3D printing method of concrete special-shaped beams without web reinforcement

A 3D printing and concrete technology, which is applied in the field of making concrete beams, can solve problems such as difficulties in making special-shaped beams, and achieve the effects of industrialization of buildings, avoiding shear damage, and reasonable stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

[0030]The method of the present invention adopts 3D concrete direct printing technology to print the beam member upside down from top to bottom.

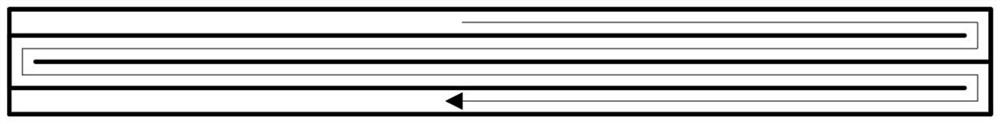

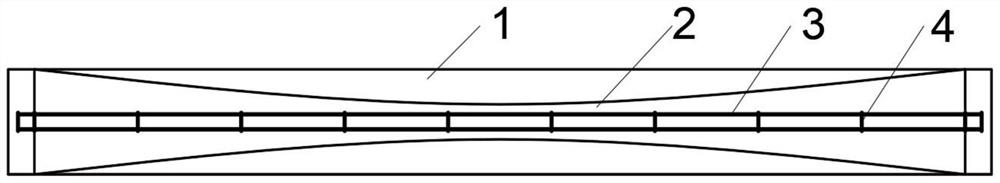

[0031]The first step is to print the rectangular flange layer 1. See the printing pathfigure 1 Because the beam flange is mainly compressed, the rectangular flange layer adopts a printing path from the edge to the center and prints layer by layer until the design thickness of the rectangular flange layer is satisfied.

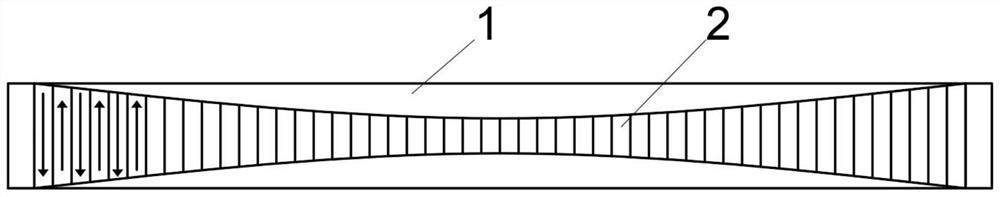

[0032]The second step is to print the curved web layer 2 on the basis of the printed rectangular flange layer. See the printing pathfigure 2 , In order to facilitate printing, print reciprocatingly along the width of the beam in a straight zigzag path, stacking layer by layer; the outer contour of the printed concrete plane of each layer is hyperbolic, and the length of each concrete strip decreases sym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com