Ring lock type double-row outer scaffold cantilever structure and construction method thereof

A scaffolding and overhanging technology, which is applied in the field of scaffolding, can solve the problem that the overhanging I-beam can not be guaranteed to be just at the position of the pole of the buckle-type scaffolding, the workload of pre-embedding and repair after dismantling is large, and the quality of the main structure is affected. To achieve the effect of improving material turnover rate, improving effective utilization rate and saving material input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the invention are described in detail below, but the invention can be implemented in a number of different ways as defined and covered by the claims:

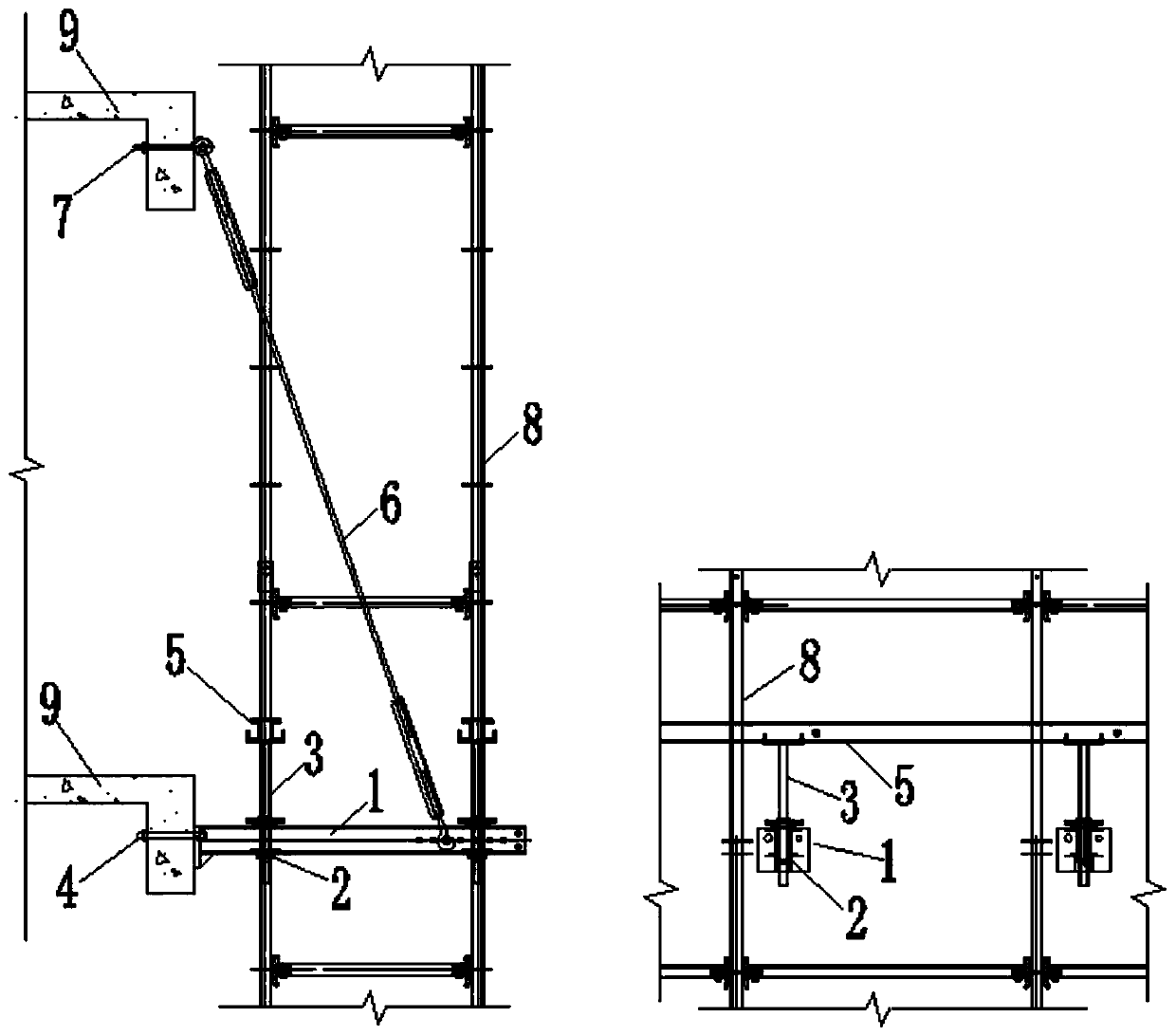

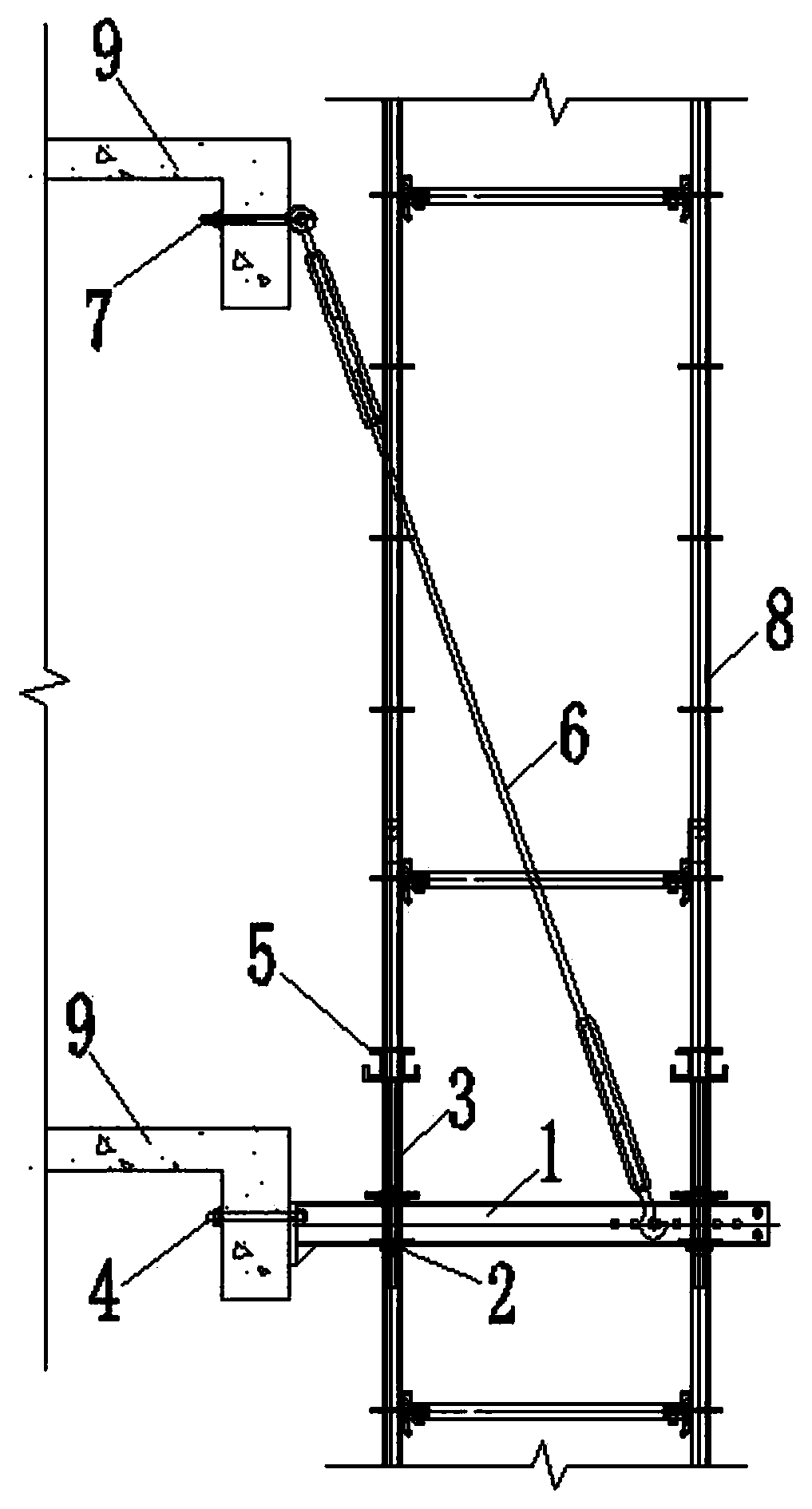

[0029] Please refer to figure 1 , the present invention provides a cantilever structure and construction method for a double-row external scaffolding with disc buttons, including scaffolding, which is composed of several bodies 16, and the body 16 includes a horizontal bar, a diagonal bar, four vertical bars 8, two vertical Between the poles 8 and between the other two vertical poles 8, double-slot longitudinal beams 5 are installed, and the two double-slot longitudinal beams 5 are arranged in parallel.

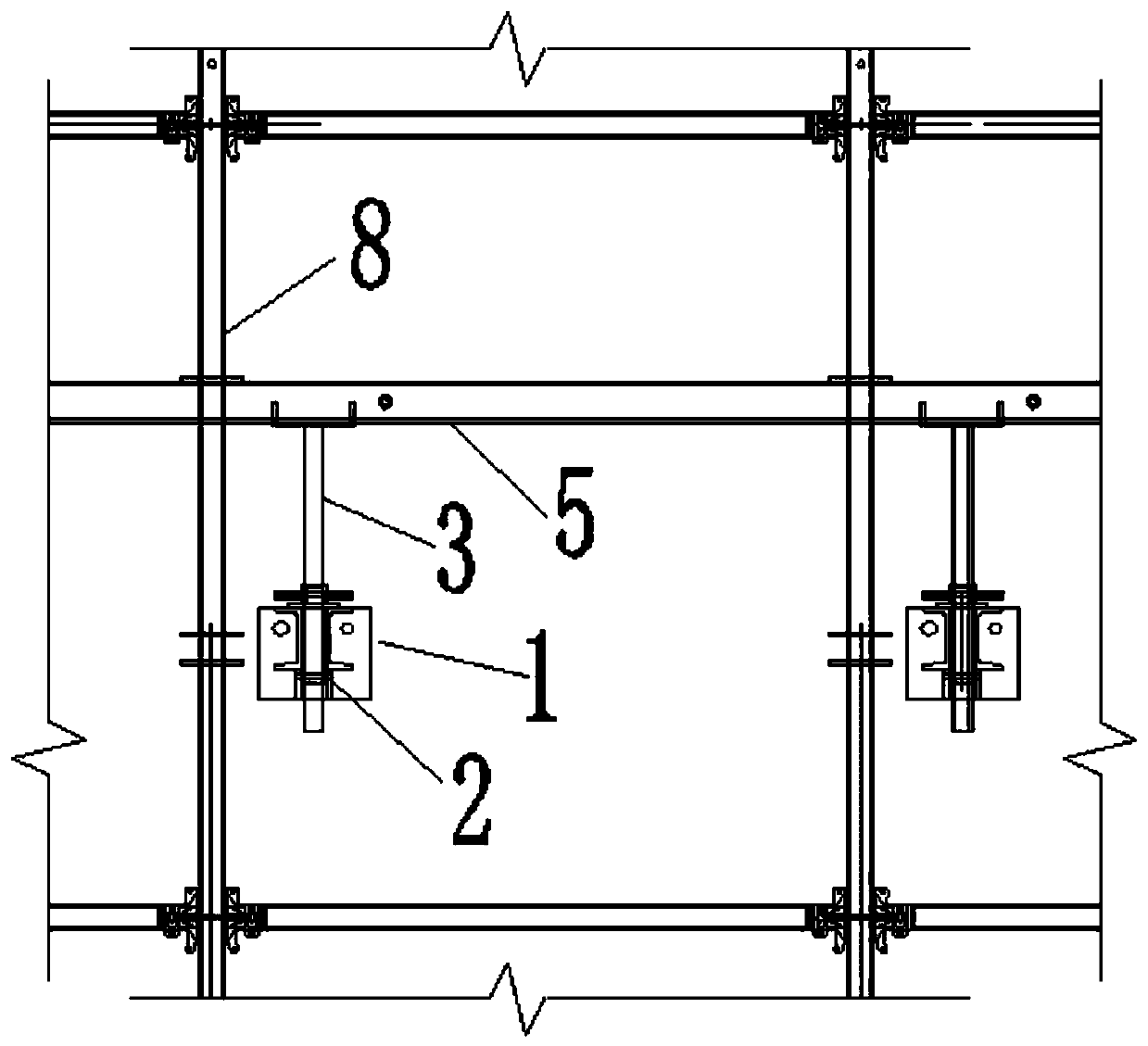

[0030] Please refer to figure 1 , image 3 as well as Figure 4 , The double-groove longitudinal beam 5 is connected with an adjustable bracket 3, and the adjustable bracket 3 is provided with an adjustable bracket sleeve 2 that can move up and down relative to the adjustable bracket 3.

[0031] Pleas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com