Construction Method of Combined Cofferdam Suitable for Deep Foundation Pit in Weak Geology

A technology with weak geology and construction methods, applied in the direction of foundation structure engineering, excavation, sheet pile walls, etc., can solve problems such as high cost, long sinking period, and difficult demolition in the later stage, and achieve green construction, save construction costs, and speed up construction progress effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

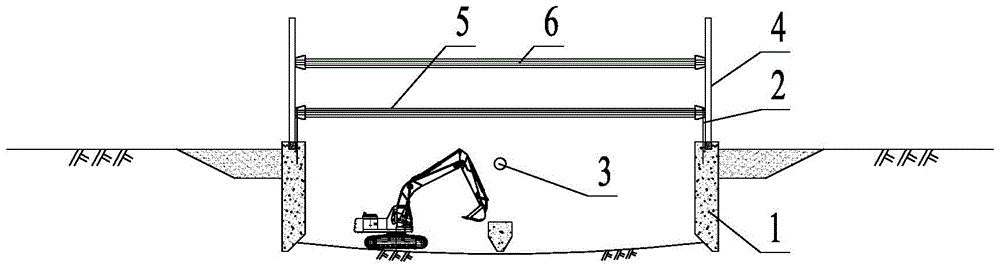

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0019] An embodiment of the present invention provides a construction method for a combined cofferdam suitable for deep foundation pits in weak geology, comprising the following steps:

[0020] S1: constructing foundation bored piles, setting out and positioning the construction position of the concrete cofferdam 1 above the bored piles; after replacing the basement at the construction position, building an island on the basement, and turning to step S2.

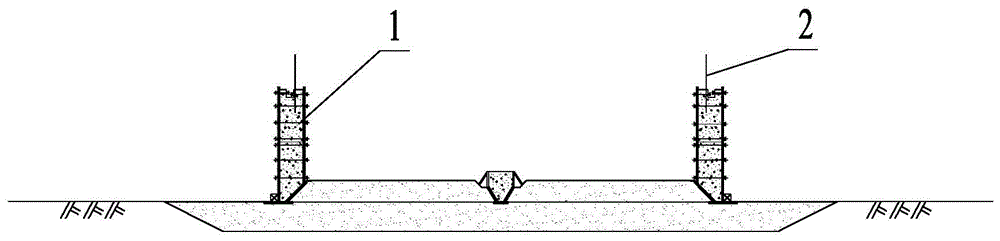

[0021] S2: see figure 1 As shown, support skids and steel blade feet are laid on the construction site, steel bars are bound, concrete cofferdam 1 is poured, and several anchor steel bars 2 are pre-embedded on the top surface of concrete cofferdam 1. The distance between them is the same, generally 2-2.8m, go to step S3.

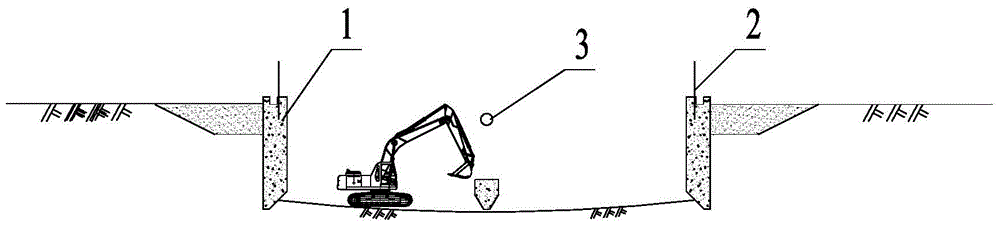

[0022] S3: see figure 2 As shown, the concrete cofferdam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com