Construction method for steel plate concrete wall of primary loop cabin of high temperature gas cooled reactor

A steel plate concrete, nuclear reactor technology, applied in building structures, walls, buildings, etc., can solve the problems of long critical path time, large amount of work on the construction site of nuclear power plants, unfavorable economy, safety and quality assurance requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

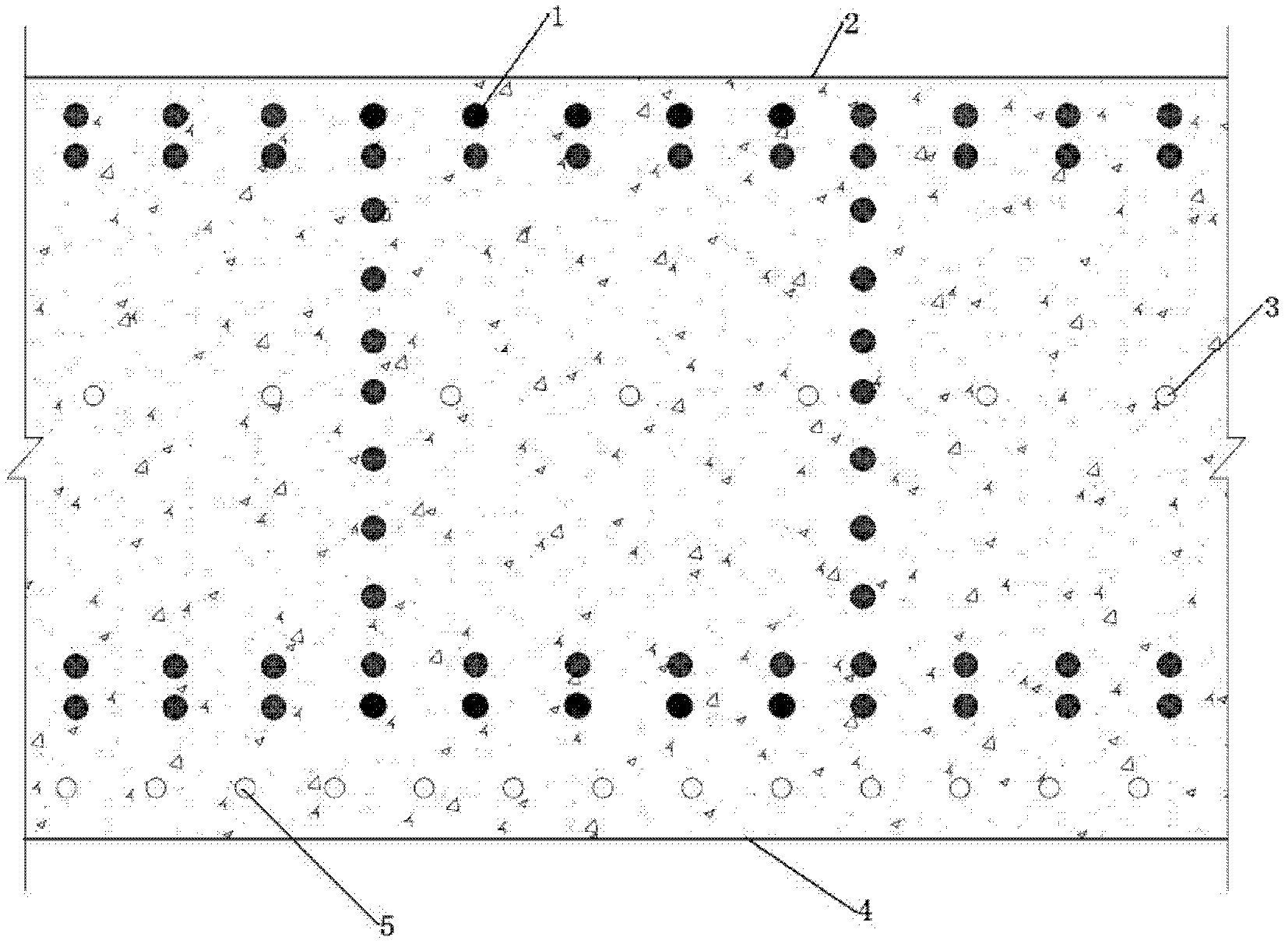

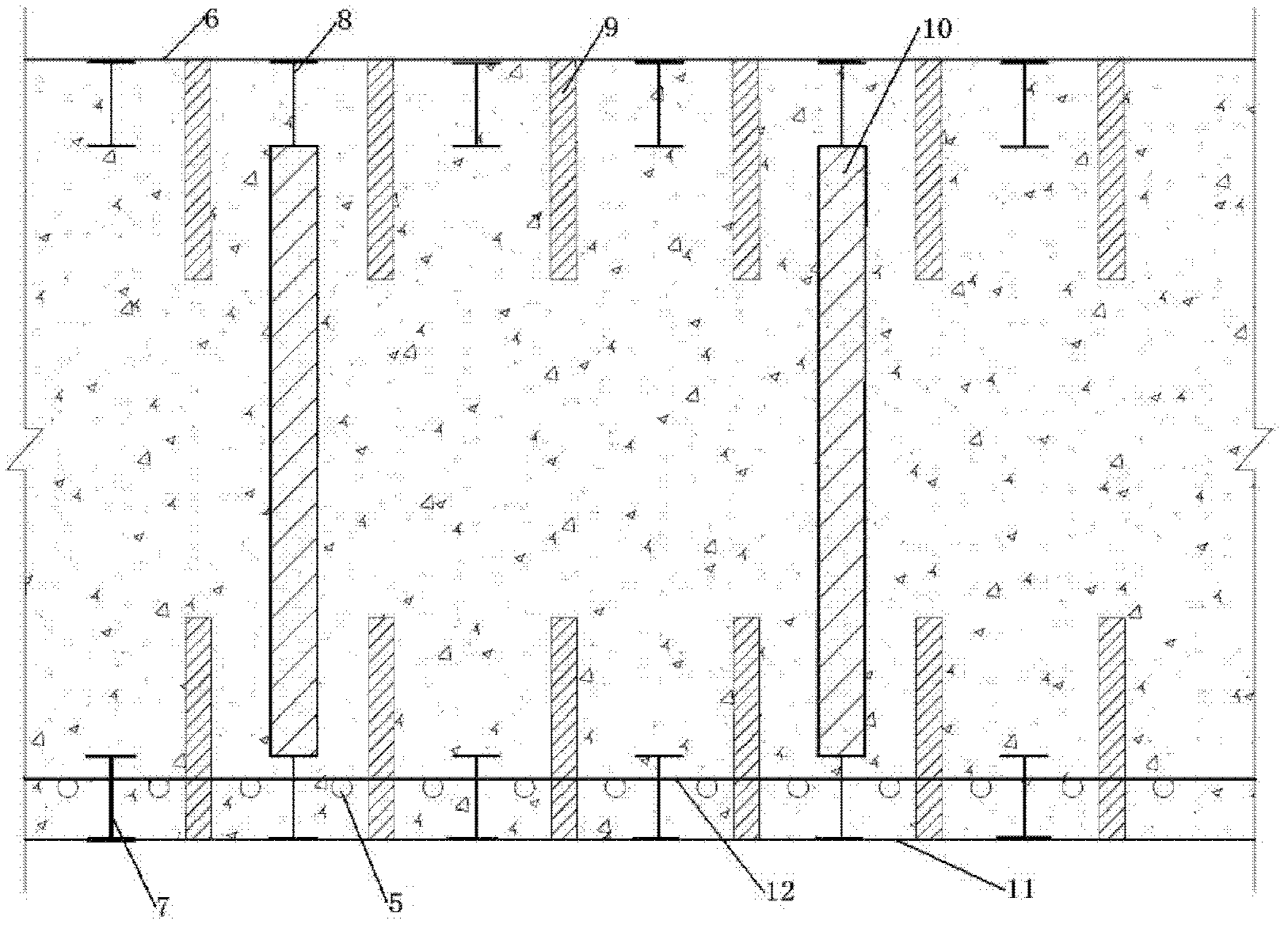

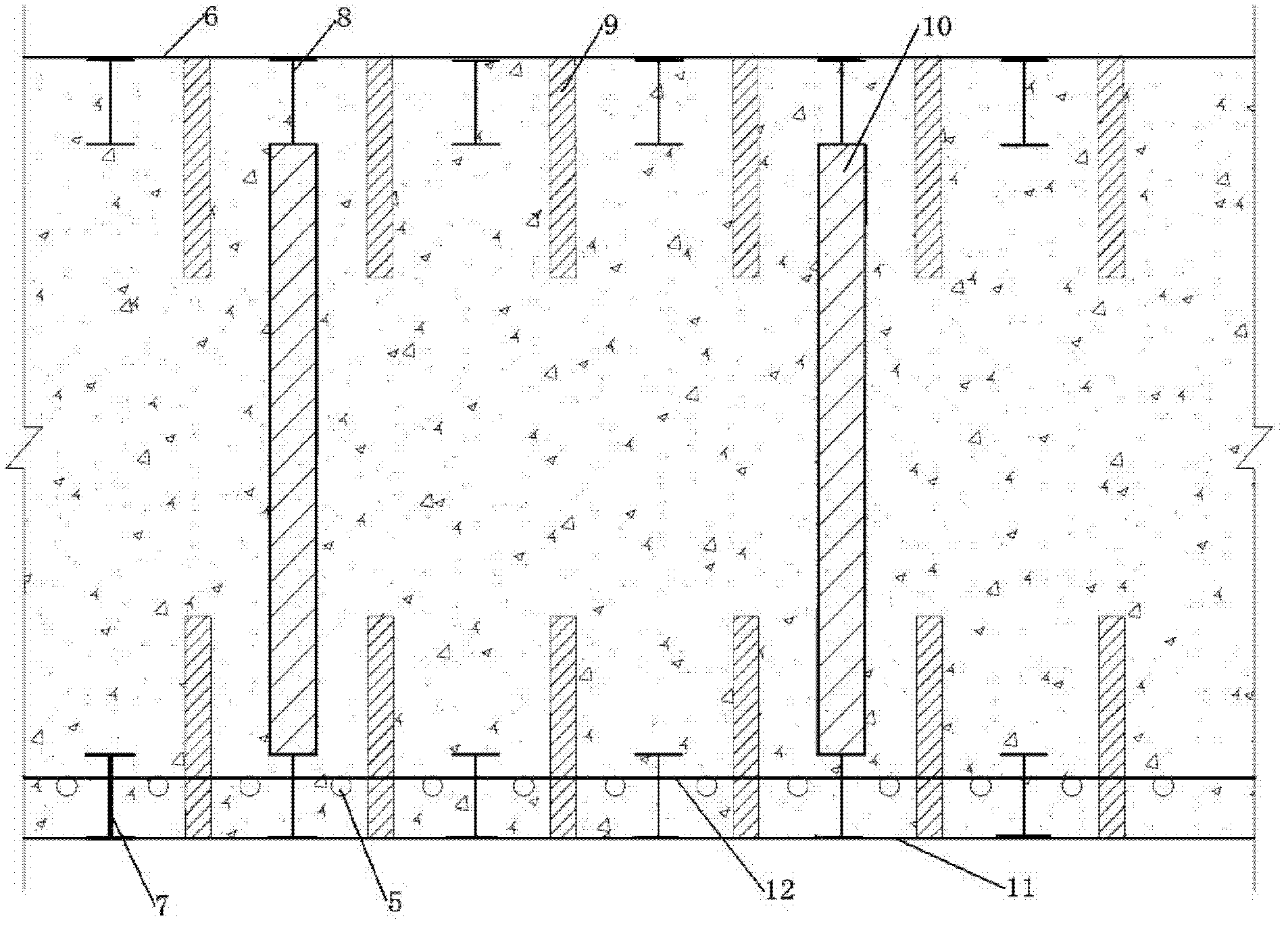

[0019] The construction method of the steel plate concrete wall of the primary circuit cabin of the high-temperature air-cooled nuclear reactor proposed by the present invention, the structural diagram of the constructed wall is as follows figure 2 As shown, the construction method includes the following steps:

[0020] (1) According to the size and strength design requirements of the primary circuit cabin of a high-temperature gas-cooled nuclear reactor, the inner row of load-bearing steel columns 7, the outer row of load-bearing steel columns 8, the load-bearing beams 10 and the connecting beams 12 are arranged, and the load-bearing beams 10 are arranged at intervals in opposite positions. Between the inner row of load-bearing steel columns 7 and the outer row of load-bearing steel columns 8, the two ends of the load-bearing beam 10 are respectively welded on the load-bearing steel columns 10; the connecting beam 12 is transversely welded to one side of the inner row of load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com