Tool type concrete composite slab cast-in-situ connecting section formwork supporting device

A formwork support and concrete technology, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problems of formwork installation accuracy and installation quality, mutual interference of supports, large amount of support materials, etc. problems, to achieve the effect of facilitating construction operations, high installation accuracy, and increased construction space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

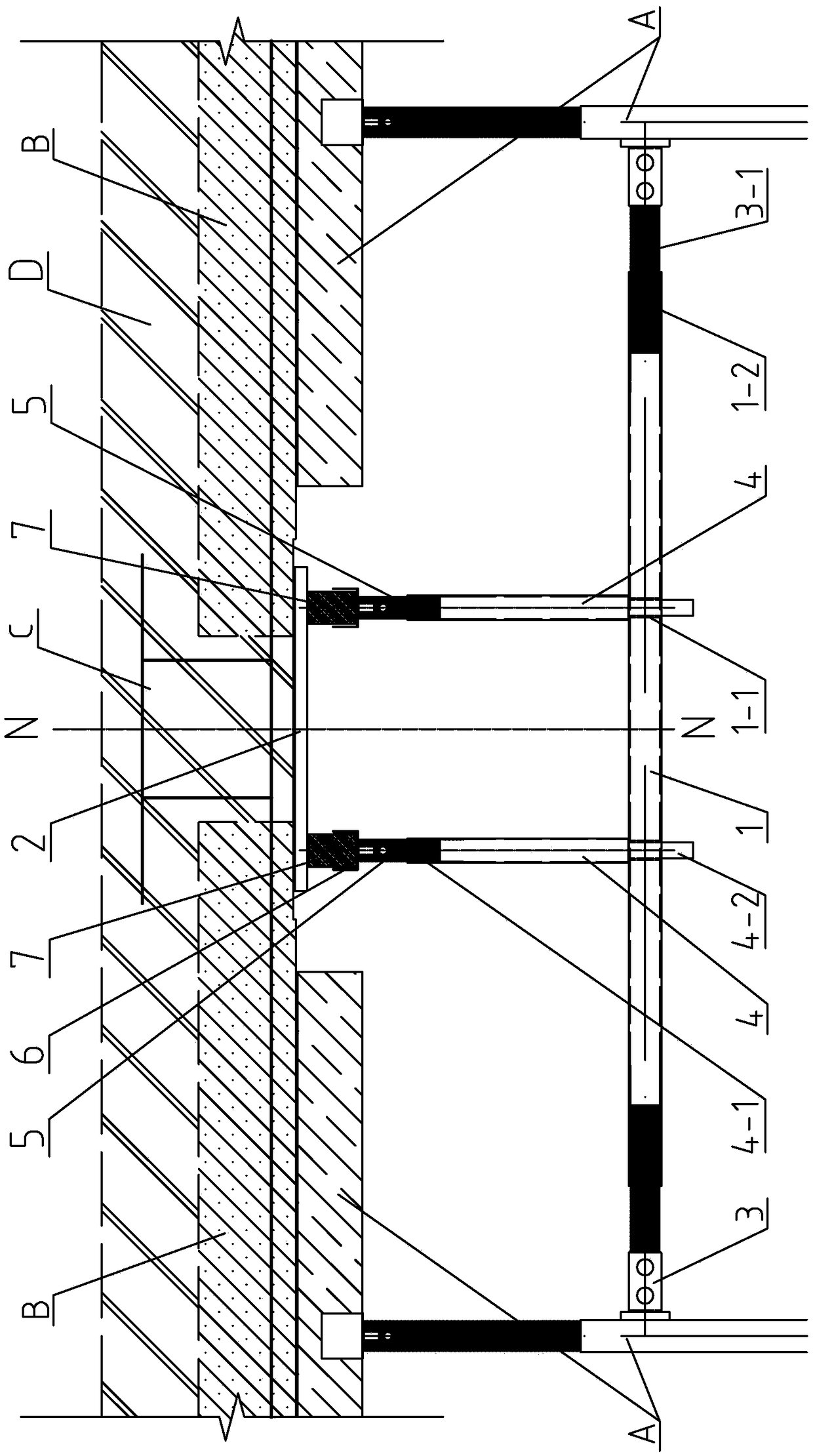

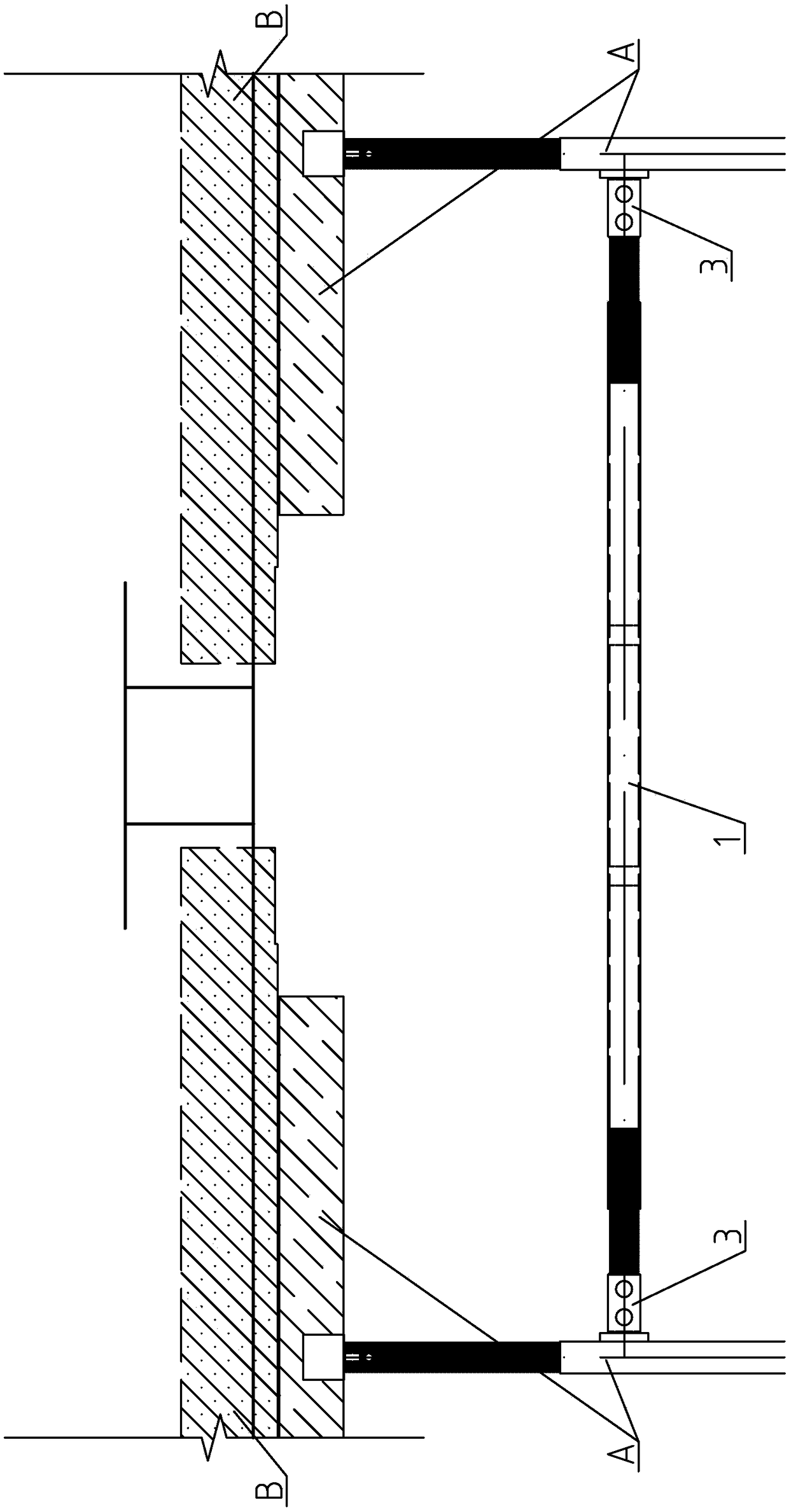

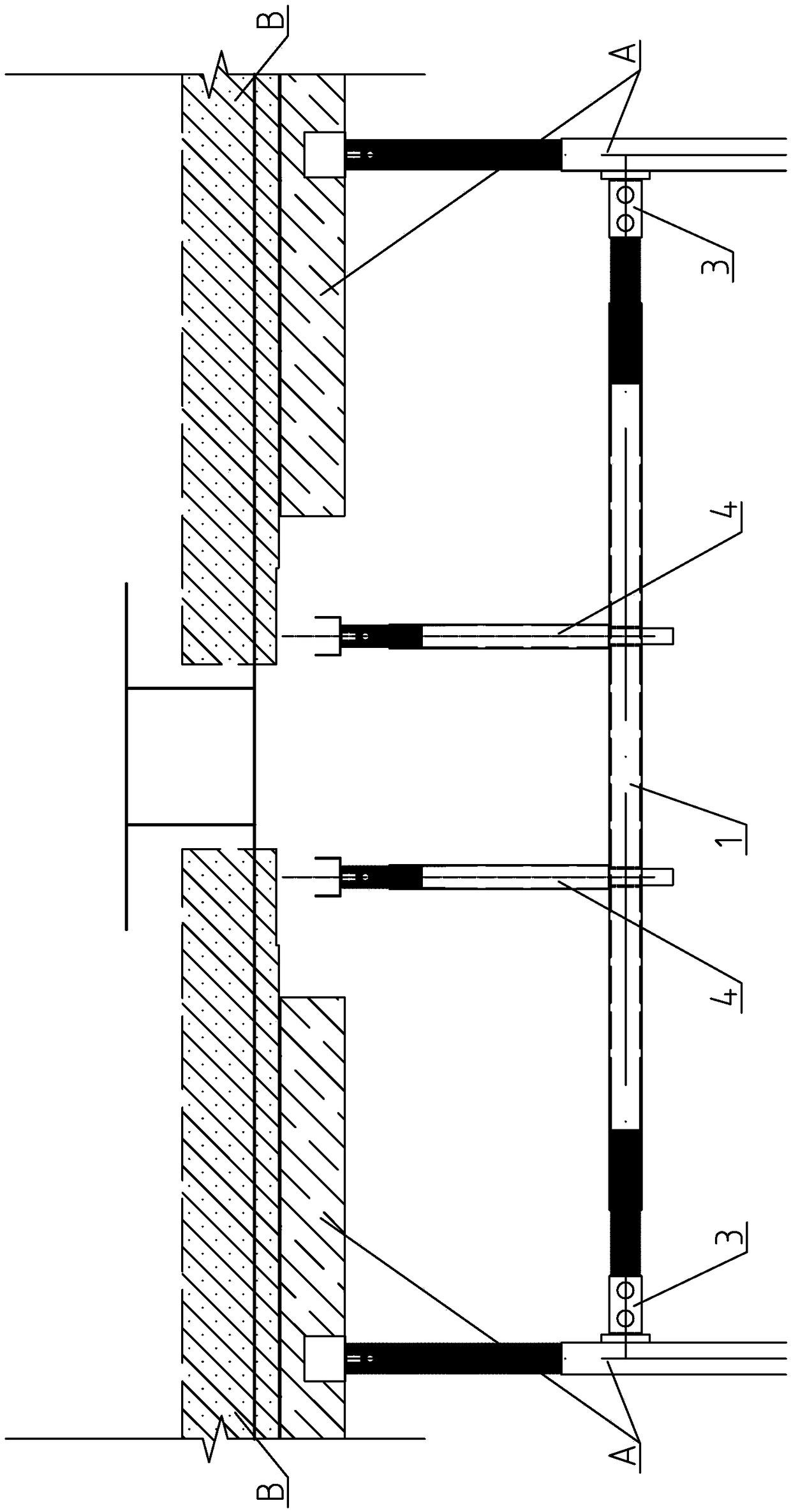

[0028] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment includes a support beam 1, a bottom formwork 2, two horizontal adjustment members 3, two support columns 4, two vertical adjustment members 5, two U-shaped brackets 6 and two formwork holders Beam 7;

[0029] The middle part of the support beam 1 is provided with two support column jacks 1-1, and the two lateral adjustment members 3 are symmetrically arranged at both ends of the support beam 1, and the lateral adjustment member 3 is threadedly connected with the support beam 1, and the two support columns 4 corresponds to the two support column jacks 1-1 one by one, and the support column 4 is plugged with the support beam 1, and the upper end of each support column is threaded to a vertical adjustment piece 5, and each vertical adjustment piece 5 The upper end is screwed to a U-shaped bracket 6, and each U-shaped bracket 6 is equipped with a template joist 7, and the bottom te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com