A barrier-free cleaning device for abandoned piles

A cleaning device and barrier-free technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of increasing the load of lifting equipment, increasing the labor intensity of workers, blocking the tunneling of shield machines, and reducing the lifting weight. , The effect of improving lifting efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

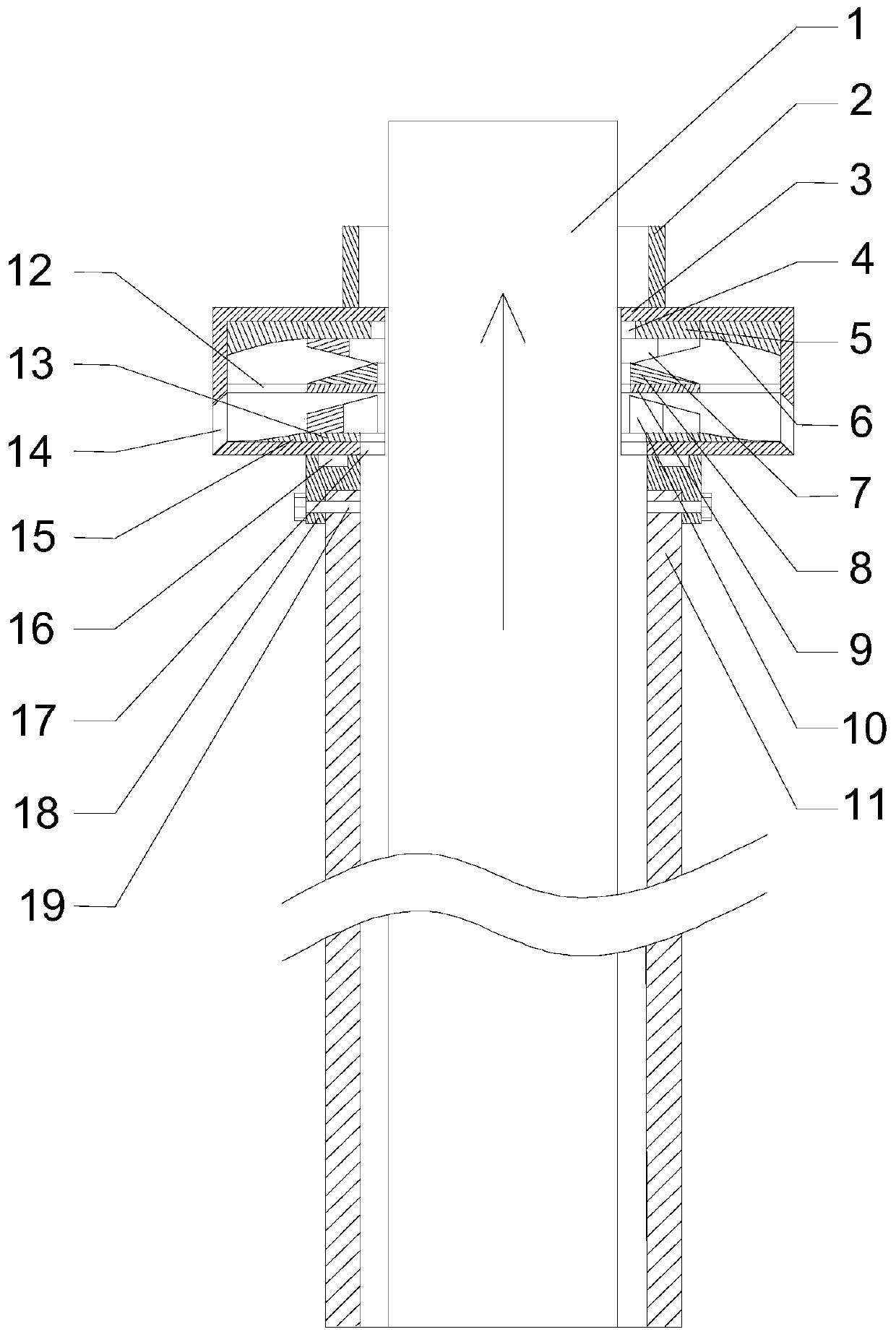

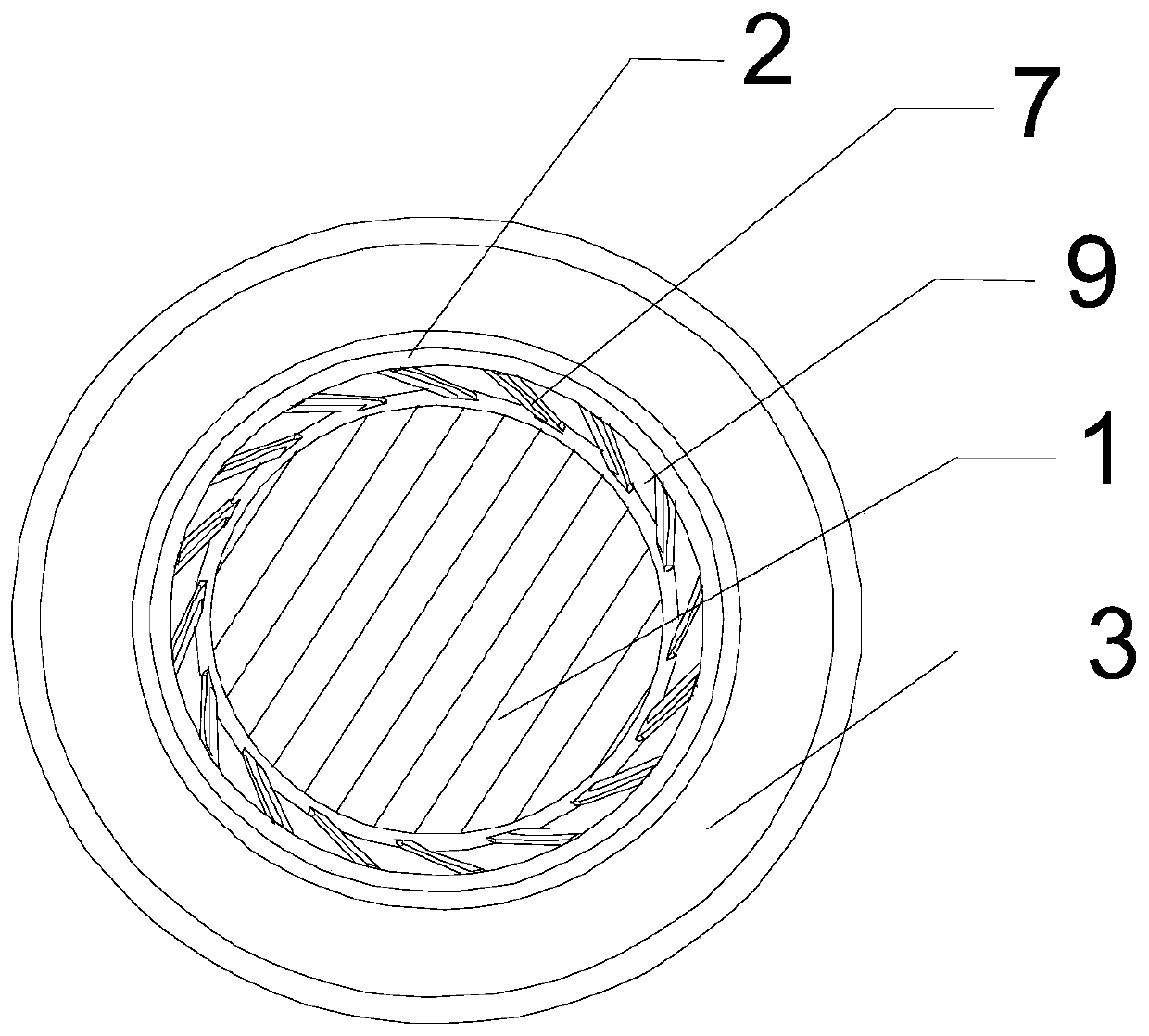

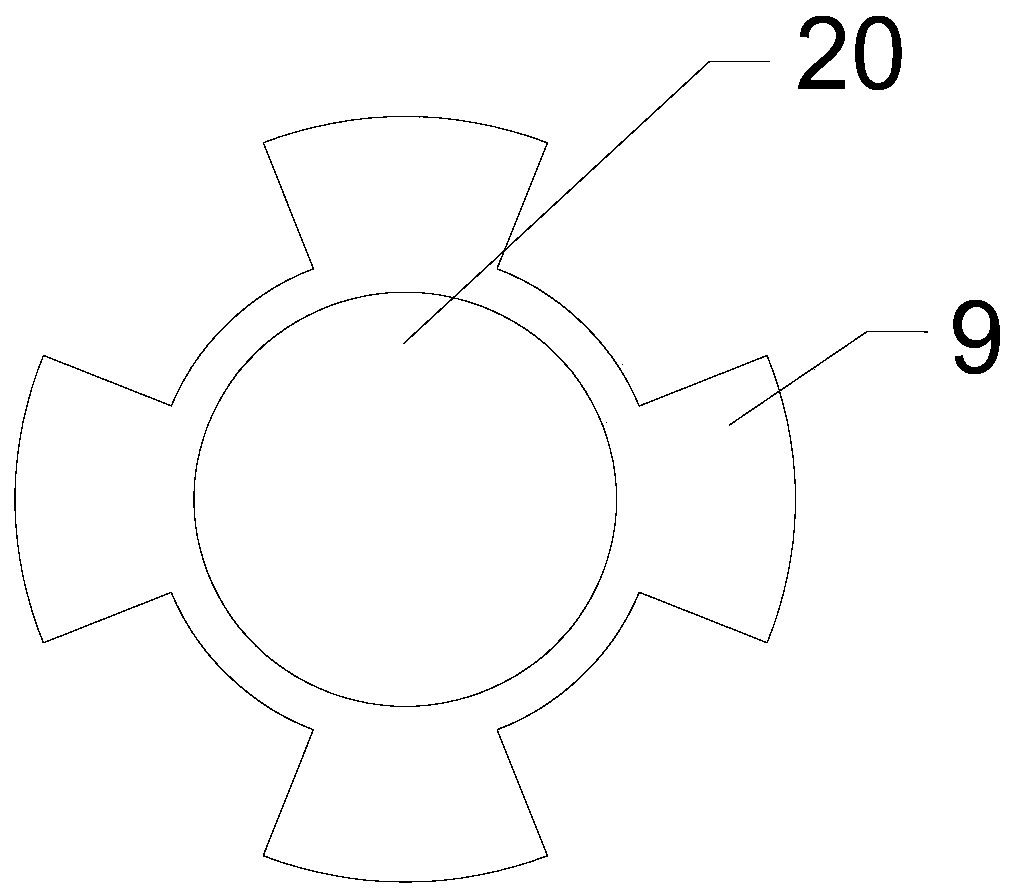

[0025] Such as Figure 1 to Figure 3 As shown, an obstacle-free cleaning device for abandoned piles includes a casing 3 arranged above the lower casing 11 of a full-automatic full-rotary drilling rig and having a cylindrical cavity inside, and an upper casing 2 is arranged on the upper surface of the casing 3 , and an upper through hole 4 communicating with the upper casing 2 is opened on the upper wall of the housing 3, and a lower through hole 17 corresponding to the upper through hole 4 is opened on the lower wall of the housing 3, and in the middle of the cavity of the housing 3 A circular support plate 9 parallel to the upper and lower surfaces of the housing 3 is fixed. In this embodiment, the edge of the support plate 9 is welded to the side surface of the inner cavity of the housing 3 by welding; the middle part of the support plate 9 has a A through hole 20 for the waste pile 1 to pass through, and a plurality of slag discharge holes 12 are evenly opened around the th...

Embodiment 2

[0029] Since the cavity of the housing 3 is cylindrical, when the upper scraper 7 cleans the attached soil on the surface of the waste pile 1, there is always a lot of soil that is thrown to the corner of the cavity and the support plate through the interval between the blades. 9 and the bottom of the cavity of the housing 3; thereby increasing the weight of the device, and at the same time because the distribution of the soil in the cavity is random, it is easy to cause the uneven quality of the housing 3, which is easy to make The device produces eccentricity during rotation, which seriously affects its stability and service life.

[0030] Therefore, the difference between this embodiment and Embodiment 1 is that an annular upper baffle plate 6 coaxial with the upper ring seat 5 is provided between the upper ring seat 5 and the inner side wall of the housing 3, and the upper baffle plate 6 The upper surface is fixed on the upper inner side wall of the housing 3, the lower su...

Embodiment 3

[0032] The difference between this embodiment and Embodiment 2 is that there is a base 18 provided between the casing 3 and the lower casing 11, a hole for the waste pile 1 to pass is opened in the middle of the base 18, and an annular concave hole is provided on the upper surface of the base 18. Groove, the lower surface of the housing 3 is provided with four sliders 16 matching the annular groove, and the four sliders 16 are all embedded in the annular groove, and the base 18 is fixedly connected with the lower sleeve 11. In this embodiment, in order to facilitate the installation and disassembly of the base 18 , fastening bolts 19 are used to connect it to the lower casing 11 .

[0033] When the housing 3 rotates under the drive of the upper casing 2, the slider 16 slides in the chute without causing the lower casing 11 to rotate. When the lower casing 11 has a tendency to tilt, the rotation of the slider 16 will The correction thereof effectively ensures the stability of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com