Phase-I installation method for gate slot of hydropower station gate

An installation method and technology for hydropower stations, which are applied in water conservancy projects, marine engineering, coastline protection, etc., can solve problems such as affecting civil construction period, outstanding safety risks, and damage to gates and grooves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

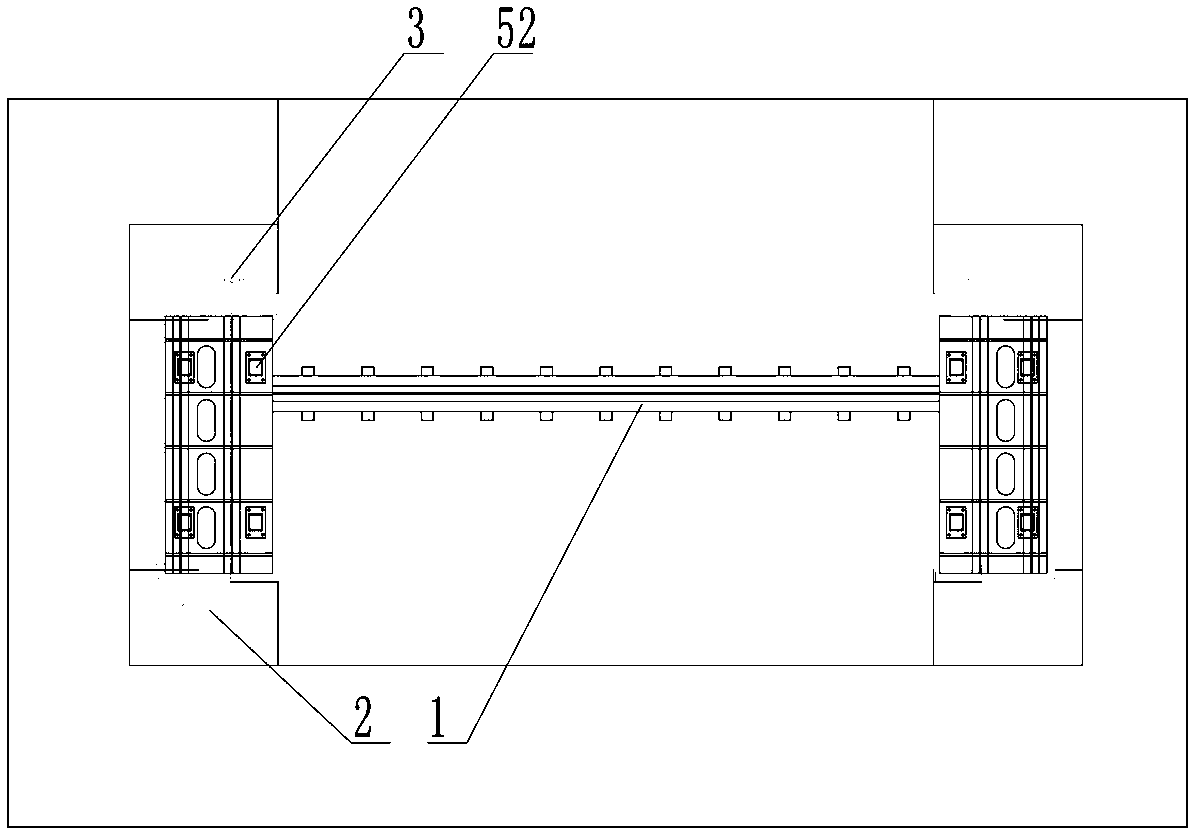

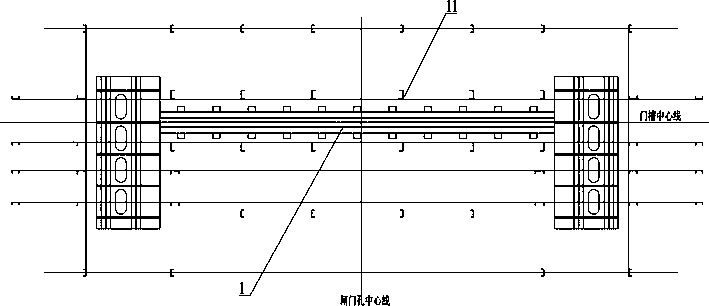

[0108] Such as Figure 1~Figure 21 Among them, a first-phase installation method of the gate slot of a hydropower station, which includes the following steps:

[0109] Step 1, install the sill 1; stake out the benchmark, adjust the height and mileage of the sill 1; support the sill 1;

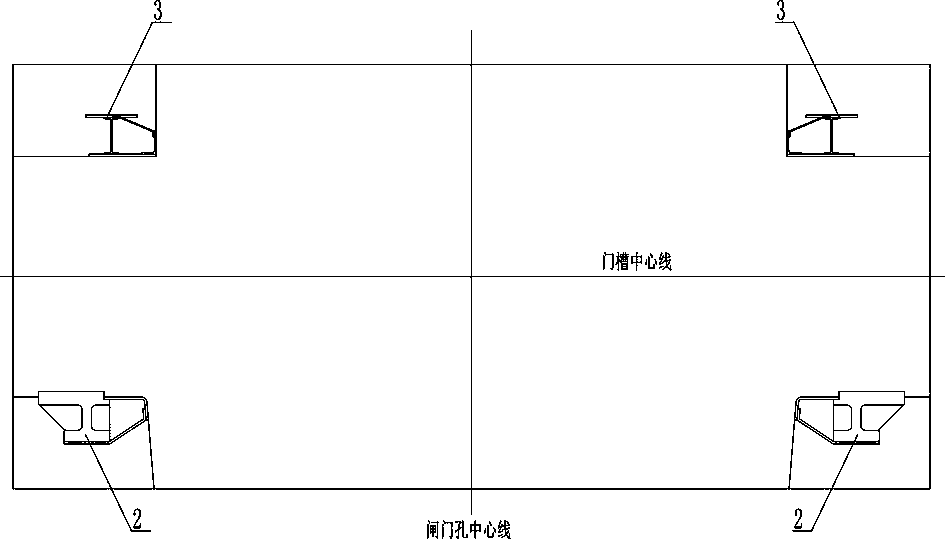

[0110] Step 2, installation of main rail 2 and counter rail 3; setting out installation datum; installing main rail 2; hoisting jack-up trolley 5; installing counter-rail 3; ;

[0111] Step 3, install the lintel 4; inspect and stake out, set the position of the lintel 4; hoist the lintel 4, measure and adjust the deviation value; fix the lintel 4;

[0112] Step 4, lifting the jack-up trolley 5; disconnect the jack-up trolley 5 to make it in a free state; turn on the linkage operation mode and lift, and continue to lift after stopping for inspection;

[0113] Step 5, the self-elevating trolley 5 is fixed; the lower hanging seat 51 is removed; the guide rail is fixed; the self-elevating trolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com