Half-inverted-mounting construction structure and method for frame or cylinder bearing high-rise modular building

A frame structure and construction method technology, applied in building components, special structures, building structures, etc., can solve the problems of inability to ensure safety, speed, and efficiency, and achieve the goal of reducing tool rental costs, shortening construction periods, and reducing construction costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

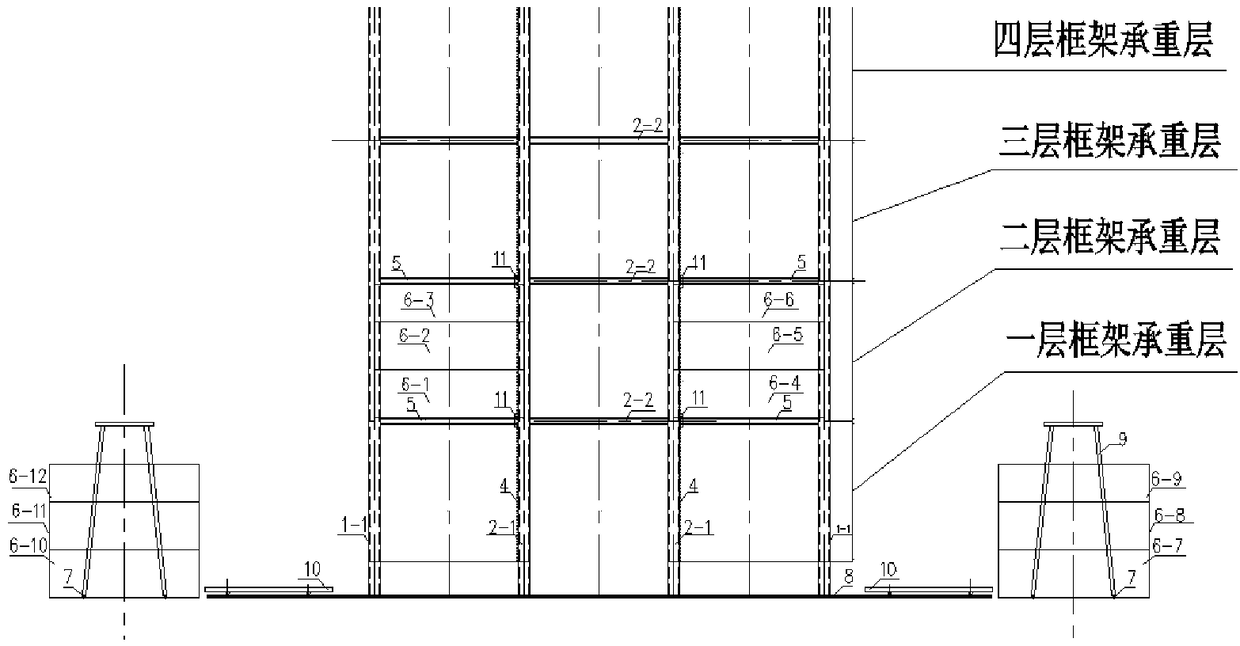

[0058] An embodiment of the semi-inverted construction method of a frame or cylinder load-bearing high-rise modular building provided by the present invention will be further described below in conjunction with the accompanying drawings.

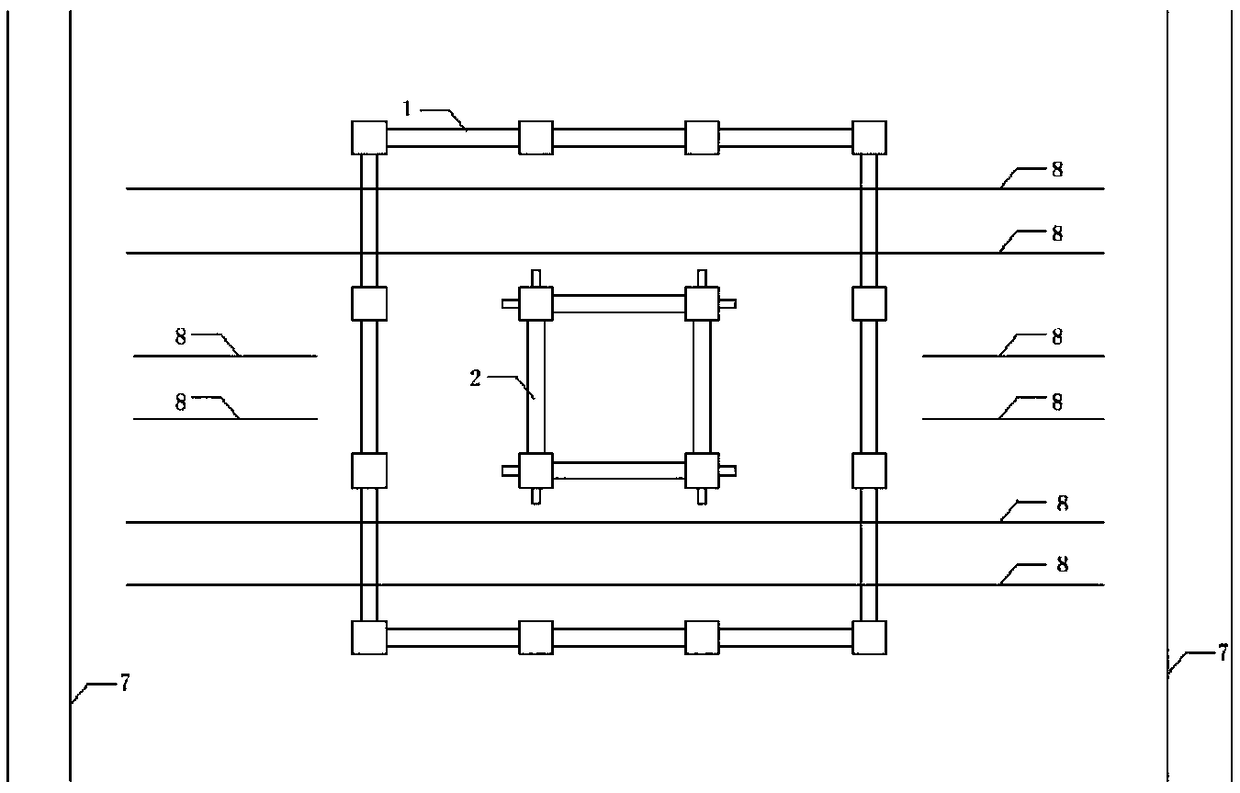

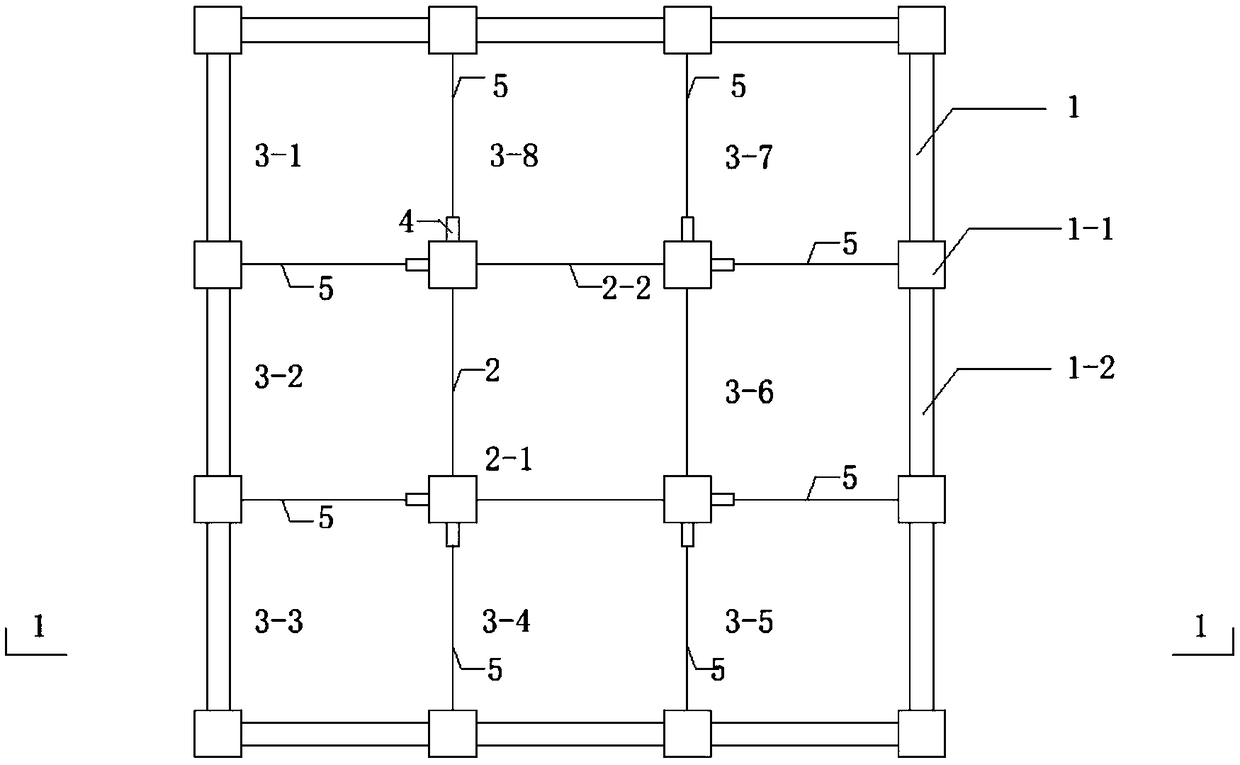

[0059] 1. As attached figure 1 As shown, build (or pour) the frame (including the external frame 1 and the core tube 2) to two or more layers of the frame load-bearing layer (in this embodiment, the height of each frame load-bearing layer and the assembly formed by the accumulation of three standard module layers The overall height of the unit is the same), and the rack transport device 4 is installed on the inner frame column 2-1 or the core tube. For the embodiment of the concrete frame structure, the rack is fixed through the embedded parts, and for the embodiment of the steel frame structure, the rack is fixed through the bolt holes.

[0060] In the embodiment of the present invention, preferably, the frame structure adopts a combined s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com