Sound insulation coating and preparation method thereof

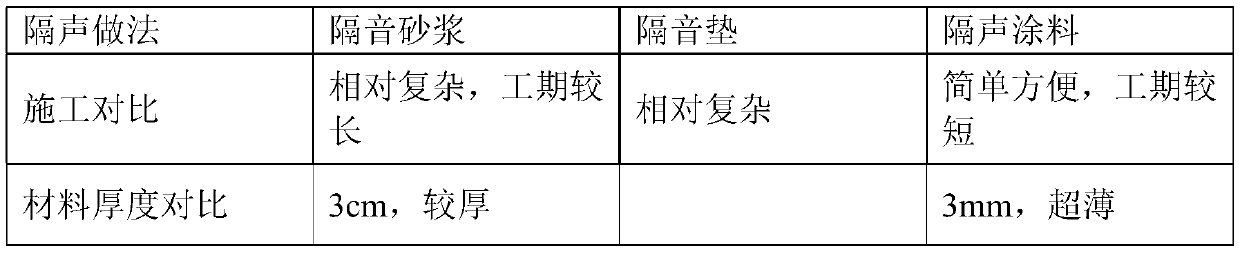

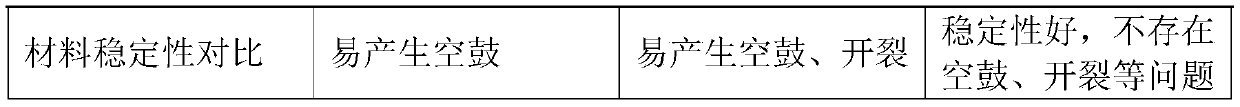

A coating and sound insulation technology, applied in the direction of fireproof coatings, coatings, etc., can solve the problems of unenvironmental protection, poor sound insulation effect, environmental pollution, etc., and achieve the effects of saving paint, not easy to heat bridge, and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A sound-insulating coating, comprising the following components in parts by weight:

[0042] 6 parts of polyvinyl acetate;

[0043] 1 part of silica powder;

[0044] 2 parts glass fiber;

[0045] 6 parts of alumina powder;

[0046] 9 parts of dicalcium silicate powder;

[0047] 2 parts of magnesium oxide powder;

[0048] 1 part of barium sulfate powder;

[0049] 50 parts of distilled water.

[0050] Wherein, the particle size of the polyvinyl acetate is 200 μm; the particle size of the silicon dioxide powder is 50 μm. The glass fiber has a diameter of 5 μm and a length of 1 mm. The particle size of the alumina powder is 45 μm. The particle size of the dicalcium silicate powder is 45 μm. The particle size of the magnesium oxide powder is 50 μm. The particle size of the barium sulfate powder is 20 μm.

Embodiment 2

[0052] A sound-insulating coating, comprising the following components in parts by weight:

[0053] 7 parts of polyvinyl acetate;

[0054] 2 parts of silica powder;

[0055] 3 parts glass fiber;

[0056] 7 parts of alumina powder;

[0057] 10 parts of dicalcium silicate powder;

[0058] 3 parts of magnesium oxide powder;

[0059] 2 parts of barium sulfate powder;

[0060] 51 parts of distilled water.

[0061] Wherein, the particle size of the polyvinyl acetate is 250 μm. The particle size of the silica powder is 45 μm. The glass fiber has a diameter of 10 μm and a length of 1 mm. The particle size of the alumina powder is 75 μm. The particle size of the dicalcium silicate powder is 70 μm. The particle size of the magnesium oxide powder is 65 μm. The particle size of the barium sulfate powder is 30 μm.

Embodiment 3

[0063] A sound-insulating coating, comprising the following components in parts by weight:

[0064] 6.5 parts of polyvinyl acetate;

[0065] 2 parts of silica powder;

[0066] 3 parts glass fiber;

[0067] 6 parts of alumina powder;

[0068] 9 parts of dicalcium silicate powder;

[0069] 2.5 parts of magnesium oxide powder;

[0070] 1 part of barium sulfate powder;

[0071] 51 parts of distilled water.

[0072] Wherein, the particle size of the polyvinyl acetate is 300 μm. The particle size of the silica powder is 60 μm. The glass fiber has a diameter of 13 μm and a length of 1 mm. The particle size of the alumina powder is 70 μm. The particle size of the dicalcium silicate powder is 55 μm. The particle size of the magnesium oxide powder is 60 μm. The particle size of the barium sulfate powder is 20 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com