Patents

Literature

68results about How to "Slow down the curing speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for increasing mechanical strength of dielectric film by using sequential combination of two types of UV irradiation

InactiveUS20080220619A1Enhance porogen-removing effectHigh mechanical strengthSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectricLength wave

A method for increasing mechanical strength of a dielectric film includes: providing an initial dielectric film containing porogen; irradiating the initial dielectric film with first UV light having a first wavelength which is substantially or nearly similar to a maximum light absorption wavelength of the porogen for removing the porogen; and then irradiating the porogen-removed dielectric film with second UV light having a second wavelength which is shorter than the first wavelength, thereby increasing mechanical strength of the dielectric film.

Owner:ASM JAPAN

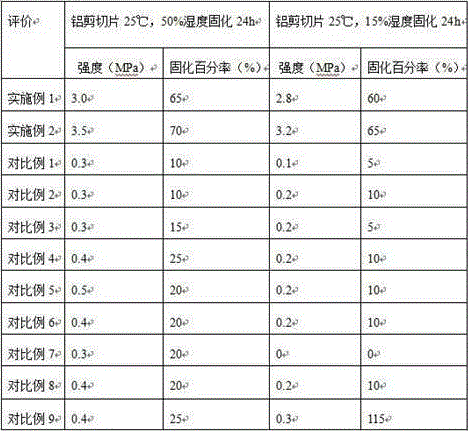

Method for preparing polyurethane hot melt adhesive capable of achieving quick positioning

ActiveCN105131896AHigh bonding strengthOvercome the effects of differences in expansion coefficientsNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolyol

The invention relates to a method for preparing polyurethane hot melt adhesive capable of achieving quick positioning. The preparing method includes the steps that 1, reactive tackifier and hydrogenated bisphenol A are added into a reaction still, dehydration is conducted for 2 hours at the temperature of 110 DEG C and the pressure intensity of -0.095 MPa, the mixture is cooled to 70 DEG C, a catalyst and polyisocyanate are added, stirring is conducted at the rotation speed of 400-700 r / min, a reaction is conducted for 1-3 hours at the temperature of 70 DEG C-80 DEG C, then a silane modifier is added, a reaction is conducted for 2-5 hours at the temperature of 70 DEG C-80 DEG C, and modified prepolymer at the sending end of silane is obtained; 2, dehydration is conducted on polyester polyol, polyether polyol and acrylic resin for 2 hours at the temperature of 120 DEG C and the pressure intensity of -0.095 MPa, after dehydration is conducted, the polyisocyanate is added, stirring is conducted at the rotation speed of 400-700 r / min, a reaction is conducted for 1-3 hours at the temperature of 100 DEG C-120 DEG C, then the prepared modified prepolymer at the sending end of the silane, antioxygen and the catalyst are added, the temperature is raised to 110 DEG C, vacuumizing is conducted till the pressure intensity is below -0.095 MPa, air bubble removing is conducted for 30 minutes, discharging and sealed packing are conducted, and the polyurethane hot melt adhesive capable of achieving quick positioning is obtained.

Owner:YANTAI DARBOND TECH

Scraping coating type polyurea elastomer corrosion-resistant and wear-resistant material and preparation method thereof

ActiveCN105802460AHigh mechanical strengthAnti-corrosion and wear-resistantAnti-corrosive paintsPolyurea/polyurethane coatingsElastomerEnd-group

The invention discloses a scraping coating type polyurea elastomer corrosion-resistant and wear-resistant material and a preparation method thereof. The scraping coating type polyurea elastomer corrosion-resistant and wear-resistant material is characterized by comprising an ingredient A and an ingredient B, wherein the ingredient A is prepolymers with NCO end groups obtained through the reaction between 30 to 40 mass percent of polyether polyol and 60 to 70 mass percent of polyisocyanates; the ingredient B is prepared from 30 to 40 mass percent polyaspartic acid ester, 60 to 70 mass percent of filling materials and a small number of auxiliary agents through high-speed dispersion grinding. In the use process, the prepared ingredient A and the prepared ingredient B are weighed according to the weight ratio of 1:4, and are then uniformly mixed; next, scraping coating construction is performed. The material has the characteristics of high mechanical intensity, corrosion resistance, wear resistance, good anti-seeping performance, aging resistance, proper reaction speed, no solvent, convenient construction and the like. The scraping coating type polyurea elastomer corrosion-resistant and wear-resistant material is particularly suitable for industrial and mining enterprise equipment and spare part anti-corrosion wear-resistant liners.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

High-temperature cured two-component pouring sealant and preparation method thereof

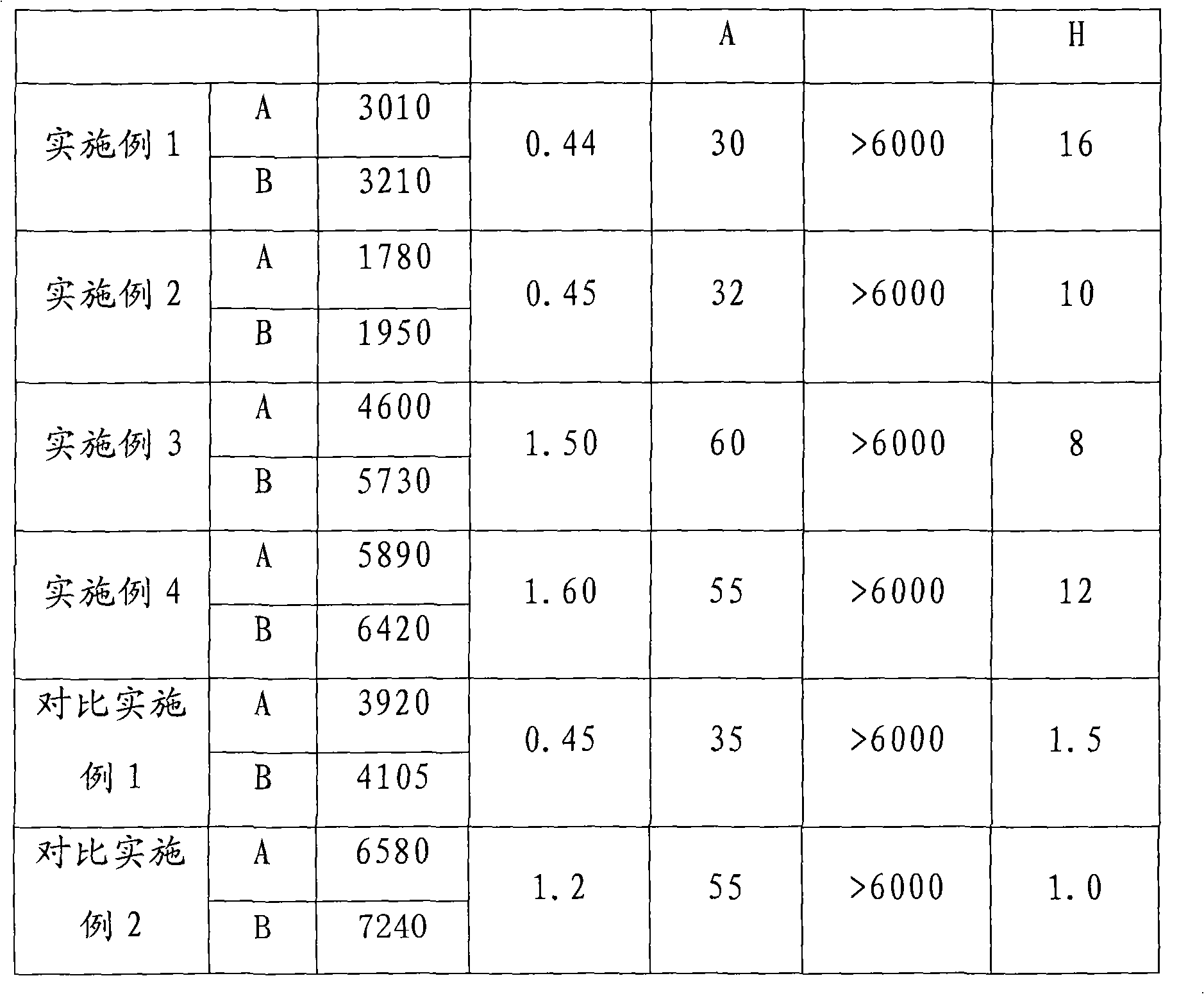

InactiveCN102093838AEasy to moveApplicable for a long timeNon-macromolecular adhesive additivesOther chemical processesHeat conductingSealant

The invention relates to a high-temperature cured two-component pouring sealant and a preparation method thereof, and the heat-conducting pouring sealant is prepared by an A component and a B component according to the weight ratio of 100: 80-100: 125, wherein the A component comprises the following raw materials by weight percent: 45.00%-85.00% of heat-conducting powder, 14.00%-50.00% of low-viscosity liquid silicon oil, 0.15%-15.00% of silane curing agent, 0.005-0.02% of inhibitor, and 0.00-5.00% of color toner; and the B component comprises the following raw materials by weight percent: 45.00%-85.00% of heat-conducting material, 14.00%-55.00% of the low-viscosity liquid silicon oil, 0.04%-1.00% of catalyst and 0.00-5.00% of the color toner. The preparation method of the heat-conducting pouring sealant comprises the following steps: respectively preparing the A component and the B component, uniformly mixing the A component with the B component according to the weight ratio of 100: 80-100: 125 during the use, and heating and curing for 2 hours at the temperature of 60-80 DEG C for preparation.

Owner:YANTAI DARBOND TECH

Preparation method of polyurethane hot melt adhesive adhered with lower surface energy material

ActiveCN107652937AExcellent low surface energy adhesive propertiesGood flexibility and bulk tensile strengthPolyureas/polyurethane adhesivesSurface energyExpansion factor

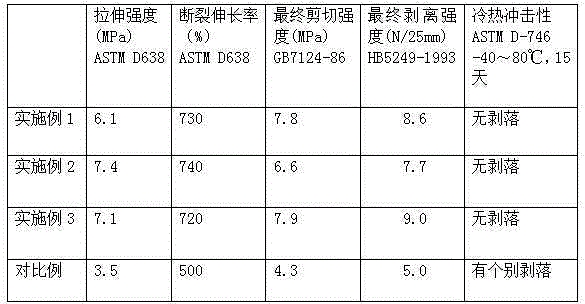

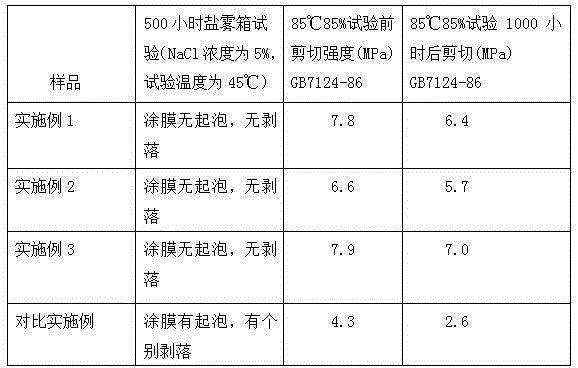

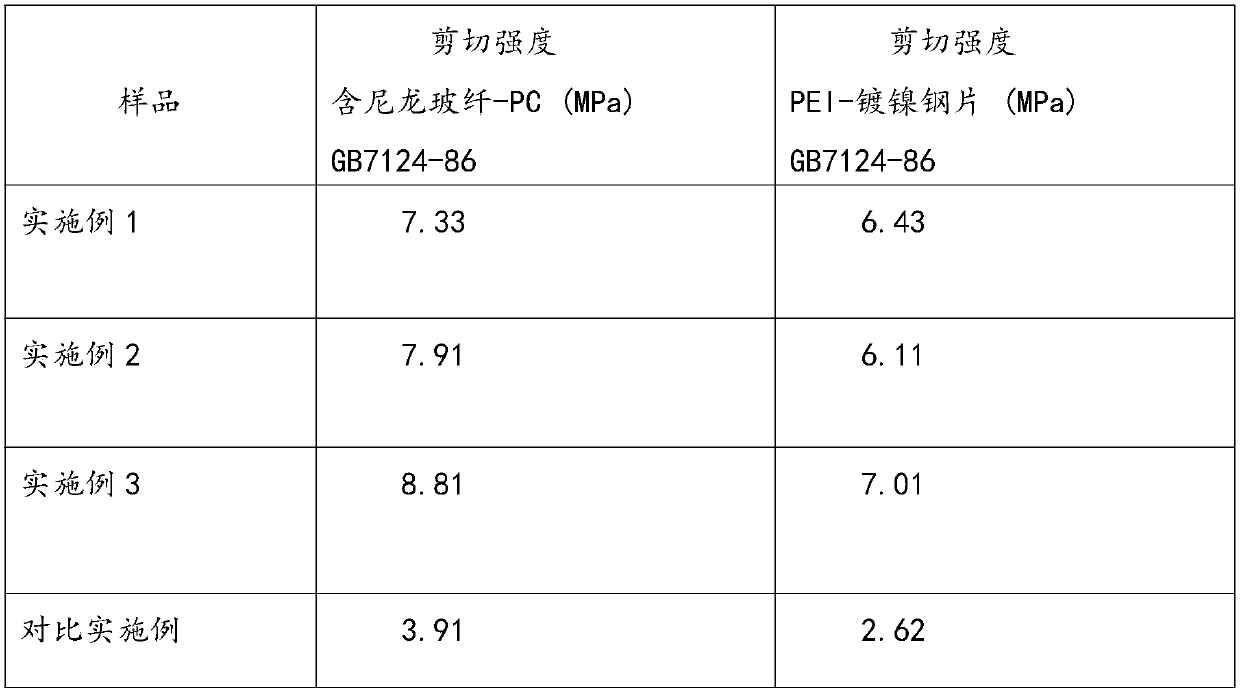

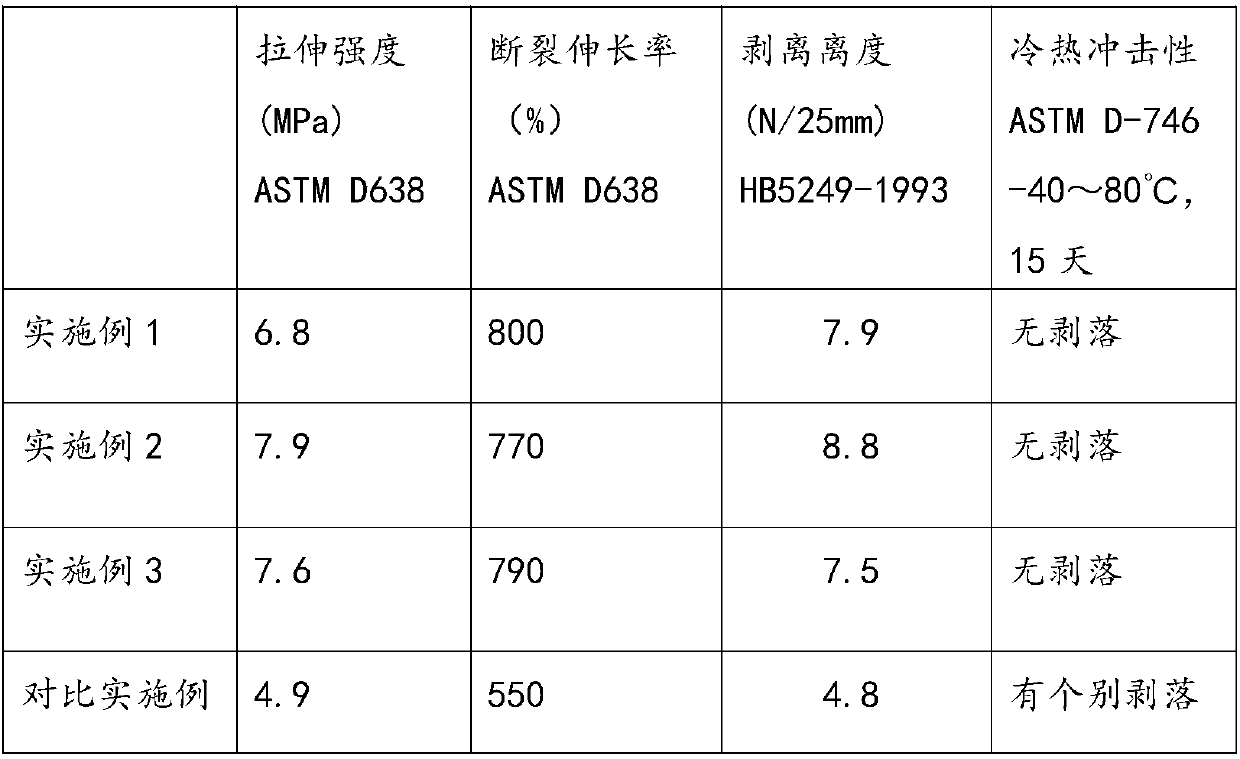

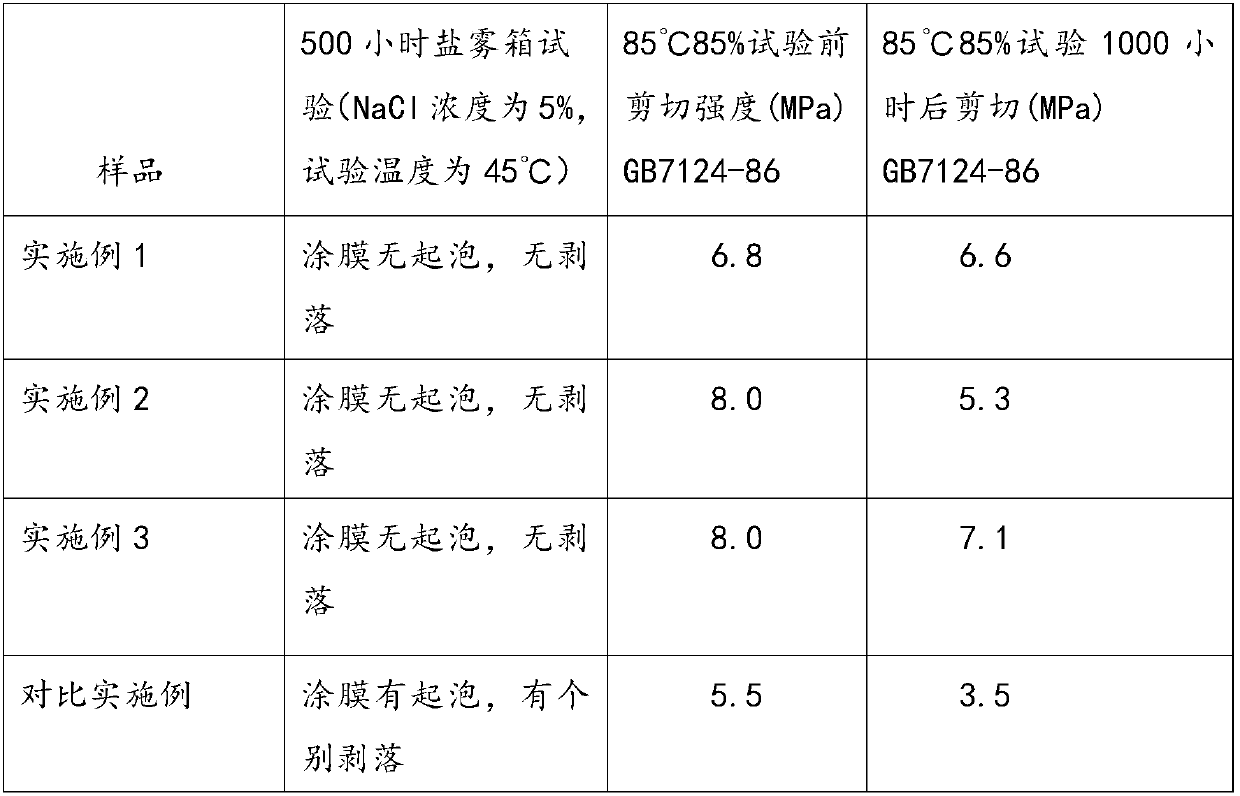

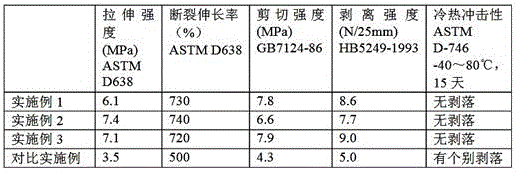

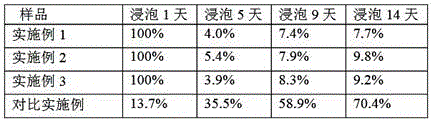

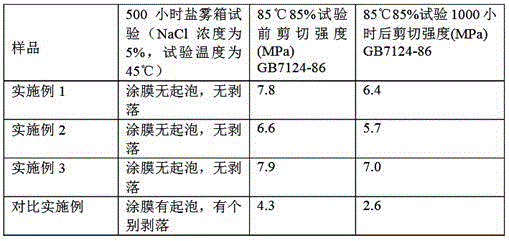

The invention relates to a preparation method of a polyurethane hot melt adhesive adhered with a lower surface energy material. The polyurethane hot melt adhesive prepared by the method provided by the invention has favorable flexibility and body tensile strength, can overcome the influence of an expansion factor difference between different materials, and is uniform in stress distribution so as to adapt to base materials in different types; an anti-dropping performance is good: the times for dropping a roller is higher than 300 times; the adhesion strength is high: the adhesion strength of PEI and a nickel-plated steel disc is higher than 6.0MPa; salt spray resistant and ageing-resistant performances are good: no damage is caused after a salt spray test is carried out for 500 hours, and no remarkable intensity attenuation is caused after a dual-85 test is carried out for 1000 hours.

Owner:YANTAI DARBOND TECH

Air filtration membrane with functions of killing bacteria and removing formaldehyde

ActiveCN107051232AImprove filtering effectPurification and decompositionSemi-permeable membranesBreathing filtersAir filtrationParticulates

The invention discloses an air filtration membrane with functions of killing bacteria and removing formaldehyde. The air filtration membrane is of a three-layer nanofiber membrane composite structure, wherein the upper layer is an activated carbon nanofiber membrane, the middle layer is a pure TiO2 nanofiber membrane, and the lower layer is a nano-silver antibacterial fiber membrane; the pure TiO2 nanofiber membrane is prepared from a high polymer material / TiO2 precursor composite nanofiber membrane through heat treatment, and the high polymer material / TiO2 precursor composite nanofiber membrane is prepared with an electrospinning method; the activated carbon nanofiber membrane is an electrospun activated carbon nanoparticle / high polymer material composite nanofiber membrane; the nano-silver antibacterial fiber membrane is an electrospun nano-silver particle / high polymer material composite nanofiber membrane. The air filtration membrane not only can filter solid particulate pollutants very well, but also is good in breathability, and can remove and decompose formaldehyde in air and filter and kill harmful bacteria in air, thereby guaranteeing health of a respiratory system better.

Owner:保定源汉升新材料科技有限公司

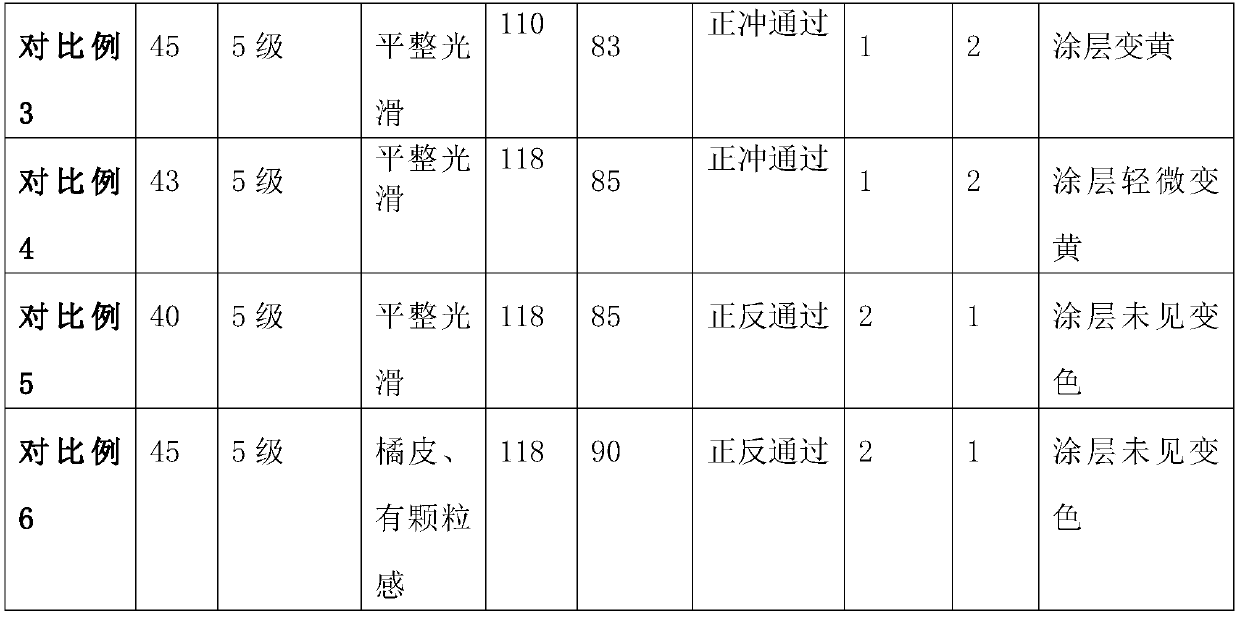

Graphene powder coating for radiator and preparation technology of graphene powder coating

InactiveCN106867360AFully curableSlow down the curing speedFireproof paintsPowdery paintsShock resistanceTitanium oxide

The invention relates to a graphene powder coating for a radiator and a preparation technology of the graphene powder coating. The graphene powder coating is prepared from the following components: phenolic aldehyde modified epoxy resin, hydroxyl saturated polyester resin, a solidification accelerator, rutile titanium oxide, butyl polyacrylate, yellowing resisting benzoin, a polysiloxane defoamer, a crosslinking agent, aminated graphene, carboxylic nanometer polytetrafluoroethylene and hydrogenated castor oil. As for the powder coating provided by the invention, the hydroxyl saturated polyester resin can enable the coating to ensure optimal leveling while the solidification speed is slowed down; combined use of the graphene and polytetrafluoroethylene can enable the whole coating to have better hardness, wear resistance and lubricating effect, be suitable for coating the surfaces of radiator type household appliances and be better in weatherability and yellowing resistance; the color of a coating film cannot change under the solidification condition with the temperature being 195-205 DEG C, and the solidified coating film cannot yellow permanently under the high-temperature working environment of the radiator after being solidified, is good in salt fog resistance, light fastness and shock resistance and is suitable for being further popularized and applied.

Owner:JIANGSU HUAGUANG POWDER

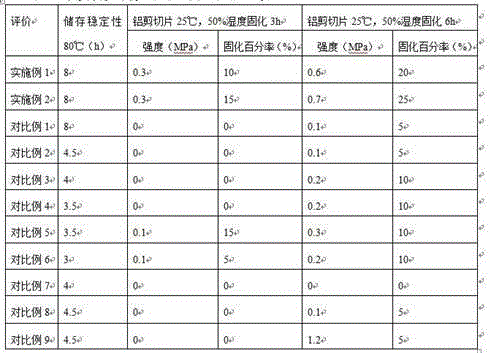

Quickly cured anaerobic plane sealant and initiator composition and preparation method

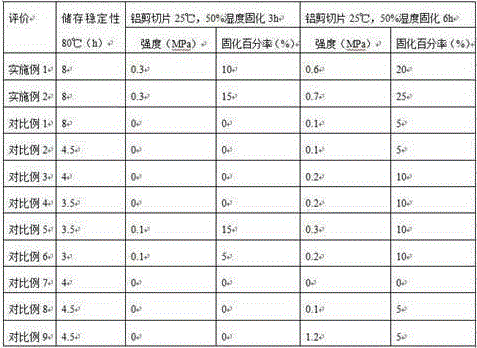

InactiveCN104356997ANo loss of stabilityFacilitated releaseNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesMethacrylatePolymer science

The invention relates to an anaerobic plane sealant which has an effect of increasing the curing speed on an aluminum and aluminum alloy material, and a preparation method of the anaerobic plane sealant. The invention mainly provides a novel approach of promoting the curing speed of the anaerobic plane sealant on aluminum and aluminum alloy without influencing the storage stability. The method comprises the step of adding a proper amount of water and dimethyl sulfoxide into an anaerobic curing sealant containing polyurethane-methacrylate prepolymer, free radical polymerizable monomer, organic peroxide, an accelerant and a stabilizer. The preparation method provided by the invention is simple and convenient, and the anaerobic plane sealant has excellent storage stability, and can still be used for quickly well adhering aluminum and aluminum alloy at a low-humidity environment.

Owner:TONSAN ADHESIVES INC

Method for preparing large-diameter high-sphericity polymer hollow micro-spheres

InactiveCN106040116AInhibited DiffusionDelayed curing speedMicroballoon preparationMicrocapsule preparationChemistryEmulsion

The invention discloses a method for preparing large-diameter high-sphericity polymer hollow micro-spheres. The method has the advantages that curing speed reducing and rotary curing processes are organically combined with one another, curing containers are sealed in procedures for preparing polymer hollow micro-spheres by the aid of microfluidic technologies, the quantities of dual-emulsion particles in external water phases and the quantities of preliminarily added organic solvents are changed, diffusion of the organic solvents towards the external water phases can be suppressed by the aid of the solubility of the organic solvents in the external water phases, the curing speeds of dual-liquid droplet can be reduced, and spheroidization of the dual-emulsion particles can be promoted; horizontal inclination angles, rotation modes and the rotational speeds of rotary flasks are controlled, accordingly, dispersion states of the dual-emulsion particles in the external water phases can be controlled, adhesion, coalescence and emulsion breaking of the dual-emulsion particles due to mutual collision can be prevented, non-spheroidization tendency of the dual-emulsion particles can be lowered, and the large-diameter high-sphericity polymer hollow micro-spheres can be prepared; the large-diameter high-sphericity polymer hollow micro-spheres can be applied to laser inertial confinement fusion physical experiments.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

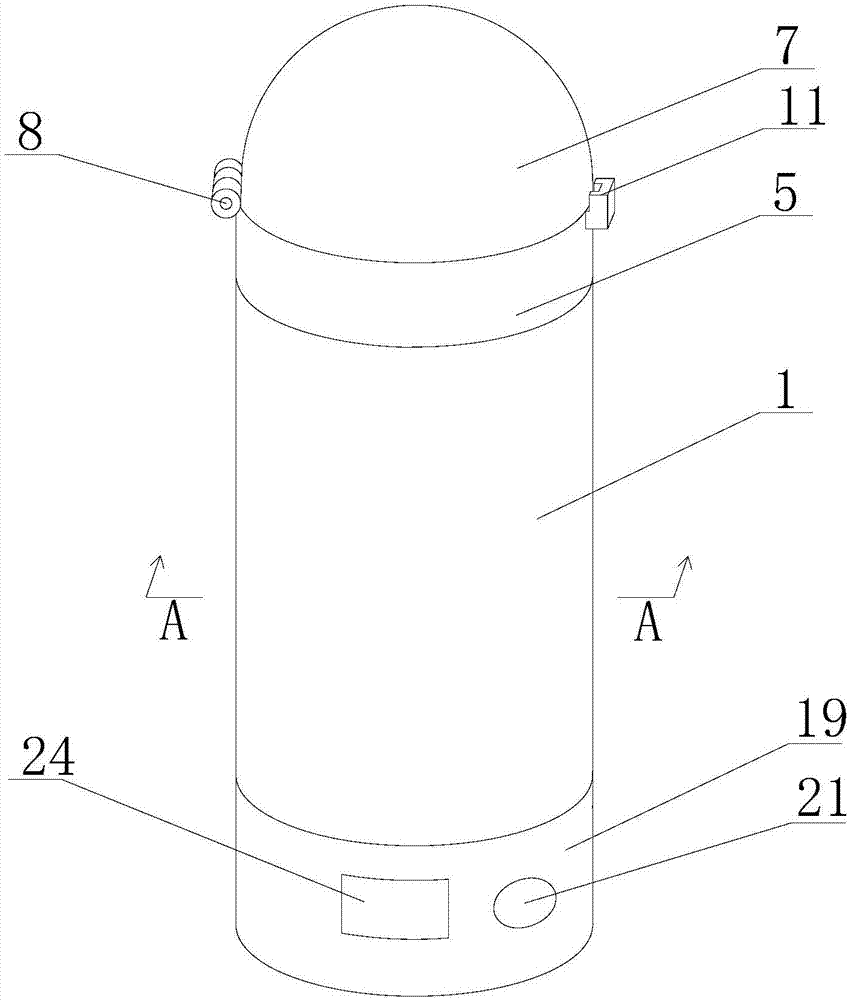

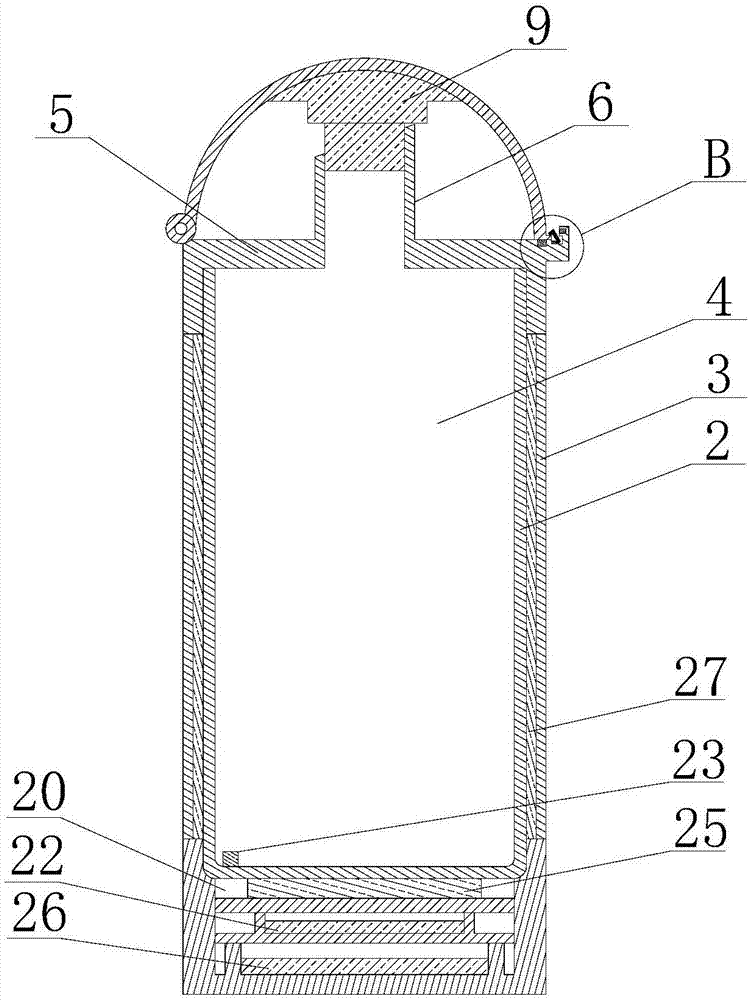

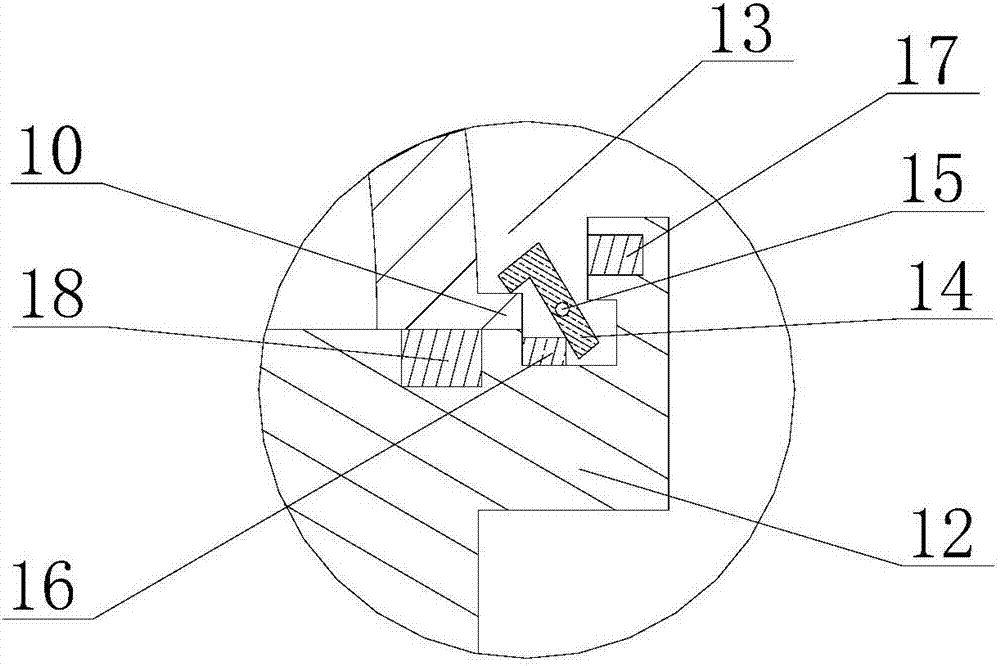

Portable thermal-insulation cup

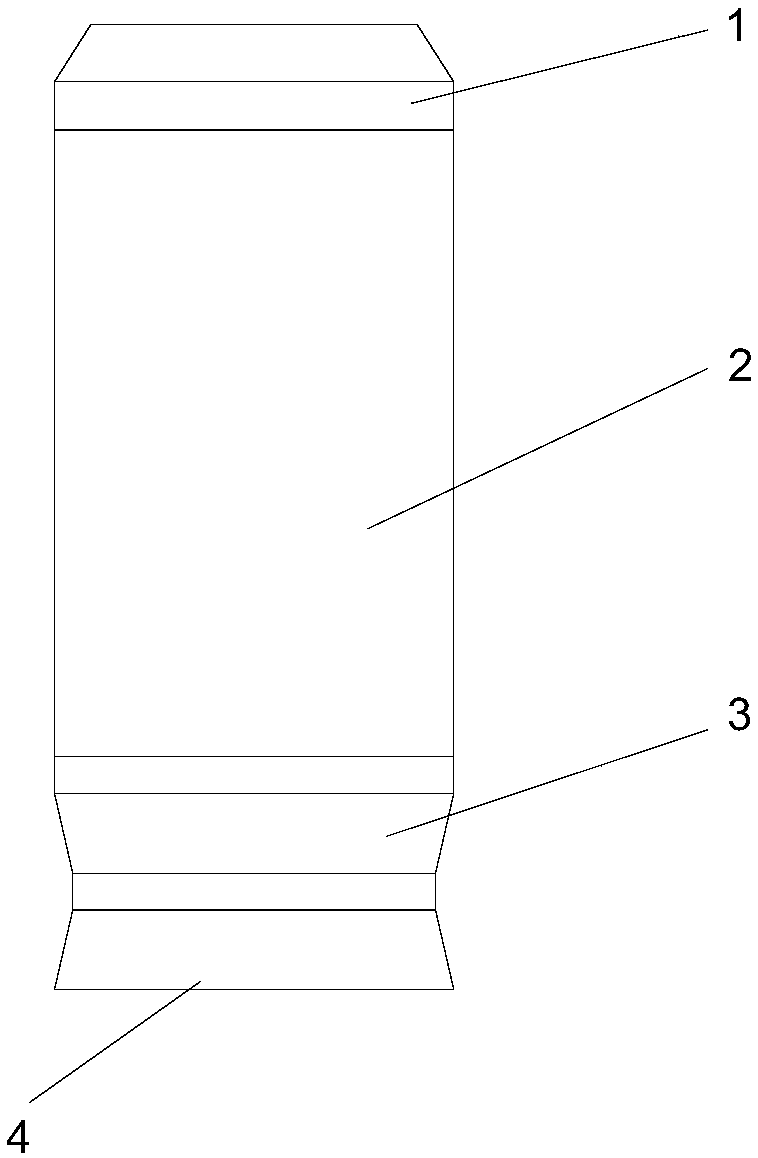

ActiveCN107468016AAvoid pollutionAvoid automatic openingTravelling sacksDrinking vesselsThermal insulationEngineering

The invention discloses a portable thermal-insulation cup, and belongs to the technical field of articles of daily use. The portable thermal-insulation cup comprises a cup body, an inner cup lid, an outer cup lid, a locking device, a detection device, a base, an infrared sensing switch and a controller; the cup body is internally provided with an inner cavity, the inner cup lid is arranged at the upper portion of the cup body, and the outer cup lid is hinged to the upper portion of the inner cup lid, and is provided with a first lug which is matched with the locking device to lock the outer cup lid; the locking device comprises a second lug, a pressing rod, an electromagnet, an elastic part and a second overturn shaft; the detection device is inset at the upper edge of the inner cup lid; the base is arranged at the bottom of the cup body, and is provided with an electric appliance mounting cavity; the infrared sensing switch is arranged at the outer circumference surface of the base; the controller is arranged in the electric appliance mounting cavity. According to the portable thermal-insulation cup, automatic opening and locking of the outer cup lid are achieved, and the problem that the cup opening is easily contaminated when a lid of a traditional thermal-insulation cup needs to be unscrewed with hands is solved.

Owner:南丹县产品质量检验所

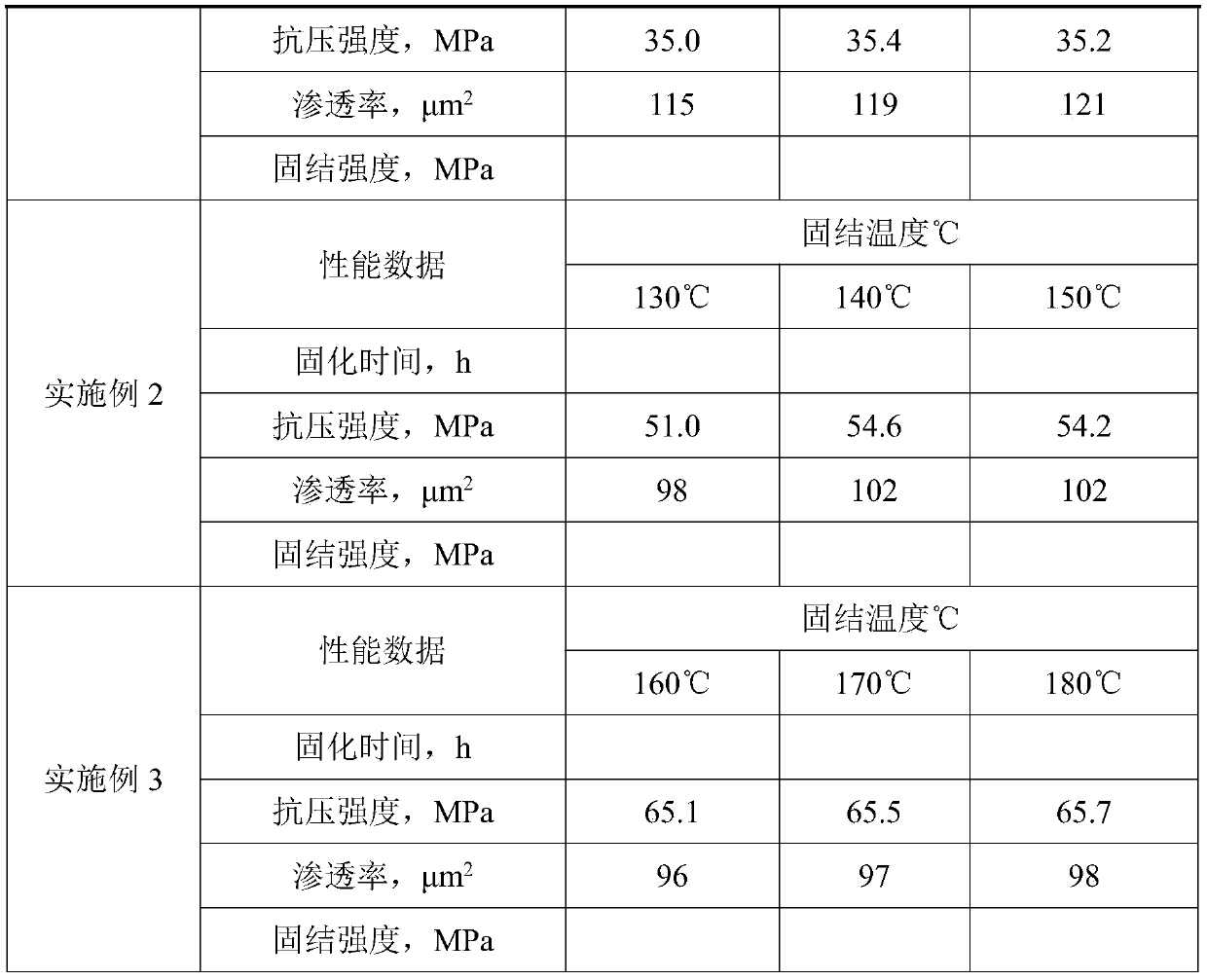

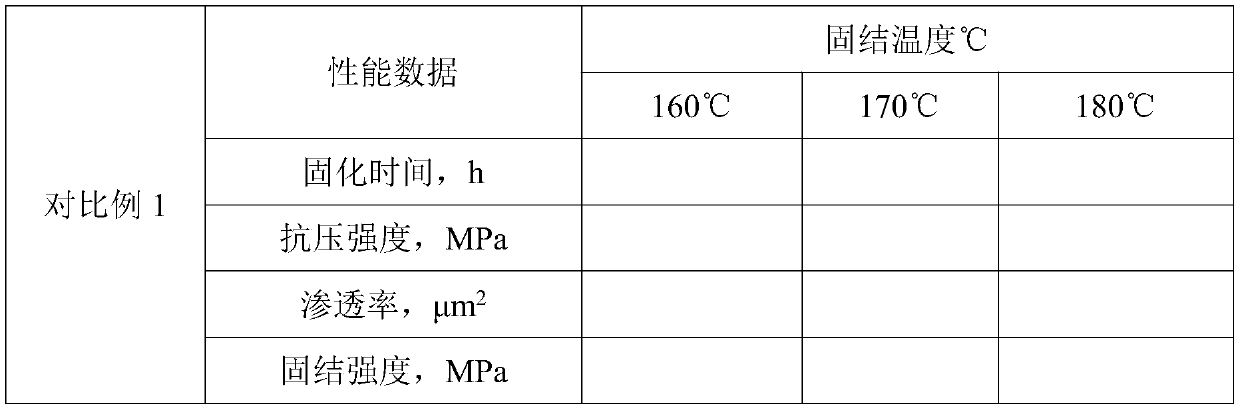

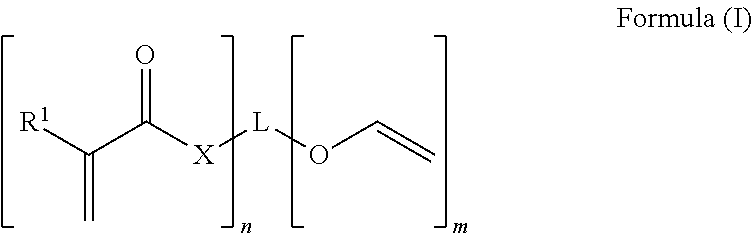

Self-polymerized consolidated pressure-resistant permeation-increasing temperature-resistant sand preventing agent

ActiveCN110684517AImprove thermal stabilityHigh decomposition temperatureDrilling compositionP-nitrobenzoic acidPoly ethylene

The invention discloses a self-polymerized consolidated pressure-resistant permeation-increasing temperature-resistant sand preventing agent. The self-polymerized consolidated pressure-resistant permeation-increasing temperature-resistant sand preventing agent comprises the following components, in percentage by mass: 30-40% of a resin compounding system; 40-50% of an organic solvent; 5-7% of a coupling agent; 5-8% of a filler; 4 to 5% of a curing agent, and 5 to 8% of an emulsifier; wherein the sum of the mass percentages of the components is 100%; the curing agent is p-nitrobenzoic anhydrideand tetrachlorophthalic anhydride which are mixed in equal mass; the filler is high-temperature-resistant multi-mineral fine powder and phenolic fiber; and the high-temperature-resistant multi-mineral fine powder is a mixture of magnesium oxide, aluminum oxide and silicon oxide; the resin compounding system is formed by compounding epoxy resin E-44, epoxy resin E-51, phenolic resin F-51 and polyvinylpyrrolidone K30. The sand preventing agent is mainly used for chemical sand control of high-temperature and high-pressure wells, can be injected into stratums without moving tubular columns, andachieve the purposes of sand control and sand consolidation.

Owner:SICHUAN JIEBEITONG ENERGY TECH CO LTD

Urea-formaldehyde resin additive, urea-formaldehyde resin containing the same and preparation method thereof

ActiveCN101205348ASolve Exhaust ProblemsSave resource usageAldehyde/ketone condensation polymer adhesivesAluminium sulfateResin adhesive

The invention provides an additive with urea formaldehyde, a preparation method and a urea formaldehyde resin adhesive. The additive is provided by the invention. The raw material of the additive is comprised of the dispersion medium, the dried egg white of the degreased bean and the complexing agent, the weight ratio of the raw material is: 70-80 of dispersion medium, 20-35 of dried egg white of the degreased bean, 1-3 of complexing agent, the complexing agent is consisted of the aluminium sulphate and the zirconium carbonate with the weight ratio of 0.4-2.4:1. The additive provided by the invention contains dried egg white of the degreased bean, and then both the bond strength of the prepared veneer is increased and the formaldehyde emission of the preparing artificial slabs is effective decreased when adding the additive into the urea formaldehyde.

Owner:CHANGZHOU JOEL PLASTIC

Low speed cross-linking catalyst for silane-grafted plastomers

ActiveUS20210324189A1Excellent EPDM replacementSlow down the curing speedFlexible pipesPolymer sciencePtru catalyst

The present invention relates to silane crosslinking catalyst comprising: —75 to 85 wt.-% of an olefin acrylate interpolymer and—15 to 25 wt.-% of a hindered amine light stabilizer (HALS) having a number average molecular weight Mn of 1500 to 4000 g / mol; and—optionally up to 5 wt.-% wax, wherein the silane crosslinking catalyst is free of tin, carboxylic acid(s) and sulphonic acid(s), all weight percentages with respect to the total weight of the silane crosslinking catalyst.

Owner:BOREALIS AG

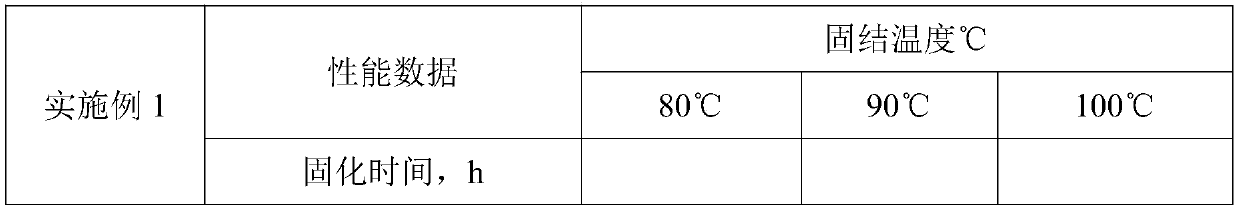

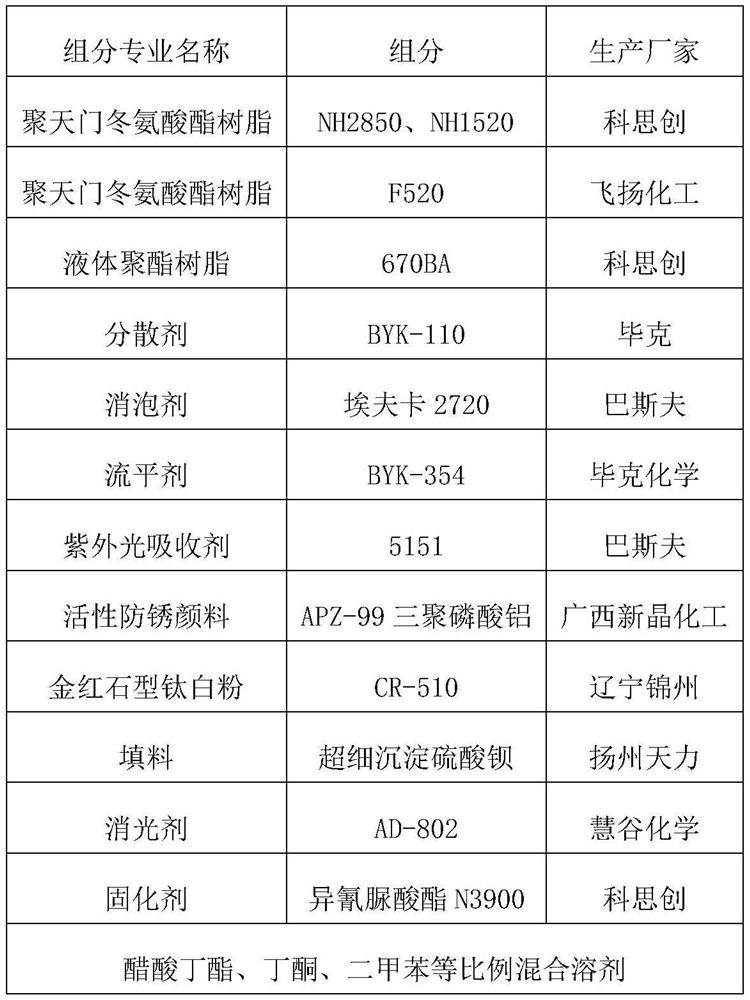

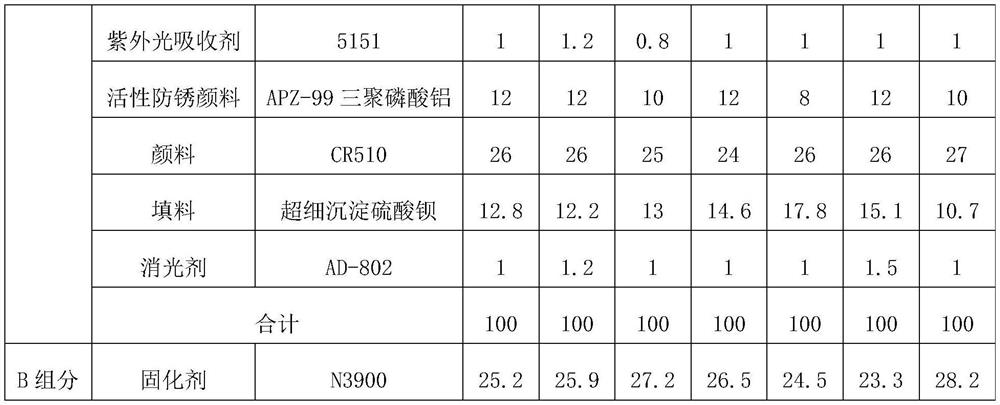

High-solid-content and low-viscosity polyaspartic acid ester primer-topcoat coating suitable for high-pressure airless spraying and preparation method thereof

ActiveCN112210279ANormal levelingImprove general performanceAnti-corrosive paintsPolyurea/polyurethane coatingsPolymer sciencePolyaspartic acid

The invention relates to a high-solid-content and low-viscosity polyaspartic acid ester primer-topcoat coating suitable for high-pressure airless spraying and a preparation method thereof. The high-solid-content low-viscosity polyaspartic acid ester primer-topcoat coating comprises the following components in percentage by mass: 30-40% of polyaspartic acid ester resin; 10%-20% of polyester resin;0.3%-1.5% of a dispersing agent; 0.3%-1.0% of a defoaming agent; 1%-3% of a dehydrating agent; 0.3%-0.8% of a leveling agent; 0.4%-1.5% of an anti-sagging agent; 1%-3.0% of an ultraviolet absorber; 34%-45% of pigment; 10%-25% of a filler; 6%-10% of a solvent; 20%-29% of curing agent. Conventional high-pressure airless spraying equipment can be adopted for construction, it is guaranteed that the mixed paint can be normally constructed after 30 min at the environment temperature of 30 DEG C, the surface of a paint film is leveled normally, the defects of pinholes, shrinkage cavities, bubbles andthe like are avoided, the weather resistance, gloss retention, color retention and weather resistance are excellent, the solid content is high, and the requirements of environment-friendly paint aremet; the one-time film forming thickness can reach 150-350mu m, the surface drying and hard drying time is fast, and the working life is long.

Owner:JIANGSU LANLING POLYMER MATERIAL CO LTD +1

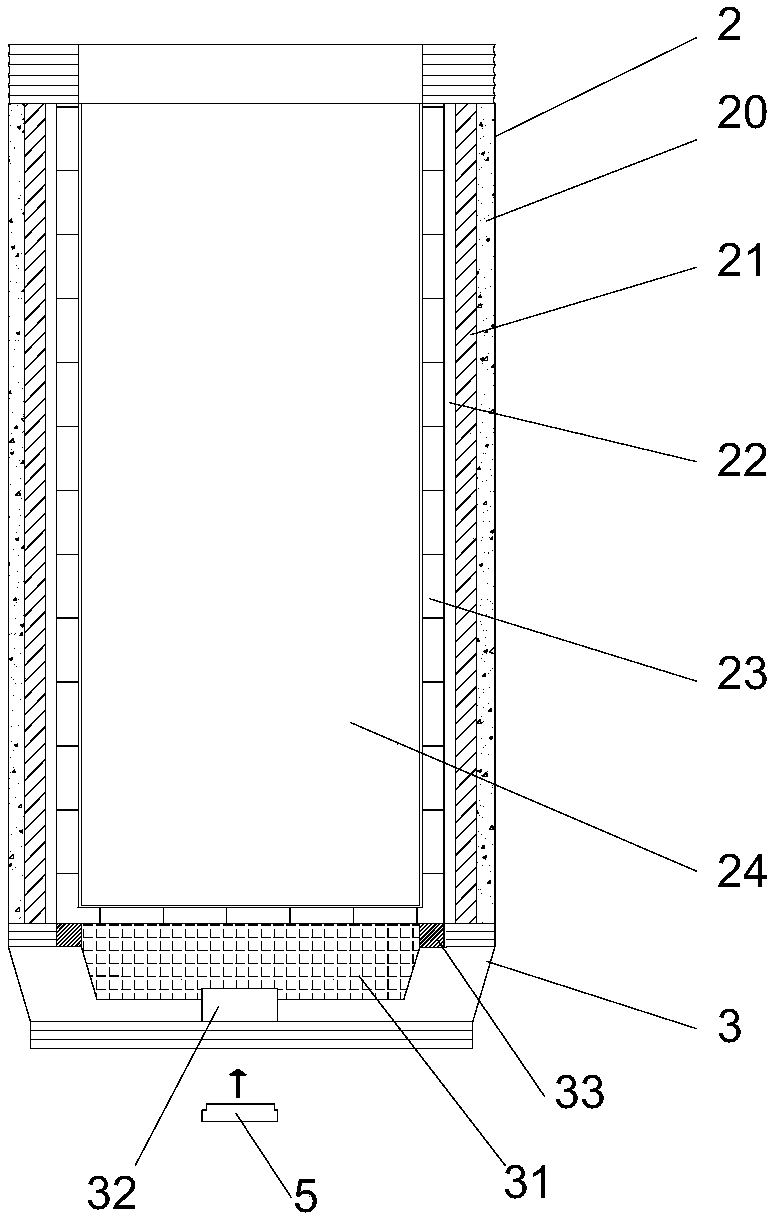

Electric water heater

Owner:GUANGXI UNIV

Preparation method of polyurethane hot-melt adhesive being sweat resistant

ActiveCN106634776AHigh initial bond strengthImprove toughnessPolyureas/polyurethane adhesivesElastomerPliability

The invention relates to a preparation method of a polyurethane hot-melt adhesive being sweat resistant. Terminal-hydroxyl liquid petroleum resin and terminal active liquid polybutadiene are used as a compound modifying agent, wherein the two components are both strong-hydrophobic monomers, so that a synergistic effect is achieved. Through a reaction with polyisocyanate and then molecular hybridization by a silane modifier, the compound modifying agent is significantly improved in anti-salt-spray-corrosion performance. The two components are flexible elastomers, so that the two components, as excellent flexibilizers, can effectively improve flexibility and anti-falling-impact performance. The polyurethane hot-melt adhesive is excellent in sweat corrosion resistance and has excellent comprehensive performance.

Owner:YANTAI DARBOND TECH

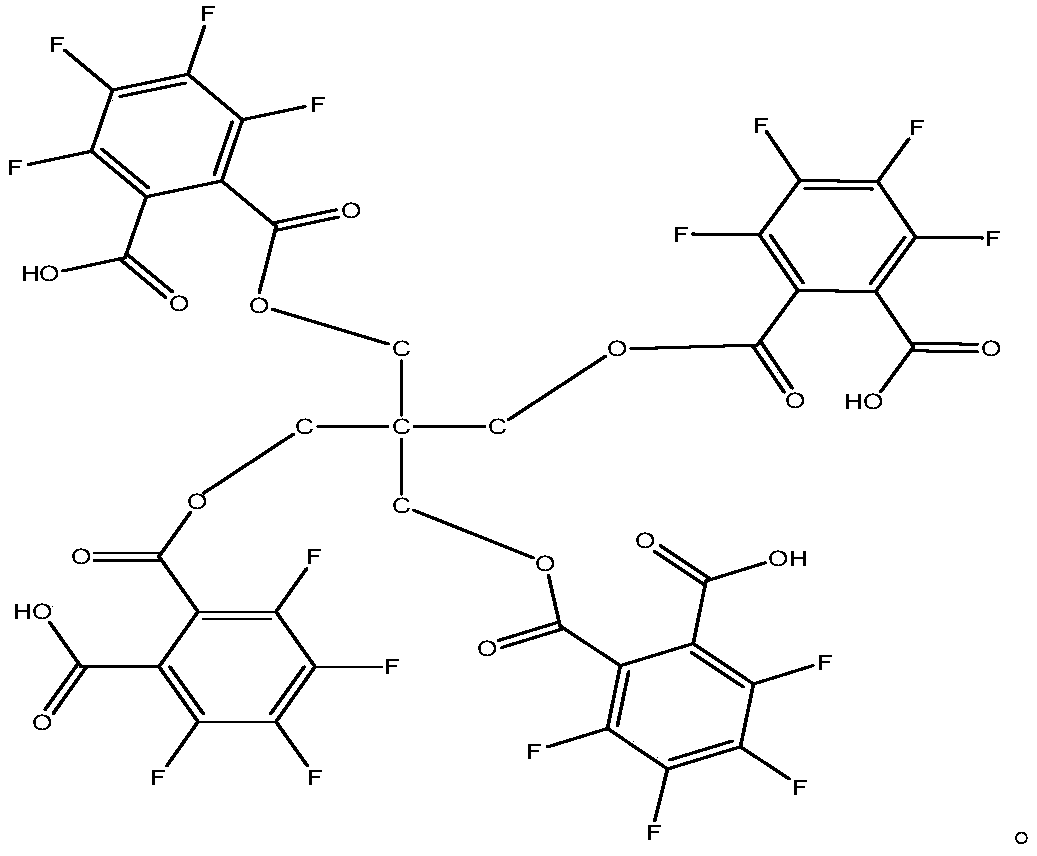

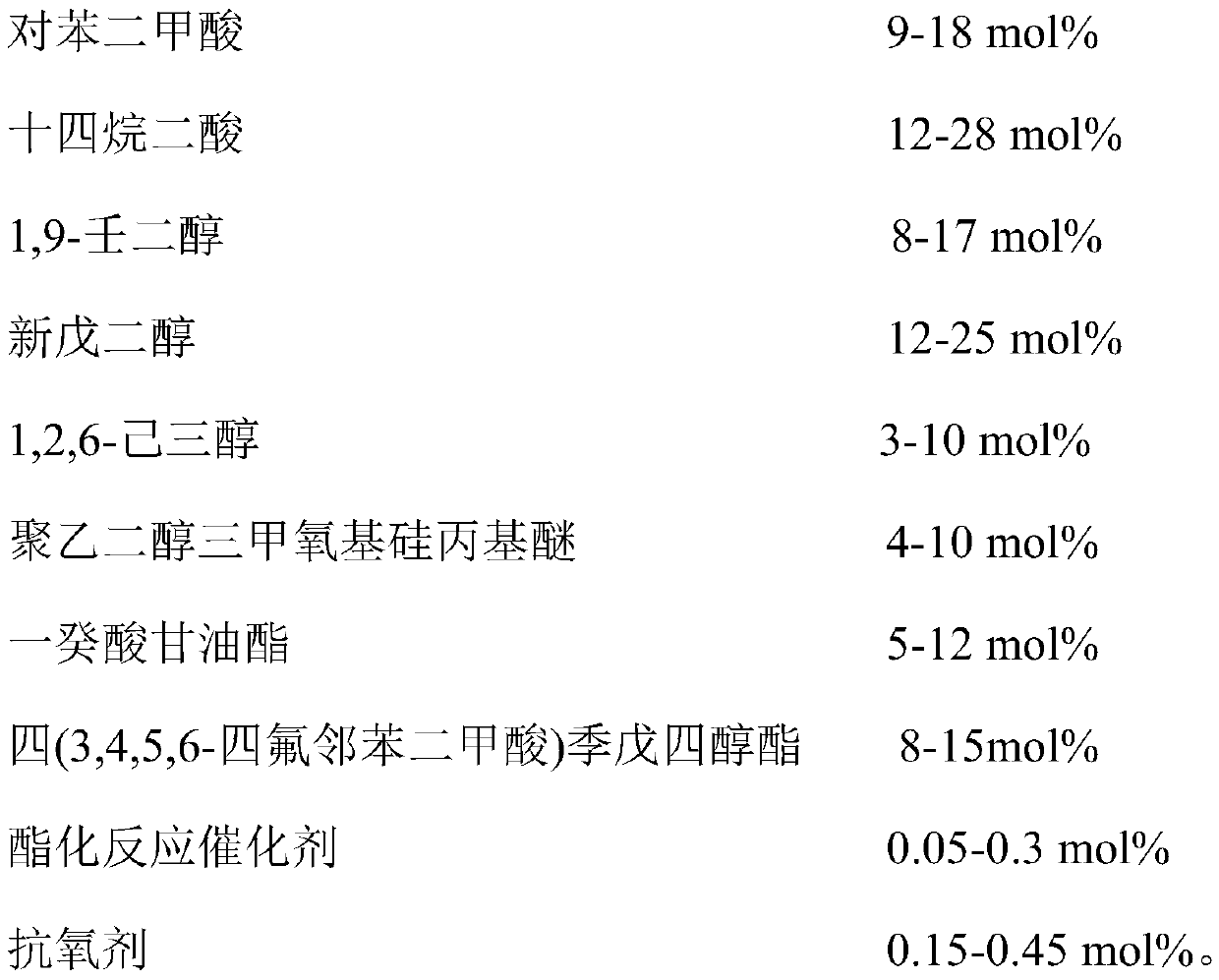

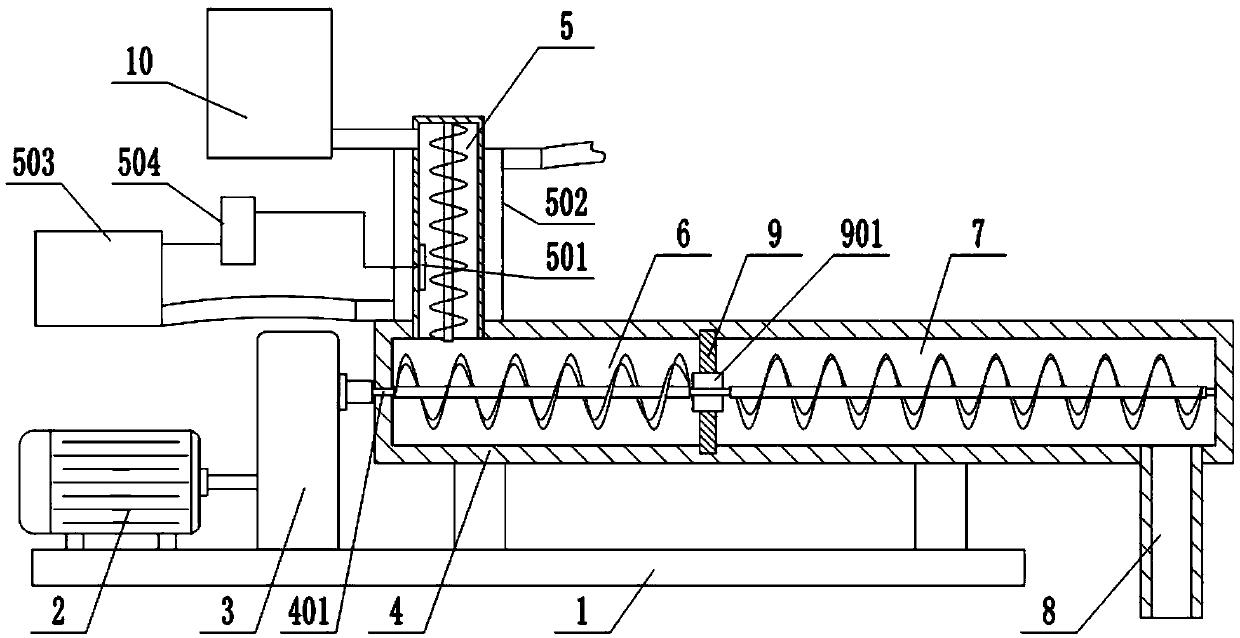

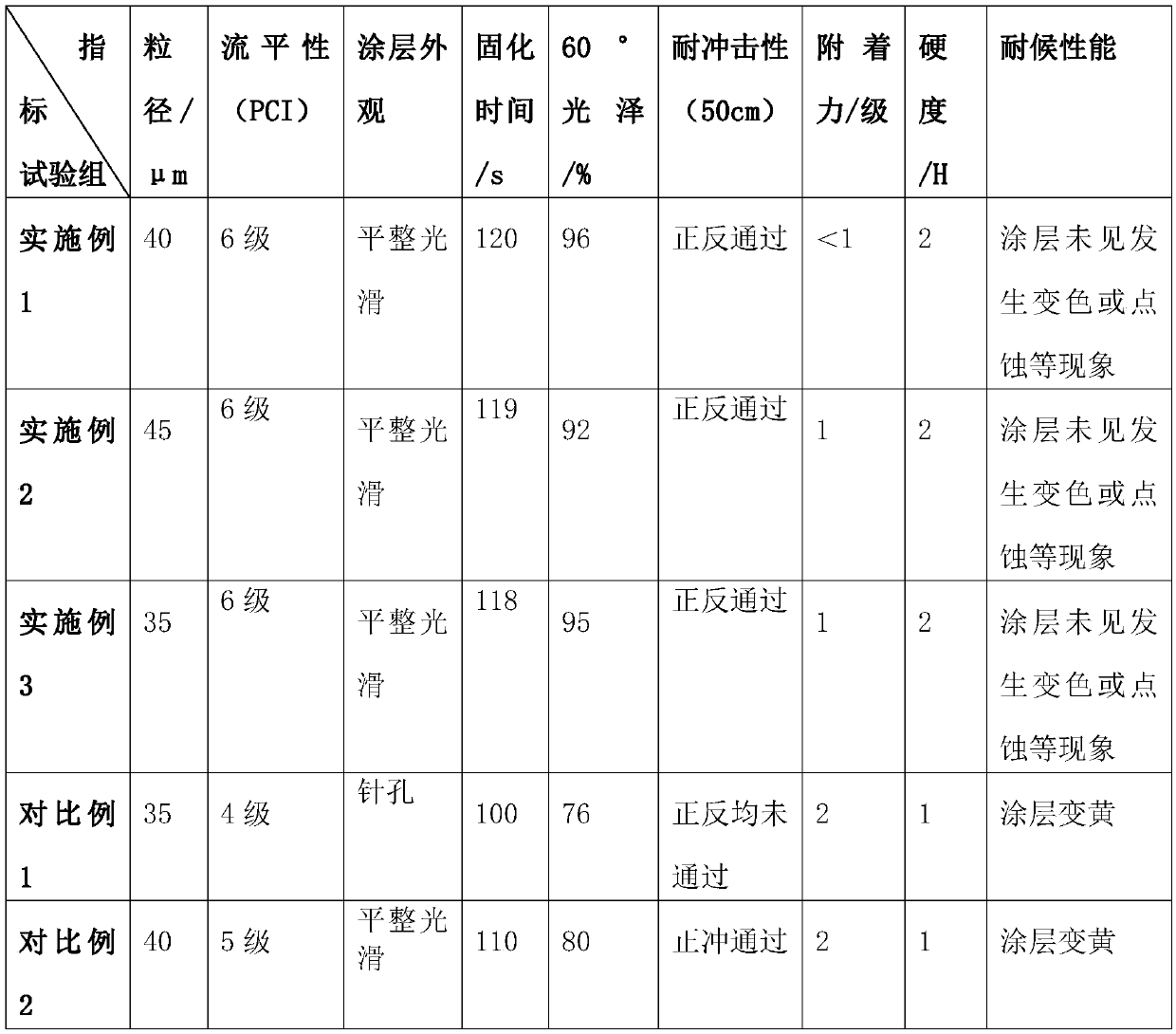

Epoxy cured 70:30 polyester resin excellent in levelability and solvent resistance and preparation method thereof

ActiveCN109824879AImprove compatibilityHelp leveling finenessPowdery paintsEpoxy resin coatingsSolventChemistry

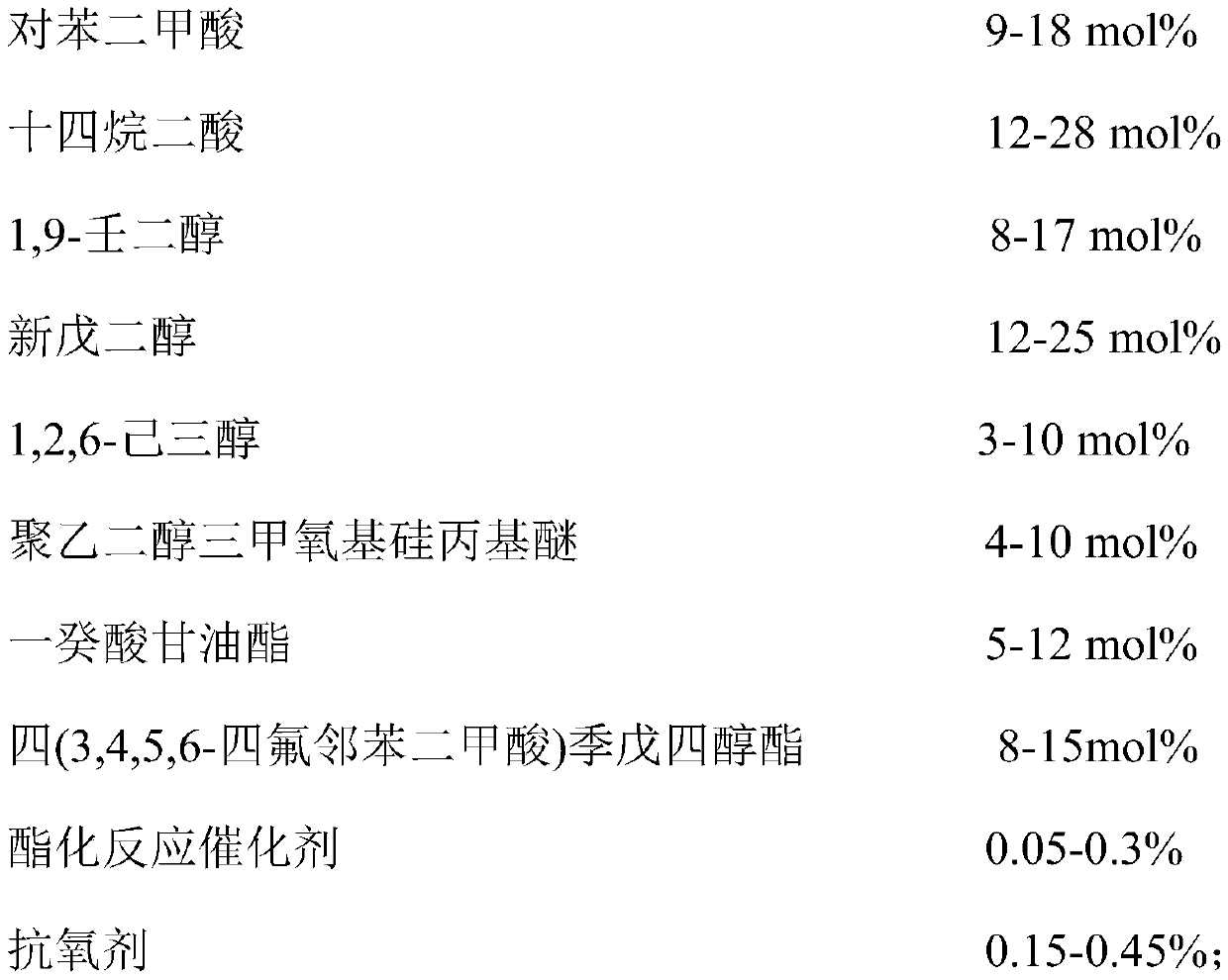

The invention relates to an epoxy cured 70:30 polyester resin excellent in levelability and solvent resistance, and a preparation method thereof, and belongs to the technical field of power paint chemistry. According to the preparation method, long chain flexible raw materials such as tetradecanedioic acid are adopted, so that polyester melting viscosity is reduced effectively, and coating film surface levelability is improved; high-functionality fluorine-containing end-capping reagent tetra(3, 4, 5, 6-tetrafluorophthalic acid) pentaerythritol ester is adopted for polyester end capping to reduce polyester resin carboxyl end group activity, reducing curing speed with E-12 epoxy resin, prolonging gelling time, ensuring enough leveling time, and achieving excellent cured coating film levelability; the end capping reagent is extremely high in functionality, so that cured coating film crosslinking density is large; end capping reagent self fluorine content is high, so that the cured coatingfilm possesses excellent resistance on routine organic solvents; the epoxy cured 70:30 polyester resin is applied in powder paint, so that coating layers excellent in levelability and solvent resistance are obtained. The raw materials are easily available, operation of the preparation process is simple and convenient, the preparation method is suitable for large scale production, and it is benefical for improvement of powder paint popularization and applications.

Owner:安徽永利新材料科技有限公司

Energy-saving paint and preparation method thereof

InactiveCN106978048ASlow down the curing speedIncrease viscosityPolyurea/polyurethane coatingsEpoxy resin coatingsPolyesterEnvironmental resistance

The invention relates to an energy-saving paint and a preparation method thereof. The paint comprises epoxy acrylate, butyl acetate, ethylene glycol, sodium fatty alcohol sulfate, polyurethane acrylate, polyester acrylate, a polyfunctional monomer, a pigment, a leveling agent and a dispersant. The paint prepared through mixing above components and processing the obtained mixture has the advantages of good adhesion, low cost of materials, realization of energy saving, emission reduction, few raw materials and wide raw material sources in the making process, certain environmental protection meaning, difficulty in color fading, no pollution to environments, very good water resistance, bright color, smooth surface and very good practical effects.

Owner:合肥天沃能源科技有限公司

Solvent-free environment-friendly coating and preparation method thereof

InactiveCN109608999ASlow down the curing speedImprove performancePowdery paintsPolyester coatingsSolvent freeSolvent

The invention belongs to the technical field of coatings, and particularly discloses a solvent-free environment-friendly coating and a preparation method thereof, which comprises the following raw materials in percentage by mass: 50-60% of polyester resin and 2-10% of hydroxyalkyl amide, 15-25% of auxiliary materials, 10-15% of pigment and filler and 3-5% of nano calcium carbonate, 3% -5% of hollow glass beads and 0.02% -0.1% of a curing inhibitor, 0.1-0.5% of a lubricant, 0.5-2% of a flatting agent and 0.5-1% of benzoin, 0.5-1% of an ultraviolet absorbent and 0.5-1% of an anti-ultraviolet absorbent; and the auxiliary material comprises high-gloss barium sulfate, precipitated barium sulfate and calcium carbonate; the pigment filler comprises titanium dioxide and mica powder. According to the invention, the polyester resin is selected as the main raw material and is safe and non-toxic hydroxyalkyl amide (HAA)) is a curing agent, and nano calcium carbonate and hollow glass beads are added, a curing inhibitor and a lubricant, so that the problem that a pinhole phenomenon of an HAA system coating is easy to occur is solved, the comprehensive performance of the coating is improved, andthe dispersibility, leveling property and weather resistance are improved.

Owner:CHONGQING QICAIHONG CHEM

Low speed cross-linking catalyst for silane-grafted plastomers

ActiveUS11299617B2Slow down the curing speedGood flexibilityFlexible pipesPolymer sciencePtru catalyst

Owner:BOREALIS AG

Production method of bamboo floor

InactiveCN102398290AControl chromatic aberrationIncrease incomeWood working apparatusEngineeringBatten

The invention discloses a production method of bamboo floor, which comprises the steps of material selection, cooking treatment and drying of bamboo battens, finish planing of the bamboo battens, sorting, adhesive coating and assembly, hot press and surface finishing. The production method is characterized in that: after the bamboo battens are subjected to finish planing, separation of surface patches from bottom patches is carried out, adhesive is coated and the color selection of the surface patches is carried out. According to the production method disclosed by the invention, the problems of difficulty in controlling the color difference and the like in the traditional production process of the bamboo floor are solved; and the production method has the advantages of simple work procedures, convenience in operation, small color difference and the like.

Owner:朱江福

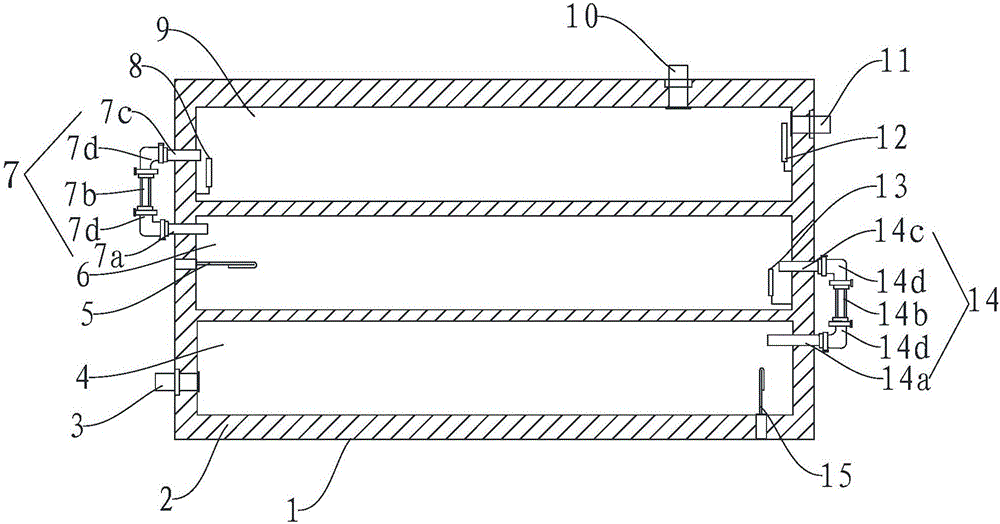

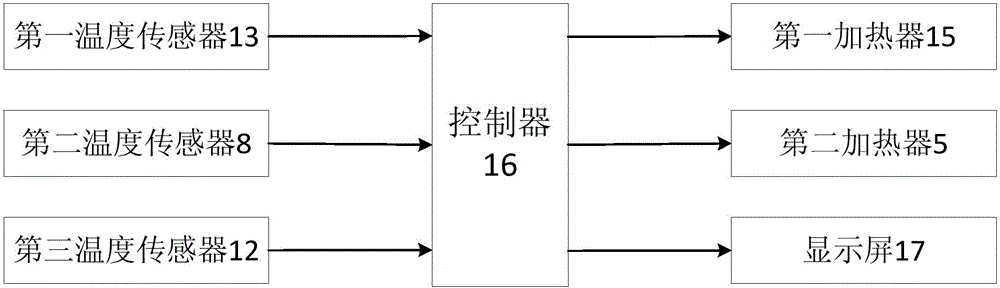

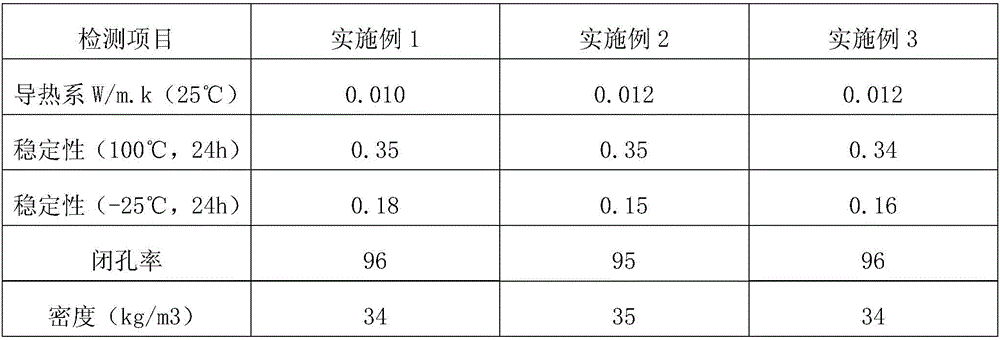

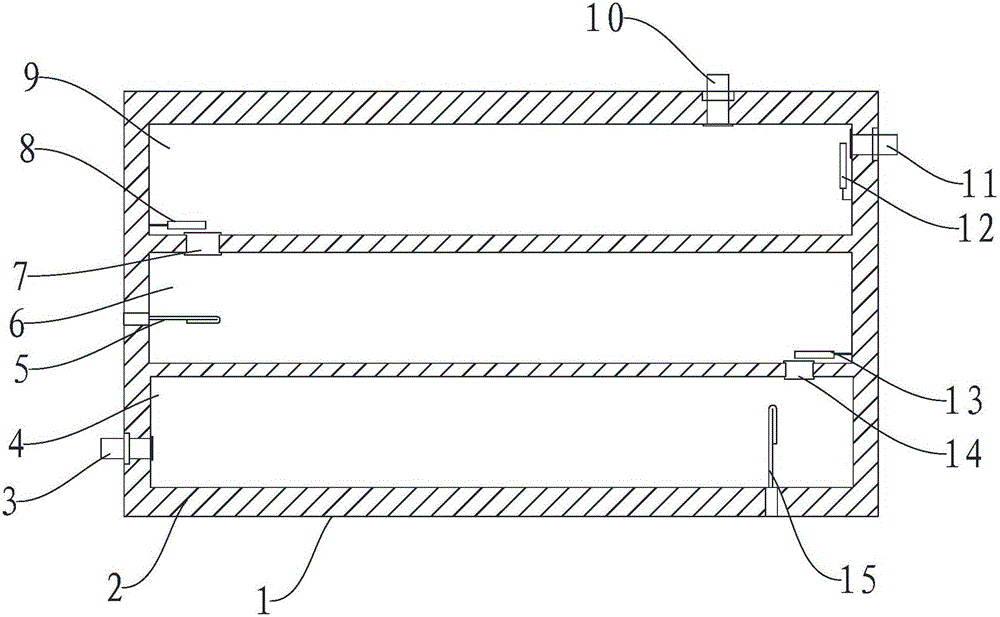

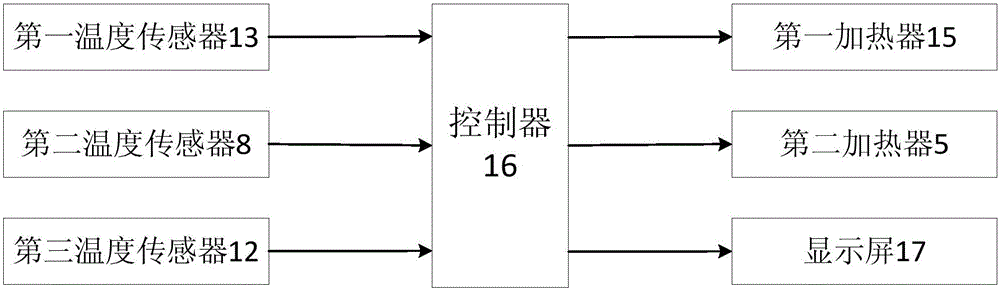

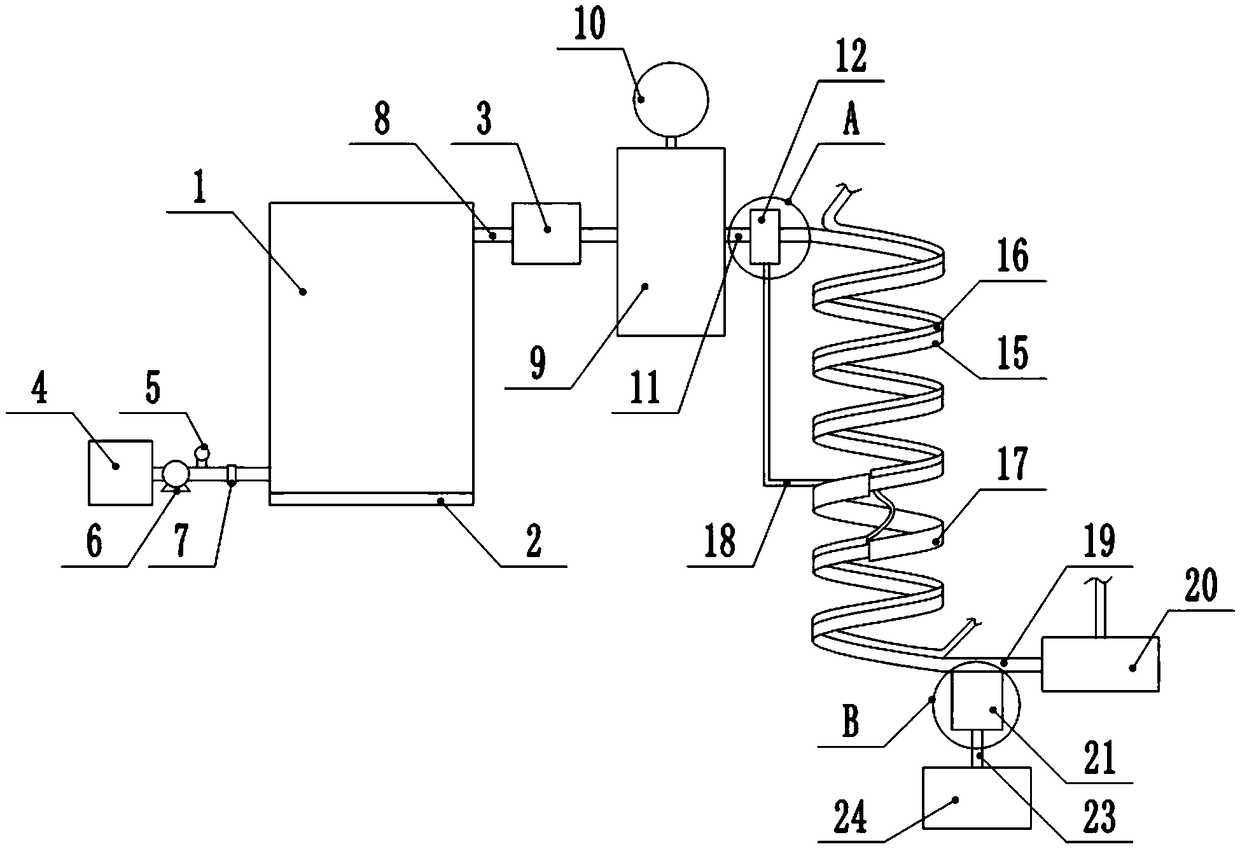

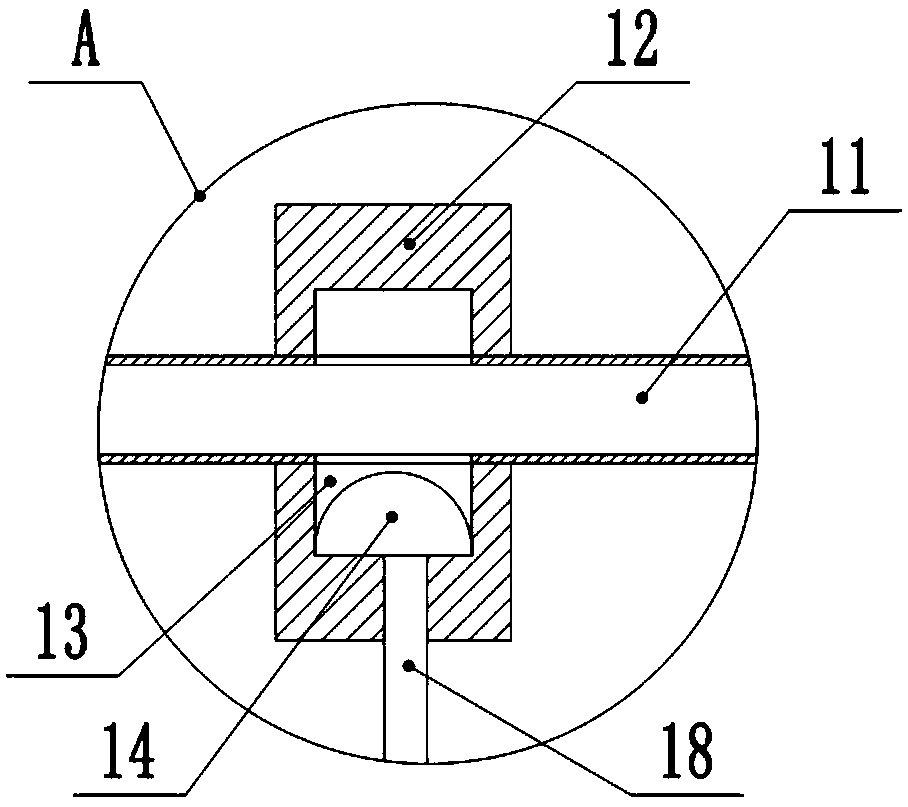

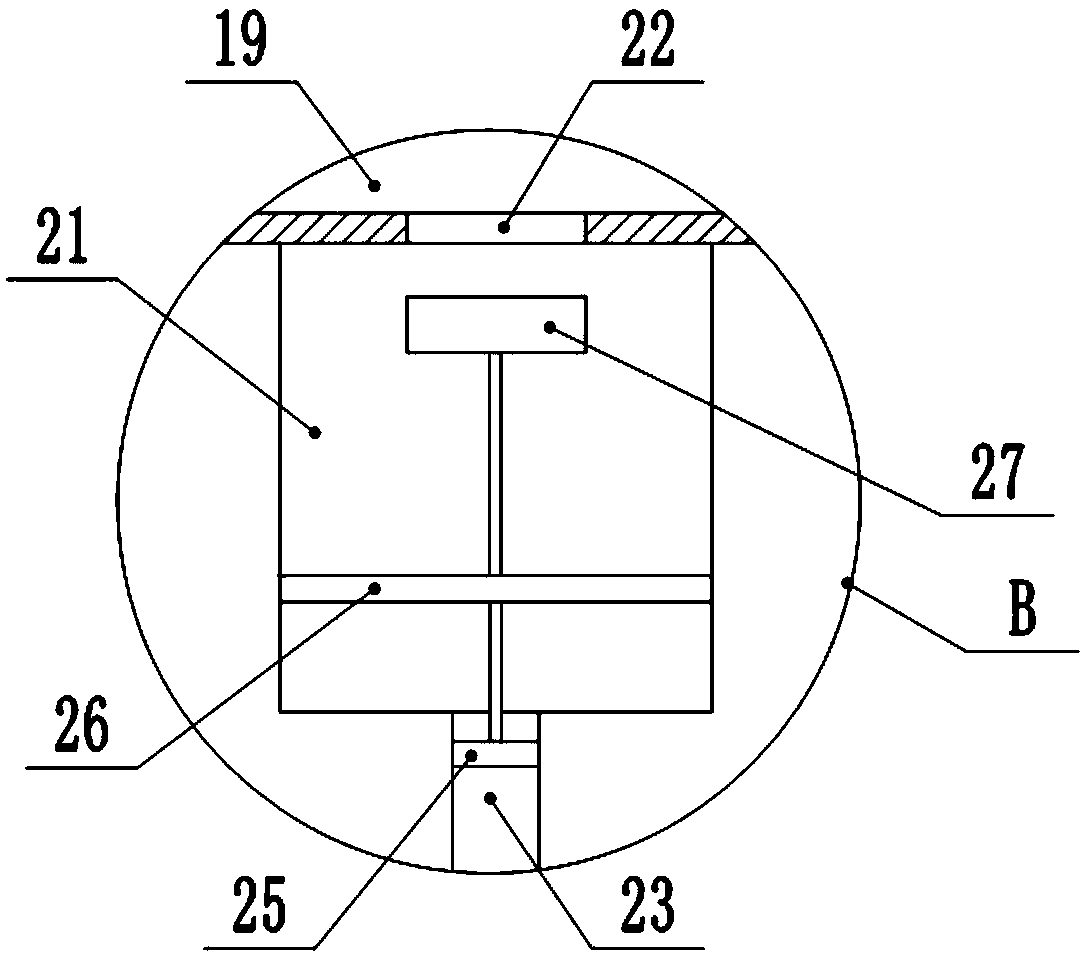

Energy saving and heat preserving type electric water heater

The invention provides an energy saving and heat preserving type electric water heater and belongs to the technical field of water heater water tanks. The energy saving and heat preserving type electric water heater comprises a shell, wherein three liners are distributed in the shell from top to bottom, and heat preserving layers are arranged between the shell and the liners. According to the water heater, three liners are adopted, hot water rapidly and preferentially reaches a hot water outlet by skillfully arranging a mode for connecting a water inlet, the water outlet and the liners according to the principles that hot water rises and cold water drops, and a purpose of rapidly getting hot water is achieved. A common water heater is only provided with a temperature sensor for detecting the temperature of the water outlet, but the energy saving and heat preserving type electric water heater realizes graded heating by arranging a plurality of temperature sensors and a plurality of heating devices in different liners, thereby being more accurate to control. The water heater has the advantages of being high in water temperature rise speed, being great and lasting in heat preserving effect, being safe and healthy in use and the like.

Owner:GUANGXI UNIV

Fast-curing anaerobic plane sealant and initiator composition and preparation method

InactiveCN104356997BNo loss of stabilityFacilitated releaseNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesMethacrylatePolymer science

The invention relates to a kind of anaerobic plane sealant with the effect of improving the curing speed on aluminum and aluminum alloy materials and a preparation method thereof. It mainly provides a new way to increase the curing speed of anaerobic plane sealants on aluminum and aluminum alloys without affecting storage stability. It is mainly formed by adding an appropriate amount of water and dimethyl sulfoxide to the anaerobic curing sealant containing urethane methacrylate prepolymer, free radical polymerizable monomer, organic peroxide, accelerator and stabilizer. preparation. The preparation method provided by the invention is simple and convenient, has good storage stability, and can still have a fast and good bonding effect on aluminum and aluminum alloys in a low-humidity environment.

Owner:TONSAN ADHESIVES INC

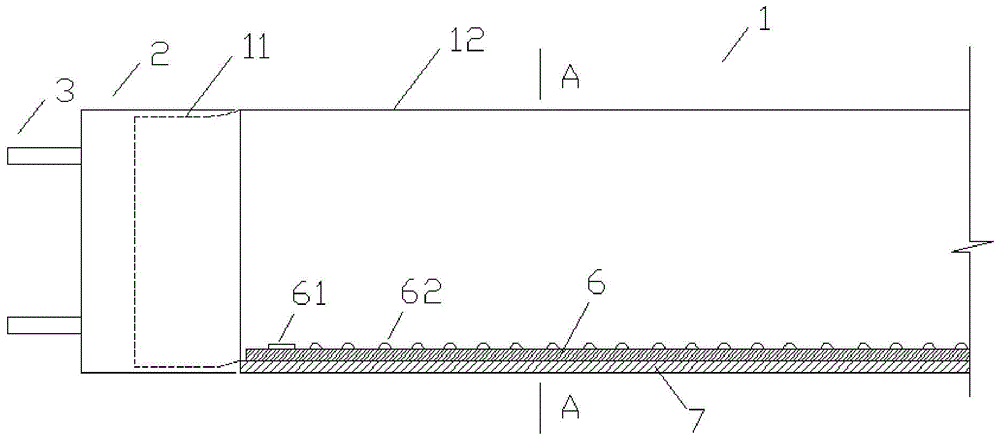

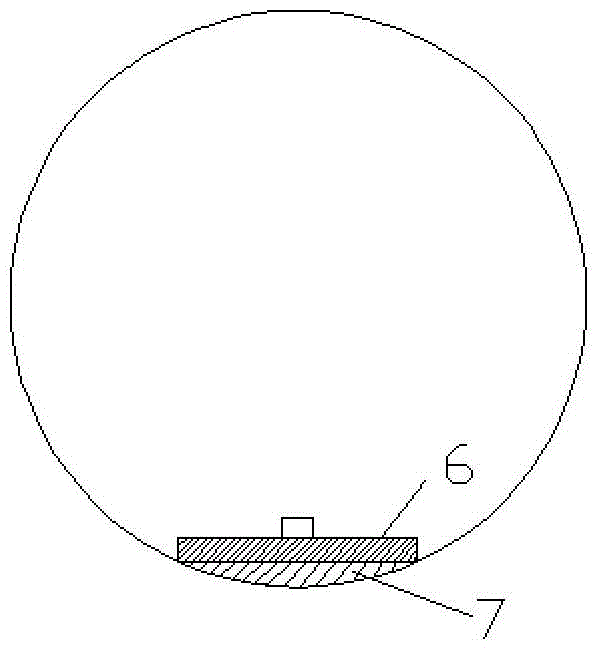

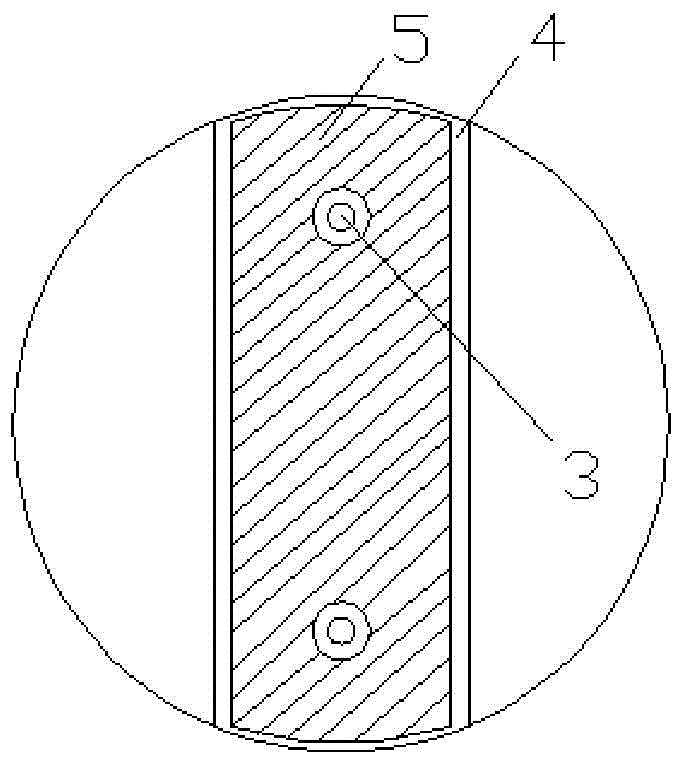

LED lamp

ActiveCN105674114ASimple structureReasonable structureNon-macromolecular adhesive additivesElectrical apparatusAdhesiveEngineering

The invention relates to an LED lamp. The LED lamp comprises a tube and a metal lamp holder capable of being used for high-frequency heating, wherein the tube comprises a straight part and necked parts arranged at two ends of the straight part, and smooth transition sections are arranged between the necked parts and the straight part; a lamp belt adheres to the straight part by the aid of an adhesive, and a patch power supply and LED light-emitting units are arranged on the lamp belt; the metal lamp holder is arranged outside the necked parts and is closely connected with the necked parts by the aid of welding mud; the metal lamp holder is 10-12 mm long, the necked parts are 6-8 mm long, and the gap between the metal lamp holder and the necked parts is 1-2 mm; the patch power supply is arranged in the position close to one end of the straight part, and the distance between the patch power supply and the end of the straight part is 3-5 mm. The LED lamp is simple in structure, high in lighting efficiency and low in rejection rate, comprises few components, is beneficial to industrial production line production and has unique technical advantages in aspects of breaking through the production bottleneck and substantially increasing the profit margin of products, and the welding mud is efficient and quick to solidify.

Owner:CHENHUI GUANGBAO TECH CO LTD

Scratch-coated polyurea elastomer corrosion-resistant and wear-resistant material and preparation method thereof

ActiveCN105802460BIncrease crosslink densityHigh tensile strengthAnti-corrosive paintsPolyurea/polyurethane coatingsElastomerWear resistant

The invention discloses a scraping coating type polyurea elastomer corrosion-resistant and wear-resistant material and a preparation method thereof. The scraping coating type polyurea elastomer corrosion-resistant and wear-resistant material is characterized by comprising an ingredient A and an ingredient B, wherein the ingredient A is prepolymers with NCO end groups obtained through the reaction between 30 to 40 mass percent of polyether polyol and 60 to 70 mass percent of polyisocyanates; the ingredient B is prepared from 30 to 40 mass percent polyaspartic acid ester, 60 to 70 mass percent of filling materials and a small number of auxiliary agents through high-speed dispersion grinding. In the use process, the prepared ingredient A and the prepared ingredient B are weighed according to the weight ratio of 1:4, and are then uniformly mixed; next, scraping coating construction is performed. The material has the characteristics of high mechanical intensity, corrosion resistance, wear resistance, good anti-seeping performance, aging resistance, proper reaction speed, no solvent, convenient construction and the like. The scraping coating type polyurea elastomer corrosion-resistant and wear-resistant material is particularly suitable for industrial and mining enterprise equipment and spare part anti-corrosion wear-resistant liners.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

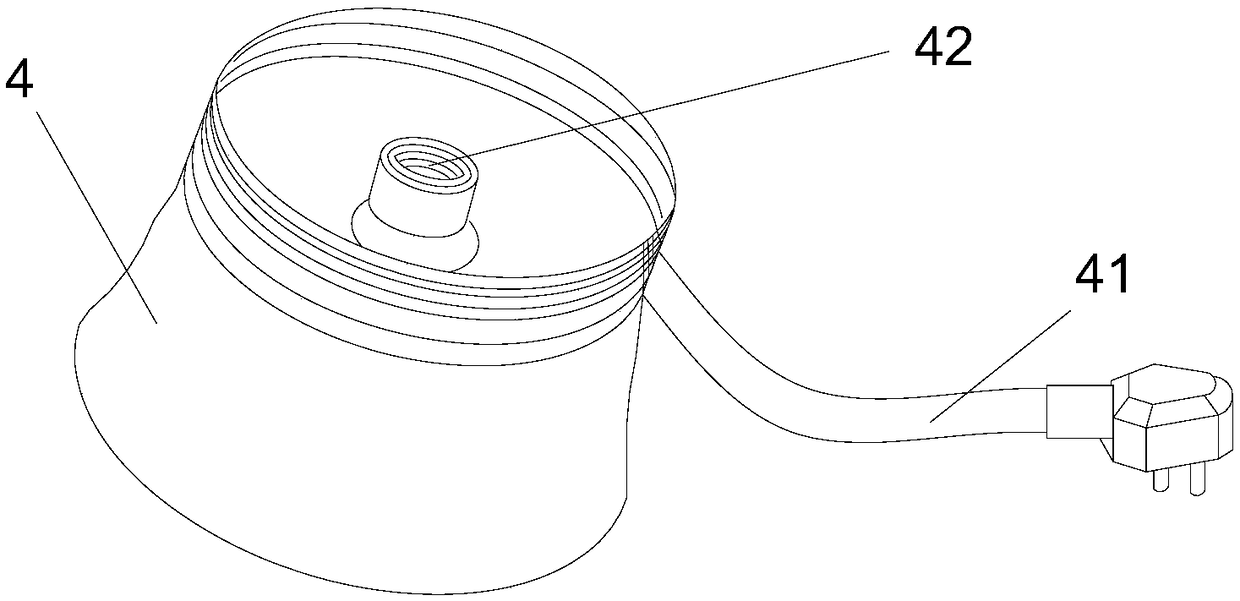

An electric thermos cup

ActiveCN106361167BIngenious designEasy to carryTravelling sacksWarming devicesElectricityEngineering

The invention discloses an electric heating vacuum cup which comprises a cup body. The cup body comprises a cup cover, a cup main body and a cup base. The cup base comprises a first cup base and a second cup base. The two ends of the first cup base are detachably connected with the cup main body and the second cup base respectively. A heating assembly and a first conductive connecting port electrically connected with the heating assembly are arranged in the first cup base, the second cup base is a plug-in base disc, the plug-in base disc is connected with a power plug, a second conductive connecting port capable of being connected with the first conductive connecting port and starting the heating assembly to perform heating after power supply is arranged in the plug-in base disc, the cup main body is a cylinder with the upper end provided with an opening, the bottom of the cup main body is provided with a groove, a peripheral ring made of an insulating material is sleeved according to the diameter of the groove, and a heating disc can be connected to a heating layer through the groove. The cup cover is connected with the opening at the upper end of the cup main body through a thread. According to the electric heating vacuum cup, through ingenious design, outdoor exercise people's urgent requirements for a cup which is convenient to carry and can perform heating and heat insulation can be met.

Owner:启东市清源环境检测技术有限公司

Dewaxing pre-sintering furnace

The invention relates to the technical field of dewaxing equipment, and particularly discloses a dewaxing pre-sintering furnace. The dewaxing pre-sintering furnace comprises a furnace body, a hydrogenintroducing system, a heating device and a vacuumizing device, an air extracting pipe communicates between the furnace body and the vacuumizing device, the vacuumizing device is connected with a gasstorage chamber, the gas storage chamber communicates with a gas outlet pipe, a flow control block is fixedly arranged on the gas outlet pipe, the gas outlet pipe is connected with a spiral pipe, a cooling pipe is tightly attached to the outer wall of the spiral pipe, a cavity is tightly attached to the outer wall of the spiral pipe, a glycerol liquid is contained in the cavity, a gas conveying pipe communicates between the cavity and the flow control block, the spiral pipe is connected with a horizontally-arranged second pipeline, and a liquid collecting tank used for gas-liquid separation isfixedly installed on the second pipeline. According to the furnace, the flow control block on the gas outlet pipe can be controlled through the gasification of the glycerol in the cavity, then the flow of the mixed gas entering the spiral pipe is controlled, the gaseous paraffin in the mixed gas is fully liquefied, the liquid paraffin and hydrogen are separated by utilizing the liquid collectingtank, and then recovery of the paraffin is realized.

Owner:ZUNYI ZHONGBO CEMENTED CARBIDE

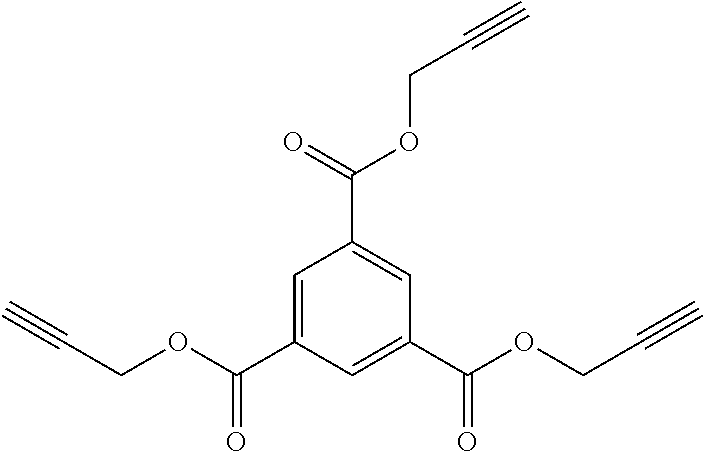

UV curable inkjet inks

ActiveUS20190071578A1Improve curing speedNo odourInksOther printing apparatusOrganic solventPhotoinitiator

An aqueous UV free radical curable inkjet ink contains a liquid phase A dispersed in a continuous liquid phase B by a polymeric dispersant; wherein the liquid phase A contains at least a photoinitiator, a colour pigment, and one or more polymerizable compounds, and the continuous liquid phase B contains water and optionally one or more organic solvents.

Owner:AGFA NV

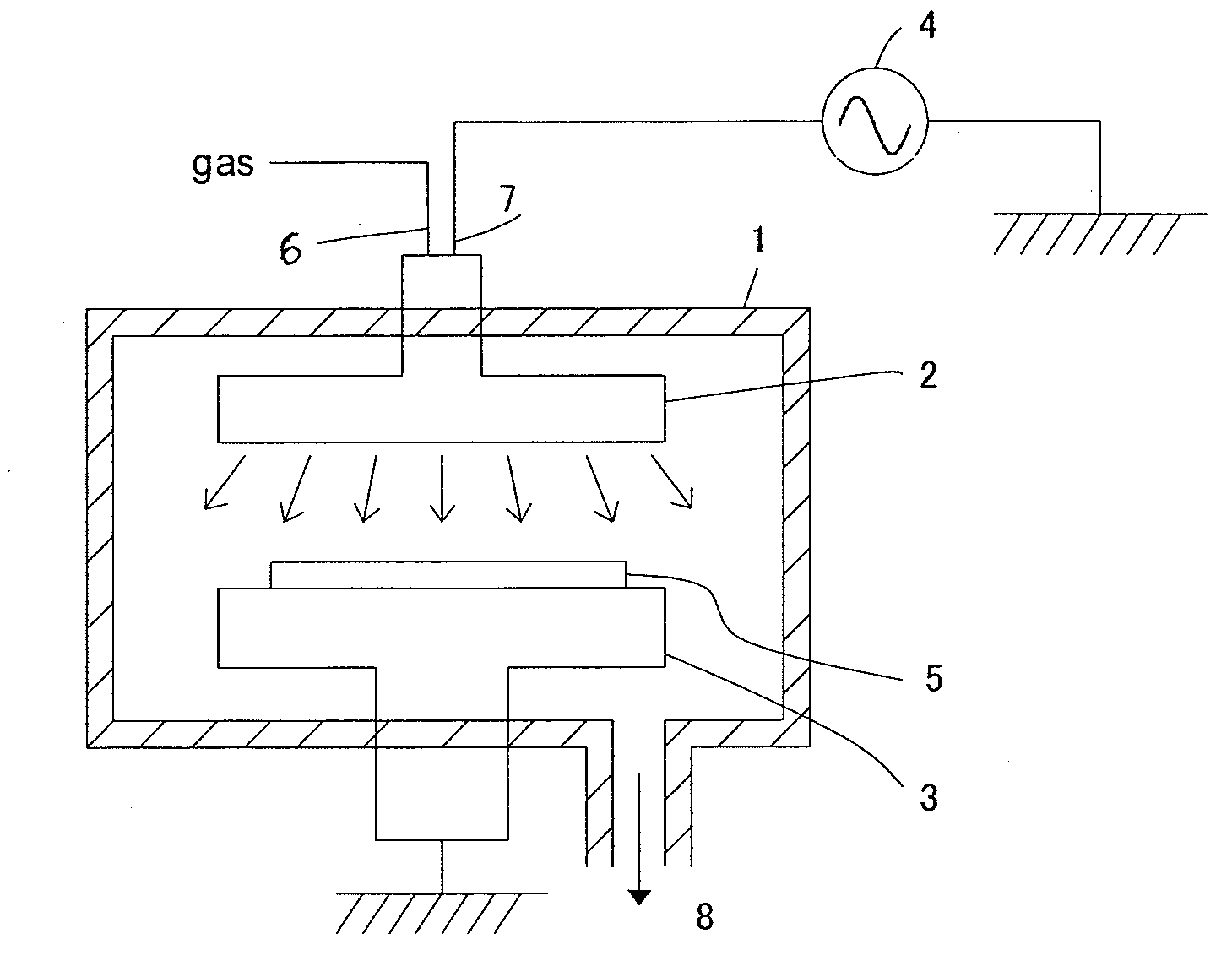

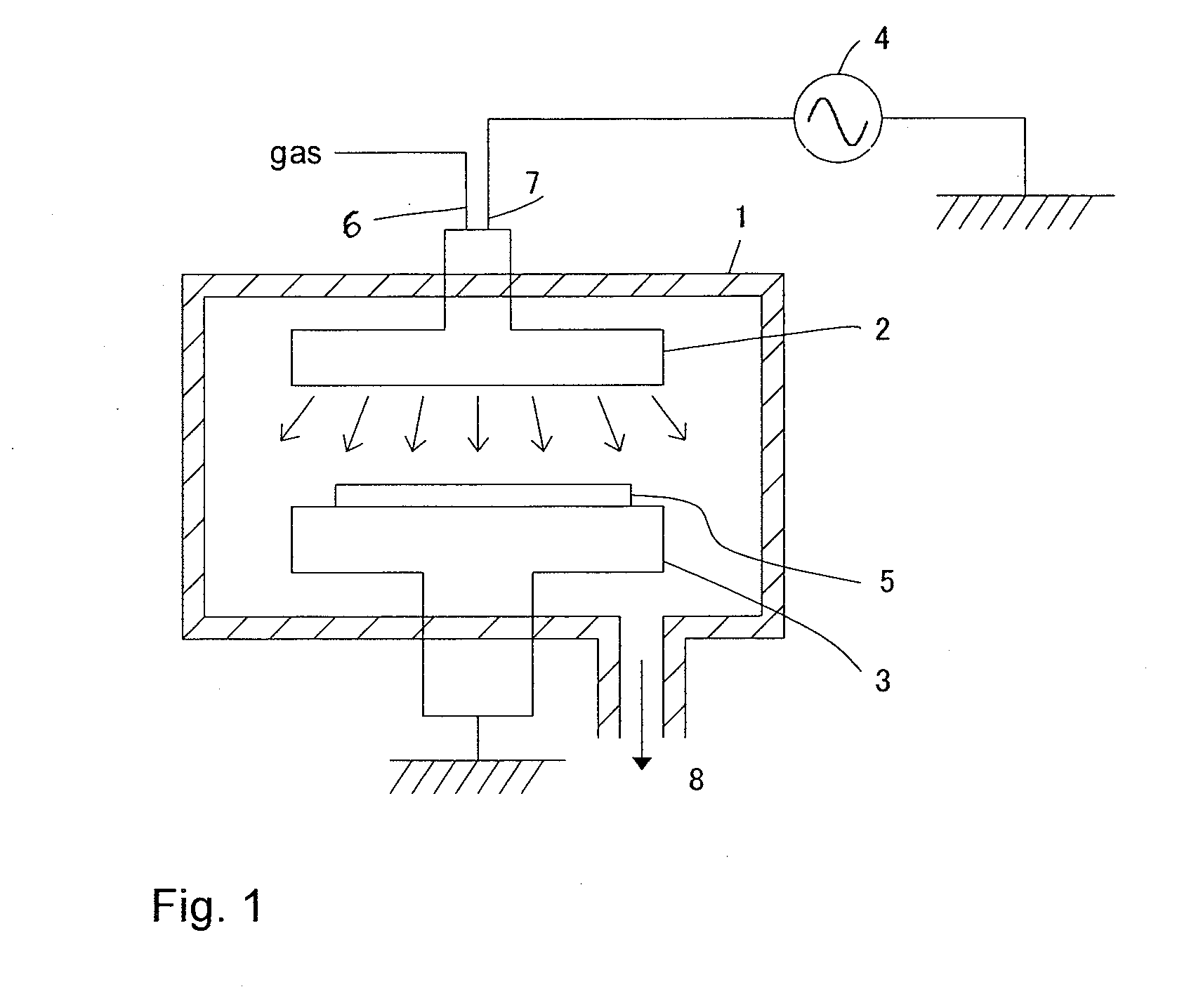

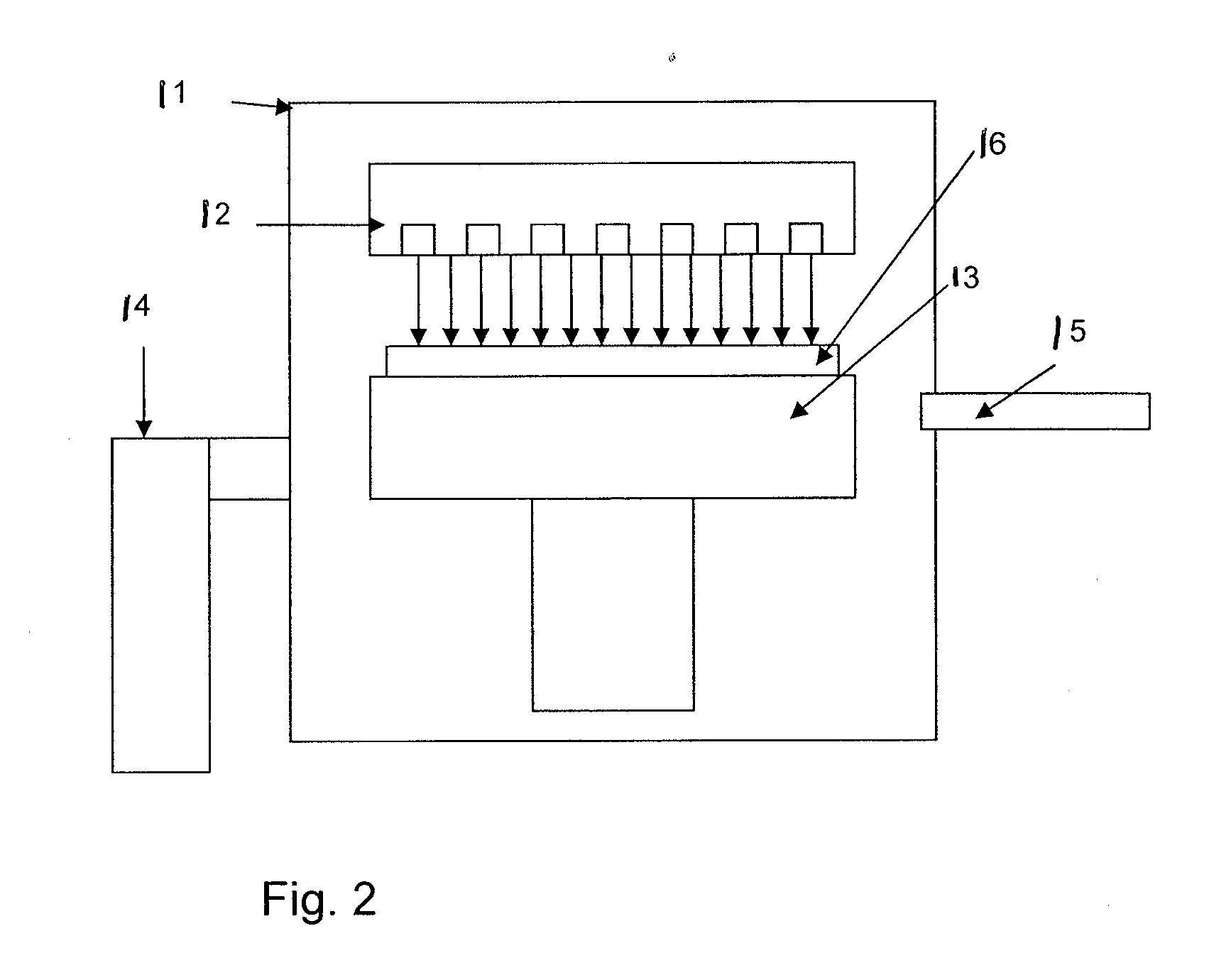

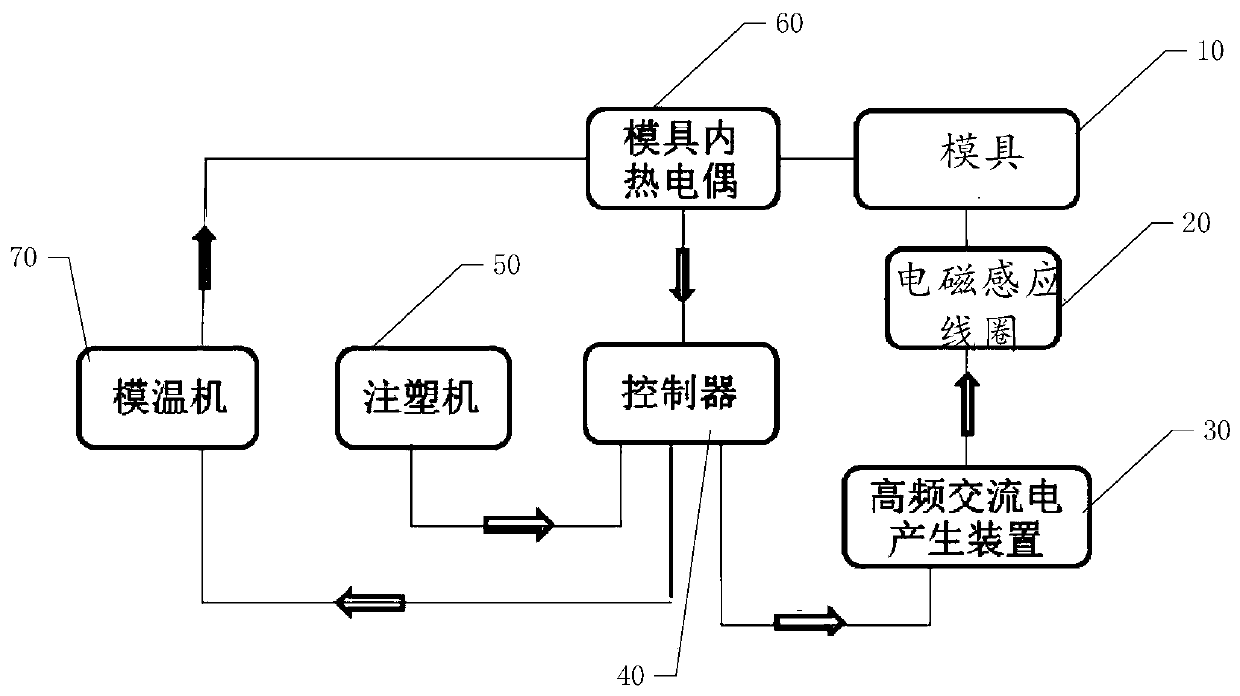

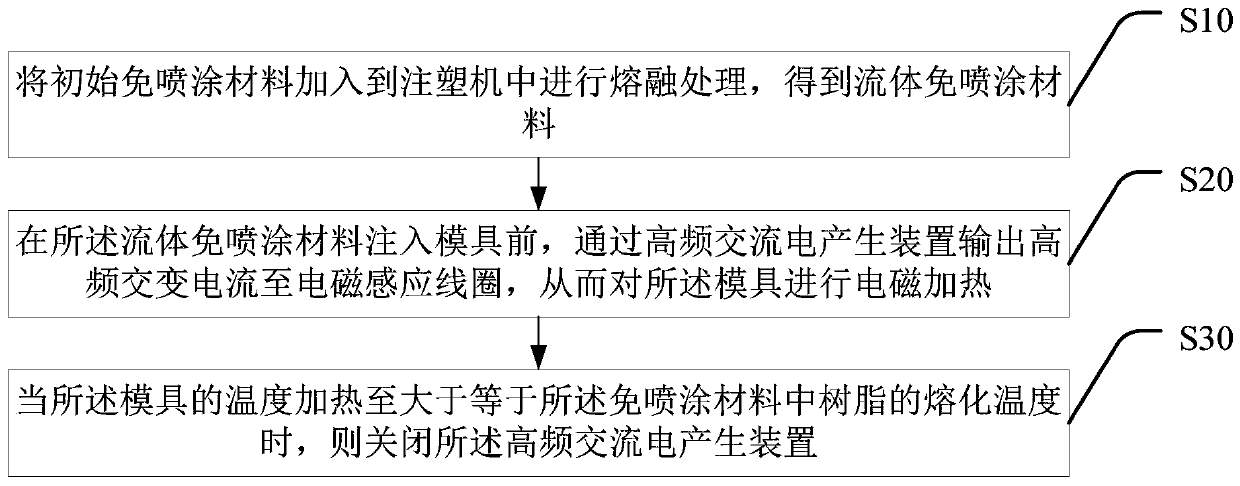

System and method for eradicating flow marks and water inclusion marks of spraying-free material during processing and forming

The invention discloses a system and method for eradicating flow marks and water inclusion marks of a spraying-free material during processing and forming, wherein the system comprises a mold, an electromagnetic induction coil and a high-frequency alternating current generation device; the mold is used for injection molding of the spraying-free material; the electromagnetic induction coil is disposed on the surface of the mold; and the high-frequency alternating current generation device is electrically connected with the electromagnetic induction coil. According to the system and the method in the invention, the mold is heated in an electromagnetic heating manner, so that the mold is rapidly heated to the temperature close to or higher than the melting temperature of resin in the spraying-free material; on the one hand, the curing speed of the fluid spraying-free material in a mold cavity is reduced; on the other hand, the viscosity of the fluid spraying-free material in the mold cavity is reduced; the shear strength of powder in the fluid spraying-free material in the mold cavity is greatly reduced; the arrangement and curing time of the powder in the cavity is prolonged; the arrangement intensity of the powder is obviously reduced; and the problems of the flow marks and the water inclusion marks of the spraying-free material during processing and forming can be completely eradicated.

Owner:深圳市同益实业股份有限公司

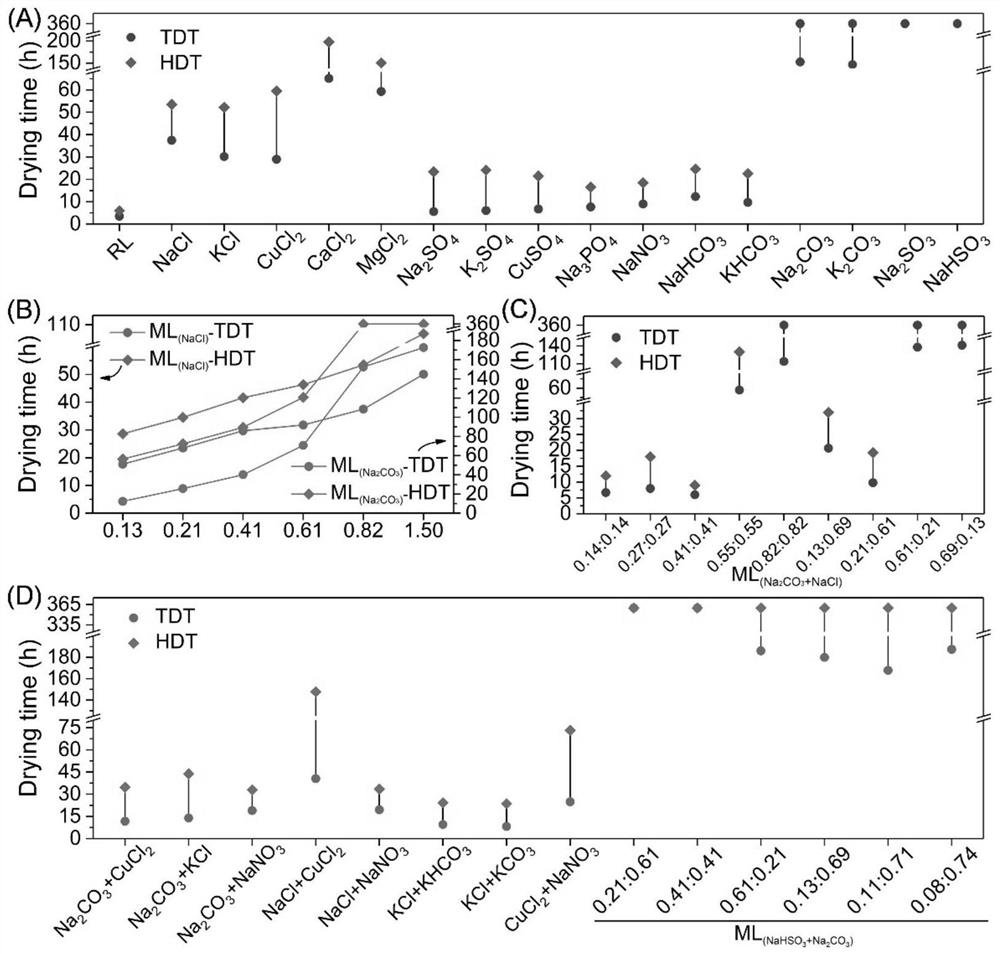

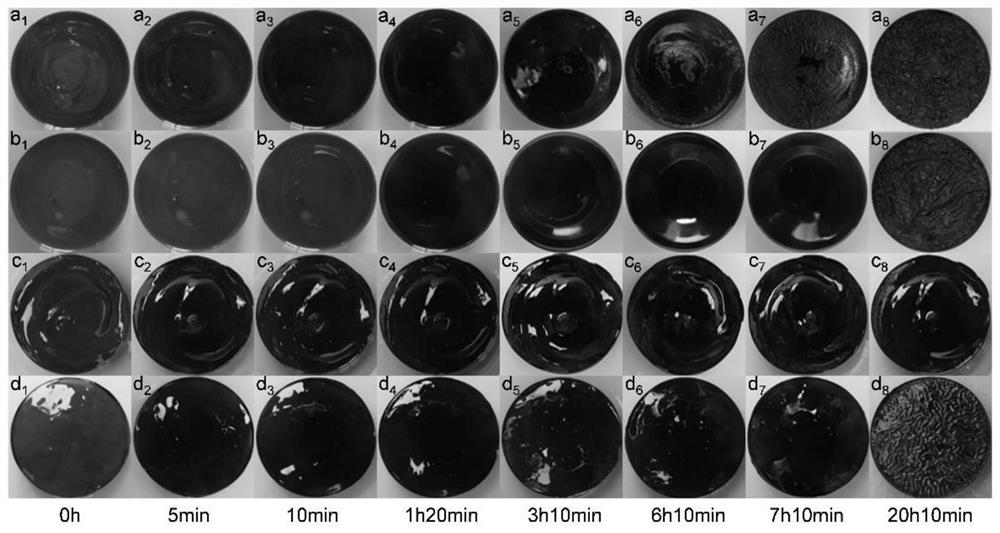

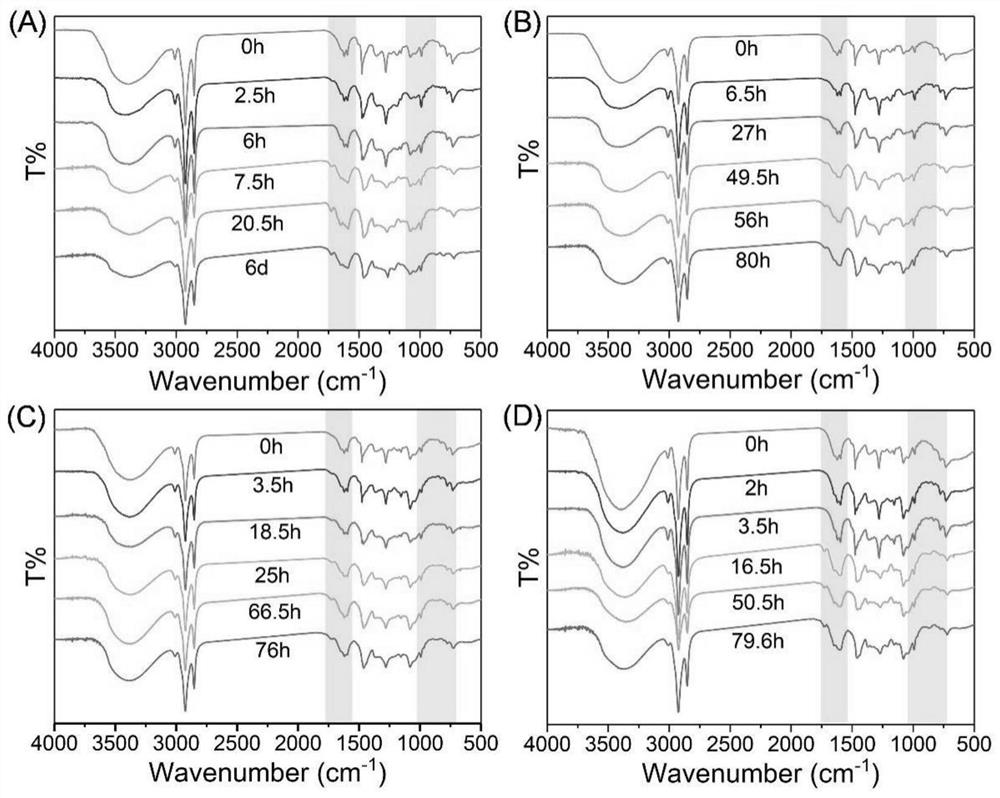

Method for changing curing speed of raw lacquer

ActiveCN113462289AExtended drying time and recoverySolve wasteNatural resin coatingsSodium bicarbonateOil emulsion

The invention discloses a method for changing the curing speed of raw lacquer, and belongs to the technical field of polymer coatings.Inorganic salt is added into the raw lacquer. The inorganic salt comprises one or more of sodium chloride, potassium chloride, copper chloride, calcium chloride, magnesium chloride, sodium sulfate, potassium sulfate, copper sulfate, sodium phosphate, sodium nitrate, sodium bicarbonate, sodium carbonate, potassium carbonate, sodium sulfite or sodium hydrogen sulfite. On the premise of not destroying the structure of the water-in-oil emulsion, the laccase activity is regulated by using inorganic salt for the first time; The drying time of the paint liquid is prolonged and recovered, the problem of film formation waste caused by long-term storage and transportation of the paint liquid can be avoided, but the drying time of the paint liquid can be recovered or shortened by adding sodium carbonate and / or sodium chloride again in actual use.

Owner:MINJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com