LED lamp

A technology of LED lamps and lamp tubes, applied in the use of semiconductor lamps, adhesive types, shellac adhesives, etc., can solve the problems of unfavorable mass production, lower yield, sales discount, etc., and solve the problem that the output cannot be increased , Improve production efficiency, reduce the effect of time required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063]

Embodiment 2

[0065]

[0066]

Embodiment 3

[0068]

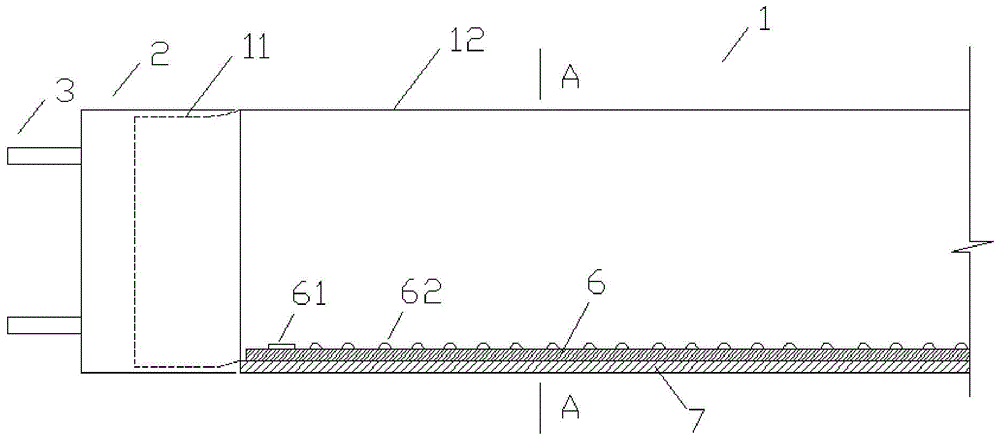

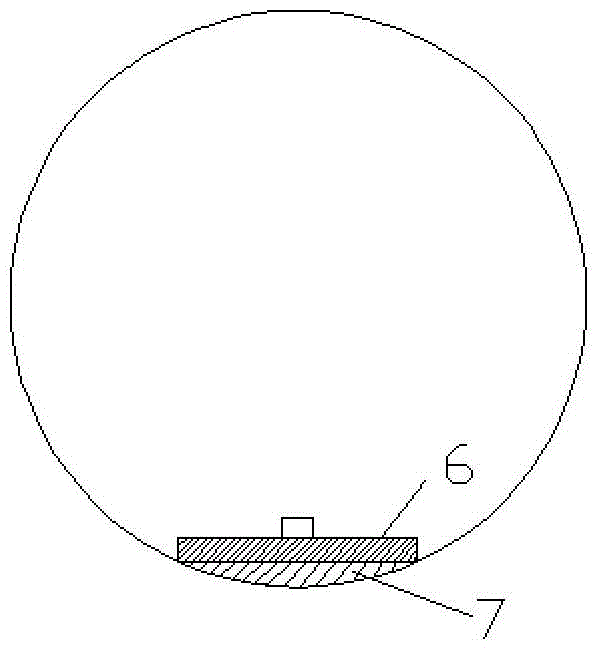

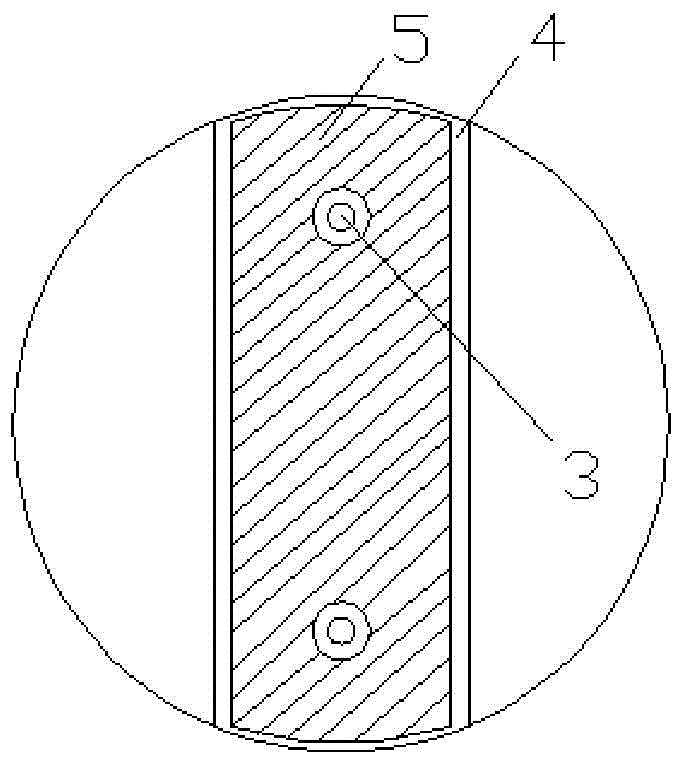

[0069] Preferably, the outer surface of the metal lamp cap 2 is flush with the outer surface of the straight portion 12 of the lamp tube 1 . The advantage of this arrangement is that, in the transportation and handling project, the entire LED lamp is uniformly stressed along its length, and stress concentration and damage will not occur due to the large diameter of the lamp cap or the large diameter of the lamp tube. In addition, this setting method will also make the LED lamp more beautiful as a whole. Wherein, the lamp tube 1 can be a plastic lamp tube or a glass lamp tube, or can be wrapped with a PPT plastic film on the inner or outer surface of the lamp tube, which can withstand a high temperature of 240°C. The material of the metal lamp cap 2 should be selected as a metal material capable of conducting heat to the welding mud through high-frequency heating equipment, and the welding mud is solidified and expanded by heating to achieve a tight connection betwe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com