Reductive regeneration system and reductive regeneration process for pavement surface milling material

A technology of regeneration system and milling material, applied in the direction of roads, roads, road repair, etc., can solve the problems of surface layer materials cannot be protected and utilized, processing technology equipment cannot be equipped, and alternative materials cannot be used, so as to prevent water pollution. , High production efficiency, small production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

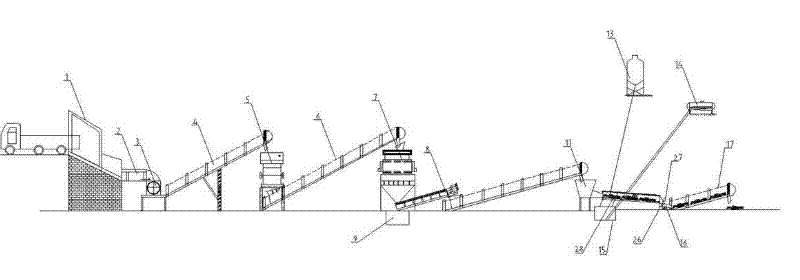

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

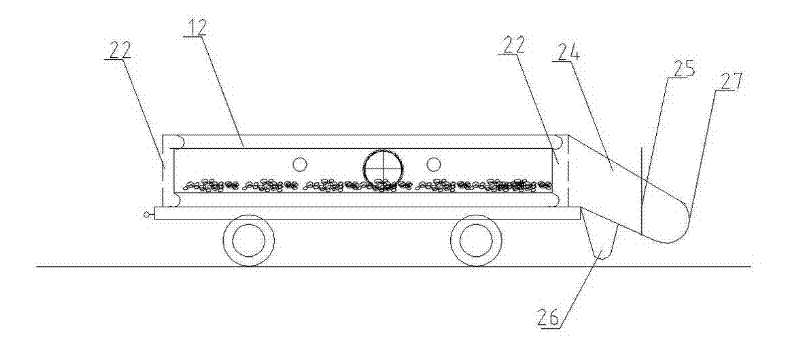

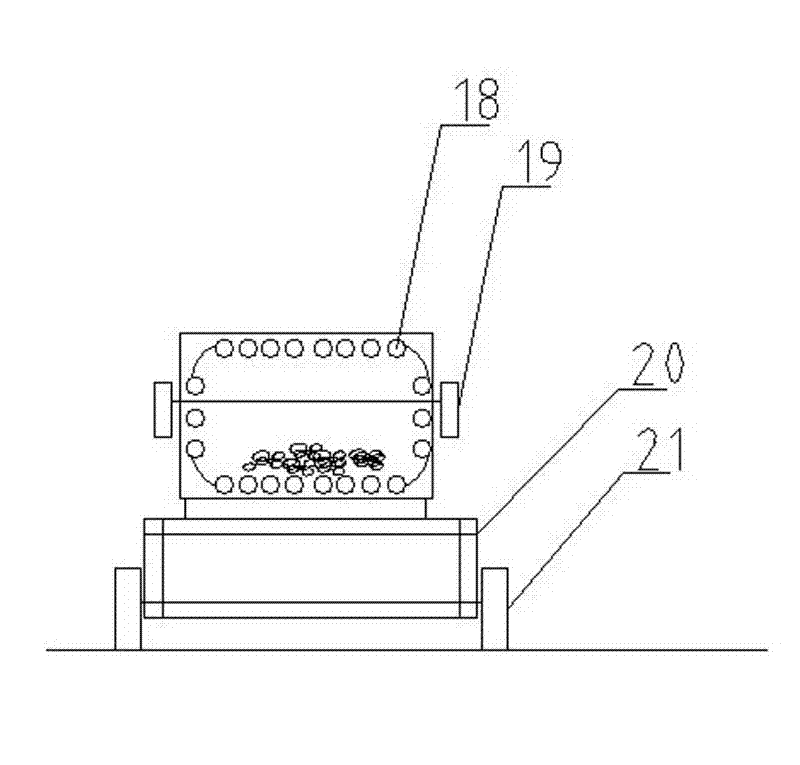

[0023] see Figure 1-4 , the present invention includes a decomposing and dedusting unit and a leach reduction unit, and the decomposing and dedusting unit includes a feeding hopper 1, a vibrating feeder 2, a rough stripping machine 3, a first conveyor belt 4, a fine stripping machine 5, and a second conveyor belt 6 connected in sequence , classifier 7, material-water separator 8, several third conveyer belts 10, the lower end of material-water separator 8 is provided with settling tank 9, rough stripper 3 is provided with high-pressure water sprayer, and fine stripper 5 is provided with high-pressure sprayer The water dispenser, the classifier 7 is provided with a high-pressure water sprayer, the classifier 7 divides the dedusted milling material into several types according to the size, and the outlet of each distribution box of the classif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com