Automatic container wharf handling system and method for right-angled shoreline multi-berth arrangement

A loading and unloading system and container technology, which is applied in the loading and unloading field of port container terminals, can solve the problems of reducing system loading and unloading efficiency, increasing system operating costs, and increasing horizontal transportation distance, so as to improve loading and unloading efficiency and energy saving level, facilitate linkage, reduce The effect of transport distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

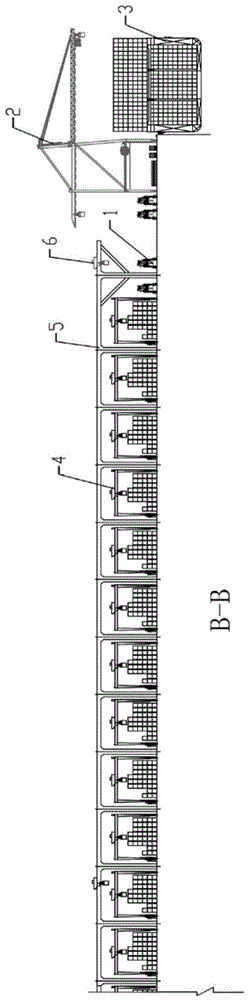

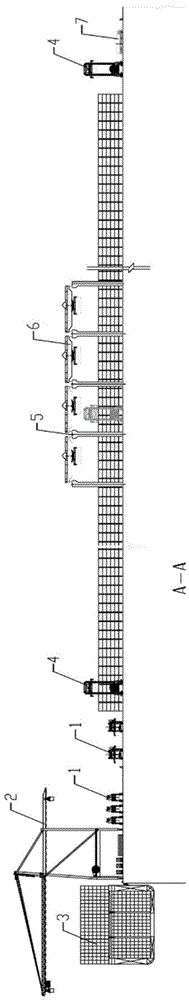

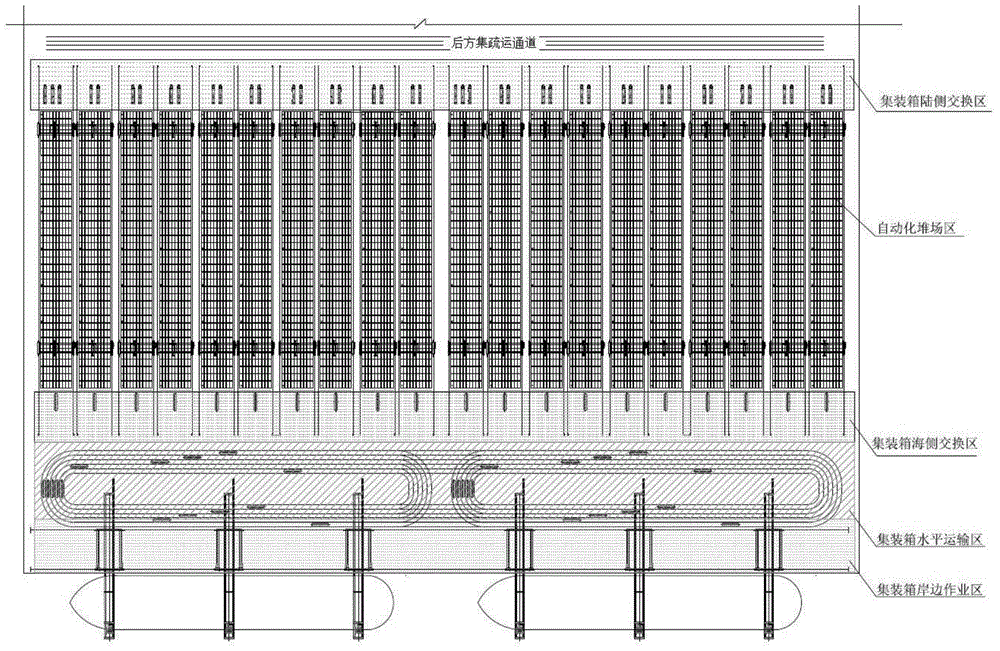

[0036] An automated container terminal loading and unloading system with multiple berths arranged on a right-angle shoreline includes a quay crane 2, a straddle carrier 1, an ARMG4, and an elevated crane subsystem. The elevated crane subsystem is composed of an elevated bridge 5 and an elevated crane 6.

[0037] The quay cranes 2 are respectively arranged at the front of the front berth and the front of the side berth, and their tracks are respectively parallel to the shoreline direction of the front berth and the shoreline direction of the side berth. The quay crane 2 is used for the vertical and horizontal transportation of the container from the container ship 3 to the shore operation area.

[0038] The ARMG4 track of the container yard is arranged perpendicular to the shoreline of the front berth, and ARMG4 is located on the ARMG4 track. The area of the container yard close to the front berth end is the front berth end of the yard, the area of the container yard close ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com