Patents

Literature

90results about How to "Avoid constant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

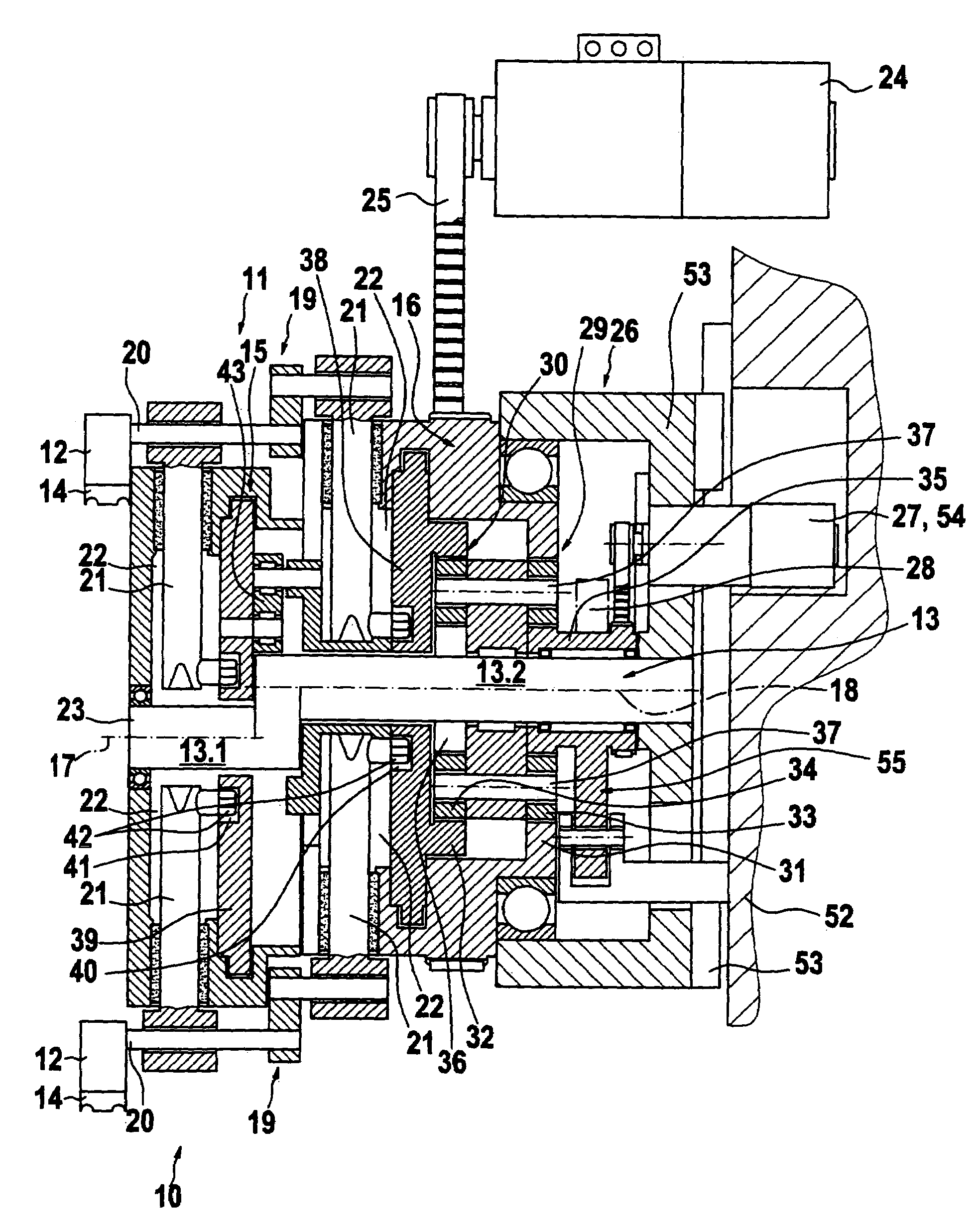

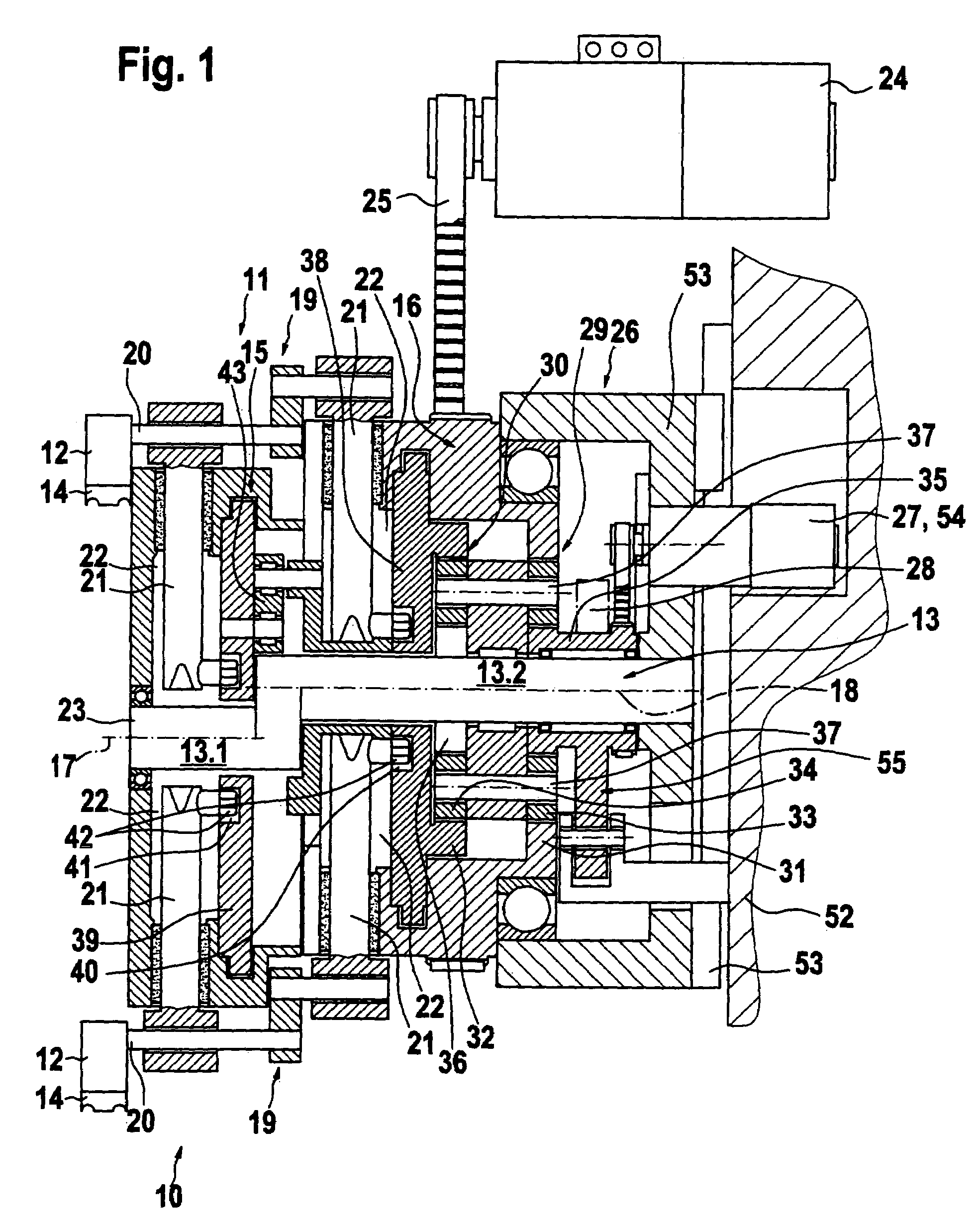

Surgical machine and method for controlling and/or regulating a surgical machine

ActiveUS7362062B2Guaranteed uptimeEasy to startElectronic commutation motor controlDC motor speed/torque controlMotor controllerControl theory

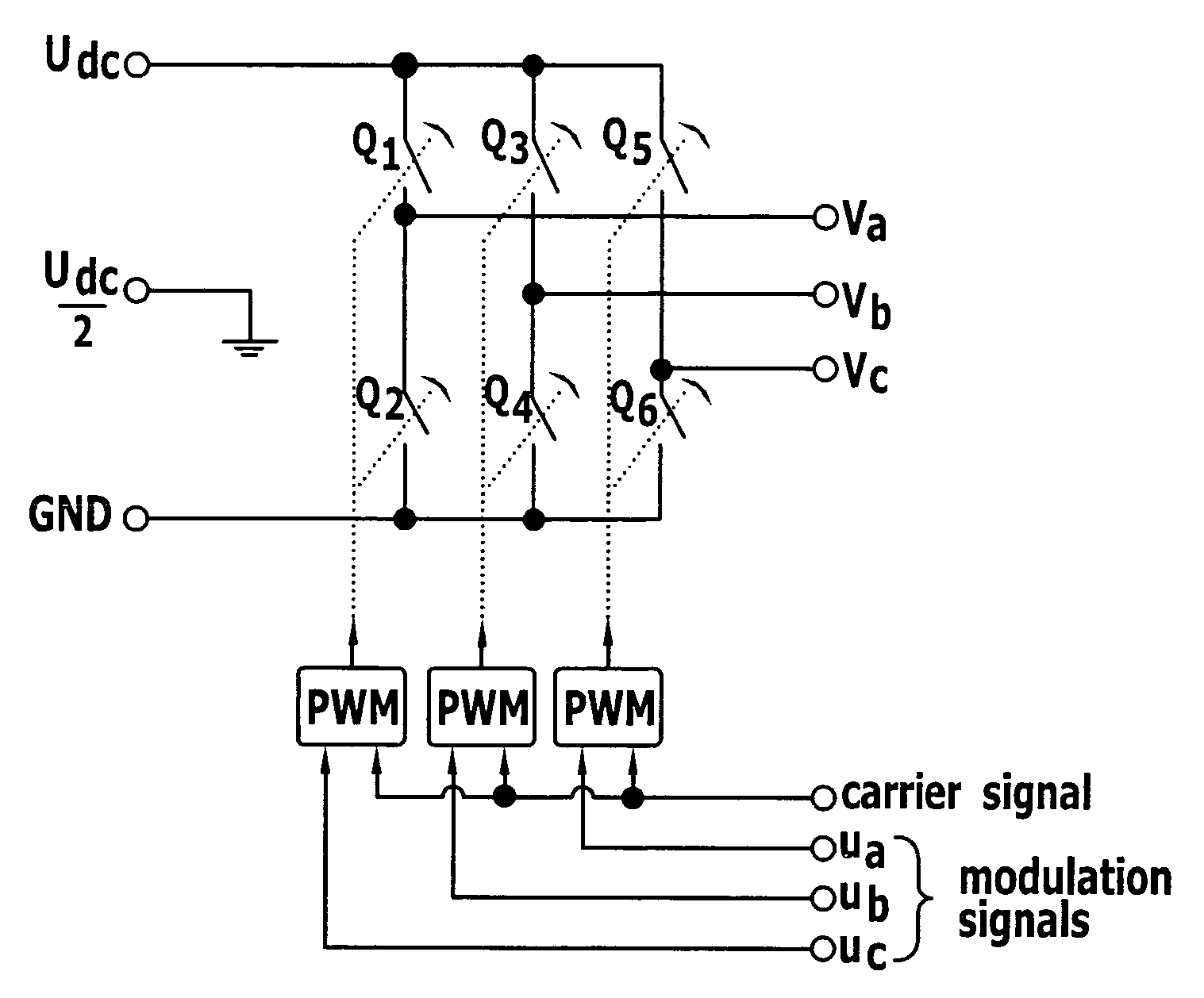

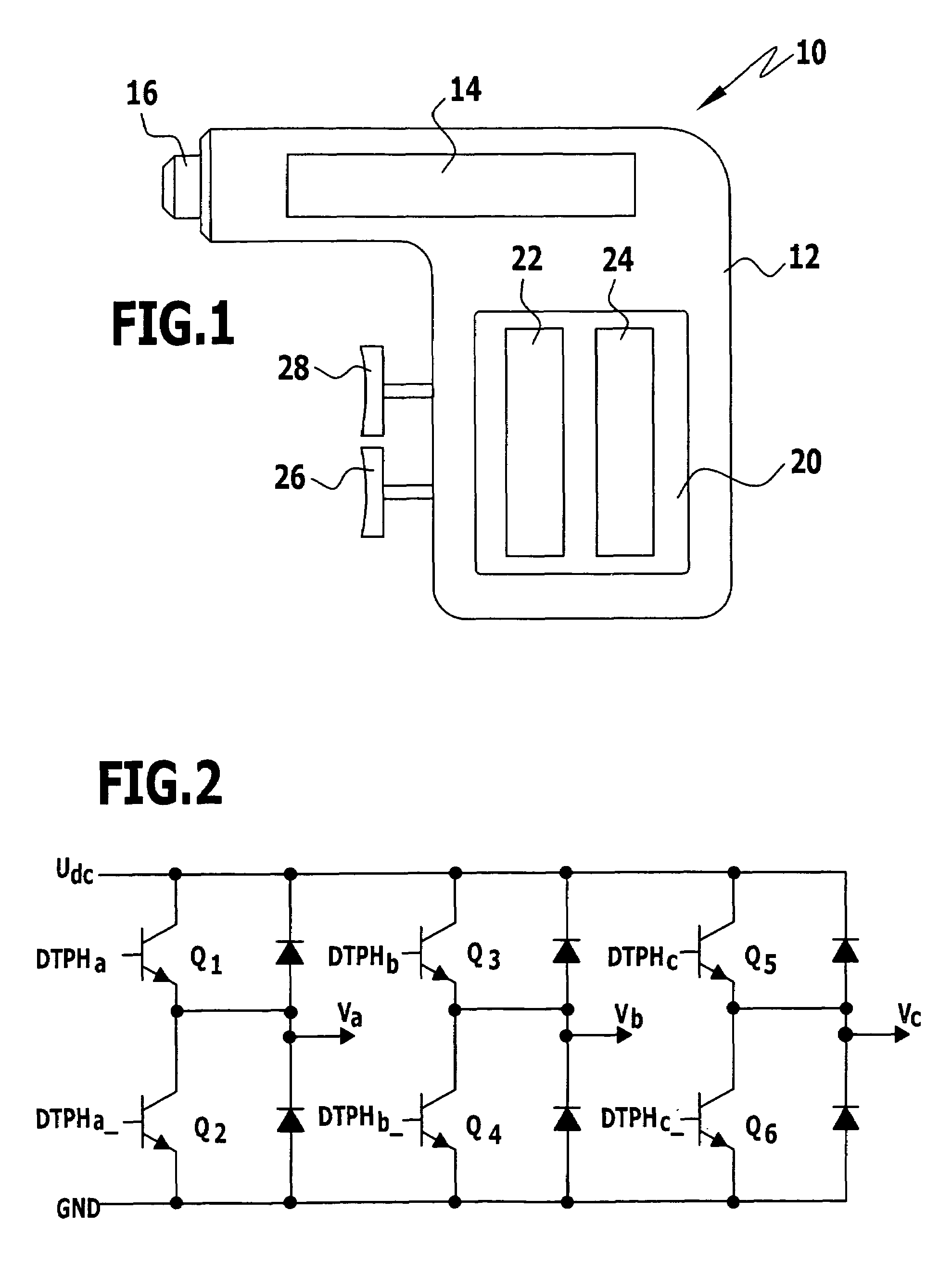

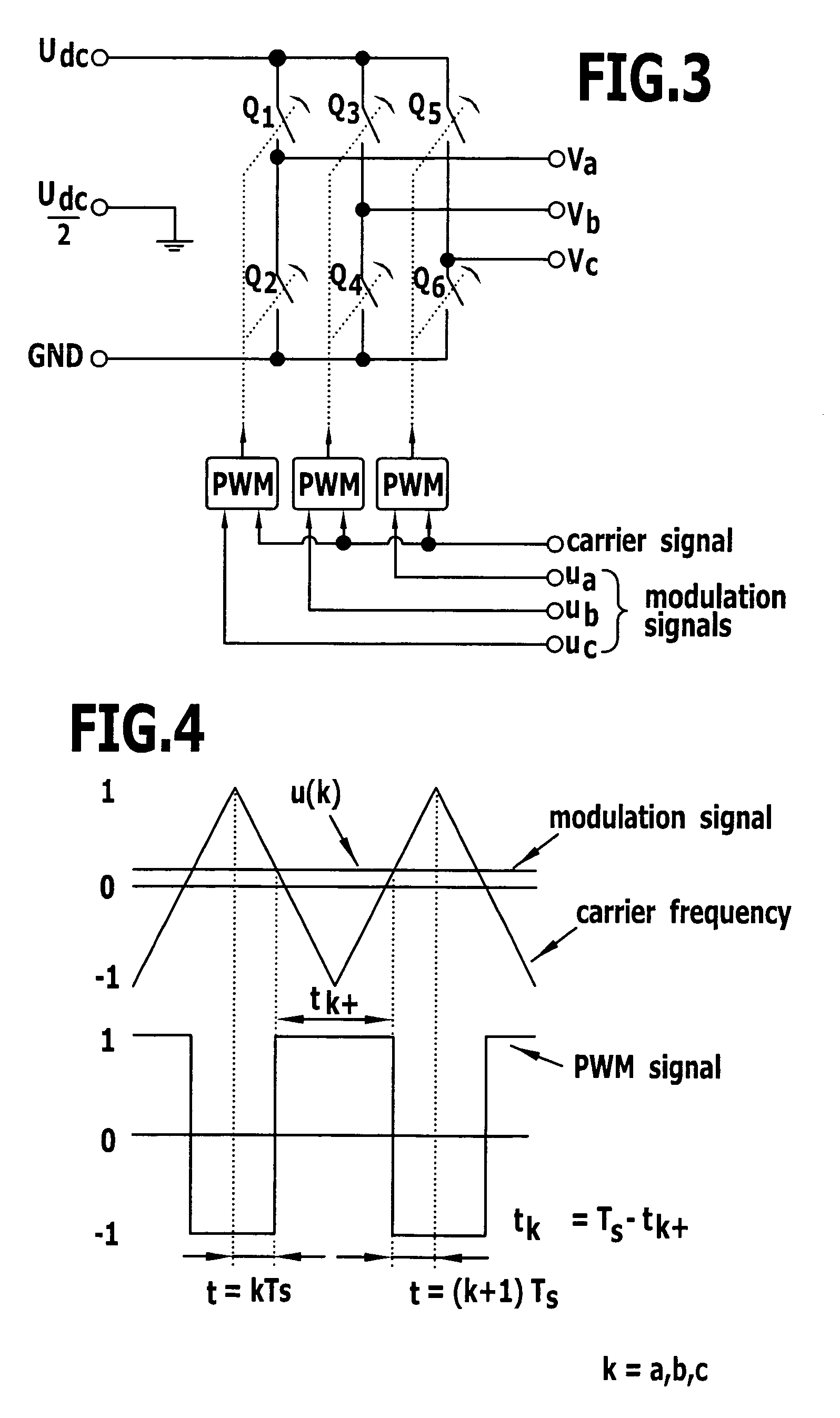

To improve a surgical machine with a sensorless electric motor comprising a rotor and at least two motor windings, and with a motor controller for controlling and / or regulating the electric motor, so that the electric motor is operable with optimum efficiency at low rotational speeds and a starting of the motor in accordance with the purpose, also under load, is enabled, it is proposed that a space vector pulse width modulation (SVPWM) method for controlling and / or regulating the electric motor, in which all motor windings are able to be simultaneously supplied with electric current, be performable with the motor controller. A method for controlling and / or regulating a surgical machine is also proposed.

Owner:AESCULAP AG

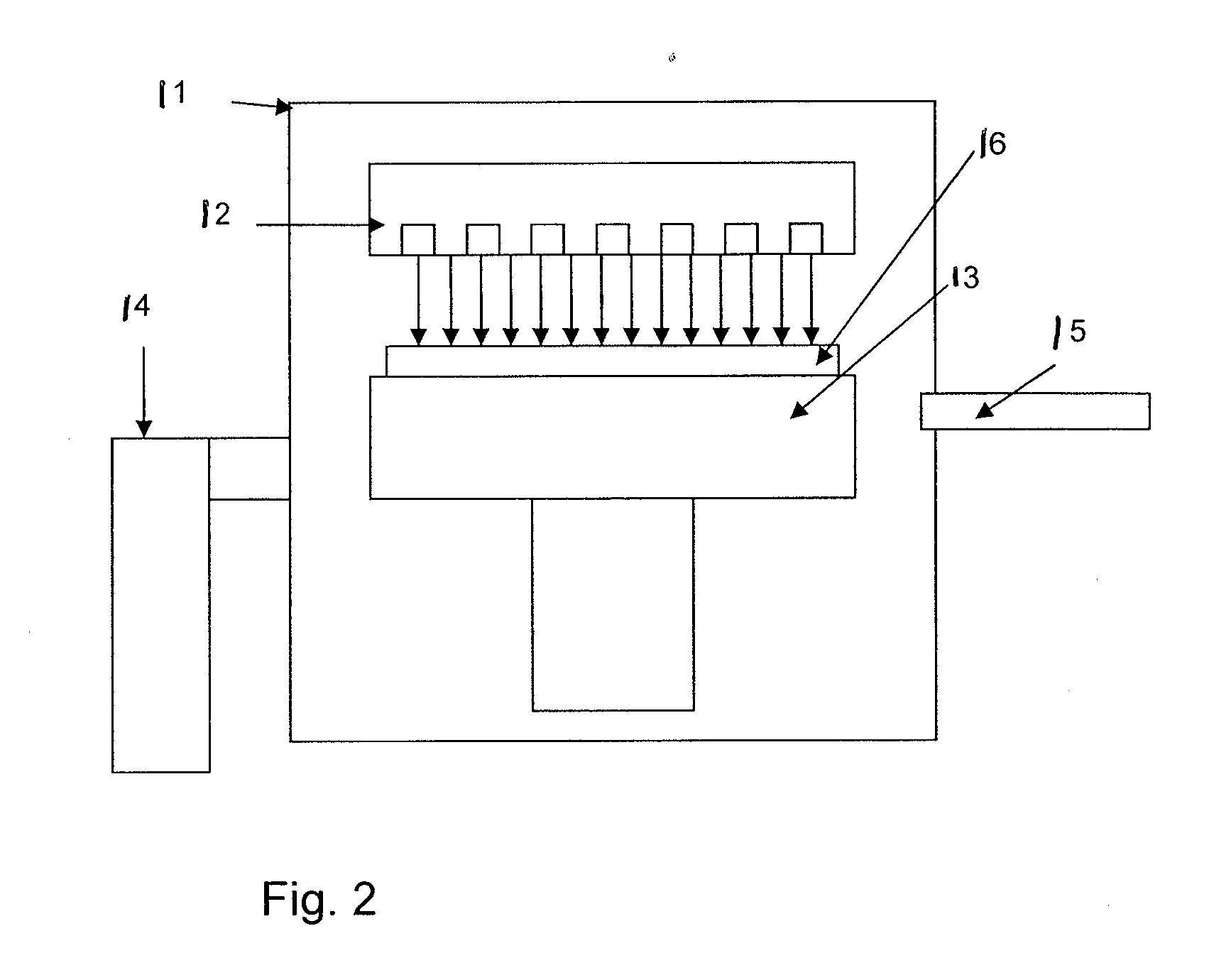

Method for increasing mechanical strength of dielectric film by using sequential combination of two types of UV irradiation

InactiveUS20080220619A1Enhance porogen-removing effectHigh mechanical strengthSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectricLength wave

A method for increasing mechanical strength of a dielectric film includes: providing an initial dielectric film containing porogen; irradiating the initial dielectric film with first UV light having a first wavelength which is substantially or nearly similar to a maximum light absorption wavelength of the porogen for removing the porogen; and then irradiating the porogen-removed dielectric film with second UV light having a second wavelength which is shorter than the first wavelength, thereby increasing mechanical strength of the dielectric film.

Owner:ASM JAPAN

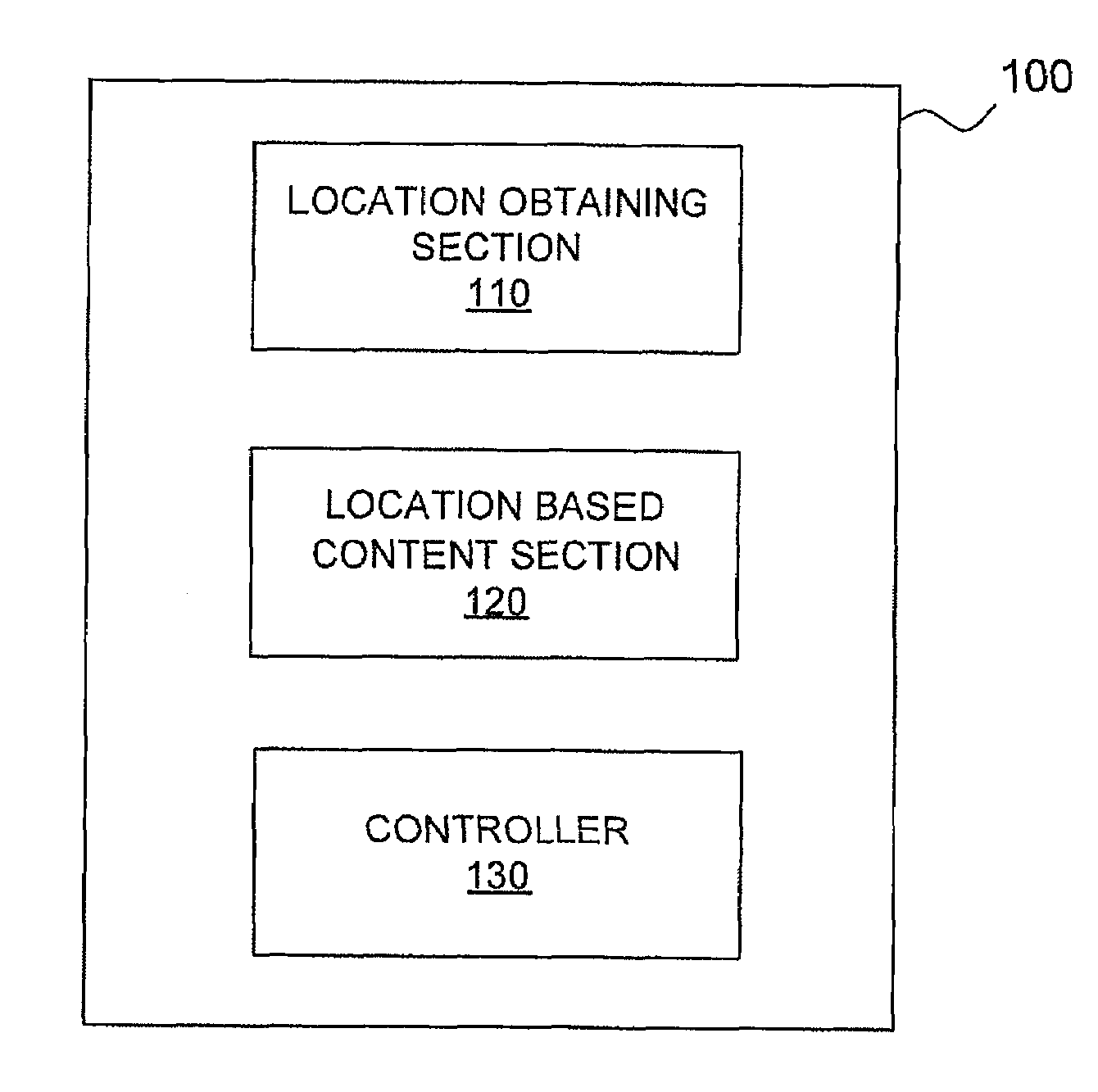

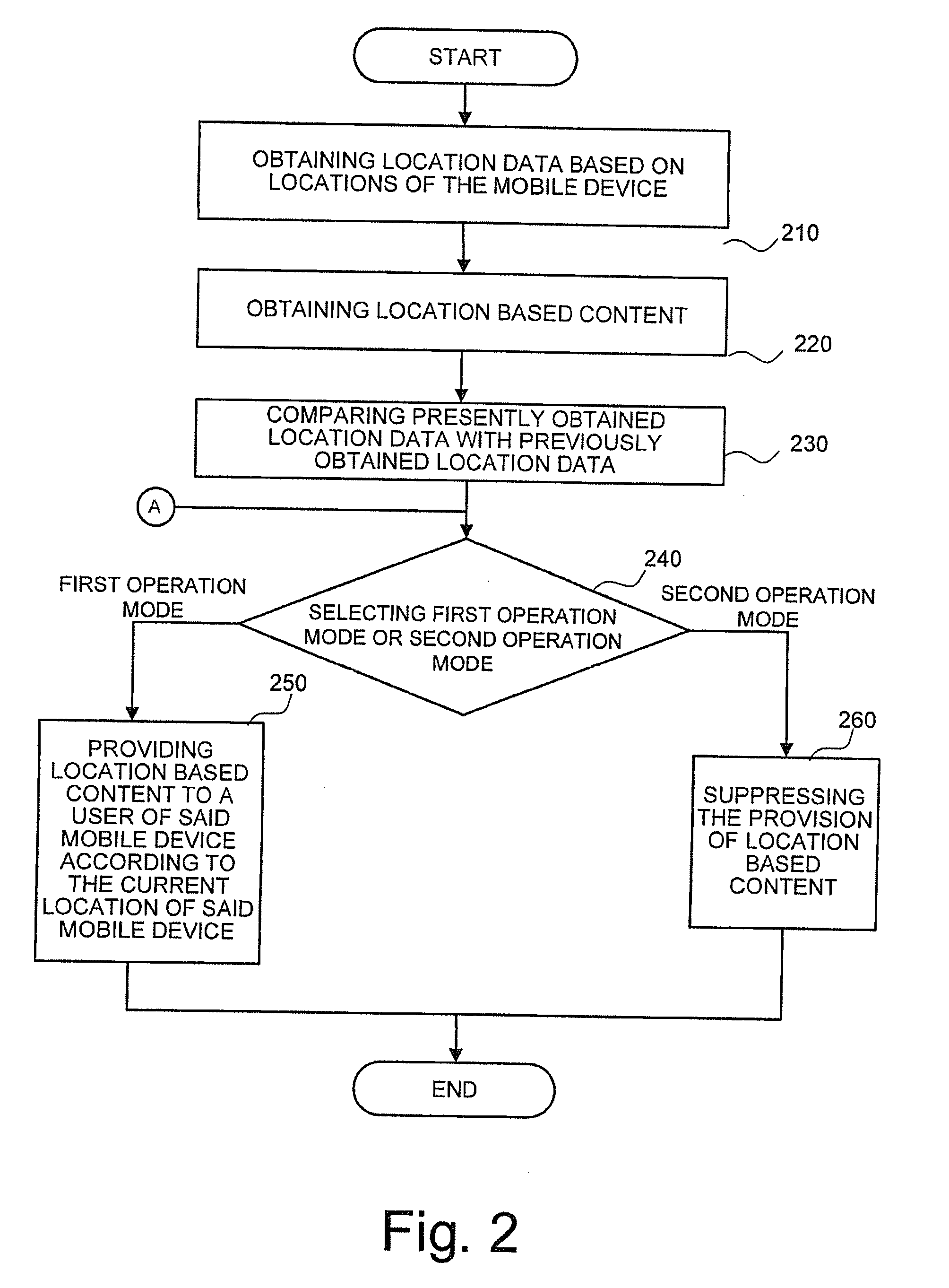

Mobile device and method for providing location based content

ActiveUS20100190513A1Prevent information overloadAvoid constantInformation formatServices signallingOperation modeMobile device

A mobile device and method are disclosed to provide location based content to a user of a mobile device based on the current location, wherein the provision of location based content depends on obtained location data. The mobile device comprises a location obtaining section for obtaining location data based on locations of the mobile device, location based content section for obtaining location based content, and a controller adapted to compare presently obtained location data with previously obtained location data and to select between a first operation mode and a second operation mode according to the comparison, wherein in the first operation mode the location based content section is adapted to provide location based content to a user of the mobile device according to the current location of the mobile device and in the second operation mode providing of location based content is suppressed.

Owner:SONY CORP

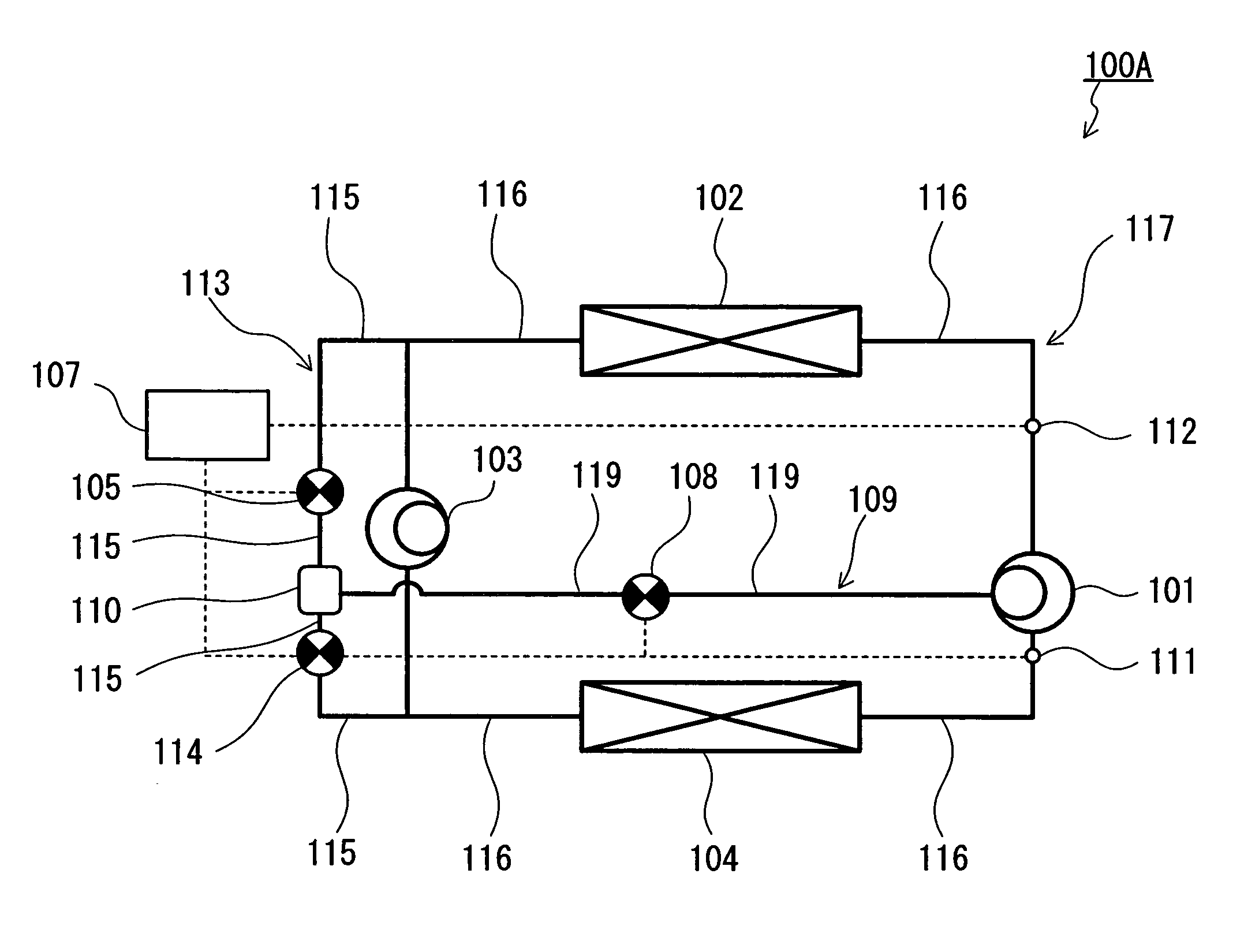

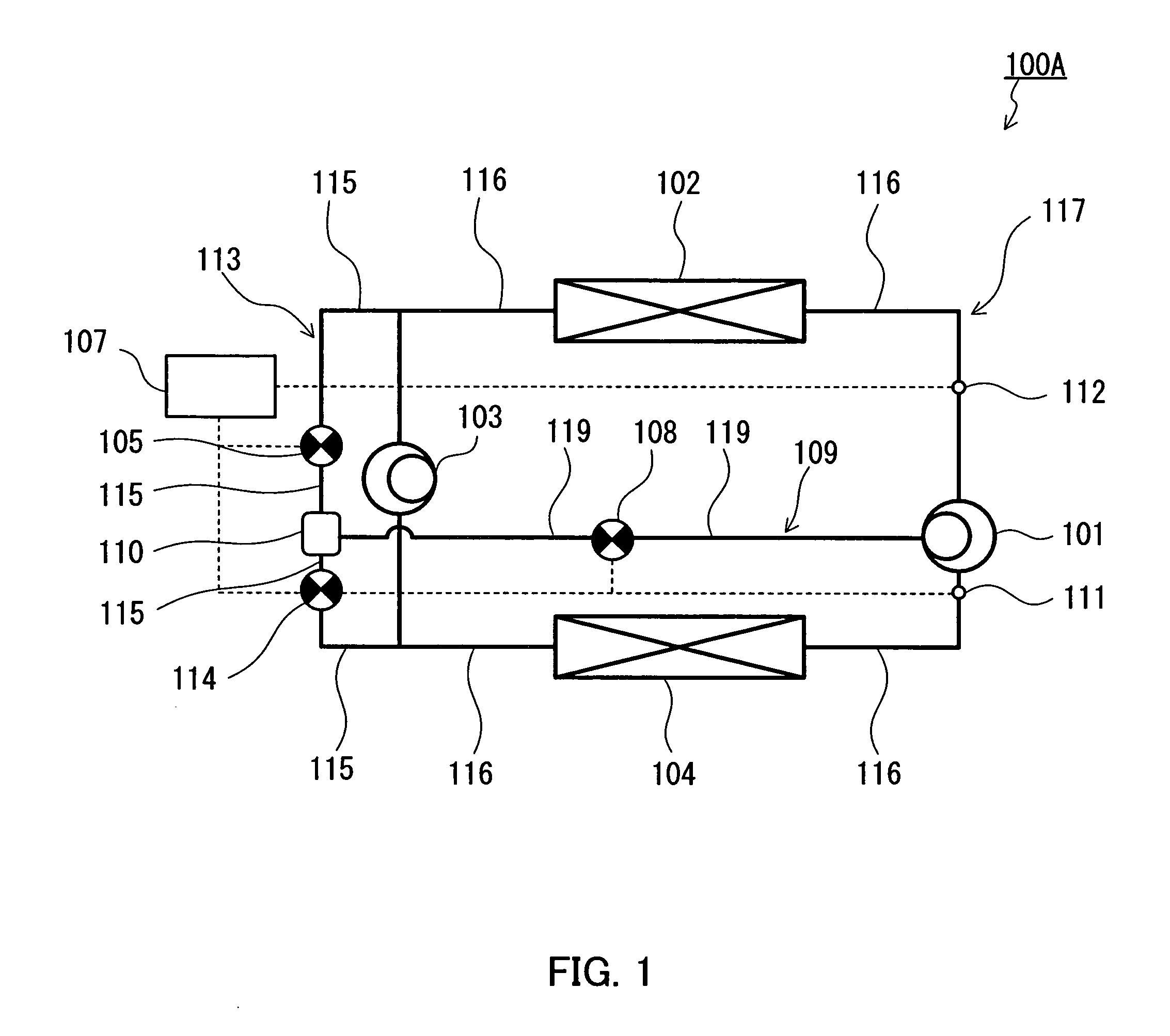

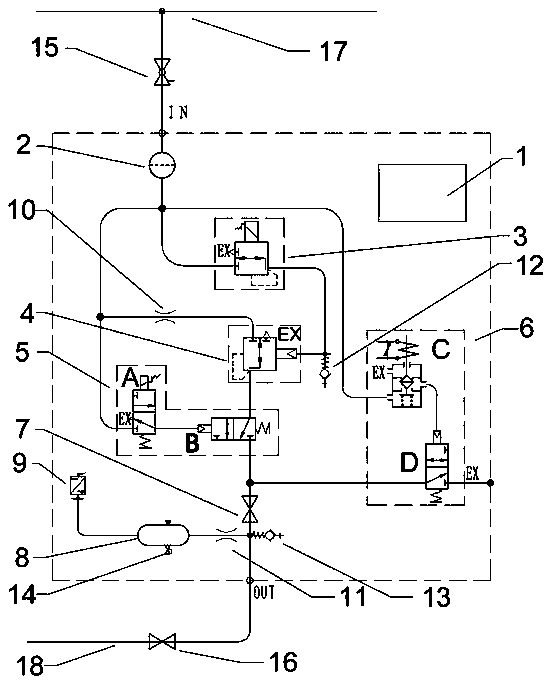

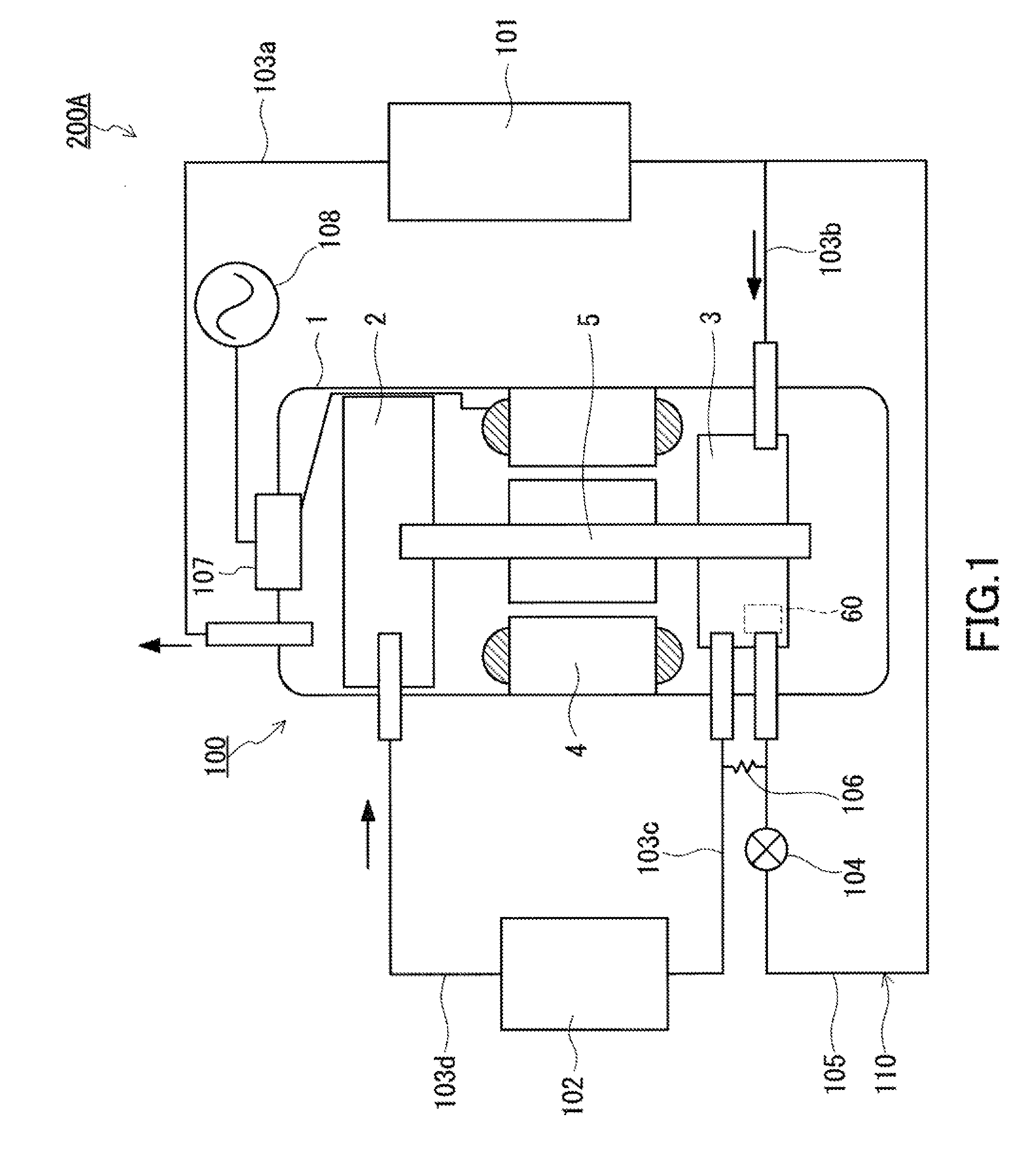

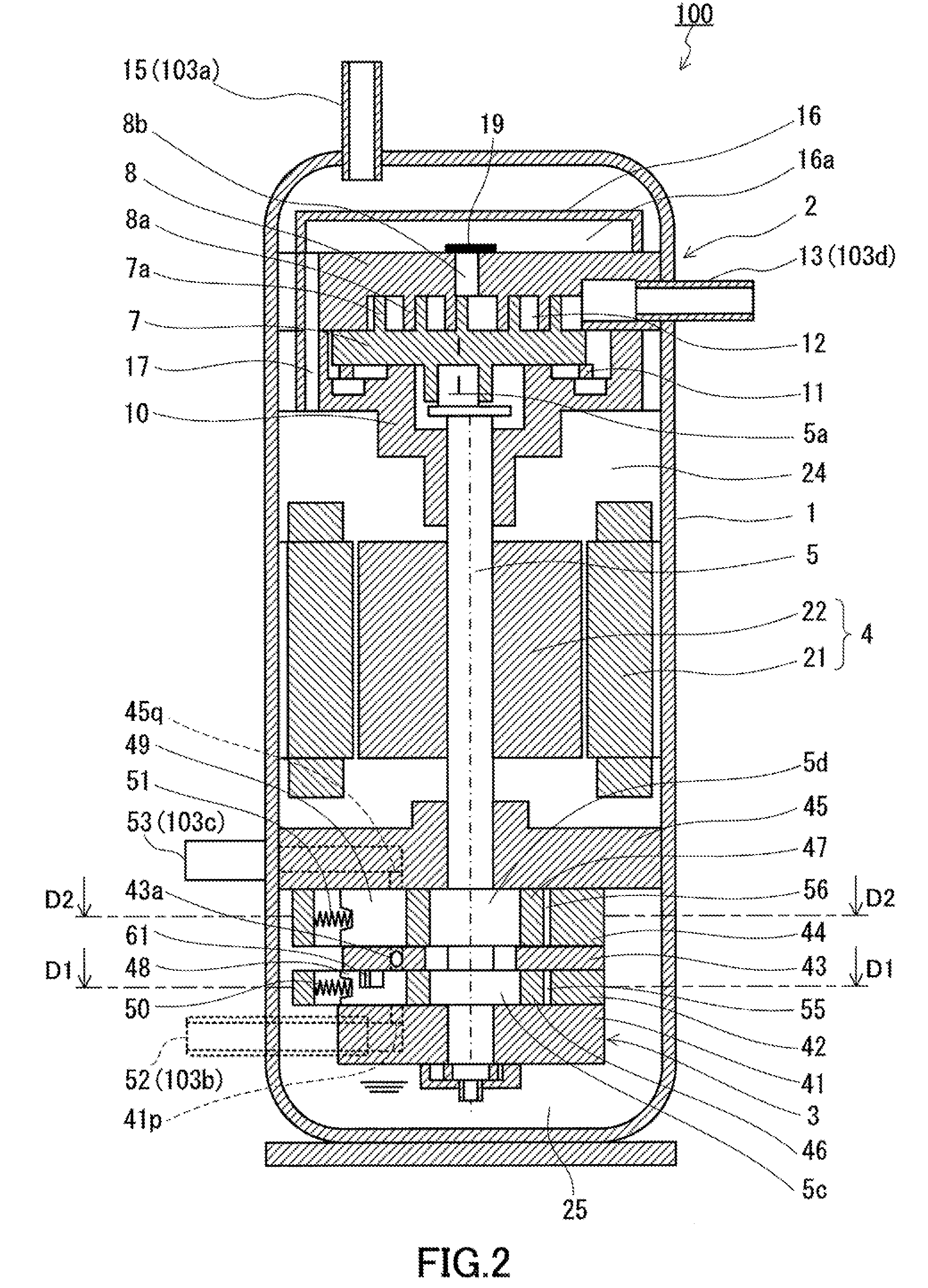

Refrigeration cycle apparatus

InactiveUS20070151266A1Density ratio is avoidedImprove cooling effectMechanical apparatusCompression machines with non-reversible cycleVapor–liquid separatorEngineering

A refrigeration cycle apparatus includes a compressor, a radiator, an expander, an evaporator, a bypass circuit, and an injection circuit. The bypass circuit has a flow rate control valve and a gas-liquid separator. One end of the bypass circuit is connected to an intake conduit of the expander and the other end thereof is connected to a discharge conduit of the expander so that a portion of refrigerant passed through the radiator bypasses the expander and is guided to the flow rate control valve and that the liquid refrigerant separated by the gas-liquid separator returns to the discharge conduit of the expander. One end of the injection circuit is connected to a gas outlet portion of the gas-liquid separator and the other end thereof is connected to an intermediate pressure portion of the compressor.

Owner:PANASONIC CORP

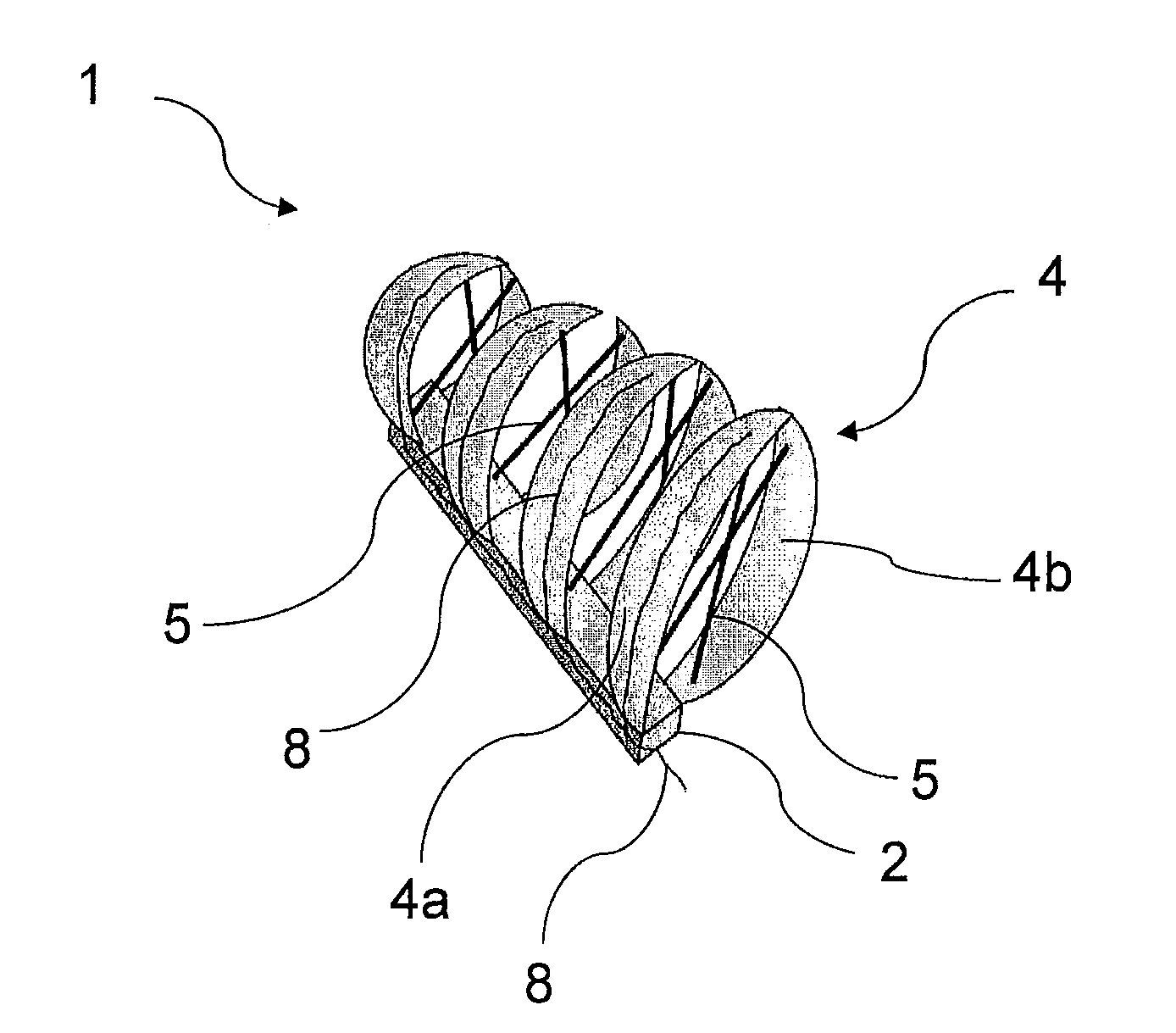

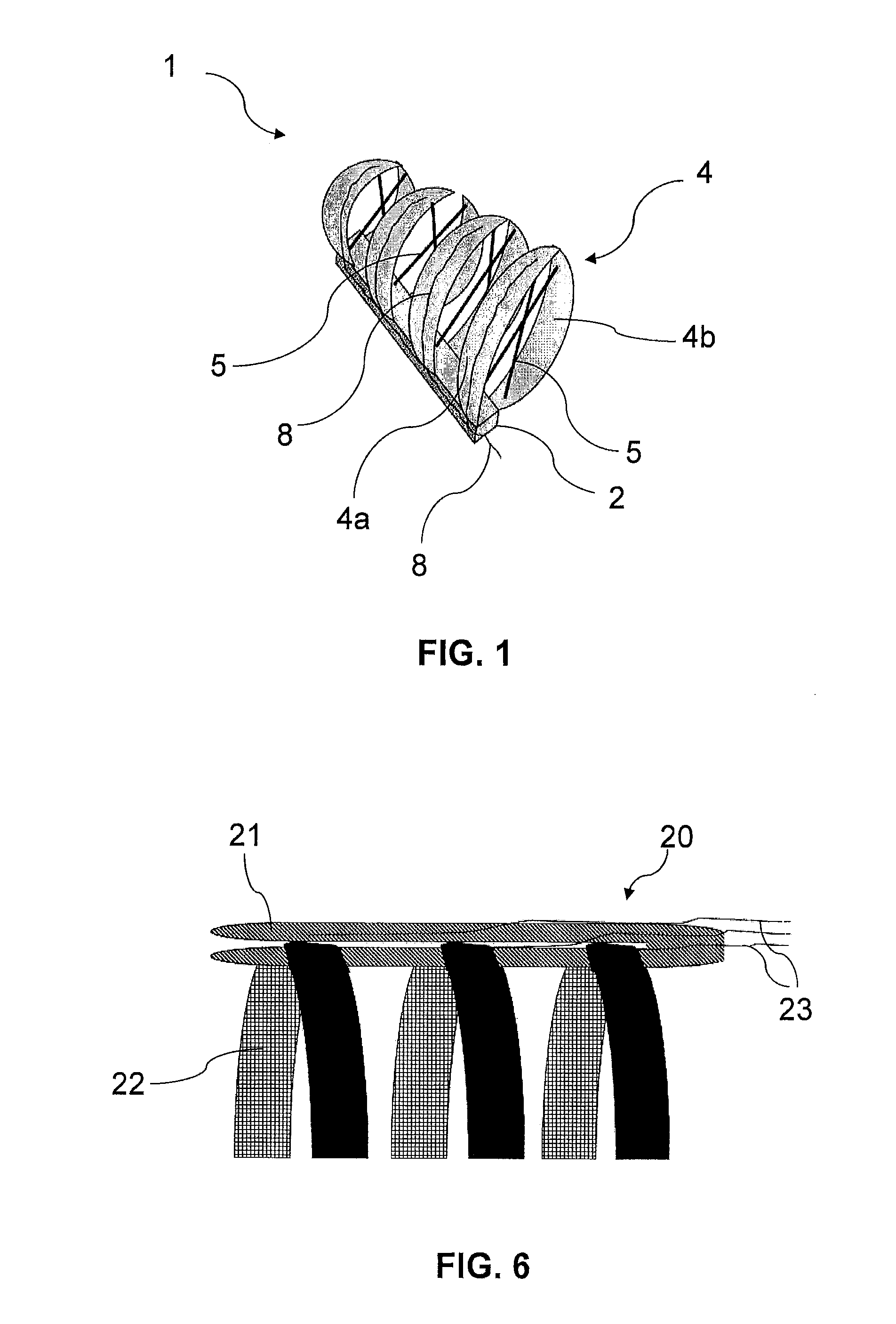

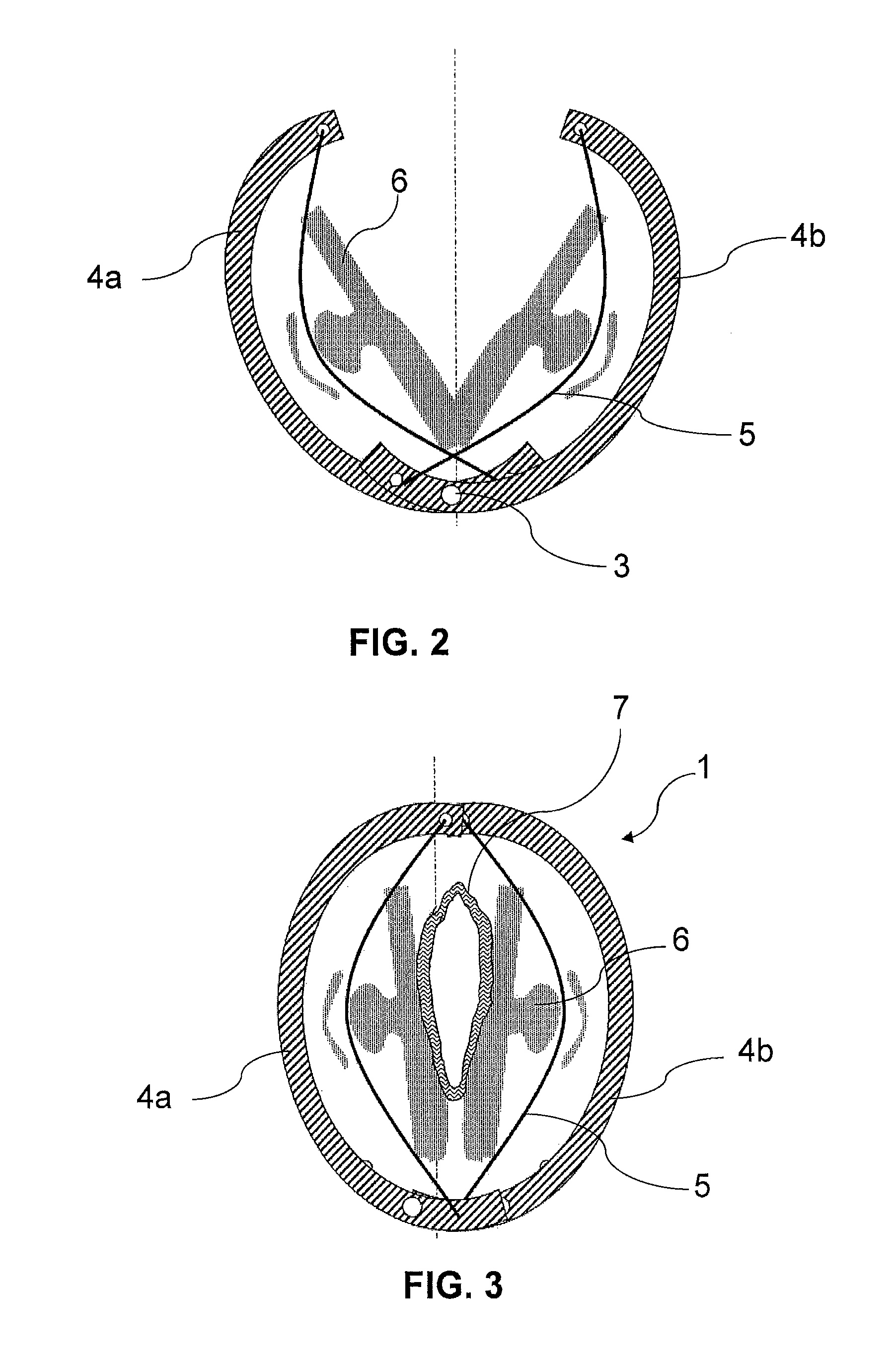

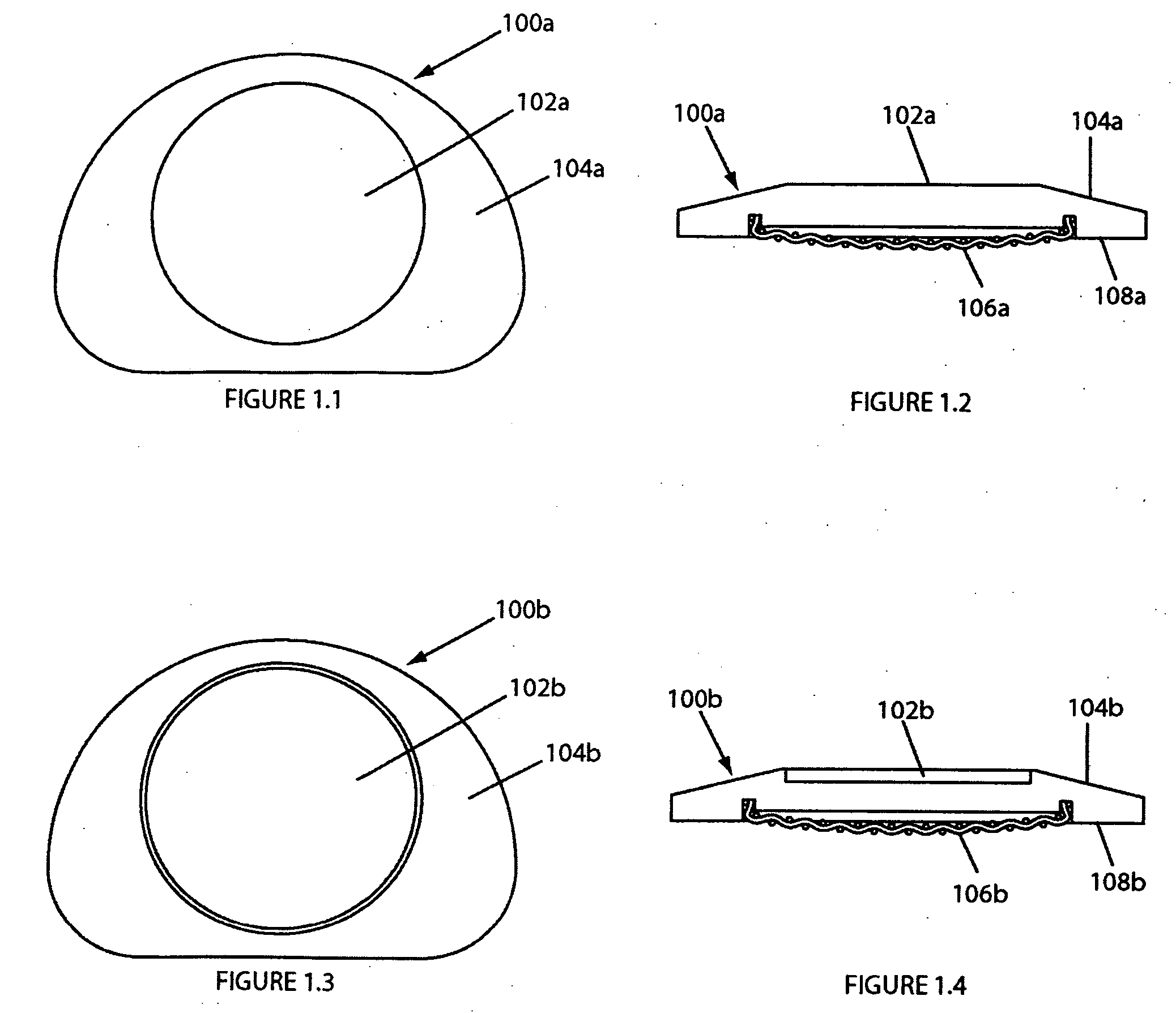

Artificial contractile structure and apparatus comprising such structure

ActiveUS20100204803A1Avoid constantMinimize and suppress leakingElectrotherapyAnti-incontinence devicesFiberRest position

An artificial contractile structure generally devised to be used in the medical field to assist the functioning of an organ, includes a support (2) and one or more fibers (5) fixed thereto. The fibers are made of a contractile material which can be activated by an activator so as to provide the structure in a rest or activated position, the activated position being defined with fibers of reduced length compared to their length in the rest position. The structure is adapted to be placed around a hollow part of an organ to be contracted. The fibers are distributed along the support in order to be able to reduce the volume of the hollow part, when the fibers are contracted. The fibers and the activator are designed so that the temperature of fluids or tissues surrounding the organ does not increase above 40° C., preferably 39° C., and more preferably 38° C.

Owner:MYOPOWERS MEDICAL TECH FRANCE

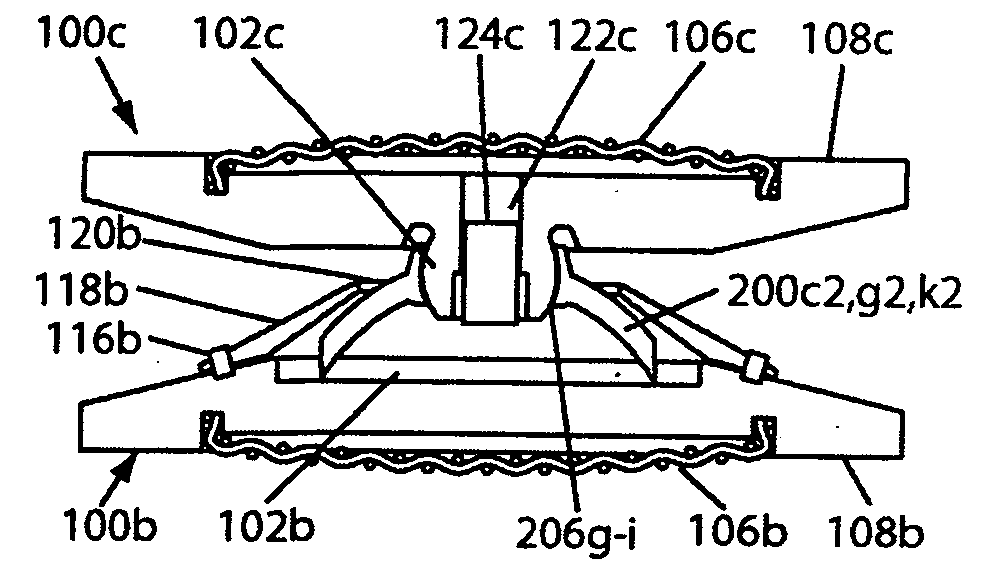

Intervertebral implant having features for controlling angulation thereof

InactiveUS20060235529A1Improve securityStrong forceJoint implantsSpinal implantsSpherical formBiomedical engineering

An intervertebral implant includes a first plate having an inner surface, an outer surface, a ball shaped protuberance projecting from the inner surface and an annular groove surrounding the ball shaped protuberance. The implant includes a second plate having an inner surface, an outer surface, a curvate socket formed in the inner surface of the second plate and a raised rim surrounding the curvate socket. The first and second plates are assembled together so that the inner surfaces of the plates oppose one another and the ball shaped protuberance is disposed in the curvate socket and the annular groove aligned with the raised rim. The assembled first and second plates angulate and rotate relative to one another.

Owner:TOYOTA JIDOSHA KK +1

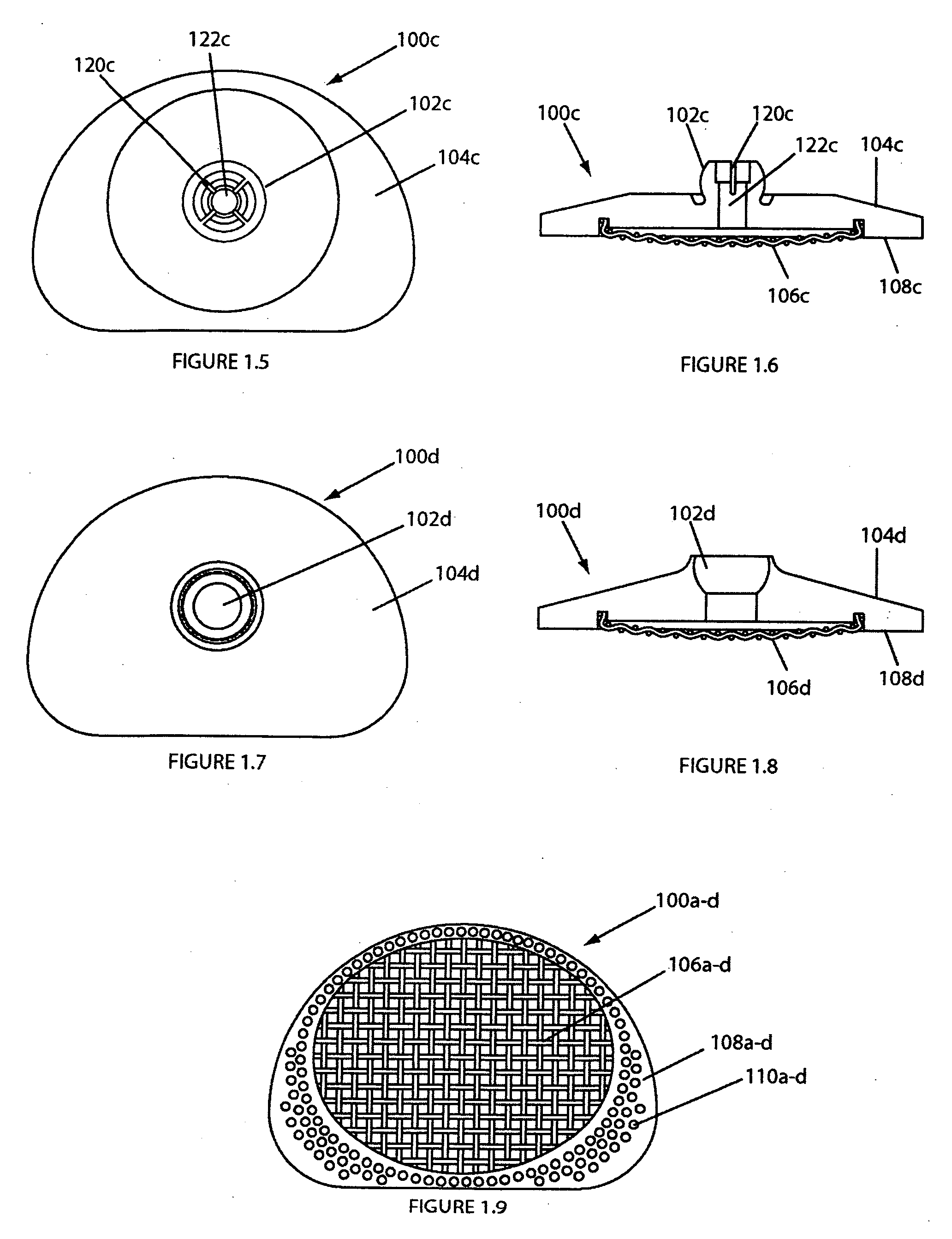

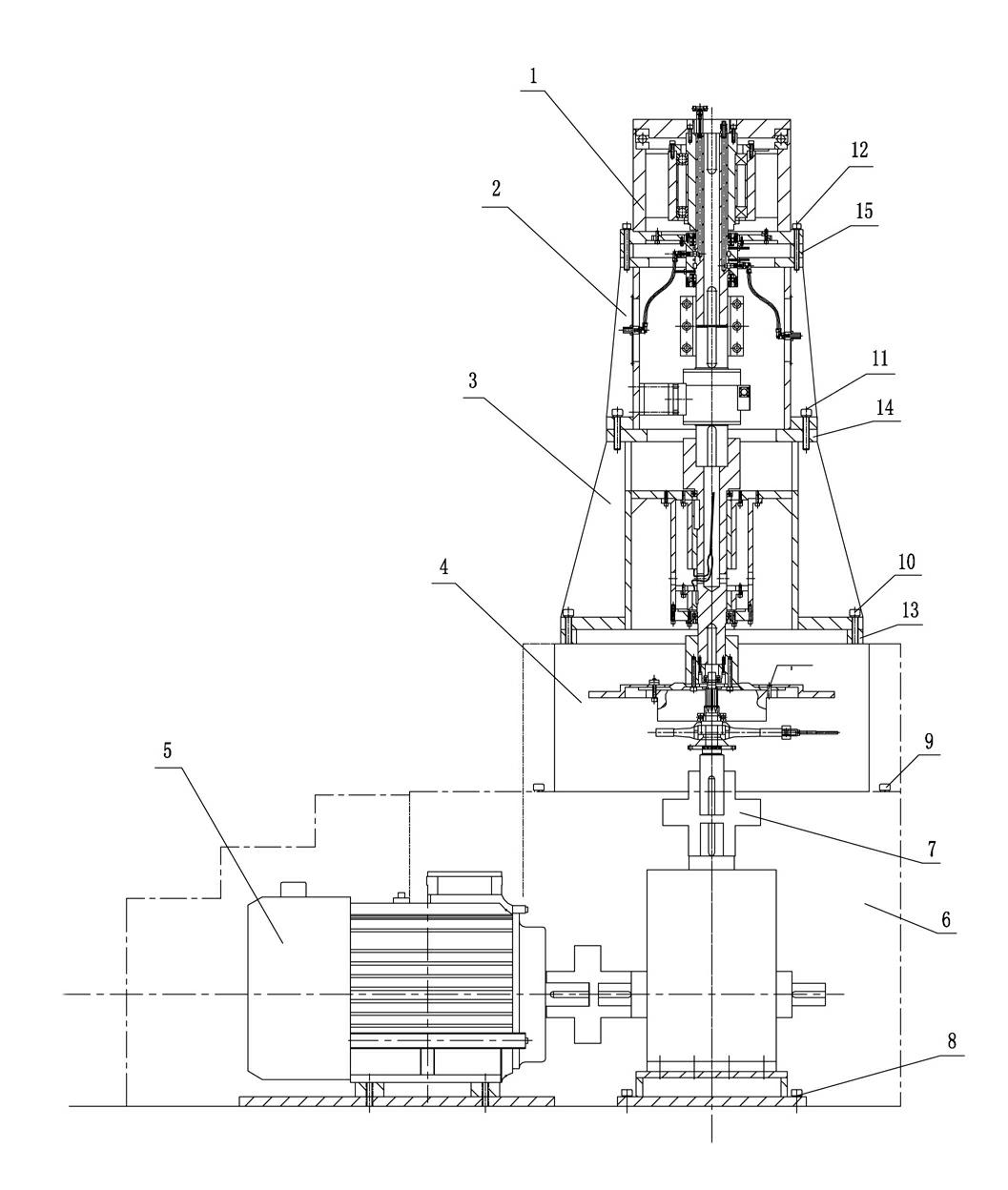

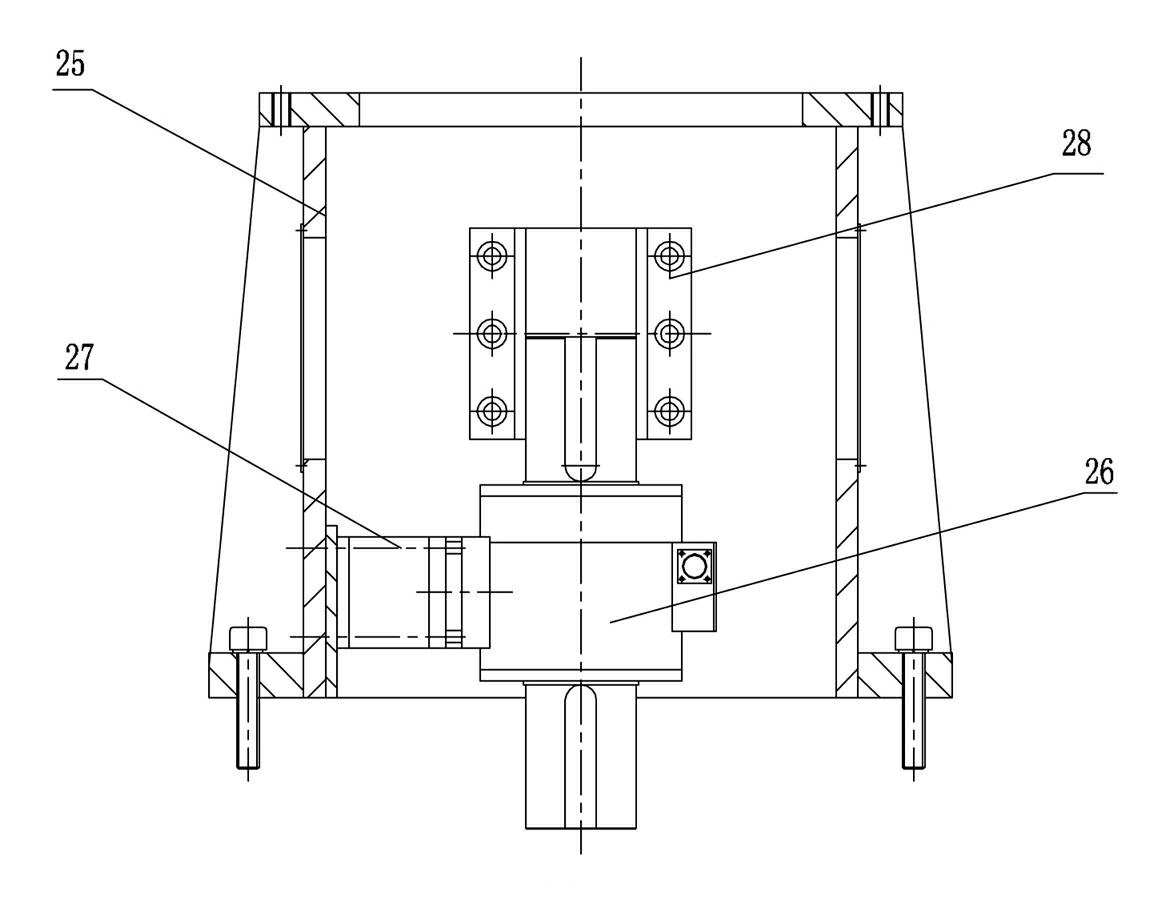

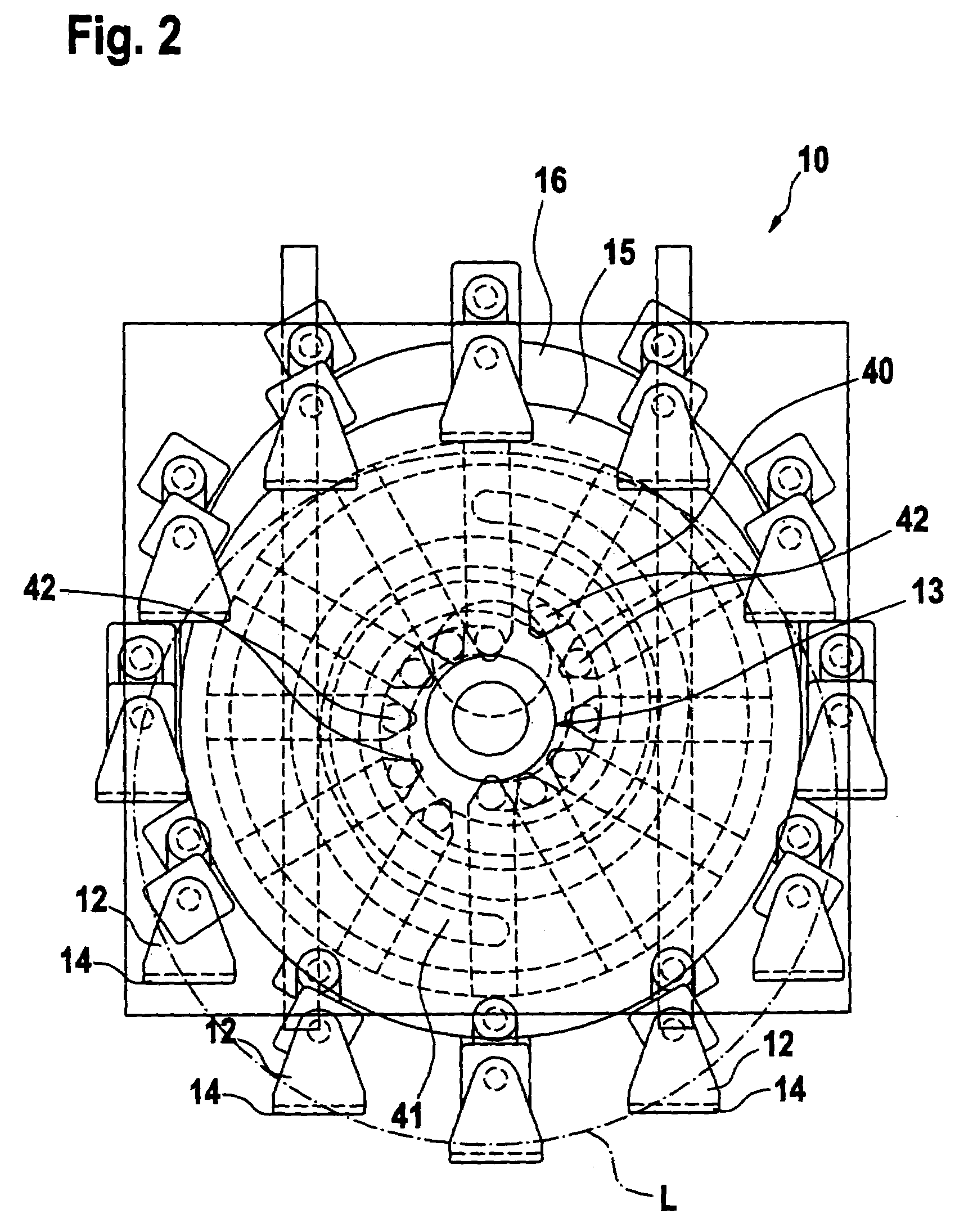

Test turntable for aircraft engine

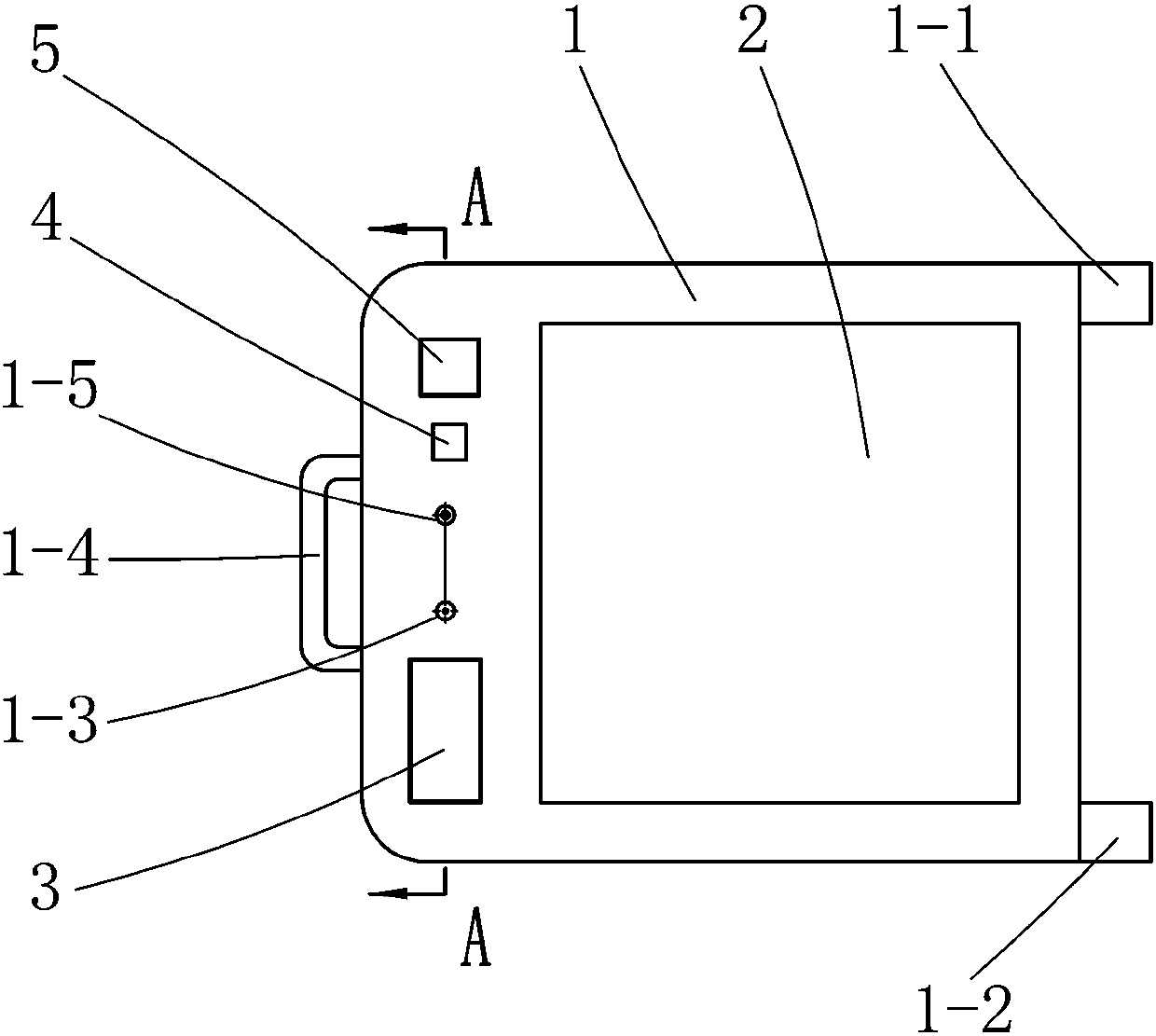

The invention discloses a test turntable for an aircraft engine, and relates to continuously-rotating test equipment in the aviation field, in particular to the test turntable which is suitable for tests and rotor wings of engines of fixed models and other devices and used for dragging experiment. The test turntable comprises a turntable part, a sensor part, an electric conduction slip ring part, a clutch and brake device part, and a motor and bevel gear transmission case part; the motor and bevel gear transmission case part is fixed into a foundation through screws; the clutch and brake device part is fixed on the foundation through screws; the clutch and brake device part is connected with the motor and bevel gear transmission case part through a coupler; the electric conduction slip ring part is fixed on the clutch and brake device part through screws through screws and is adjusted horizontally through an adjusting shim; the sensor part is connected with the electric conduction slip ring part through screws and is horizontally adjusted through the adjusting shim; and the turntable part is connected with the sensor part through the screws and is horizontally adjusted through the adjusting shim.

Owner:南京硕航机电有限公司

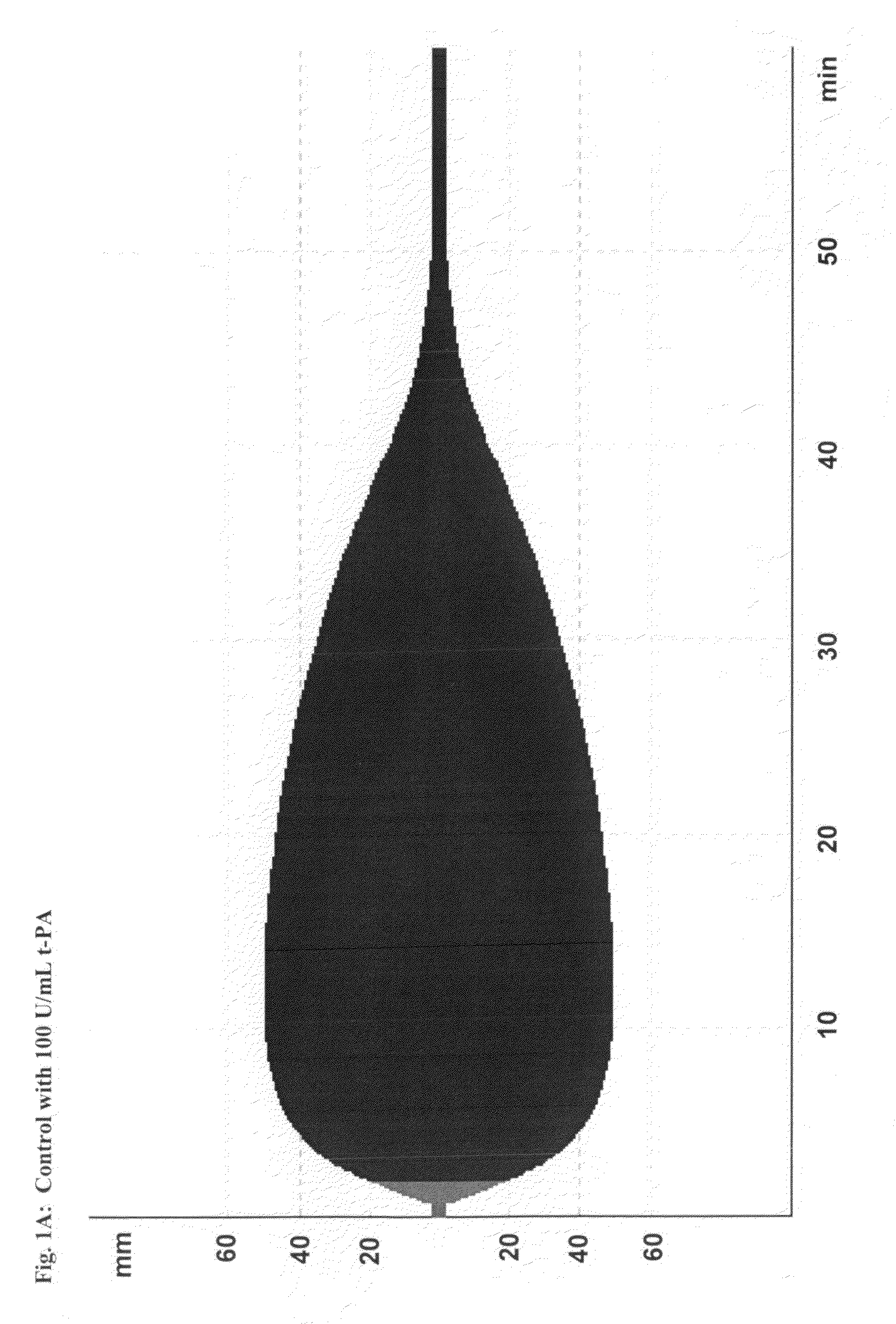

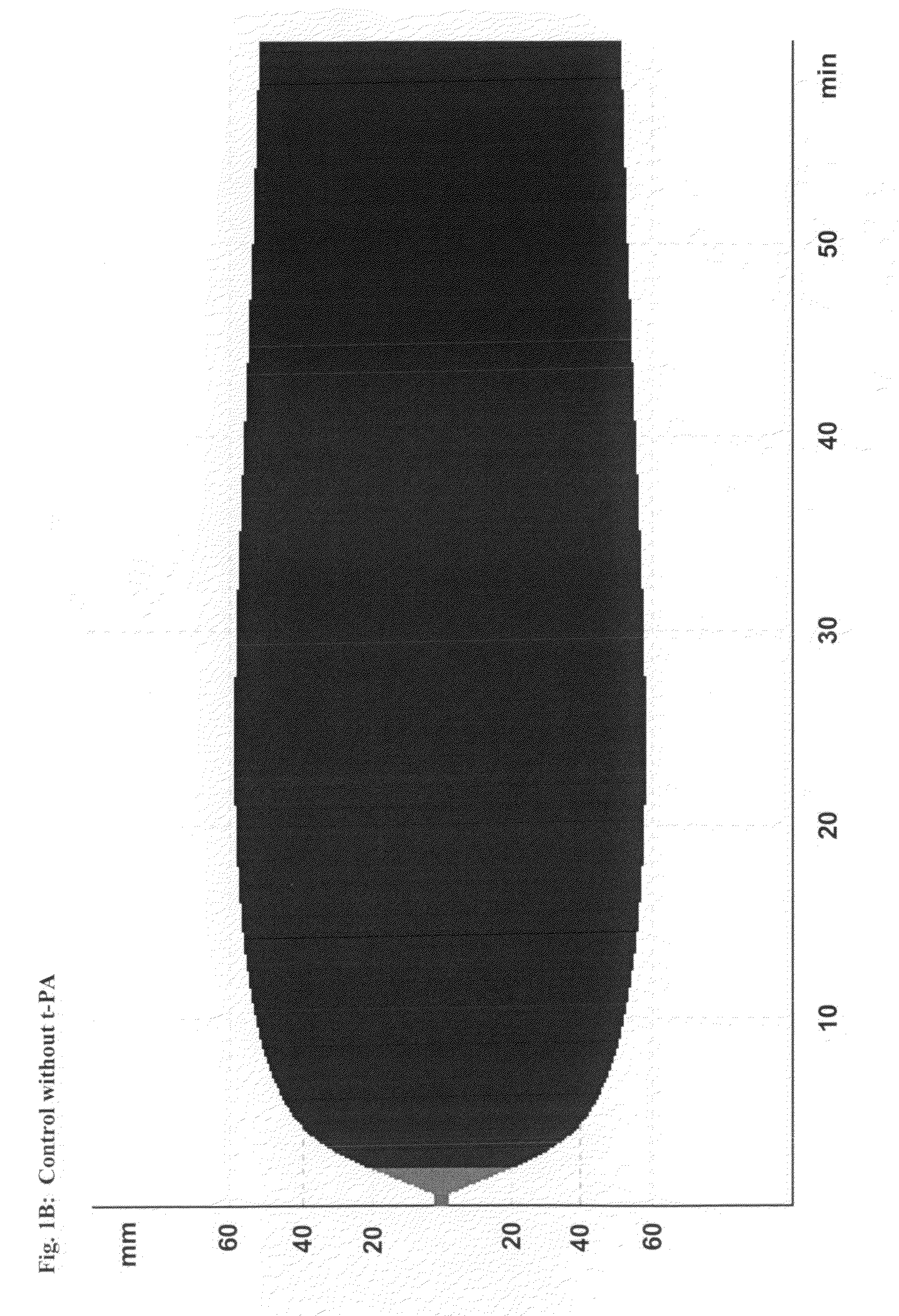

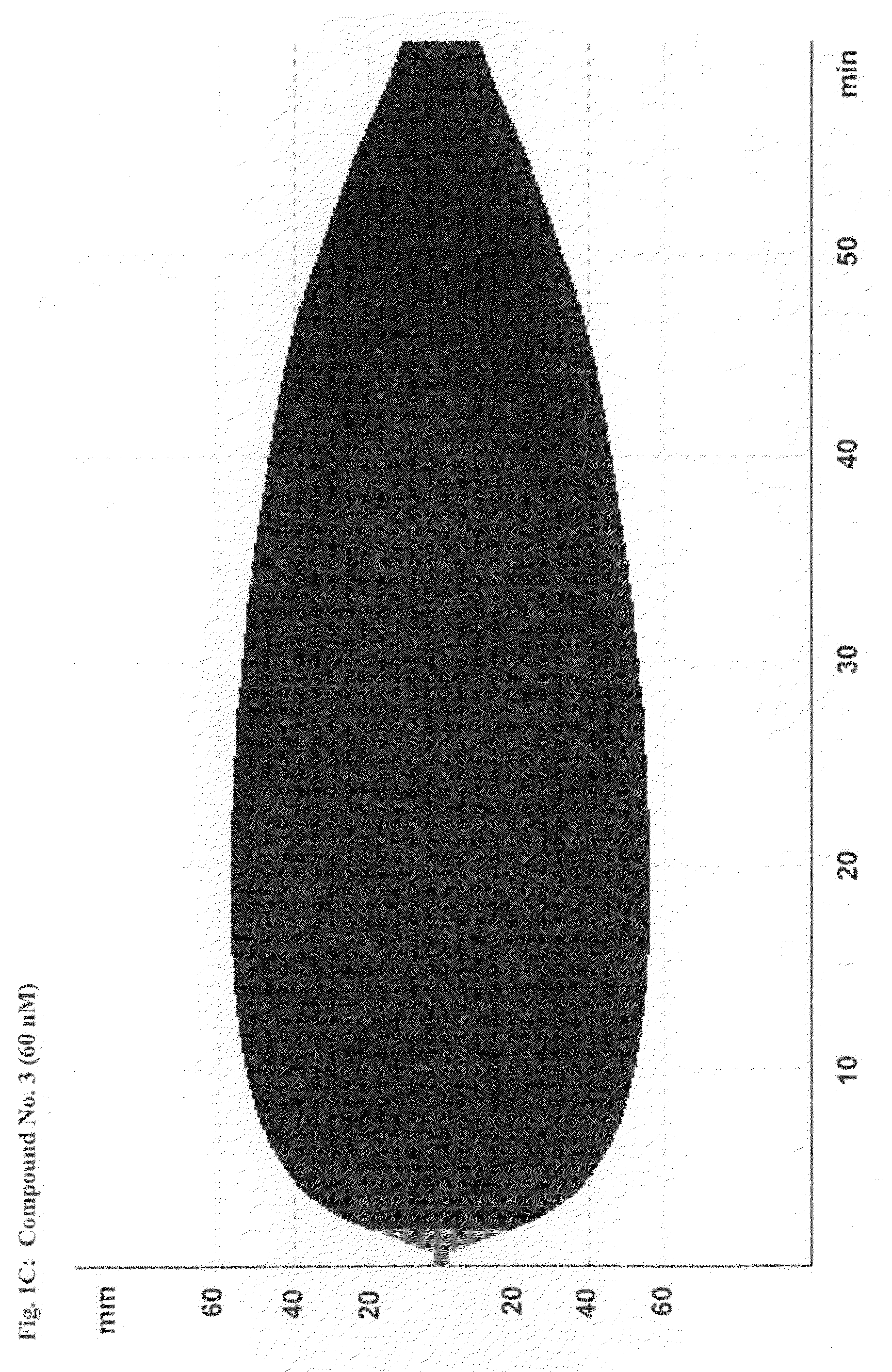

Trypsin-like serine protease inhibitors, and their preparation and use

InactiveUS20100022781A1Good effectAvoid constantOrganic compound preparationPeptidesMedicineOrgan transplanting

The invention relates to inhibitors of trypsin-like serine proteases of the general formula (I) which, as well as plasmin, also inhibit plasma kallikrien, and to their preparation and use as medicaments, preferably for treatment of blood loss, especially in the case of hyperfibrinolytic states, in organ transplants or heart surgery interventions, in particular with a cardiopulmonary bypass, or as a constituent of a fibrin adhesive.

Owner:THE MEDICINES CO (LEIPZIG) GMBH

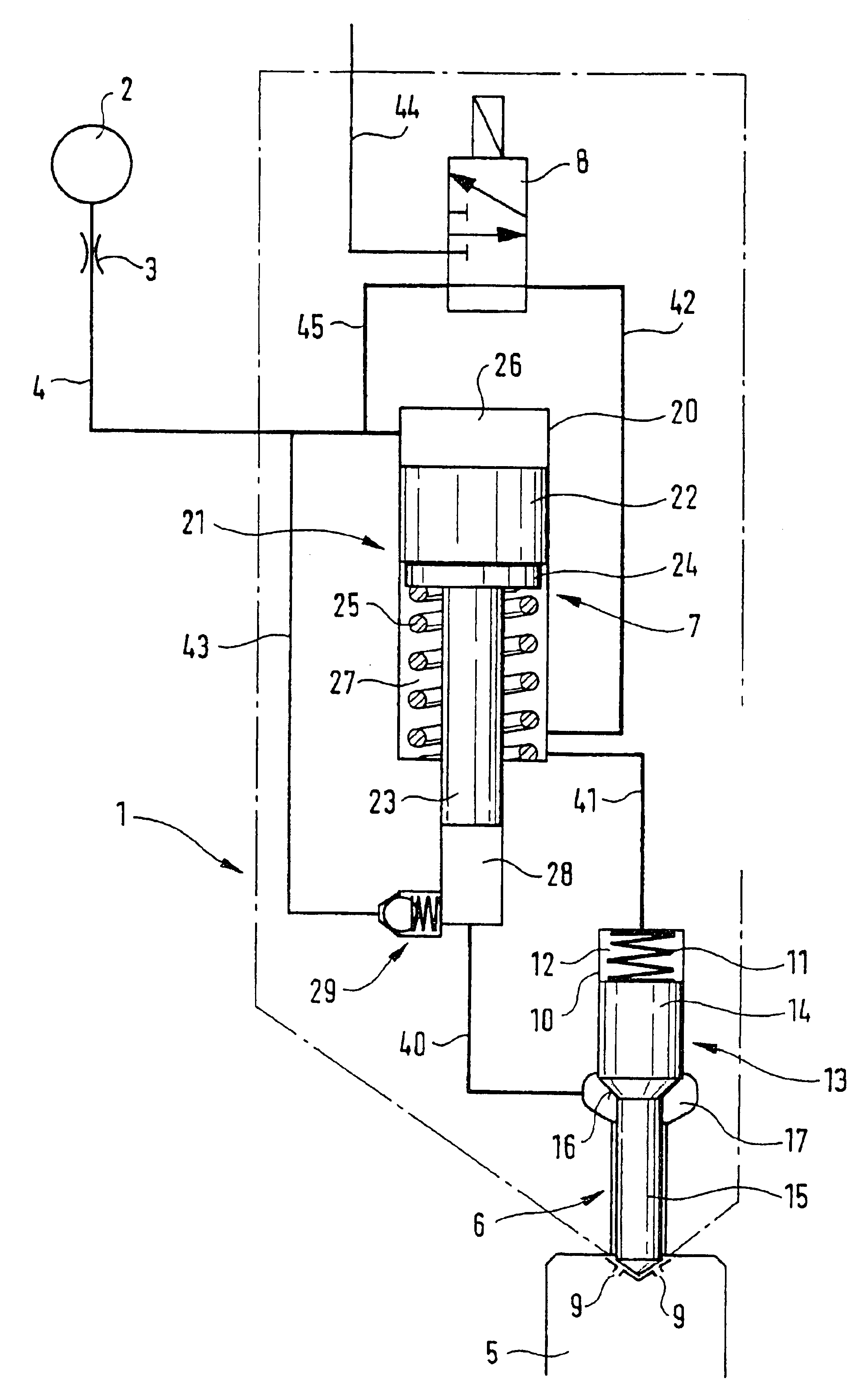

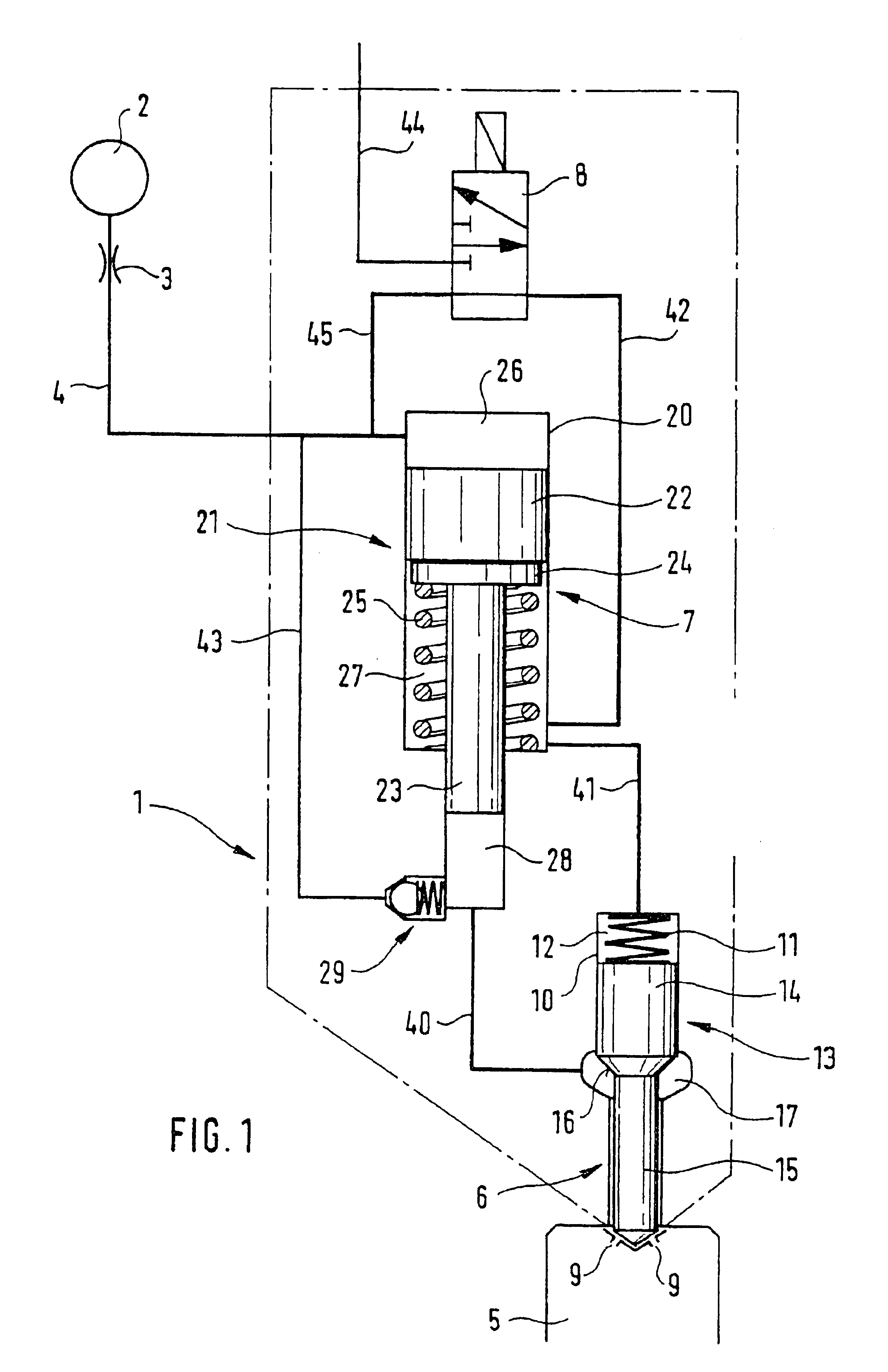

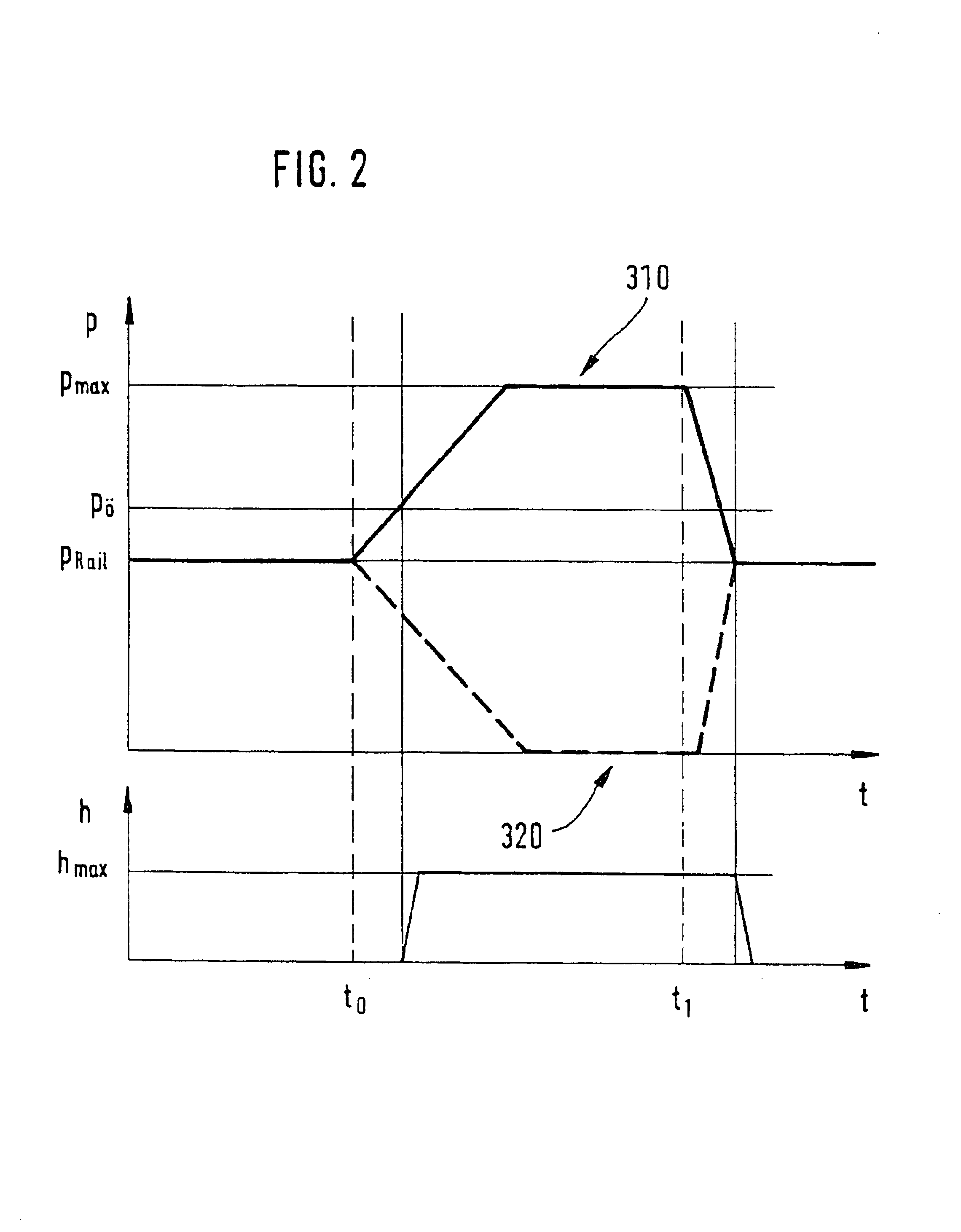

Fuel injection device

InactiveUS6880527B2Low pressure boosting ratioHighly dynamic pressure buildupFuel injection with piezoelectric/magnetostrictive elementsMachines/enginesCombustionEngineering

A fuel injection system for internal combustion engines includes an injector supplied from a high-pressure fuel source and with a pressure booster device, in which the closing piston can be acted upon by fuel pressure to attain a force exerted on the closing piston in the closing direction, and in which the closing pressure chamber and the return chamber of the pressure booster device are formed by a common closing pressure return chamber, and all the portions of the closing pressure return chamber communicate with one another permanently for exchanging fuel, so that despite a low pressure boost by the pressure booster device, a relatively low injection opening pressure is attainable.

Owner:ROBERT BOSCH GMBH

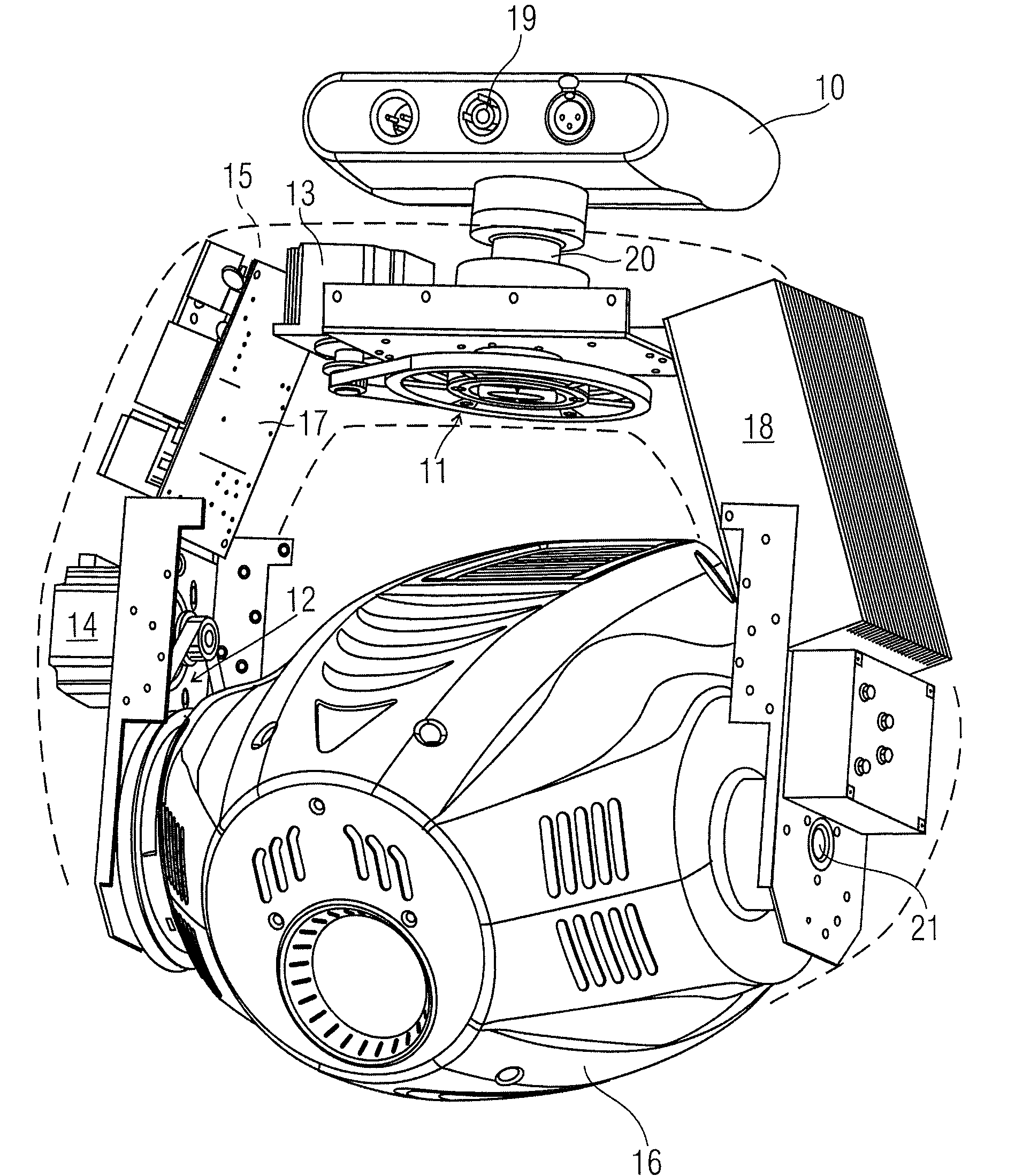

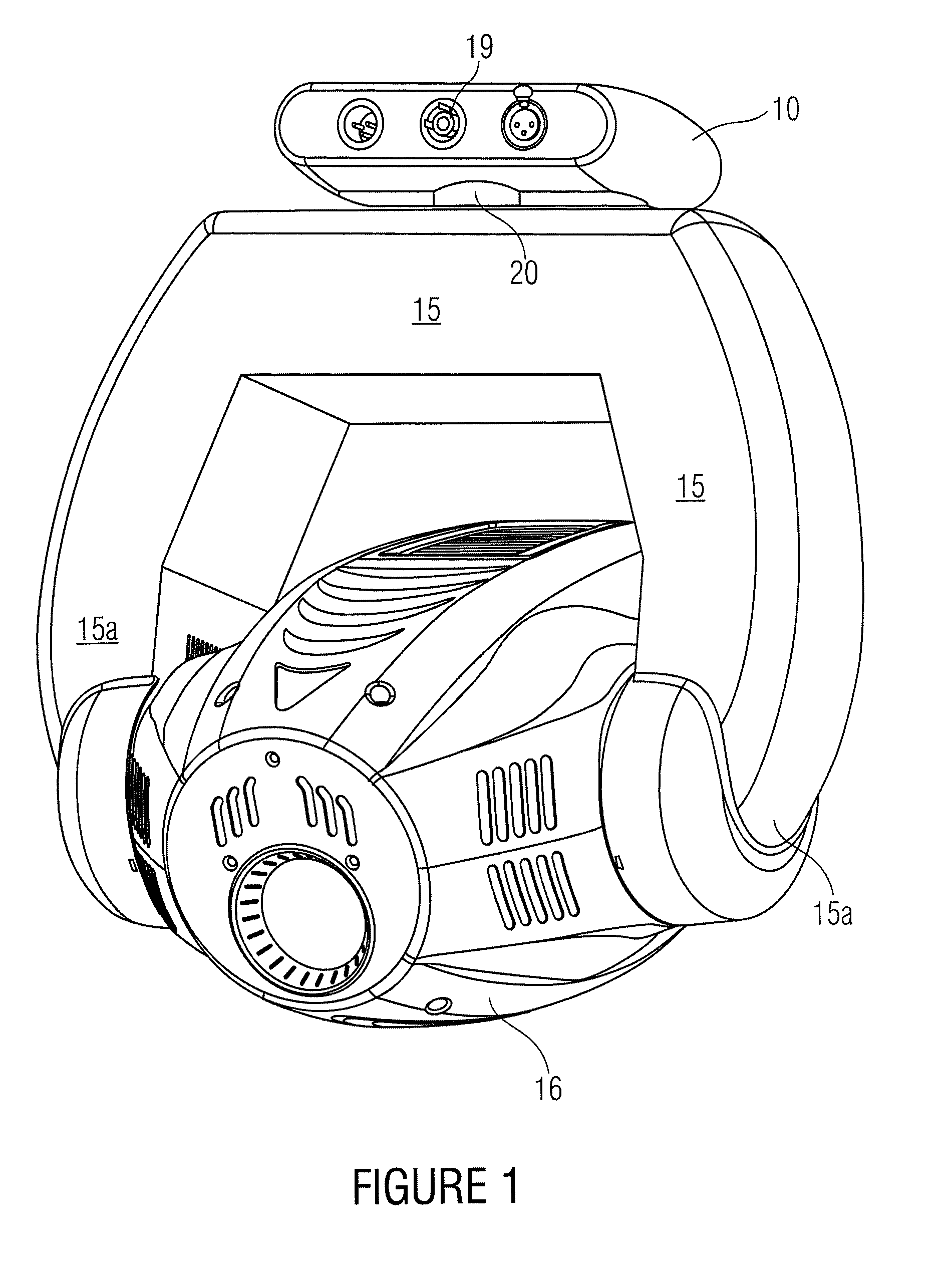

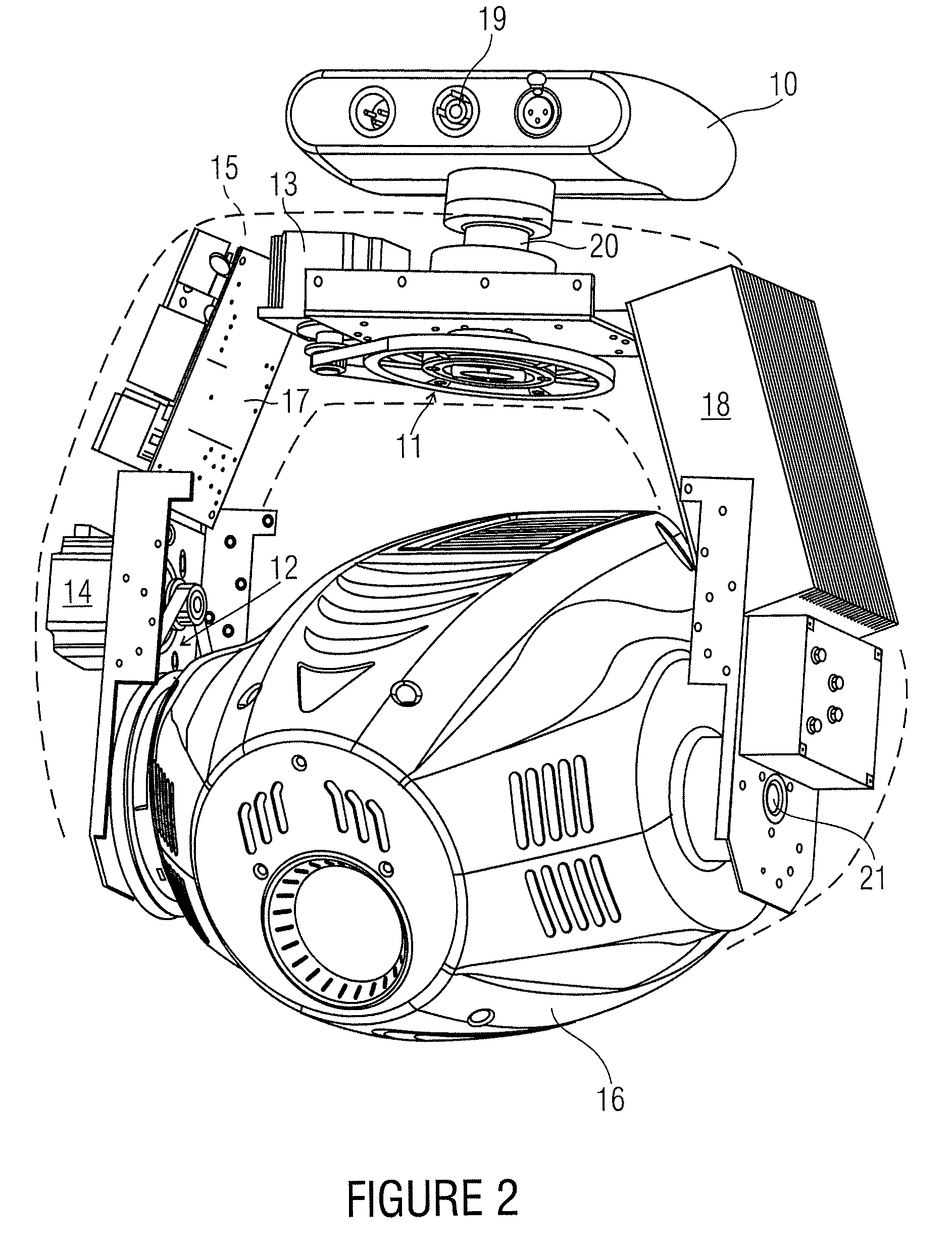

Device for influencing a light beam in particular for stage illumination

ActiveUS8096684B2Small sizeGood lookingLighting applicationsMechanical apparatusControl electronicsLight beam

Owner:GLP GERMAN LIGHT PRODS

Apparatus for the transfer of rod-shaped articles

InactiveUS7281621B2Reduce expenditureAvoid constantCigar manufactureCigarette manufactureEngineeringMechanical engineering

Owner:HAUNI MASCHINENBAU AG

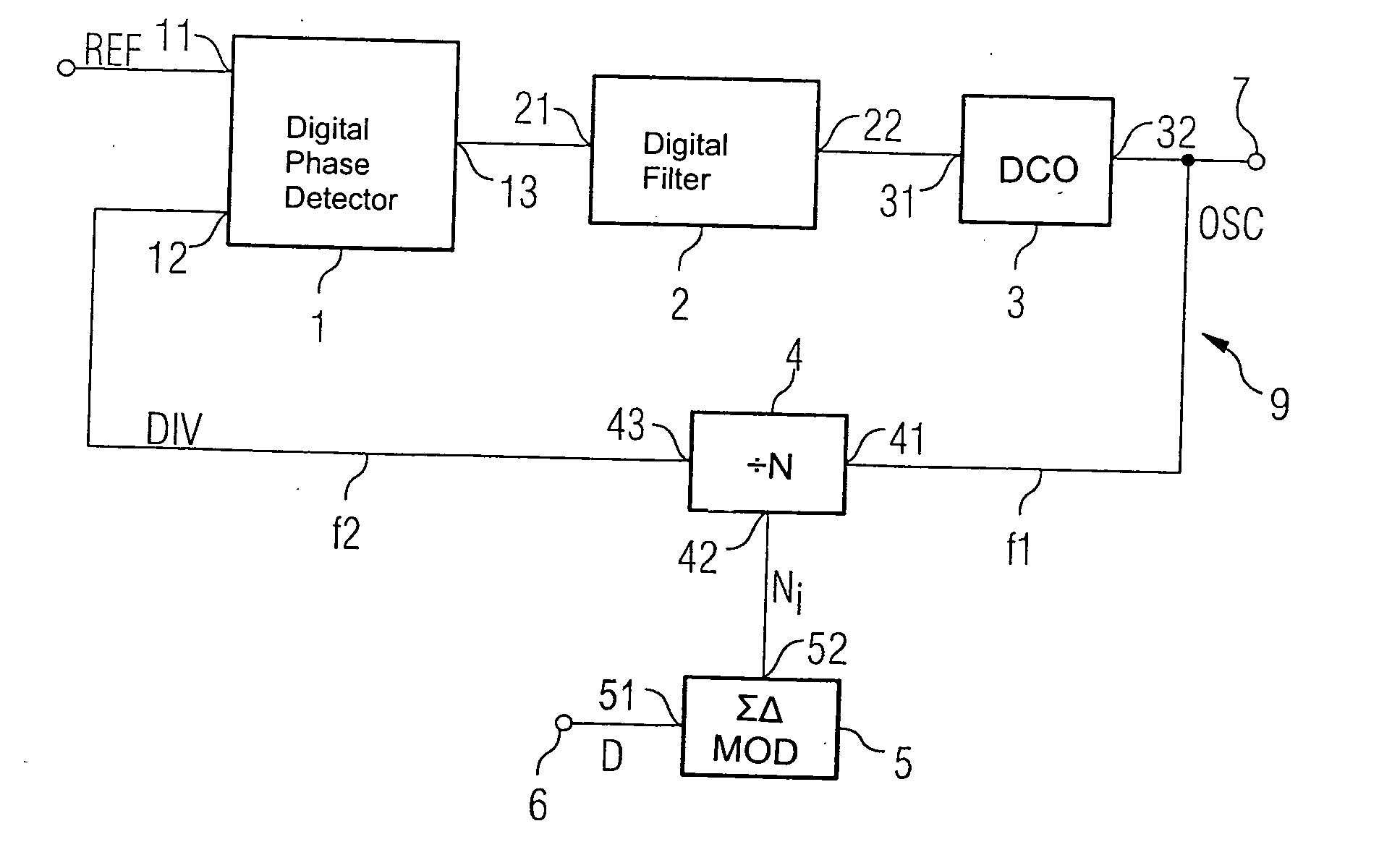

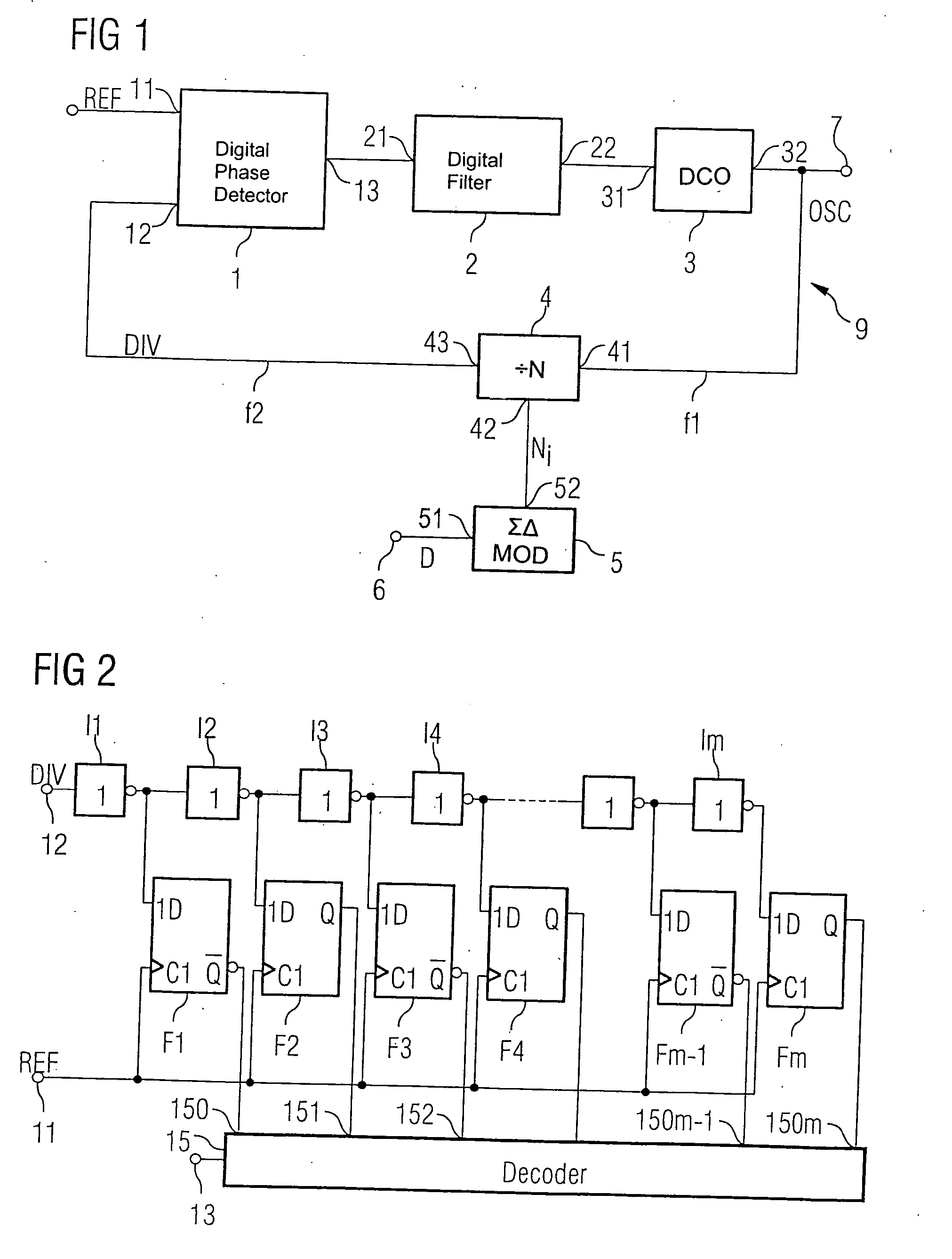

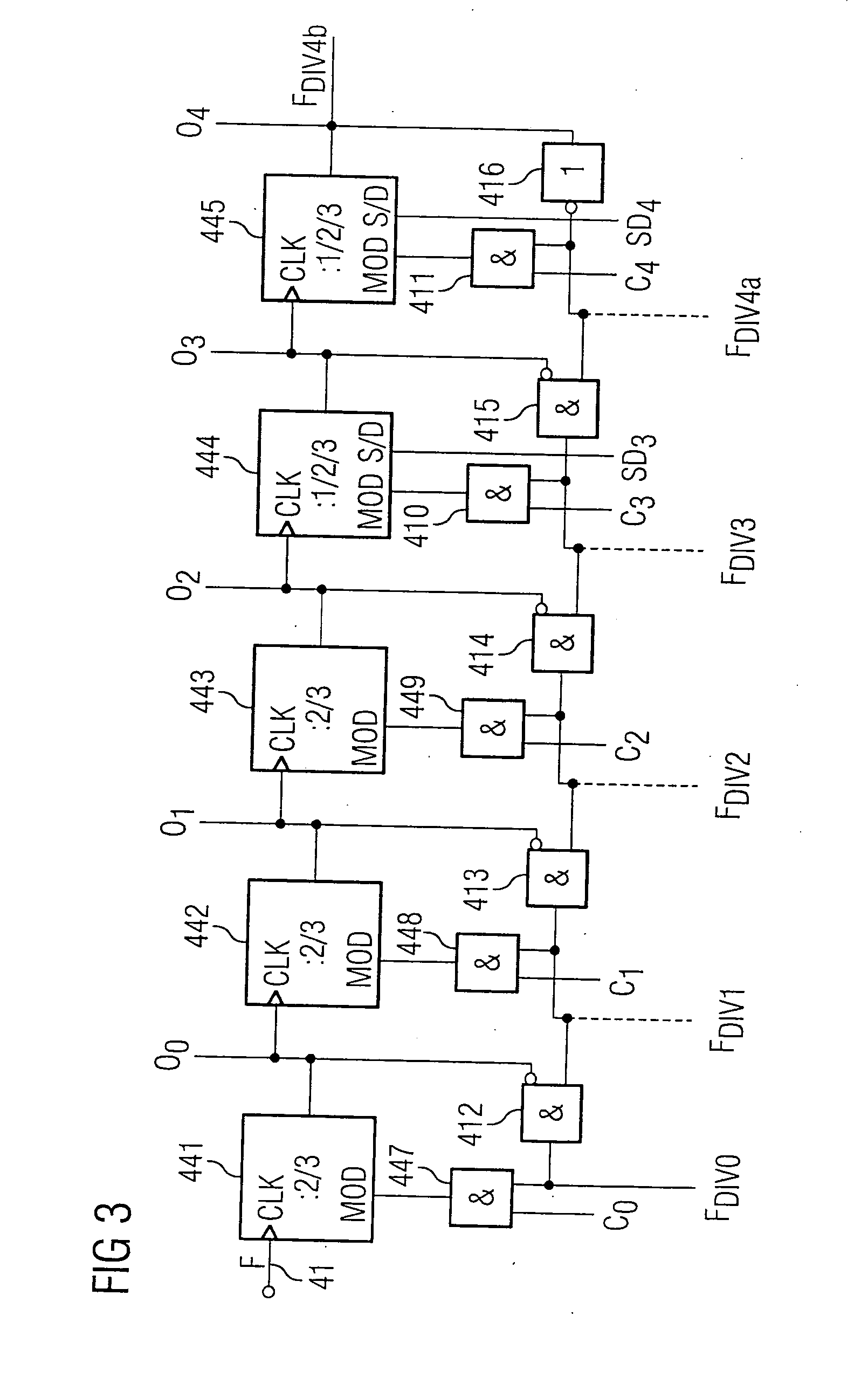

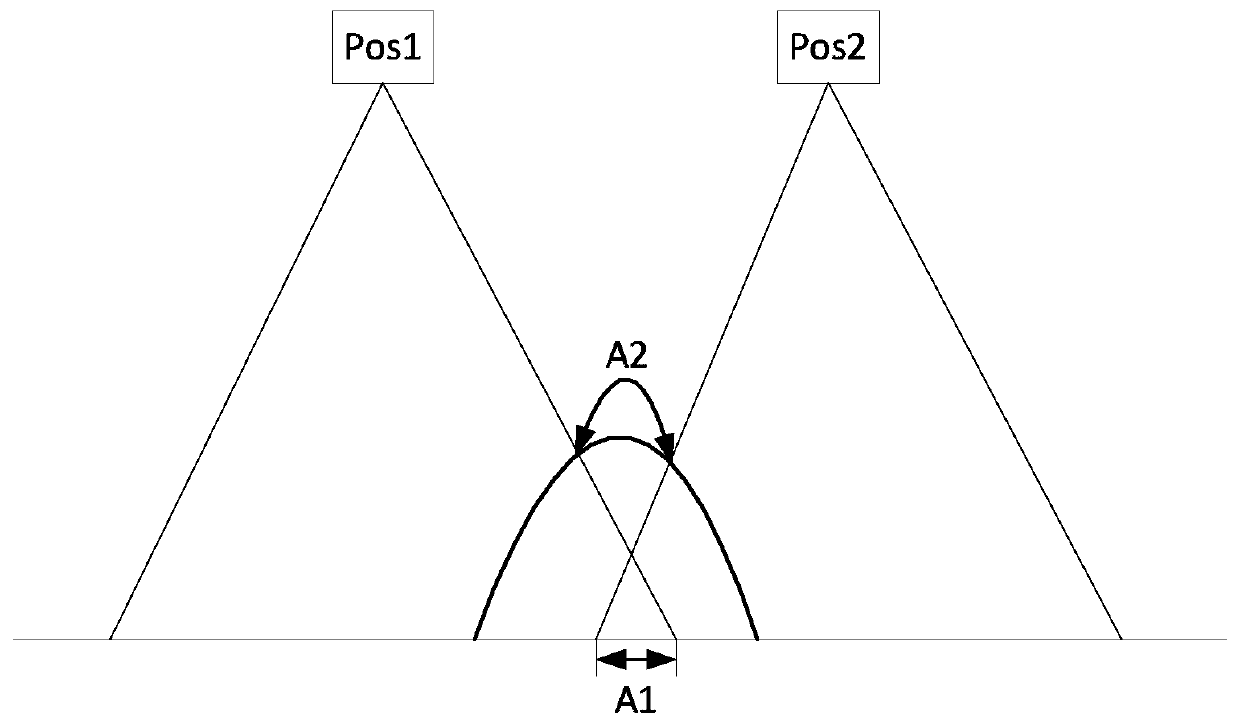

Digital phase locked loop, method for controlling a digital phase locked loop and method for generating an oscillator signal

InactiveUS20070008040A1Improve stabilityAvoid constantPulse automatic controlCounting chain pulse countersPhase detectorDigital filter

A digital phase locked loop includes a digital phase detector, a downstream digital filter and an oscillator. In addition, a frequency divider resides in a feedback path and has an actuating input for setting a divider ratio, the input of which is connected to the oscillator and the phase detector. The phase locked loop comprises a sigma-delta modulator having a data input for supplying a data word and having an actuating output for supplying a frequency setting word to the actuating input of the frequency divider. The data word is configured such that the sigma-delta modulator generates jitter in the frequency setting word, with the result that the signal which is applied to the feedback input of the phase detector is not constant over a relatively long period of time.

Owner:INFINEON TECH AG

Instruction converting device for loopback rescue of D-series high-speed train

ActiveCN109677385AAchieve mutual rescueSimple interfaceBraking action transmissionBrake safety systemsRelay valveExhaust valve

The invention discloses an instruction converting device for the loopback rescue of a D-series high-speed train. The instruction converting device comprises an electronic control unit, wherein a pressure sensor is connected to an input end of the electronic control unit, an electric pneumatic switching valve is connected to an output end of the electronic control unit and is connected with a totalwind pipe and a relay valve, respectively, the relay valve is connected with a mode switching valve and the total wind pipe, respectively, and the mode switching valve is connected with a train pipeand the total wind pipe, respectively; an emergent exhaust valve is connected with the total wind pipe and the train pipe, respectively; and an air cylinder is connected to the train pipe, a pressuresensor is connected to the air cylinder and is used for collecting the pressure of the train pipe and inputting a pressure signal to the electronic control unit. According to the instruction converting device, the mutual function between a single-pipe braking D-series high-speed train and a double-pipe braking D-series high-speed train is realized; and an interface of the device is simple, and theintegration level of the device high.

Owner:NANJING CRRC PUZHEN HAITAI BRAKE EQUIP CO LTD

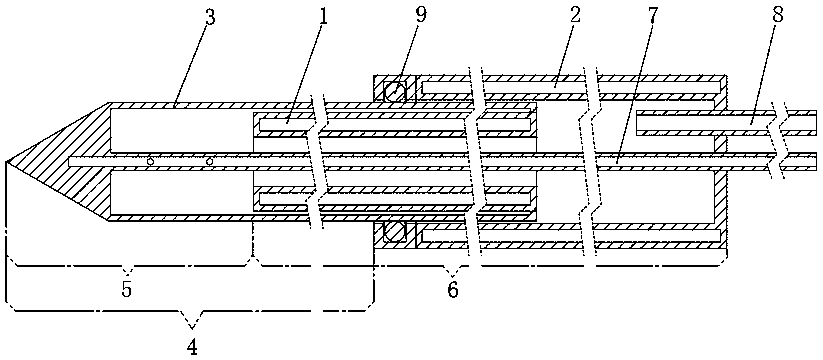

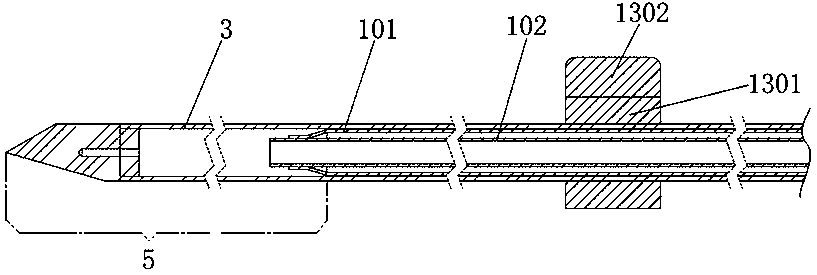

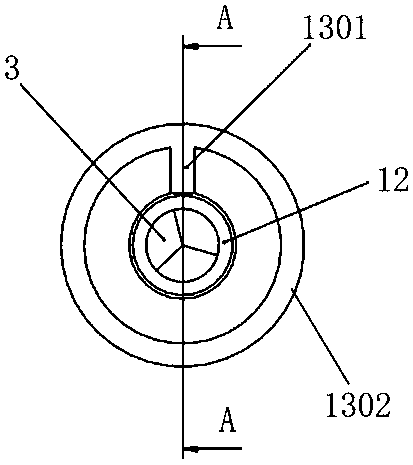

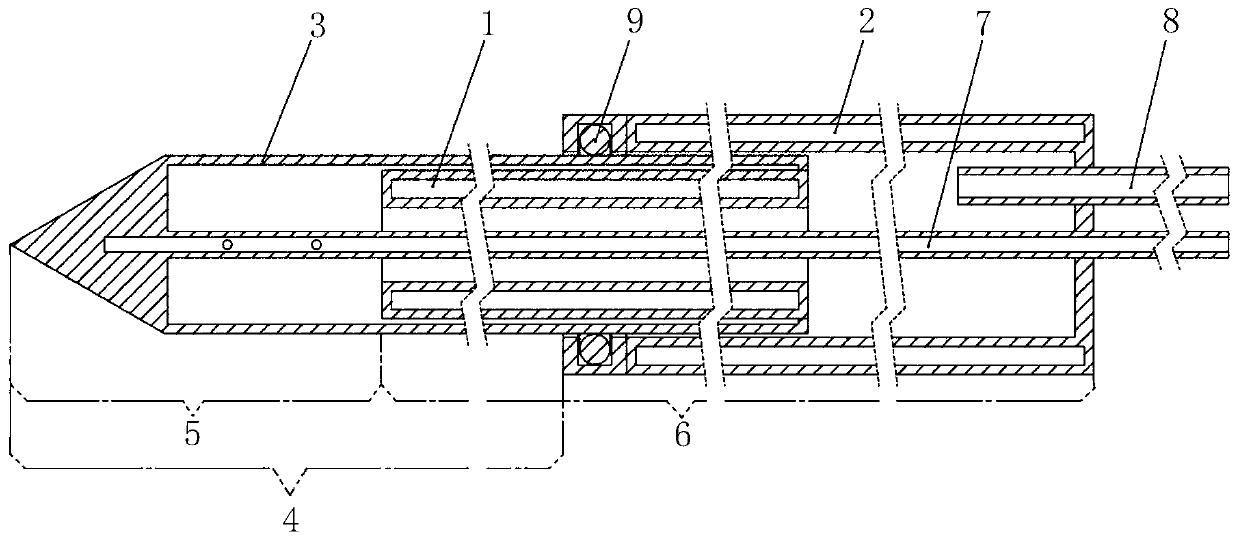

Adjustable cryoablation needle

ActiveCN110251224AAvoid bendingAvoid constantDiagnosticsSurgical instruments for coolingAbnormal tissue growthEngineering

The invention provides an adjustable cryoablation needle, comprising a shank, a front heat-insulating tube, a rear heat-insulating tube and an intake structure penetrating the shank and the front heat-insulating tube; the shank can move along the axis of the rear heat-insulating tube relative to the rear heat-insulating tube so as to adjust a first axial distance between the front end of the rear heat-insulating tube and the front end of the shank; the front heat-insulating tube can move along the axis of the rear heat-insulating tube relative to the rear heat-insulating tube so as to adjust a second axial distance between the front end of the front heat-insulating tube and the front end of the rear heat-insulating tube. The adjustable cryoablation needle helps prevent the inconveniences caused by surgeons selecting cryoablation needle types, can adapt fully to different entering depths, allows the length of the exposed shank to be as small as possible to prevent bending of the shank and prevent the injury risks, such as tear of human tissues. The adjustable cryoablation needle herein can also further meet conveniently the treatment needs of tumors of different sizes at the premise of satisfying different entering depths.

Owner:ACCUTARGET MEDIPHARMA (SHANGHAI) CO LTD

Infrared induction based non-contact novel dustbin

InactiveCN105584758AAvoid pollutionAvoid the problem of mosquito breedingWaste collection and transferRefuse receptaclesControl systemEngineering

An infrared induction based non-contact novel dustbin comprises a barrel cover; a control chip is arranged in the barrel cover; an infrared inductor and a distance induction sensor are arranged outside the barrel cover; a dynamo electric gear is arranged in a connecting portion between the barrel cover and the barrel body; the top of the barrel cover is provided with a solar panel; when people throw garbage to the dustbin, the dustbin can sense hand approaching, and the built in control system can automatically open the barrel cover; when the people is sensed to leave, the barrel cover can be automatically closed; in addition, the garbage level in the barrel can be detected so as to obtain present garbage volume, and different colors of an indication lamp on the barrel cover can display different volumes; when the dustbin is full, a prompt voice can be given so as to remind people to timely clean; the novel dustbin is intelligent, environmental protective, and energy saving.

Owner:XIAN INTEVIEW INFORMATION & TECH

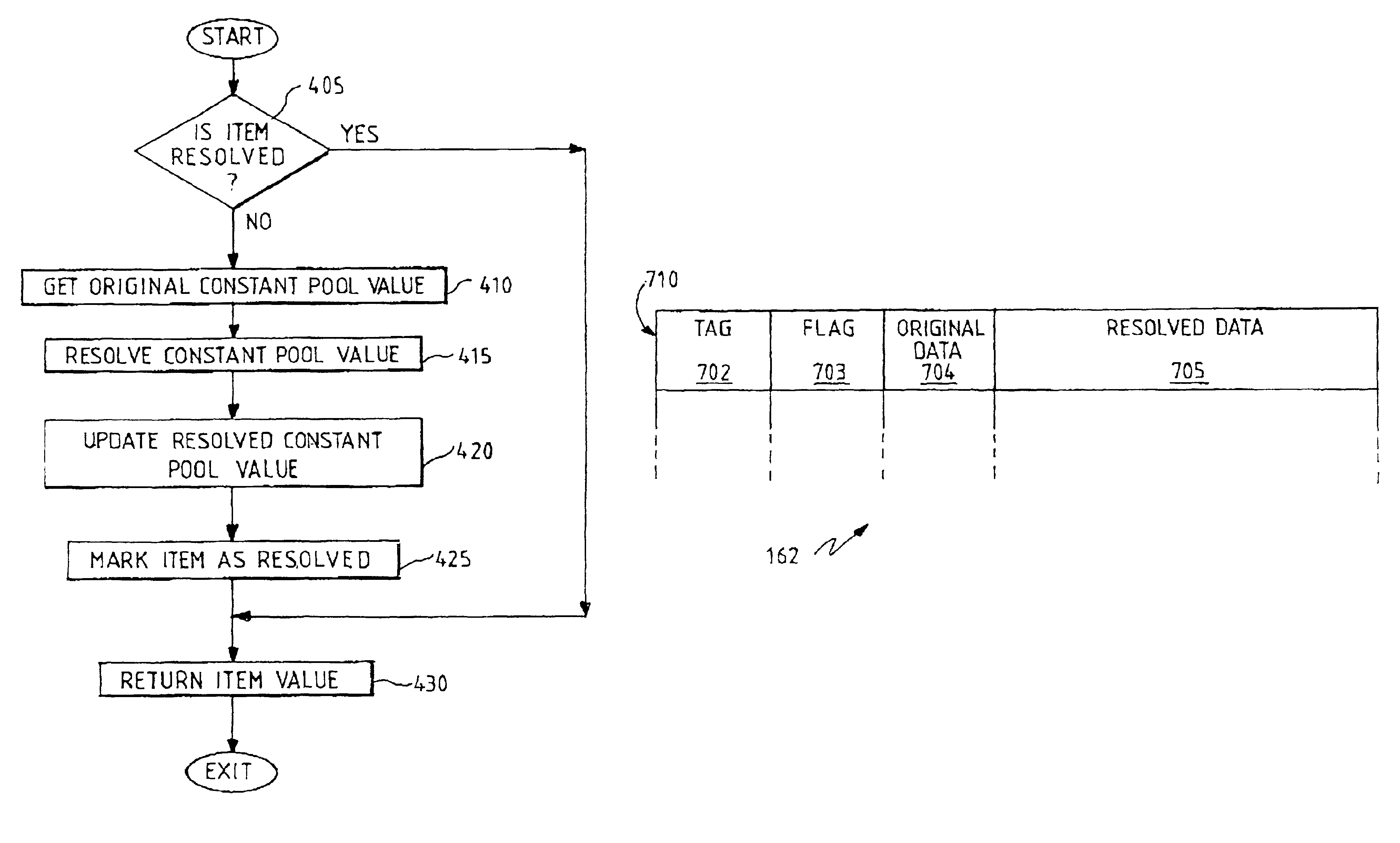

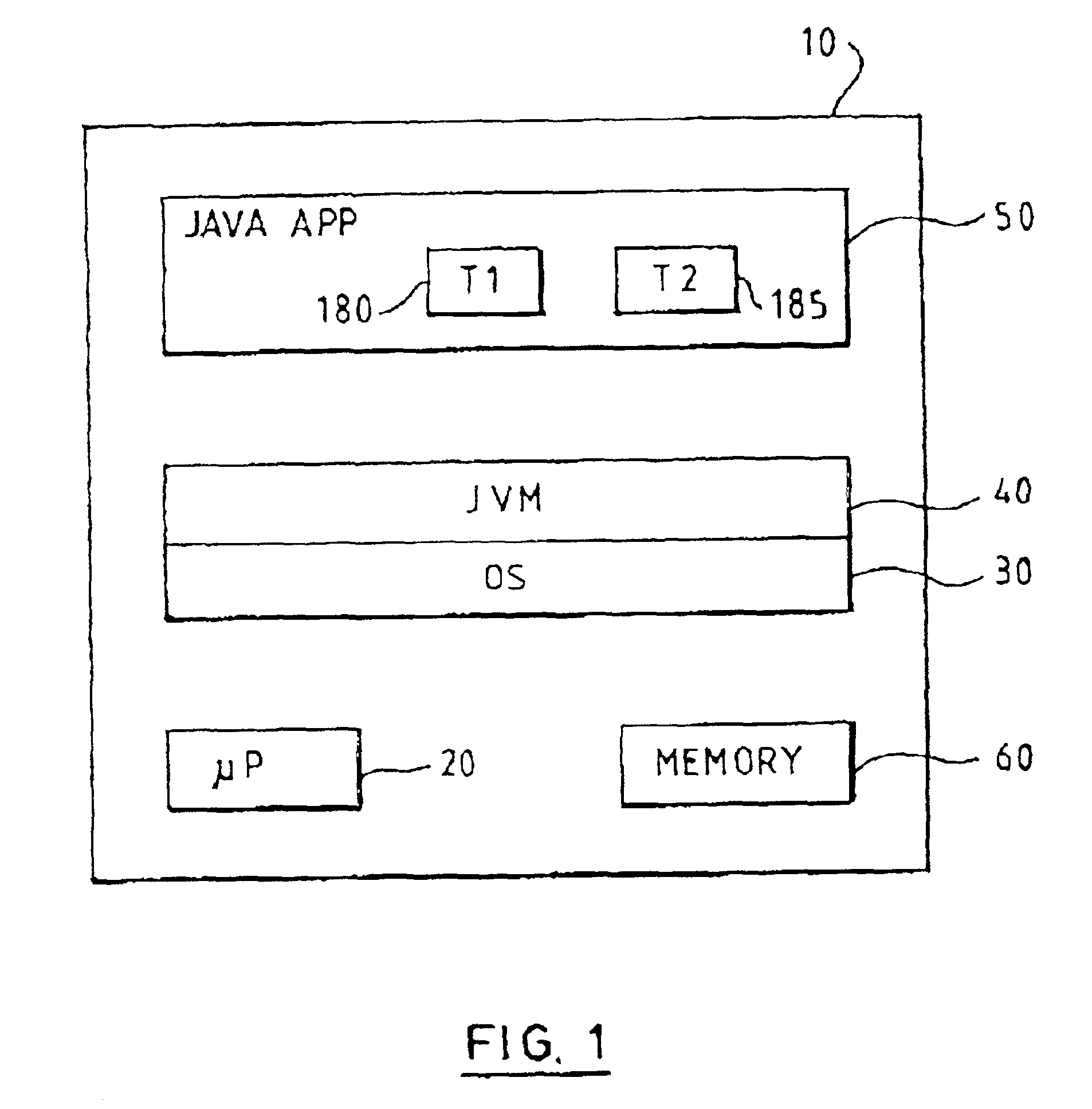

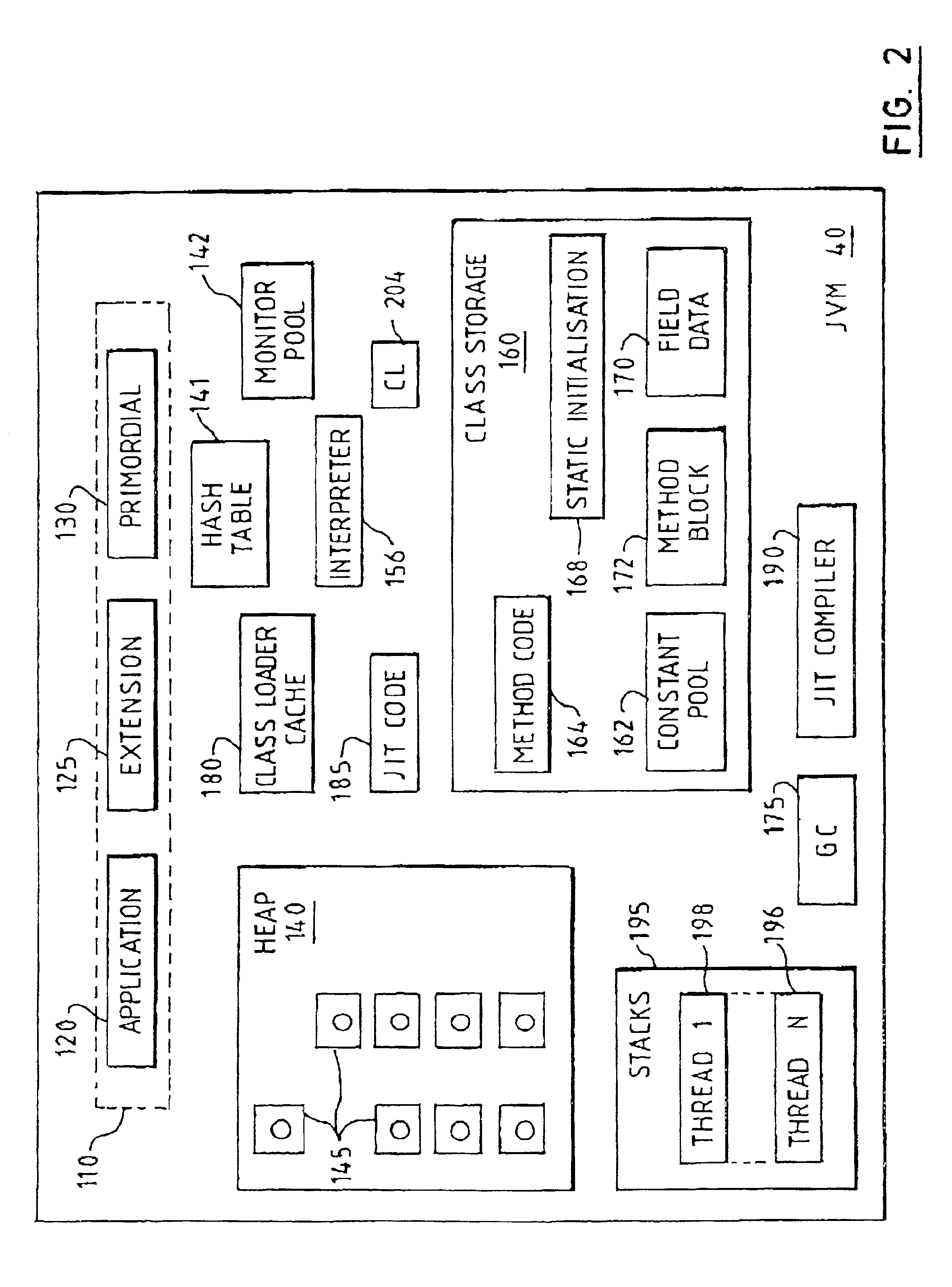

Computer system and method for constant pool operations

InactiveUS6934944B2Improve efficiencyImprove scalabilityProgram loading/initiatingMemory systemsImage resolutionComputerized system

A computer system has one or more program classes loaded in it. Each class includes a constant pool which is used for storing data items related to the program class. At least some of these data items need to undergo a resolution before they can be used, which transforms them from their initially loaded value into a usable value. In accordance with the invention, the system maintains both the unresolved value and the resolved value in the constant pool entry for a resolved data item. This allows the resolution process to be performed without using locks, thereby avoiding potential system delays due to contention for locks.

Owner:INTELLECTUAL DISCOVERY INC

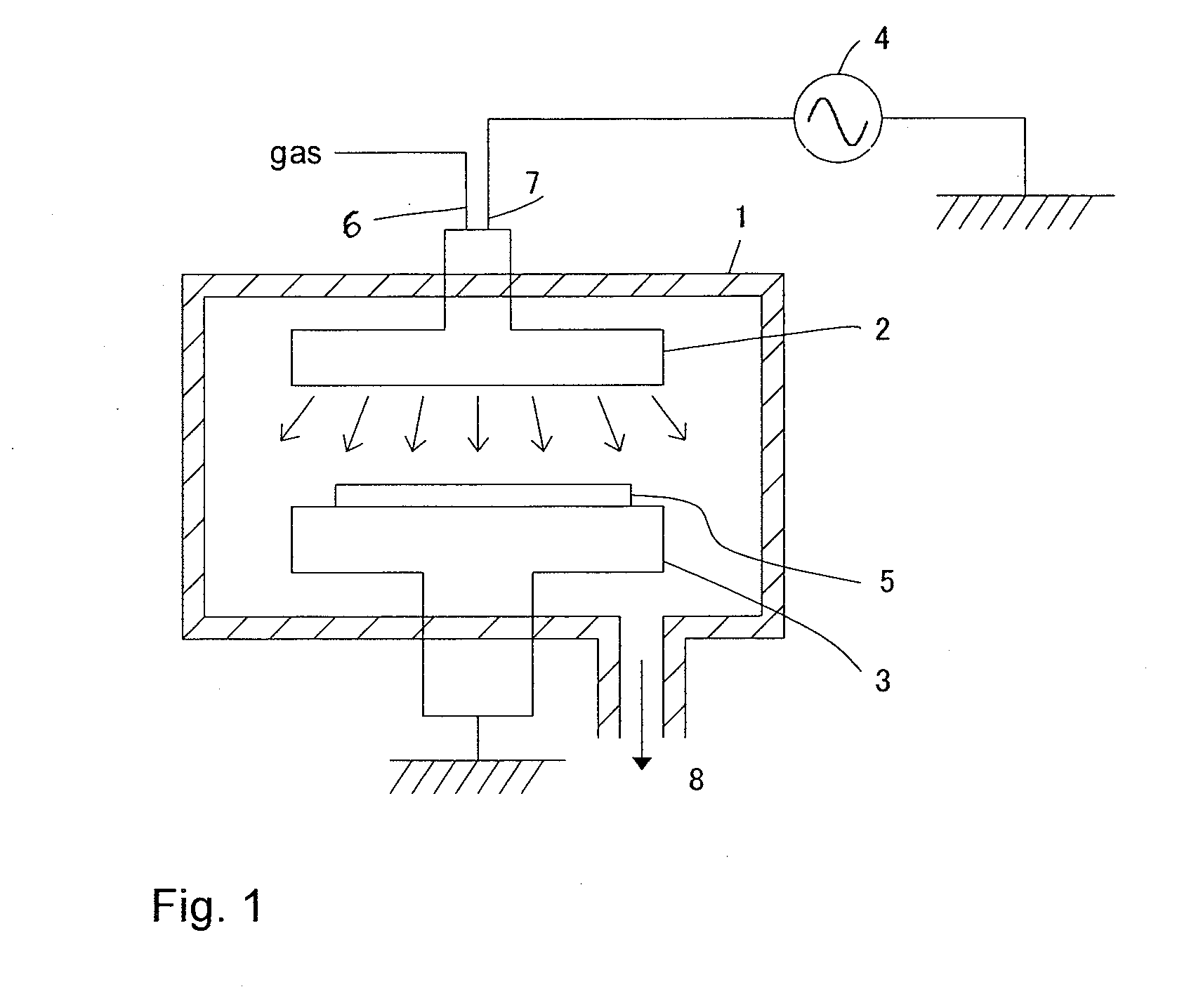

Method of cleaning semiconductor substrate conductive layer surface

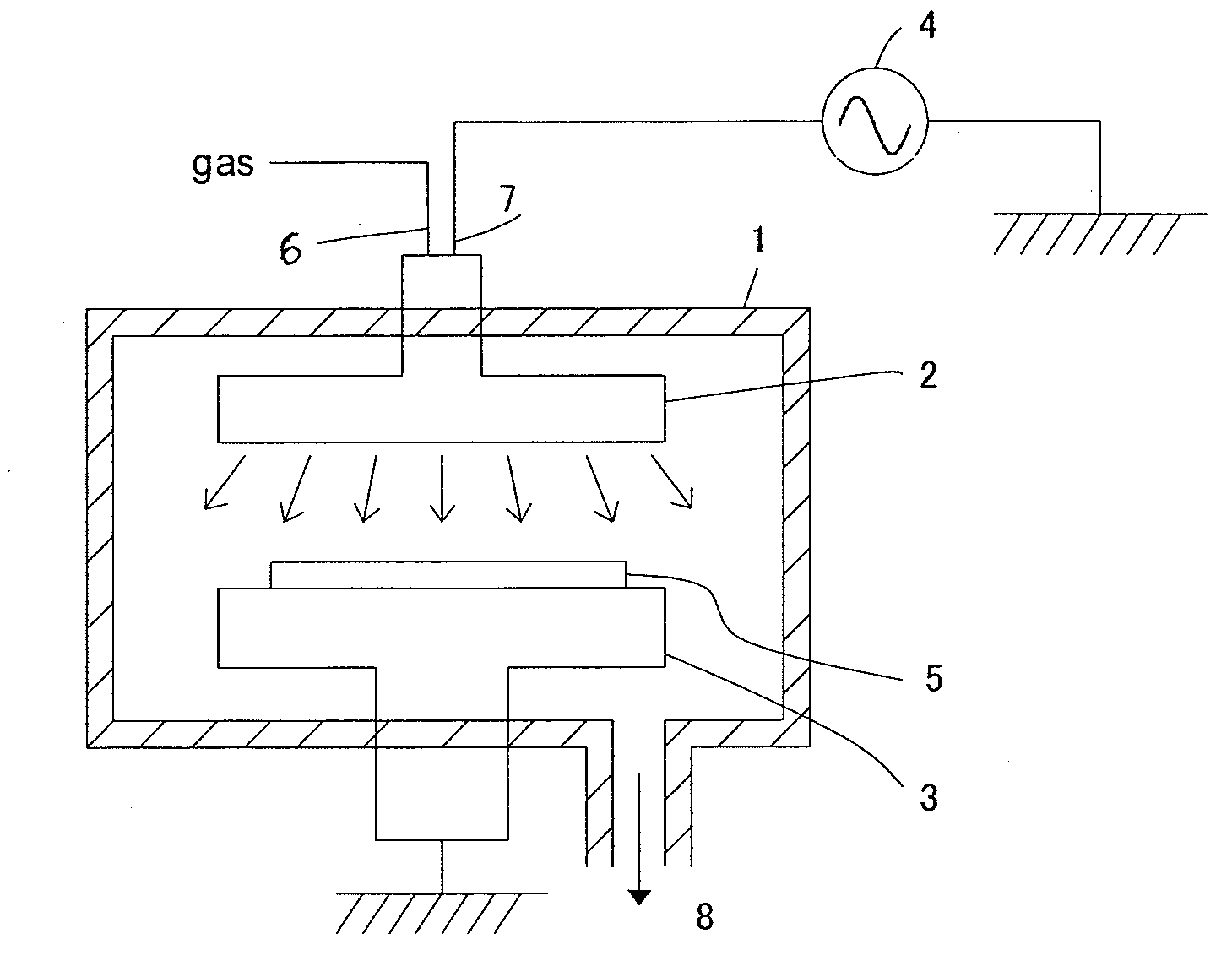

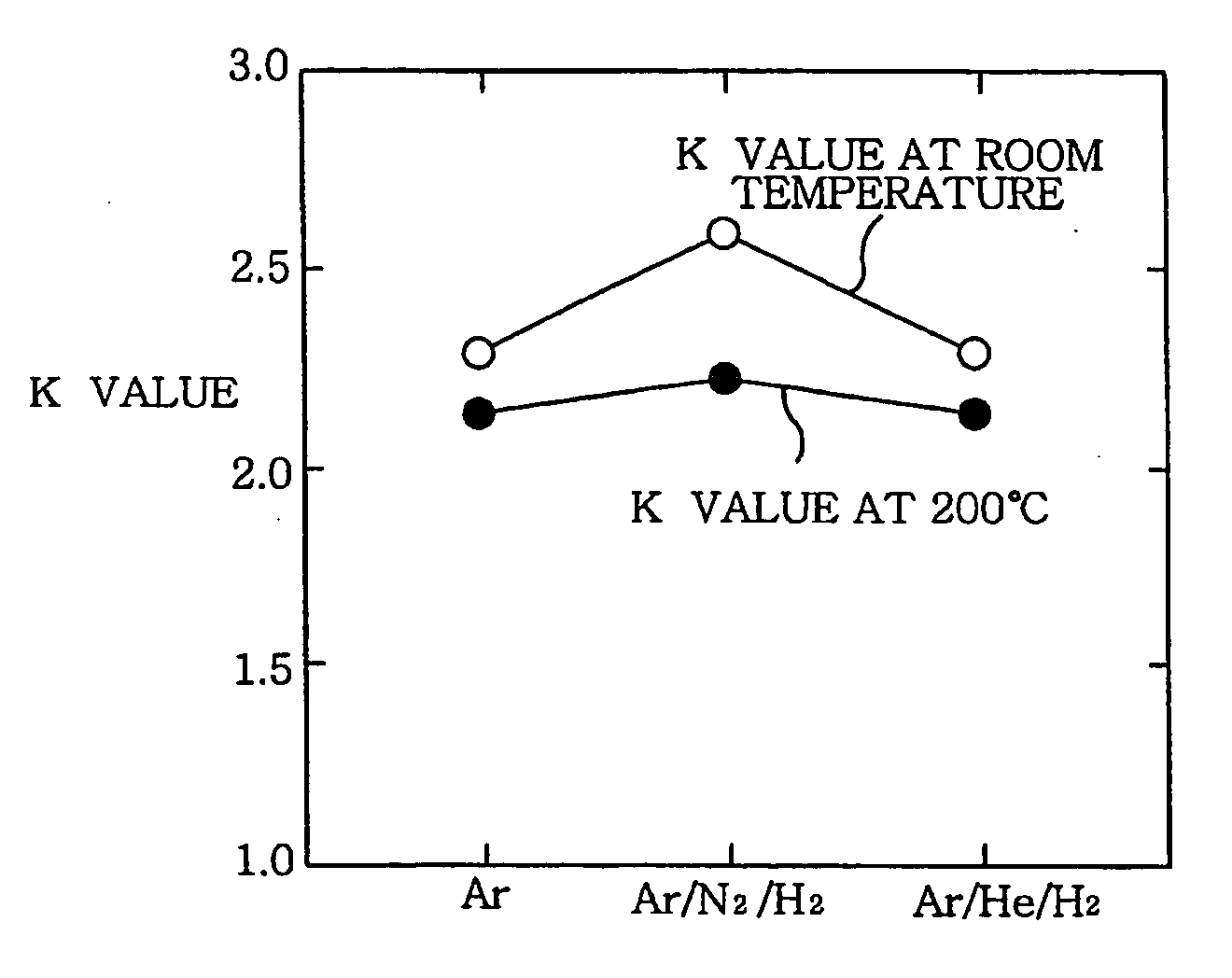

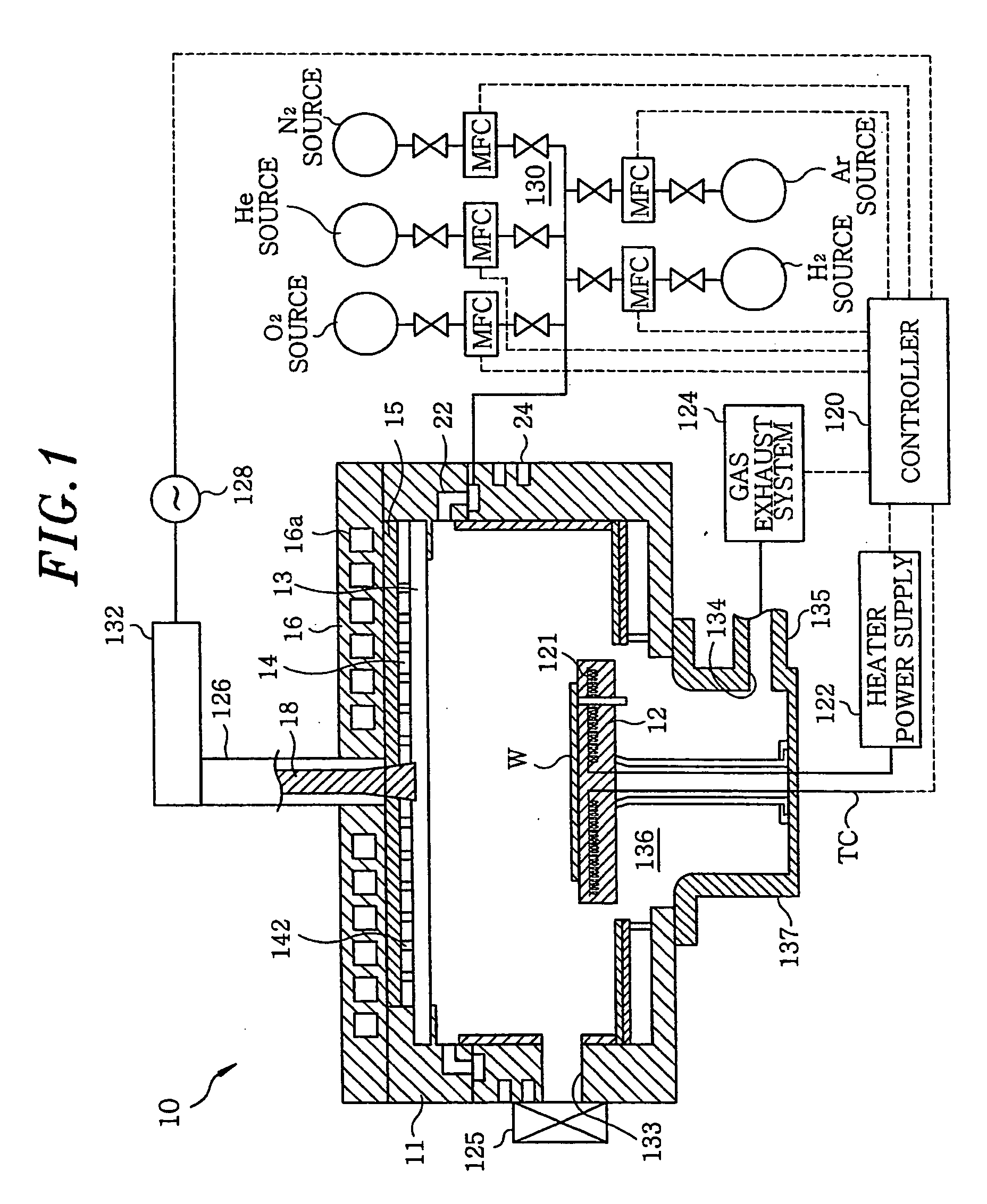

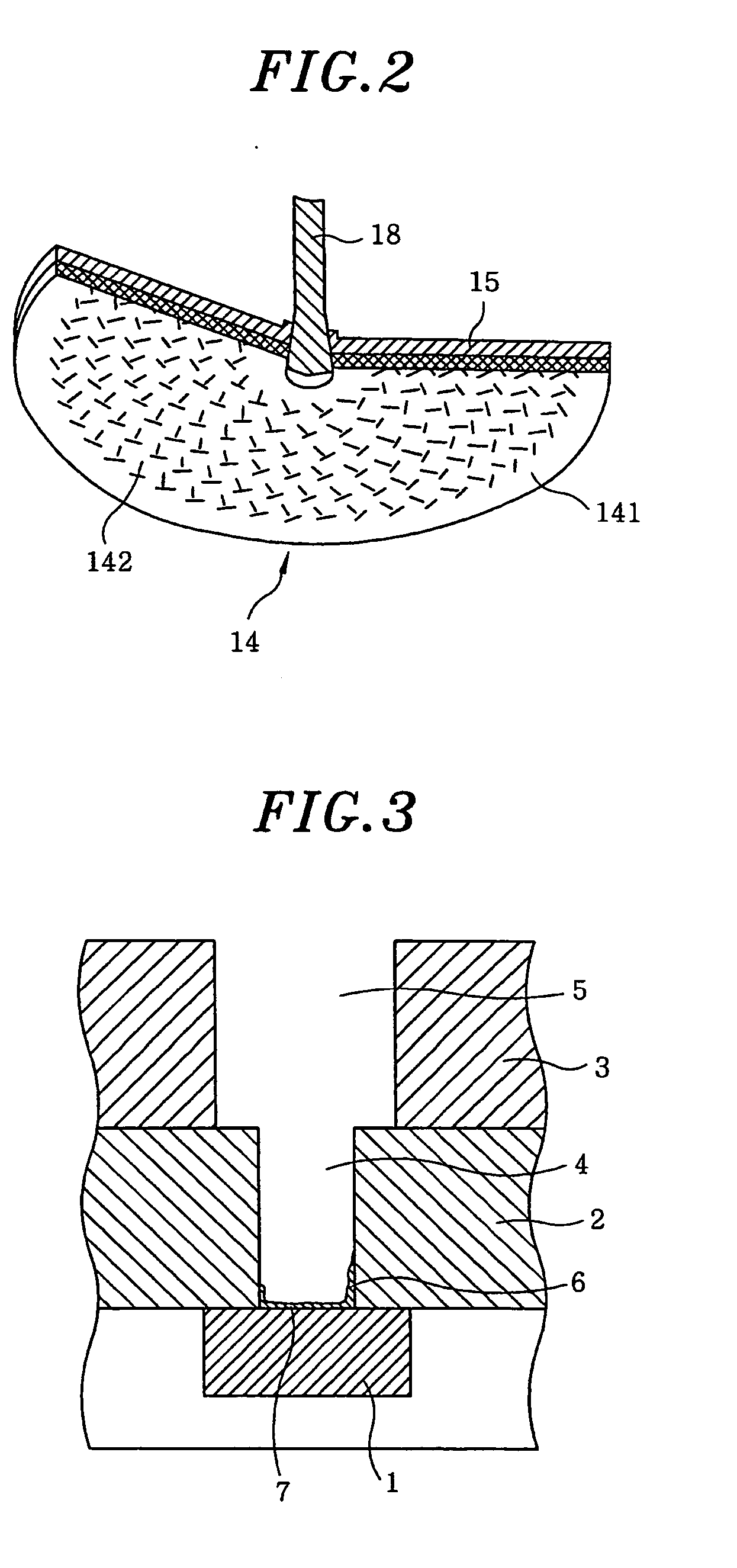

InactiveUS20070111528A1Preventing damage sideFully removedElectric discharge tubesSemiconductor/solid-state device manufacturingHydrogenDevice material

A method of cleaning a semiconductor substrate conductive layer surface that can remove a residual organic material and a natural oxide satisfactorily and does not adversely affect a k value without damaging the side-wall insulation film of a via hole. A semiconductor device, including insulation films formed on the surface of a conductive layer of a semiconductor substrate and a via hole formed in an insulation film to partly expose the conductive layer, is carried into a reaction vessel, plasma including hydrogen is generated in the reaction vessel to clean the surface of the conductive layer at the bottom of the via hole, a residual organic material is decomposed and removed by ashing, and a copper oxide film on the surface of the conductive layer is reduced to Cu.

Owner:TOKYO ELECTRON LTD

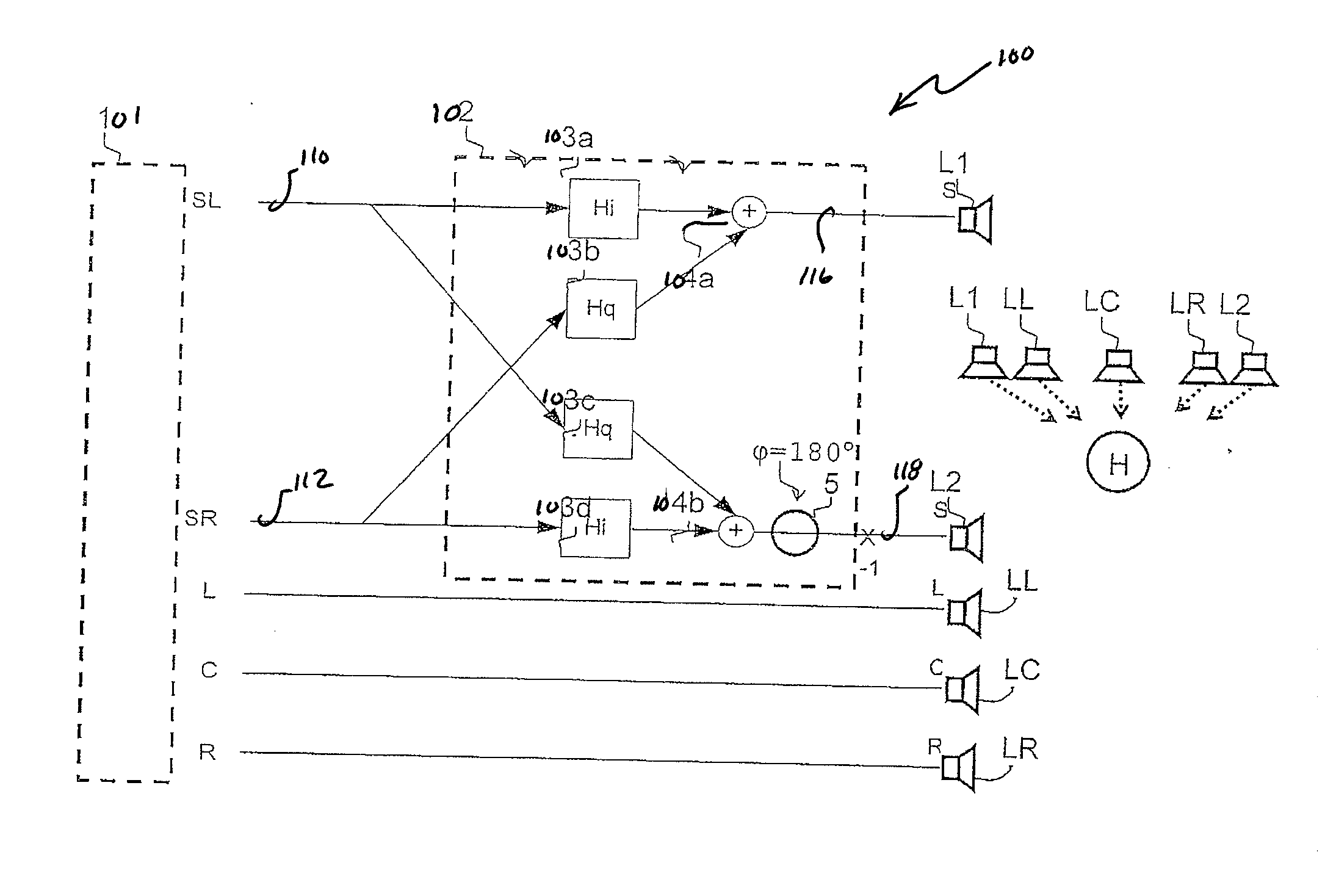

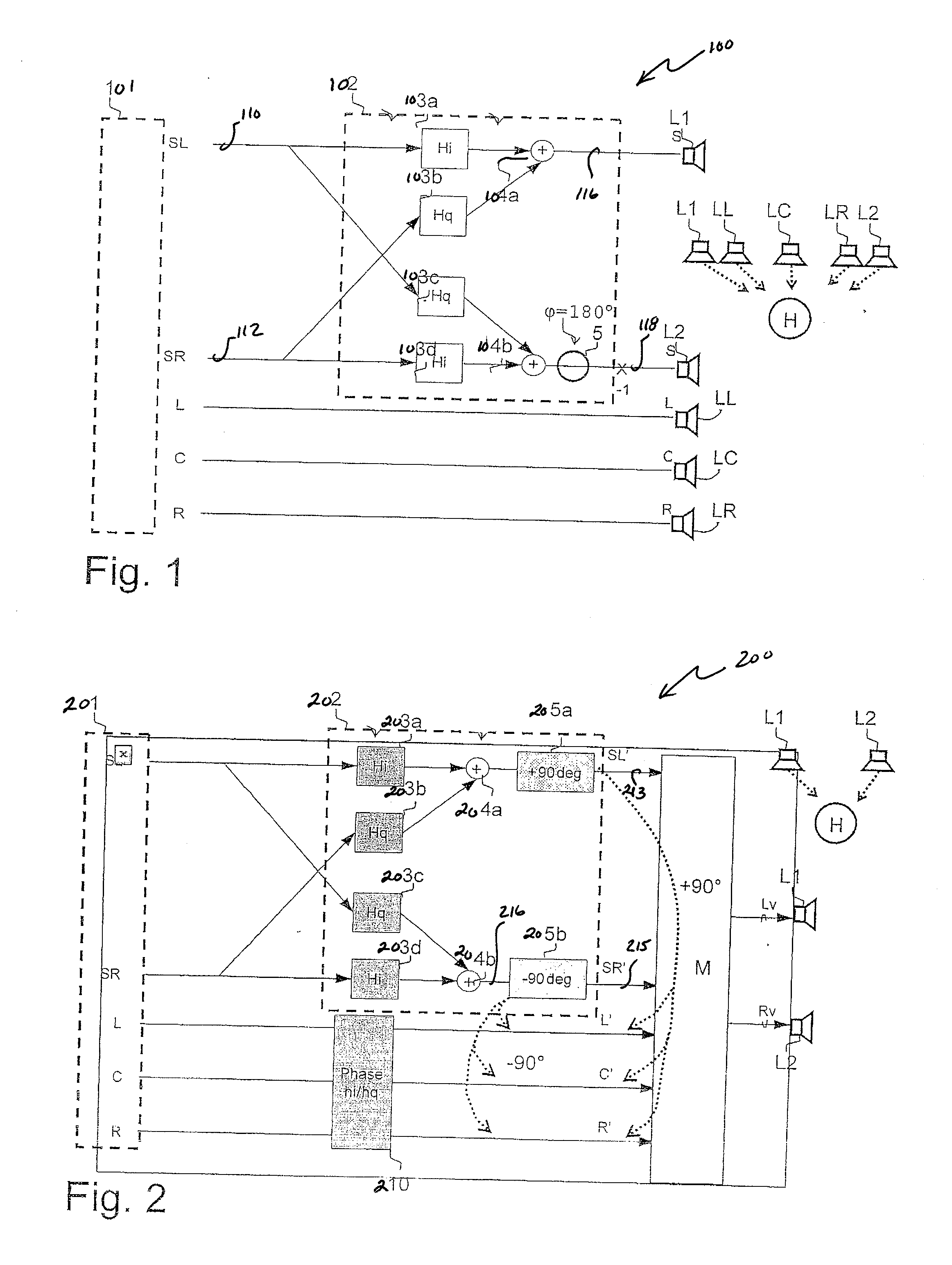

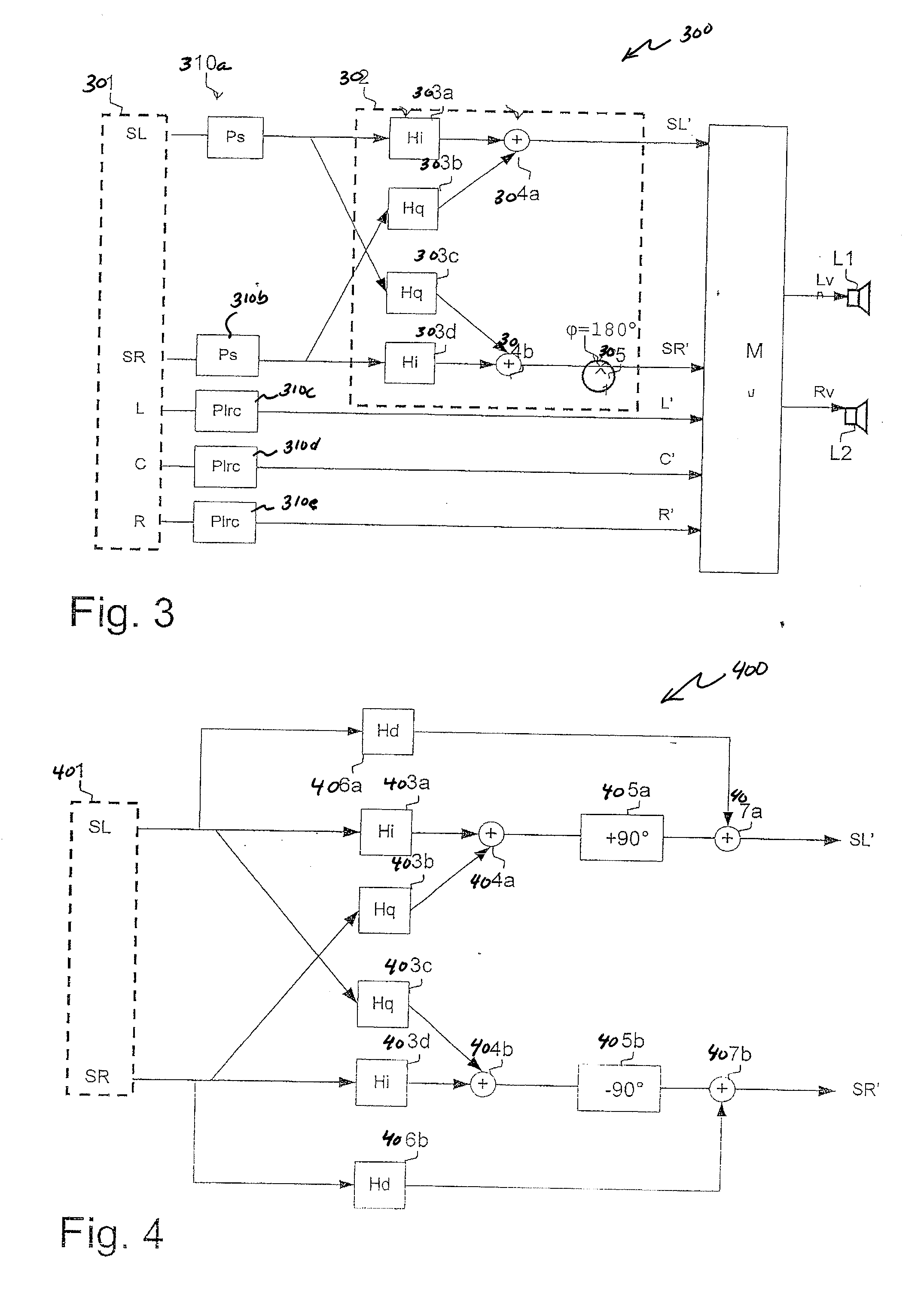

Device and Method for Producing a Surround Sound

InactiveUS20090285420A1Large spacingReduce complexityLoudspeaker spatial/constructional arrangementsStereophonic systemsPhase shiftedEngineering

A surround sound audio processing system includes a source that supplies a first signal for producing a first sound impression and a second signal for producing a second sound impression. A processing unit modifies the first signal and the second signal to produce a third sound impression of a virtual source, and provides first and second modified signals indicative thereof. The processing unit modifies the first signal and the second signal relative to each other such that the first and second modified signals have a phase shift of between 170° to 190°.

Owner:ENTROPIC COMM INC

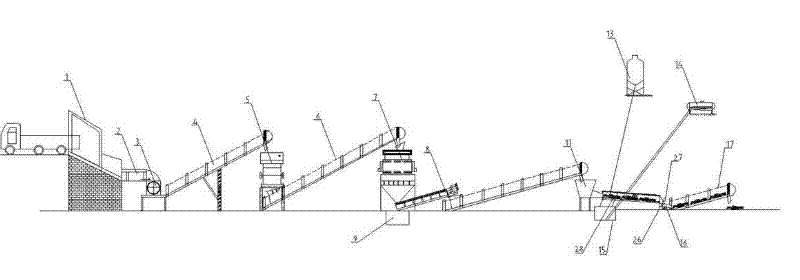

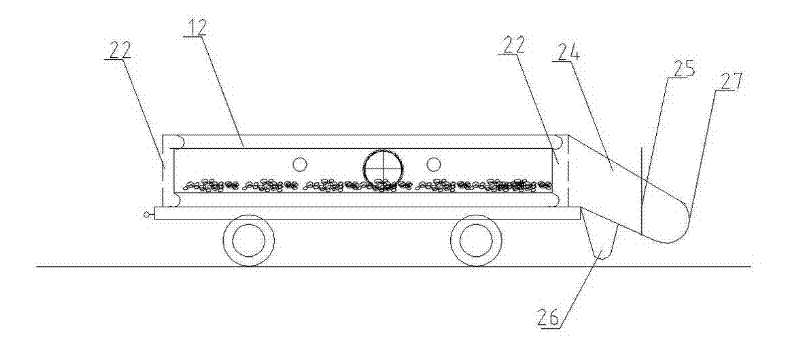

Reductive regeneration system and reductive regeneration process for pavement surface milling material

The invention relates to a reductive regeneration system and a reductive regeneration process for a pavement surface milling material. At present, most road milling materials in China are used as stones and used with cement or directly abandoned, and asphalt is wasted, for mainly the processing technology and the processing equipment are not matched with the road milling materials. The system comprises a decomposition and dust removal unit and an asphalt material reduction unit, wherein the decomposition and dust removal unit comprises a feed hopper, a vibratory feeder, a crude stripper, a first conveyor belt, a fine stripper, a second conveyor belt, a classifier, a material-water separator and a plurality of third conveyor belts; the asphalt material reduction unit comprises a mixed hopper, an asphalt material recovery coating vibration reciprocating stirrer and a cold material conveyor belt; and the mixed hopper consists of a plurality of hoppers. The system ensures that the components of asphalt are not changed and the asphalt can be recycled, is considerable in benefit, advanced in process, reasonable in structure, clean in decomposition, uniform in recovery coating, low in investment, good in use performance, multi-purpose, suitable for cold and hot materials and net in suction and discharge, does not leave wastes, and has high production efficiency.

Owner:西安砺研再生资源科技有限责任公司

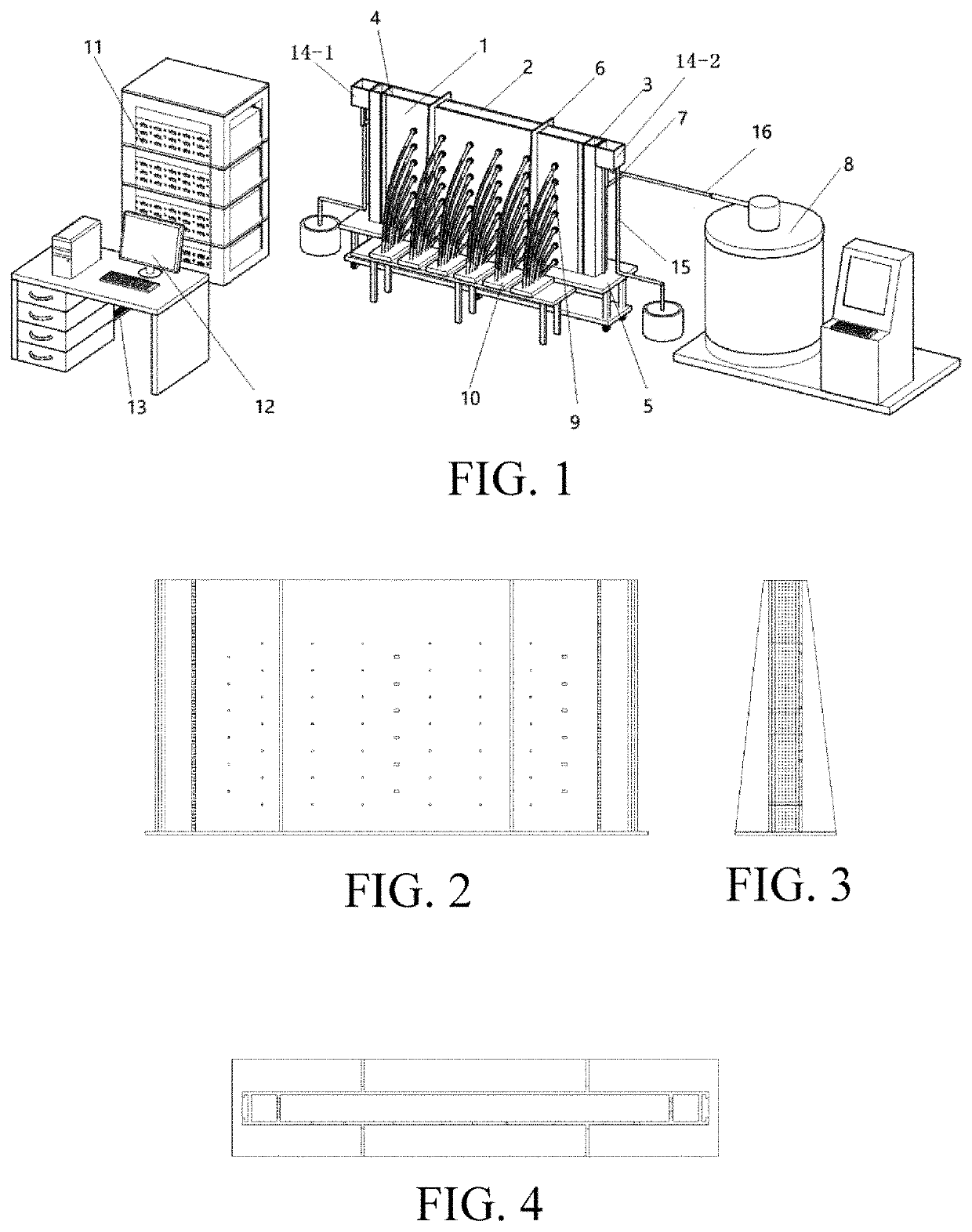

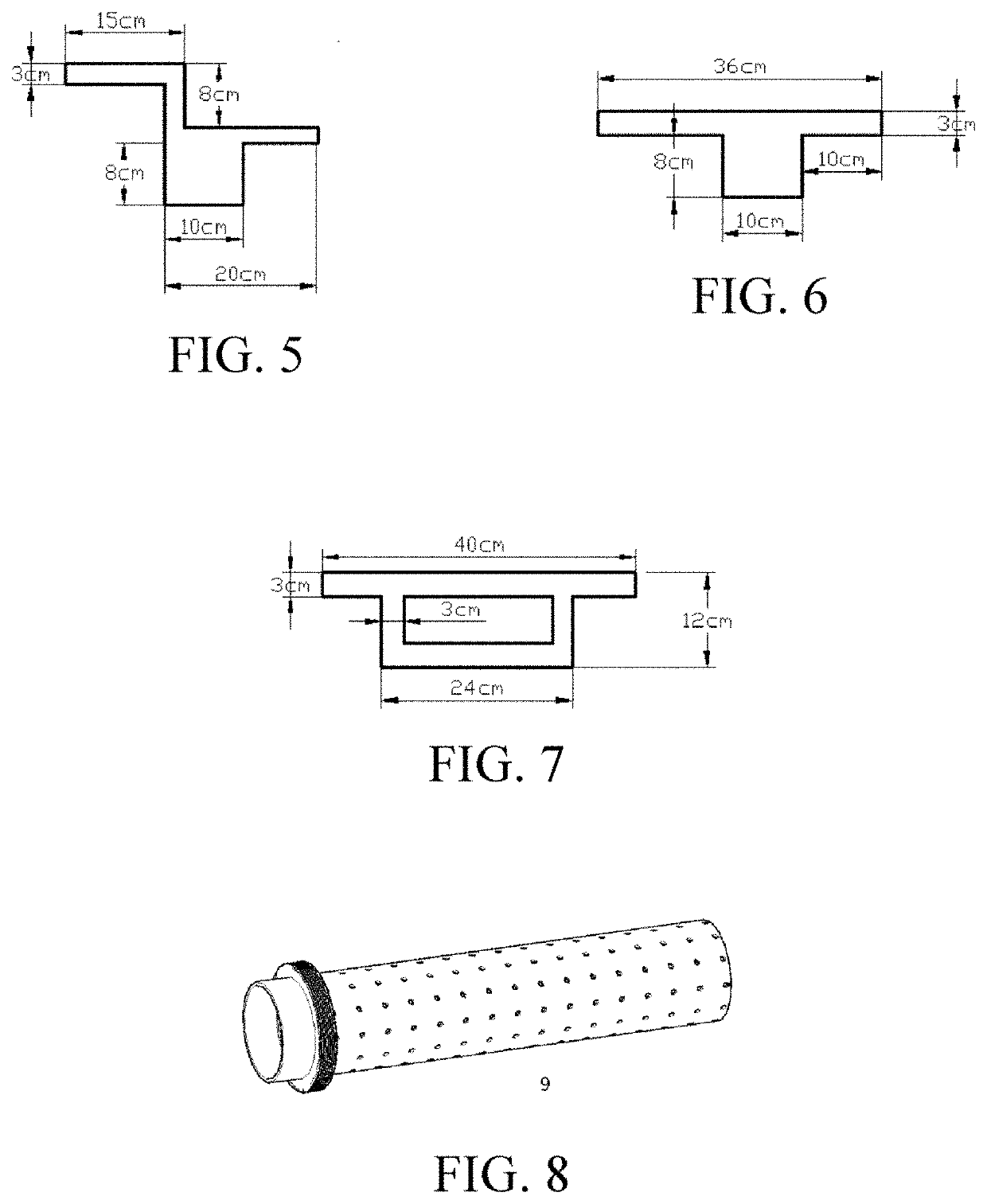

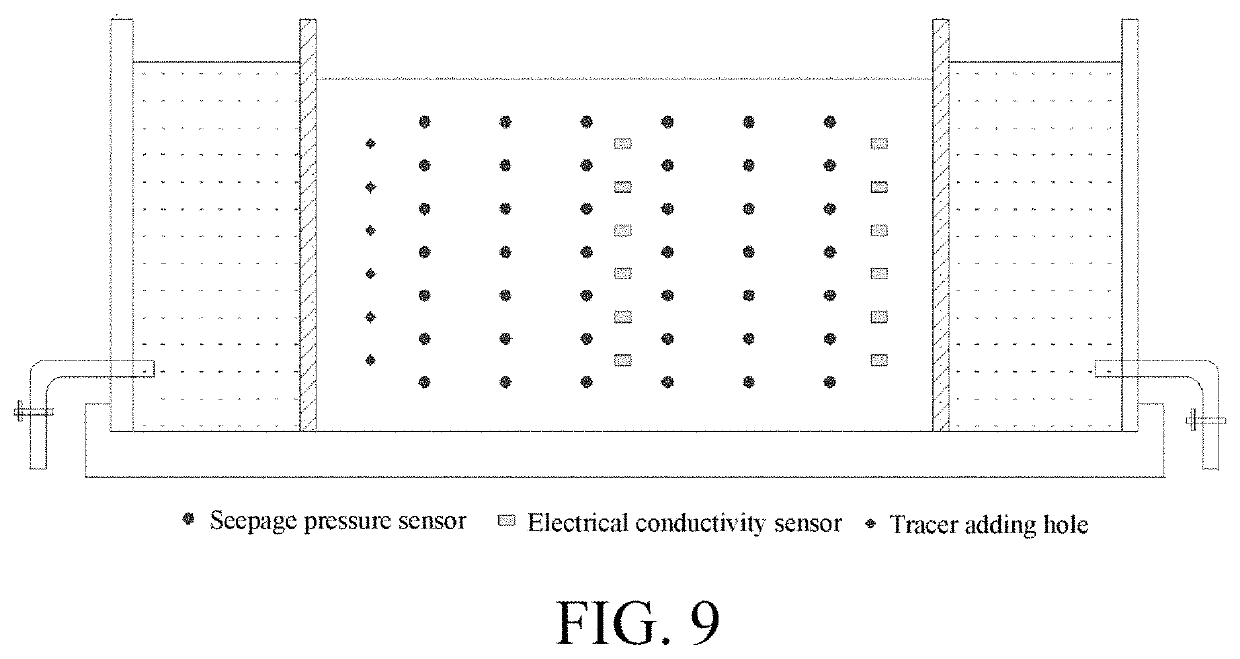

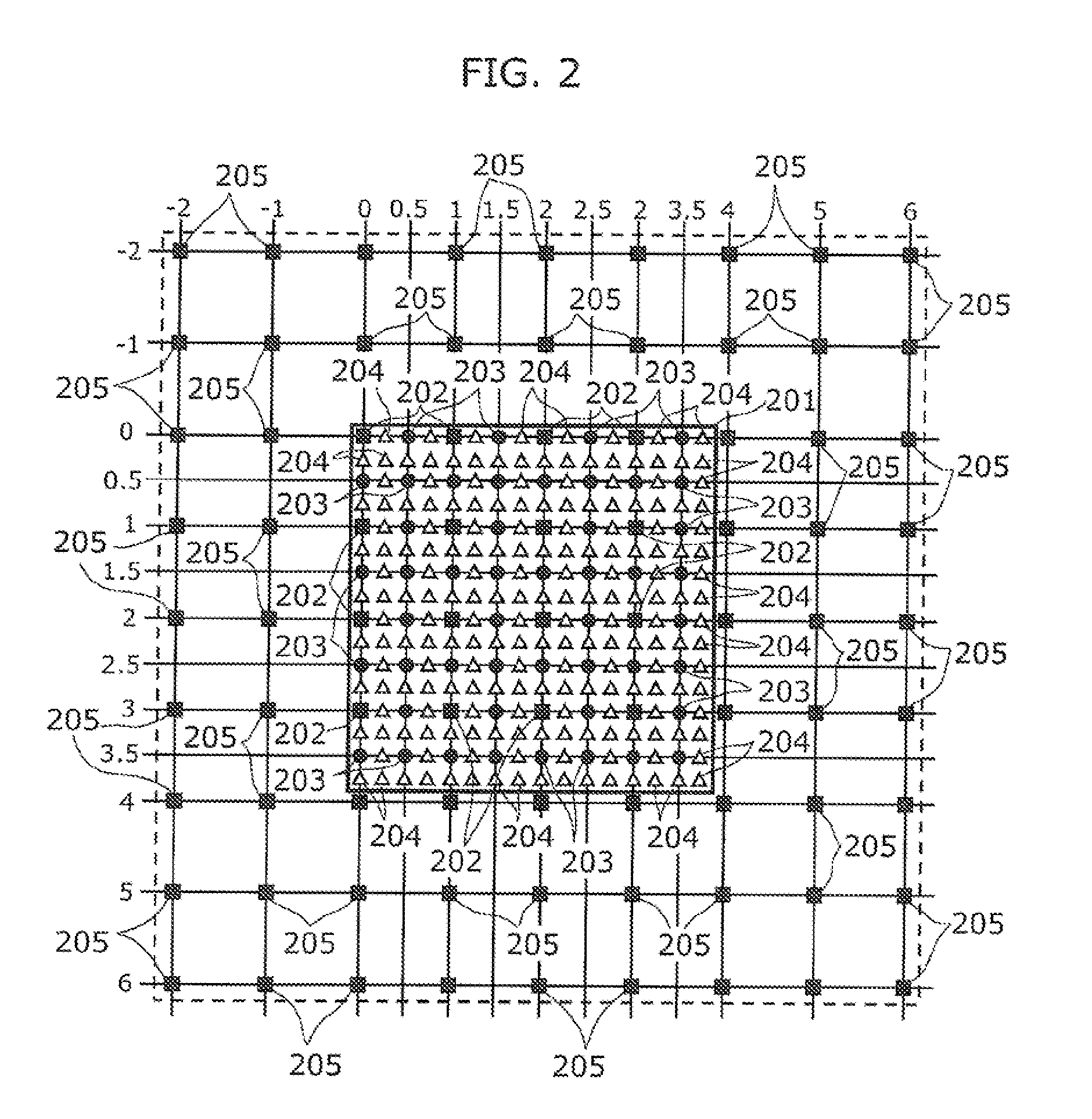

Sandbox test system and method for karst aquifer based on tracer-hydraulic tomography inversion

ActiveUS20210223156A1Long costKeep for a long timeEarth material testingEducational modelsPeristaltic pumpWater storage tank

A sandbox test system and method for a karst aquifer based on tracer-hydraulic tomography inversion, including a visual sandbox apparatus, a karst conduit, a water flow control apparatus, a horizontal well, a data acquisition apparatus, and a data processing apparatus. The visual sandbox apparatus forms a sand layer packing space. The karst conduit is buried in a sand layer. The water flow control apparatus is a constant water head storage tank. A back plate is provided with a horizontal well mounting hole and tracer adding hole. The horizontal well is mounted in each horizontal well mounting hole. A monitoring well is connected to a seepage pressure sensor or an electrical conductivity sensor. A water injection and pumping well is connected to a peristaltic pump. The electrical conductivity sensor, seepage pressure sensor, and peristaltic pump connect to the data acquisition apparatus. The data acquisition apparatus connects to the data processing apparatus.

Owner:SHANDONG UNIV

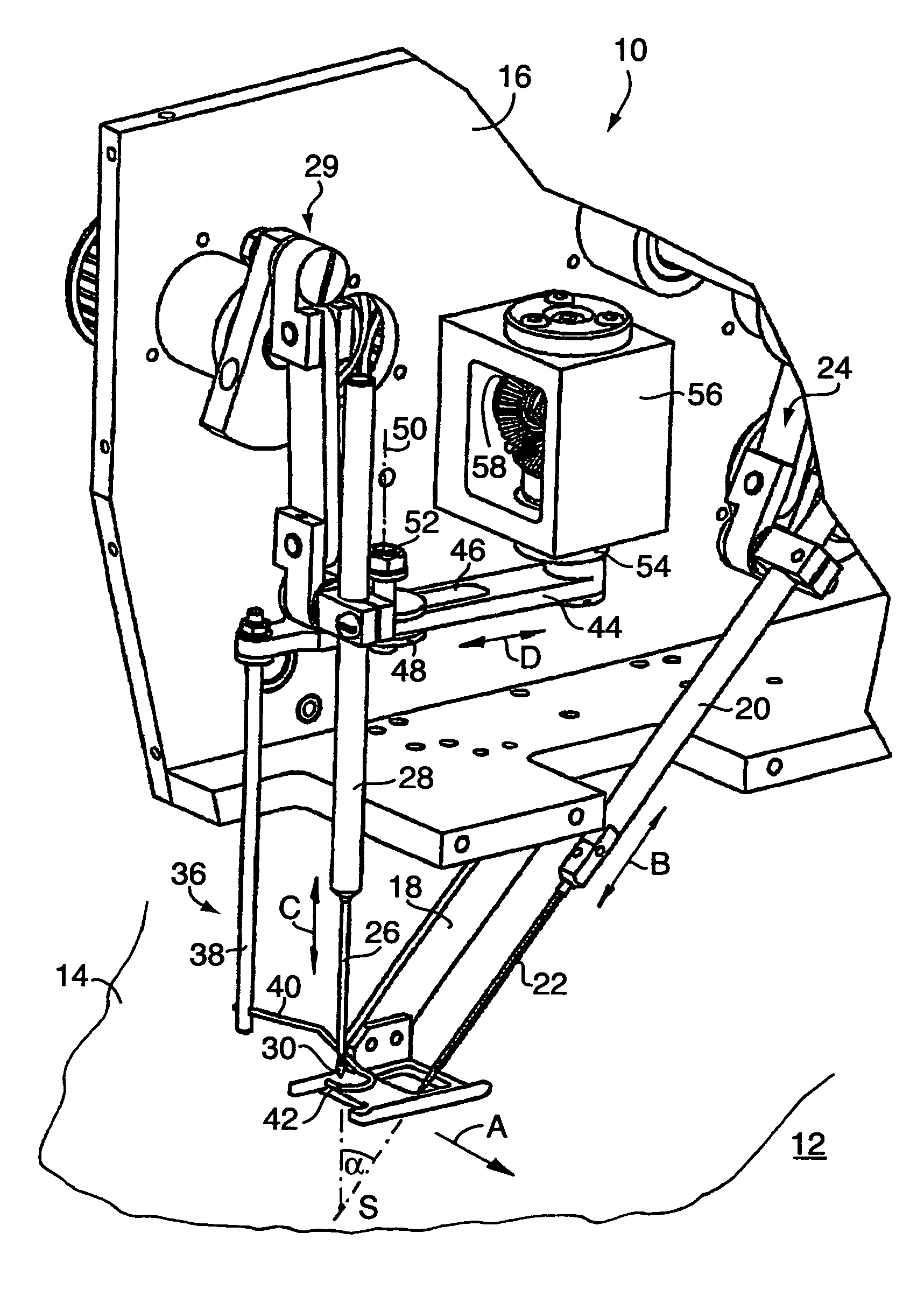

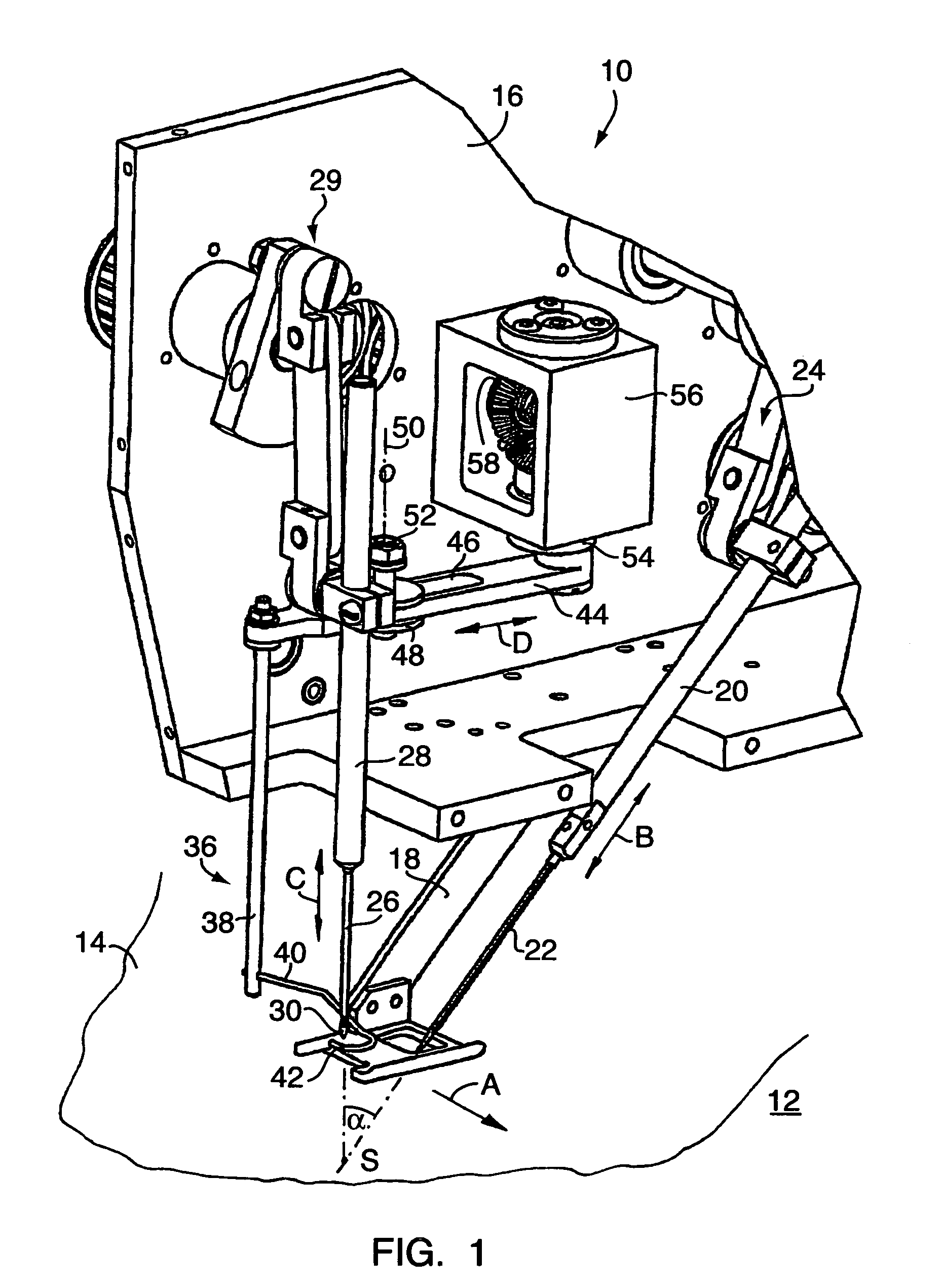

Chain stitch sewing mechanism

ActiveUS6973887B2Easy constructionReliable functionSewing-machine control devicesSewing needlesReciprocating motionSharp angle

In a chain stitch sewing mechanism with a sewing head movable parallel to the sewn material plane, including a needle rod with a needle drive for reciprocating a thread carrying needle, a catcher drive for reciprocating a needle shaped thread catcher with an open catching hook. The needle and thread catcher have movement paths forming a sharp angle with one another whose apex lies beneath the sewn material plane and the needle and catcher being so controlled such that a loop formed by the withdrawal of the needle is caught by the thread catcher and pulled through the material. A thread puller on a movable thread arm is moved towards the thread catcher and cooperates with the thread catcher for deflecting the loop hanging off the thread catcher at an angle to the movement path of the thread catcher toward the side opposite to that of the hook opening.

Owner:PFAFF INDUSTRIESYSTEME & MASCH GMBH

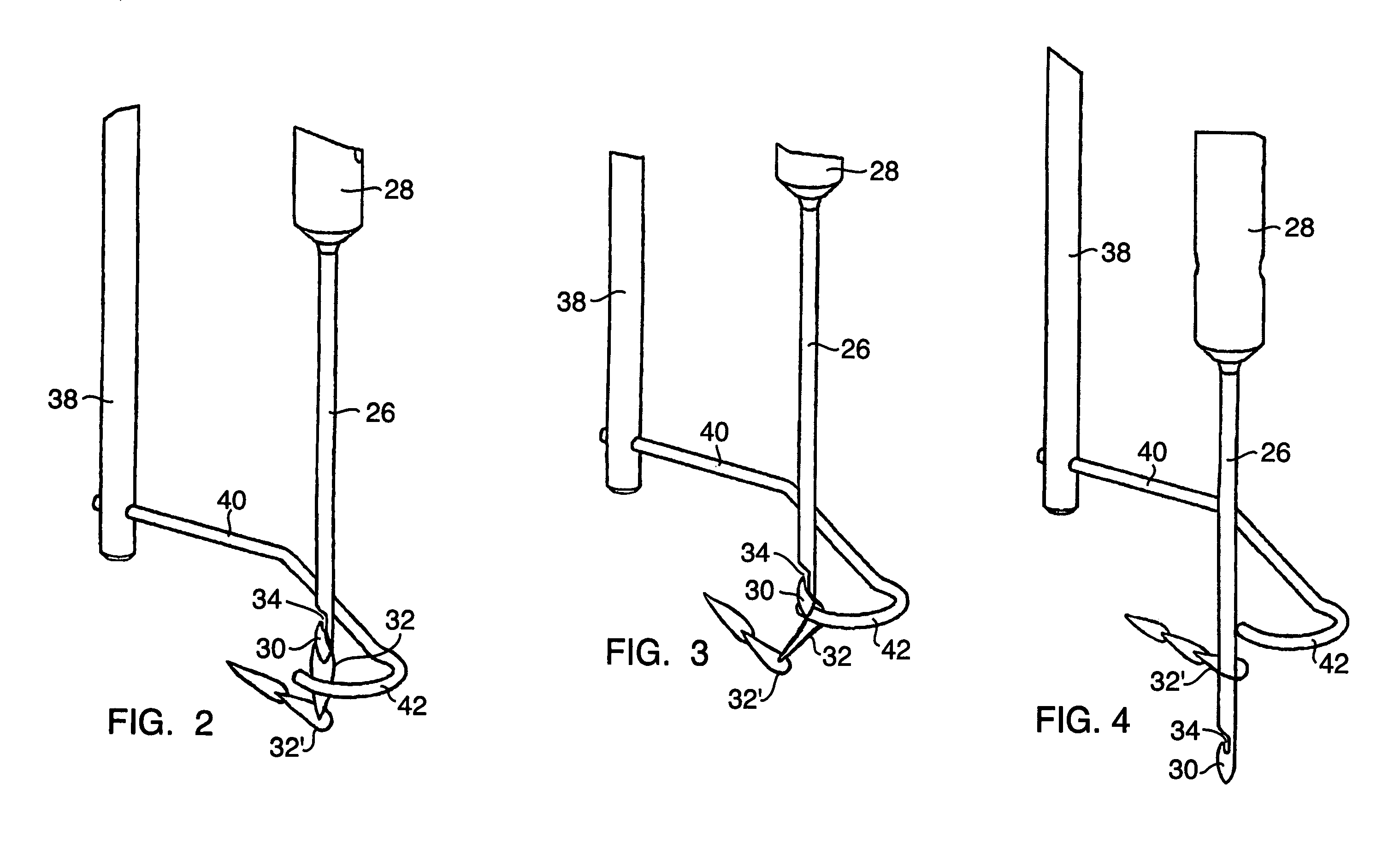

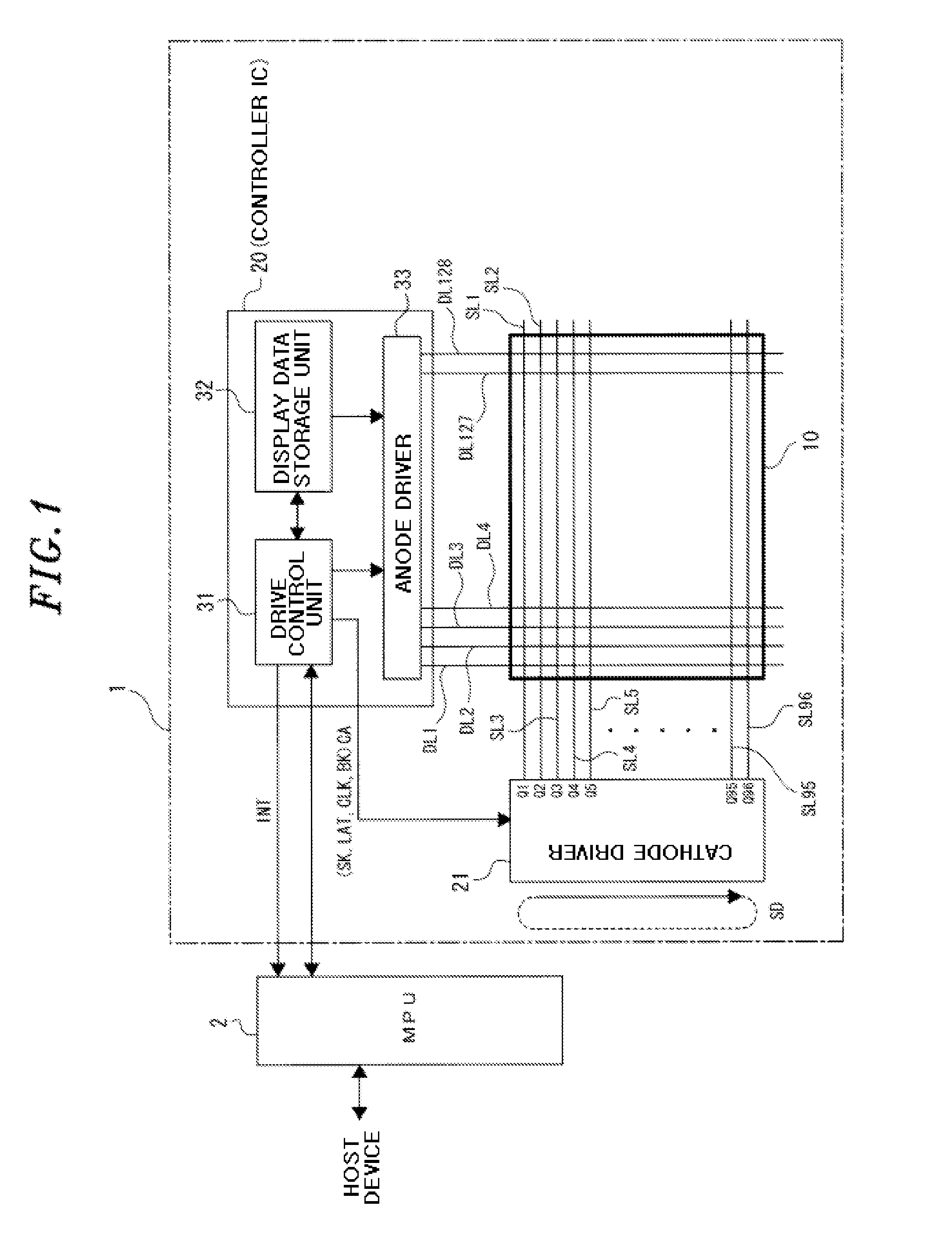

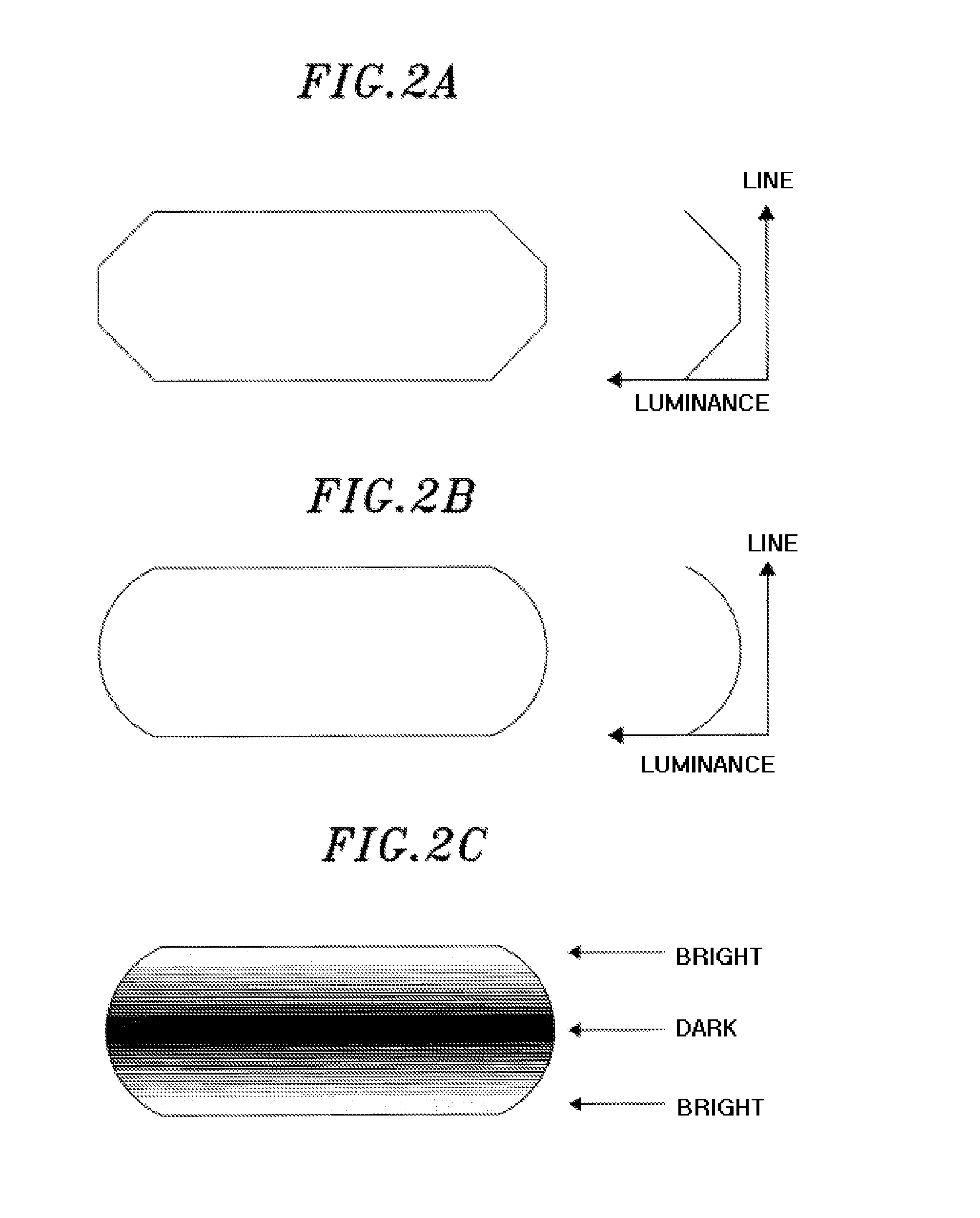

Display driving device, display driving method and display apparatus

ActiveUS20150170612A1Improve display qualityReduce display unevennessCathode-ray tube indicatorsInput/output processes for data processingEngineeringElectrical current

A display driving device performs display drive based on display data with respect to a display unit including pixels arranged at respective intersections of data lines and scanning lines. The device includes: a current setting unit configured to store current gradation values which are set for the respective scanning lines that constitute a frame of the display data; a current gradation control unit configured to, at each of scan timings for the respective scanning lines within one frame, generate a constant current corresponding to a current gradation value for a corresponding scanning line among the current gradation values stored in the current setting unit; and a data line driving unit configured to supply the constant current generated by the current gradation control unit to the respective data lines for time periods corresponding to pixel gradation values defined by the display data.

Owner:FUTABA CORPORATION

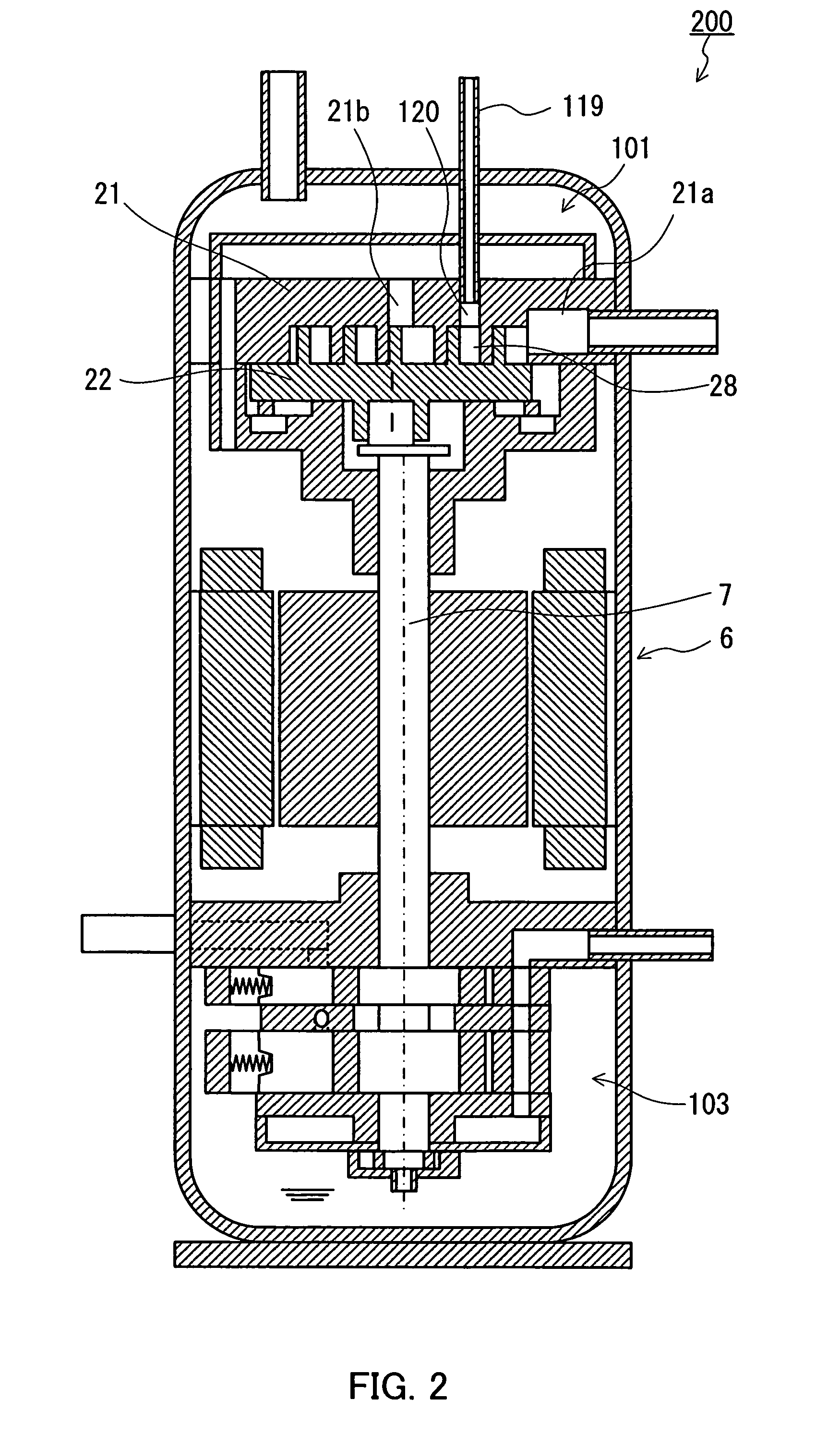

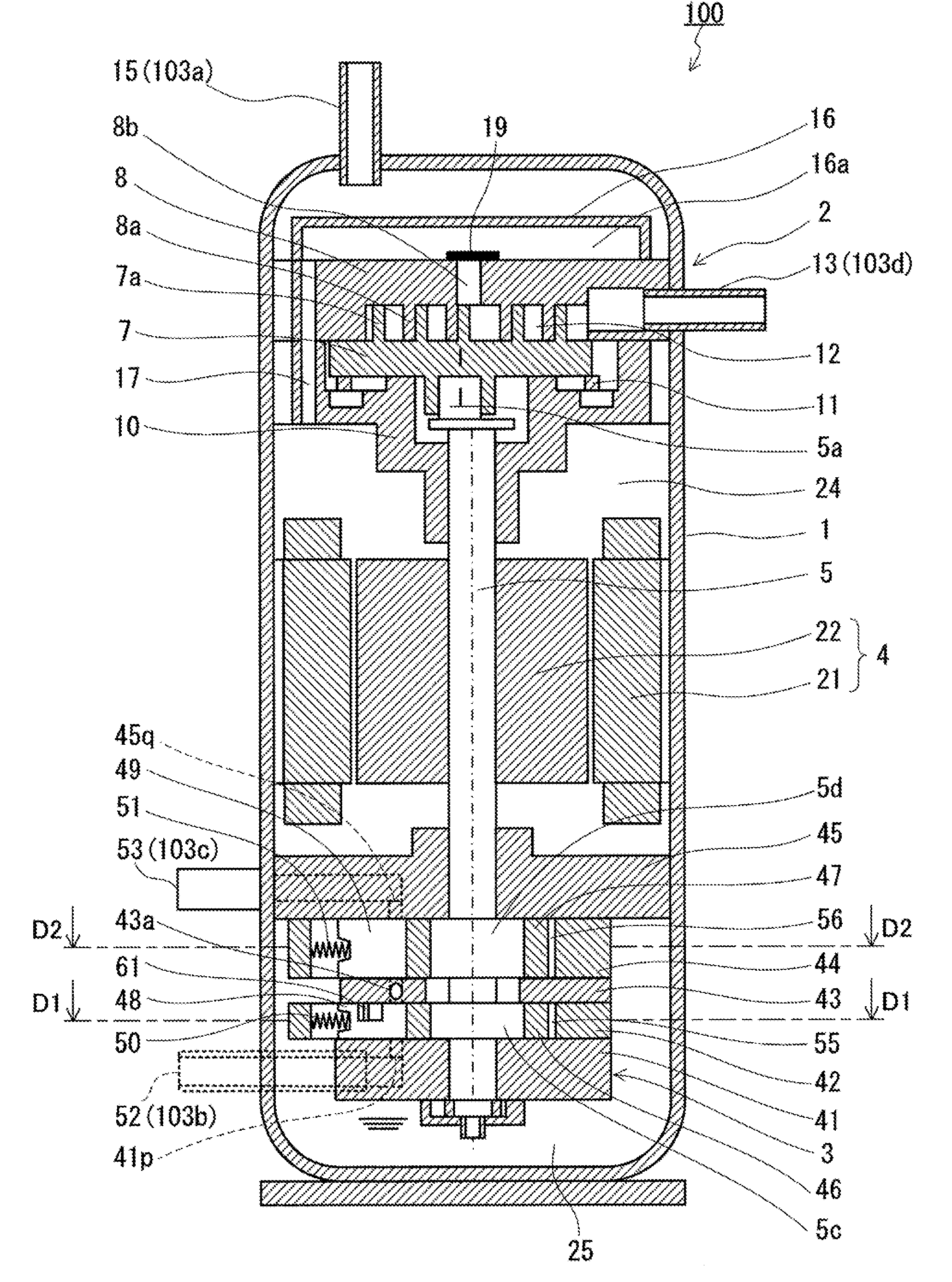

Two-stage rotary expander, expander-integrated compressor, and refrigeration cycle apparatus

InactiveUS20110070115A1Improve power recovery efficiencyAvoid constantRotary/oscillating piston combinations for elastic fluidsOscillating piston enginesPistonWorking fluid

An expander-integrated compressor (100) includes: a compression mechanism (2) for compressing a working fluid; an expansion mechanism (3) for expanding a working fluid; and a shaft (5) that couples the compression mechanism (2) and the expansion mechanism (3). The expansion mechanism (3) includes a variable vane mechanism (60). The variable vane mechanism (60) controls the movement of a first vane (48) so that the ratio of a period P2 to a period P1 (P2 / P1) can be adjusted, where P1 denotes the period during which the first vane (48) is in contact with a first piston (46) in the course of one rotation of the shaft (5), and P2 denotes the period during which the first vane (48) is spaced from the first piston (46) in the course of one rotation of the shaft (5).

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

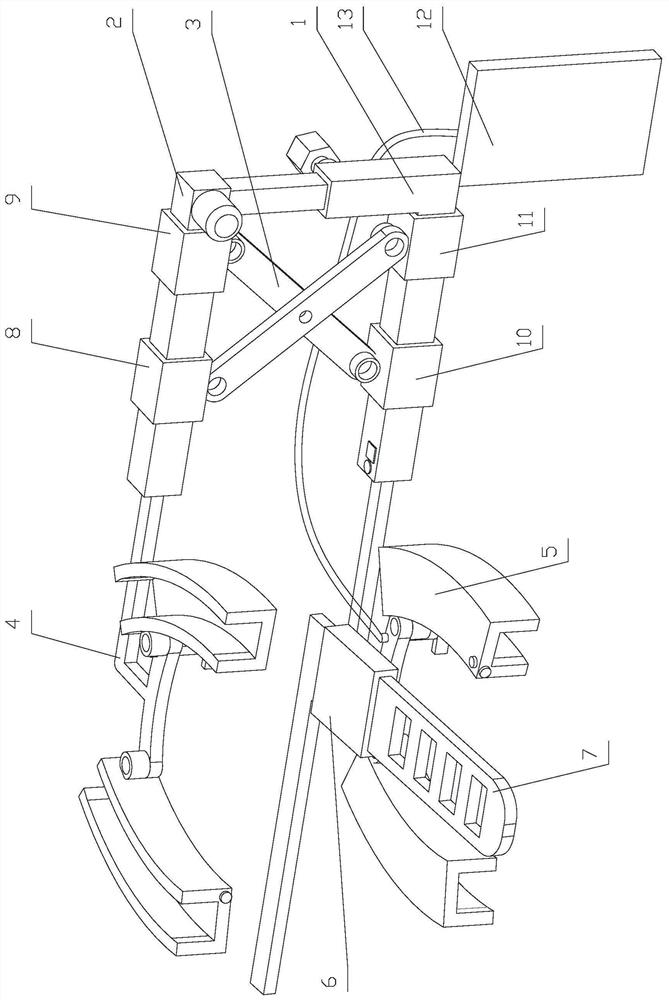

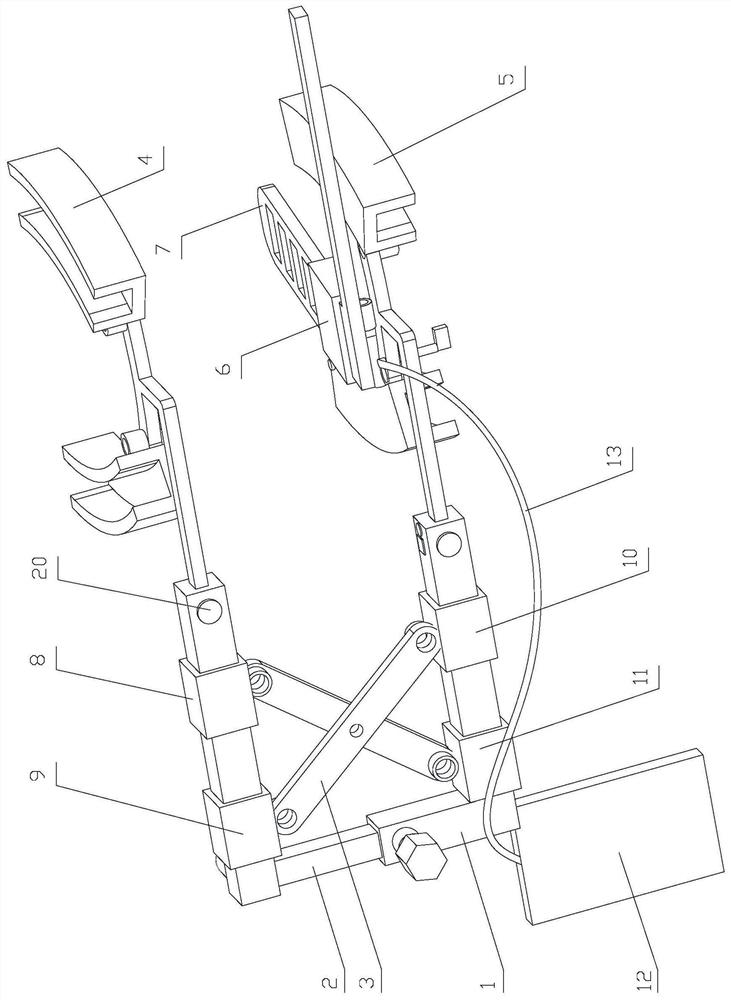

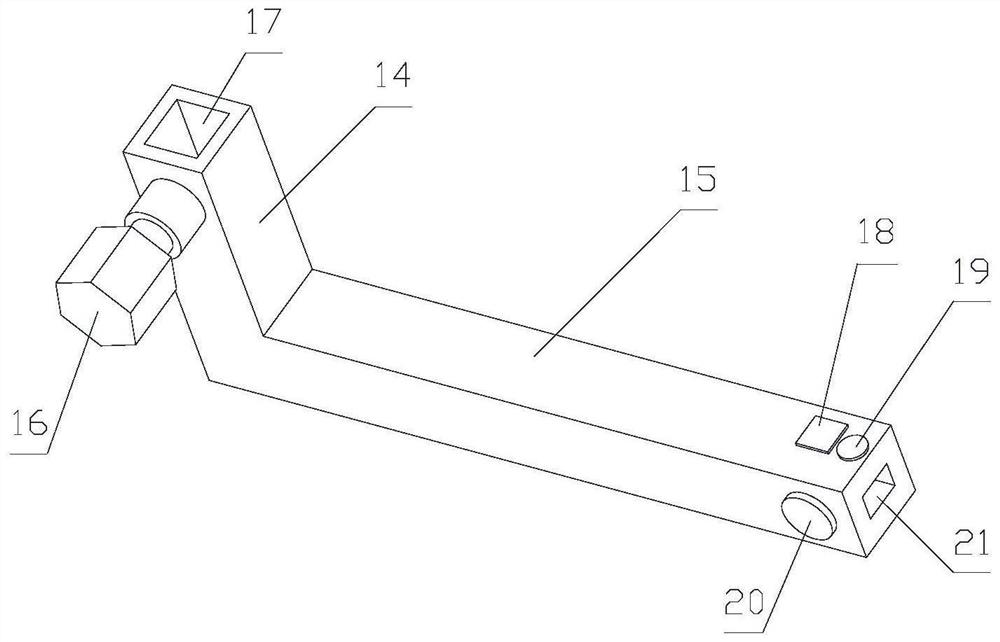

Tongue depressor for department of pediatrics

The invention relates to a tongue depressor for department of pediatrics. The tongue depressor comprises a lower bracket, an upper bracket, connecting plates, an upper denture assembly, a lower denture assembly, a tongue depressing plate, an upper sliding seat, an upper fixed seat, a lower sliding seat and a lower fixed seat, wherein the upper bracket can be arranged on the lower bracket in an up-and-down sliding manner; the upper fixed seat is arranged on the upper bracket; the upper sliding seat is arranged on the upper bracket; the lower fixed seat is arranged on the lower bracket; the lower sliding seat is arranged on the lower bracket; the connecting plates are arranged between the upper sliding seat and the lower fixed seat, as well as between the upper fixed seat and the lower sliding seat; the upper denture assembly is arranged on the upper bracket; the lower denture assembly is arranged on the lower bracket; a rotating seat is arranged on the lower denture assembly; and the tongue depressing plate is arranged in the rotating seat. Through the adoption of the tongue depressor for department of pediatrics disclosed by the invention, teeth of a sick child can be convenientlypushed open to an appropriate position and positioned, the situation that during inspection, the sick child voluntarily closes mouth and teeth, and the inspection is inconvenient is avoided.

Owner:THE PEOPLES HOSPITAL WEIFANG CITY CN0

Advertising method and system for health related fields

InactiveUS20050114183A1Easy and affordable and readily availableMeet actual needsHealthcare resources and facilitiesMarketingMedical recordApplication computers

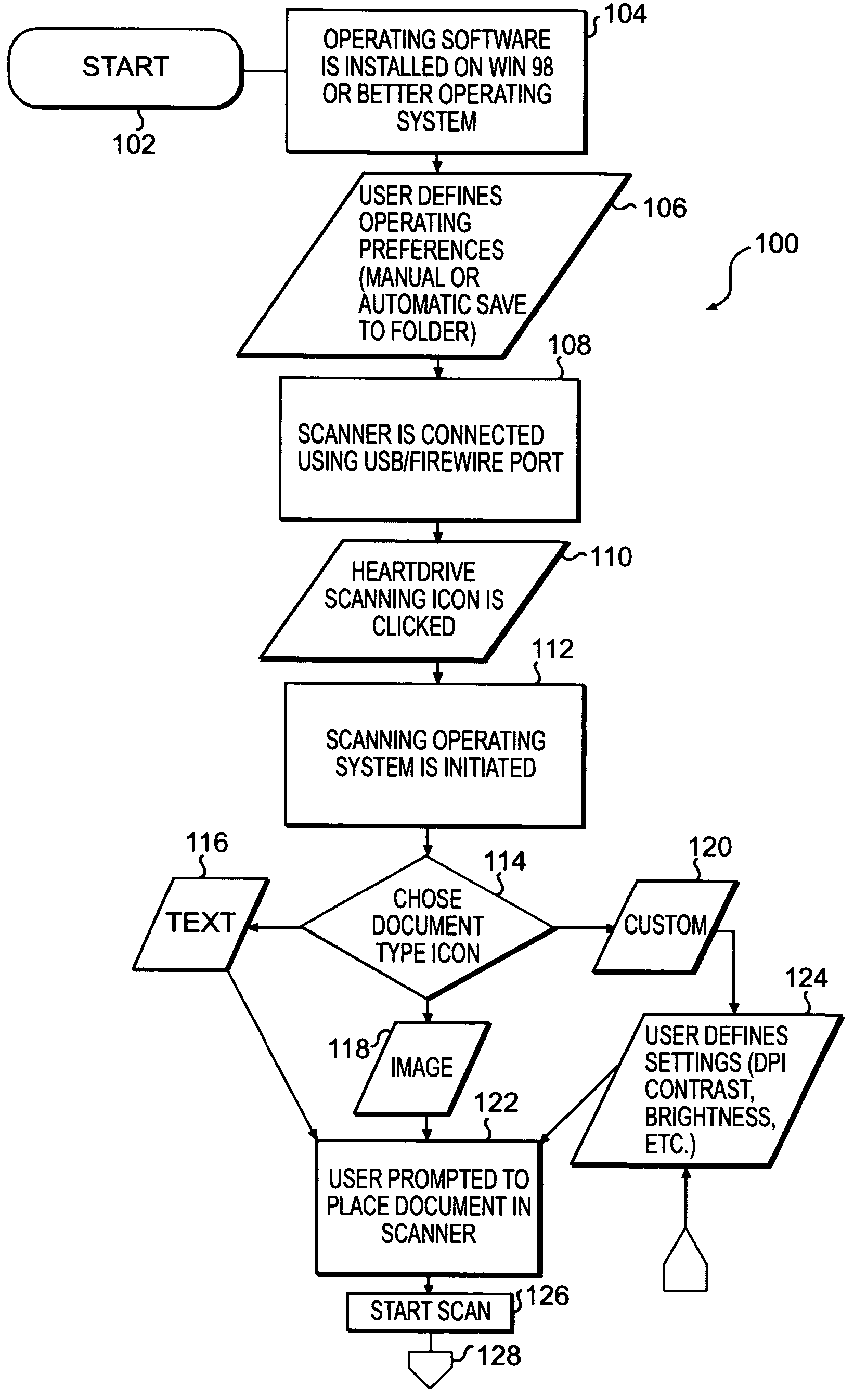

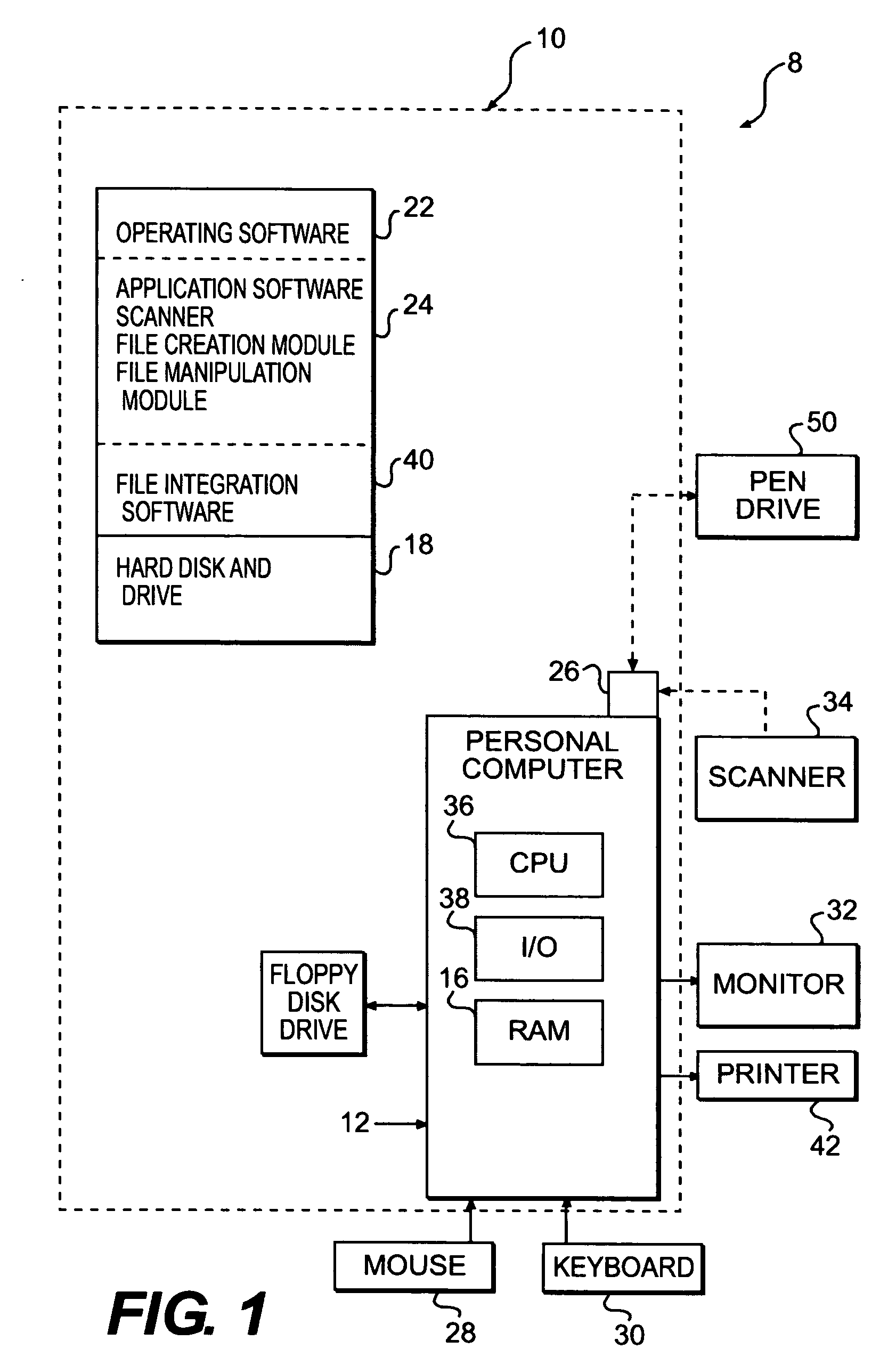

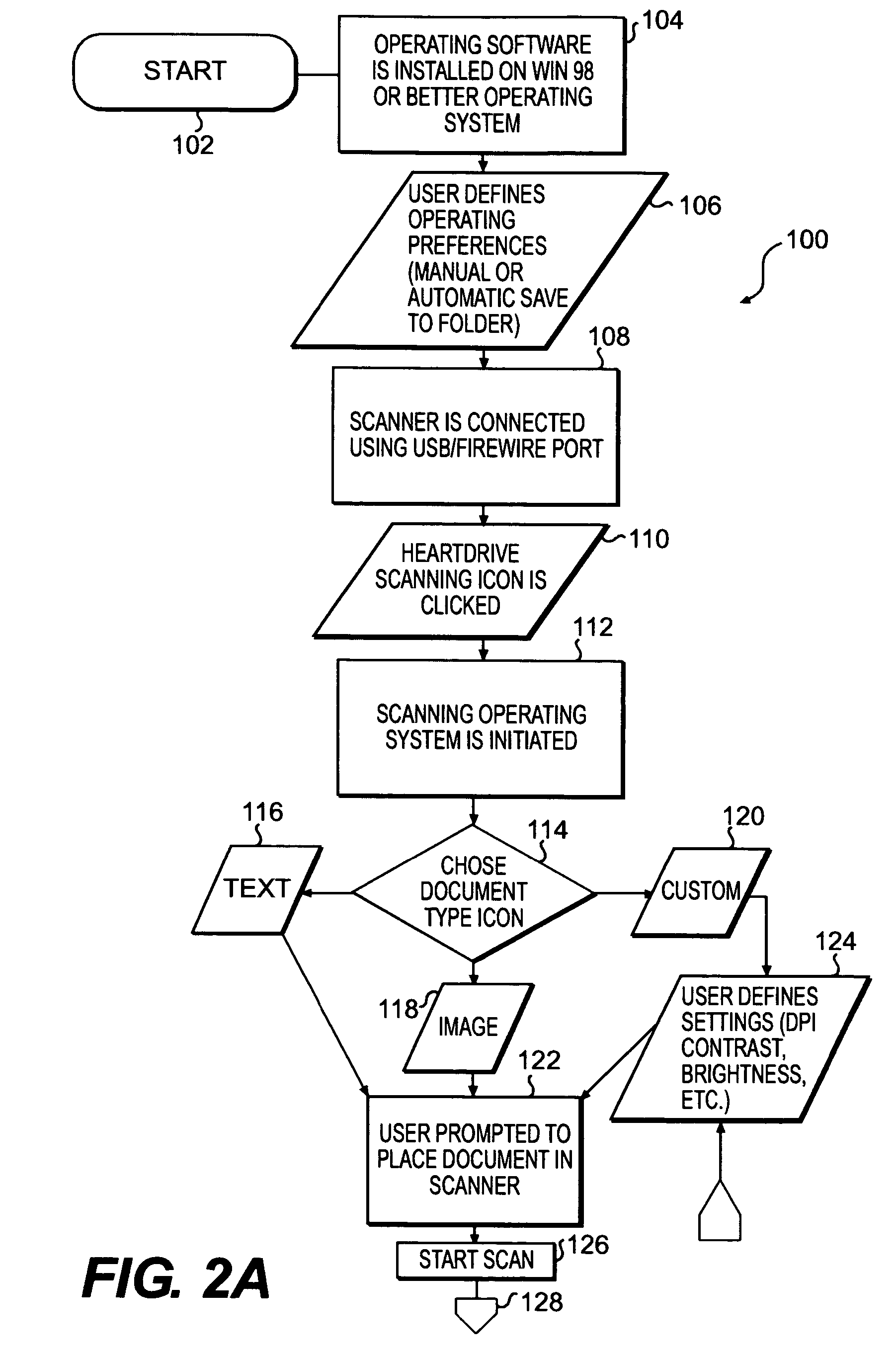

A permissible advertising method and system for the health care field is disclosed in which promotional information about a medical company is provided to patients and anyone accessing information about the patient. The system includes a portable storage device such as a pen drive that is kept by the patient and that is connectable to a universal port of a computer. Medical records and information about only that patient are stored on the pen drive in a plurality of self-executing files. Also stored on the pen drive is promotional information about the medical company and an application computer program that will provide the promotional information along with a file when the file is opened and displayed by the computer on either or both a monitor and a document printed by a printer. Alternatively, the promotional information and / or the application computer program can be kept on the accessing computer. Advertising indicia or logos of the medical company can be located on the pen drive.

Owner:DIGIOVANNA LEONARD D +1

Windshield lock for vehicle violation

InactiveCN107650859AAvoid constantTo achieve the purpose of locking the carAnti-theft devicesSquare cavityElectrical and Electronics engineering

The invention discloses a windshield lock for automobile violations, which comprises a lock body, two protrusions facing each other on one side of the lock body, shaft holes are respectively arranged in the protrusions, and the lock body is located in the middle of the side opposite to the protrusions. There is a handle, and the other side of the lock body is equipped with a solar panel, a control card, a two-digit code, a battery and two through holes, and an air suction nozzle and an air discharge nozzle are installed in the through holes, and the lock body is connected with the solar energy. There are bosses around the opposite side of the battery board, and a sealing ring is installed on the bosses. The bosses and the sealing rings form a "mouth"-shaped square cavity. Two parallel rotating shafts are arranged on the connecting body, and a lock body is connected to the rotating shafts respectively. , the lock body can rotate around the shaft connected to it. When the two lock bodies on the connecting body are unfolded to an angle of about 180°, the two sealing rings on the lock body are attached to a plane at the same time and folded to the angle. When it is about 0°, the two sealing rings on the lock body fit closely. The invention creates a new way of locking illegal vehicles, which is simple and convenient to operate and suitable for popularization.

Owner:吴文杰

Image decoding device, image decoding method, integrated circuit, and receiving device

InactiveUS20110032993A1Gain is not constantEfficient executionColor television with pulse code modulationColor television with bandwidth reductionDecoding methodsReference image

An image memory access control unit (502) judges whether or not an additional pixel required for motion compensation is necessary, the additional pixel not being included in a plurality of pixels forming an image shown by a reference block. When the additional pixel is judged to be necessary, a yet-to-be-obtained-pixel interpolating unit (503) generates at least one additional pixel, and generates a reference image to be used for motion compensation using the generated at least one additional pixel and at least a part of the image shown by the reference block. When the additional pixel is judged to be unnecessary, the yet-to-be-obtained-pixel interpolating unit (503) outputs at least a part of the image shown by the reference block as the reference image.

Owner:PANASONIC CORP

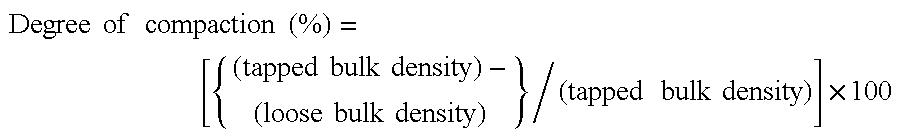

Hypromellose acetate succinate for use as hot-melt extrusion carrier, hot-melt extrusion composition, and method for producing hot-melt extrudate

Provided are hypromellose acetate succinates (HPMCAS) for use as a hot-melt extrusion carrier having a volume average particle size (D50) of from 70 to 300 as measured by dry laser diffraction and a loose bulk density of from 0.25 to 0.40 g / cm3; and a hot-melt extrusion composition comprising the HPMCAS and a drug. Also provided is a method for producing a hot-melt extrudate including the steps of: hot-melting the hot-melt extrusion composition at a hot-melt temperature equal to or higher than a melting temperature of the HPMCAS, or at a hot-melt temperature equal to or higher than a temperature at which both of the HPMCAS and the drug become melt; and extruding the hot-melted composition.

Owner:SHIN ETSU CHEM IND CO LTD

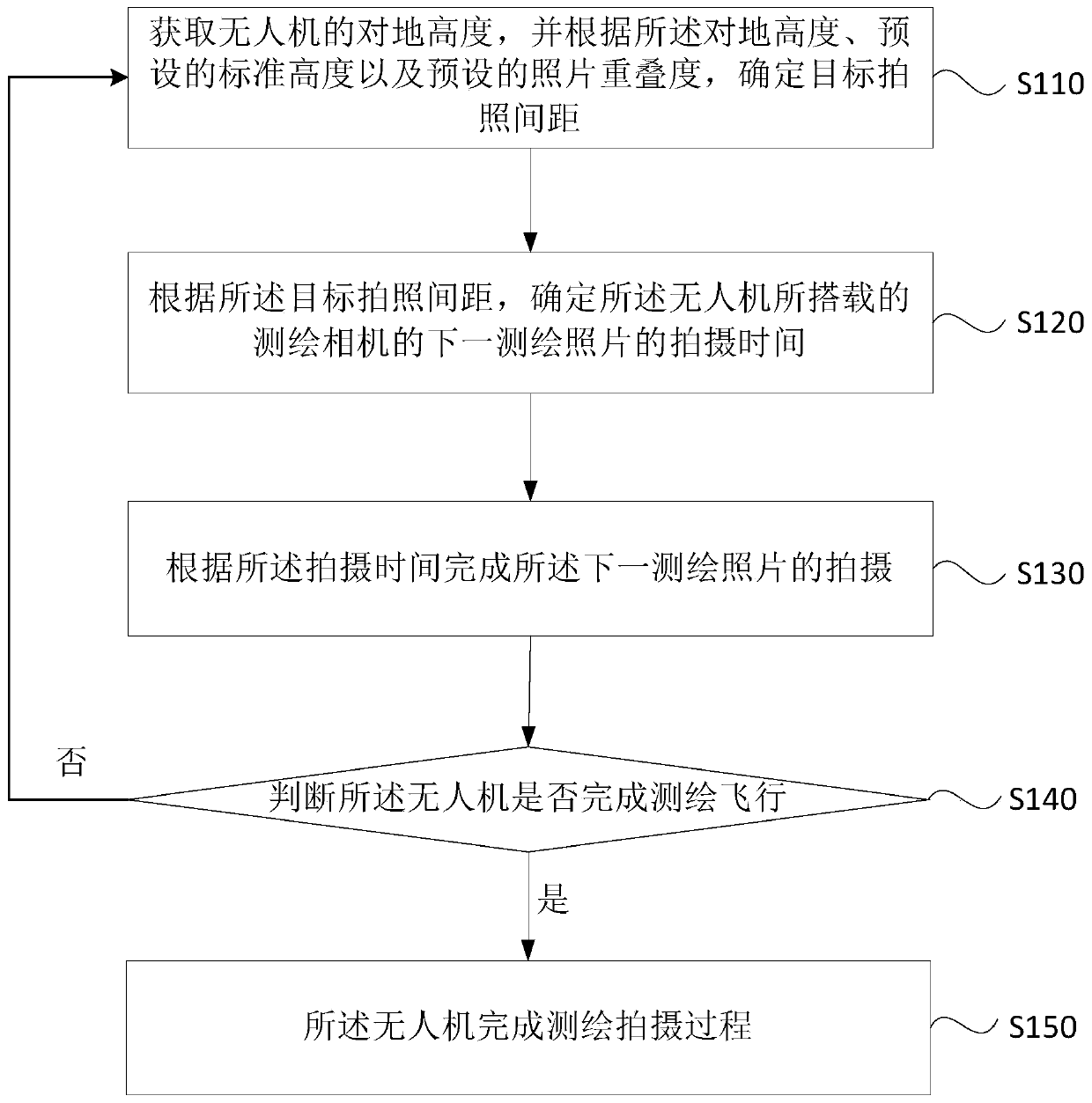

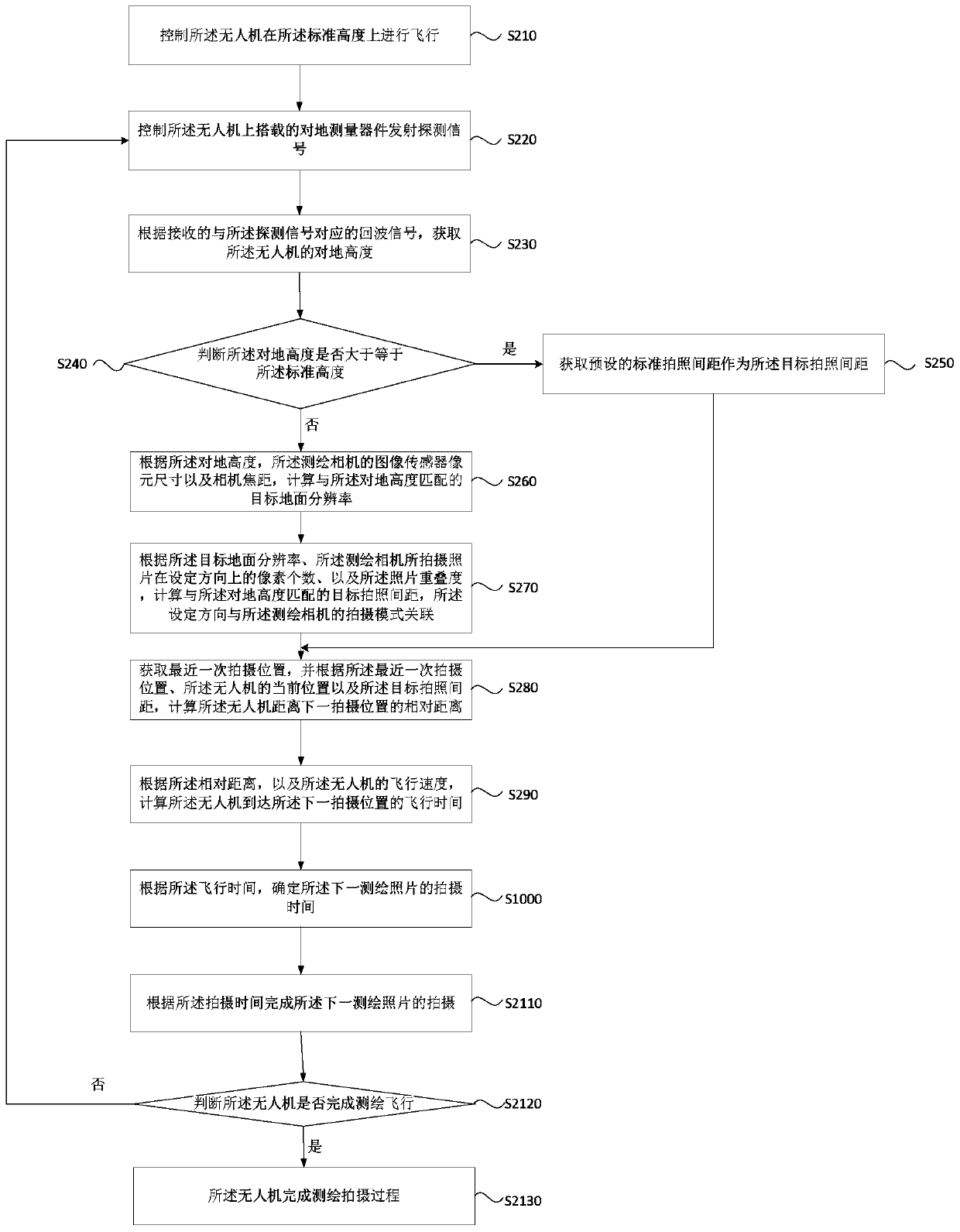

Photographing control method and device of unmanned aerial vehicle, unmanned aerial vehicle and storage medium

PendingCN110716586AAvoid constantMeet the overlap requirementPosition/course control in three dimensionsUncrewed vehicleEngineering

Owner:GUANGZHOU XAIRCRAFT TECH CO LTD

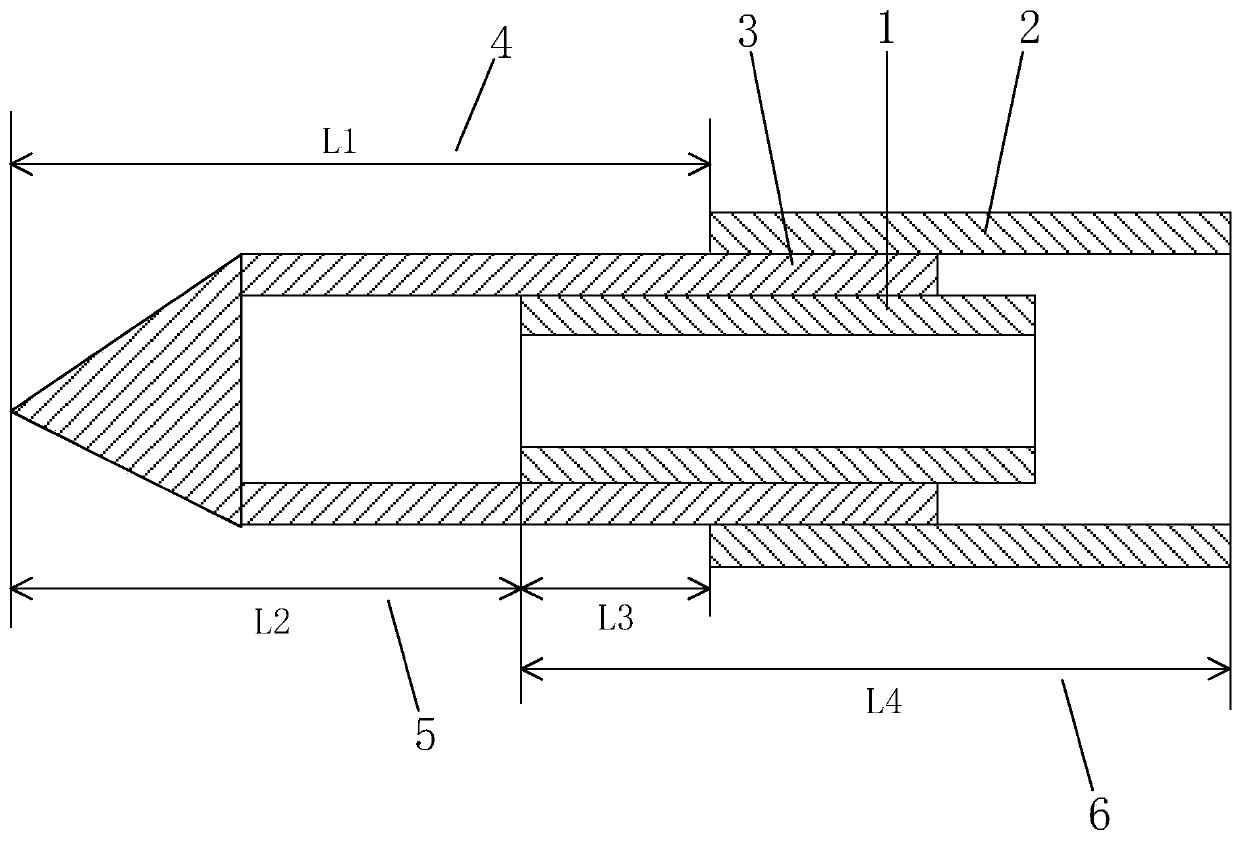

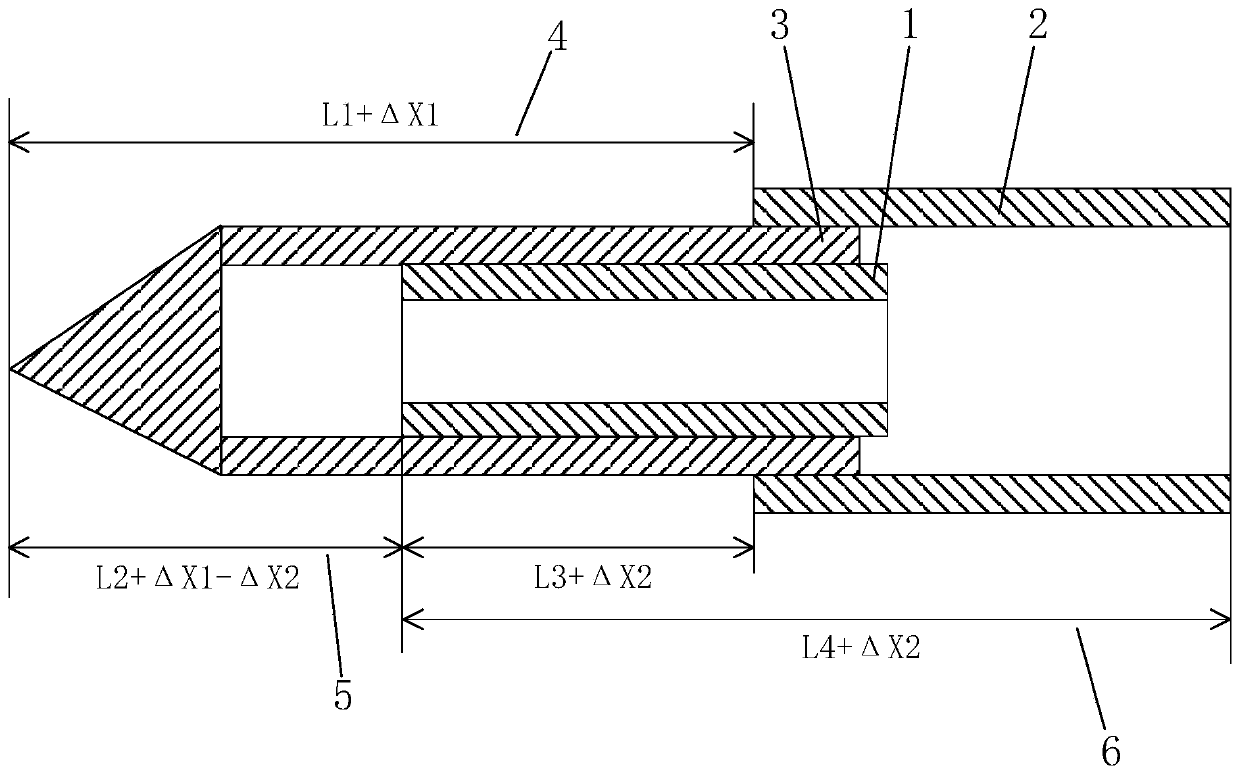

Adjustable cryoablation needle

PendingCN110327109AAvoid bendingAvoid constantSurgical instruments for coolingEngineeringHumans tissues

The invention provides an adjustable cryoablation needle, which comprises a needle bar, a front section heat insulating tube, and a rear section heat insulating tube.The needle barcan move relative tothe rear section heat insulating tube in the axial direction of the rear section insulating tube so as toadjust an axial direction first distance between the front end of the rear section insulatingtube and the front end of the needle bar; and the front section insulating tube can move relative to the rear section insulating tube in the axial direction of the rear section insulating tube so as to adjust an axial direction second distance between the front end of the front section insulating tube and the front end of the rear section insulation tube.According to the adjustable cryoablation needle,inconvenience brought by a doctor to select the type of the cryoablation needle can be avoided, theadjustable cryoablation needle can also fully adapt to different needle inserting depths, so that the length of the exposed needle barpartis as short as possible to avoid bending of the needle bar and damages such as tearing of human tissues. According to the adjustable cryoablation needle, thetreatment needs of different sizes of tumorscan be further met while the different needle depths are met.

Owner:ACCUTARGET MEDIPHARMA (SHANGHAI) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com