Heat absorber hoisting portal

A heat absorber and hoisting technology, which is applied in the direction of cranes, etc., can solve problems such as difficult to obtain scientific, reasonable and economical mechanical equipment and installation schemes, no mature and reliable hoisting mast scheme, and difficult to ensure reliable suspension of heat absorbers. , to achieve the effect of reducing the use time and labor costs, shortening the operation time on the tower, and reducing a large number of high-altitude operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Reference will now be made in detail to various embodiments, one or more examples of which are illustrated in the figures. Each example is provided by way of explanation, not meant as a limitation. For example, features illustrated or described as part of one embodiment can be used or combined with any other embodiment to yield a still further embodiment. The present invention is intended to cover such modifications and variations.

[0039] In the following description of the drawings, the same reference numerals designate the same or similar components. Generally speaking, only the differences of individual embodiments will be described. Unless otherwise specified, descriptions for parts or aspects in one embodiment can also be applied to corresponding parts or aspects in another embodiment.

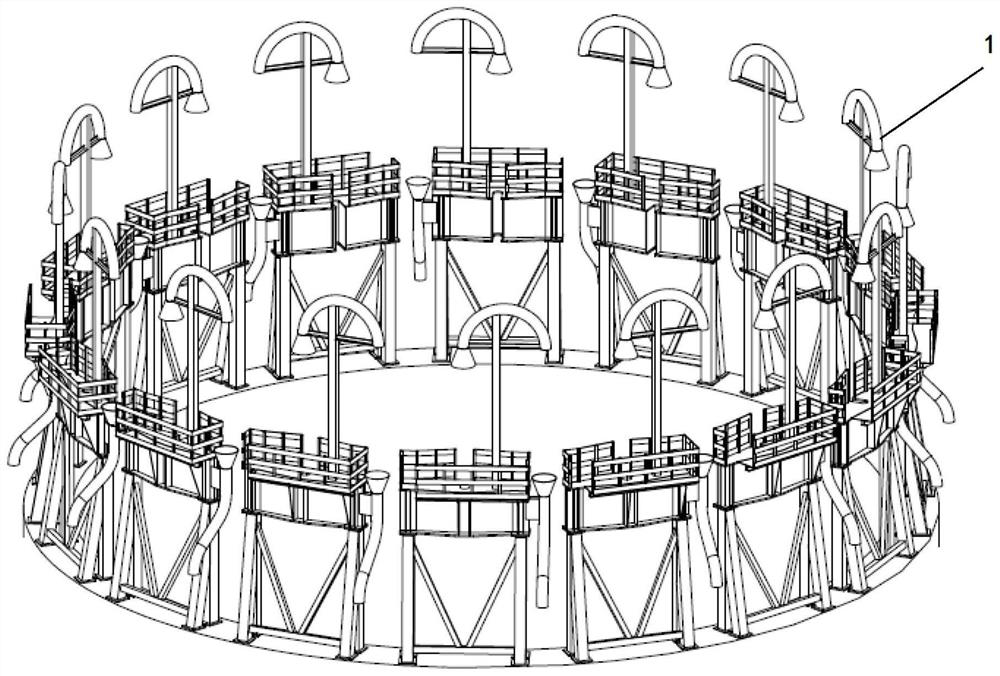

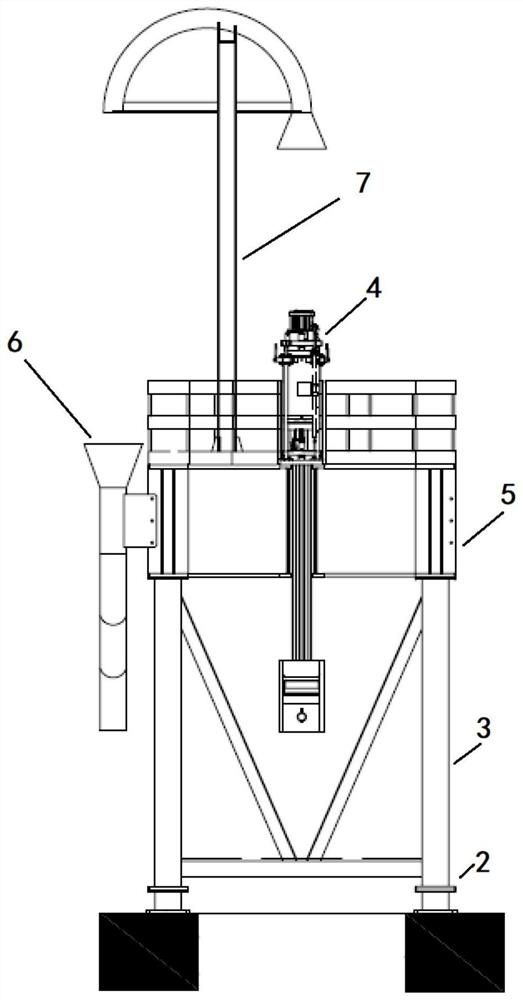

[0040] Such as figure 1 Shown is the rendering of the hoisting gantry on the top of the light tower. The hoisting gantry on the top of the heat-absorbing tower is composed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com