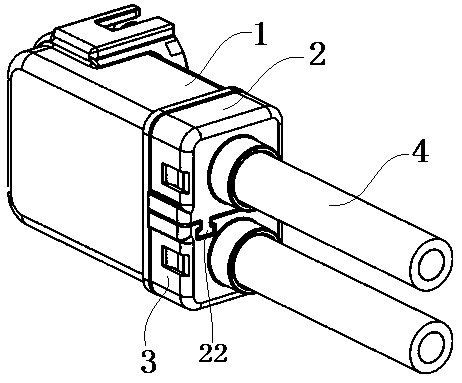

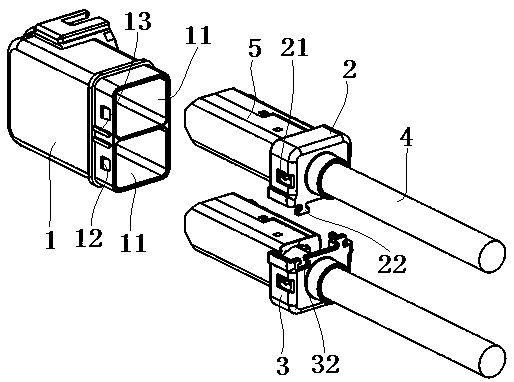

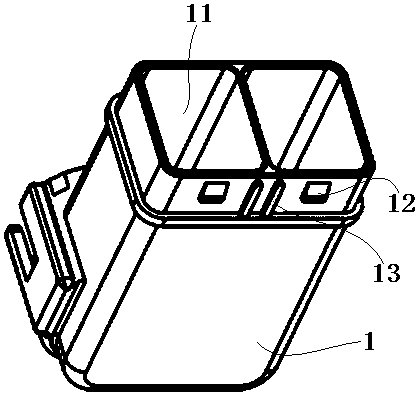

Connectors and Connector Backshells

A technology of connectors and tail caps, which is applied in the direction of connection, parts of connection devices, devices for reducing stress at wire connections, etc., can solve the problems of low assembly efficiency, improve work efficiency, enhance strength, and facilitate turnover and transportation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 3

[0030] The third specific embodiment of the connector of the present invention, in this embodiment, the structure of a block in the tail cap is as follows Figure 9 As shown, in this embodiment, the fastening structure between the blocks is composed of a trapezoidal fastening block 3a and a trapezoidal fastening groove 3b, and other structures are the same as those in the second embodiment, and will not be repeated here.

[0031] In other embodiments of the connector of the present invention, the connector can also be a four-core connector or a five-core connector, etc. At this time, it is only necessary to set a corresponding number of intermediate blocks; the shape of the tail cap can also be a circle shape or other shapes; the sides of one block and another block can also be fastening blocks or fastening grooves. At this time, the corresponding blocks are provided with fastening grooves or fastening grooves block; the fastening structure between the blocks can also be set t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com