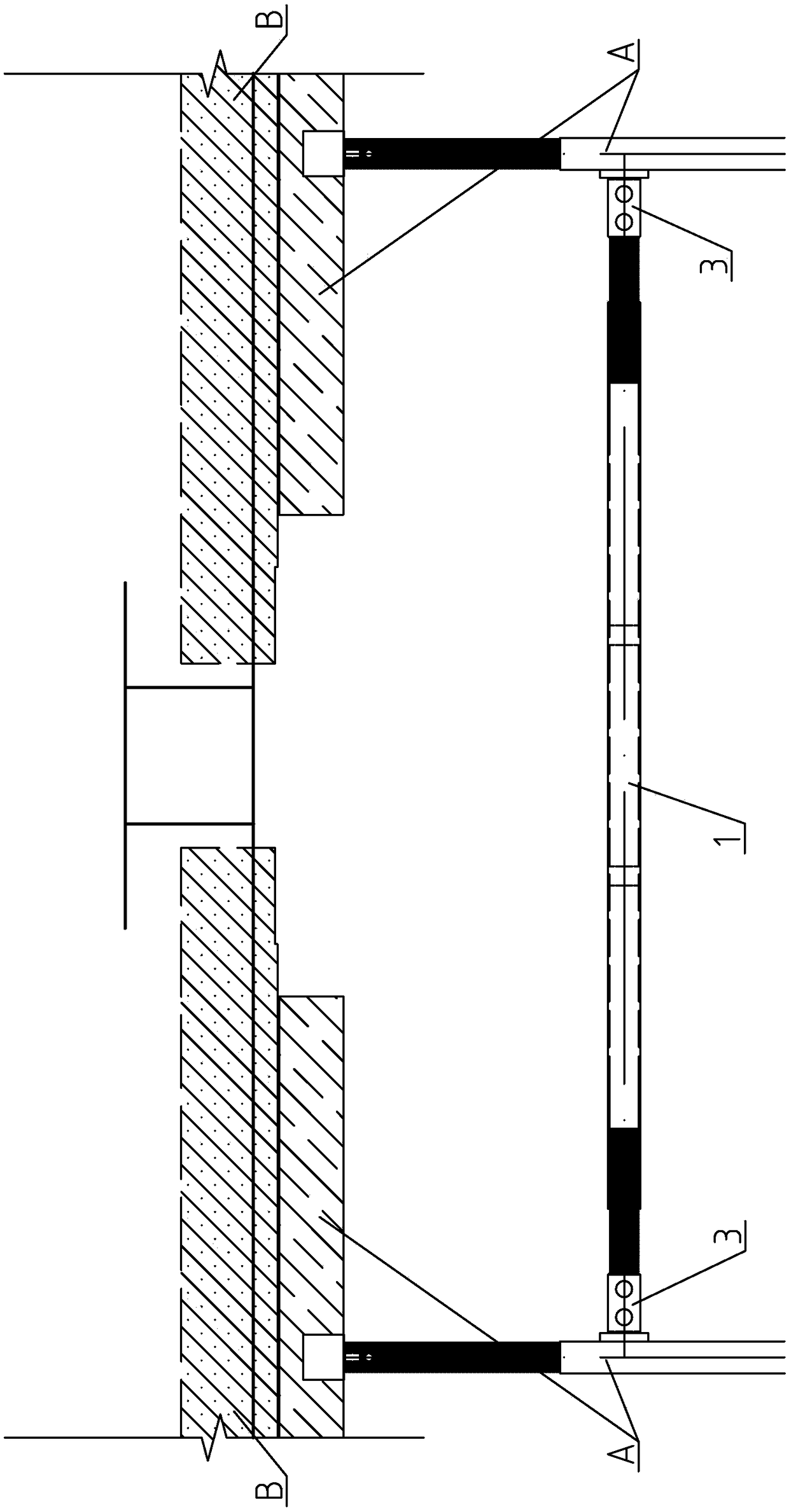

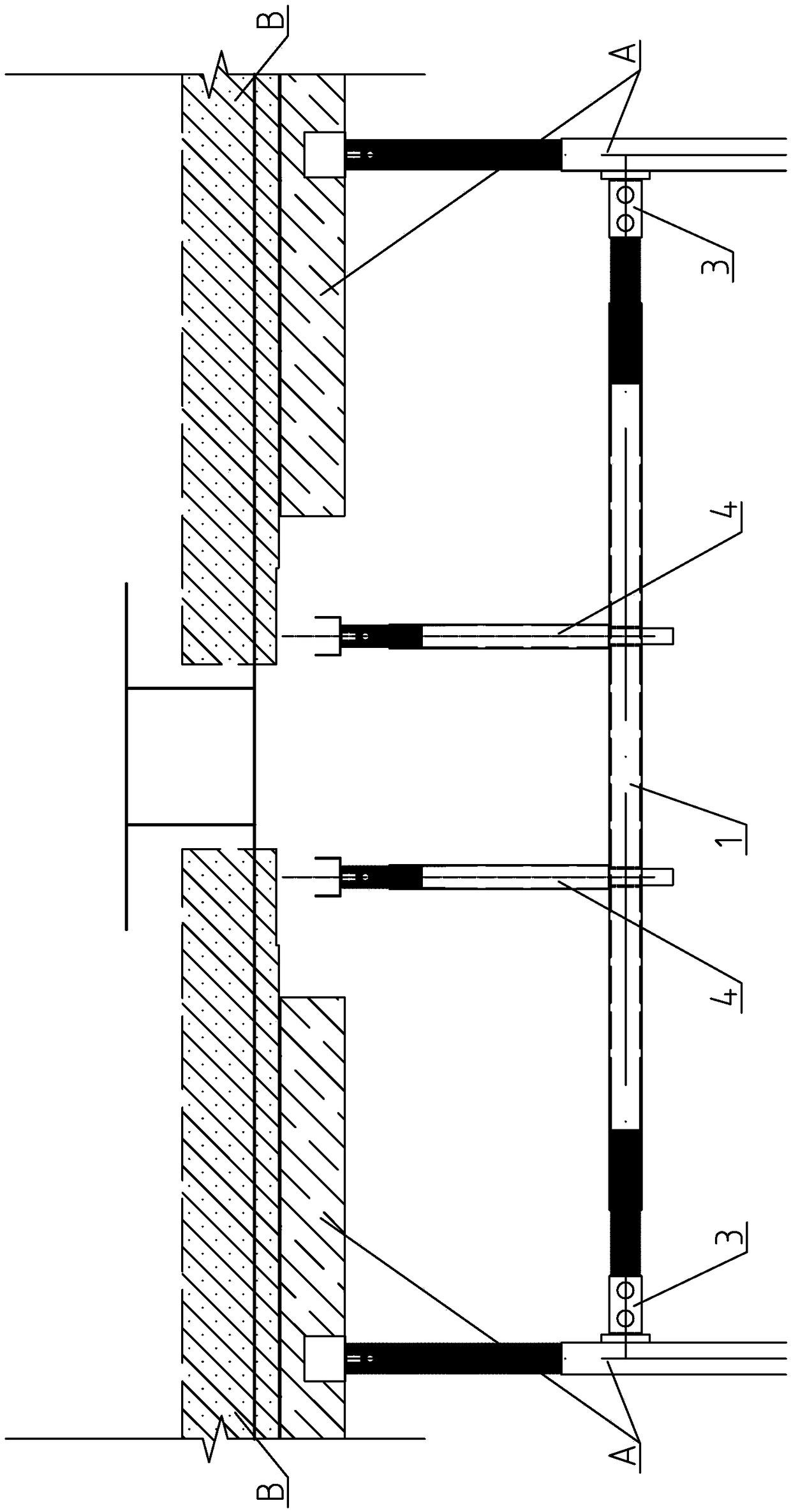

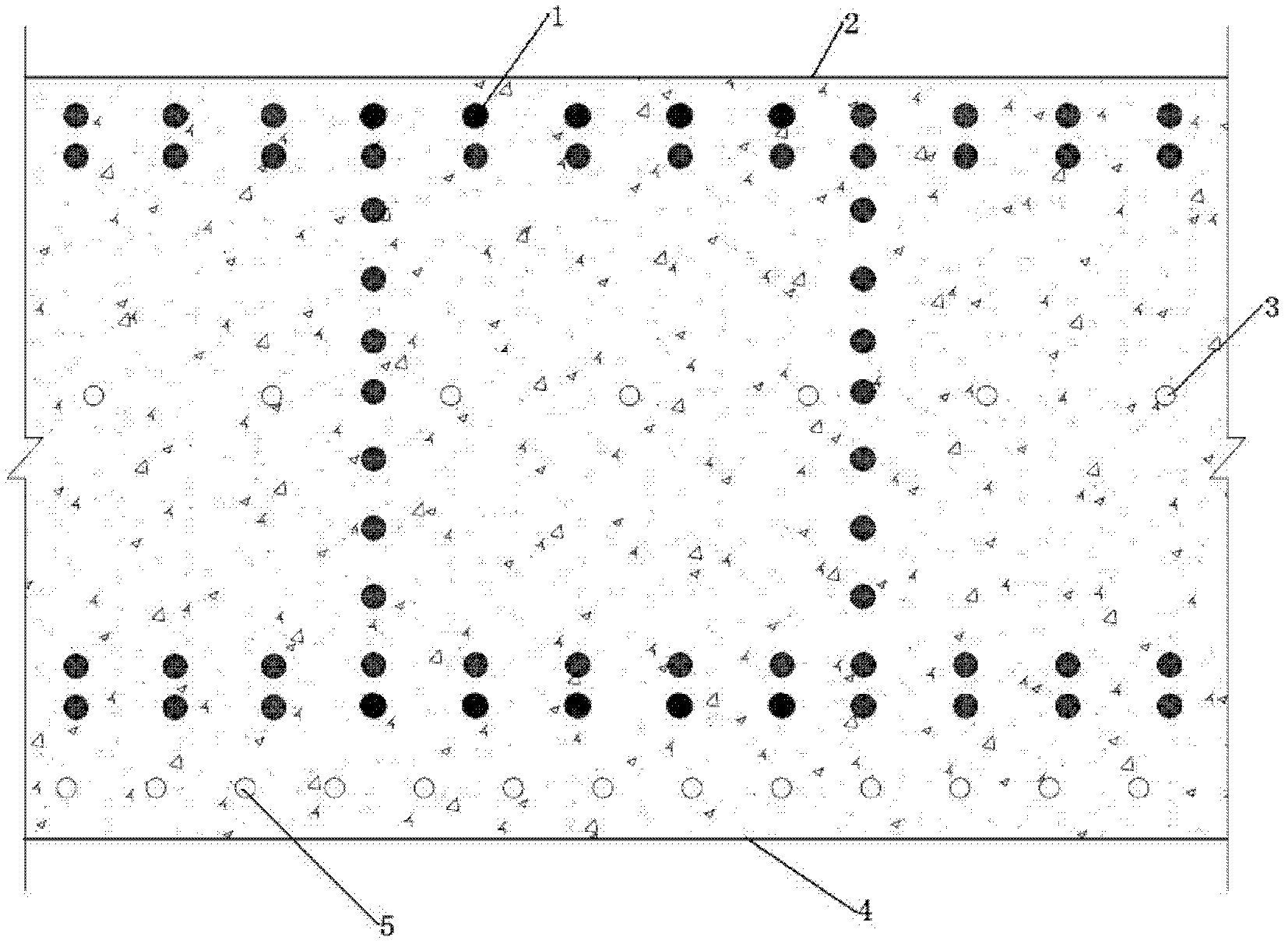

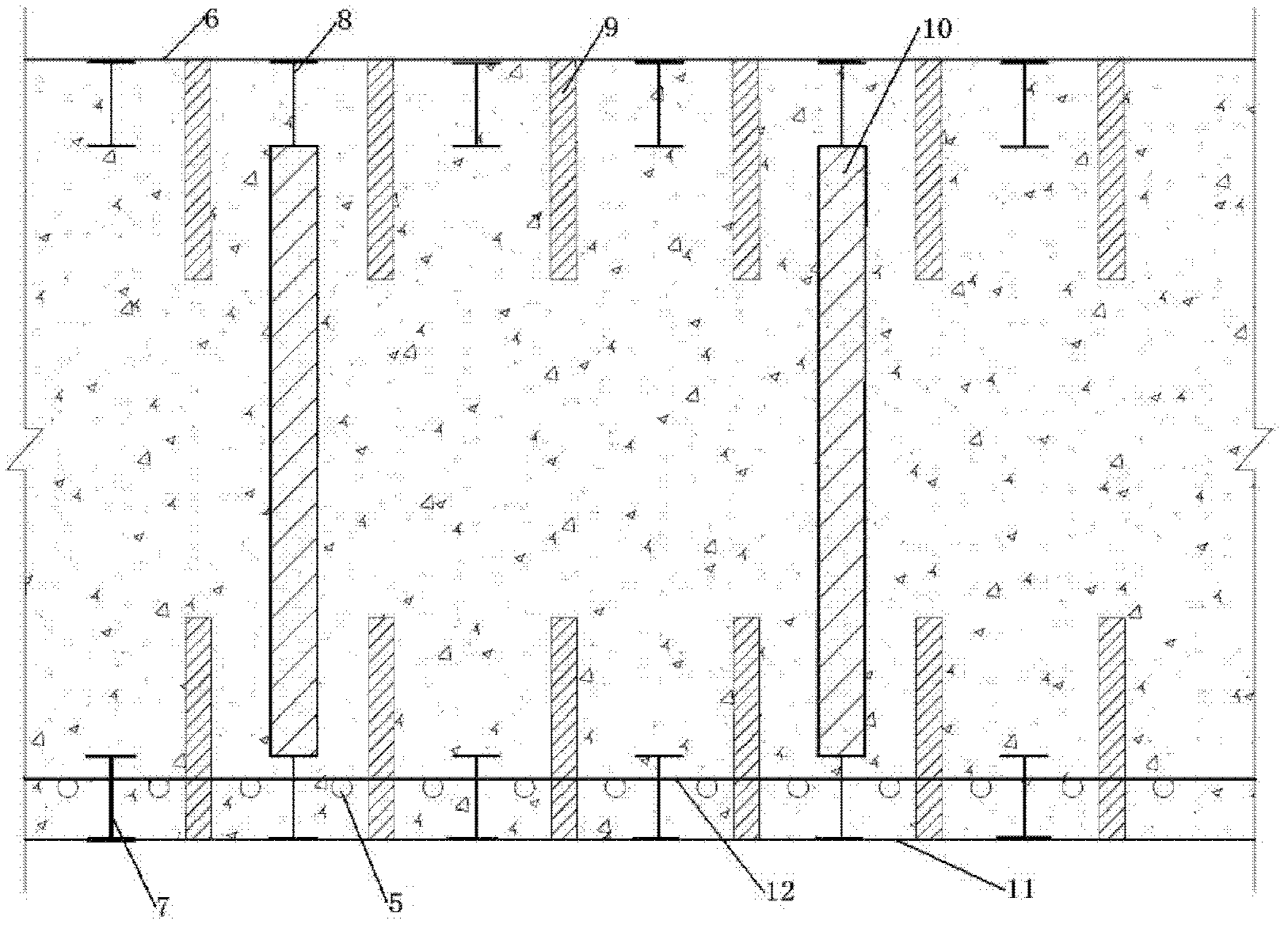

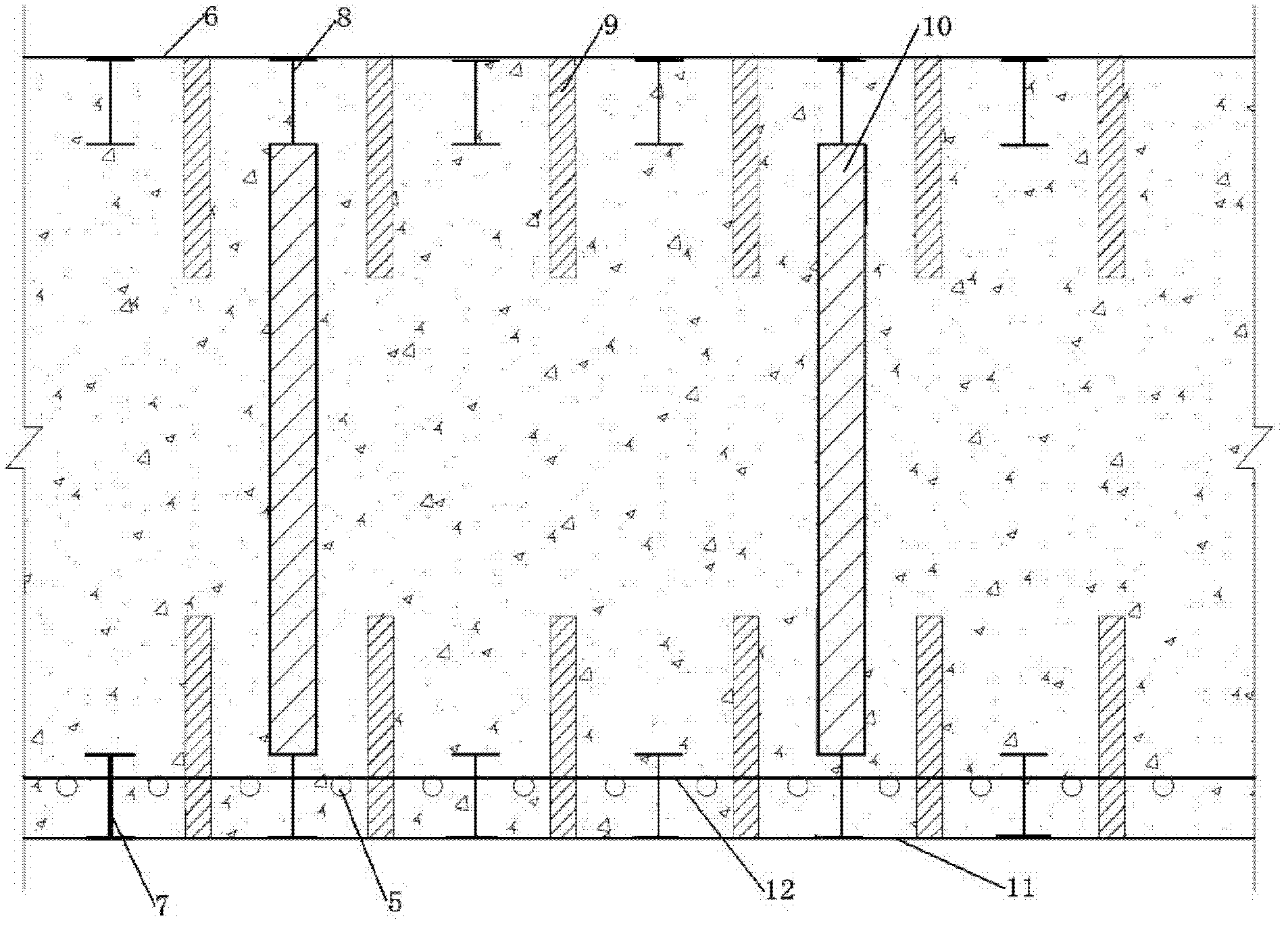

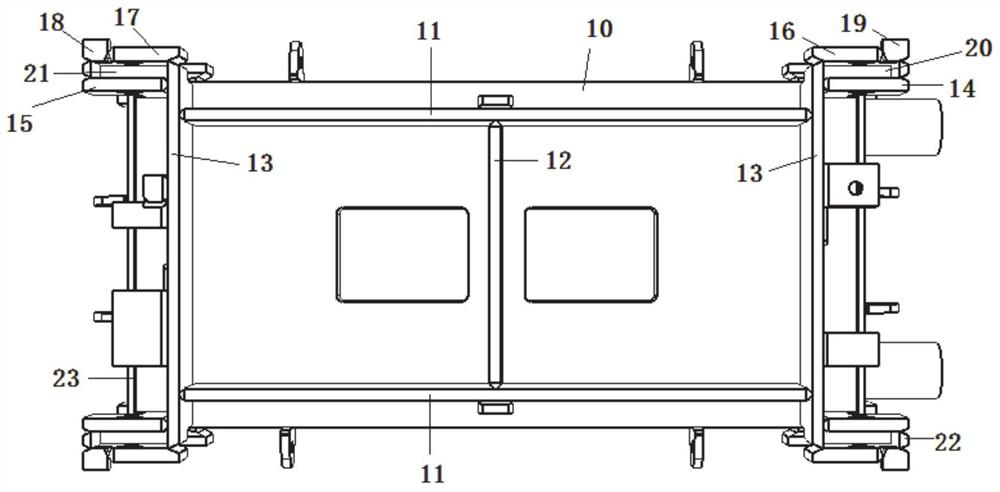

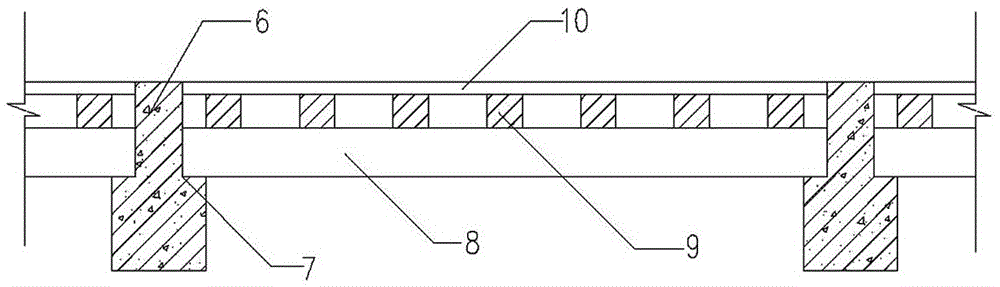

Tool type concrete composite slab cast-in-situ connecting section formwork supporting device

The invention discloses a tool type concrete composite slab cast-in-situ connecting section formwork supporting device. The tool type concrete composite slab cast-in-situ connecting section formwork supporting device solves the problem that existing concrete composite slab cast-in-situ connection adopts a hanging formwork or a traditional full-hall support method and the problems that connection section formwork support and prefabricated part support interfere with each other, supporting materials are large in dosage and the mounting accuracy and installation quality of the formwork are difficult to guarantee exist. Two supporting stand column inserting holes are formed in the middle portion of a supporting cross beam, two transverse adjusting pieces are symmetrically arranged at the two ends of the supporting cross beam, the transverse adjusting pieces are connected with the supporting cross beam in a threaded mode, two supporting stand columns correspond to the two supporting stand column inserting holes in a one-to-one mode, and the supporting stand columns are connected with the supporting cross beam in an inserting mode. Vertical adjusting pieces are connected to the upper ends of the supporting stand columns in a threaded mode, U-shaped brackets are connected to the upper ends of the vertical adjusting pieces in a threaded mode, the U-shaped brackets are internally provided with formwork supporting beams, and a bottom formwork is arranged above the two formwork supporting beams. The tool type concrete composite slab cast-in-situ connecting section formwork supportingdevice is used in the construction of fabricated composite concrete floor.

Owner:HARBIN UNIV

Construction method for steel plate concrete wall of primary loop cabin of high temperature gas cooled reactor

ActiveCN102605951AShorten the critical pathEnsure correct executionWallsBuilding material handlingSteel platesNuclear reactor

The invention relates to a construction method for a steel plate concrete wall of a primary loop cabin of a high temperature gas cooled reactor, which belongs to the technical field of reactor structures. The method includes: arranging inner bearing steel posts, outer bearing steel posts, bearing crossbeams and connecting beams according to design requirements, sequentially arranging shielding cooling water pipes, outer steel plates, inner steel plates and a plurality of transverse shearing nails to form a wall framework module, hoisting the module to the position of the primary loop cabin ofthe high temperature gas cooled reactor, concreting to form a lower-layer steel plate concrete wall module, hoisting an upper-layer module on the lower-layer steel plate concrete wall module, and cycling so to form the wall of the primary loop cabin of the high temperature gas cooled reactor. By the construction method, time of constructional critical paths can be shortened, cross workload on a construction site can be reduced, and work intensity on the construction site is relieved. Further, accurate execution of construction schedule can be guaranteed while construction quality is improved and construction period is shortened.

Owner:CHINERGY CO LTD

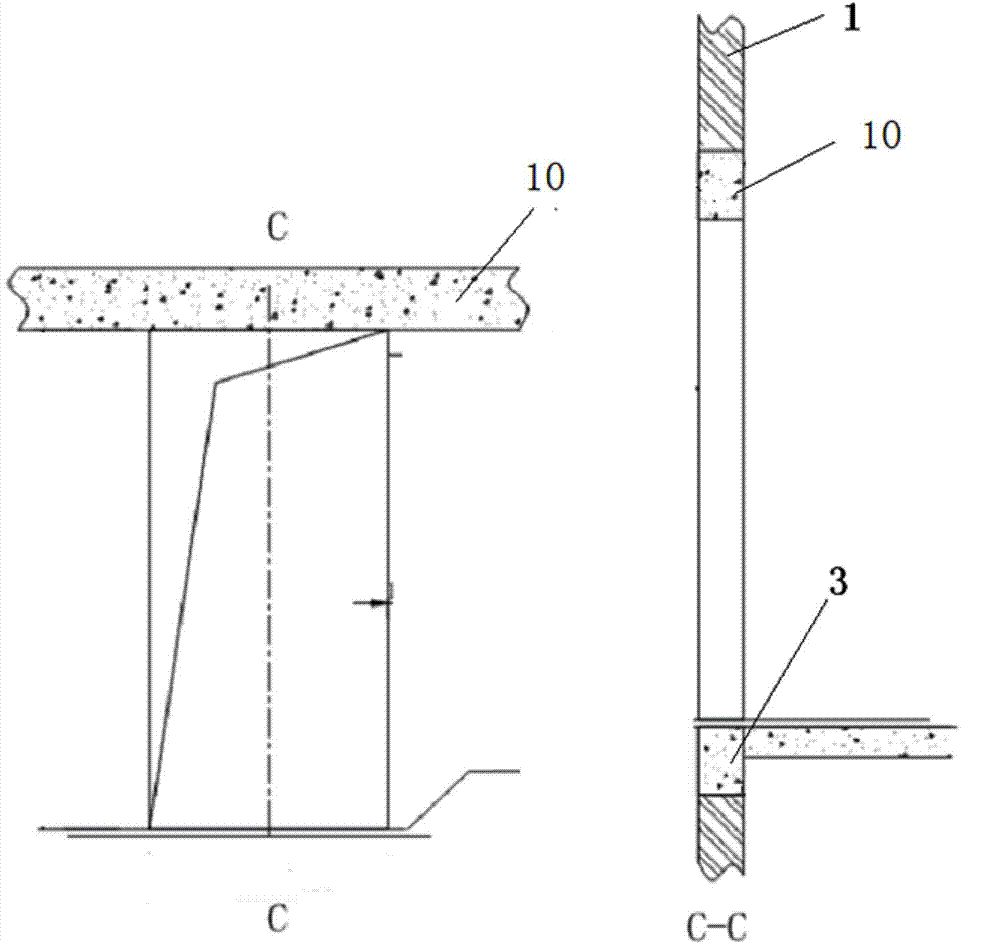

Method for mounting elevator landing door

InactiveCN103787183AReduce cross workShorten the construction period andBuilding liftsFloor levelEngineering

The invention discloses a method for mounting an elevator landing door. The method comprises the steps that 1, an entrance / exit of an elevator well is reserved in each floor; 2, a fixed base is fixedly arranged on the side, close to the elevator well, of a landing door wall body, and the position of the fixing base corresponds to a ring beam of each floor; 3, a perpendicular fixing guide rail of the landing door is manufactured, and two perpendicular fixed guide rails corresponding to the fixed base are fixedly arranged on the side, close to the elevator well, of the landing door wall body; 4, the two ends of an upper bank component of a landing door device and the two ends of a sill component of the landing door device are horizontally connected with the perpendicular fixed guide rails respectively; 5, the perpendicularity and the parallelism of the upper bank component and the sill component of the landing door device of each floor are adjusted so as to conform to the mounting technical standard of the elevator landing door. The method has the advantages of being short in construction period and high in mounting quality and precision.

Owner:甘肃博程技术咨询服务有限公司

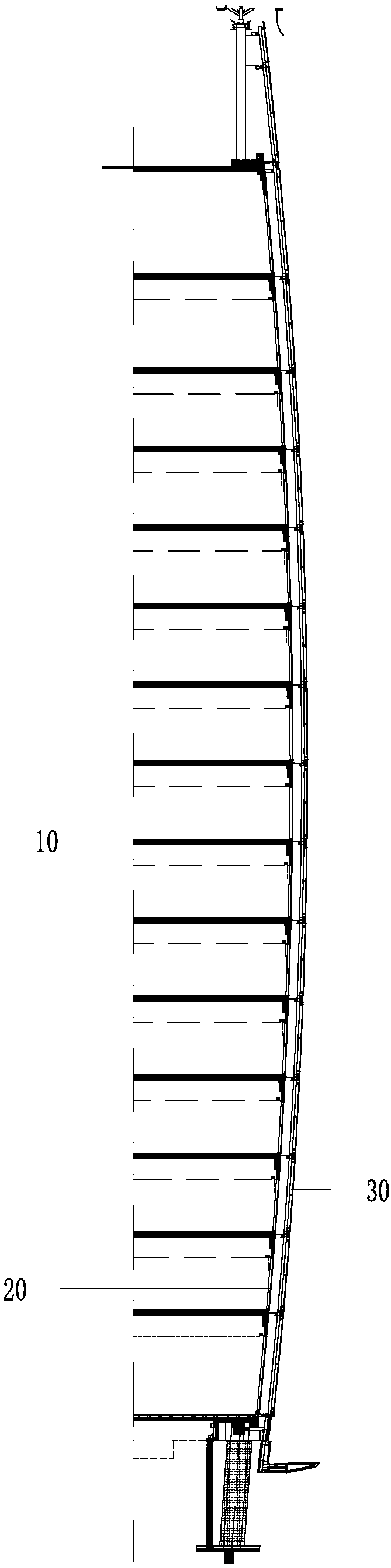

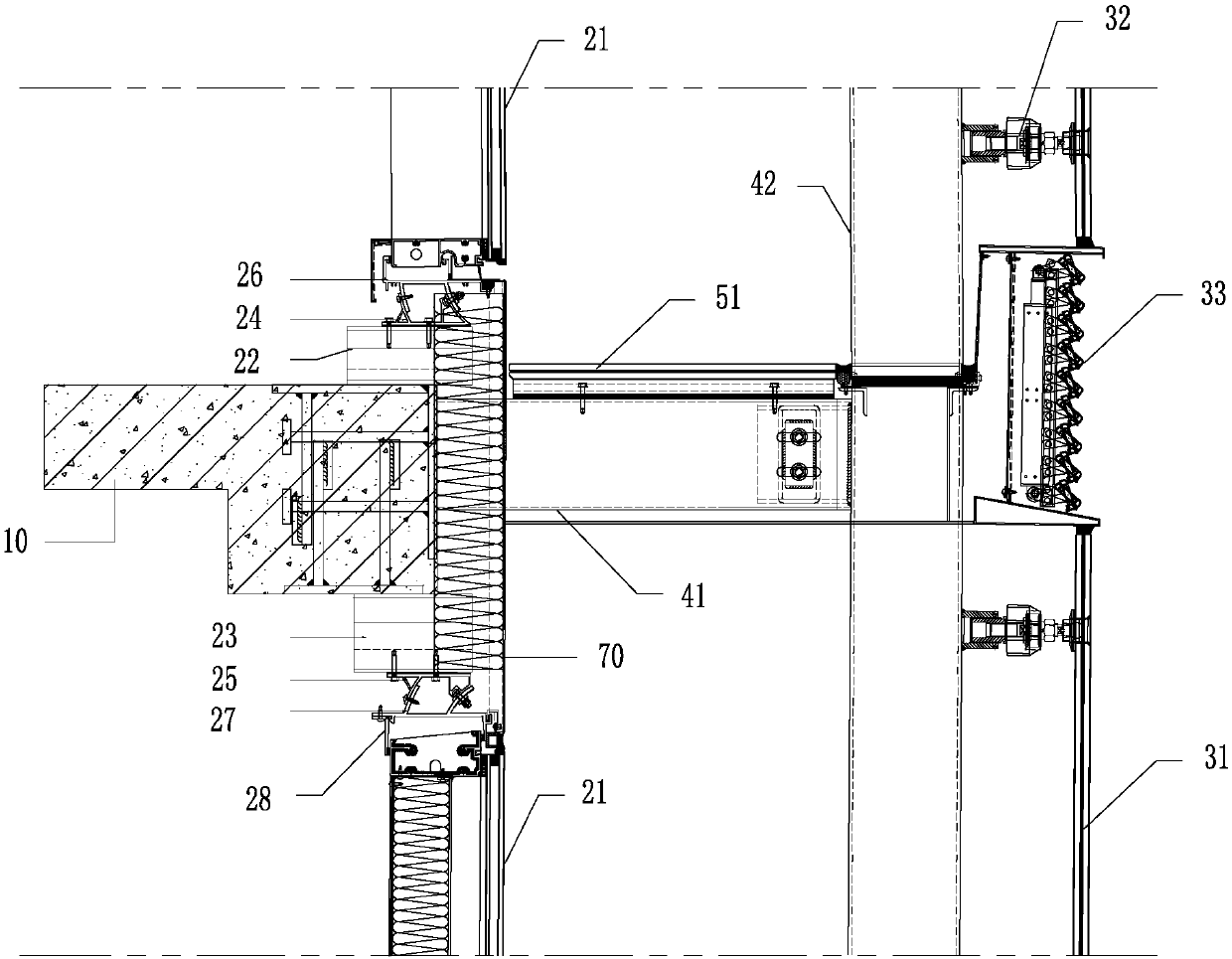

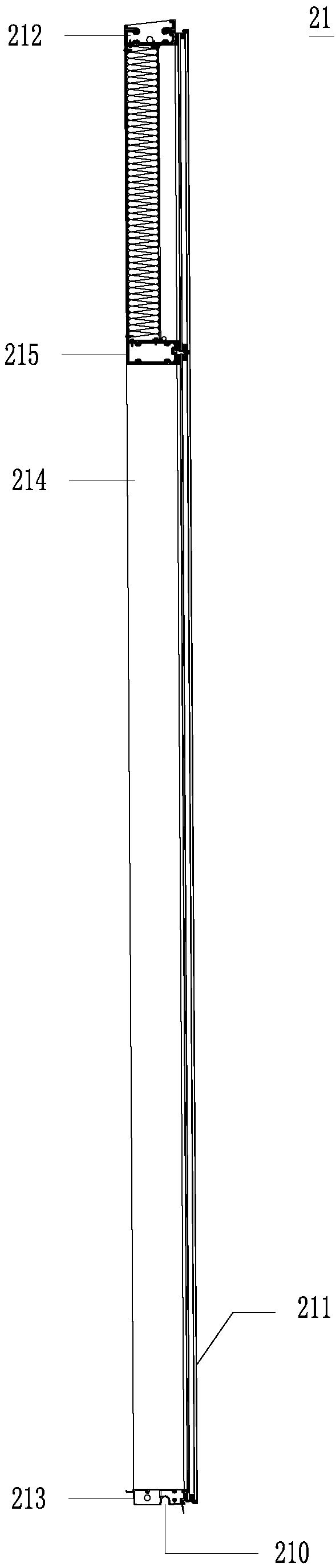

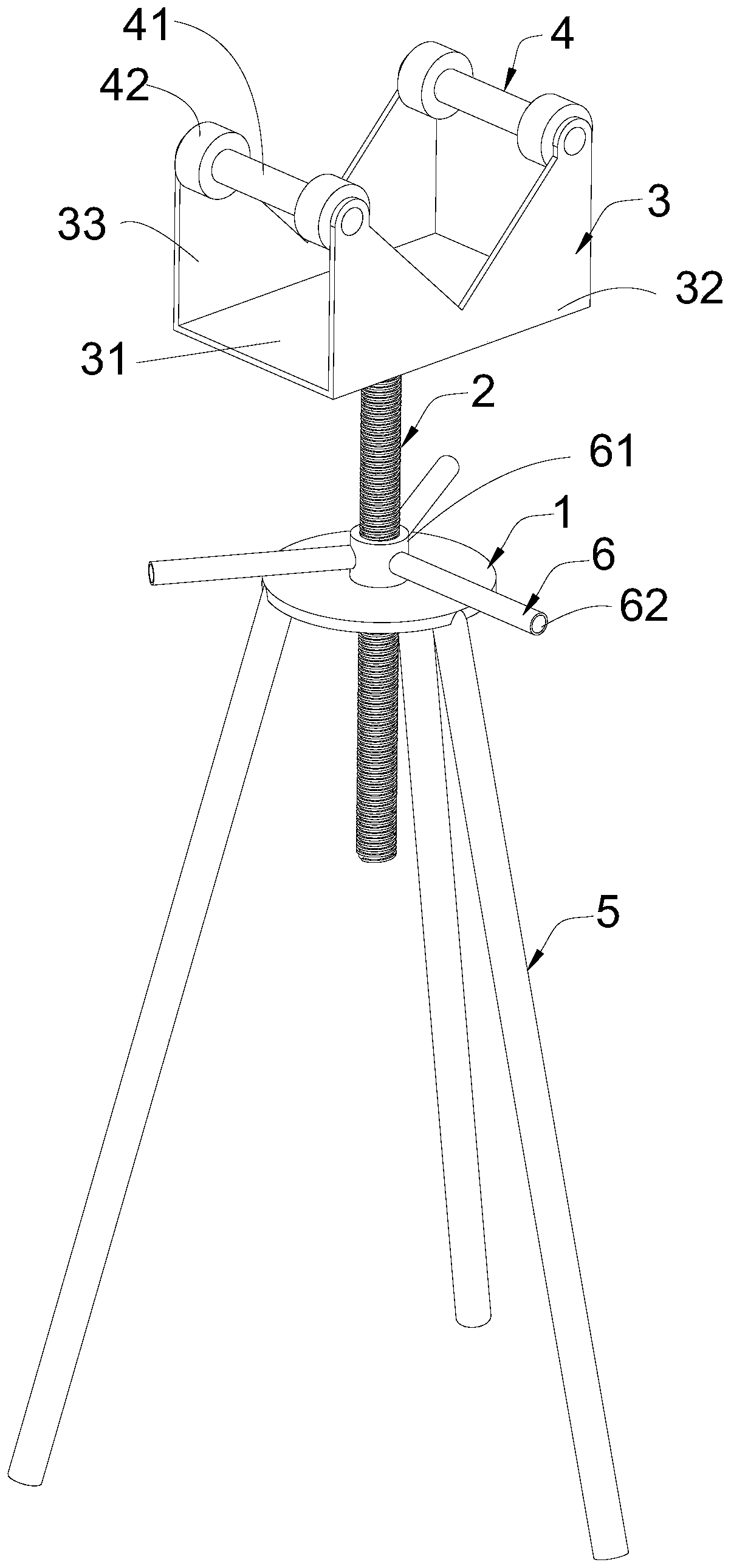

Ground type external-circulation double-layer curved-face curtain wall and installation technology thereof

ActiveCN107654005AMeet the appearance and visual needsImprove structural safetyWallsSupporting systemUpper floor

The invention discloses a ground type external-circulation double-layer curved-face curtain wall and an installation technology thereof. The ground type external-circulation double-layer curved-face curtain wall comprises a curved-face inner curtain wall body and a curved-face outer curtain wall body, wherein the curved-face inner curtain wall body is installed on a main body structure, and the curved-face outer curtain wall body is located on the outer side of the inner curtain wall body and fixed to the main body structure through an outer supporting system penetrating through the inner curtain wall body. An inner curtain wall unit body is installed between the upper and lower adjacent floors of the main body structure, the bottom of the inner curtain wall unit body is supported on a concentric rotary bottom adjusting assembly installed at the top of the lower floor, the top of the inner curtain wall unit body is fixed to a concentric rotary top adjusting assembly installed at the bottom of the upper floor, and the concentric rotary bottom adjusting assembly and the concentric rotary top adjusting assembly adjust the inclination and upward-facing angle, towards the indoor space,of the inner curtain wall unit body through a concentric rotary mode. According to the ground type external-circulation double-layer curved-face curtain wall and the installation technology thereof, the curtain wall structure is simple, the energy-saving effect of double-layer curtain-wall external circulation is achieved, the appearance visual demand of a smooth curved face is further met, the structural safety performance is good, the installation technology is easy to implement and not tedious, and the construction efficiency is high.

Owner:JANGHO GRP

Auxiliary device of dismounting and mounting of production tree hydraulic drive main valve

PendingCN111456662AImprove work efficiencyImprove securityBorehole/well accessoriesScrew jointIndustrial engineering

The invention relates to an auxiliary device of dismounting and mounting of a production tree hydraulic drive main valve. The device comprises a base, a lifting nut, a bracket and a supporting part, ascrew joint hole is formed in the middle of the base, the lifting nut is arranged in the screw joint hole in a penetrating manner to be mounted into the base, the lifting nut can do lifting motion along the base, the bracket is mounted on the top of the lifting nut, and comprises a bottom plate connected with the lifting nut and two side plates which are mounted on the bottom plate in a relatively perpendicular manner and extend upwards, a supporting bearing assembly used for bearing a production tree hydraulic drive main valve is arranged on the edge of the top of each side plate, and the supporting part mounted on the bottom of the base and used for positioning and supporting the whole device. Compared with a traditional method that a production tree hydraulic drive main valve is dismounted and mounted through cooperation of at least three persons in one day, the auxiliary device has the advantages that one person can finish dismounting and mounting work with two hours, time and labor are saved, work efficiency is improved, work cost is reduced, safety is improved, aerial work and lifting work are not needed, and crossed work is reduced.

Owner:CNOOC DEEPWATER DEV +1

Welding method and assembly process of press machine trolleys

ActiveCN112191994AGuarantee welding qualityImprove welding efficiencyWelding accessoriesProcess engineeringWelding deformation

The invention relates to a welding method and an assembly process of press machine trolleys, and belongs to the technical field of press machine assembly. The method comprises the following steps of marking cross center lines at the bottoms of supporting bottom plates of the press machine trolleys; assembling bottom transverse supporting plates and bottom longitudinal supporting plates by taking the cross center lines as references; assembling remaining parts on the press machine trolleys on the basis of the supporting bottom plates, and meanwhile, performing positioned welding on each part; and combining and fixing the faces, used for containing materials, of the supporting bottom plates of the two press machine trolleys together, welding welding seams of the two press machine trolleys atthe same time, and after welding is completed, separating the two supporting bottom plates of the two press machine trolleys. By means of the method, welding deformation of the press machine trolleysis controlled, and the welding quality is guaranteed.

Owner:中船发动机有限公司

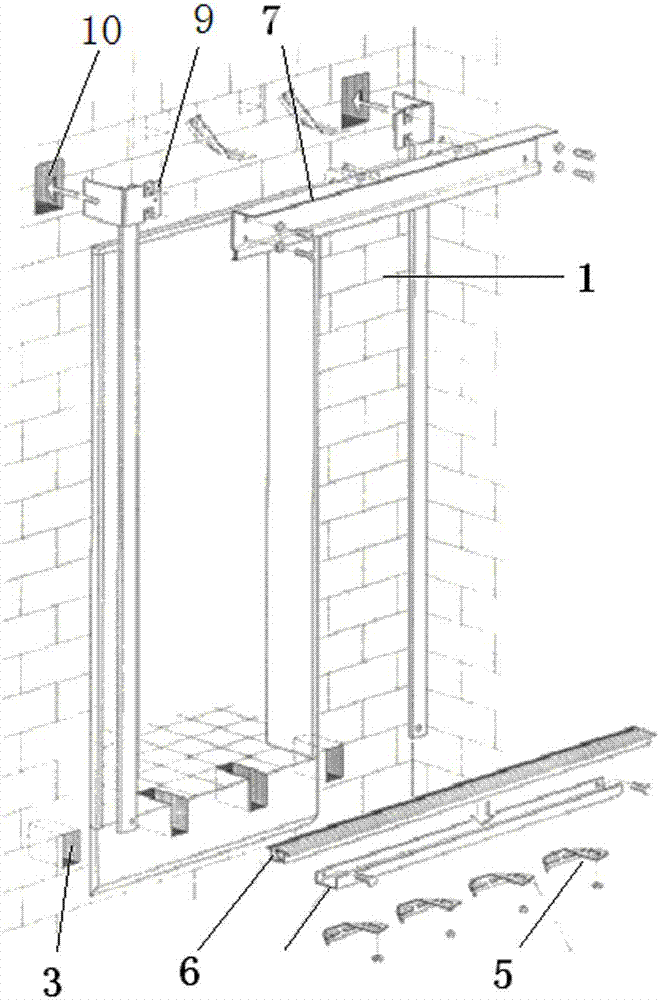

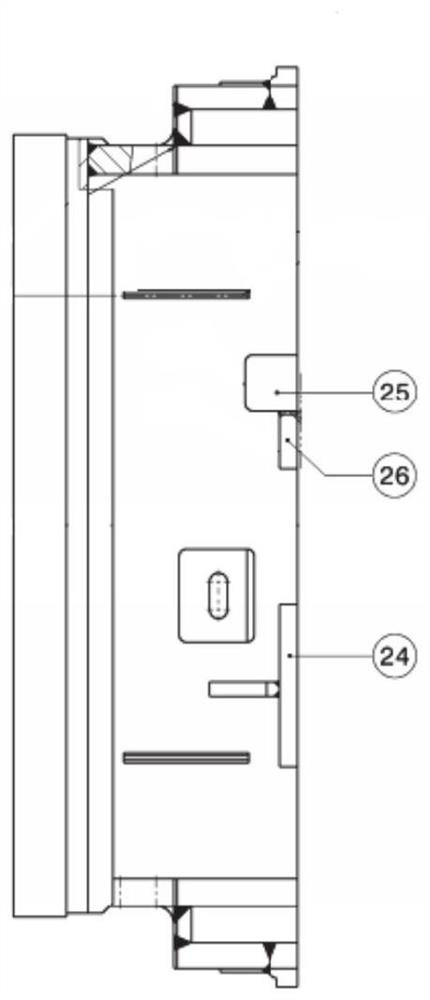

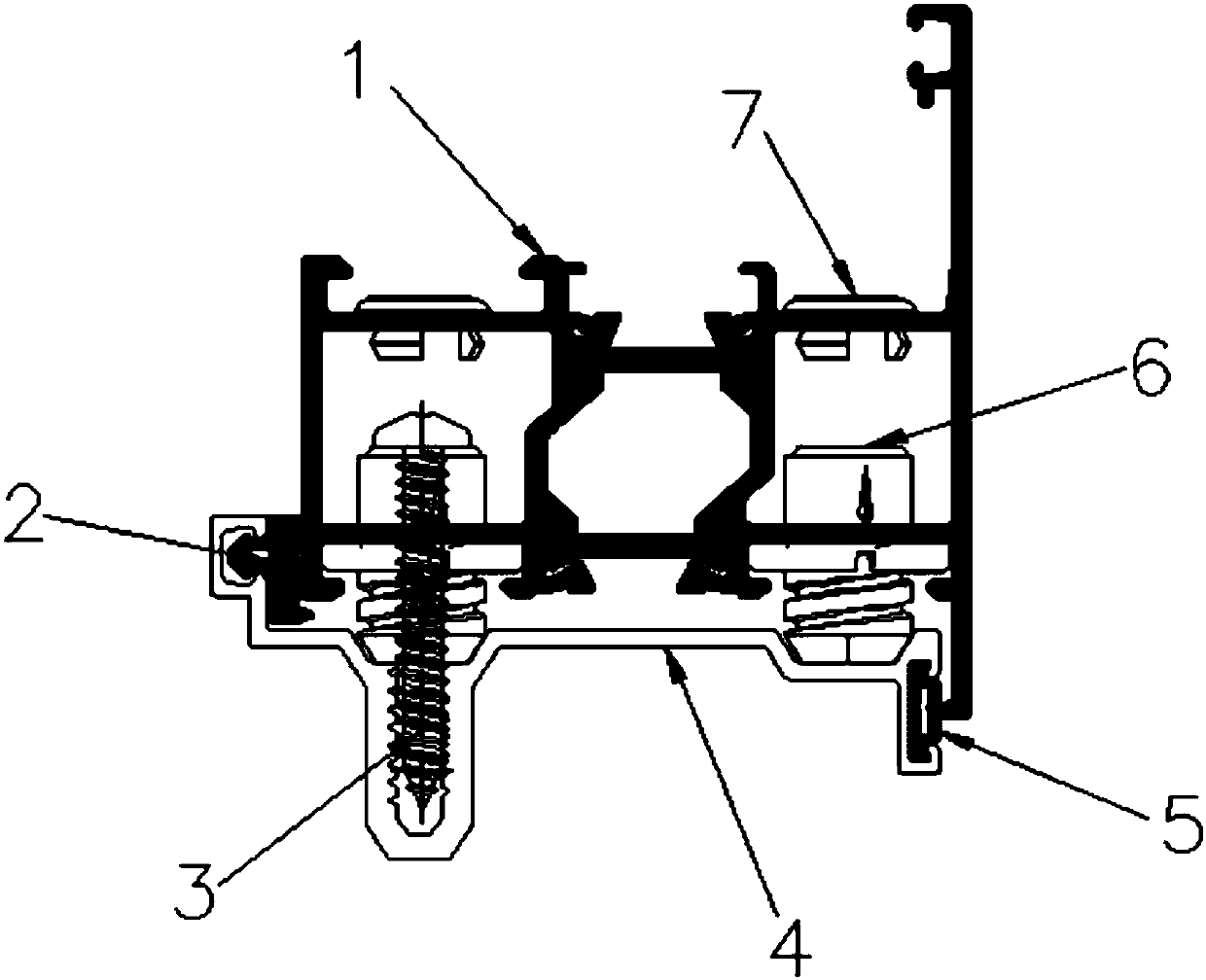

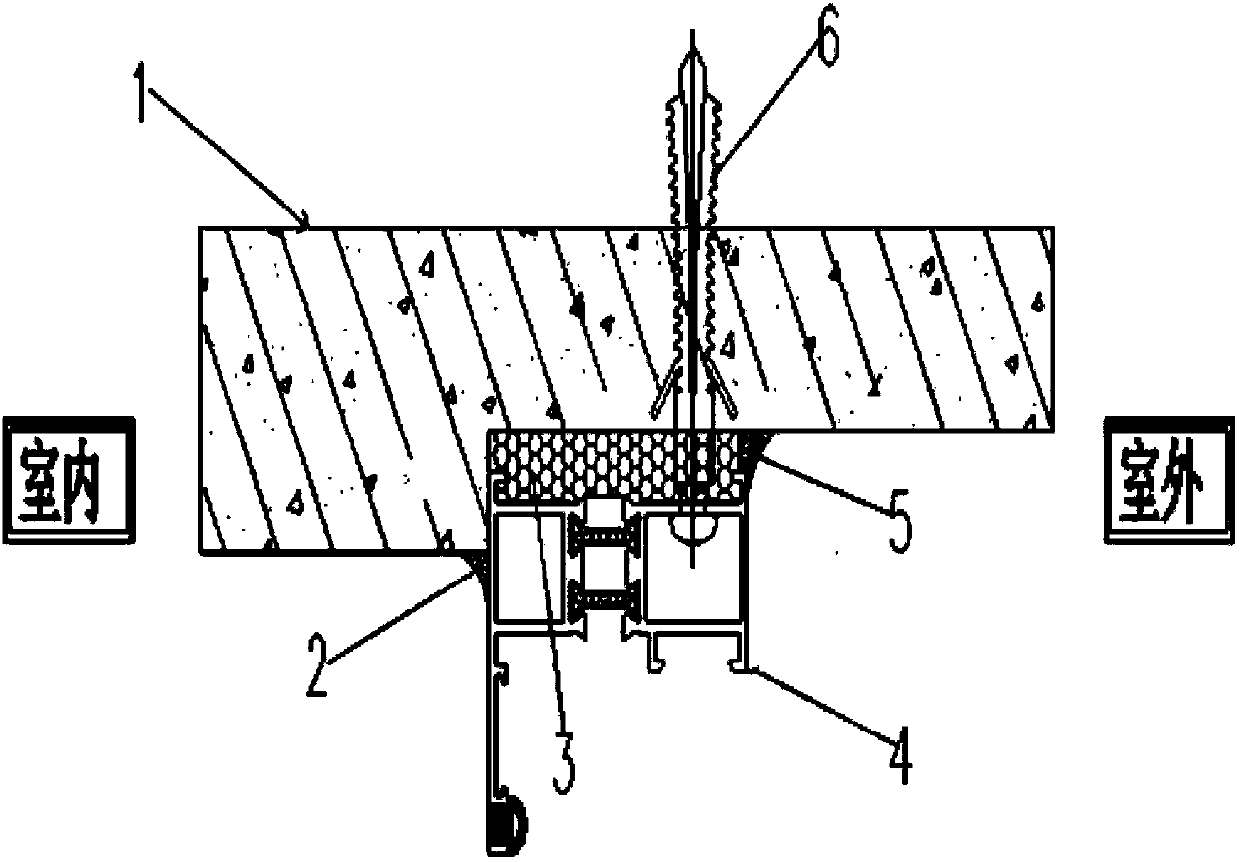

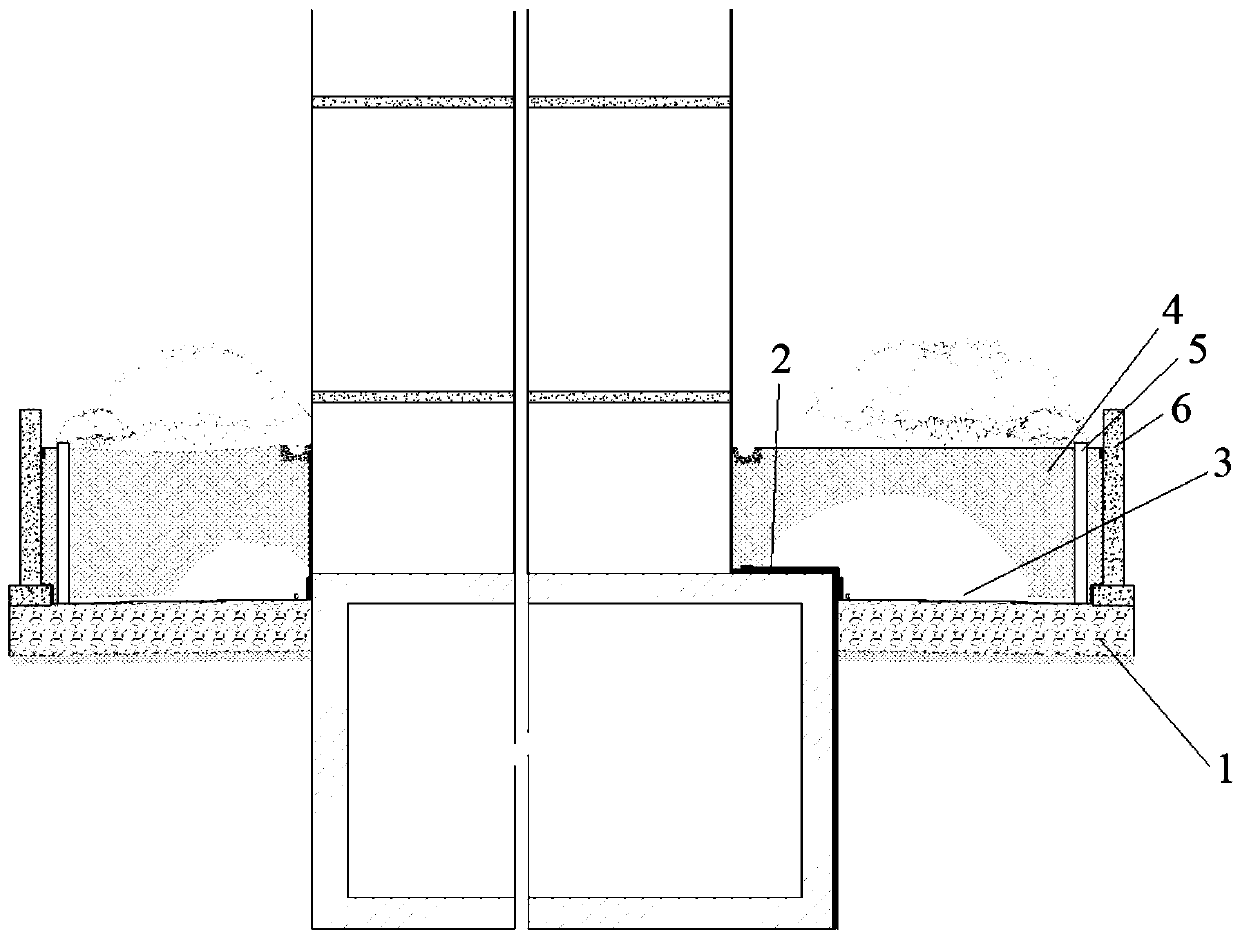

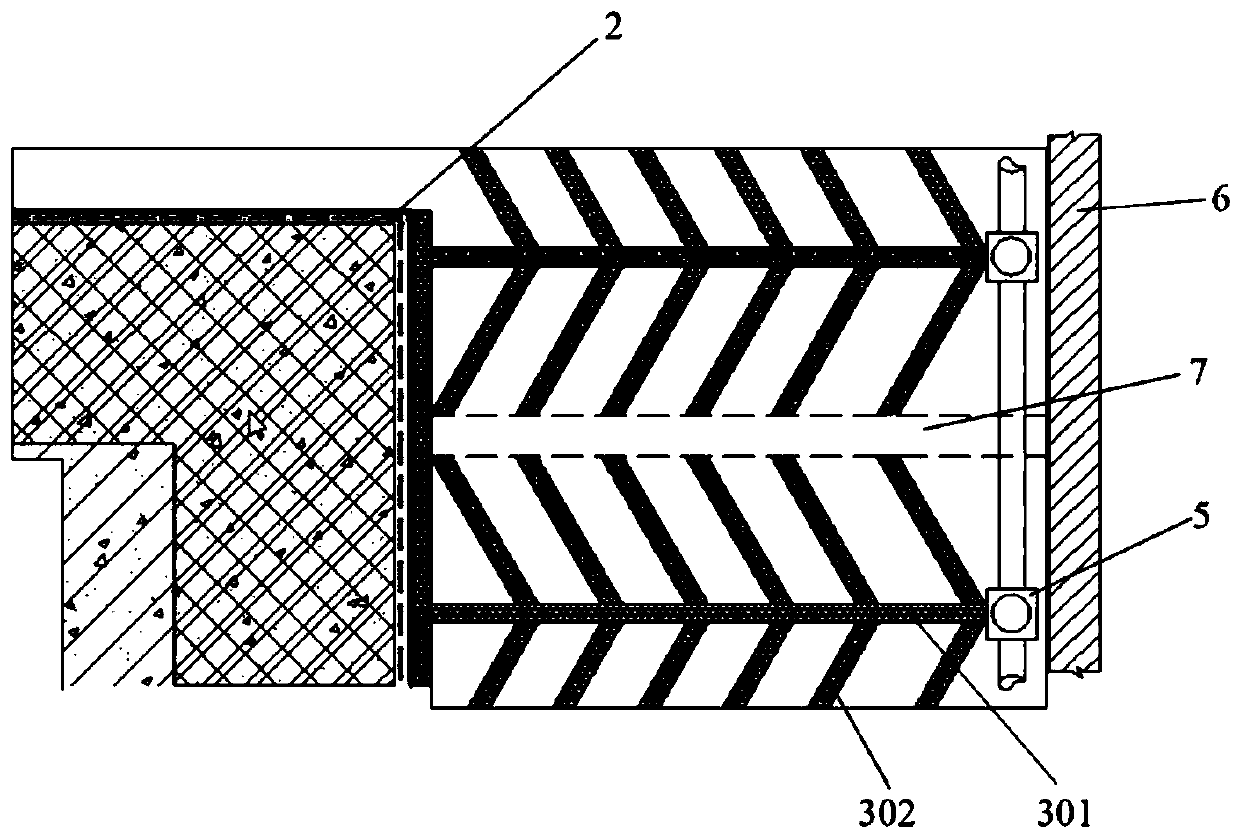

Doo window embedded structure of assembly type building and construction and installation method of door window embedded structure

The invention discloses a door window embedded structure of an assembly type building and a construction and installation method of the door window embedded structure. The door window embedded structure comprises an embedded part, an aluminum profile outer frame, a regulator, a self-tapping screw, a waterproof adhesive tape, a sealing rubber strip and a hole cover, sealing holes are formed in twoends of the embedded part respectively; and a groove and a screw hole are formed in the middle of the embedded part; the regulator is arranged at the position, opposite to the groove, of the aluminumprofile outer frame in a penetrating mode till the regulator abuts against the interior of the groove of the embedded part so as to adjust the distance between the aluminum profile outer frame and theembedded part. A screw penetrates through the position, corresponding to the screw hole, of the aluminum profile outer frame until the aluminum profile outer frame is in threaded connection into thescrew hole, so that the aluminum profile outer frame is fixedly connected with the embedded part. The sealing holes in two ends are filled with a waterproof rubber strip and a sealing rubber strip respectively so that junctions of two sides of the aluminum profile outer frame and the embedded part are in a sealed mode, and two hole covers are arranged in the aluminum profile outer frame in a penetrating mode.

Owner:HUNAN KURBON CURTAIN WALL DECORATION

Sound insulation coating and preparation method thereof

InactiveCN111154353AEasy constructionAvoid node processingFireproof paintsGlass fiberPolyvinyl acetate

The invention provides a sound insulation coating and a preparation method thereof. The coating comprises the following components in parts by weight: 6-7 parts of polyvinyl acetate; 1-2 parts of silicon dioxide powder; 2-3 parts of glass fibers; 6-7 parts of aluminum oxide powder; 9 to 10 parts of dicalcium silicate powder; 2-3 parts of magnesium oxide powder; 1-2 parts of barium sulfate powder;and 50-51 parts of distilled water. The method comprises the following steps: uniformly stirring dicalcium silicate powder, silicon dioxide powder, aluminum oxide powder, magnesium oxide powder, barium sulfate powder, polyvinyl acetate and glass fibers to obtain a mixture, uniformly stirring the mixture and distilled water, and continuously stirring for 2 hours to obtain the sound insulation coating. The coating is an environment-friendly aqueous coating, is soundproof, damping and shock-absorbing, and has a wide application range; the construction is simple and convenient; and the sound insulation coating is good in adhesion, good in permeability, good in compatibility with a base material, free of cracking, capable of achieving a good sound insulation effect only by forming a coating layer of 3-5 mm, environmentally friendly and free of pollution.

Owner:珠海玖筑新材料有限公司

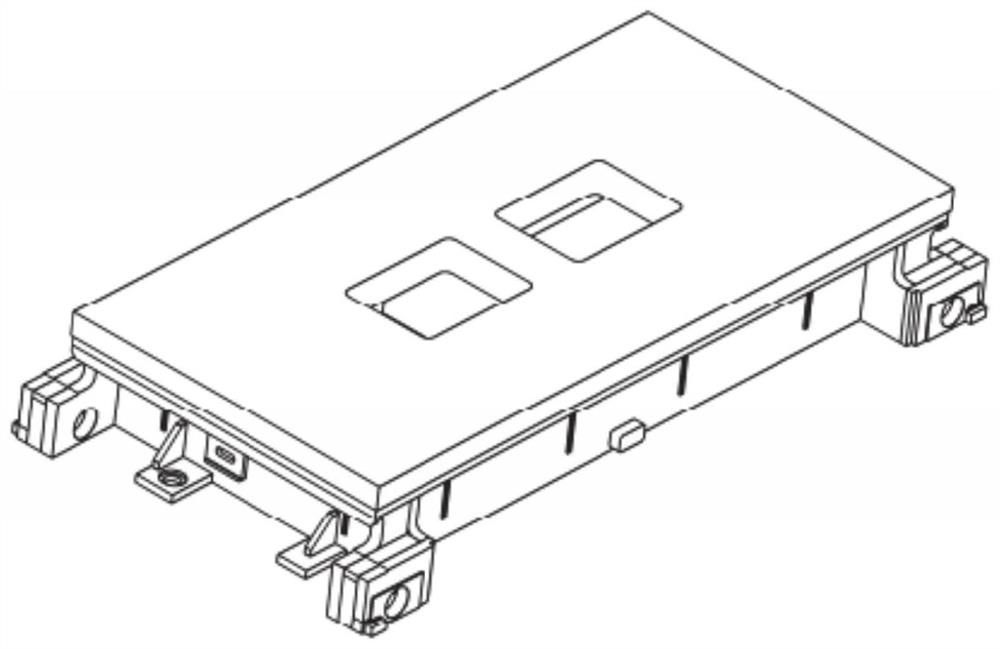

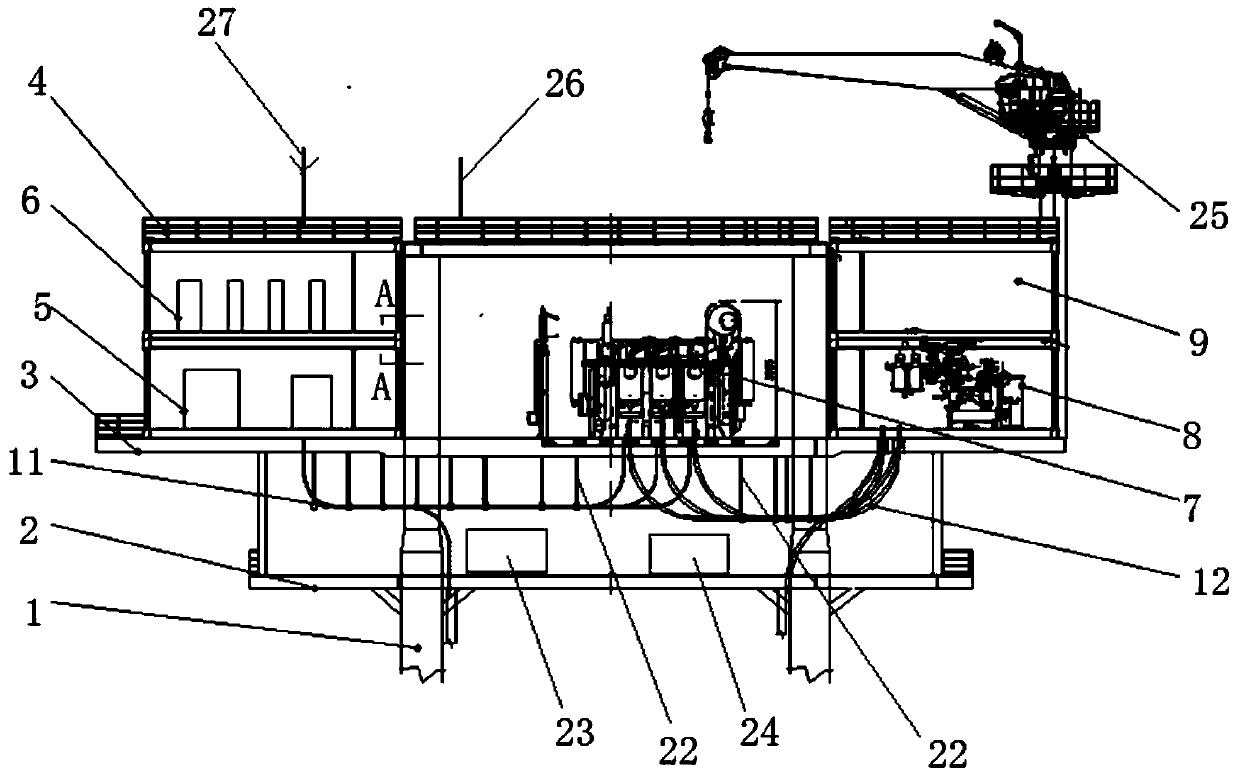

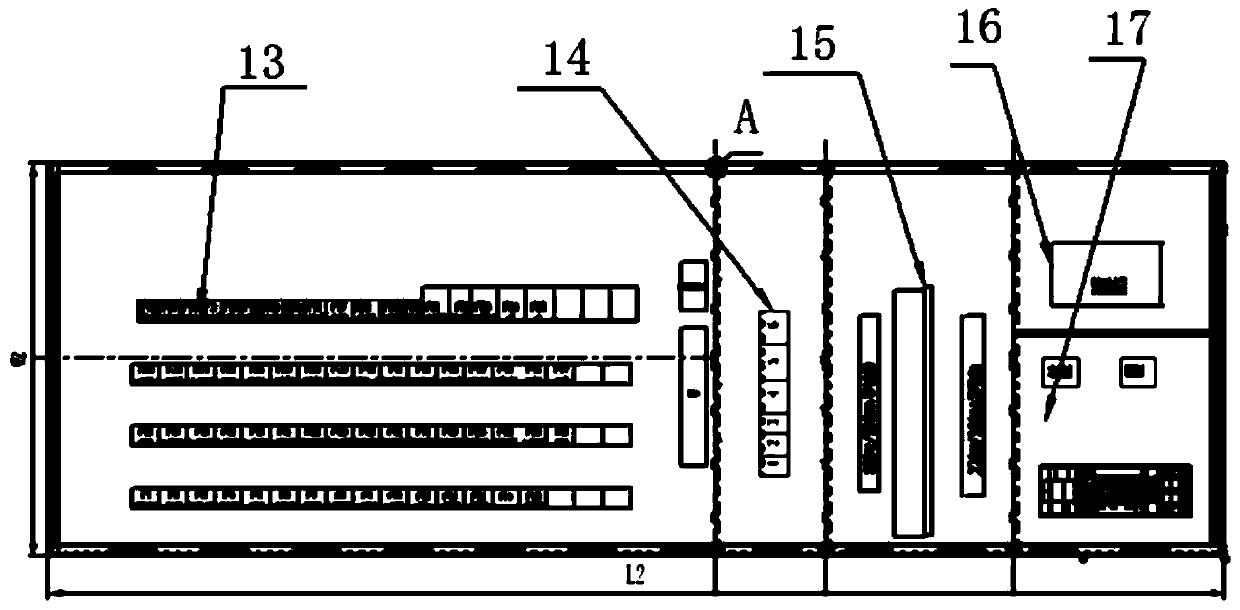

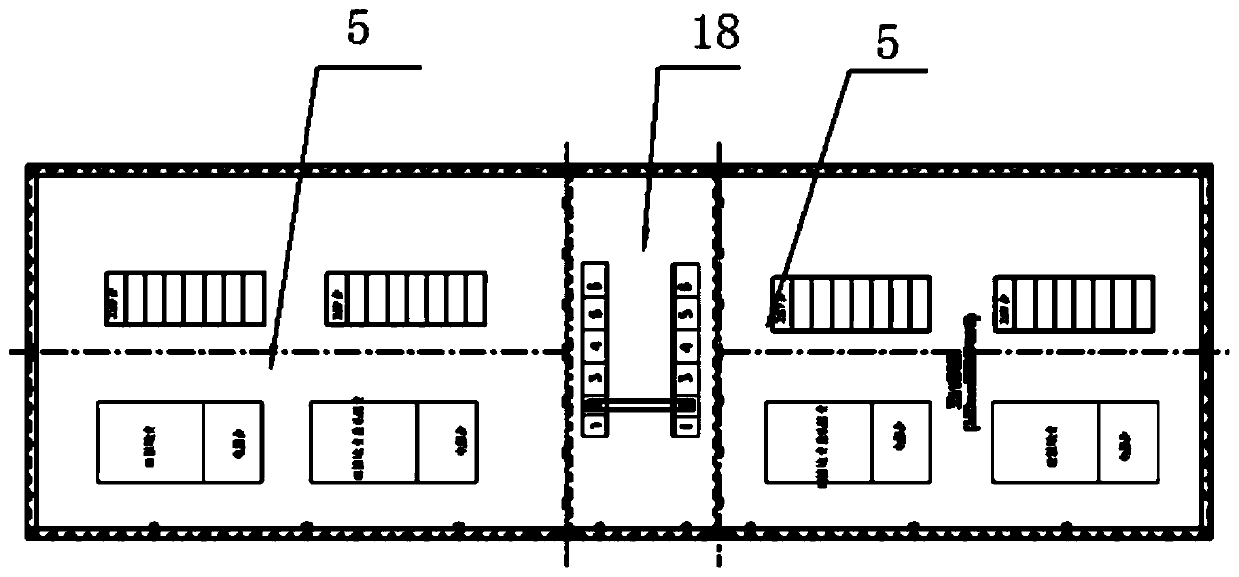

Prefabricated offshore booster station upper module and construction method thereof

PendingCN111490485AReduce volumeThe superstructure and functions are clearly dividedTransformer housesWaterborne vesselsTransformerElectric cables

The invention discloses a prefabricated offshore booster station upper module and a construction method thereof. The upper module comprises a first-layer deck and a second-layer deck which are arranged on a jacket; a 35KV power distribution chamber and a screen body room are arranged on a left side of the second-layer deck, a main transformer chamber is arranged in the middle, a GIS power distribution chamber and an auxiliary equipment chamber are arranged on the right side, a screen body chamber is located above the 35KV power distribution chamber and connected with the 35KV power distribution chamber through a T-shaped hook, and the auxiliary equipment chamber is located above the GIS power distribution chamber and connected with the GIS power distribution chamber through a T-shaped hook; the main transformer chamber and the 35KV power distribution chamber are connected through a 35KV cable, the main transformer chamber and the GIS power distribution chamber are connected through a 220KV cable, and the 35KV cable and the 220KV cable are both located between the first-layer deck and the second-layer deck. According to the upper module and the construction method thereof, a modularprefabricated booster station is adopted, and the upper module and the construction method thereof have the advantages of being short in construction period, less in cross operation, low in management cost, less in redundant design and safe in construction.

Owner:QINGDAO TGOOD ELECTRIC

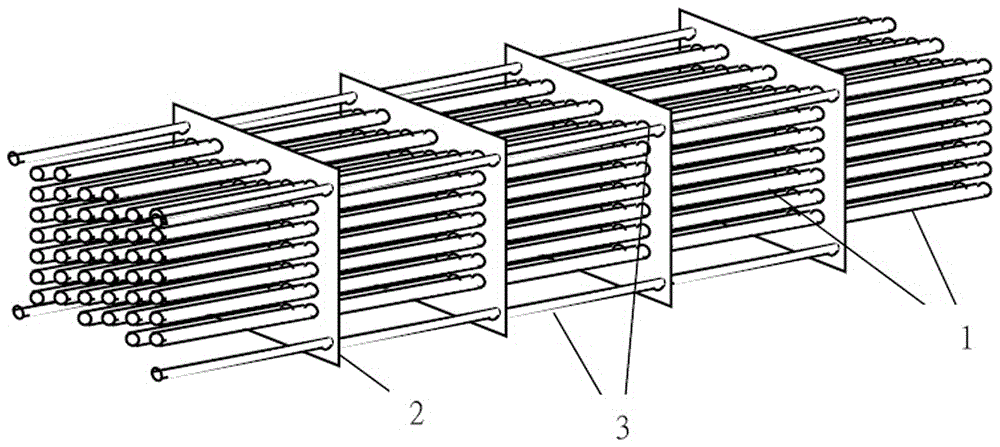

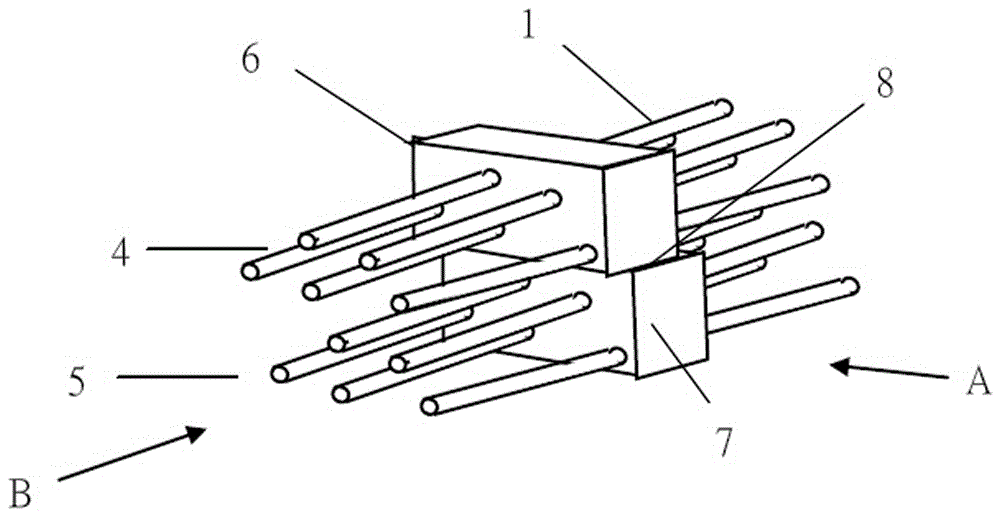

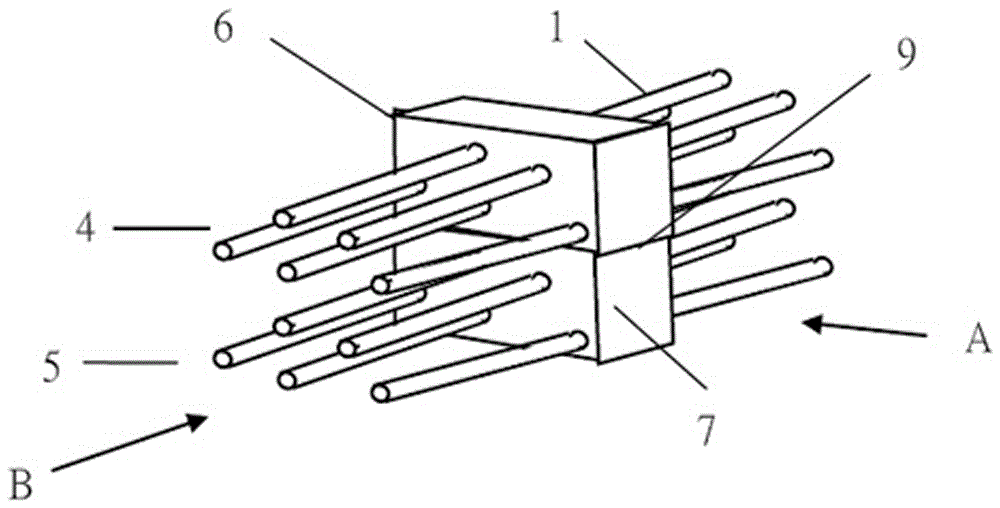

Heating furnace with coil pipes capable of being pulled away

ActiveCN105953630AImproved production conditions and product qualityReduce work at heights and cross workFurnace componentsHeat exchanger casingsChemistryHeating furnace

The invention discloses a heating furnace with coil pipes capable of being pulled away. The heating furnace is formed by assembling a plurality of heat exchange coil pipe modules; each heat exchange coil pipe module comprises furnace walls on the two sides, bend boxes arranged at the two ends of each furnace wall and the coil pipes arranged in the furnace walls; each coil pipe is formed by connecting and installing and welding of a pipe plate, a furnace pipe, a bend, a flange short pipe and a collection box; the pipe plates are borne on supporting lugs on the inner sides of the furnace walls, and the coil pipes can be drawn out from the furnace walls or pushed into the furnace walls; the coil pipes of the heat exchange pipe module at the lower portion of the heating furnace are changed to be assembled and welded on the job site of the furnace, and a new efficient and safe construction method of the building block modular type heating furnace is perfected; during construction, the upper modules are not affected by the delivery period of the furnace pipes of the modules on the lower portion, production conditions and product quality conditions are improved, the phenomenon that outdoor construction sites are affected by poor weather is avoided, and aerial work and crossing work at the job site are greatly reduced; and the individual coil pipes which are prone to being damaged are conveniently constructed, overhauled and replaced, the structure is simple, and the service life of the whole heating furnace can be prolonged.

Owner:THE CHALLENGE PETROCHEM MACHINERY CORP

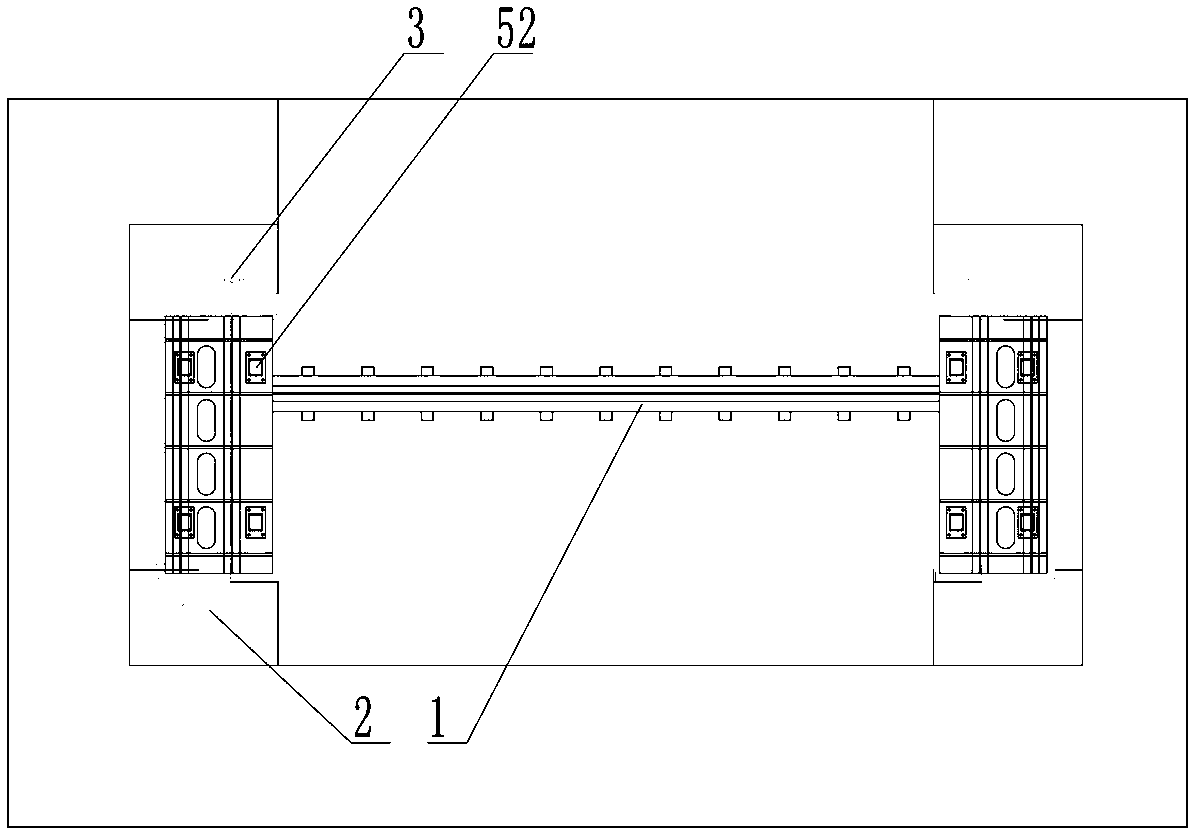

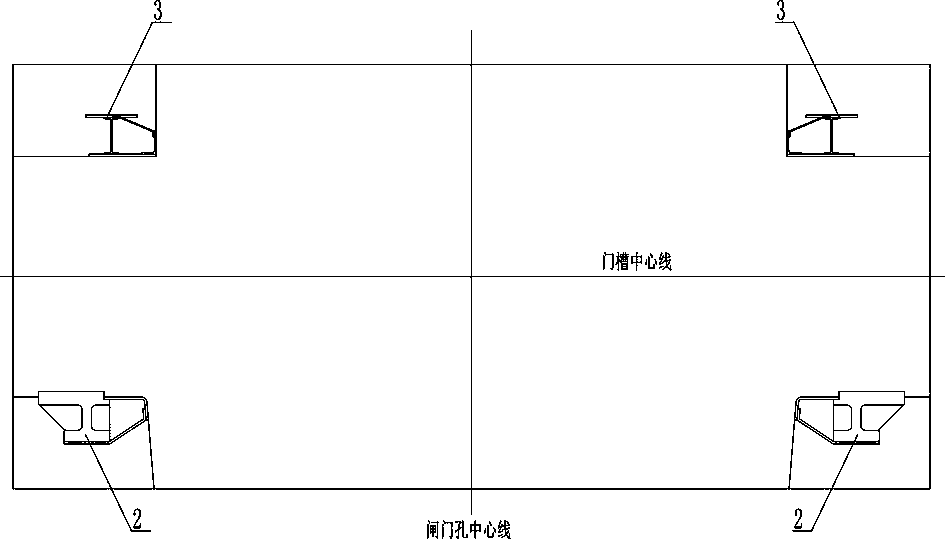

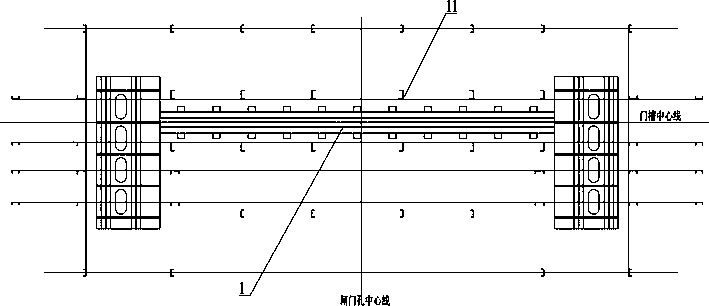

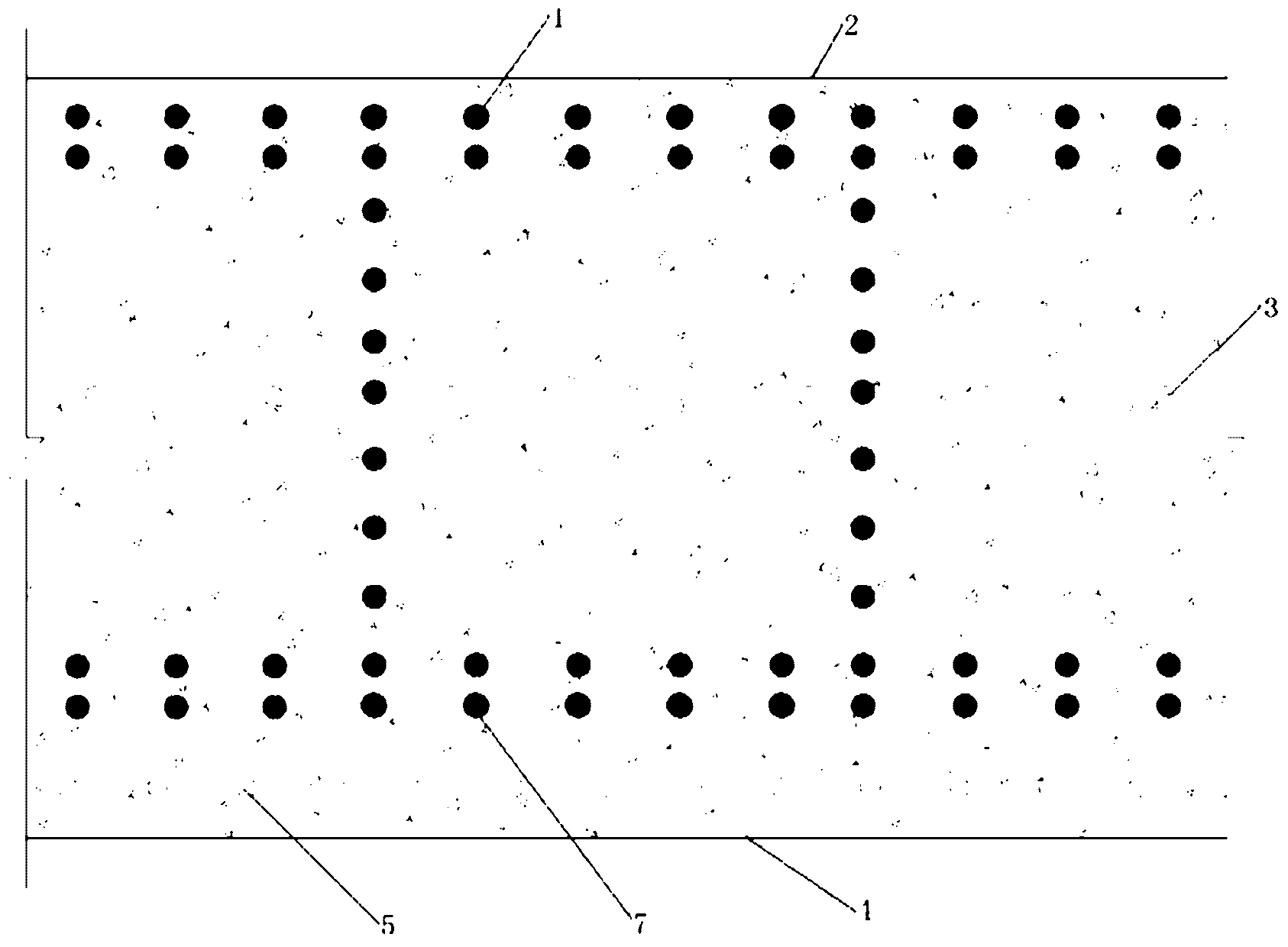

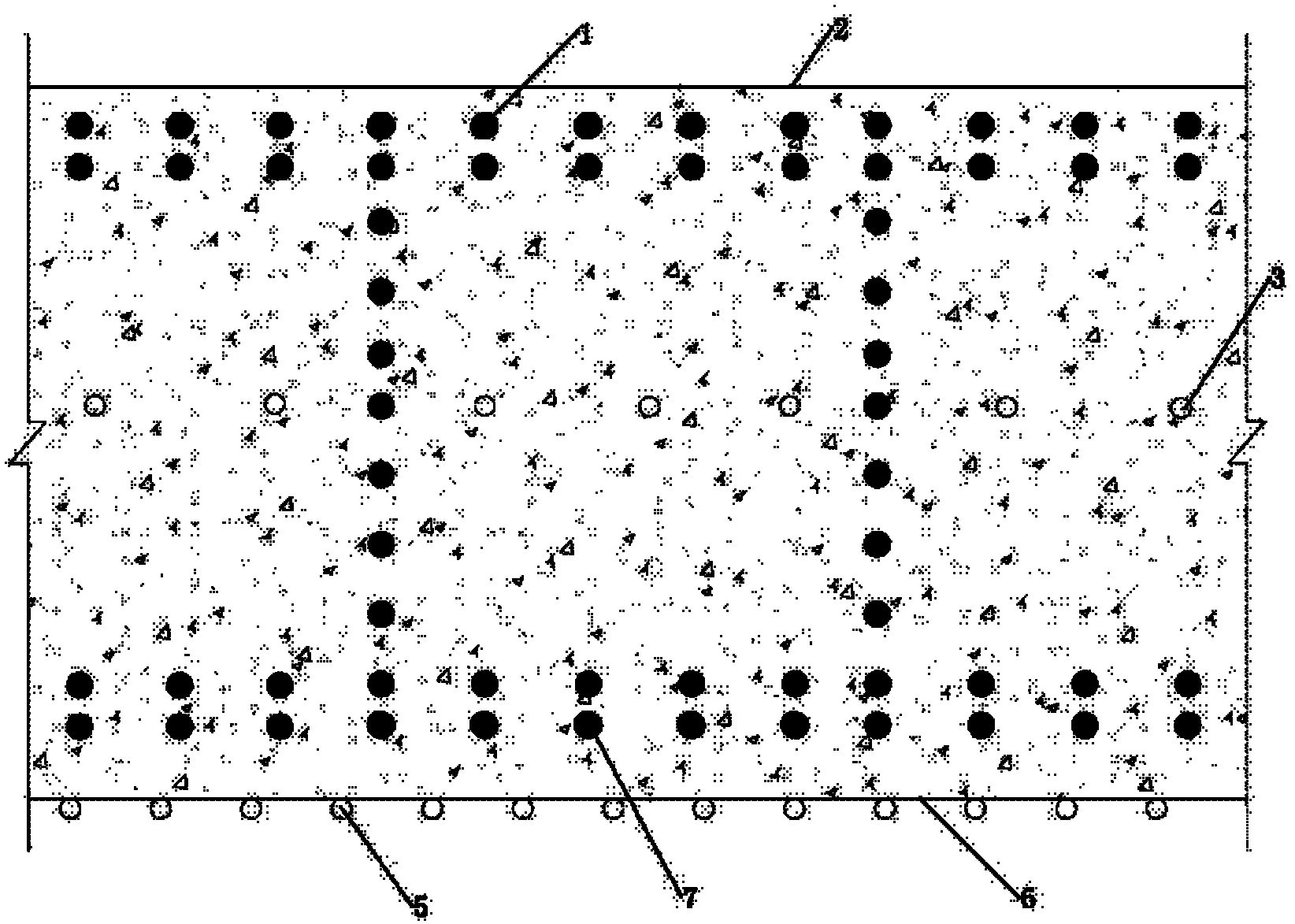

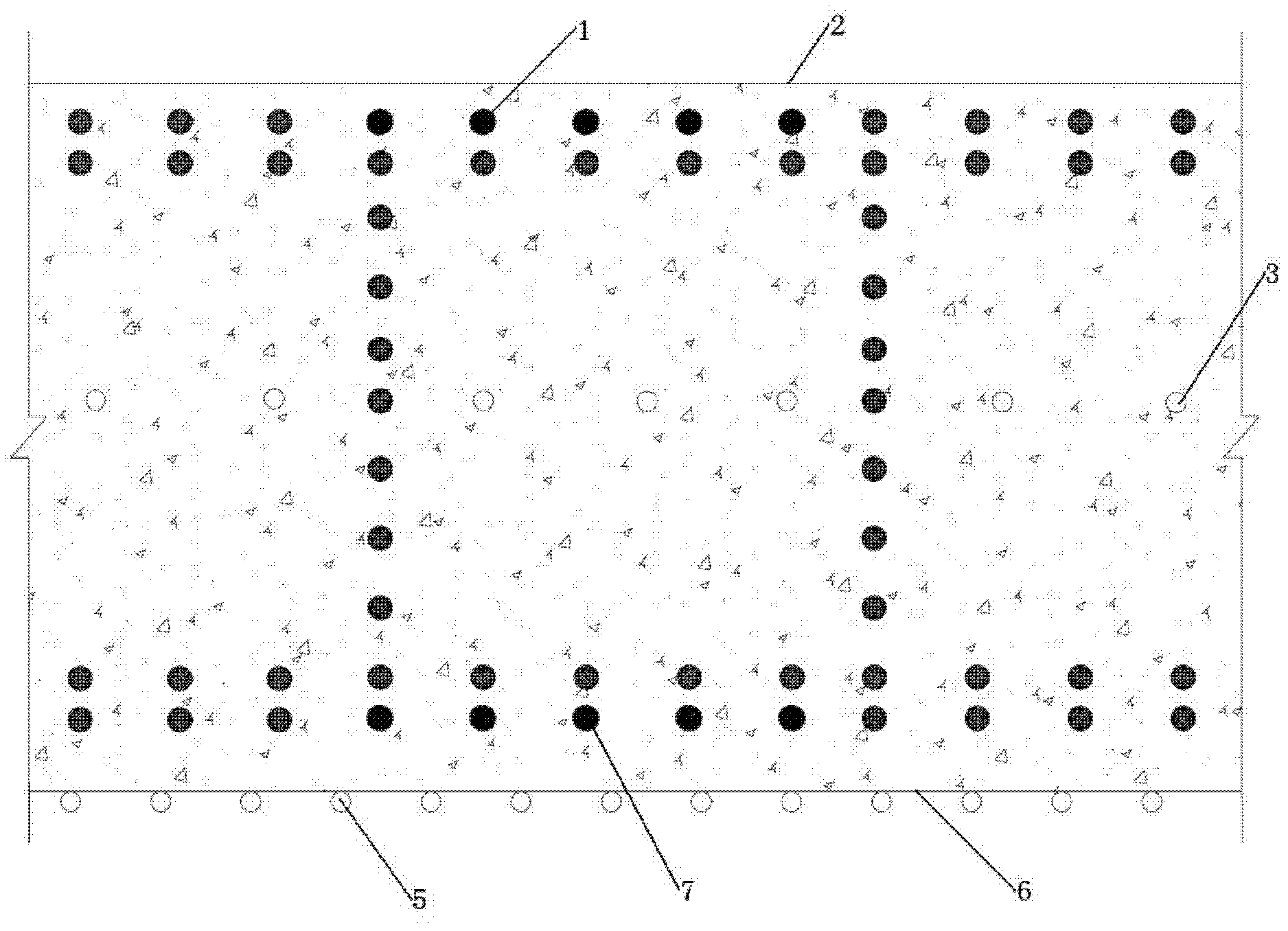

Phase-I installation method for gate slot of hydropower station gate

InactiveCN111101485AAvoid damageReduction of multiple welding ribsBarrages/weirsHydropowerScaffolder

The invention relates to a phase-I installation method for a gate slot of a hydropower station gate. A self-lifting trolley is adopted in a narrow and small space so that an embedded part is connectedinto an integrated structure and stressed jointly, and a template is automatically lifted for suspension construction through the self-lifting trolley. The installation method overcomes the problemsof large potential safety hazard and long period of cross operation caused by the traditional installation method of the gate slot of the original hydropower station requiring to weld a joint bar andinstall and disassemble a scaffold for many times, and the method has the characteristics of reducing multiple welding of the joint bar, no need to set up the scaffold, no need of cross operation, improving the safety during operation and avoiding damage to the gate slot during pouring.

Owner:CHINA YANGTZE POWER

Construction method for shielding cooling system and steel lining wall of high temperature gas cooled reactor

ActiveCN102605952AShorten the critical pathShorten the timeBuilding material handlingNuclear reactorEngineering

The invention relates to a construction method for a shielding cooling system and a steel lining wall of a high temperature gas cooled reactor, which belongs to the technical field of reactor structures. The method includes: arranging a steel lining according to design requirements and welding cooling water pipes to the inner surfaces of the steel lining to form a combined structure module, hoisting the module to the position of a primary loop cabin of the high temperature gas cooled reactor, sequentially binding inner main reinforcement bars, auxiliary reinforcement bars and outer main reinforcement bars, erecting a constructional outer mould plate, concreting between the steel lining and the constructional outer mould plate to form a lower-layer combined structural wall module, hoistingan upper-layer module on the lower-layer combined structural wall module, and cycling so to form the wall of the primary loop cabin of the high temperature gas cooled reactor. Using the construction method can shorten time of constructional critical paths, reduce cross workload on a construction site, relieve work intensity on the construction site and guarantee accurate execution of constructionschedule while improve construction quality and shorten construction period.

Owner:CHINERGY CO LTD

Cable-stayed bridge concrete beam combined hanging basket construction method

InactiveCN111042003AReduce the influence of internal forceReduce lowering heightBridge erection/assemblyConcrete beamsArchitectural engineering

The invention discloses a cable-stayed bridge concrete beam combined hanging basket construction method. Stay cable construction is divided into two times of tensioning, the two times of tensioning are conducted after segment pouring and hanging basket walking respectively, the internal force influence on new concrete and old concrete due to different working conditions is reduced, cross operationis reduced, and effective control over the line shape of a finished bridge is enhanced; due to the fact that a small cross beam is arranged between two box chambers of a main beam, when a hanging basket moves forwards after concrete pouring is completed, due to blocking of the cross beam, a hanging basket bottom die system needs to be lowered firstly. Therefore, small wood molds convenient to mount and demount should be adopted for the cross beam portion plate, the demounted formwork and the demounted support are flatly laid on the hanging basket bottom mold, the lowering height of the hanging basket hanging system is reduced, lowering time is saved, and the underbridge navigation clearance requirement can be met. The method is applied to the field of bridge hanging basket construction.

Owner:CHINA RAILWAY GUANGZHOU ENG GRP CO LTD +1

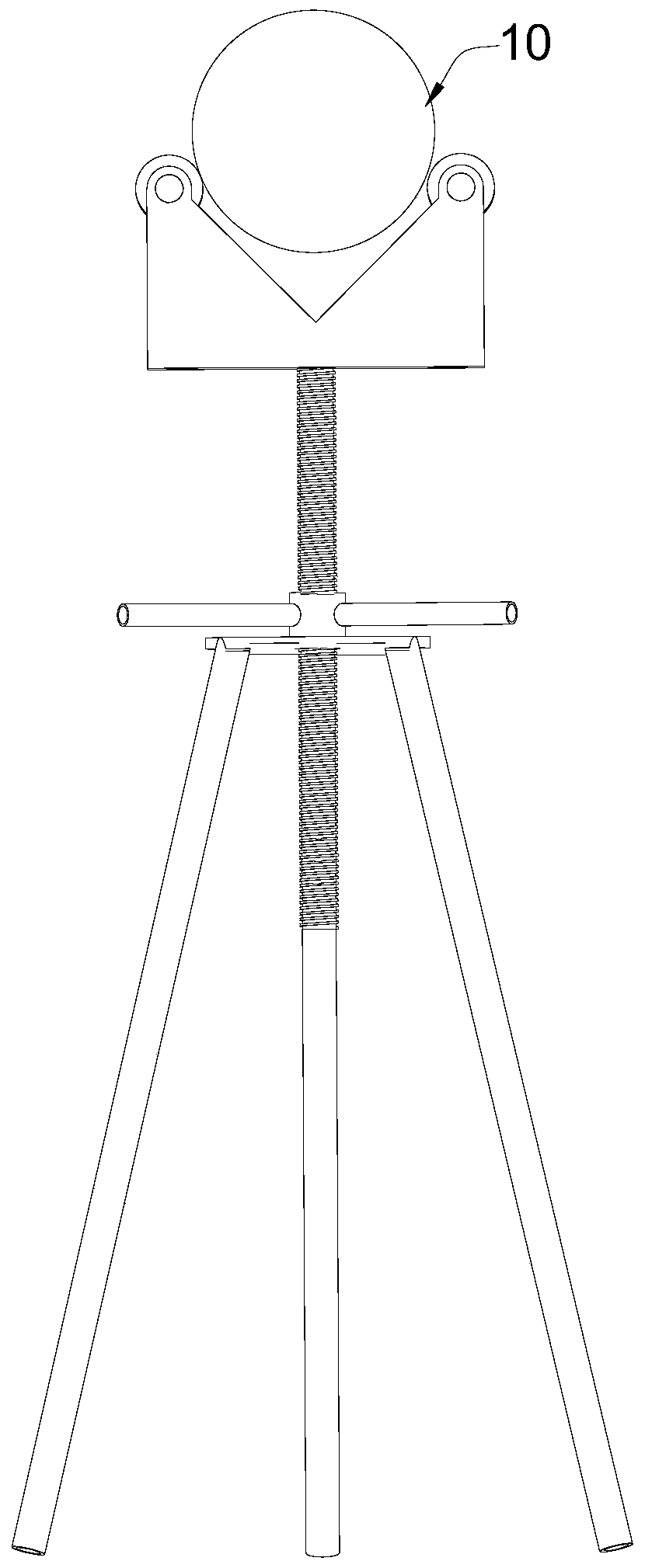

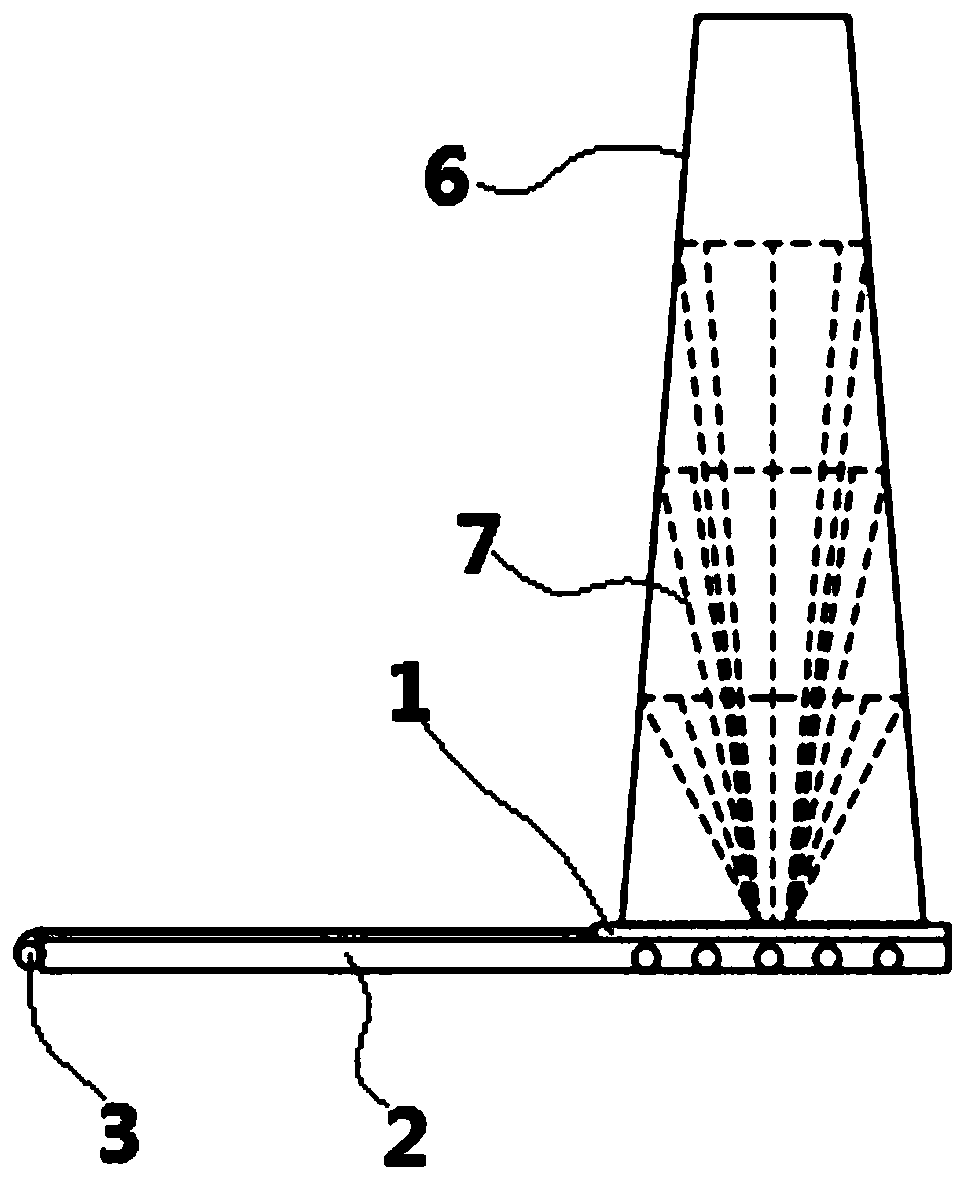

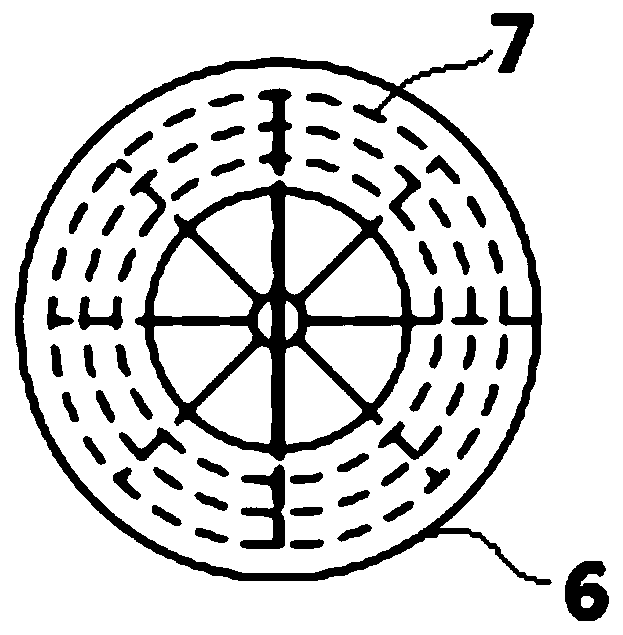

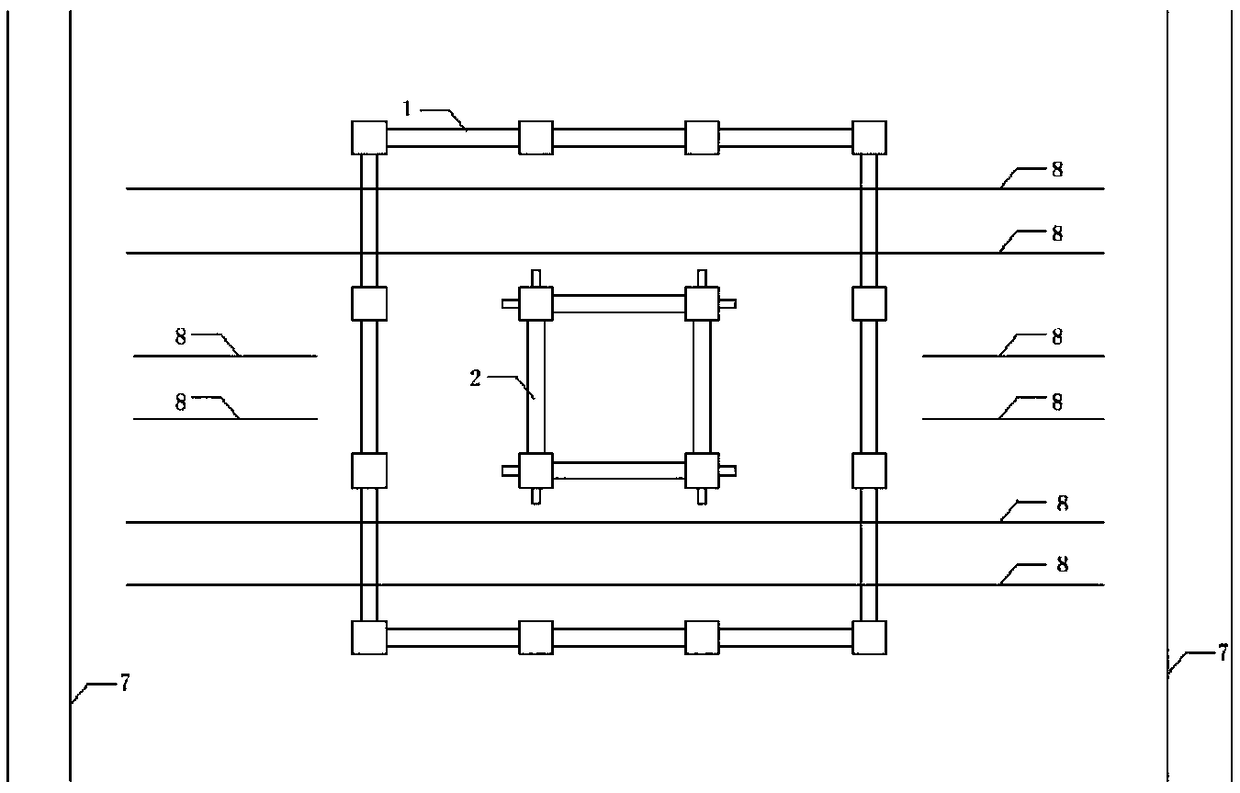

Fabricated wind power tower quick assembling device and construction method

PendingCN111336071AClear functionReduce cross workWind motor supports/mountsPortable liftingArchitectural engineeringTower

The invention discloses a fabricated wind power tower quick assembling device and construction method. The fabricated wind power tower quick assembling device comprises an assembling table and transporting tracks and is mounted in a site, the site comprises an assembling area and a plurality of to-be-lifted areas, and the transporting tracks are formed between the assembling area and all the to-be-lifted areas. The assembling table is arranged in the assembling area, towers are assembled on the assembling table, and the towers and the assembling table slide to all the to-be-lifted areas alongthe transporting tracks. The fabricated wind power tower quick assembling device and construction method have the beneficial effects that site function division is clear, the use cost of a truck cranein the assembling process is lowered, the area occupied by the site is decreased, the assembling quality is easier to control, the space for track transferring is saved, reliability is high, the lifting efficiency is advantageously improved, and green construction is facilitated.

Owner:CHONGQING UNIV

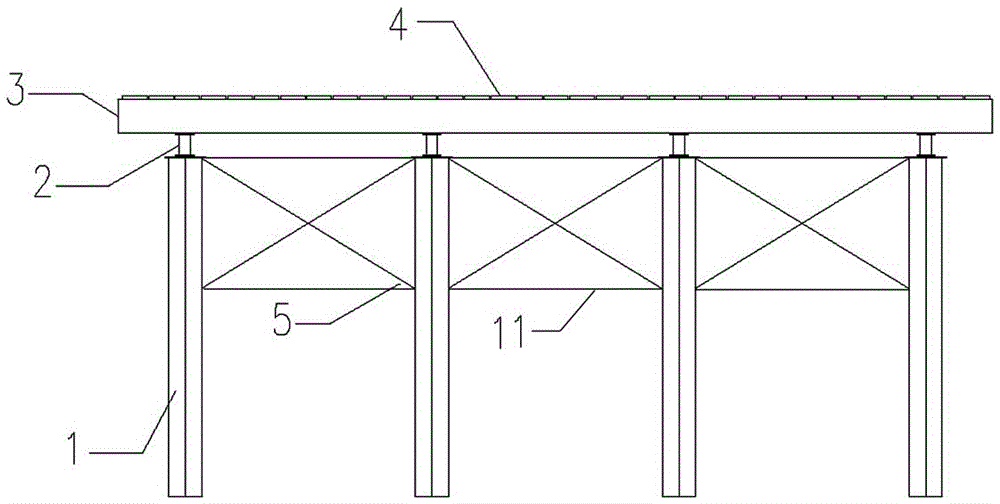

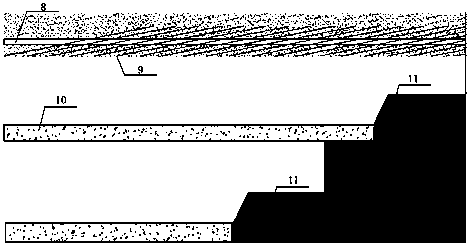

A kind of water building construction platform and its erection method and use method

ActiveCN104532813BSolve the demolition problemEasy constructionArtificial islandsUnderwater structuresFloor slabCofferdam

Owner:JIANGXI PROVINCE URBAN CONSTR GRP

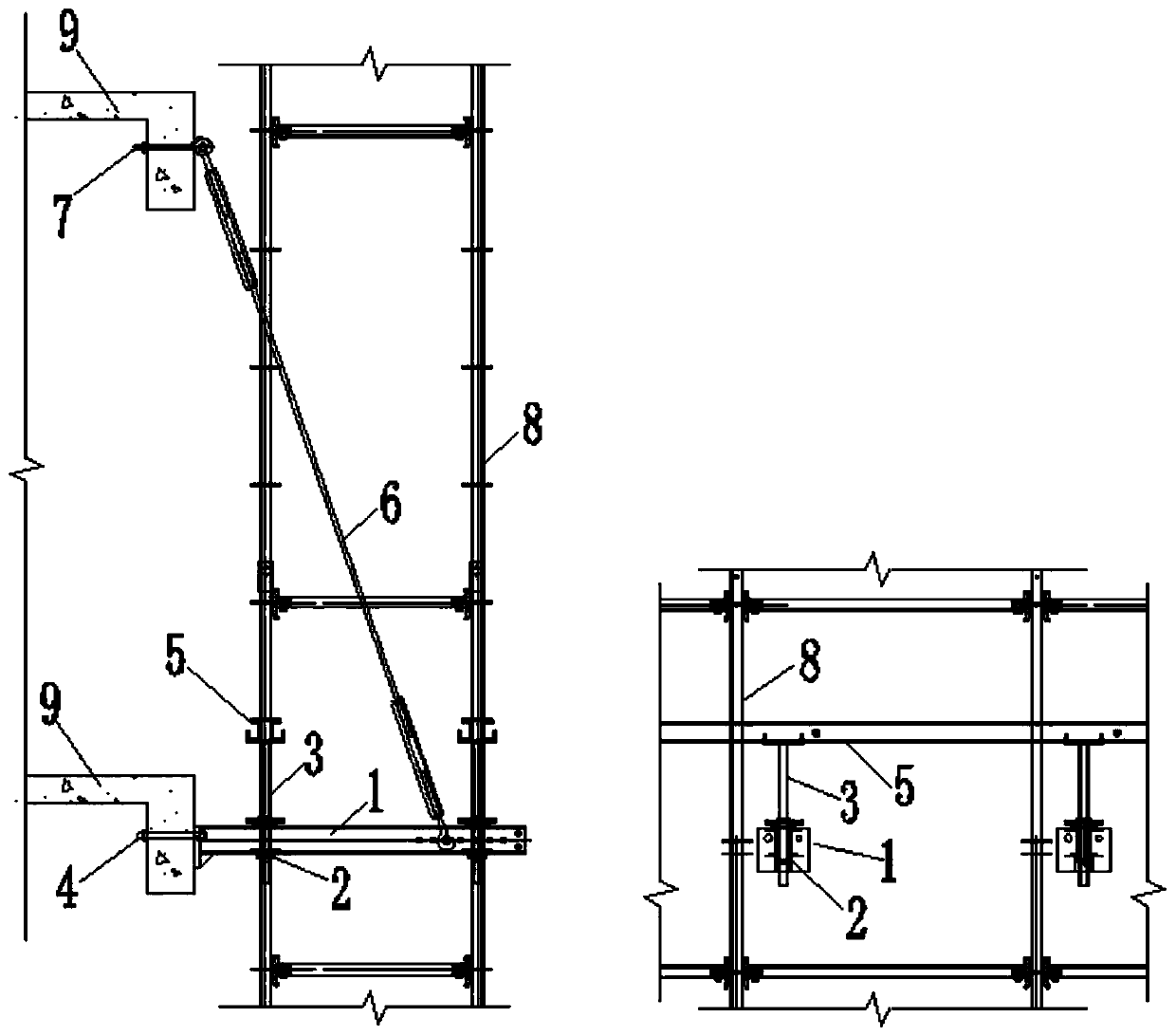

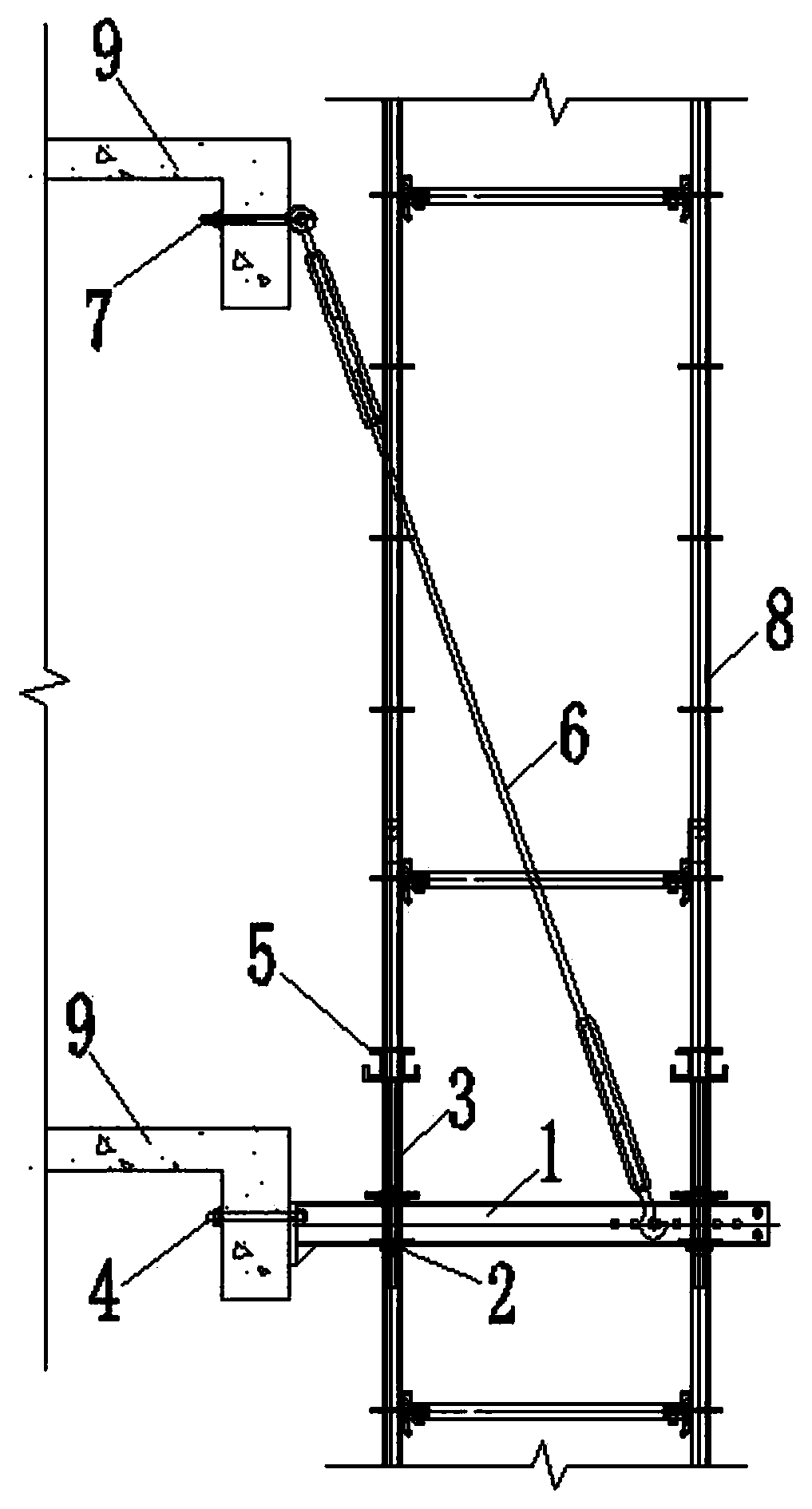

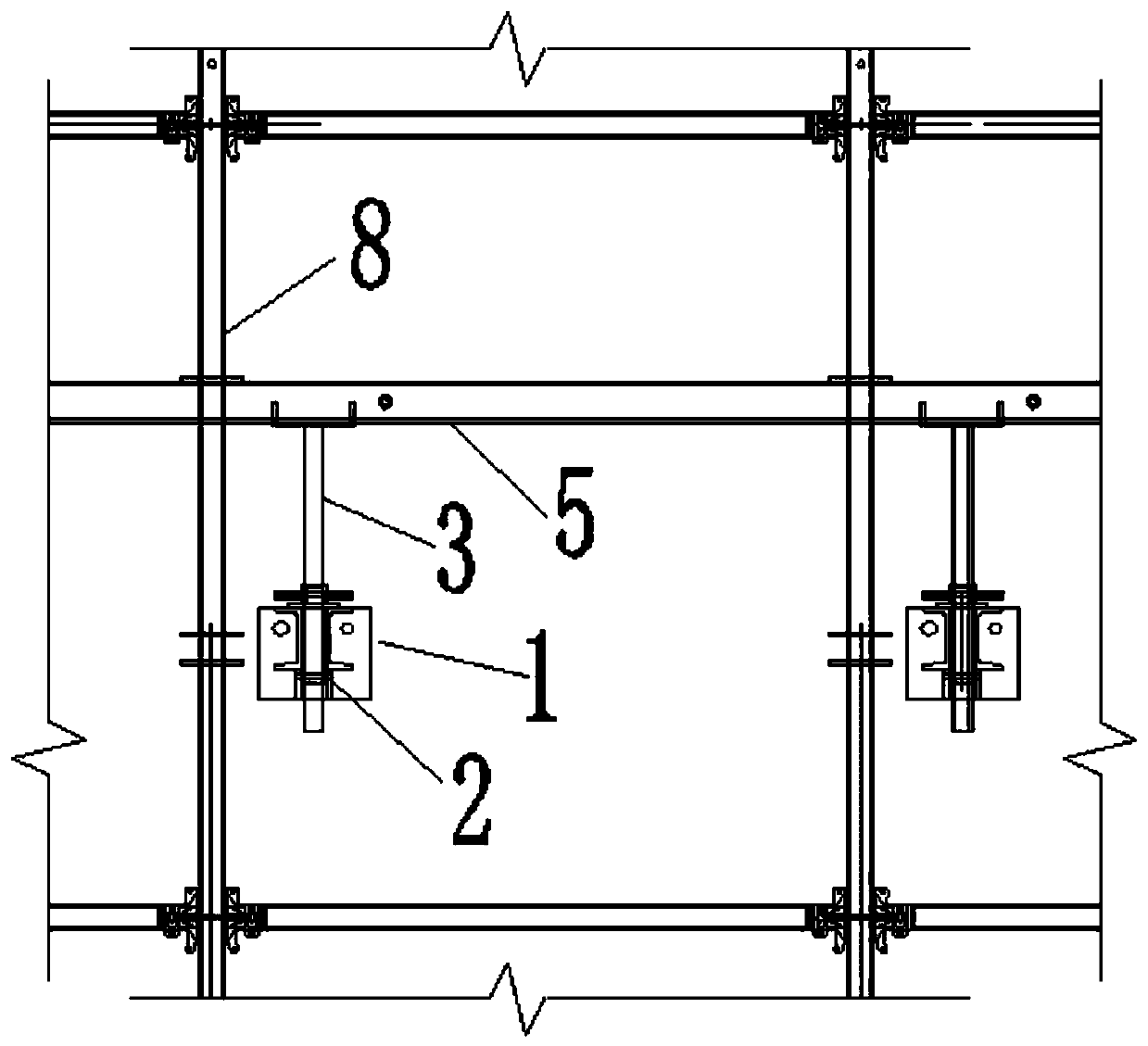

Ring lock type double-row outer scaffold cantilever structure and construction method thereof

ActiveCN110939261AReduce investmentReduce cross workScaffold accessoriesBuilding support scaffoldsEngineeringCantilever

The invention discloses a ring lock type double-row outer scaffold cantilever structure. The ring lock type double-row outer scaffold cantilever structure comprises a scaffold. The scaffold is composed of multiple bodies. Each body comprises a horizontal rod, an inclined rod and four vertical rods, wherein double-groove type longitudinal beams are mounted between two vertical rods and the other two vertical rods, the two double-groove type longitudinal beams are arranged in parallel, an adjustable supporting seat is connected to the double-groove type longitudinal beams, an adjustable supporting seat sleeve is arranged on the adjustable supporting seat, the adjustable supporting seat and the adjustable supporting seat sleeve can relatively move up and down, the adjustable supporting seat comprises a lead screw with an outer thread, a jacking baffle with a groove type opening and an adjustable nut screwed to the lead screw, and the jacking baffle is connected to the bottoms of the double-groove type longitudinal beams. Each adjustable supporting seat sleeve comprises a round steel sleeve, a cushion plate with a round hole and a sleeve limiting plate, wherein the cushion plate and the sleeve limiting plate are welded to the upper end and the lower end of the round steel sleeve. The round steel sleeves sleeve the lead screws, the cushion plates are located below the adjustable nuts, and a double-groove type cantilever steel beam is arranged between the two round steel sleeves. The ring lock type double-row outer scaffold cantilever structure is ingenious in design and convenient to construct.

Owner:ANHUI ZULIN NEW MATERIALS

Six-pilot-tunnel twelve-step underground space excavation support and protection method

ActiveCN108374674AImprove construction safetyNarrowing excavation across bordersUnderground chambersTunnel liningTwo stepUnderground space

Owner:JINAN URBAN CONSTR GRP +1

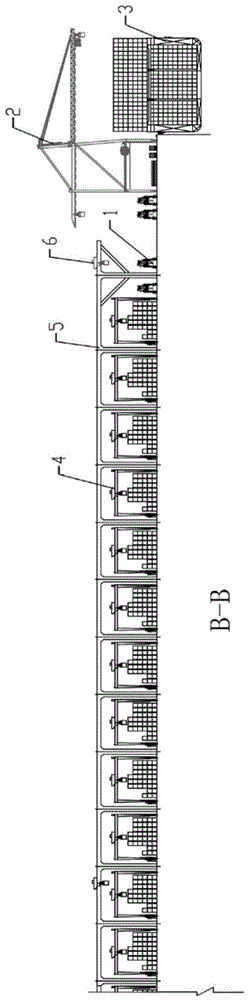

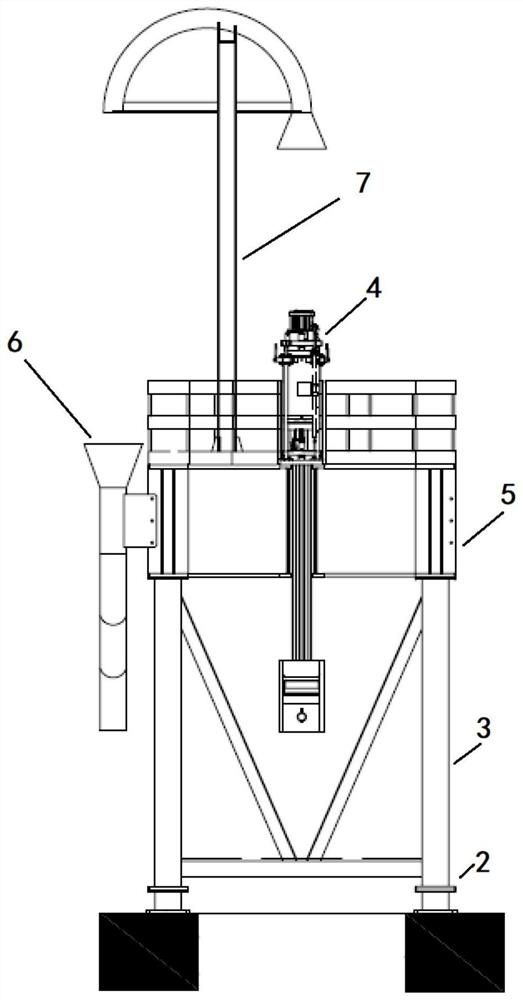

Heat absorber hoisting portal

The invention provides a heat absorber hoisting portal. The heat absorber hoisting portal comprises a flange base, supporting legs, a crane, a hydraulic crane operation platform, a steel strand guidepipe, a steel strand support and connecting pieces, wherein the supporting legs are arranged above the flange base; and the crane, the crane operation platform, the steel strand guide pipe and the steel strand support are installed on the supporting legs.

Owner:THE SECOND CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU

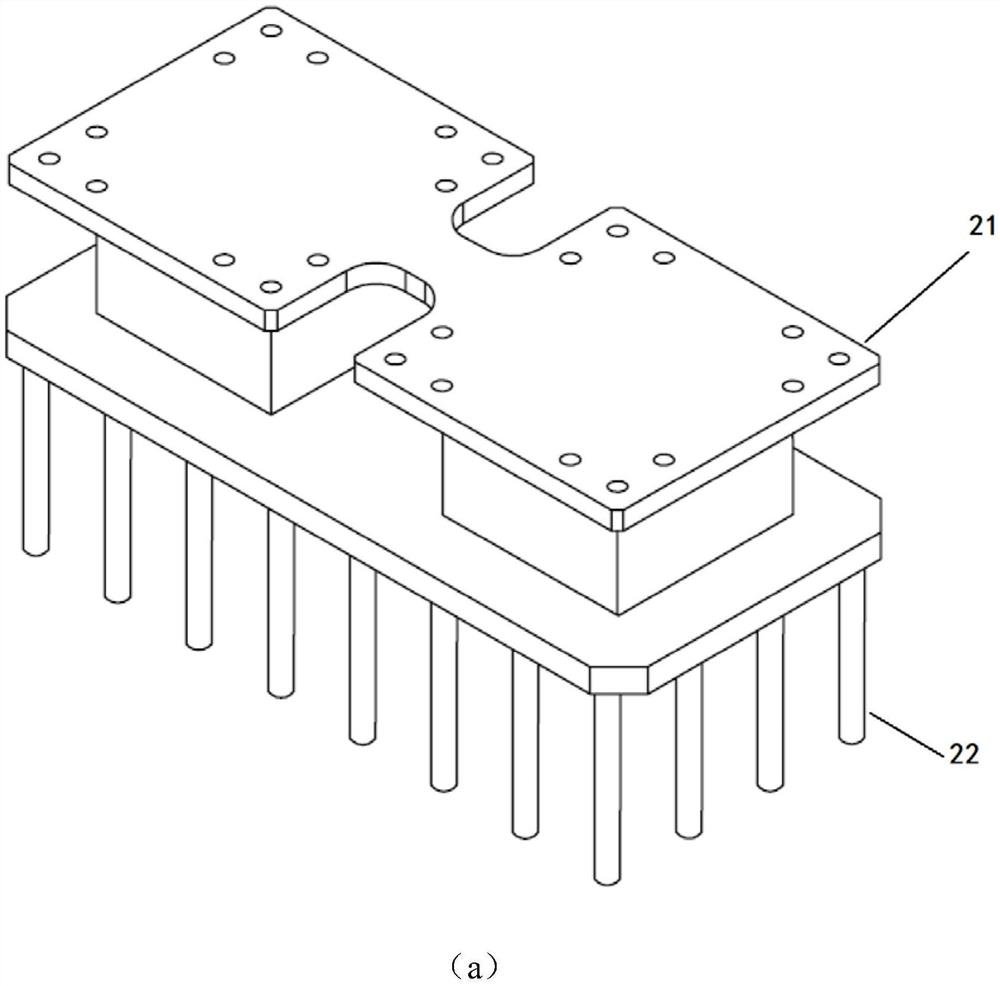

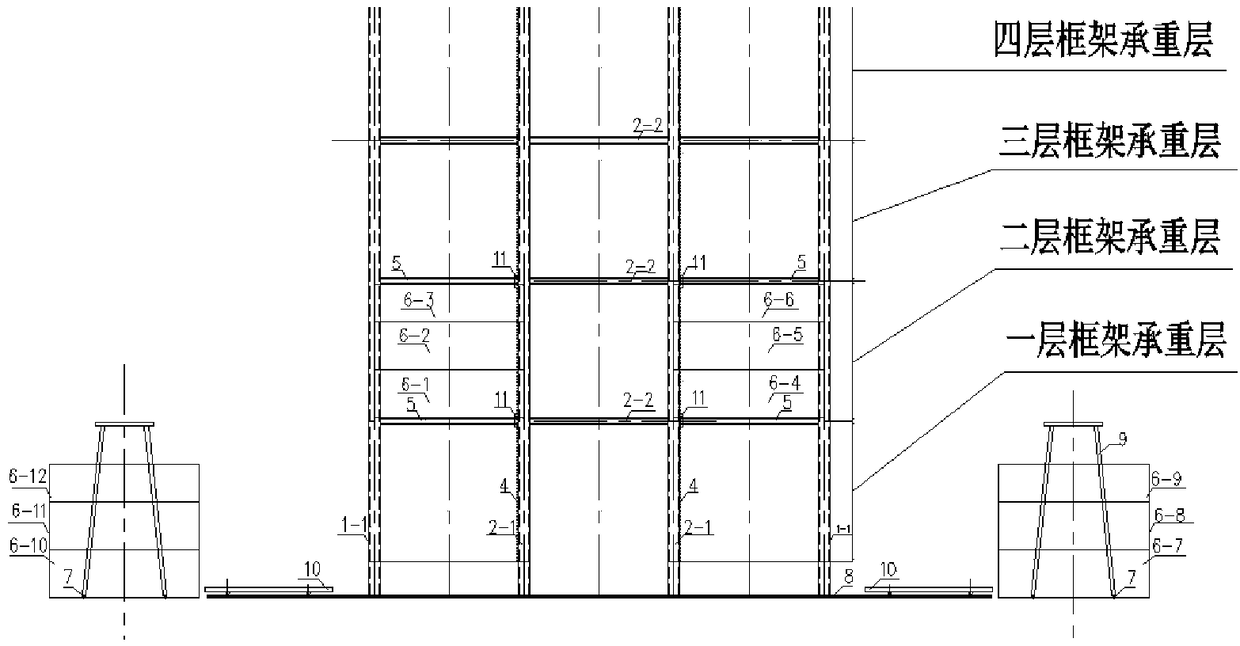

Half-inverted-mounting construction structure and method for frame or cylinder bearing high-rise modular building

PendingCN109296082AEasy to turn around and transportFlexible operationExtraordinary structuresComputer moduleEngineering

The invention provides a half-inverted-mounting construction structure and method for a frame or cylinder bearing high-rise modular building. The half-inverted-mounting construction structure comprises a frame structure, standard module layers mounted in a frame, rack transporting devices mounted on frame columns, and hoisting devices independent from the frame structure. The half-inverted-mounting construction method comprises the steps that firstly, upright-mounting construction of the frame is conducted, the standard module layers are accumulated into multiple module layers by the hoistingdevices and then transported into the frame structure to constitute an accumulated hoisting unit, and then inverted mounting of the standard module layers is conducted with the whole layer of combination units as a unit. The half-inverted-mounting construction structure and method for the frame or cylinder bearing high-rise modular building have the beneficial effects that the half-inverted-mounting construction structure and method can be used for safe, rapid and economic mounting, the construction period can be effectively shortened, and the cost is saved.

Owner:TIANJIN 20 CONSTR

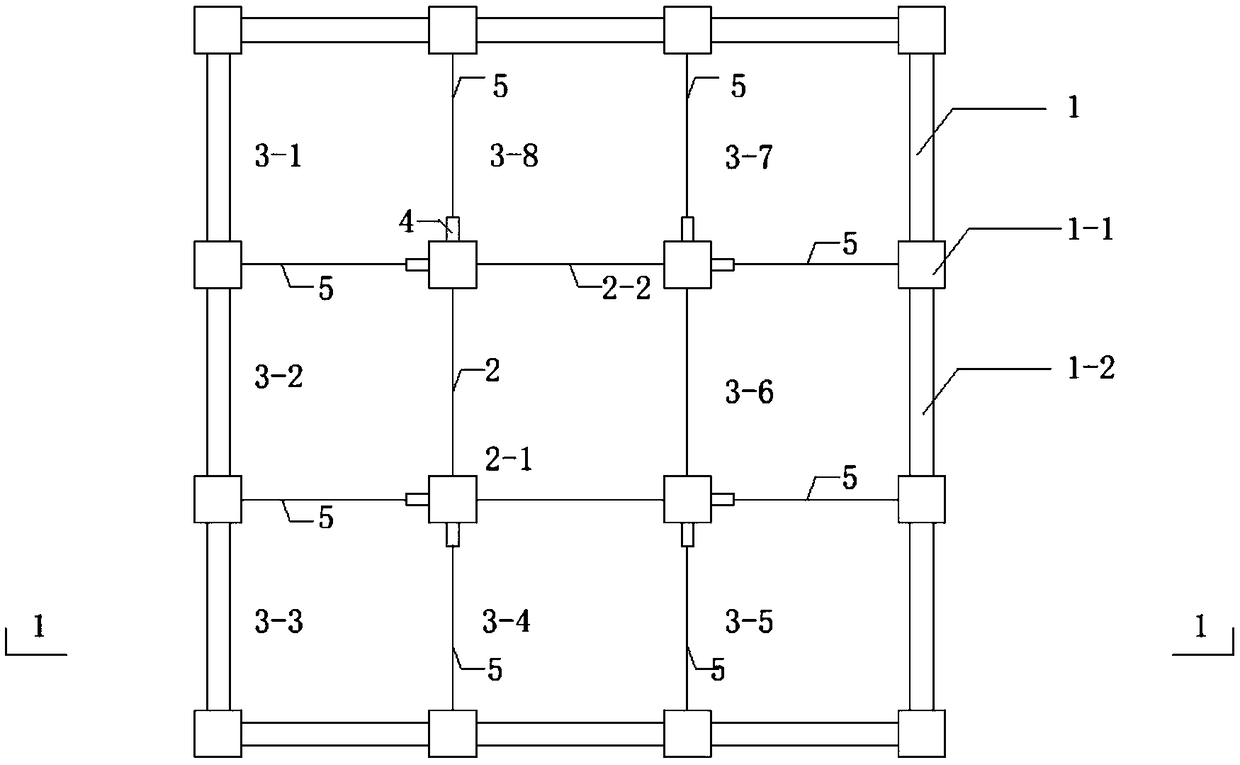

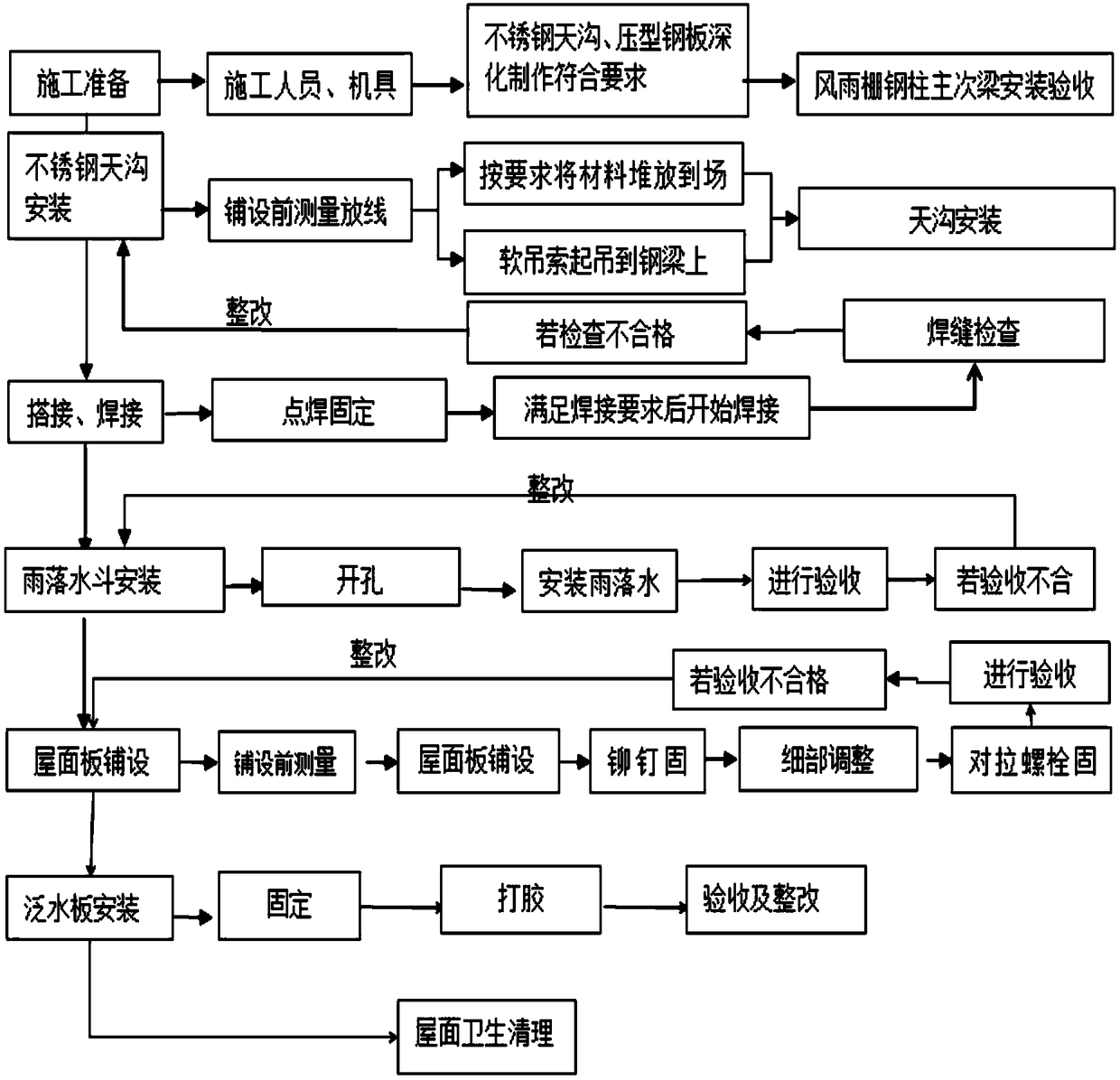

Construction method of novel corrosion-resistant pressed metal shelter roof

InactiveCN109138283AHigh strengthImprove corrosion resistanceRoof covering using slabs/sheetsRoof drainageUltimate tensile strengthMetal

The invention discloses a construction method of a novel corrosion-resistant pressed metal shelter roof. Novel corrosion-resistant pressed stainless steel plates are successively connected in an overlap joint manner on a beam to form a roof panel and the roof panel is connected with the beam. And Novel corrosion-resistant pressed stainless steel plates are successively connected in an overlap joint manner on the beam to form a gutter and the gutter is connected with the beam. The construction method has the following beneficial effects: on the basis of the strength and rigidity of the novel corrosion-resistant pressed stainless steel plates, the plates can serve as a working platform to support the staff and thus no extra supporting structure to support the under-construction roof and theconstruction staff is needed, so that construction of the supporting structure is saved and thus the use of materials, manpower and equipment can be reduced; the construction period occupied by the construction of the supporting structure is saved, so that the construction period is shortened and the construction cost is saved.

Owner:中铁八局集团第四工程有限公司

Novel building window frame and mounting method thereof

InactiveCN109750943AReduce cross workConducive to site protectionFrame fasteningJoints tightening/coveringFoaming agentEngineering

The invention discloses a novel building window frame and a mounting method thereof. The novel building window frame comprises a main body structure, a window frame body, screws, a foaming agent, an indoor sealant and an outdoor sealant, and a hole of the main body structure is of a notch type structure. The window frame body is attached to and extends into the notch until a certain gap is reserved between the window frame body and the main body structure, and the screws are arranged at the window frame body in a penetrating mode to be in threaded connection with the main body structure. The gap between the window frame body and the main body structure is filled with the foaming agent, the boundary position of one side of the window frame body and the main body structure is coated with theindoor sealant for sealing, and a boundary position of the other side of the window frame, the foaming agent and the main body structure is coated with the outdoor sealant for sealing. According to the novel building window frame and the mounting method thereof, the space between an aluminum frame and a wall body is filled with a foaming agent soft heat preservation material, and the aluminum frame does not make contact with cement and is in flexible connection with the cement.

Owner:HUNAN KURBON CURTAIN WALL DECORATION

Vertical type flow-line forming method for PCCP cores

InactiveCN106363796AIncrease productivityImprove working conditionsAuxillary shaping apparatusCeramic shaping plantsAgricultural engineeringSteel cylinder

The invention provides a vertical type flow-line forming method for PCCP cores, which can realize flow-line production of the PCCP cores to increase the production efficiency. The method comprises the following steps: 1) designing flow lines suitable for forming the PCCP cores according to a productivity requirement; 2) performing PCCP core demoulding, including cleaning top covers and outer moulds of vertical type PCCP moulds and spraying a release agent to the top covers and the outer moulds of the vertical type PCCP moulds; 3) cleaning inner moulds and bases of the vertical type PCCP moulds and spraying the release agent to the inner moulds the bases of the vertical type PCCP moulds; 4) mounting steel cylinders and assembling the vertical type PCCP moulds; 5) pouring concrete; 6) troweling concrete at the spigot ends of the PCCP cores; and 7) curing the PCCP cores with the vertical type PCCP moulds.

Owner:SHANDONG ELECTRIC POWER PIPELINE ENG

Method and drainage structure for preventing and treating collapsible loess subsidence

InactiveCN110230310AReduce cross workSimple processSewerage structuresProtective foundationEngineeringSubsidence

The invention discloses a method and drainage structure for preventing and treatingcollapsible loess subsidence, and relates to the field of construction. The method comprises the following steps thata working site isdetermined according to a ground elevation; replacement filling soil ispaved on a lower bearing layer of the working site and the replacement filling soil iscompacted; a waterproof material is paved on the replacement soil; water-permeable blind pipesare paved transversely on the waterproof material; and after the water-permeable blind pipesarepaved, the working site is backfilled to the ground elevation. According to the method and drainage structure, during construction, the constructioncan be divided into block flow insertion work, the cross work in the construction iseliminatedcompared with a conventional method, the processes aresimplified, the construction period isshortened, and the method and drainage structure are especially suitable for a thick collapsible loessarea.

Owner:上海斐晟企业管理有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com