Water-based sound insulation coating for ground sound insulation and shock absorption, and preparation method thereof

A sound-insulating paint, water-based technology, applied in the field of paint, can solve the problems of unenvironmental chemical additives, complex use process of paint, high material cost, and achieve good protection, simple and convenient construction, and good penetration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

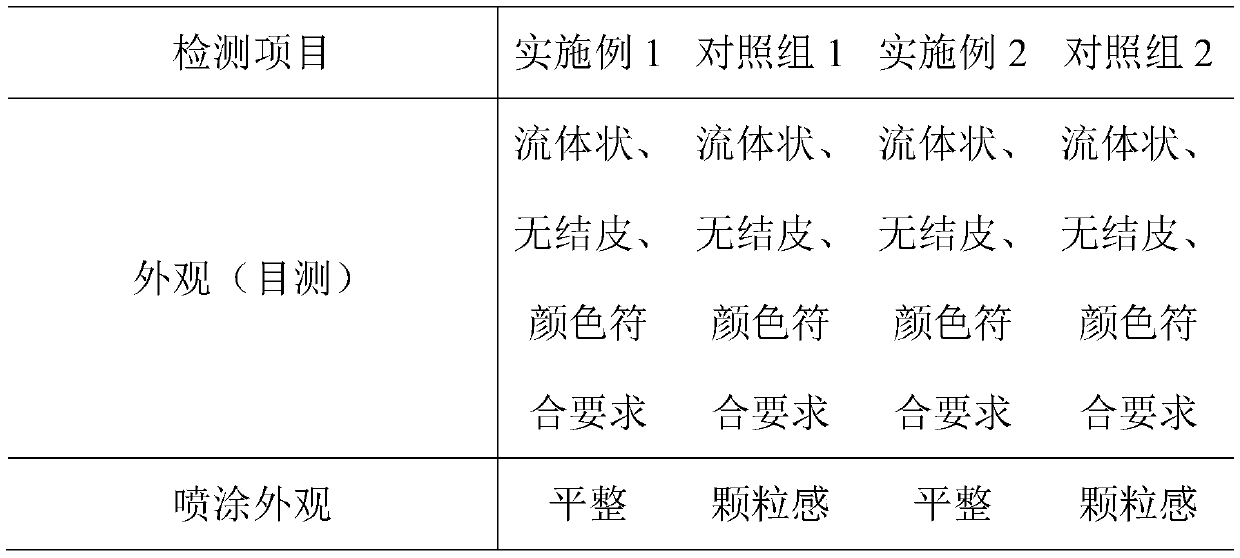

Embodiment 1

[0031] 1) Filtrate 25% epoxy-modified acrylic emulsion and heat to 50-150°C, add 1% organic aluminum hypophosphite and 10% rubber particles under stirring to obtain mixture A;

[0032] 2) Add 1% CL-14 paint fungicide and 1% dispersant to 40% deionized water, and heat to 60-80°C under stirring to obtain mixture B;

[0033] 3) Heat mixture B to 50-70°C, add 1% thickener, 0.1% polydimethylsiloxane and 5% carbon fiber / natural rubber under stirring to obtain mixture C;

[0034] 4) Mix mixture A and mixture C, add 8% filler and 8% aggregate under high-speed homogeneous dispersion (750r / min), keep stirring, disperse for 10min, stop dispersing, and obtain a coating product after cooling.

Embodiment 2

[0036] 1) Filtrate 20% elastic acrylic emulsion and heat to 50-150°C, add 4% organic aluminum hypophosphite and 10% rubber particles under stirring to obtain mixture A;

[0037] 2) Add 0.1% CL-14 paint fungicide and 1% dispersant to 28% deionized water, and heat to 60-80°C under stirring to obtain mixture B;

[0038] 3) Heat mixture B to 50-70°C, add 1% thickener, 1% fluorosilicone and 5% carbon fiber / nitrile rubber under stirring to obtain mixture C;

[0039] 4) Mix mixture A and mixture C, add 15% filler and 15% aggregate under high-speed homogeneous dispersion (750r / min), keep stirring, disperse for 10 minutes, stop dispersion, and obtain a coating product after cooling.

Embodiment 3

[0041] 1) Filtrate 30% water-based styrene-acrylic emulsion and heat to 50-150°C, add 5% triphenyl phosphate and 15% rubber particles under stirring to obtain mixture A;

[0042] 2) Add 1% CL-14 paint fungicide and 0.1% dispersant to 25% deionized water, and heat to 60-80°C under stirring to obtain mixture B;

[0043] 3) Heat mixture B to 50-70°C, add 1% thickener, 1% ethylene glycol siloxane and 2% wadding fiber / ethylene-propylene-diene rubber under stirring to obtain mixture C;

[0044] 4) Mix mixture A and mixture C, add 8% filler and 12% aggregate under high-speed homogeneous dispersion (750r / min), keep stirring, disperse for 10min, stop dispersion, and obtain a coating product after cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com