Construction method of novel corrosion-resistant pressed metal shelter roof

A construction method and anti-corrosion technology, which is applied to roofs, roof coverings, and roofs using flat/curved panels, etc., can solve problems that affect the fastening of profiled steel plates, large manpower and material resources, and long construction periods, and achieve good results. Heat insulation and noise reduction performance, save the construction period, save the effect of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] In this embodiment, a new type of corrosion-resistant pressure-type metal shelter roof construction method uses new-type corrosion-resistant pressure-type stainless steel plates on the beams to sequentially overlap to form roof panels, and connects the roof panels to the beams. Corrosion-resistant pressed stainless steel plates are overlapped sequentially to form the gutter and connect the gutter to the beam.

[0047] The new corrosion-resistant pressed stainless steel plate refers to the steel plate material that is pressed by adding modified asphalt and aluminum foil protection on the basis of traditional galvanized steel plate. The new corrosion-resistant pressed stainless steel plate has the advantages of strong corrosion resistance, strong wind resistance, high strength and good heat insulation and noise reduction performance.

[0048] Compared with the traditional reinforced concrete structure, it has a channel structure after pressing and can be directly used in ...

Embodiment 2

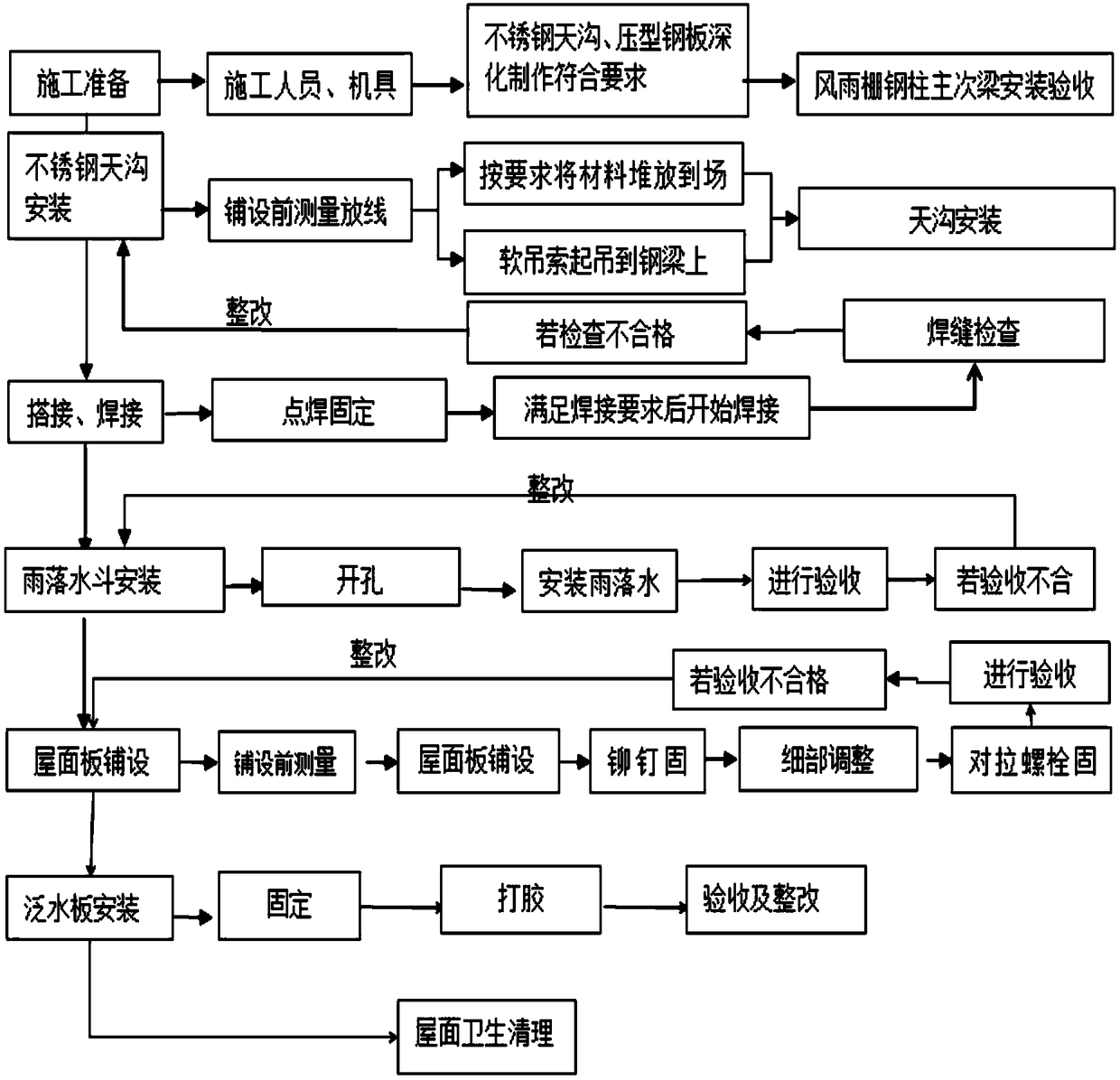

[0052] Such as figure 1 As shown, a new type of corrosion-resistant pressure-type metal shelter roof construction method, including the following steps:

[0053] Step S1: Construction preparation. After the construction of the main and secondary beams of the canopy steel columns is completed, their positions and elevations are measured and accepted, and the materials for the construction of the roof are prepared, including new corrosion-resistant materials for the construction of gutters and roof panels. Pressed stainless steel plate. It specifically includes the following steps:

[0054] Step S11: checking the previous process. The previous process refers to the completion of the construction of the primary and secondary beams of the canopy steel columns. When constructing the roof, it is necessary to measure and accept the position and elevation of the primary and secondary beams of the canopy steel columns, so as to avoid that the profiled steel plates cannot be pasted du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com