Lining mounting construction device and method for movable steel roof face

A construction device and steel roofing technology, which is applied in the direction of house structure support, house structure support, house structure support scaffolding, etc., can solve the problems of difficult construction and potential safety hazards, and achieve easy installation and disassembly, ensure installation quality, and speed up installation The effect of progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

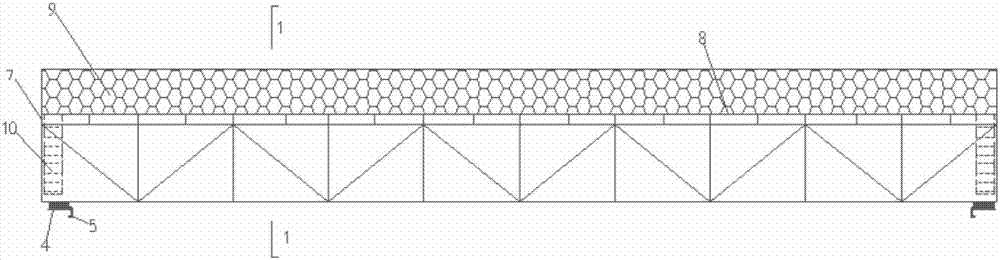

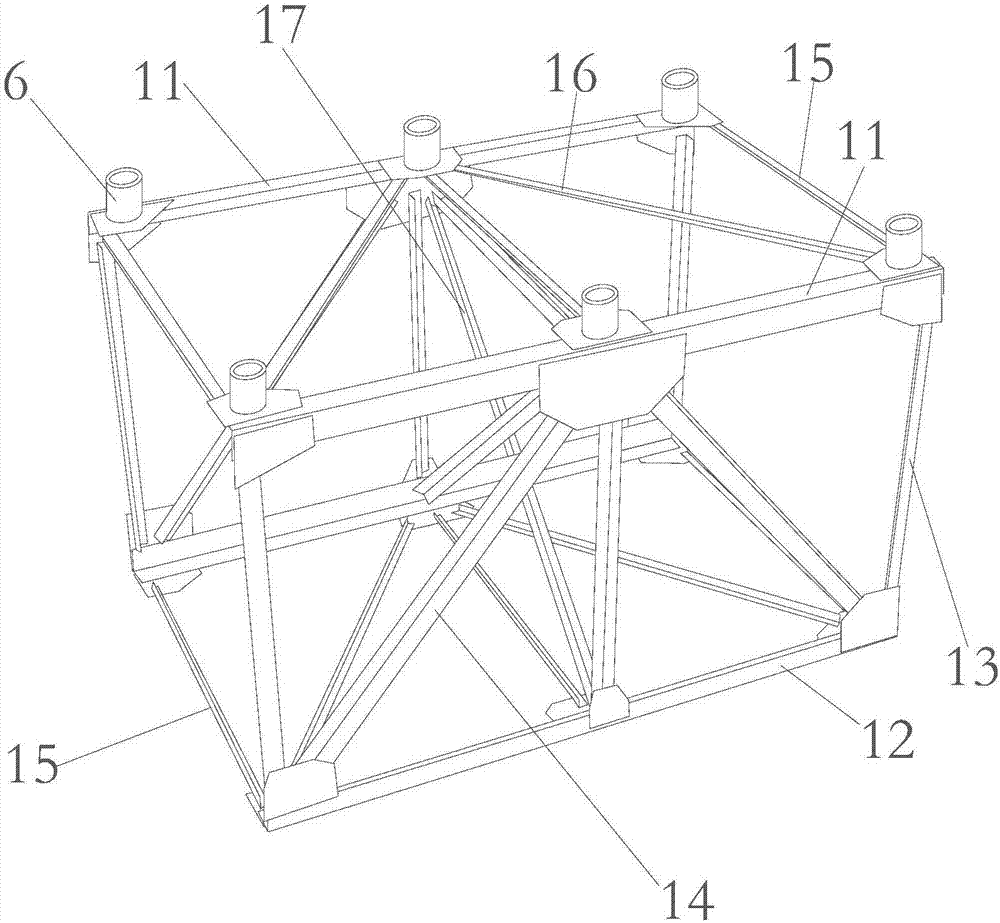

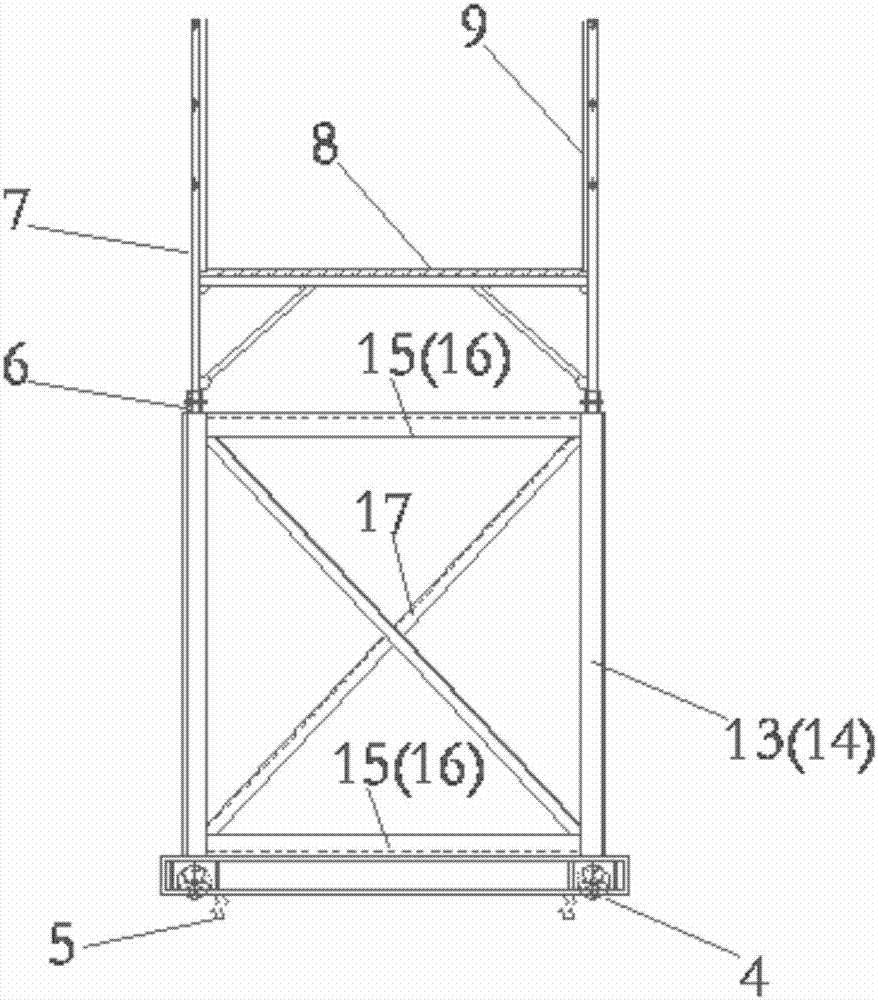

[0023] like Figure 1-4 As shown, a movable steel roof lining installation construction device includes a truss platform system 3 attached to the driving beam 2, a guide wheel 4 with electric drive and a riser installation sleeve 6, wherein the driving beam 2 is installed On the steel column 1 of the factory building, a space truss system with electric drive guide wheels 4 is installed on the driving beam 2 to ensure the flatness of the entire mobile construction platform. , truss vertical webs 13, truss upper and lower chord horizontal supports 15 to form a cuboid frame structure, each plane diagonal of the cuboid frame is respectively provided with truss oblique webs 14, truss upper and lower chord horizontal horizontal braces 16, and the cuboid The middle plane of the frame is provided with truss vertical transverse braces 17, and the left and right sides of the space truss system are respectively provided with climbing ladders 10, and the upper end of the space truss syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com